In today’s fast-paced global market, sourcing a reliable 120V portable air compressor can pose significant challenges for international B2B buyers. With a myriad of options available, selecting the right compressor that meets specific application needs—whether for automotive, construction, or recreational use—can be daunting. This guide aims to simplify that process, offering a comprehensive overview of the various types of 120V portable air compressors, their applications, and essential factors to consider when evaluating suppliers.

From understanding the performance capabilities and features of different models to navigating pricing structures, this resource is designed to empower B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Nigeria. The insights provided will enable informed purchasing decisions, ensuring that buyers not only select products that meet their operational requirements but also align with their budget and quality standards.

Additionally, the guide will cover best practices for supplier vetting, allowing businesses to establish partnerships with reputable manufacturers and distributors. By focusing on actionable insights and market trends, this guide serves as a vital tool for businesses looking to thrive in the competitive landscape of portable air compressors.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Garage Tire Inflators | Compact design, often dual voltage (120V/12V), portable | Automotive repair shops, roadside assistance | Pros: Easy to use, lightweight. Cons: Limited power for heavy-duty tasks. |

| Heavy-Duty Portable Compressors | Robust construction, high PSI output, oil-free operation | Construction sites, manufacturing | Pros: Versatile, can power pneumatic tools. Cons: Bulkier, higher initial cost. |

| Contractor Air Compressors | Larger tanks (15-60 gallons), designed for continuous use | Construction, woodworking, metalworking | Pros: Sustained air supply, reliable for heavy workloads. Cons: Requires more space and power. |

| Vehicle-Mounted Compressors | Compact, often 12V, designed for on-the-go use | Off-road vehicles, emergency response | Pros: Highly portable, ideal for remote locations. Cons: Limited to specific applications. |

| Digital Portable Compressors | Integrated digital gauges, programmable settings | Automotive, sports equipment maintenance | Pros: Precise inflation, user-friendly. Cons: May have lower durability compared to mechanical models. |

Garage tire inflators are compact devices designed primarily for inflating tires quickly and efficiently. They often feature dual voltage options, allowing them to be powered by both 120V AC and 12V DC sources. This versatility makes them suitable for automotive repair shops and roadside assistance services, where speed and portability are crucial. However, while they excel in convenience, their power may not suffice for more demanding applications, making them less suitable for heavy-duty tasks.

Heavy-duty portable compressors are built for performance, offering high PSI outputs and robust construction. They are typically oil-free, which minimizes maintenance and enhances reliability. Their versatility allows them to power various pneumatic tools, making them ideal for construction sites and manufacturing environments. While their initial investment is higher, the ability to handle multiple applications justifies the cost for businesses that require dependable air supply.

Contractor air compressors are designed for sustained use, featuring larger tanks that can hold between 15 to 60 gallons of air. This design allows for continuous operation, which is essential in construction, woodworking, and metalworking applications. Their reliability in delivering a consistent air supply makes them a preferred choice for contractors. However, they require more space and power, which could be a consideration for smaller businesses or those with limited storage.

Vehicle-mounted compressors are compact, often powered by 12V systems, making them ideal for on-the-go applications. They are particularly useful in off-road situations or emergency response scenarios where mobility is key. Their portability allows for quick deployment in remote locations, but they are generally limited to specific applications, such as inflating tires or powering small tools, which may restrict their versatility compared to other types.

Digital portable compressors come equipped with integrated digital gauges and programmable settings, enhancing user experience through precision. They are particularly beneficial for automotive and sports equipment maintenance, where accurate inflation is critical. While they are user-friendly and often more convenient, their durability may not match that of more mechanical models, which could be a concern for businesses looking for long-term reliability.

| Industry/Sector | Specific Application of 120v Portable Air Compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for vehicles | Quick and efficient service, leading to increased customer satisfaction and retention. | Reliability, portability, and ease of use are critical; consider local support and service availability. |

| Construction | Operating pneumatic tools and equipment | Enhances productivity by powering tools, reducing downtime during projects. | Assess power requirements for tools, noise levels, and durability against harsh environments. |

| Manufacturing | Inflating products and operating air-driven machinery | Ensures consistency in production quality and operational efficiency. | Evaluate energy consumption, maintenance needs, and compatibility with existing systems. |

| Agriculture | Powering irrigation systems and agricultural tools | Improves crop yield through efficient irrigation and tool operation. | Focus on adaptability to various terrains and reliability in remote locations. |

| Recreational Vehicles | Inflating tires and equipment for off-road vehicles | Facilitates outdoor activities and ensures safety through proper tire pressure. | Look for compact designs and multi-functional capabilities for diverse applications. |

In the automotive repair sector, a 120v portable air compressor is essential for tire inflation and routine maintenance. It enables mechanics to quickly inflate tires, ensuring vehicles are roadworthy and safe. This application not only saves time but also enhances customer satisfaction by providing prompt service. For B2B buyers, reliability and ease of use are paramount; sourcing compressors that offer local support and service options can significantly enhance operational efficiency.

In construction, 120v portable air compressors are vital for powering pneumatic tools such as nail guns and air hammers. Their ability to operate multiple tools simultaneously increases productivity and reduces project downtime. Buyers should consider the compressor’s power output and noise levels, as job sites often require equipment that can withstand harsh conditions while maintaining a quieter operation to comply with local regulations.

Manufacturers utilize 120v portable air compressors for various applications, including inflating products and operating air-driven machinery. This reliance on compressed air ensures consistent quality and efficiency in production processes. For international buyers, evaluating energy consumption and maintenance needs is crucial, as these factors can impact overall operational costs and productivity.

In agriculture, these compressors are used to power irrigation systems and agricultural tools, contributing to improved crop yields through effective irrigation practices. Their portability allows farmers to use them in diverse terrains, making them invaluable for remote operations. Buyers should prioritize compressors that are adaptable and reliable, ensuring they can function effectively in various environmental conditions.

For recreational vehicles, a 120v portable air compressor is essential for inflating tires and other equipment. This application ensures safety during outdoor activities by maintaining proper tire pressure. Buyers should look for compact and multifunctional compressors that can serve multiple purposes, providing convenience for off-road adventures.

The Problem: B2B buyers often struggle to find reliable suppliers for 120v portable air compressors, especially in regions like Africa and South America where access to quality products can be limited. The challenge is compounded by the presence of counterfeit products in the market, which can lead to increased costs and operational downtime. Buyers may face difficulties in verifying the quality of compressors, leading to uncertainty about whether the equipment will meet their operational needs.

The Solution: To overcome this challenge, B2B buyers should prioritize sourcing from established manufacturers and distributors with a proven track record. Conduct thorough research on suppliers, looking for certifications and customer reviews that attest to their reliability. Participating in industry trade shows can also provide opportunities to engage directly with manufacturers, allowing buyers to inspect products firsthand. Additionally, consider forming partnerships with local distributors who can provide ongoing support and maintenance, ensuring that the compressors remain functional and effective over time. Establishing a clear procurement process that includes vetting suppliers based on performance metrics can further mitigate risks associated with sourcing.

The Problem: Another common issue faced by international B2B buyers is the incompatibility of 120v portable air compressors with local electrical systems, particularly in countries that use different voltage standards. This can lead to operational disruptions, increased costs for voltage converters, and potential damage to the compressors themselves. Buyers may find themselves unable to use the equipment they purchased, resulting in lost time and revenue.

The Solution: To address this issue, B2B buyers should carefully assess the electrical specifications of both their facilities and the portable air compressors they intend to purchase. When sourcing equipment, it is essential to verify whether the compressor can operate efficiently within the local voltage range. Engage with suppliers who offer dual-voltage models, which can operate at both 120v and 240v, providing greater flexibility for international operations. Furthermore, consider investing in localized training for staff to ensure they are knowledgeable about the electrical requirements and safe operation of the equipment. This proactive approach can prevent costly mistakes and ensure that the compressors are used effectively.

The Problem: Maintaining 120v portable air compressors can be a significant pain point for B2B buyers, particularly in regions where access to skilled technicians and spare parts is limited. Regular maintenance is critical to ensure the longevity and efficiency of the compressors, but many buyers find themselves struggling to perform necessary repairs or locate replacement parts, leading to prolonged downtime.

The Solution: To mitigate maintenance challenges, B2B buyers should invest in compressors known for their durability and ease of maintenance. It is advisable to select models with a strong reputation for reliability and support, including warranties that cover parts and labor. Establishing a relationship with local service providers who specialize in air compressor maintenance can also be beneficial. Buyers should consider negotiating service agreements that include regular check-ups and emergency repair services. Additionally, creating a detailed maintenance schedule based on the manufacturer’s recommendations can help in planning downtime effectively, ensuring that the compressors remain operational and efficient for longer periods. Providing training for in-house staff on basic troubleshooting and maintenance can further reduce reliance on external services, enhancing operational efficiency.

When selecting materials for 120V portable air compressors, several factors influence performance, durability, and cost-effectiveness. Below are analyses of four common materials used in the construction of these compressors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and good thermal conductivity. It typically withstands temperatures up to 400°F and pressures around 150 psi.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it ideal for portable applications. It is also resistant to corrosion, which is crucial for compressors used in humid or coastal environments. However, aluminum can be more expensive than steel and may require more complex manufacturing processes, such as welding or anodizing.

Impact on Application: Aluminum’s lightweight and corrosion-resistant properties make it suitable for applications requiring mobility and exposure to various environmental conditions. However, it may not be suitable for high-pressure applications exceeding its limits.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Africa and South America should consider local availability and cost, as aluminum may be less accessible than other materials.

Key Properties: Steel offers high tensile strength and can withstand high pressures and temperatures, typically rated for up to 500°F and 300 psi.

Pros & Cons: The key advantage of steel is its durability and ability to handle high-stress applications. It is also generally less expensive than aluminum. However, steel is heavier, which may affect portability, and it is susceptible to corrosion unless treated or coated.

Impact on Application: Steel is ideal for stationary applications or where high pressure is required. Its durability makes it suitable for industrial settings, but it may not be the best choice for portable units that need to be easily transported.

Considerations for International Buyers: Steel components must meet local standards for quality and safety. Buyers should also consider the implications of shipping costs and tariffs, particularly in regions with high import duties.

Key Properties: Plastics, such as high-density polyethylene (HDPE) and polycarbonate, are lightweight and resistant to corrosion, with temperature ratings generally up to 200°F.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing. It can be molded into complex shapes, which can reduce assembly time. However, plastics may not withstand high pressures as well as metals and can degrade under UV exposure.

Impact on Application: Plastic components are often used in non-structural parts of air compressors, such as housings or covers. They are suitable for applications where weight savings are critical, but their limitations in pressure ratings may restrict their use in certain models.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with relevant safety and environmental regulations, particularly in the EU, where standards can be stringent.

Key Properties: Copper is known for its excellent electrical and thermal conductivity, with temperature ratings up to 400°F and pressure ratings around 200 psi.

Pros & Cons: Copper’s key advantage is its conductivity, making it ideal for electrical connections and heat exchangers. However, it is relatively expensive and can be prone to corrosion if not properly coated or alloyed.

Impact on Application: Copper is often used in electrical components and heat exchangers within air compressors, enhancing efficiency. However, its cost may be a limiting factor for budget-conscious buyers.

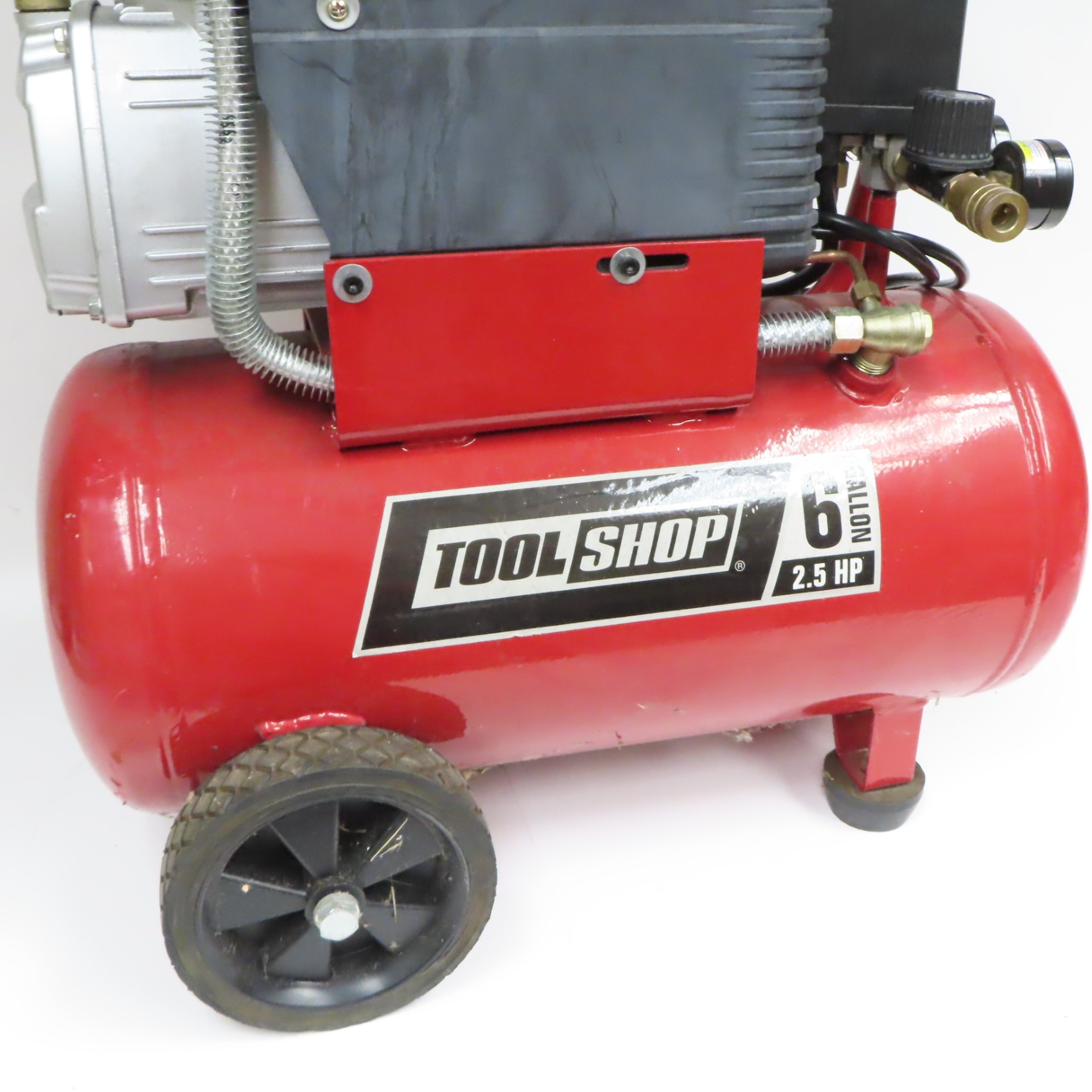

Illustrative image related to 120v portable air compressor

Considerations for International Buyers: Compliance with international standards for electrical components is crucial. Additionally, buyers should be aware of fluctuations in copper prices and their impact on overall costs.

| Material | Typical Use Case for 120V Portable Air Compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable compressor bodies | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Stationary high-pressure applications | High durability and strength | Heavier and corrosion-prone | Low |

| Plastic | Non-structural components like housings | Cost-effective and easy to mold | Limited pressure resistance | Low |

| Copper | Electrical connections and heat exchangers | Excellent conductivity | High cost and corrosion potential | High |

This guide provides a comprehensive overview of material considerations for 120V portable air compressors, helping international B2B buyers make informed decisions based on their specific needs and regional requirements.

The manufacturing process of a 120V portable air compressor typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure that the final product meets the required performance standards and quality expectations.

Material Preparation

The first step involves sourcing high-quality materials, such as aluminum or steel for the compressor body, and durable plastics for housing and connectors. Suppliers are carefully vetted to ensure they meet international standards, and materials undergo initial quality checks to assess their properties. This stage often involves cutting raw materials to size and preparing them for further processing.

Forming

During the forming stage, the prepared materials are shaped into components using techniques like machining, stamping, or casting. For instance, the compressor cylinder might be machined to precise tolerances to ensure optimal performance and efficiency. Advanced technologies such as CNC machining are frequently employed to achieve high accuracy and repeatability.

Assembly

The assembly process is where various components come together to form the complete air compressor. This stage often follows a systematic approach where components are assembled in a clean environment to minimize contamination. Automated assembly lines may be utilized for efficiency, but skilled technicians are also crucial for tasks requiring manual dexterity, such as wiring and fitting intricate parts.

Finishing

Finishing touches include surface treatments, painting, and quality inspections. Surface treatments can enhance corrosion resistance, while painting provides aesthetic appeal and additional protection. This stage also involves final assembly checks to ensure all components fit correctly and operate smoothly.

Quality assurance (QA) is a vital aspect of the manufacturing process for 120V portable air compressors. It involves a series of inspections and tests to ensure that each unit meets established quality standards and performs reliably.

Relevant International Standards

Compliance with international standards such as ISO 9001 is crucial for manufacturers. ISO 9001 outlines requirements for a quality management system, ensuring that companies consistently produce products that meet customer and regulatory requirements. In addition to ISO certifications, compliance with industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) is critical for safety and performance.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Common checkpoints include:

Testing is an integral part of the QA process for 120V portable air compressors. Various methods are employed to ensure that the compressors meet performance and safety standards.

Functional Testing

Functional tests evaluate the compressor’s operational capabilities, including airflow rates, pressure output, and noise levels. These tests simulate real-world conditions to verify that the compressor performs effectively.

Durability Testing

Durability tests assess the compressor’s resilience under extended use. This may involve running the compressor for several hours or cycles to identify any potential failures or performance drops.

Safety Testing

Safety tests focus on electrical safety and overheating prevention. Compliance with electrical safety standards is crucial, especially when exporting to regions with stringent regulations.

Illustrative image related to 120v portable air compressor

For B2B buyers, ensuring the quality of the products they purchase is critical, especially when dealing with international suppliers. Here are several strategies to verify supplier quality control:

Supplier Audits

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits can be performed by the buyer or through third-party inspection services to ensure objectivity.

Quality Control Reports

Requesting detailed QC reports from suppliers can help buyers understand the quality assurance measures in place. These reports should include information on testing methods, inspection results, and compliance with relevant standards.

Third-Party Inspections

Engaging third-party inspection services can offer additional assurance of product quality. These inspections can be conducted at various stages of manufacturing, providing an unbiased assessment of the products before shipment.

When purchasing 120V portable air compressors from international suppliers, buyers must navigate various quality control and certification nuances:

Understanding Local Regulations

Different regions may have specific regulations regarding electrical appliances. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with these regulations to ensure compliance.

Certification Validity

Buyers should verify the validity of supplier certifications. This can include checking the issuing bodies and ensuring that the certifications are up to date. For instance, CE certification is essential for products sold within the European market, and buyers should ensure the supplier’s certification covers the specific product being purchased.

Cultural Considerations

Cultural differences may influence quality perceptions. For instance, some regions may place more emphasis on durability and reliability, while others may prioritize cost efficiency. Understanding these nuances can help buyers communicate their quality expectations more effectively.

Illustrative image related to 120v portable air compressor

The manufacturing processes and quality assurance measures for 120V portable air compressors are complex and multifaceted. For B2B buyers, especially those in diverse international markets, understanding these processes can significantly impact purchasing decisions. By focusing on supplier quality control, verifying certifications, and engaging in thorough inspections, buyers can ensure they procure reliable and high-quality products that meet their operational needs.

This practical sourcing guide is designed to assist B2B buyers in procuring high-quality 120V portable air compressors. By following this step-by-step checklist, you will ensure that your purchasing process is efficient, cost-effective, and tailored to your specific business needs.

Before initiating the procurement process, clearly define the technical specifications required for your 120V portable air compressor. Consider factors such as pressure capacity (measured in PSI), tank size, power consumption, and intended applications (e.g., automotive, construction, or recreational use). This step is crucial as it sets the foundation for identifying products that meet your operational requirements.

Conduct thorough market research to identify various brands and models available in the market. Look for reputable manufacturers known for their reliability and performance. Utilize online resources, trade publications, and industry forums to gather insights about the latest technologies and customer reviews. This knowledge will empower you to make informed decisions and compare different products effectively.

Before committing, it’s crucial to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Investigate their track record regarding delivery timelines, customer service, and product support. A reliable supplier will not only provide quality products but also offer post-purchase assistance to ensure your compressor operates efficiently.

Ensure that the compressors you are considering comply with international standards and regulations relevant to your region. Look for certifications such as CE, ISO, or UL, which indicate that the product meets safety and quality standards. Compliance is essential to mitigate risks associated with equipment failure and to ensure that the compressors can operate legally in your market.

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, shipping costs, and any additional fees. Analyze the quotes to understand the total cost of ownership, including maintenance and operational costs. Comparing pricing is vital to ensure you are getting the best value for your investment, but also consider the long-term reliability and support offered by the supplier.

Review the warranty terms and after-sales support offered by the supplier. A robust warranty demonstrates the manufacturer’s confidence in their product and provides you with peace of mind. Additionally, inquire about the availability of spare parts and technical support, as these factors can significantly impact your operational efficiency over time.

After carefully evaluating all factors, proceed with your purchase from the chosen supplier. Once you receive the compressor, monitor its performance closely during the initial weeks of operation. This proactive approach allows you to address any potential issues early and ensures that the compressor meets your expectations in real-world applications.

When sourcing 120V portable air compressors, understanding the cost structure is crucial. The primary components include:

Materials: High-quality materials such as metal casings, motors, and compressors are essential for durability and performance. The choice of materials directly impacts the cost and longevity of the product.

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor is often necessary for assembly, especially for compressors with advanced features.

Manufacturing Overhead: This includes expenses related to utilities, rent, equipment depreciation, and other fixed costs associated with running a manufacturing facility. Efficient manufacturing processes can help reduce these overheads.

Tooling: Initial tooling costs can be significant, particularly for custom or specialized designs. These costs are amortized over production runs, influencing the pricing of smaller orders.

Quality Control (QC): Ensuring that each unit meets safety and performance standards adds to the cost but is essential for maintaining brand reputation and customer satisfaction.

Logistics: Transportation costs depend on the shipping method, distance, and any customs duties applicable for international shipping. Efficient logistics can mitigate high costs.

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can vary based on competition and market demand.

Several factors influence the pricing of 120V portable air compressors:

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often qualify for bulk discounts, reducing the per-unit cost.

Specifications and Customization: Tailoring compressors to meet specific requirements—such as unique voltage needs or additional features—can increase the cost due to specialized manufacturing processes.

Materials: The choice of materials not only affects durability but also the overall cost. Premium materials will lead to higher prices but can offer better performance and longevity.

Quality and Certifications: Products that meet international safety and performance standards (like ISO certifications) may carry a higher price tag, reflecting their enhanced reliability and market acceptance.

Supplier Factors: Supplier reliability, reputation, and production capacity can also influence costs. Established suppliers may offer better quality assurance but at a premium price.

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is vital. They dictate who bears responsibility for shipping costs and risks, which can affect overall pricing.

B2B buyers can take several steps to ensure cost-effective sourcing:

Negotiate Effectively: Engage suppliers in discussions about pricing, especially if you are a repeat customer. Leverage bulk purchases to negotiate better terms.

Consider Total Cost of Ownership (TCO): Evaluate the total cost over the product’s lifecycle, including maintenance, energy efficiency, and potential repair costs. A slightly higher upfront cost may result in lower long-term expenses.

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, be aware of additional costs such as import tariffs, shipping fees, and currency fluctuations. These can significantly affect the final price.

Research Local Suppliers: When possible, consider sourcing from local manufacturers to reduce logistics costs and improve supply chain efficiency.

Request Multiple Quotes: Don’t settle for the first offer. Obtaining quotes from multiple suppliers can provide insights into market pricing and help you secure the best deal.

Sourcing 120V portable air compressors requires a comprehensive understanding of cost structures and pricing influences. By considering these factors and employing effective negotiation strategies, international buyers can optimize their purchasing decisions and ensure they receive value for their investments. Always remember to account for the total cost of ownership and be mindful of local market conditions when making procurement choices.

When evaluating the best solutions for air compression needs, it’s essential to consider various alternatives to the 120V portable air compressor. Different technologies and methods can cater to specific requirements, such as mobility, power source, and application. This analysis will compare the 120V portable air compressor with two viable alternatives: 12V DC air compressors and cordless battery-operated air compressors.

| Comparison Aspect | 120V Portable Air Compressor | 12V DC Air Compressor | Cordless Battery-Operated Air Compressor |

|---|---|---|---|

| Performance | High pressure, suitable for heavy-duty tasks | Moderate pressure, ideal for smaller inflations | Variable pressure, typically lower than both |

| Cost | Medium to high | Generally lower | Higher upfront cost due to battery tech |

| Ease of Implementation | Requires access to power outlet | Can be used in vehicles; portable | User-friendly, ready to use without cords |

| Maintenance | Moderate (oil changes, etc.) | Low maintenance, simple design | Low maintenance, battery replacement needed |

| Best Use Case | Workshops, garages, and heavy-duty applications | Roadside assistance, automotive use | Light-duty tasks, home use, and travel |

12V DC air compressors are designed to operate directly from a vehicle’s power supply, making them ideal for roadside assistance and smaller tasks. They typically offer moderate pressure and are lightweight, enhancing portability. The primary advantage is their low cost and ease of use in emergencies. However, their performance may be limited for more demanding applications, such as inflating larger tires or powering pneumatic tools. They are best suited for automotive use and small-scale tasks.

Cordless battery-operated air compressors offer a high level of convenience, allowing users to operate them without being tethered to a power source. These compressors are user-friendly and often designed for light-duty applications, such as inflating sports equipment or small tires. The primary drawback is that they can have a higher upfront cost and may require periodic battery replacements, which can add to long-term expenses. Their versatility makes them excellent for home use and travel, especially in areas without reliable electricity.

Selecting the appropriate air compression solution depends on specific operational needs and contexts. For businesses and professionals requiring high-performance, heavy-duty tasks, the 120V portable air compressor is the most suitable option. However, for mobile applications or emergency situations, a 12V DC compressor might be more practical. Cordless battery-operated compressors serve well for light-duty tasks and offer unparalleled convenience. B2B buyers should assess their operational environment, budget constraints, and intended use cases to make an informed decision that aligns with their requirements.

Illustrative image related to 120v portable air compressor

When considering a 120V portable air compressor, several technical specifications can significantly impact performance and suitability for various applications. Understanding these properties is essential for B2B buyers to make informed decisions.

PSI (Pounds per Square Inch)

PSI measures the air pressure generated by the compressor. A higher PSI indicates the compressor’s ability to perform more demanding tasks, such as powering pneumatic tools or inflating larger tires. For industrial applications, a compressor with a PSI rating of 90-150 is generally considered adequate, while specialized tasks may require even higher ratings.

CFM (Cubic Feet per Minute)

CFM indicates the volume of air the compressor can deliver. This metric is crucial for determining whether the compressor can keep up with the air demands of tools and equipment. For instance, nail guns typically require around 2-3 CFM, while impact wrenches may need 4-6 CFM. Ensuring the CFM rating aligns with your tools’ requirements can prevent downtime and inefficiencies.

Tank Capacity

The tank capacity, measured in gallons, dictates how much compressed air can be stored and used at once. A larger tank can provide a steady air supply for extended periods, making it suitable for continuous use in workshops or construction sites. Conversely, smaller tanks may suffice for occasional tasks but can lead to more frequent cycling, which can wear down the compressor more quickly.

Power Rating

Measured in horsepower (HP), the power rating indicates the compressor’s motor strength. A unit with higher horsepower can compress air more quickly and is often more efficient for heavy-duty applications. For example, a 2 HP compressor is ideal for contractors needing reliable performance for tools that demand high air pressure and volume.

Portability Features

Many 120V portable air compressors come with features that enhance mobility, such as wheels, lightweight materials, and ergonomic handles. These features are vital for B2B buyers who require equipment that can easily be transported to different job sites without sacrificing performance.

Noise Level

Noise output, measured in decibels (dB), can impact the work environment, particularly in residential or urban areas. Compressors that operate at lower noise levels (typically below 70 dB) are preferred in settings where noise pollution is a concern, ensuring compliance with local regulations and fostering a better work atmosphere.

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions involving 120V portable air compressors.

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality replacement parts or accessories that are compatible with their compressors.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can affect inventory management and purchasing costs. Knowing the MOQ helps businesses plan their orders to avoid excess inventory or stock shortages.

RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers. When considering a 120V portable air compressor, issuing an RFQ can help buyers compare prices and terms, ensuring they receive competitive quotes tailored to their specific needs.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers involved in importing compressors, as they define who pays for shipping, insurance, and tariffs, impacting overall costs.

Warranty Period

The warranty period specifies the duration during which a buyer can claim repairs or replacements for defects. Understanding warranty terms is essential for evaluating the long-term reliability and cost-effectiveness of a compressor purchase.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For businesses that rely on air compressors for operations, understanding lead times can facilitate better project planning and resource allocation.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the complexities of purchasing 120V portable air compressors more effectively, leading to better investment decisions and enhanced operational efficiency.

The global market for 120V portable air compressors is experiencing significant growth driven by several factors. The increasing demand for versatile and efficient tools across various sectors, including automotive, construction, and home maintenance, is propelling the market forward. Technological advancements are also shaping the landscape, with innovations such as lightweight designs, enhanced portability, and energy-efficient models gaining traction. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed purchasing decisions.

Emerging trends include the rise of dual-voltage compressors that offer flexibility for both 120V and 12V usage, catering to a broader range of applications. The integration of smart technology is another significant trend, with manufacturers developing compressors that can be monitored and controlled via mobile apps. This shift towards smart solutions aligns with the growing emphasis on efficiency and convenience in B2B operations.

Moreover, as global supply chains become more interconnected, buyers must navigate sourcing complexities, including fluctuating raw material costs and varying trade regulations. Establishing relationships with reliable suppliers who can provide quality products at competitive prices is essential for maintaining operational efficiency.

Sustainability is increasingly becoming a priority for B2B buyers in the 120V portable air compressor market. The environmental impact of manufacturing processes, from raw material extraction to product disposal, is under scrutiny. Companies are now expected to adopt sustainable practices and reduce their carbon footprint. This shift not only enhances brand reputation but also aligns with the values of environmentally conscious consumers.

Ethical sourcing plays a pivotal role in this context. Buyers are encouraged to seek suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainable and ethical practices.

Additionally, the demand for ‘green’ materials, such as recyclable components and eco-friendly packaging, is on the rise. By prioritizing sustainability in their sourcing decisions, B2B buyers can contribute to a circular economy while also meeting regulatory requirements and consumer expectations.

The evolution of the 120V portable air compressor has been marked by significant technological advancements and shifts in consumer demand. Initially designed for basic tire inflation and pneumatic tool operation, these compressors have transformed into multifunctional devices. Early models were often bulky and less efficient, but modern iterations boast compact designs, enhanced performance, and energy efficiency.

The introduction of lightweight materials and the integration of digital technology have further revolutionized the sector. Buyers today can choose from a variety of models equipped with features such as automatic shut-off, digital pressure gauges, and portability options that cater to diverse applications. This evolution reflects a broader trend in the B2B market toward efficiency, convenience, and adaptability, making the 120V portable air compressor a valuable asset for businesses across various industries.

How do I choose the right 120V portable air compressor for my business needs?

Selecting the right 120V portable air compressor involves assessing your specific applications. Consider factors such as required PSI (pounds per square inch), CFM (cubic feet per minute), and tank size. If you need it for tire inflation, a smaller, lightweight model may suffice, while heavy-duty tasks like operating pneumatic tools require more robust options. Additionally, evaluate portability, noise levels, and any special features like dual power options. Always consult with suppliers to ensure the compressor meets your operational demands.

What are the advantages of a 120V portable air compressor over other types?

120V portable air compressors offer several advantages, particularly in convenience and versatility. They are ideal for both professional and personal use, easily powering pneumatic tools, inflating tires, and other tasks. Their compact design allows for easy transport and storage, making them suitable for job sites or home garages. Additionally, these compressors typically require standard household electricity, eliminating the need for specialized power sources, thus broadening their usability across different settings.

What should I consider when vetting suppliers for 120V portable air compressors?

When vetting suppliers, focus on their reputation, product quality, and customer service. Check for certifications that ensure compliance with international safety and quality standards. Request references or case studies from previous customers, particularly those in your region. Evaluate their response time and willingness to provide technical support. It’s also crucial to assess their logistics capabilities, especially regarding shipping times and costs, to ensure they can deliver to your location efficiently.

What are common minimum order quantities (MOQs) for 120V portable air compressors?

Minimum order quantities can vary significantly depending on the supplier and the specific model of the compressor. Generally, MOQs can range from a single unit for smaller suppliers to several dozen units for larger manufacturers. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business objectives. Keep in mind that higher order volumes may lead to better pricing and shipping terms, benefiting your overall procurement strategy.

What payment terms should I expect when sourcing 120V portable air compressors internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (often 30% to 50%) with the balance due upon shipment or delivery. Some suppliers may offer net terms, allowing payment within a specified period after delivery. Always clarify payment methods accepted (e.g., wire transfer, credit terms) and ensure they align with your financial processes. It’s also wise to confirm any potential currency exchange fees or charges that could impact your total costs.

How can I ensure quality assurance (QA) for my purchased 120V portable air compressors?

To ensure quality assurance, request detailed product specifications, certifications, and warranty information from suppliers. Many reputable manufacturers will provide product testing results or quality control documentation. Consider arranging for third-party inspections before shipment to verify that the compressors meet your standards. Establishing a strong communication channel with your supplier can also facilitate better quality management and prompt resolution of any issues that may arise during or after delivery.

What logistics considerations should I keep in mind for shipping 120V portable air compressors?

Logistics considerations include understanding shipping costs, timelines, and customs regulations specific to your country. Evaluate whether the supplier can handle shipping logistics or if you need to engage a freight forwarder. Ensure that the compressors are packaged correctly to prevent damage during transit. Additionally, consider the location of the supplier in relation to your business to minimize shipping time and costs. Confirm the shipping method (air, sea, or land) based on urgency and budget constraints.

Can I customize the features of a 120V portable air compressor for my business?

Many suppliers offer customization options for 120V portable air compressors, allowing you to tailor features such as tank size, PSI settings, and additional attachments or accessories to better suit your business needs. Discuss your specific requirements with potential suppliers to see what customization options are available. Keep in mind that customization may affect lead times and costs, so be sure to factor these into your purchasing decision.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 120v tire inflator for pickup truck, suitable for topping up tires at home, looking for options in the $100 range that are durable and reliable.

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: Portable & Vehicle Mounted Air Compressor Systems | ARB 4×4 USA. ARB Air Compressors are designed for reliable, on-the-go air to power tires, tools, and Air Lockers. Key products include: 1. Twin Motor Onboard 12V Air Compressor CKMTA12 – $593.95 2. Single Motor Onboard 12V Air Compressor CKMA12 – $323.95 3. Single Motor Portable 12V Air Compressor CKMP12V2 – $449.95 4. Twin Motor Portable 12V Air…

Domain: tacomaworld.com

Registered: 2006 (19 years)

Introduction: 1. Senco PC1010 – 1/2 Horsepower, 1-Gallon, Portable Hot Dog Air Compressor, Gray/Red, 373 watts running power, 4.5 startup amps. 2. DEWALT D55140 – 135-PSI Max, 1 Gallon Tank, 2.6 Amp. 3. Porter Cable C1010 – 2.6 Amp. 4. VIAIR 300P – 30033 Tire Inflator, Portable Offroad Air Compressor, 12V, 150 PSI, $166. 5. VIAIR 88P – 00088 Tire Inflator, Portable, 12V, 120 PSI, $90.

As the demand for 120V portable air compressors continues to grow across diverse industries, understanding the nuances of strategic sourcing becomes paramount for international B2B buyers. Key takeaways include the importance of selecting reliable suppliers who can provide high-performance, durable products tailored to specific operational needs. Engaging with manufacturers that offer robust warranties and support can also mitigate risks associated with equipment downtime, ensuring seamless operations.

Furthermore, the versatility of 120V compressors—from automotive repairs to pneumatic tool operation—underscores their value in various markets, particularly in regions like Africa, South America, the Middle East, and Europe. As these markets develop, the need for reliable and efficient tools will only increase, making it essential for buyers to prioritize quality and performance in their purchasing decisions.

Looking ahead, B2B buyers should leverage strategic sourcing to not only enhance their supply chains but also position themselves as leaders in their respective industries. By investing in high-quality 120V portable air compressors, businesses can improve productivity and customer satisfaction. Now is the time to act—evaluate your sourcing strategies, explore partnerships with trusted suppliers, and prepare to meet the evolving demands of your market with confidence.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.