In an era where mobility and efficiency are paramount, sourcing a reliable battery charged air pump can be a significant challenge for international B2B buyers. Companies across diverse industries—from automotive to sports equipment—are increasingly seeking portable and versatile inflators that deliver performance without the constraints of traditional power sources. This comprehensive guide addresses the complexities of the global market for battery charged air pumps, offering insights into various types, applications, and critical considerations for supplier vetting.

Understanding the nuances of battery powered air pumps is essential for informed purchasing decisions. This guide delves into the different models available, their applications in various sectors, and the technological advancements driving innovation in this space. Additionally, it covers vital aspects such as cost analysis, quality assurance, and supplier credibility, ensuring that buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Nigeria—can make strategic choices that align with their operational needs.

By equipping B2B buyers with actionable insights and practical knowledge, this guide empowers them to navigate the competitive landscape effectively. Whether you are looking to enhance your product offerings or streamline your procurement processes, understanding the battery charged air pump market is crucial for achieving your business objectives.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Portable, rechargeable, often with digital pressure gauges | Automotive, fleet maintenance, retail | Pros: Easy to use, no cords; Cons: Battery life can vary. |

| High-Pressure Pumps | Designed for heavy-duty applications, high PSI capabilities | Construction, industrial, commercial vehicles | Pros: High efficiency, suitable for larger tasks; Cons: Heavier, often pricier. |

| Multi-Purpose Inflators | Versatile, can inflate various items (tires, sports balls) | Retail, sports, outdoor activities | Pros: Multi-functional; Cons: May lack specialized features for specific tasks. |

| Compact Air Compressors | Small, lightweight, designed for easy transport | Emergency services, personal use | Pros: Space-saving, convenient; Cons: Limited power for larger tasks. |

| Dual-Power Supply Pumps | Operate on both battery and AC/DC power sources | Automotive, outdoor events, emergency kits | Pros: Flexibility in power options; Cons: More complex, potential for higher maintenance. |

Cordless tire inflators are designed for portability and ease of use, making them ideal for automotive applications. They typically feature rechargeable batteries and may include digital pressure gauges for precise inflation. These inflators are particularly suitable for businesses involved in automotive maintenance, fleet operations, and retail, where quick and efficient tire inflation is essential. When purchasing, businesses should consider battery life, inflation speed, and ease of use to ensure they meet operational needs.

High-pressure pumps are engineered for demanding environments, capable of inflating tires and equipment that require higher PSI levels. Commonly used in construction and industrial settings, these pumps can efficiently handle larger tasks, making them invaluable for businesses that rely on heavy machinery. Buyers should evaluate the pump’s PSI capacity, durability, and maintenance requirements to ensure compatibility with their operational demands.

Multi-purpose inflators are versatile tools that can inflate a range of items, from tires to sports equipment. This flexibility makes them appealing to retailers and businesses in the sports and outdoor sectors. While they provide a convenient solution for various inflation needs, buyers should consider whether the inflator’s capabilities align with specific applications, as these models may lack the specialized features found in dedicated inflators.

Compact air compressors are lightweight and designed for easy transport, making them suitable for emergency services and personal use. Their space-saving design allows for convenient storage in vehicles. However, these compressors often have limitations in power and capacity, which buyers should consider based on the types of inflation tasks they need to perform, especially in emergencies where time and efficiency are crucial.

Dual-power supply pumps offer the flexibility of operating on both battery and AC/DC power sources, making them ideal for various applications, including automotive and outdoor events. This adaptability ensures that businesses can use the pump in different environments without worrying about power availability. When selecting a dual-power pump, buyers should assess the ease of switching between power sources and the overall durability of the device to ensure reliability in diverse conditions.

| Industry/Sector | Specific Application of Battery Charged Air Pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Tire Inflation for Passenger and Commercial Vehicles | Enhances safety and efficiency in vehicle maintenance | Ensure compatibility with various tire sizes and pressures |

| Sports Equipment | Inflation of Sports Balls and Equipment | Reduces downtime and improves performance in sports events | Look for portability and battery life for frequent use |

| Construction | Inflating Air Tools and Equipment | Increases productivity and reduces reliance on power sources | Evaluate power output and charging options |

| Outdoor Recreation | Inflating Camping Gear and Recreational Items | Facilitates convenience in outdoor activities | Consider weight, size, and battery capacity for portability |

| Agriculture | Inflating Agricultural Equipment (e.g., sprayers) | Improves operational efficiency and reduces labor costs | Assess durability and battery longevity for field use |

In the automotive industry, battery charged air pumps are primarily used for tire inflation in both passenger and commercial vehicles. These pumps provide a quick and efficient solution to maintain optimal tire pressure, which is crucial for safety and fuel efficiency. International buyers from regions like Africa and South America should consider pumps that can handle various tire sizes and pressures, ensuring compatibility with local vehicle types. The added benefit of a cordless design allows for easy transport and use in remote areas, addressing the challenge of limited access to power sources.

Illustrative image related to battery charged air pump

Battery charged air pumps are essential for inflating sports balls and equipment, ensuring they are ready for use in games and training sessions. This application is particularly beneficial for sports teams and facilities that require quick and reliable inflation solutions. For buyers in the Middle East and Europe, sourcing pumps that are lightweight and portable can significantly reduce downtime during events, enhancing overall performance. Additionally, features like auto shut-off functions can prevent over-inflation, a common concern among sports equipment managers.

In the construction sector, battery charged air pumps are utilized for inflating air tools and equipment, which streamlines operations on job sites. These pumps eliminate the need for cumbersome power cords or gas-powered compressors, allowing for greater mobility and efficiency. Buyers in regions with developing infrastructure, such as Nigeria or South America, should prioritize pumps with high power output and various charging options to ensure they can meet the demands of diverse construction tasks. The ability to operate without a constant power supply can also lead to significant cost savings.

For outdoor enthusiasts, battery charged air pumps are invaluable for inflating camping gear, inflatable boats, and recreational items like pool toys. These pumps offer convenience, allowing users to quickly set up their gear without worrying about finding an electrical outlet. Buyers from Europe and the Middle East should look for models that balance weight and battery capacity, ensuring they can easily transport the pump on outdoor trips. The versatility of these pumps also enhances user experience, making outdoor activities more enjoyable and less time-consuming.

Illustrative image related to battery charged air pump

In agriculture, battery charged air pumps are used to inflate equipment such as sprayers and other pneumatic tools, improving operational efficiency. This application is particularly relevant for farmers in remote areas where power supply can be inconsistent. When sourcing these pumps, buyers should evaluate the durability and battery longevity to ensure they can withstand the rigors of fieldwork. A reliable air pump can reduce labor costs and increase productivity, making it a critical investment for agricultural businesses.

The Problem: Many B2B buyers in industries such as automotive, construction, or logistics often face issues with the battery life of cordless air pumps. When inflating multiple tires or large equipment, the battery can deplete faster than anticipated. This situation can lead to delays in operations, increased downtime, and potential financial losses, particularly in regions where access to power sources is limited.

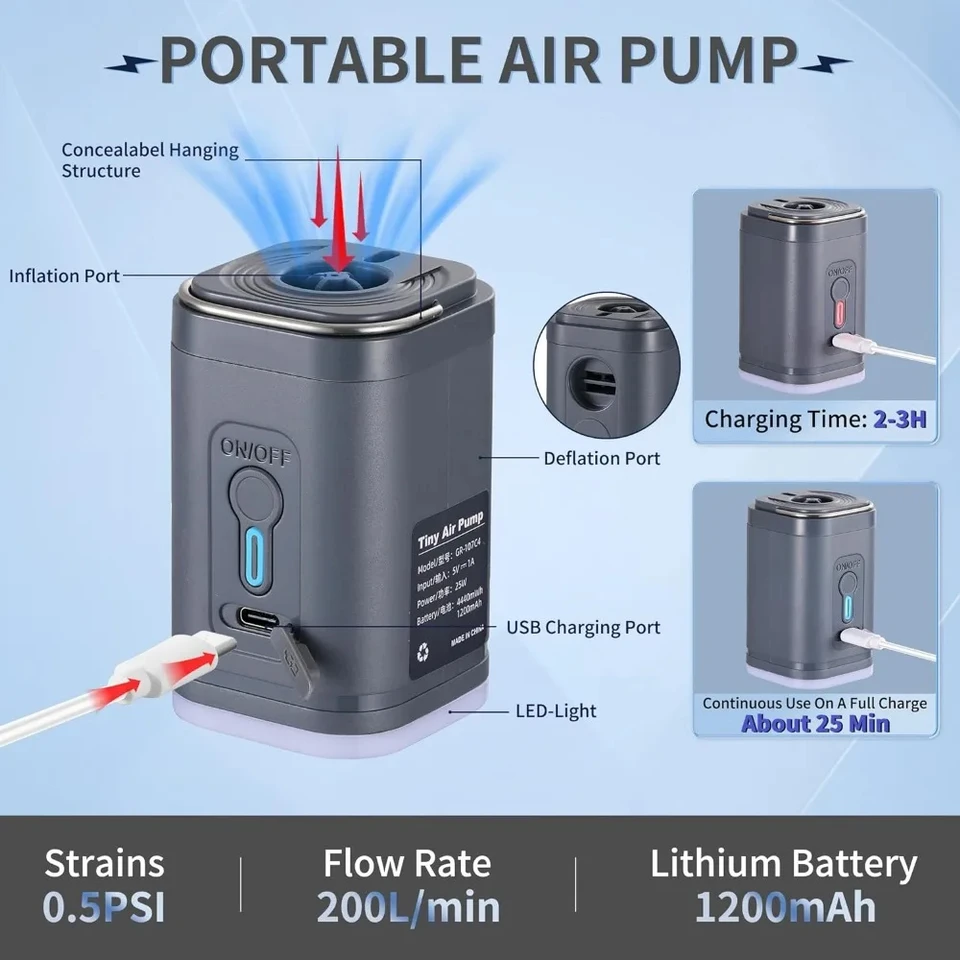

The Solution: To mitigate battery life concerns, buyers should opt for battery charged air pumps with dual power supply options, including AC and DC capabilities. This feature allows users to charge the pump while it is in use, ensuring continuous operation. Additionally, it is essential to select pumps with higher capacity lithium-ion batteries, ideally over 20V, as they tend to offer longer run times. For optimal performance, regular maintenance and proper charging practices—such as avoiding complete battery drain and storing pumps in a cool environment—can enhance battery longevity. Buyers should also consider investing in spare batteries to ensure they are always prepared for high-demand situations.

The Problem: Inaccurate pressure readings can pose significant safety risks, particularly in sectors that require precise inflation, like automotive services or construction. A pump that does not accurately gauge pressure can lead to over-inflated or under-inflated tires and equipment, which can compromise safety standards and result in equipment failure or accidents.

The Solution: To avoid these issues, it is crucial for buyers to choose battery charged air pumps equipped with digital pressure gauges that provide accurate readings. Buyers should look for pumps that feature an auto shut-off function, allowing them to preset desired pressure levels. When the pump reaches the set pressure, it automatically shuts off, preventing over-inflation. Additionally, regular calibration of the pressure gauge is essential. Buyers should implement a routine check to compare the pump’s readings against a calibrated pressure gauge to ensure accuracy. This practice not only enhances safety but also builds trust in the equipment’s performance.

Illustrative image related to battery charged air pump

The Problem: Many businesses require versatile air pumps that can cater to various inflatables, from car tires to sports equipment and larger inflatables. However, some battery charged air pumps are designed for specific applications, leaving users frustrated when they cannot effectively inflate different types of items.

The Solution: B2B buyers should seek out multipurpose battery charged air pumps that come with multiple nozzle attachments and adjustable pressure settings. This versatility allows the same pump to be used for various applications, significantly improving operational efficiency. Furthermore, pumps that feature both inflation and deflation modes can save time when storing or transporting inflatables. When selecting a pump, buyers should review product specifications to ensure compatibility with the intended use cases. It can also be beneficial to conduct a trial of the pump in real-world scenarios to assess its performance across different applications before making a bulk purchase. This approach ensures that the investment meets the diverse needs of the business.

By addressing these common pain points, B2B buyers can make informed decisions that enhance operational efficiency, safety, and equipment versatility, ultimately leading to greater satisfaction and productivity in their respective industries.

When selecting materials for battery charged air pumps, it’s essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: plastic, aluminum, stainless steel, and rubber. Each material offers unique benefits and challenges that can significantly impact performance and suitability for various applications.

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are known for their lightweight nature and resistance to corrosion. They can withstand moderate temperatures and pressures, making them suitable for many air pump applications.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which allows for complex shapes and designs. However, plastics may not perform well under extreme temperatures or pressures, and their longevity can be compromised in harsh environments.

Impact on Application: Plastic components are typically used in non-pressurized sections of air pumps. They are compatible with air but may not be suitable for applications involving aggressive chemicals or high-temperature gases.

Considerations for International Buyers: Compliance with local standards such as ASTM or ISO is crucial. Buyers in regions like Africa and South America should ensure that the selected plastic meets local environmental regulations regarding waste and recyclability.

Key Properties: Aluminum is lightweight, has excellent thermal conductivity, and offers good corrosion resistance, especially when anodized. It can handle higher pressures than plastic, making it suitable for more demanding applications.

Illustrative image related to battery charged air pump

Pros & Cons: The advantages of aluminum include its strength-to-weight ratio and resistance to corrosion, which extends the life of the pump. However, the cost of aluminum is generally higher than plastic, and the manufacturing process can be more complex due to the need for specialized machining.

Impact on Application: Aluminum is often used in the housing and structural components of air pumps, where strength and durability are critical. It is compatible with a wide range of gases and is particularly effective in automotive applications.

Considerations for International Buyers: Buyers should verify that aluminum components comply with international standards such as DIN or JIS, particularly in regions like Europe and the Middle East, where regulatory compliance is stringent.

Key Properties: Stainless steel offers exceptional strength, corrosion resistance, and durability, making it ideal for high-pressure applications. It can withstand extreme temperatures and is often used in environments where chemical exposure is a concern.

Illustrative image related to battery charged air pump

Pros & Cons: The primary advantage of stainless steel is its longevity and reliability in demanding conditions. However, it is significantly more expensive than both plastic and aluminum, and its manufacturing requires more energy and resources.

Impact on Application: Stainless steel is commonly used in high-pressure air pumps and in applications where hygiene is paramount, such as in medical or food-related industries. Its compatibility with various gases and liquids makes it a versatile choice.

Considerations for International Buyers: Buyers must ensure that the stainless steel used meets specific grades (e.g., 304, 316) and complies with international standards. In regions like Saudi Arabia and Nigeria, where environmental and safety regulations are evolving, compliance is critical.

Illustrative image related to battery charged air pump

Key Properties: Rubber is flexible, resilient, and provides excellent sealing capabilities. It can handle a range of temperatures and pressures, depending on the specific type of rubber used (e.g., nitrile, silicone).

Pros & Cons: The advantages of rubber include its ability to create airtight seals and its cost-effectiveness. However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures, which may limit its lifespan.

Impact on Application: Rubber is primarily used in seals, gaskets, and hoses within air pumps, ensuring that air remains contained and preventing leaks. Its compatibility with air and various liquids makes it suitable for a wide range of applications.

Considerations for International Buyers: Buyers should consider the specific type of rubber and its compliance with relevant standards. In regions with varying climates, such as Africa and South America, the choice of rubber can impact performance and durability.

| Material | Typical Use Case for battery charged air pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Non-pressurized components | Low cost and easy to manufacture | Limited temperature and pressure tolerance | Low |

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Stainless Steel | High-pressure applications | Exceptional strength and durability | High cost and energy-intensive production | High |

| Rubber | Seals and gaskets | Excellent sealing capabilities | Degrades over time under harsh conditions | Low |

This strategic material selection guide provides B2B buyers with crucial insights into the materials used in battery charged air pumps, helping them make informed decisions based on performance, cost, and compliance considerations.

The manufacturing of battery charged air pumps involves several critical stages that ensure the final product meets both performance and safety standards.

The first step in manufacturing is the selection and preparation of materials. Manufacturers typically use durable plastics, metals, and rubber for various components. High-density polyethylene (HDPE) is often utilized for the outer casing due to its resistance to impact and environmental conditions. Metals, such as aluminum and steel, are chosen for internal components requiring strength and durability.

Quality control begins at this stage, where raw materials undergo inspection to verify compliance with specifications and international standards, such as ISO 9001. This ensures that only high-quality materials proceed to the next stage.

Once materials are prepared, they undergo various forming processes. These may include injection molding for plastic components, machining for metal parts, and extrusion for hoses.

Illustrative image related to battery charged air pump

Injection molding is particularly significant in producing the air pump casing and other intricate components. This method allows for high precision and the ability to create complex shapes that enhance the pump’s functionality. Machining ensures that metal parts fit together seamlessly, which is crucial for maintaining the pump’s structural integrity.

The assembly stage is where all components come together. Assembly lines are often utilized for efficiency, allowing for systematic integration of parts.

Automated and manual assembly techniques are used in tandem. For example, automated systems may be employed for tasks such as the installation of motors and wiring, while skilled technicians perform quality-sensitive tasks like sealing and testing the pump’s functionality.

Illustrative image related to battery charged air pump

During assembly, manufacturers implement in-process quality control (IPQC) checks to ensure that each unit meets specified tolerances and performance metrics.

The final stage of manufacturing involves finishing processes, which may include painting, coating, and packaging. These processes not only enhance the aesthetic appeal of the product but also protect it from environmental factors such as moisture and UV exposure.

Coatings often include anti-corrosive treatments, while the final quality assurance checks ensure that the product is free from defects and meets all regulatory standards before packaging.

Quality assurance (QA) is integral to the manufacturing of battery charged air pumps, ensuring that each unit is reliable and safe for consumers.

International standards such as ISO 9001 are crucial for manufacturers to demonstrate their commitment to quality management systems. Compliance with these standards indicates that the manufacturer has established processes for continuous improvement and customer satisfaction.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards may be applicable, especially if the pumps are intended for specialized applications.

Quality control involves several checkpoints throughout the manufacturing process:

Testing methods for battery charged air pumps typically include:

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks.

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should review the supplier’s quality management certifications and procedures.

Request Quality Reports: Buyers can ask for detailed quality assurance reports, including results from IQC, IPQC, and FQC. This documentation can provide reassurance that the supplier adheres to international quality standards.

Third-Party Inspections: Engaging independent third-party inspection services can add an additional layer of assurance, ensuring that the products meet the required specifications before shipment.

B2B buyers must be aware of regional regulations and standards that may influence quality assurance. For instance, products sold in Europe must comply with CE standards, while those in the Middle East may require certification from local regulatory bodies. Understanding these nuances helps buyers make informed decisions and avoid potential compliance issues.

The manufacturing processes and quality assurance protocols for battery charged air pumps are critical to ensuring product reliability and performance. For B2B buyers, understanding these aspects not only aids in selecting the right supplier but also in ensuring that the final products meet their specific market needs. By focusing on manufacturers who adhere to international standards and maintain rigorous quality control, buyers can mitigate risks and foster successful business relationships.

In the competitive landscape of B2B procurement, sourcing a reliable battery-charged air pump is crucial for businesses that require efficient inflation solutions. This checklist is designed to guide international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, through the essential steps to ensure they make informed purchasing decisions.

Start by clearly outlining the technical requirements for the air pump. Consider factors such as flow rate, maximum pressure, and battery capacity.

– Flow Rate: Ensure the pump can inflate tires or objects within a reasonable time frame, enhancing operational efficiency.

– Maximum Pressure: Choose a model that meets the needs of your applications, whether for vehicle tires or smaller inflatables.

Stay informed about the latest advancements in battery-charged air pump technology.

– Emerging Features: Look for pumps with features like auto shut-off, digital pressure gauges, and multiple power supply options, which can improve user experience and safety.

– Consumer Feedback: Analyze reviews and case studies to understand how new technologies are performing in real-world applications.

Thoroughly vet suppliers to ensure reliability and quality.

– Request Documentation: Ask for company profiles, certifications, and references from other businesses in your industry.

– Check Compliance: Ensure that the suppliers meet international standards relevant to your market, particularly those regarding safety and quality.

Illustrative image related to battery charged air pump

Compare pricing structures among potential suppliers while considering payment flexibility.

– Transparent Pricing: Look for clear pricing models that include all costs, such as shipping and handling, to avoid unexpected expenses.

– Payment Terms: Favor suppliers that offer favorable payment terms, such as credit options or discounts for bulk purchases.

A robust warranty and reliable customer support are indicators of a trustworthy supplier.

– Warranty Coverage: Check the duration and extent of warranty coverage to protect your investment against manufacturing defects.

– Customer Support: Ensure the supplier provides accessible customer service for troubleshooting and maintenance, which can minimize downtime.

Before committing to a large order, consider making a smaller trial purchase.

– Performance Testing: Use this opportunity to assess the pump’s performance under your specific conditions and requirements.

– Feedback Loop: Gather feedback from your team on usability and effectiveness, which will inform your decision on future orders.

Once you’ve selected a supplier, finalize your procurement strategy.

– Long-term Partnerships: Consider establishing a long-term relationship with the supplier for better pricing and priority service.

– Review and Adjust: Periodically review the performance of the air pumps and the supplier relationship to ensure ongoing alignment with your business needs.

By following this checklist, B2B buyers can navigate the complexities of sourcing battery-charged air pumps effectively, ensuring they choose products that align with their operational goals and market demands.

When sourcing battery charged air pumps, understanding the comprehensive cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to battery charged air pump

Materials: The choice of materials significantly impacts the overall cost. High-quality plastics, metals, and electronic components can elevate prices, but they ensure durability and reliability. Suppliers often source materials locally or internationally, affecting pricing based on availability and transportation costs.

Labor: Labor costs vary by region. Countries with lower labor costs may offer competitive pricing; however, this can sometimes lead to quality concerns. Buyers should consider not only the direct labor costs but also the skill level and efficiency of the workforce.

Manufacturing Overhead: This includes utilities, factory rent, and administrative expenses. Overhead costs can differ greatly depending on the supplier’s location and operational efficiency. Understanding these costs can help buyers assess the overall pricing strategy of potential suppliers.

Tooling: Custom designs may require specialized tooling, which can significantly affect initial costs. Buyers should inquire about tooling fees, especially for unique specifications, as these can be amortized over larger order volumes.

Quality Control (QC): Implementing robust QC processes ensures product reliability, but it adds to the cost. Buyers should evaluate the supplier’s QC practices, as rigorous checks can prevent costly defects in the long run.

Logistics: Transportation and handling costs are essential in the total cost calculation. Factors such as shipping distance, mode of transport, and customs duties can significantly influence the final price.

Margin: Finally, the supplier’s profit margin plays a critical role in pricing. Understanding typical margins in the industry can help buyers negotiate more effectively.

Several factors influence the pricing of battery charged air pumps in B2B transactions:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts to maximize cost efficiency.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether the added functionalities justify the higher prices and ensure that they align with market demand.

Material Quality and Certifications: Higher quality materials and necessary certifications (e.g., CE, ISO) can raise costs but may be necessary for compliance in certain markets. Buyers should weigh the benefits of certification against the additional costs.

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers with a proven track record may charge a premium, but they often provide greater reliability and support.

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping costs and risks, which can impact the final landed cost of products.

For international buyers, especially those in regions like Africa, South America, the Middle East, and Europe, effective negotiation is key to securing favorable terms:

Conduct Thorough Research: Understand the market prices and trends for battery charged air pumps. This knowledge empowers buyers during negotiations.

Explore Total Cost of Ownership (TCO): Assess not just the purchase price but the entire lifecycle cost, including maintenance, warranty, and potential failure costs. A slightly higher initial price may be justifiable if it leads to lower long-term costs.

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

Be Aware of Pricing Nuances: Factors such as currency fluctuations and regional economic conditions can affect pricing. Buyers should account for these variables when planning their budget.

Leverage Volume for Discounts: If possible, commit to larger orders in exchange for discounts. Suppliers are often willing to negotiate on price for guaranteed sales.

By understanding these cost components, pricing influencers, and negotiation strategies, B2B buyers can make informed decisions that enhance their procurement processes for battery charged air pumps.

When considering the acquisition of a battery charged air pump, it’s essential for B2B buyers to explore alternative solutions that can fulfill similar operational needs. This analysis compares battery charged air pumps against two viable alternatives: electric air compressors and manual hand pumps. Each solution has distinct advantages and disadvantages, which can influence procurement decisions based on specific use cases and operational contexts.

| Comparison Aspect | Battery Charged Air Pump | Electric Air Compressor | Manual Hand Pump |

|---|---|---|---|

| Performance | Moderate flow rate, portable, ideal for light to medium tasks | High flow rate, suitable for heavy-duty applications | Low flow rate, labor-intensive, best for small inflatables |

| Cost | Moderate ($50 – $100) | Higher ($150 – $500) | Low ($10 – $30) |

| Ease of Implementation | Very easy; requires minimal setup | Requires electrical outlet and may need installation | Simple; no setup required |

| Maintenance | Low; occasional battery check | Moderate; regular maintenance required | Very low; minimal maintenance needed |

| Best Use Case | Car tires, bicycles, small inflatables | Automotive shops, workshops, large inflatables | Camping, emergency kits, small items |

Electric air compressors are powerful tools designed for high-volume tasks. They offer significantly higher flow rates compared to battery charged air pumps, making them ideal for heavy-duty applications like automotive repairs or large inflatable setups. However, they require a constant electrical source, which limits mobility and can increase operational costs. Additionally, maintenance can be more involved, as electric compressors often have moving parts and may require regular servicing.

Manual hand pumps are the most basic option for inflating air, typically used for small inflatables like sports balls and air mattresses. They are cost-effective and require no electricity, making them convenient for outdoor use or emergency situations. However, the performance is significantly lower, requiring more physical effort and time to achieve desired inflation levels. While they are easy to use, they are not suitable for larger tasks or for users requiring efficiency.

Illustrative image related to battery charged air pump

Choosing the right air pump solution depends on your specific operational requirements and budget constraints. If your business involves frequent mobility and requires a balance of performance and cost, a battery charged air pump may be the most suitable option. On the other hand, if your operations demand high performance and you have access to electrical outlets, investing in an electric air compressor may yield better productivity in the long run. Conversely, if your needs are minimal and focused on small items, a manual hand pump could be the most economical choice.

In conclusion, B2B buyers must evaluate each option against their unique use cases, operational environments, and financial considerations. Understanding the strengths and weaknesses of battery charged air pumps, electric compressors, and manual pumps will empower businesses to make informed decisions that align with their operational goals and budgetary constraints.

When evaluating battery charged air pumps, understanding their technical specifications is essential for B2B buyers. Here are critical properties that define their performance and suitability for various applications:

Illustrative image related to battery charged air pump

The airflow rate indicates how much air the pump can deliver per minute. Measured in liters per minute (L/min) or cubic feet per minute (CFM), this metric is vital for determining how quickly the pump can inflate tires or other inflatables. A higher airflow rate translates to faster inflation times, which is particularly important for commercial applications where efficiency is key.

Maximum pressure, typically measured in pounds per square inch (PSI), indicates the highest pressure the pump can achieve. This is crucial for ensuring the pump can handle various inflation tasks, from car tires to sports equipment. B2B buyers should assess the maximum pressure requirements of their specific applications to ensure compatibility and avoid damage.

The battery capacity, measured in amp-hours (Ah), reflects how long the pump can operate on a single charge. A higher capacity means longer operational time between charges, which is beneficial for users who need to inflate multiple items or work in remote locations without immediate access to power. Understanding battery life is critical for planning usage and ensuring productivity.

The weight of a battery charged air pump influences its portability. Lightweight models are easier to transport, making them ideal for mobile use in fields such as automotive repair, event management, and outdoor activities. For B2B buyers, assessing the weight can guide purchasing decisions based on intended usage scenarios.

Illustrative image related to battery charged air pump

The construction materials of the pump determine its durability and longevity. Pumps made from high-grade plastics or metals are typically more resistant to wear and tear, making them suitable for rigorous use. B2B buyers should consider the environmental conditions in which the pump will be used, as this will impact the choice of materials.

Noise level, measured in decibels (dB), is an often-overlooked specification that can affect user experience and compliance with local regulations. Quieter pumps are preferable for use in residential areas or indoor environments. B2B buyers should assess the noise levels to ensure they meet their operational requirements.

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some common terms relevant to battery charged air pumps:

OEM refers to companies that produce components or products that are used in another company’s end product. Understanding OEM relationships is crucial for B2B buyers looking for quality assurance and compatibility with existing equipment.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, particularly for businesses looking to scale their operations.

Illustrative image related to battery charged air pump

An RFQ is a formal document requesting pricing information from suppliers. When sourcing battery charged air pumps, issuing an RFQ can help buyers compare offers and negotiate better terms.

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and rights, reducing potential disputes.

These terms refer to the commitments made by the manufacturer regarding the quality and longevity of the product. Understanding warranty terms is crucial for B2B buyers to ensure they are protected against defects and service issues.

Lead time is the duration between placing an order and receiving the product. Knowing the lead time is essential for supply chain planning, especially when dealing with time-sensitive projects or inventory replenishment.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing battery charged air pumps, ensuring they select products that meet their operational needs while optimizing costs and efficiencies.

The battery charged air pump market is experiencing significant growth driven by increasing consumer demand for portable and efficient inflating solutions. Key global drivers include the rising popularity of outdoor activities, the growth of the automotive sector, and the increasing need for convenient inflating devices in various applications—from car tires to sports equipment. Emerging technologies such as smart inflators, which integrate digital pressure gauges and automatic shut-off features, are enhancing user experience and safety, making them attractive options for B2B buyers.

Internationally, markets in Africa, South America, the Middle East, and Europe are witnessing a shift towards battery-powered solutions due to their ease of use and portability. For instance, in regions with limited access to power supply, battery-operated inflators provide a reliable alternative, reducing downtime and ensuring convenience for end-users. Additionally, the ongoing trend towards e-commerce is reshaping sourcing strategies, allowing B2B buyers to access a broader range of suppliers and products, thereby increasing competition and driving innovation.

Price sensitivity remains a crucial factor for buyers in these regions, particularly in emerging markets where affordability is essential. However, there is also a growing willingness to invest in higher-quality products that offer durability and advanced features, indicating a shift towards value over cost. This dynamic encourages suppliers to innovate continuously and cater to diverse customer needs.

Sustainability is becoming a central theme in the battery charged air pump market as businesses increasingly recognize the environmental impact of their operations. The production of battery-powered devices often involves materials that can be harmful if not sourced responsibly. Therefore, B2B buyers are urged to prioritize suppliers who adhere to ethical sourcing practices and have transparent supply chains.

The importance of sustainability extends beyond sourcing; it encompasses the entire lifecycle of the product. Businesses are looking for battery charged air pumps that utilize recyclable materials and environmentally friendly manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the shift towards ‘green’ certifications is gaining traction in the market. Products that are energy-efficient and use eco-friendly batteries are increasingly preferred by buyers who aim to minimize their carbon footprint. This trend not only aligns with global sustainability goals but also enhances brand reputation, making it a strategic focus for B2B buyers looking to differentiate themselves in a competitive landscape.

The evolution of battery charged air pumps traces back to the early development of portable inflating devices, which initially relied on manual operation or AC power. With the advent of battery technology, particularly lithium-ion batteries, the sector witnessed a transformative shift towards more portable and user-friendly designs.

Illustrative image related to battery charged air pump

Historically, the focus was predominantly on functionality, but as consumer expectations evolved, manufacturers began integrating features like digital displays, programmable pressure settings, and ergonomic designs. This evolution has positioned battery charged air pumps as essential tools across various industries, including automotive, sports, and outdoor recreation. Today, these devices are not just about inflating tires or sports equipment; they represent a blend of innovation, convenience, and sustainability, making them crucial for modern B2B buyers.

As the market continues to grow, understanding this historical context can help B2B buyers appreciate the advancements that have shaped current offerings and anticipate future trends in the battery charged air pump sector.

How do I choose the right battery charged air pump for my business needs?

Selecting the right battery charged air pump involves assessing your specific requirements, including the types of products you’ll be inflating (e.g., car tires, sports equipment), desired pressure levels, and flow rate. Consider the pump’s portability, battery life, and dual power options, such as AC and DC compatibility. Additionally, check for features like auto shut-off and ergonomic design for ease of use. Conducting a thorough market comparison and reading user reviews can also guide your decision-making process.

What are the typical minimum order quantities (MOQs) for battery charged air pumps?

Minimum order quantities for battery charged air pumps can vary significantly by supplier and region. Generally, MOQs may range from 50 to 500 units, depending on the manufacturer and product specifications. If you are a smaller buyer, it’s advisable to negotiate with suppliers or seek out manufacturers willing to accommodate lower MOQs. This flexibility can help you manage inventory and reduce upfront investment while still meeting market demands.

What payment terms should I expect when sourcing battery charged air pumps internationally?

Payment terms can vary based on the supplier’s policies and the buyer’s negotiation. Common options include a deposit (typically 30%) before production, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment through escrow services for added security. Ensure to clarify payment methods and terms in your contract to avoid misunderstandings and protect your investment during international transactions.

How can I vet suppliers for battery charged air pumps?

To vet suppliers, start by checking their business credentials, including industry certifications and references from previous clients. Utilize platforms like Alibaba or Global Sources to review supplier ratings and feedback. Request product samples to assess quality and performance. Additionally, consider visiting their production facilities if feasible or conducting virtual inspections. Establishing communication and building a rapport can also provide insights into their reliability and customer service.

What quality assurance measures should I look for in battery charged air pumps?

When sourcing battery charged air pumps, inquire about the supplier’s quality assurance processes. Look for certifications like ISO 9001, which indicates adherence to international quality management standards. Suppliers should conduct rigorous testing on their products, including pressure testing, safety checks, and performance evaluations. Request documentation of their quality control procedures and any warranties offered to safeguard against defects.

How can I ensure timely logistics and delivery for my battery charged air pump order?

To ensure timely logistics, work closely with your supplier to establish a clear production timeline and shipping schedule. Discuss preferred shipping methods (air freight vs. sea freight) based on urgency and budget. Utilize freight forwarders experienced in international shipping, especially in your target regions. Regularly communicate with both your supplier and logistics partners to monitor progress and address any potential delays promptly.

What customization options are available for battery charged air pumps?

Many manufacturers offer customization options for battery charged air pumps, which can include branding (private labeling), color choices, and specific features like pressure gauges or additional attachments. Discuss your requirements with the supplier during the initial negotiation phase to understand the extent of customization they can accommodate. Be aware that customization may affect MOQs, lead times, and costs.

Are there specific regulations I need to comply with when importing battery charged air pumps?

Yes, importing battery charged air pumps often involves compliance with international trade regulations and local standards. This may include safety certifications, environmental regulations, and labeling requirements specific to your destination country. Research these regulations and ensure your supplier provides the necessary documentation, such as CE marking in Europe or FCC compliance in the U.S. Partnering with a customs broker can also facilitate the import process and ensure compliance with all legal requirements.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a small, reliable, rechargeable tire inflator. Users recommend brands like Ryobi, Milwaukee, Dewalt, and Kobalt. Specific models mentioned include a Royobi air pump with a 4ah 18v battery, an EPAUTO air pump that plugs into a cigarette lighter, and a VIAIR 12v cigarette lighter air pump. One user mentioned the IILUEE Tire Inflator Portable Air Compressor with 160PSI and a 7800mAh batte…

As the demand for battery charged air pumps continues to rise globally, strategic sourcing becomes increasingly vital for businesses looking to enhance their operational efficiency and product offerings. Key insights from this guide highlight the importance of selecting high-quality, versatile pumps that cater to various applications, from automotive to recreational use. Prioritizing features such as fast inflation, dual power supply options, and safety mechanisms can significantly impact customer satisfaction and brand loyalty.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should focus on building relationships with reliable suppliers who can provide innovative solutions tailored to their market needs. This strategic approach not only mitigates supply chain risks but also enhances competitive positioning in an evolving marketplace.

Looking ahead, the battery charged air pump industry is poised for growth, fueled by advancements in technology and increasing consumer awareness of portable solutions. B2B buyers are encouraged to explore partnerships that emphasize sustainability and efficiency. Now is the time to act—invest in strategic sourcing that aligns with your business goals and positions you for success in a dynamic global landscape.

Illustrative image related to battery charged air pump

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.