In today’s fast-paced global market, sourcing the best tire air pump can be a significant challenge for B2B buyers. With diverse applications ranging from automotive to industrial uses, the demand for reliable and efficient tire inflators is on the rise. This guide is designed to navigate you through the complexities of selecting the right tire air pump for your specific needs, whether you are operating a fleet of vehicles in Africa, managing logistics in South America, or servicing customers in Europe and the Middle East.

We delve into various types of tire air pumps available, their applications, and the critical aspects of supplier vetting to ensure quality and reliability. Understanding the cost structures associated with these products is essential for making informed purchasing decisions that align with your budget and operational requirements.

This comprehensive resource empowers international B2B buyers by providing actionable insights and practical recommendations tailored to regional markets, such as Brazil and Vietnam. By leveraging this guide, you can streamline your procurement process, enhance operational efficiency, and ultimately achieve greater customer satisfaction through the reliable performance of tire air pumps. Together, let’s simplify the path to finding the best tire inflator that meets your business’s unique demands.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-powered, portable, often with digital gauges | Automotive repair shops, roadside assistance | Pros: Portable, easy to use, no power outlet needed. Cons: Limited battery life, may require recharging. |

| 12V Plug-In Tire Inflators | Connects to vehicle’s 12V outlet, often compact | Fleet maintenance, vehicle service centers | Pros: Continuous power from vehicle, lightweight. Cons: Limited range, dependent on vehicle availability. |

| Heavy-Duty Tire Inflators | High PSI capacity, often for larger tires | Heavy machinery, trucking companies | Pros: Fast inflation, suitable for high-pressure tires. Cons: Bulkier, requires connection to a power source. |

| Ultra-Compact Tire Inflators | Extremely portable, often USB rechargeable | Emergency kits, personal vehicles | Pros: Fits in small spaces, convenient for quick fixes. Cons: Limited power and speed, may not handle larger tires. |

| Multi-Functional Tire Inflators | Includes additional features like lighting, USB ports | General automotive use, outdoor activities | Pros: Versatile for various tasks, good for emergencies. Cons: Potentially higher cost, may sacrifice speed for features. |

Cordless tire inflators are battery-powered devices that provide a high level of portability and convenience, making them ideal for roadside assistance and automotive repair shops. Their compact design often includes digital pressure gauges, allowing for accurate inflation without the need for a power outlet. B2B buyers should consider battery life and charging options, as these factors directly influence usability in emergency scenarios.

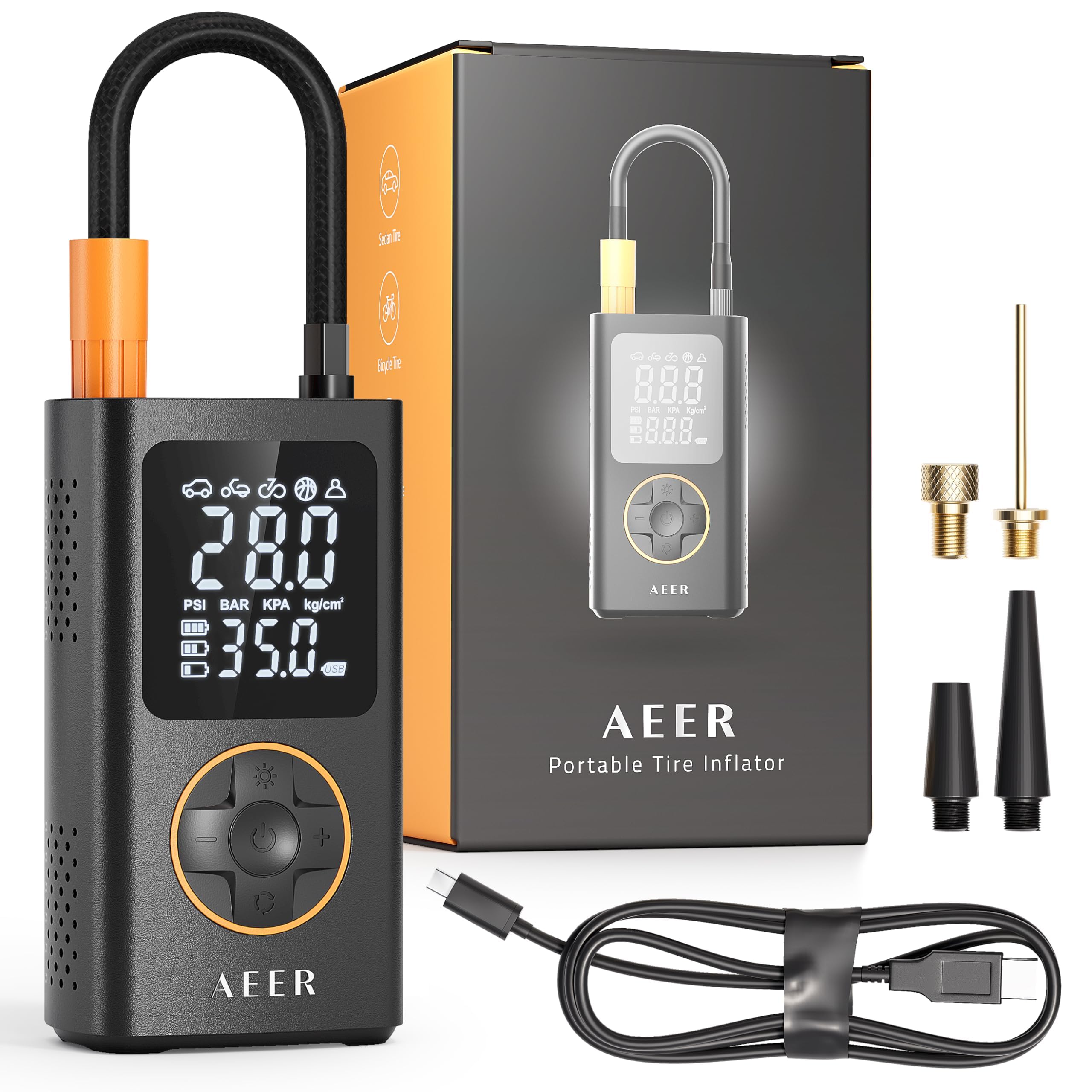

Illustrative image related to best tire air pump

12V plug-in tire inflators connect directly to a vehicle’s power outlet, making them a reliable choice for fleet maintenance and vehicle service centers. These inflators are typically lightweight and easy to operate, but their range is limited to the vehicle’s proximity. When purchasing, businesses should assess the inflator’s hose length and compatibility with various tire sizes to ensure optimal performance.

Heavy-duty tire inflators are designed to handle high PSI requirements, making them crucial for industries that rely on large vehicles, such as trucking and heavy machinery. They offer fast inflation times and robust construction, but they usually require a direct power source, which can limit their mobility. B2B buyers must weigh the speed and efficiency against the need for a power connection when selecting these inflators.

Ultra-compact tire inflators are designed for maximum portability, often fitting into glove compartments or small bags. They are particularly useful for emergency kits and personal vehicles, providing a quick solution for minor tire issues. However, their limited power capacity can restrict their use for larger tires. Businesses should consider the trade-off between size and performance when selecting these inflators.

Multi-functional tire inflators offer added features such as built-in lights and USB charging ports, making them versatile tools for various applications beyond tire inflation. They are suitable for general automotive use and outdoor activities, providing convenience during emergencies. However, the inclusion of extra features may lead to higher costs and potentially slower inflation rates. B2B buyers should evaluate the balance of features against their specific operational needs.

| Industry/Sector | Specific Application of best tire air pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Regular tire maintenance and repair services | Improved service efficiency and customer satisfaction | Reliability, ease of use, and compact design for storage |

| Logistics and Transportation | Fleet maintenance for trucks and delivery vehicles | Enhanced safety and reduced downtime due to tire issues | High PSI capability, durability for heavy-duty use |

| Construction and Mining | Inflating tires for heavy machinery and equipment | Minimizes equipment downtime and operational delays | Robustness, ability to handle high pressure, portability |

| Agriculture | Maintaining air pressure in agricultural vehicles | Ensures optimal performance of tractors and harvesters | Power source options, adaptability to different tire sizes |

| Recreational Vehicle Rentals | Quick tire inflation for RVs and trailers | Increases rental turnover and customer satisfaction | Lightweight, portable designs with multiple power options |

In automotive repair shops, the best tire air pump serves as an essential tool for routine tire maintenance and emergency repairs. These pumps facilitate the quick inflation of tires, ensuring that customers can return to the road safely and efficiently. By maintaining correct tire pressure, repair shops can enhance vehicle performance and fuel efficiency for their clients. For international B2B buyers, sourcing reliable and user-friendly tire pumps that can handle a variety of tire sizes is crucial, especially in regions with diverse vehicle types like Africa and South America.

In the logistics and transportation sector, tire air pumps are vital for maintaining the fleets of trucks and delivery vehicles. Regular tire pressure checks and adjustments can significantly reduce the risk of blowouts and improve fuel efficiency, ultimately leading to cost savings. Buyers in this sector should prioritize pumps with high PSI capabilities and durability to withstand the rigors of daily use. Given the diverse climates in regions such as the Middle East and Europe, choosing pumps that can perform reliably in varying conditions is essential.

In construction and mining industries, where heavy machinery and equipment are prevalent, the best tire air pump is indispensable for inflating tires efficiently. These pumps help minimize downtime by ensuring that equipment is always ready for operation, which is critical in high-stakes environments. Buyers in these sectors should focus on sourcing robust pumps that can handle high-pressure requirements and are designed for portability, as equipment may need to be transported across job sites.

Agricultural vehicles, such as tractors and harvesters, require consistent tire pressure for optimal performance. The best tire air pump enables farmers to maintain their equipment efficiently, reducing the likelihood of tire-related issues during critical planting and harvesting seasons. For buyers in the agricultural sector, it’s important to consider pumps that offer multiple power source options and can adapt to various tire sizes, especially in regions like Brazil and Vietnam, where agricultural practices may vary widely.

Illustrative image related to best tire air pump

In the recreational vehicle rental industry, the best tire air pump is crucial for ensuring the readiness of RVs and trailers for customer use. Quick tire inflation can significantly enhance the rental process, allowing for faster turnover and improved customer satisfaction. Buyers in this market should look for lightweight and portable tire pumps that offer multiple power options, making them easy to store and use. Ensuring that these pumps can accommodate larger tires typically found on RVs is also vital for meeting customer needs.

The Problem: Many B2B buyers face the challenge of selecting tire air pumps that can accommodate varying power sources, especially when working in diverse geographical regions. For instance, a company operating in remote areas of Africa or South America may have limited access to electricity, making it difficult to use traditional electric pumps. Additionally, some pumps may only operate on vehicle batteries, which can be impractical for users who are not familiar with automotive systems. This variability can lead to frustration and operational downtime when an appropriate power source isn’t readily available.

The Solution: To overcome this challenge, B2B buyers should prioritize tire air pumps with multi-power capabilities. When sourcing products, look for models that offer options like rechargeable batteries, 12-volt car adapters, and even solar-powered alternatives. Ensure that the pumps have enough battery capacity to inflate multiple tires on a single charge. For example, models like the AstroAI Cordless Tire Inflator are designed to inflate multiple tires without needing to recharge, making them ideal for users in areas with unstable electricity. Furthermore, consider providing training or detailed instructions on how to operate these pumps, focusing on their power options to ensure that all users can effectively utilize them.

Illustrative image related to best tire air pump

The Problem: Inaccurate tire pressure readings can lead to significant issues, including tire wear, reduced fuel efficiency, and even accidents. B2B buyers often encounter tire air pumps with unreliable pressure gauges, resulting in overinflated or underinflated tires. This problem is particularly prevalent in regions with extreme temperature variations, where tire pressure can fluctuate significantly. The consequences of inaccurate readings can be costly, affecting fleet operations and overall safety.

The Solution: To mitigate the risks associated with inaccurate pressure readings, B2B buyers should invest in tire air pumps equipped with high-quality, digital pressure gauges. When evaluating options, it’s essential to look for pumps that have undergone rigorous testing for accuracy and reliability. Additionally, consider models that include an automatic shut-off feature, which stops inflation once the desired pressure is reached. This feature not only prevents overinflation but also enhances user convenience. Providing regular maintenance checks for the pumps and training employees on how to interpret pressure readings correctly can further ensure safety and operational efficiency.

The Problem: Compact tire air pumps are often marketed as portable and easy to use, but they may struggle with high-pressure demands, particularly for heavy-duty vehicles like trucks and SUVs. B2B buyers in industries such as logistics or construction may require air pumps that can handle larger tires but find that smaller, compact models frequently fall short in performance. This can lead to prolonged downtime when dealing with flat tires or insufficient inflation, ultimately impacting productivity.

The Solution: When selecting tire air pumps, it is crucial for B2B buyers to assess the maximum PSI capabilities of the pumps in relation to their specific vehicle requirements. Heavy-duty applications necessitate pumps that can achieve higher pressure outputs, such as the Viair 88P, which is specifically designed for larger tires. Buyers should also consider the duty cycle of the pump, ensuring it can handle prolonged use without overheating. In addition, providing employees with clear guidelines on which pumps to use for different vehicles can help prevent misuse and ensure that the right tool is available for the job. Regular training sessions on pump operation and maintenance will also empower staff to utilize these tools effectively, minimizing downtime and enhancing overall operational efficiency.

When selecting the best tire air pump for B2B applications, the choice of materials plays a crucial role in product performance, durability, and compliance with international standards. Below, we analyze four common materials used in tire air pumps: plastic, aluminum, steel, and rubber. Each material has unique properties that impact the overall functionality and suitability of the air pump for various markets.

Key Properties: Plastic is lightweight, corrosion-resistant, and can withstand moderate pressure. Common types include polypropylene and ABS, which have temperature ratings up to 80°C and pressure ratings around 150 psi.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which allows for intricate designs and mass production. However, its durability can be a concern, especially in extreme temperatures or under heavy use, leading to potential cracking or deformation over time.

Illustrative image related to best tire air pump

Impact on Application: Plastic components are often used for housing and non-pressurized parts of the pump. While they are suitable for low to medium-pressure applications, they may not be ideal for heavy-duty use or in harsh environments.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the plastic materials used comply with local regulations regarding environmental impact and safety. Standards such as ASTM or ISO may apply, especially for products intended for consumer use.

Key Properties: Aluminum is lightweight, strong, and exhibits excellent corrosion resistance. It can handle high pressures, often exceeding 200 psi, and has a temperature range suitable for various climates.

Pros & Cons: The primary advantage of aluminum is its strength-to-weight ratio, making it ideal for portable tire inflators. However, it is generally more expensive than plastic and may require more complex manufacturing processes, including machining and anodizing for surface protection.

Impact on Application: Aluminum is commonly used for high-pressure components, such as the pump casing and fittings, making it suitable for both consumer and commercial applications. Its durability ensures longevity, even in challenging environments.

Considerations for International Buyers: Buyers in the Middle East and Europe should look for aluminum components that meet specific standards, such as DIN or JIS, to ensure reliability and performance. Additionally, compliance with recycling regulations is crucial in many regions.

Key Properties: Steel is known for its high strength and durability, with pressure ratings often exceeding 300 psi. It is resistant to wear and can withstand extreme temperatures.

Illustrative image related to best tire air pump

Pros & Cons: The main advantage of steel is its robustness, making it suitable for heavy-duty applications. However, its weight can be a drawback for portable models, and it is susceptible to corrosion if not properly treated or coated.

Impact on Application: Steel components are typically used in high-performance pumps designed for commercial vehicles or heavy machinery. They can handle demanding conditions but may require additional maintenance to prevent rust.

Considerations for International Buyers: Buyers from regions with high humidity or saline environments, such as coastal areas in South America or Africa, should prioritize stainless steel or coated options to enhance corrosion resistance. Compliance with international standards for material safety is also essential.

Key Properties: Rubber is flexible, resilient, and can withstand various temperatures. It is commonly used in seals and hoses, with pressure ratings typically around 100 psi.

Pros & Cons: Rubber’s flexibility allows for easy connection and disconnection of hoses, making it user-friendly. However, it can degrade over time due to exposure to UV light and ozone, leading to cracks and leaks.

Illustrative image related to best tire air pump

Impact on Application: Rubber is critical for ensuring airtight seals in tire inflators, enhancing performance and safety. Its compatibility with various gases makes it suitable for multiple applications.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that rubber components meet health and safety standards, as well as environmental regulations regarding material disposal and recycling.

| Material | Typical Use Case for best tire air pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-pressurized parts | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Aluminum | High-pressure components | Strong and corrosion-resistant | Higher manufacturing complexity and cost | Medium |

| Steel | Heavy-duty applications | Extremely robust and durable | Heavier and prone to corrosion | High |

| Rubber | Seals and hoses | Flexible and user-friendly | Degrades over time with exposure | Medium |

This analysis provides B2B buyers with a comprehensive overview of material options for tire air pumps, enabling informed decisions based on performance, cost, and regional compliance requirements.

The manufacturing process for tire air pumps involves several key stages, each critical for ensuring product quality and functionality. Understanding these stages can help B2B buyers make informed decisions about their sourcing and supplier partnerships.

Illustrative image related to best tire air pump

The first step in the manufacturing process is the selection and preparation of materials. Common materials for tire air pumps include high-density plastics, metals (such as aluminum for housing), rubber for seals, and electronic components for digital gauges. Each material must meet specific quality standards to ensure durability and performance.

Quality assurance begins here, as suppliers must provide material certifications to verify compliance with international standards, such as ISO 9001. Buyers should request documentation that details the origin, properties, and certifications of these materials to ensure they meet their operational requirements.

The forming stage involves shaping the materials into the required components. This may include injection molding for plastic parts, machining for metal components, and rubber molding for seals. Advanced techniques like CNC machining can enhance precision, ensuring that parts fit together seamlessly.

In this stage, manufacturers often implement process controls and utilize computer-aided design (CAD) software to guarantee that components are produced to specifications. These practices are crucial for reducing waste and ensuring efficiency in production.

Once components are formed, they move to the assembly stage. This is where the tire air pump is put together, integrating the motor, pressure gauge, and other electronic components. Automated assembly lines are common in larger manufacturing facilities, enhancing speed and accuracy while minimizing human error.

Illustrative image related to best tire air pump

During assembly, manufacturers implement a series of checks to ensure that each component is correctly installed. For example, they may use torque wrenches to ensure screws are tightened to specified levels, preventing issues related to air leakage or component failure.

The finishing stage involves several processes aimed at enhancing the pump’s aesthetics and performance. This may include surface treatment, painting, and quality checks for visual defects. Additionally, manufacturers apply protective coatings to prevent corrosion and increase the longevity of the product.

Final assembly also includes the installation of user-friendly features, such as digital displays and safety mechanisms. Each pump undergoes a thorough inspection to ensure it meets the required specifications and quality standards before packaging.

Quality assurance is critical in manufacturing tire air pumps to ensure safety, reliability, and customer satisfaction. B2B buyers should be aware of the international standards and industry-specific regulations that guide these practices.

Many manufacturers adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates that a manufacturer has established processes to ensure consistent product quality and improvement.

Additionally, certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for pumps used in specific applications may be relevant. Buyers should verify that suppliers possess these certifications, as they often indicate adherence to safety and performance benchmarks.

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. Key checkpoints include:

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials and components before they enter production. Buyers should ensure their suppliers have stringent IQC processes to avoid defects in the final product.

In-Process Quality Control (IPQC): This involves continuous monitoring during the manufacturing process. Techniques such as statistical process control (SPC) can be employed to detect deviations early and minimize waste.

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to ensure they meet specifications. Common testing methods for tire air pumps include pressure tests, performance tests, and durability tests.

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are some effective strategies:

Illustrative image related to best tire air pump

Conducting supplier audits can provide valuable insights into a manufacturer’s quality processes. Buyers should consider scheduling regular audits to assess compliance with quality standards and operational efficiencies. Audits can include on-site inspections, review of quality documentation, and discussions with key personnel involved in production and QC.

Buyers should request detailed quality control reports from suppliers, which outline testing results, defect rates, and corrective actions taken. These reports can offer transparency and assurance regarding the reliability of the products being sourced.

Engaging third-party inspection services can add an additional layer of confidence for B2B buyers. These inspectors can verify compliance with industry standards and conduct independent testing of products before shipment. This is particularly important for international buyers who may face challenges in assessing quality from a distance.

Illustrative image related to best tire air pump

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific challenges and nuances in quality control.

Different regions may have specific regulations that impact product compliance. For instance, import regulations in certain countries might require additional certifications or testing before products can be sold. Buyers should familiarize themselves with these regulations to avoid potential compliance issues.

Cultural differences can also influence perceptions of quality. For example, standards may vary significantly between regions, and what is considered acceptable in one market may not be in another. B2B buyers should communicate clearly with suppliers about their quality expectations and ensure alignment on standards.

In summary, understanding the manufacturing processes and quality assurance measures for tire air pumps is essential for B2B buyers looking to source reliable products. By focusing on material preparation, forming, assembly, and finishing, along with stringent quality control measures, buyers can make informed decisions that align with their operational needs and market requirements.

Illustrative image related to best tire air pump

This practical sourcing guide is designed to assist B2B buyers in identifying and procuring the best tire air pumps for their needs. By following this checklist, you can ensure that you select a product that meets your operational requirements while also providing value and reliability.

Begin by outlining the specific technical requirements for the tire air pump you need. Consider factors such as maximum PSI, power source (cordless vs. corded), and intended use (personal vehicles, trucks, or multiple applications). This clarity will help narrow down your options significantly.

Understanding current market trends and customer reviews can provide insight into which tire air pumps are favored in your industry. Look for recent reviews from credible sources to ensure you are considering reliable products.

Illustrative image related to best tire air pump

Before finalizing any procurement, it is essential to evaluate potential suppliers thoroughly. Request detailed company profiles, case studies, and references from other buyers in your industry or region.

Compile a list of potential tire air pumps and compare their features against your specifications and budget. Assess both the base price and any additional costs, such as shipping or maintenance.

Assess any potential risks associated with your purchase, including warranty terms, return policies, and supplier reliability. This step is crucial to mitigate any future operational disruptions.

Once you have made your selection, finalize the purchase agreement by clarifying terms such as payment methods, delivery timelines, and after-sales support. Ensure all parties understand the expectations to avoid misunderstandings.

By following these steps, B2B buyers can confidently procure the best tire air pumps suited to their needs, enhancing operational efficiency and ensuring quality in service delivery.

Analyzing the cost structure and pricing strategies for sourcing the best tire air pumps requires a comprehensive understanding of various cost components and market dynamics. Below is a detailed breakdown tailored for international B2B buyers, focusing on actionable insights.

Materials: The primary materials for tire air pumps include high-quality plastics, metal components, and electronic parts. The choice of materials significantly impacts the durability and performance of the inflator. For instance, pumps with robust construction may use reinforced plastics or aluminum, which can increase costs but enhance longevity.

Labor: Labor costs vary by region and can significantly influence overall pricing. In regions with higher labor costs, such as Europe, manufacturers may implement automation to reduce expenses, whereas labor-intensive production may be more common in countries with lower wage rates, such as those in Africa or South America.

Manufacturing Overhead: This includes costs related to the facility, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, allowing for competitive pricing.

Tooling: The initial setup for manufacturing a new tire air pump model can be costly. Tooling costs encompass the design and creation of molds and dies, which are essential for producing consistent and high-quality products. Custom designs will naturally incur higher tooling costs.

Quality Control (QC): Rigorous QC processes are crucial for ensuring that the inflators meet safety and performance standards. The costs associated with testing and certification can vary based on the required standards (e.g., ISO certifications), influencing the final price.

Logistics: Shipping and handling costs, especially for international buyers, can be significant. Factors such as shipping distance, mode of transport, and fuel prices directly affect logistics costs. Understanding Incoterms can help buyers navigate these expenses effectively.

Margin: Manufacturers typically add a markup to cover costs and achieve profitability. This margin can vary based on market demand, competition, and brand positioning.

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to negotiate better pricing based on anticipated demand.

Specifications and Customization: Tailored solutions can drive up costs. If a buyer requires specific features (e.g., built-in pressure gauges, LED lights), they should be prepared for higher prices due to the additional engineering and materials involved.

Quality and Certifications: Pumps that meet international safety standards or specific regional certifications often come at a premium. Buyers should evaluate the necessity of these certifications against their target market requirements.

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established manufacturers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential. These terms dictate who bears costs and risks at various stages of shipping, impacting the total landed cost of the product.

Negotiation Strategies: Engage in open dialogue with suppliers to discuss pricing, payment terms, and potential discounts for larger orders. Building a long-term relationship can often yield better pricing in subsequent orders.

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance and operational costs. A slightly more expensive pump that is more durable may save money in the long run.

Pricing Nuances for International Buyers: Buyers from diverse regions should be aware of currency fluctuations, import duties, and local taxes that can affect the final cost. It’s advisable to work with suppliers who understand these regional dynamics.

Disclaimer for Indicative Prices: Prices for tire air pumps can vary widely based on the aforementioned factors. It’s crucial for buyers to obtain current quotes and consider all cost components to make informed purchasing decisions.

By understanding these elements, international B2B buyers can effectively navigate the sourcing landscape for tire air pumps, ensuring they secure the best products at competitive prices.

When it comes to maintaining proper tire pressure, tire air pumps are often the go-to solution for both personal and commercial needs. However, there are alternative solutions that can achieve similar goals, each with its own set of advantages and disadvantages. This analysis aims to provide B2B buyers with a comprehensive understanding of how the best tire air pump compares to other viable options.

| Comparison Aspect | Best Tire Air Pump | Portable Compressor | Manual Hand Pump |

|---|---|---|---|

| Performance | High PSI capability, fast inflation | Moderate PSI, slower inflation | Low PSI, time-consuming |

| Cost | $40 – $90 | $30 – $150 | $10 – $30 |

| Ease of Implementation | Simple, plug-and-play | Requires power source | No power needed |

| Maintenance | Minimal (occasional checks) | Moderate (cleaning filters) | Low (manual care) |

| Best Use Case | Quick inflation for vehicles | Off-road vehicles, home use | Emergency or infrequent use |

Portable compressors serve as a popular alternative to traditional tire air pumps. They are typically more powerful than manual options, providing sufficient pressure for a variety of applications, including inflating tires and sporting equipment. However, these devices require a power source, which can limit their usability in remote areas. While the price range is broader, from $30 to $150, buyers should consider the balance between performance and cost. Maintenance is moderately required, especially in cleaning filters to ensure optimal performance. This option is ideal for B2B buyers who need a versatile tool for both vehicle and home use.

Manual hand pumps are the most basic alternative and are often the most affordable option on the market, typically ranging from $10 to $30. They require no power source, making them exceptionally portable and suitable for emergency situations. However, they are less efficient, taking significantly longer to inflate tires and generally achieving lower pressures. Maintenance is minimal, as these devices simply need to be stored properly. While manual hand pumps are best for infrequent use or as a backup option, they may not meet the demands of regular tire maintenance in a commercial setting.

When selecting the right solution for tire inflation, B2B buyers must consider their specific needs, including the frequency of use, required performance, and budget. The best tire air pump stands out for its speed and efficiency, making it a suitable choice for businesses that prioritize quick turnaround times. However, for those operating in remote locations or requiring a multi-functional tool, a portable compressor may offer the necessary versatility. Meanwhile, manual hand pumps can serve as a cost-effective emergency backup. Evaluating these factors will help buyers make informed decisions that align with their operational requirements and financial constraints.

When selecting a tire air pump for commercial purposes, understanding its technical specifications is crucial. Here are some critical specifications to consider:

Maximum Pressure (PSI)

The maximum pressure a tire inflator can achieve is typically measured in pounds per square inch (PSI). Most passenger vehicles operate around 30-35 PSI, but heavy-duty vehicles may require up to 80 PSI. A pump with a higher PSI capability is essential for versatility, particularly for businesses that service various types of vehicles.

Duty Cycle

This specification indicates how long a tire inflator can operate before it needs to cool down. For instance, a 25-minute duty cycle means the pump can run for 25 minutes before requiring a rest period. In a B2B context, knowing the duty cycle is vital for ensuring efficiency during high-demand periods, such as busy service stations.

Power Source

Tire air pumps can be powered by batteries, 12-volt outlets, or standard AC power. Battery-operated models offer portability, while those powered by AC are generally more powerful but less mobile. Understanding the power source helps in selecting a pump that aligns with operational needs and the typical environment of use.

Hose Length and Type

The length and type of hose can affect usability. A longer hose allows for easier access to all tires without repositioning the pump. Additionally, some hoses are designed to withstand higher pressures, which is crucial for heavy-duty applications. Evaluating hose specifications ensures that the pump can meet various operational demands.

Pressure Gauge Accuracy

An accurate pressure gauge is essential for proper tire inflation. Digital gauges typically offer higher accuracy compared to analog ones. For businesses, using inflators with reliable gauges minimizes the risk of over-inflation or under-inflation, which can lead to safety issues and increased tire wear.

Weight and Portability

The weight of a tire inflator can affect its portability. Lightweight models are easier to transport and can be particularly beneficial for mobile services or businesses that require frequent relocation of equipment. Assessing weight helps in choosing a model that balances functionality with ease of handling.

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, knowing whether a product is OEM can assure buyers of its quality and compatibility with existing systems.

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product a supplier is willing to sell. Understanding MOQ helps businesses plan their purchases and manage inventory effectively, especially when sourcing tire pumps for fleet operations.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price for specific goods or services. This process is vital for B2B buyers to compare prices and specifications, ensuring they receive the best value for tire inflators.

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps businesses navigate shipping and logistics, ensuring clarity on costs, risks, and delivery obligations.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For tire inflators, understanding lead times is crucial for inventory management and ensuring that operations remain uninterrupted.

Warranty and After-Sales Support

Warranty refers to the guarantee provided by the manufacturer regarding the performance and reliability of the product. After-sales support includes services like maintenance and repairs. These factors are vital for B2B buyers to consider, as they impact long-term operational efficiency and cost management.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when selecting tire air pumps that align with their operational needs and market conditions.

Illustrative image related to best tire air pump

The tire air pump market is currently experiencing significant growth driven by several key global factors. An increase in vehicle ownership across emerging markets in Africa, South America, and parts of Asia, particularly Vietnam, is propelling demand for tire maintenance products. Additionally, the rising awareness of vehicle safety and the necessity of maintaining optimal tire pressure to enhance fuel efficiency is influencing purchasing decisions. As consumers and businesses alike become more conscientious about vehicle upkeep, the demand for reliable tire air pumps is expected to rise.

Emerging technologies, such as smart tire inflators equipped with digital interfaces and connectivity features, are reshaping the market landscape. These innovations enable users to monitor tire pressure via mobile apps, providing added convenience and efficiency. Furthermore, the trend towards cordless and portable inflators is gaining traction, particularly among urban consumers who prioritize compact, easy-to-use solutions that fit into small storage spaces.

In the context of international B2B sourcing, buyers must navigate diverse regulatory environments and standards, particularly in regions like Europe and the Middle East, where product compliance and quality assurance are paramount. Building relationships with manufacturers that prioritize robust testing protocols and adhere to international certifications can significantly enhance sourcing strategies.

Sustainability is becoming a cornerstone of the tire air pump sector as both consumers and businesses increasingly demand environmentally responsible products. The environmental impact of manufacturing processes and materials used in tire air pumps is under scrutiny. B2B buyers are now looking for suppliers that demonstrate a commitment to minimizing their carbon footprint through sustainable practices, including energy-efficient production and waste reduction.

Moreover, ethical sourcing is gaining importance as companies face pressure to ensure their supply chains are free from exploitative labor practices and environmentally harmful materials. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming key differentiators in supplier selection. By prioritizing manufacturers with these certifications, B2B buyers can align their procurement strategies with ethical and sustainable practices.

Illustrative image related to best tire air pump

The adoption of eco-friendly materials, such as recycled plastics and sustainable packaging, is also on the rise. Products that incorporate these materials not only appeal to environmentally conscious consumers but can also enhance brand reputation. Consequently, B2B buyers should consider suppliers that offer green alternatives and highlight their commitment to sustainability in their marketing efforts.

The evolution of tire air pumps dates back to the late 19th century when manual pumps were the primary means of inflating tires. Over the decades, technological advancements have transformed these devices from simple hand-operated tools to sophisticated electric inflators. The introduction of battery-powered and portable air pumps in the early 2000s revolutionized the market, catering to the growing need for convenience and efficiency.

Today, tire air pumps are not just maintenance tools but also essential safety devices that contribute to vehicle performance and fuel economy. This historical progression underscores the importance of innovation in the sector, as manufacturers strive to meet the ever-changing demands of B2B buyers. Understanding this evolution can help buyers appreciate the technological advancements and quality improvements that define contemporary products, guiding them in making informed purchasing decisions.

In summary, the tire air pump market is influenced by a confluence of global trends, sustainability imperatives, and a rich historical context. B2B buyers can leverage this knowledge to enhance their sourcing strategies and align with modern consumer expectations.

Illustrative image related to best tire air pump

How do I choose the right tire air pump for my business needs?

Choosing the right tire air pump involves assessing the specific requirements of your business operations. Consider the types of vehicles you service—passenger cars, trucks, or heavy machinery—as this will determine the pump’s PSI capacity. Evaluate the portability, power source (cordless vs. corded), and additional features like built-in pressure gauges and adaptors for different inflation tasks. Lastly, assess the unit’s durability and warranty to ensure it can withstand frequent use in various environments.

What is the best tire air pump for high-pressure applications?

For high-pressure applications, the Viair 88P is often recommended due to its ability to inflate tires up to 120 PSI, making it suitable for trucks and SUVs. It offers fast inflation times, which can enhance efficiency in operations. Additionally, ensure the selected pump is compatible with the tire sizes you commonly encounter and that it can handle the required duty cycle for your business needs.

How can I verify the quality of a tire air pump supplier?

To verify a tire air pump supplier’s quality, start by checking their certifications, such as ISO standards, which indicate adherence to quality management systems. Request samples to assess product performance and durability firsthand. Look for reviews and testimonials from other B2B clients, and inquire about their manufacturing processes and quality assurance measures. Establishing direct communication can also provide insights into their responsiveness and customer service.

What are the common payment terms when sourcing tire air pumps internationally?

Common payment terms in international sourcing include options like Letter of Credit (LC), Telegraphic Transfer (TT), or PayPal for smaller transactions. It’s essential to negotiate terms that align with your financial capabilities and risk tolerance. Many suppliers may require a deposit before manufacturing, with the balance payable upon shipment or delivery. Ensure you clarify all terms in the purchase agreement to prevent any misunderstandings.

What is the typical minimum order quantity (MOQ) for tire air pumps?

The MOQ for tire air pumps varies by supplier and can range from as low as 50 units to several hundred. Factors influencing MOQ include the pump’s complexity, customization options, and the supplier’s production capacity. Discuss your needs with potential suppliers to find a balance between your inventory requirements and their manufacturing capabilities. Some suppliers may offer flexibility on MOQ for first-time orders or bulk purchases.

How do I handle logistics for international shipments of tire air pumps?

When managing logistics for international shipments, consider hiring a freight forwarder to streamline the process. They can assist with customs clearance, shipping documentation, and choosing the most cost-effective shipping method (air vs. sea). Ensure your supplier provides all necessary paperwork, including invoices and packing lists. Additionally, factor in shipping times and costs, as these can significantly impact your inventory management and cash flow.

What customization options are available for tire air pumps?

Many suppliers offer customization options for tire air pumps, including branding, color schemes, and additional features like built-in LED lights or digital pressure gauges. Discuss your specific needs with potential suppliers to understand the extent of customization they can provide. Customization may involve additional costs and longer lead times, so plan accordingly to align with your market strategy.

How can I ensure the tire air pumps meet safety and compliance standards?

To ensure tire air pumps meet safety and compliance standards, request certifications from your suppliers that validate their adherence to international safety regulations, such as CE or UL marks. Conduct thorough inspections during the manufacturing process and upon receipt of goods. Additionally, consider third-party testing for critical components to verify quality and safety. Keeping abreast of the latest compliance requirements in your target markets will also help mitigate risks.

Domain: macheforum.com

Registered: 2018 (7 years)

Introduction: 1. Fanttik X8 Apex inflator – recommended by multiple users for its compact size and efficiency. 2. AstroAI inflator – includes a jump starter, mentioned as a good option. 3. Ryobi inflator – used by a member who has Ryobi batteries for power tools. 4. Lasfit inflator – mentioned positively by a user. 5. Built-in inflator in the Ford Mustang Mach-E – noted for its dual functionality (air-only mode…

Domain: automoblog.com

Registered: 2004 (21 years)

Introduction: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power Cordless Tire Inflator – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX Tire Inflator – Built for lifetime usage and ownership. 5. Milwaukee M18 Cordless Tire Inflator – Robust and powerful with four different memory …

The selection of the best tire air pump is a critical decision for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Key factors to consider include performance, portability, and versatility, as highlighted by the top contenders in our guide. Products like the AstroAI Cordless Tire Inflator stand out for their efficiency and multi-functional capabilities, making them ideal for diverse markets and vehicle types.

Strategic sourcing is essential in ensuring that businesses not only acquire high-quality inflators but also benefit from competitive pricing and reliable supply chains. Establishing strong relationships with manufacturers can lead to better negotiation outcomes and access to the latest technology, which is vital for meeting customer demands and enhancing service offerings.

As you evaluate options for tire air pumps, consider the evolving landscape of automotive maintenance tools. The increasing emphasis on sustainability and efficiency presents opportunities for innovation in this sector. We encourage you to explore partnerships that align with your operational goals and customer needs, ultimately driving growth and success in your market.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to best tire air pump

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.