In an era where vehicle maintenance can significantly impact operational efficiency, sourcing high-quality car air pumps presents a unique challenge for international B2B buyers. The market is inundated with various options, each boasting different features, functionalities, and price points. This comprehensive guide aims to demystify the complexities surrounding car air pumps, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations. By providing actionable insights and expert recommendations, this guide empowers buyers—particularly those from regions like Africa, South America, the Middle East, and Europe, including Brazil and Saudi Arabia—to make informed purchasing decisions that align with their specific needs.

Understanding the nuances of car air pumps is crucial for businesses looking to optimize their automotive offerings or enhance their service capabilities. Whether you are interested in portable inflators for roadside emergencies or industrial-grade pumps for high-volume applications, this guide will equip you with the knowledge to navigate the global market effectively. With a focus on practical solutions and best practices, we aim to help you identify reputable suppliers, assess product quality, and evaluate cost-effectiveness, ultimately ensuring your investment leads to enhanced customer satisfaction and operational success.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Tire Inflators | Compact, battery or vehicle-powered, lightweight | Automotive repair shops, roadside assistance | Pros: Easy to store, quick inflation. Cons: Limited power for larger tires. |

| Heavy-Duty Air Compressors | High-capacity, multi-purpose, often stationary | Workshops, tire shops, industrial applications | Pros: Fast inflation, suitable for heavy use. Cons: Bulkier, requires more space. |

| Digital Tire Pressure Monitors | Integrated pressure gauge, automatic shut-off | Fleet management, automotive service centers | Pros: Accurate readings, reduces over-inflation. Cons: Battery-dependent, may require calibration. |

| Combination Units (Inflator/Jump Starter) | Multifunctional, portable, includes jump-start feature | Emergency service providers, automotive retailers | Pros: Versatile, space-saving. Cons: May sacrifice performance in one function for another. |

| Manual Hand Pumps | Operated by foot or hand, no power source needed | Emergency kits, remote locations | Pros: No power needed, lightweight. Cons: Labor-intensive, slower inflation. |

Portable tire inflators are compact devices designed for quick inflation of vehicle tires. They are typically powered by rechargeable batteries or a vehicle’s 12-volt outlet, making them ideal for emergency roadside assistance or personal use. B2B buyers, such as automotive repair shops and roadside assistance services, benefit from their lightweight design and ease of storage. When purchasing, consider factors like inflation speed, hose length, and battery life to ensure efficiency in real-world applications.

Heavy-duty air compressors are robust machines capable of inflating large tires and powering pneumatic tools. These stationary or semi-portable units are essential for workshops and tire shops where high-volume inflation is required. B2B buyers should evaluate the compressor’s air delivery rate and tank size to match their operational needs. While they offer rapid inflation and durability, their bulkiness can be a drawback for those with limited workspace.

Digital tire pressure monitors provide precise tire pressure readings and often feature automatic shut-off capabilities to prevent over-inflation. These devices are particularly useful for fleet management and automotive service centers, where maintaining optimal tire pressure is crucial for safety and fuel efficiency. When selecting a monitor, consider its accuracy, ease of use, and battery life. While they enhance operational efficiency, reliance on batteries can pose challenges in remote settings.

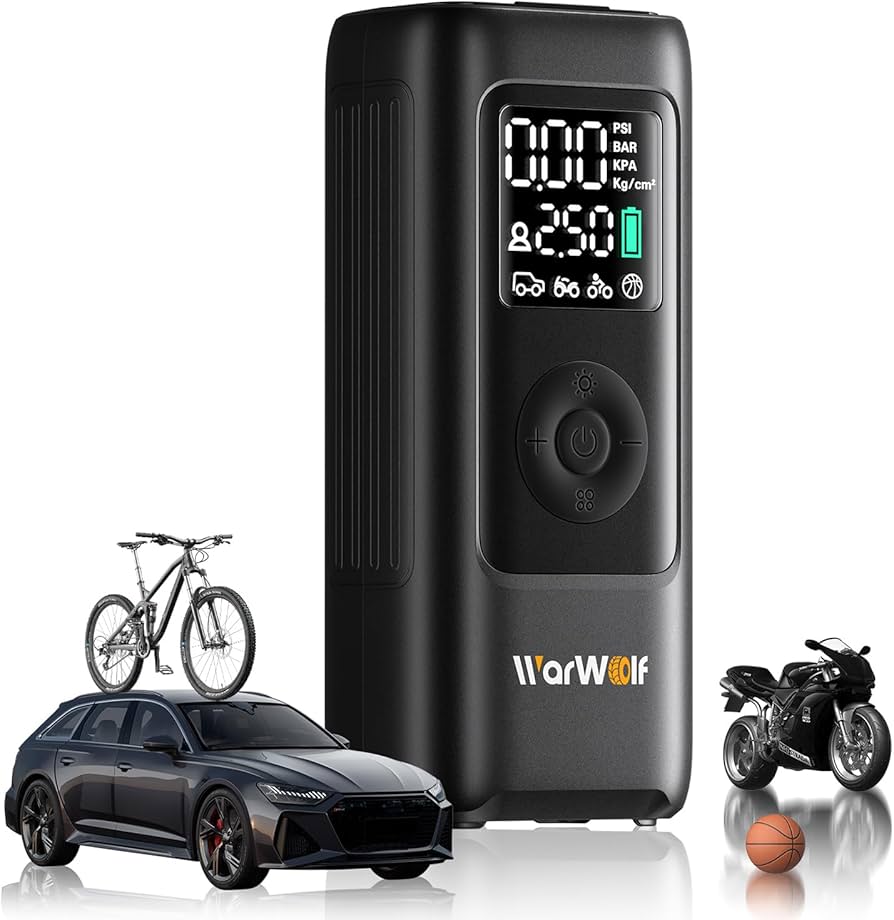

Illustrative image related to car air pumps

Combination units that serve as both tire inflators and jump starters are increasingly popular among emergency service providers and automotive retailers. These multifunctional devices save space and provide essential tools in one package. B2B buyers should assess the inflation speed and jump-starting capabilities to ensure they meet operational demands. While they offer versatility, there may be trade-offs in performance for specific functions, so understanding the primary use case is critical.

Manual hand pumps, operated by foot or hand, remain a practical choice for emergency kits and remote locations where power sources are unavailable. They are lightweight and easy to transport, making them suitable for various applications. However, B2B buyers should be aware that these pumps require physical effort and are slower than powered alternatives. When considering a manual pump, evaluate its construction quality and ease of use to ensure it meets the needs of your target market.

| Industry/Sector | Specific Application of car air pumps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation services | Enhances customer satisfaction and safety by ensuring well-inflated tires. | Durability, ease of use, and inflation speed are essential. |

| Logistics & Transport | Fleet maintenance and emergency response | Reduces downtime and improves operational efficiency in fleet management. | Portability, power options, and reliability are critical factors. |

| Construction | Equipment and vehicle tire management | Ensures equipment mobility and reduces the risk of worksite accidents. | Heavy-duty performance and compatibility with various tire types. |

| Retail Automotive Parts | Retail sales of portable inflators | Expands product offerings and attracts customers seeking convenience and safety. | Brand reputation, warranty, and customer support are key. |

| Tourism & Hospitality | Emergency kits for rental vehicles | Enhances the customer experience by providing reliable roadside assistance. | Compactness, weight, and battery life are significant considerations. |

In automotive repair shops, car air pumps are essential tools for tire inflation services. Well-inflated tires are crucial for vehicle safety and performance, making these pumps indispensable for mechanics. They help resolve common issues like flat tires and under-inflation, which can lead to accidents. When sourcing air pumps, businesses should prioritize durability, ease of use, and inflation speed, as these factors directly impact customer satisfaction and service efficiency.

In the logistics and transport sector, car air pumps are vital for maintaining fleet vehicles. Regular tire maintenance helps prevent breakdowns, thereby reducing downtime and enhancing operational efficiency. Air pumps are particularly useful in emergency response scenarios, where quick tire inflation can be critical. Buyers in this industry should consider factors such as portability, power options, and reliability when sourcing these pumps to ensure they meet the demands of their fleet operations.

Construction sites often involve heavy machinery and vehicles that require regular tire maintenance. Car air pumps facilitate quick inflation, ensuring that equipment remains mobile and reducing the risk of accidents caused by flat tires. These pumps must be robust and capable of handling various tire types, making heavy-duty performance a key consideration for construction businesses looking to source reliable air pumps.

Retail automotive parts stores can expand their product offerings by including portable tire inflators. These devices attract customers looking for convenience and safety, particularly those who frequently travel or own multiple vehicles. When sourcing inflators, retailers should focus on brand reputation, warranty, and customer support, as these factors can influence purchasing decisions and customer loyalty.

In the tourism and hospitality sector, rental vehicles must be equipped with reliable emergency kits, including car air pumps. These tools enhance the customer experience by providing peace of mind for travelers who may encounter tire issues on the road. When sourcing air pumps for this application, businesses should prioritize compactness, weight, and battery life to ensure that the pumps are easily transportable and user-friendly for customers.

The Problem: B2B buyers often encounter issues with car air pumps that perform inconsistently in varying climates and altitudes. For instance, a distributor in Brazil might find that pumps struggle to inflate tires effectively in high humidity or extreme heat, while a buyer in Europe may face challenges with pumps that fail to operate efficiently in cold weather. These performance discrepancies can lead to frustrated customers, increased returns, and a tarnished reputation for the distributor.

The Solution: To mitigate this issue, B2B buyers should prioritize sourcing car air pumps that are designed with robust, climate-resistant features. It is essential to select pumps with high-quality, durable components that can withstand extreme temperatures and humidity. When specifying products, look for those that have been rigorously tested across different conditions and come with a manufacturer’s guarantee for performance. Additionally, provide comprehensive training to end-users on how to operate the pumps effectively in varying environments, including tips for pre-use checks and maintenance to ensure consistent performance.

The Problem: Many portable tire inflators have complex user interfaces that can confuse users, particularly in emergency situations. B2B buyers in regions like the Middle East, where roadside assistance may not always be readily available, face the challenge of providing their customers with equipment that is intuitive and easy to operate. Complicated interfaces can lead to delays in tire inflation, which can be critical for businesses reliant on timely deliveries.

The Solution: To address this pain point, B2B buyers should focus on sourcing car air pumps with user-friendly designs, featuring clear instructions and straightforward controls. When evaluating products, consider models that have digital displays with easy-to-read pressure readings and preset options for inflation. Additionally, conducting usability tests with potential end-users before finalizing purchases can provide valuable insights into how the equipment performs in real-life scenarios. Offering training sessions or instructional videos on using the inflators can further empower users, ensuring they can operate the equipment confidently and effectively, minimizing downtime in critical situations.

The Problem: B2B buyers often grapple with the high maintenance costs associated with low-quality car air pumps. Frequent breakdowns and the need for repairs not only escalate costs but also disrupt operations, particularly for businesses managing fleets. For instance, a logistics company in South Africa may find that consistently unreliable inflators lead to prolonged downtime, affecting their service delivery and overall operational efficiency.

The Solution: To combat this issue, B2B buyers should invest in high-quality, commercial-grade car air pumps known for their reliability and durability. When sourcing products, it is vital to examine user reviews, warranty offerings, and the manufacturer’s reputation. Opt for pumps that come with comprehensive maintenance plans or warranties that cover repairs and parts replacement. Additionally, implementing a regular maintenance schedule and providing training for users on proper care and operation can significantly extend the lifespan of the equipment. Educating customers on the importance of routine checks, such as inspecting hoses and connectors, can help minimize unexpected failures and maintain consistent performance across the fleet.

When selecting materials for car air pumps, understanding their properties and performance implications is crucial for B2B buyers. This section analyzes four common materials used in the manufacturing of car air pumps: plastic, aluminum, steel, and rubber. Each material has distinct characteristics that affect durability, cost, and suitability for various applications.

Plastic is often used for the housing and components of car air pumps due to its lightweight and corrosion-resistant properties. Common types include polypropylene and polycarbonate, which can withstand moderate pressure and temperature variations.

Pros: Plastic is generally less expensive than metals, making it an attractive option for budget-conscious manufacturers. Its lightweight nature also contributes to the overall portability of the air pump, enhancing user convenience.

Cons: However, plastic may not be suitable for high-pressure applications, as it can deform under excessive stress. Additionally, its durability is lower compared to metals, leading to potential wear and tear over time.

Impact on Application: Plastic is compatible with a wide range of media, including air and some gases, but may not be ideal for high-temperature environments.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider the environmental impact of plastic materials, as regulations may vary by region, particularly in Europe.

Aluminum is a popular choice for components that require a balance of strength and weight. It has excellent corrosion resistance and can handle higher pressure ratings compared to plastic.

Pros: The lightweight nature of aluminum makes it easy to transport while providing sufficient strength for high-performance applications. Its thermal conductivity also aids in heat dissipation during operation.

Cons: The primary drawback of aluminum is its cost, which can be higher than plastic. Manufacturing processes can also be more complex, requiring specialized equipment for shaping and joining.

Impact on Application: Aluminum is suitable for various media and can withstand higher temperatures, making it a versatile option for different environments.

Illustrative image related to car air pumps

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant industry standards and certifications, especially in regions with stringent regulations like the EU.

Steel, particularly stainless steel, is known for its strength and durability, making it suitable for heavy-duty applications. It can endure high pressures and is resistant to corrosion.

Pros: Steel’s robustness allows it to perform well in demanding conditions, ensuring longevity and reliability. This material is often preferred for professional-grade air pumps that see frequent use.

Cons: The weight of steel can be a disadvantage for portable applications, as it increases the overall weight of the air pump. Additionally, the cost of high-quality steel can be significant.

Impact on Application: Steel is compatible with a wide range of media, including air and various gases, and can withstand extreme temperatures, making it ideal for industrial applications.

Considerations for International Buyers: Steel products must comply with international standards for safety and performance. Buyers should also consider the impact of tariffs and shipping costs, especially when sourcing from overseas.

Rubber is primarily used for seals and hoses in car air pumps due to its flexibility and ability to create airtight seals.

Pros: Rubber is excellent for vibration dampening and can withstand a range of temperatures, making it suitable for various applications. Its elasticity allows for easy installation and maintenance.

Cons: However, rubber can degrade over time due to exposure to ozone and UV light, which can lead to leaks and reduced performance.

Impact on Application: Rubber is compatible with air and gases but may not be suitable for certain chemicals, limiting its use in specialized applications.

Considerations for International Buyers: Buyers should ensure that rubber components meet relevant standards for material safety and environmental compliance, particularly in regions with strict regulations.

| Material | Typical Use Case for car air pumps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and lightweight components | Lightweight and cost-effective | Lower durability under high pressure | Low |

| Aluminum | High-performance components | Strong and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Heavy-duty applications | Extremely durable and high pressure | Heavier and more expensive | High |

| Rubber | Seals and hoses | Flexible and creates airtight seals | Degrades over time with exposure | Medium |

This guide provides insights into the strategic selection of materials for car air pumps, helping international B2B buyers make informed decisions based on performance, cost, and regional compliance.

The manufacturing of car air pumps involves several critical stages, each designed to ensure product quality and efficiency. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to car air pumps

The first step in manufacturing car air pumps is material preparation. This typically involves sourcing high-quality raw materials such as plastics, metals, and rubber components. Suppliers often use thermoplastics for housing due to their durability and lightweight properties. Metals, such as aluminum or steel, are commonly used for internal mechanisms to ensure strength and longevity.

Once the materials are sourced, they undergo various tests to confirm they meet specifications. This includes checking for tensile strength, elasticity, and resistance to wear and tear. Quality checks at this stage are crucial to prevent defects that could affect the final product’s performance.

The forming stage involves shaping the prepared materials into specific parts required for the air pump. Techniques such as injection molding are commonly used for plastic components, allowing for precise shapes and sizes. For metal parts, methods like stamping and machining are employed to achieve the necessary tolerances.

Advanced technology, such as Computer Numerical Control (CNC) machining, may be utilized to enhance precision. This level of accuracy is essential, especially for components that must fit together seamlessly to ensure optimal functionality.

Following the forming stage, the next step is assembly. This process can be manual or automated, depending on the scale of production and the complexity of the air pump design. During assembly, components like the motor, pressure gauge, hoses, and nozzles are brought together.

Illustrative image related to car air pumps

Quality assurance is vital during assembly. Manufacturers often implement standardized work instructions and checklists to ensure consistency. Automated systems may include sensors that verify correct assembly, reducing the likelihood of human error.

The finishing stage encompasses several processes aimed at enhancing the product’s appearance and performance. This may include painting, coating, or applying decals. Additionally, surface treatments such as anodizing or galvanizing are often used to improve corrosion resistance, particularly for metal components exposed to the elements.

Final inspections are conducted during this stage to ensure that the pumps meet aesthetic and functional standards. Any defects are addressed before the products are packaged for shipping.

Quality assurance (QA) is a critical component of the manufacturing process for car air pumps, ensuring that the final product meets both industry standards and customer expectations. Here are some key aspects of QA relevant to B2B buyers:

Manufacturers of car air pumps often adhere to various international standards to assure product quality. ISO 9001 is one of the most recognized certifications, focusing on quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, other certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards may apply, especially for pumps used in specialized applications. For B2B buyers, these certifications serve as a benchmark for assessing potential suppliers.

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor and ensure product quality. Common checkpoints include:

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. This includes verifying the specifications of materials against purchase orders and conducting initial tests.

In-Process Quality Control (IPQC): During manufacturing, random sampling and inspections are performed at various stages to ensure adherence to production standards. This proactive approach helps identify defects early in the process.

Final Quality Control (FQC): Once assembly is complete, a comprehensive inspection is conducted to evaluate the finished product against predetermined specifications. This may include functional tests, pressure tests, and aesthetic evaluations.

Testing is a critical aspect of quality assurance for car air pumps. Various methods are employed to ensure performance, safety, and reliability:

Functional Testing: This involves checking the pump’s operation under normal conditions to ensure it inflates tires to the required pressure levels.

Pressure Testing: Manufacturers often conduct pressure tests to verify that the pump can handle specified pressures without leaking or failing.

Durability Testing: This assesses the longevity of the pump under repeated use. Testing may simulate extended periods of operation to identify potential points of failure.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. Audits can reveal a supplier’s commitment to quality management and adherence to international standards.

Request Quality Reports: Buyers should request documentation of quality control processes, including test reports and compliance certificates. This information provides insight into the supplier’s quality assurance protocols.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. This is particularly beneficial for buyers who may not have the capability to conduct their own audits.

Understanding QC Nuances for International Trade: Different regions may have varying expectations regarding quality standards. Buyers should be aware of local regulations and certification requirements to ensure compliance and avoid potential issues during importation.

The manufacturing processes and quality assurance measures for car air pumps are complex yet essential to ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions and establish strong partnerships with manufacturers. As the automotive market continues to grow globally, particularly in regions like Africa, South America, the Middle East, and Europe, the importance of quality assurance in manufacturing cannot be overstated.

In the competitive landscape of automotive accessories, sourcing high-quality car air pumps is essential for B2B buyers looking to meet customer demands and enhance their product offerings. This guide provides a structured approach to ensure a successful procurement process.

Before initiating the sourcing process, outline the technical specifications your air pumps must meet. Consider factors such as inflation speed, power source (battery-operated, 12-volt, or AC), hose length, and noise levels. This clarity will help streamline your search and ensure that the products align with your market requirements.

Understanding current market trends is crucial for making informed purchasing decisions. Analyze consumer preferences, such as the popularity of portable versus stationary pumps, and identify regions where demand is rising. This knowledge will help you select products that are likely to sell well and cater to specific customer needs.

Illustrative image related to car air pumps

Before committing to a supplier, conduct a thorough evaluation of their background and capabilities. Request detailed company profiles, case studies, and references from other clients within your industry or region. Ensure they have a proven track record of reliability, quality, and customer service.

When assessing different air pumps, closely examine their features and performance metrics. Look for products that offer a balance of speed, portability, and durability, as these will be key selling points.

Before making a bulk purchase, request samples from shortlisted suppliers. Testing these samples allows you to evaluate their performance firsthand and assess whether they meet your defined specifications.

Once you have identified suitable suppliers, engage in negotiations to secure the best pricing and terms. Consider factors like minimum order quantities, shipping costs, and payment terms.

After negotiations, finalize your order and establish clear communication with the supplier regarding delivery timelines and quality checks. Once the products are in your inventory, monitor their performance in the market and gather feedback from customers. This will inform future sourcing decisions and help refine your product lineup.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing car air pumps effectively, ensuring they select high-quality products that meet market needs and enhance their competitive edge.

Understanding the cost structure of car air pumps is vital for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly affects the final cost. Common materials include durable plastics for the casing, metal for internal components, and rubber for hoses. Higher-quality materials typically lead to better performance and longevity but increase costs.

Labor: Labor costs vary by region. Countries with lower wage standards may offer lower manufacturing costs, while regions with skilled labor may charge more but provide superior craftsmanship.

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can minimize overhead, influencing the overall price.

Tooling: The initial investment in molds and machinery for production can be substantial. Tooling costs are usually amortized over production runs, meaning larger orders can lead to lower per-unit costs.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but also adds to the cost. Buyers should consider the implications of lower QC standards, which may result in higher failure rates and returns.

Logistics: Shipping and handling costs can vary widely based on the destination, shipping method, and volume. These costs should be factored into the total price, especially for international shipments.

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on competition, brand reputation, and market demand.

Several factors can influence the pricing of car air pumps in the B2B marketplace:

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounted rates. Suppliers may set MOQs, which can impact the overall cost-effectiveness for buyers.

Specifications and Customization: Custom features or specifications can significantly affect pricing. Standard models may be more affordable, while specialized pumps tailored to specific needs often come at a premium.

Material Quality and Certifications: Pumps made from high-quality materials or those with industry certifications (e.g., ISO, CE) generally command higher prices due to the assurance of safety and reliability.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge more due to perceived quality, while emerging suppliers may offer competitive rates to gain market share.

Incoterms: Understanding Incoterms is essential for international buyers. These terms define responsibilities for shipping, insurance, and tariffs, impacting the total landed cost of the products.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

Negotiation: Engage in negotiations to secure better pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the TCO, which includes maintenance, operational efficiency, and potential repair costs. A cheaper initial price may lead to higher long-term expenses if quality is compromised.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect the final cost. Establishing contracts in stable currencies can mitigate risks associated with exchange rate volatility.

Research and Due Diligence: Conduct thorough research on suppliers. Assess their production capabilities, customer service, and previous client reviews to ensure reliability and quality.

Stay Informed on Market Trends: Keep abreast of trends in the automotive accessories market, as innovations can influence pricing. For example, the growing demand for battery-powered inflators may shift pricing structures as manufacturers adapt.

Prices for car air pumps can vary widely based on the factors discussed. The information provided is for guidance and may not reflect current market conditions. Always verify with suppliers for the most accurate pricing and terms.

When considering tire inflation solutions, car air pumps are widely recognized for their convenience and efficiency. However, several alternatives can also serve this purpose effectively. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific operational needs, cost constraints, and application environments.

| Comparison Aspect | Car Air Pumps | Portable Battery-Powered Compressors | Foot Pumps |

|---|---|---|---|

| Performance | Quick inflation, varying PSI outputs | Moderate inflation speed, versatile | Slower inflation, manual effort |

| Cost | $40 – $300 | $60 – $250 | $20 – $50 |

| Ease of Implementation | Simple to use, plug-and-play | Requires battery charging | Manual operation, requires physical effort |

| Maintenance | Low maintenance, check hoses regularly | Moderate, battery replacement needed | Minimal maintenance |

| Best Use Case | Emergency roadside assistance | Off-road adventures, camping | Infrequent use, eco-friendly choices |

Portable battery-powered compressors provide a versatile solution for tire inflation and other applications, such as inflating sports equipment or air mattresses. They offer moderate inflation speed and can be used anywhere without needing a power outlet, making them ideal for outdoor activities or remote locations. However, they do require regular battery charging, which can be a downside for users who prefer a ready-to-use device. Additionally, their higher price point compared to standard car air pumps may deter budget-conscious buyers.

Foot pumps offer a manual and eco-friendly alternative to electric inflators. They are simple devices that require no electricity or battery, making them a reliable choice for users who prioritize sustainability. However, foot pumps are significantly slower in inflation speed and require physical effort, which may not be suitable for all users, especially in emergency situations where time is of the essence. Their lower cost makes them an attractive option for infrequent users or those who need a backup solution.

Choosing the right tire inflation solution involves assessing your specific needs, including performance requirements, budget constraints, and ease of use. For businesses requiring quick and efficient tire inflation, car air pumps are often the best choice due to their speed and ease of implementation. Alternatively, for outdoor enthusiasts or those seeking versatility, portable battery-powered compressors may be more suitable. Foot pumps, while less efficient, can be a practical and low-cost option for occasional use. Ultimately, understanding the strengths and limitations of each solution will empower B2B buyers to select the best tool for their operational context.

Understanding the technical specifications of car air pumps is crucial for B2B buyers looking to invest in reliable and efficient products. Here are several critical properties to consider:

Inflation speed, often measured in minutes to achieve a specific pressure (e.g., 30 psi), is a vital property. Faster inflation can significantly reduce downtime for users, especially in emergency situations. For B2B buyers, selecting pumps with optimal inflation speeds can lead to enhanced customer satisfaction and reduced operational delays.

Car air pumps typically operate on various power sources, including 12-volt vehicle outlets, rechargeable batteries, or standard AC power. Understanding the available power options is essential for users in different regions, as it impacts usability in diverse environments. Buyers should consider the versatility of power sources to accommodate their target markets’ needs.

The noise level of a car air pump, measured in decibels (dBA), is an important factor for both consumer comfort and regulatory compliance. Lower noise levels are desirable, particularly for urban environments where noise pollution is a concern. B2B buyers should prioritize products that offer quieter operation to enhance user experience and comply with local noise regulations.

The length and flexibility of the hose are critical for ease of use. Longer, more flexible hoses allow users to reach tires in various positions without repositioning the pump. This is particularly important for larger vehicles or those with unconventional tire placements. B2B buyers should evaluate hose specifications to ensure they meet the practical needs of end-users.

The materials used in the construction of car air pumps affect their durability and performance. Pumps made from high-grade plastics or metals tend to withstand wear and tear better. B2B buyers should assess material quality to ensure longevity and reliability, as this can lead to lower warranty claims and increased customer loyalty.

The type of valve connector, such as clamp or screw-on, can impact the ease of use and air-tightness during inflation. Different connectors may be more suitable for specific tire types or user preferences. Understanding connector types helps buyers choose pumps that align with their customers’ needs and preferences.

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are several common trade terms relevant to car air pumps:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of car air pumps, buyers may source pumps that are OEM-branded, ensuring compatibility and quality. Understanding OEM relationships can help buyers ensure they are purchasing reliable products.

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory and cash flow effectively. Buyers should negotiate MOQs that align with their sales projections to avoid excess stock or missed sales opportunities.

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. It is a critical step in the procurement process for B2B buyers, allowing them to compare offers and make informed purchasing decisions.

Incoterms are a set of predefined commercial terms used in international trade that define the responsibilities of buyers and sellers. Familiarity with Incoterms can help B2B buyers clarify shipping, risk, and cost responsibilities, ultimately facilitating smoother transactions.

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is critical for inventory management and planning, allowing buyers to ensure they have stock on hand when needed.

By comprehensively understanding these properties and terms, B2B buyers in the automotive sector can make informed purchasing decisions, ensuring they choose high-quality car air pumps that meet their operational needs.

The global car air pumps market is experiencing significant growth, driven by increasing vehicle ownership, rising awareness of vehicle maintenance, and advancements in technology. The portable tire inflator segment is particularly booming, with consumers seeking compact and multifunctional devices that enhance convenience during roadside emergencies. In regions like Africa and South America, where road infrastructure may be less developed, the demand for reliable car air pumps is even more pronounced. Buyers in these areas are often looking for cost-effective solutions that do not compromise on quality.

Emerging trends include the integration of smart technology into air pumps, allowing for features such as digital pressure gauges, automatic shut-off functions, and even connectivity to mobile applications for enhanced user experience. Additionally, the growing popularity of electric vehicles (EVs) is influencing product development, with manufacturers focusing on creating inflators compatible with EV tires. International buyers should also keep an eye on the shift towards sustainable materials and manufacturing processes, as environmental regulations become increasingly stringent in many markets, including Europe and the Middle East.

Sustainability is becoming a critical consideration for B2B buyers in the car air pumps sector. The environmental impact of production processes, packaging, and product lifecycle is under scrutiny as companies strive to meet consumer demands for eco-friendly products. Ethical sourcing is not just a trend; it’s becoming a market necessity. Companies that prioritize responsible sourcing are more likely to attract international buyers who are increasingly concerned about their supply chain’s environmental footprint.

For car air pumps, this includes using recyclable materials, reducing waste during manufacturing, and ensuring fair labor practices. Certifications such as ISO 14001 (Environmental Management) and adherence to REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations are becoming essential for suppliers looking to differentiate themselves in competitive markets. Buyers should look for suppliers who demonstrate a commitment to sustainability, as this can enhance their brand reputation and align with global environmental goals.

The car air pump market has evolved significantly over the decades, transitioning from manual foot pumps to sophisticated electronic inflators. The introduction of portable electric tire inflators in the late 20th century marked a pivotal point, making it easier for consumers to maintain proper tire pressure without relying on gas station air pumps. As technology advanced, features such as automatic shut-off and digital pressure displays became standard, catering to a more tech-savvy consumer base.

Illustrative image related to car air pumps

In recent years, the focus has shifted towards multifunctional devices, with many portable inflators now doubling as power banks or jump starters. This evolution reflects a broader trend in the automotive accessory market, where convenience, efficiency, and safety are paramount. For B2B buyers, understanding this historical context can provide valuable insights into consumer preferences and inform sourcing strategies that align with market demands.

Navigating the complexities of the car air pumps sector requires a keen understanding of market dynamics, sustainability imperatives, and historical trends. International B2B buyers must remain vigilant and adaptable, leveraging these insights to make informed sourcing decisions that not only meet current market needs but also anticipate future developments. By prioritizing quality, sustainability, and technological innovation, businesses can position themselves advantageously in this evolving marketplace.

How do I choose the right car air pump for my business needs?

Choosing the right car air pump involves assessing your target market’s requirements, such as the types of vehicles commonly in use. Consider factors like inflation speed, portability, and power options (battery-operated vs. plug-in). Evaluate the durability of the product for heavy usage and check for additional features like digital pressure gauges or multifunctionality (e.g., jump-starting capability). Lastly, request samples to test performance and compatibility with local standards.

What are the best brands of car air pumps available for B2B buyers?

Leading brands recognized for quality and reliability in car air pumps include Slime, Milwaukee, and Avid Power. These brands offer a range of products suitable for various applications, from compact inflators for personal use to heavy-duty models designed for commercial use. Research each brand’s reputation, read reviews, and inquire about warranty and after-sales support to ensure you are investing in a trusted product.

What is the minimum order quantity (MOQ) for car air pumps from suppliers?

MOQs for car air pumps can vary significantly depending on the manufacturer and the type of pump. Typically, MOQs range from 100 to 500 units, but some suppliers may offer lower quantities for custom orders. It’s essential to negotiate terms with your suppliers, especially if you are testing the market or introducing a new product line. Always clarify the MOQ before placing orders to avoid unexpected costs.

How can I verify the reliability and quality of a car air pump supplier?

To verify a supplier’s reliability, consider conducting background checks, including checking their business licenses and reading reviews from other buyers. Request product samples to assess quality firsthand and inquire about their manufacturing processes and quality assurance measures. Additionally, consider visiting their facility if feasible, and ask for references from other B2B partners to gain insights into their reputation and service reliability.

What payment terms are commonly offered by suppliers for car air pumps?

Payment terms can vary widely among suppliers. Common options include a 30% deposit with the order and the remaining 70% before shipment, or net 30/60 days after delivery. Some suppliers may also accept letters of credit or escrow services for larger orders. Always negotiate terms that align with your cash flow needs and ensure clarity in the agreement to avoid misunderstandings.

What certifications should I look for in car air pumps?

When sourcing car air pumps, look for certifications that demonstrate compliance with international safety and quality standards. Common certifications include ISO 9001 (Quality Management), CE (European Conformity), and RoHS (Restriction of Hazardous Substances). These certifications ensure that the products meet necessary safety regulations and performance criteria, which is crucial for building trust with your customers.

How do I handle logistics and shipping for car air pumps?

Effective logistics management is crucial when importing car air pumps. Work with suppliers who offer reliable shipping options and understand the regulations in your target market. Consider factors such as lead times, customs duties, and shipping methods (air vs. sea) to optimize costs and delivery times. It’s also wise to partner with a freight forwarder experienced in handling automotive products to navigate the complexities of international shipping.

Can I customize car air pumps to fit my brand?

Yes, many manufacturers offer customization options for car air pumps, including branding, color, and packaging. Customization can help differentiate your products in the market and strengthen brand identity. Discuss your specific requirements with potential suppliers and request a prototype to ensure that the final product meets your expectations before placing a larger order.

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Portable Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: acehardware.com

Registered: 1995 (30 years)

Introduction: Tire Inflators, Air Pumps & Hand Pumps available at Ace Hardware include:

1. **Electric Tire Pumps** – Plug into an outlet, pressure ratings up to 250 PSI, suitable for inflating air mattresses and larger inflatables.

2. **Portable and Cordless Tire Inflators** – Battery-operated, rechargeable, capable of inflating car tires and general use.

3. **Hand and Foot Pumps** – Ergonomically designed for…

In today’s competitive automotive market, the strategic sourcing of car air pumps is vital for international B2B buyers looking to optimize their supply chains. By understanding the diverse range of products available—ranging from budget-friendly options to advanced multifunctional inflators—businesses can make informed decisions that align with their operational needs and customer preferences. The growing demand for portable tire inflators, particularly in regions like Africa, South America, the Middle East, and Europe, underscores the importance of selecting high-quality, reliable products that enhance customer satisfaction.

Investing in reputable brands and innovative designs, such as those tested in recent evaluations, ensures that businesses provide value-added solutions to their clients. Moreover, aligning with suppliers who emphasize sustainability and efficiency can further bolster a company’s competitive edge in the marketplace.

As the automotive industry continues to evolve, the future of car air pumps looks promising. International B2B buyers are encouraged to seize this opportunity to enhance their product offerings and strengthen partnerships with trusted suppliers. By prioritizing strategic sourcing, businesses can not only meet current demands but also pave the way for future growth and innovation in the tire inflation segment.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.