In the fast-paced landscape of international commerce, sourcing a reliable Dewalt tire inflator with battery can present a significant challenge for B2B buyers. With the increasing demand for efficient inflation solutions across various sectors—from automotive to recreational industries—understanding the nuances of this product category is essential for making informed purchasing decisions. This guide aims to demystify the complexities surrounding the Dewalt tire inflator, providing a comprehensive overview of its features, applications, and the advantages of choosing battery-operated options for mobility and convenience.

Throughout this guide, we will explore the diverse types of Dewalt tire inflators available in the market, each tailored to meet specific needs such as high-pressure inflation, quick deflation, and compatibility with various power sources. Additionally, we will delve into the critical aspects of supplier vetting, ensuring that buyers can confidently select reputable manufacturers and distributors, particularly in key regions such as Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

By equipping buyers with insights on cost considerations, product specifications, and market trends, this guide empowers businesses to navigate the global market effectively. It seeks to streamline the procurement process, ultimately leading to enhanced operational efficiency and customer satisfaction. With the right knowledge at their fingertips, international B2B buyers can leverage the capabilities of Dewalt tire inflators to drive success in their respective industries.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 20V MAX Cordless Inflator | Cordless operation, high-pressure capability (up to 160 PSI), LED light | Tire inflation for vehicles, sports equipment, camping | Pros: Portable, versatile; Cons: Battery sold separately, limited runtime without spare batteries |

| Corded/Cordless Hybrid Inflator | Multiple power sources (20V, 12V, 110V), digital gauge, auto shutoff | Job sites, emergency services, recreational activities | Pros: Flexible power options; Cons: Slightly heavier due to added features |

| High-Volume Inflator | High-volume hose for quick inflation, lightweight design | Inflating air mattresses, rafts, and large inflatables | Pros: Fast inflation; Cons: Not ideal for high-pressure needs |

| Compact Inflator | Lightweight, portable design, basic inflation features | Personal use, small vehicle tires, sports equipment | Pros: Easy to carry; Cons: Limited functionality compared to larger models |

| Heavy-Duty Industrial Inflator | Rugged construction, designed for continuous use, high PSI capability | Heavy machinery, construction sites, fleet maintenance | Pros: Durable, reliable; Cons: Higher price point, may be overkill for casual users |

The 20V MAX Cordless Inflator is ideal for B2B buyers needing a portable solution for tire inflation and other applications. Its ability to operate without cords makes it suitable for remote job sites and emergency situations. However, businesses should consider the additional cost of batteries, as they are sold separately.

The Corded/Cordless Hybrid Inflator offers maximum versatility with multiple power options, making it suitable for various environments, from construction sites to outdoor activities. The digital gauge and auto shutoff features enhance accuracy and ease of use, though its slightly heavier design may be a consideration for frequent transport.

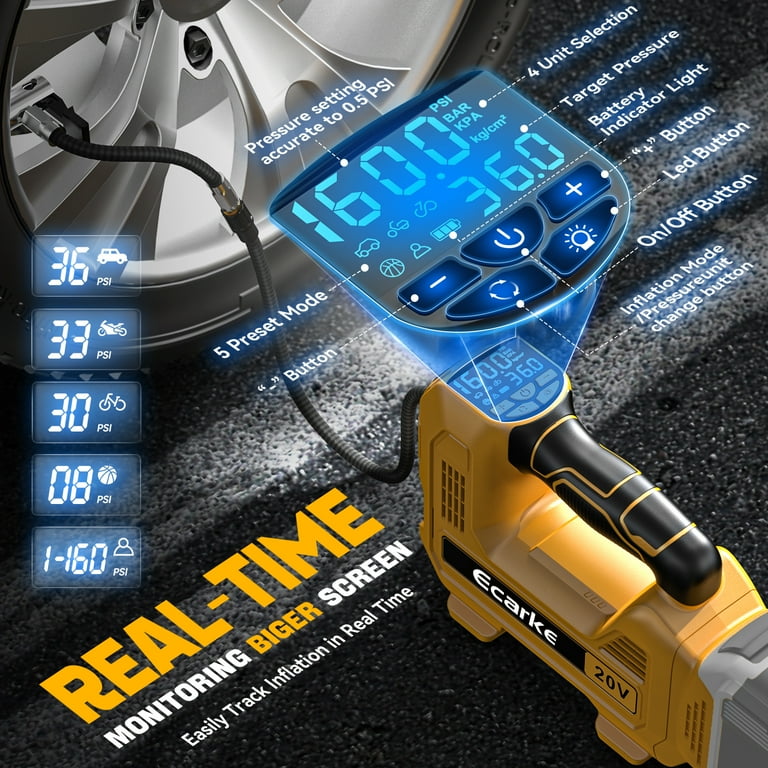

Illustrative image related to dewalt tire inflator with battery

For businesses focused on rapid inflation needs, the High-Volume Inflator stands out with its capability to quickly inflate large items. This model is particularly beneficial for recreational businesses or event coordinators dealing with inflatable products. However, it may not meet high-pressure requirements for vehicle tires.

The Compact Inflator appeals to small businesses or individual users who require a lightweight and easy-to-use device for basic inflation tasks. While it is highly portable, its limited features may not satisfy the needs of more demanding applications.

Lastly, the Heavy-Duty Industrial Inflator is designed for rigorous use in tough environments, making it suitable for fleet maintenance and construction applications. Its durability and high PSI capabilities justify the investment for businesses that require reliable and consistent performance, though the higher price may deter smaller enterprises.

| Industry/Sector | Specific Application of dewalt tire inflator with battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Services | Tire inflation and maintenance for vehicles | Ensures vehicle safety and optimal performance | Availability of compatible battery systems and accessories |

| Sports and Recreation | Inflation of sports equipment (balls, inflatable gear) | Enhances operational efficiency and readiness for events | Durability and portability for outdoor use |

| Transportation and Logistics | Routine tire checks and inflation for fleet vehicles | Reduces downtime and maintenance costs | Power source versatility to accommodate various locations |

| Construction and Heavy Equipment | Inflating tires of construction machinery and vehicles | Increases productivity by minimizing equipment downtime | Robustness to withstand harsh job site conditions |

| Outdoor and Camping Equipment | Inflation of camping mattresses and inflatable toys | Provides convenience and enhances user experience | Compact design for easy transport and storage |

In automotive services, the Dewalt tire inflator is essential for maintaining proper tire pressure in vehicles. By using the digital gauge and automatic shutoff feature, mechanics can ensure accurate inflation, which is critical for vehicle safety and efficiency. This inflator helps reduce the risk of tire blowouts and enhances fuel efficiency, leading to cost savings. International buyers in regions like Africa and the Middle East should consider local power supply compatibility and battery availability when sourcing this tool.

The Dewalt tire inflator serves a vital role in the sports and recreation industry by efficiently inflating various sporting equipment, including balls and inflatable gear. Quick inflation capabilities allow teams and organizations to prepare for events without delay, ensuring readiness. For businesses in South America and Europe, the emphasis on portability and durability is crucial, especially in outdoor settings where access to power may be limited.

Illustrative image related to dewalt tire inflator with battery

In the transportation and logistics sector, the inflator is used for routine tire checks and inflation of fleet vehicles. This proactive maintenance approach minimizes vehicle downtime and reduces overall maintenance costs. Fleet managers in Europe and Africa must prioritize the inflator’s versatility in power sources to accommodate different operational environments, whether on-site or remote.

The Dewalt tire inflator is critical for inflating tires of heavy machinery and construction vehicles. Ensuring that equipment is in optimal working condition boosts productivity and minimizes delays caused by tire issues. Buyers in the Middle East and South America should focus on the tool’s robustness and ability to function effectively in harsh job site conditions, where durability is paramount.

For businesses involved in outdoor and camping equipment, the Dewalt tire inflator simplifies the inflation of camping mattresses and inflatable toys. Its compact design ensures easy transport, making it a valuable asset for outdoor enthusiasts. When sourcing for this application, international buyers should consider the inflator’s weight and battery life, as these factors significantly influence user convenience during camping trips.

Illustrative image related to dewalt tire inflator with battery

The Problem: For B2B buyers, particularly those operating in regions with unreliable electricity supply, finding a tire inflator that can perform consistently under varying power conditions is crucial. The DeWalt tire inflator’s flexibility to run on multiple power sources (20V MAX battery, 12V DC, or 110V AC) may not be enough if the battery life is short or if the inflator frequently requires recharging. This can lead to operational downtime, especially in critical situations such as roadside assistance or urgent tire repairs.

The Solution: To ensure optimal usage, B2B buyers should consider investing in additional battery packs and a reliable charging solution to keep the inflator ready for use at all times. When sourcing the DeWalt tire inflator, it is advisable to purchase a few extra 20V MAX batteries and a fast charger. This combination allows for quick battery swaps during high-demand situations. Additionally, consider implementing a maintenance schedule to regularly check battery health and ensure that chargers are functioning correctly, thus minimizing downtime. This proactive approach will enhance operational efficiency and reliability, particularly in challenging environments.

The Problem: Many B2B buyers face the challenge of achieving precise tire inflation, which is vital for safety and performance. Inaccurate inflation can lead to increased tire wear, reduced fuel efficiency, and potential safety hazards. The DeWalt tire inflator features a digital gauge and an auto-shutoff function, but users may still struggle with ensuring the correct pressure, especially when dealing with various types of tires and inflation requirements.

Illustrative image related to dewalt tire inflator with battery

The Solution: To overcome this challenge, B2B buyers should familiarize themselves with the specific inflation requirements for each tire type they encounter. A comprehensive guide or reference chart detailing the correct PSI for different vehicles or equipment can be invaluable. When using the DeWalt tire inflator, buyers should set the desired pressure on the digital gauge before inflating. This not only streamlines the process but also allows the auto-shutoff feature to function effectively, preventing over-inflation. Additionally, regular calibration of the inflator’s gauge can help ensure consistent accuracy. Providing training sessions for staff on these best practices will further enhance efficiency and safety.

The Problem: For businesses that require tire inflation across various job sites, the need for a portable and lightweight inflator cannot be overstated. Heavy or bulky inflators can be difficult to transport, leading to inefficiencies and frustration. While the DeWalt tire inflator is designed to be portable, users may still encounter challenges related to its weight or the cumbersome nature of carrying additional accessories.

The Solution: To enhance portability, B2B buyers should invest in a dedicated carrying case that can accommodate the inflator along with all necessary accessories, such as battery packs, nozzles, and power cords. This not only protects the equipment during transport but also organizes the components for quick access. Additionally, consider utilizing vehicles equipped with designated storage for these tools, ensuring they are easily accessible without being cumbersome to move. Encouraging staff to utilize ergonomic lifting techniques and proper storage solutions will also reduce strain and improve efficiency. By optimizing transport logistics, businesses can ensure that the DeWalt tire inflator is always ready to perform, no matter the location.

When selecting materials for the Dewalt tire inflator with battery, several factors must be considered, including performance, durability, and compliance with international standards. Here, we analyze four common materials used in its construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are often used in the housing of inflators. They offer good temperature resistance (up to 80°C) and can withstand moderate pressure.

Pros & Cons: Plastics are lightweight and cost-effective, making them ideal for portable tools. However, they may not provide the same level of impact resistance as metals, and their long-term durability under extreme conditions can be questionable.

Impact on Application: The use of plastic in the inflator’s casing helps reduce overall weight, enhancing portability. However, buyers should consider the potential for deformation under high temperatures or mechanical stress.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is crucial. Buyers in regions with high UV exposure, like Africa and the Middle East, should ensure that the plastics used have UV stabilizers to prevent degradation.

Key Properties: Metals such as aluminum and steel are commonly used for structural components and internal mechanisms. They offer high strength and excellent corrosion resistance, withstanding pressures up to 160 PSI.

Pros & Cons: Metal components provide durability and reliability, essential for tools subjected to heavy use. However, they increase the weight of the inflator and can be more expensive to manufacture and transport.

Illustrative image related to dewalt tire inflator with battery

Impact on Application: The robust nature of metal components ensures that the inflator can handle various inflation tasks, from tires to sports equipment, without compromising performance.

Considerations for International Buyers: Compliance with international standards like ISO 9001 for quality management systems is critical. Buyers should also consider the availability of replacement parts in their regions, particularly in South America and Africa, where supply chains may be less developed.

Key Properties: Rubber, particularly high-pressure rubber hoses, is used for the inflator’s air delivery system. It can withstand high pressures and offers excellent flexibility and resistance to wear and tear.

Pros & Cons: Rubber hoses are durable and provide a secure connection to inflation valves, minimizing air loss. However, they can degrade over time due to exposure to ozone and UV light, which can limit their lifespan.

Impact on Application: The flexibility of rubber hoses allows for easy maneuverability during use, making them suitable for various applications, including off-roading and recreational cycling.

Considerations for International Buyers: Buyers should ensure that rubber components meet relevant standards such as ASTM D2000 for rubber products. In regions with high humidity, such as parts of South America, the susceptibility of rubber to mold and mildew should also be considered.

Key Properties: Electronic components, including digital gauges and LED lights, are critical for functionality. They require materials that can operate effectively at various temperatures and resist moisture.

Pros & Cons: Electronics enhance usability with features like auto shut-off and pressure monitoring. However, they can increase manufacturing complexity and costs, and are susceptible to failure if not adequately protected from environmental factors.

Impact on Application: The inclusion of electronic features allows for precise inflation, making the inflator suitable for a wide range of applications, from automotive to sporting equipment.

Considerations for International Buyers: Compliance with electrical safety standards such as IEC 60950 is essential. Buyers should also consider the availability of service and support for electronic components in their regions.

| Material | Typical Use Case for dewalt tire inflator with battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and casing | Lightweight and cost-effective | May deform under high temperatures | Low |

| Metal | Structural components | High strength and corrosion resistance | Increases weight and manufacturing cost | High |

| Rubber | Air delivery system (hoses) | Durable and flexible | Degrades over time due to environmental factors | Medium |

| Electronics | Digital gauges and LED lights | Enhances usability | Increases complexity and potential failure | High |

This strategic material selection guide provides crucial insights for B2B buyers, helping them make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing process for the DEWALT tire inflator is a complex sequence that emphasizes precision and quality at every stage. This is crucial for meeting the high-performance standards required in various global markets. The process generally includes several key stages: material preparation, forming, assembly, and finishing.

Material preparation is the foundation of the manufacturing process. High-quality materials such as durable plastics, metals, and rubber are sourced from trusted suppliers. These materials are then subjected to rigorous testing to ensure they meet the required specifications for durability and performance. For instance, the rubber hose must withstand high pressures, while the plastic components need to be resilient against environmental factors.

Once materials are approved, they are cut and prepped using advanced machinery. This stage may involve CNC machining for metal parts and injection molding for plastic components. By adhering to international sourcing standards, DEWALT ensures that the materials not only meet quality expectations but are also compliant with environmental regulations.

Forming techniques play a pivotal role in achieving the desired specifications for each component of the inflator. Common methods include extrusion for hoses and molds for plastic parts. For metal components, processes such as stamping and forging are utilized to enhance strength and durability.

This stage is vital for ensuring that all parts fit together seamlessly, which is crucial for the inflator’s functionality. The precision in forming techniques reduces the likelihood of defects, ensuring a high-quality end product that can withstand extensive use, whether in professional or recreational settings.

The assembly of the tire inflator is typically carried out in a controlled environment where components are meticulously assembled according to predefined specifications. Automated assembly lines often handle the initial stages, ensuring speed and consistency. However, skilled technicians oversee critical assembly points to verify that each unit is assembled correctly.

Illustrative image related to dewalt tire inflator with battery

During this stage, components like the digital gauge, the high-pressure rubber hose, and the LED light are integrated. The use of threaded connections ensures a secure fit for the inflator, which is essential for maintaining pressure during operation. This meticulous assembly process reduces the risk of operational failures, enhancing the product’s reliability.

The finishing stage includes several quality checks that ensure the inflator meets DEWALT’s high standards. This may involve surface treatments, painting, or protective coatings to enhance durability and aesthetics.

Before packaging, each unit undergoes functional testing to verify performance metrics like pressure accuracy and operational efficiency. This step is crucial for ensuring that the inflator operates correctly under various conditions, providing peace of mind to B2B buyers who depend on its reliability in the field.

Quality assurance (QA) is integral to DEWALT’s manufacturing philosophy. It encompasses international standards and industry-specific guidelines to ensure every product is safe, reliable, and efficient.

DEWALT adheres to ISO 9001 standards, which focus on quality management systems and continuous improvement. Compliance with these standards means that DEWALT has established processes to monitor and improve the quality of its products consistently.

Illustrative image related to dewalt tire inflator with battery

Additionally, products may also meet CE certification requirements, ensuring compliance with European health, safety, and environmental protection standards. For markets in Africa, South America, and the Middle East, adherence to local regulatory standards is also crucial, providing additional assurance of product safety and reliability.

Quality control checkpoints are strategically implemented throughout the manufacturing process. These include:

These checkpoints help mitigate risks associated with defects and ensure that only high-quality products reach the market.

Common testing methods include:

These methods are critical for verifying that the product meets both performance and safety standards, thereby instilling confidence in B2B buyers.

B2B buyers looking to ensure the quality of their DEWALT tire inflator purchases can take several steps to verify supplier QC practices:

Supplier Audits: Conducting onsite audits can provide firsthand insight into the manufacturing and quality assurance processes employed by the supplier. This allows buyers to assess compliance with international standards.

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the quality metrics the supplier adheres to, including defect rates and testing outcomes.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing practices and product quality.

Certification Verification: Buyers should ensure that the supplier’s certifications are current and relevant to the product’s intended market, especially in regions with strict compliance requirements.

International B2B buyers must navigate various quality control nuances specific to their regions. For instance, compliance with local regulations in Africa or South America may differ significantly from those in Europe or the Middle East. Understanding these nuances is crucial for ensuring that products meet local market requirements.

Moreover, cultural differences in business practices may influence supplier relationships and negotiations. Establishing clear communication regarding quality expectations and compliance requirements is essential for successful international transactions.

In conclusion, DEWALT’s tire inflator manufacturing process and quality assurance measures reflect a commitment to excellence, ensuring that B2B buyers receive a reliable and high-quality product suited for diverse applications across various markets.

To assist B2B buyers in procuring the DEWALT tire inflator with battery, this guide provides a structured checklist to ensure a thorough and effective sourcing process. By following these steps, buyers can make informed decisions that meet their operational needs and standards.

Establishing clear technical specifications is crucial for ensuring that the DEWALT tire inflator meets your operational requirements. Consider factors such as maximum pressure (160 PSI), power sources (20V MAX battery, 12V DC, or 110V AC), and portability needs. Documenting these specifications will help you communicate effectively with suppliers and avoid mismatches.

Investigate the market landscape to identify potential suppliers of the DEWALT tire inflator. Look for suppliers with a strong reputation in your region—especially in Africa, South America, the Middle East, and Europe. Utilize industry reports, trade shows, and online platforms to gather insights on pricing, availability, and competitor offerings.

Before making a commitment, conduct a thorough evaluation of potential suppliers. Request detailed company profiles, including their history, client testimonials, and case studies relevant to your industry. This step is essential to ensure that suppliers have a proven track record of reliability and quality.

Once you have identified potential suppliers, request detailed quotes for the DEWALT tire inflator. Ensure that quotes include all relevant costs, including shipping and taxes. Comparing pricing is important, but also consider the value offered, such as warranty terms and after-sales support.

Understanding warranty and service options is essential for long-term investment. DEWALT offers a three-year limited warranty and one year of free service, which indicates their confidence in product durability. Review the terms closely to ensure they align with your expectations for support and maintenance.

Evaluate the supplier’s shipping and delivery capabilities, especially if your operations require timely access to tools. Confirm that they can meet your delivery timelines and understand any additional costs associated with shipping to your region.

Illustrative image related to dewalt tire inflator with battery

Once you have selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This agreement should include product specifications, pricing, warranty information, and delivery schedules. A well-defined contract protects both parties and helps mitigate risks associated with procurement.

By adhering to this checklist, B2B buyers can effectively navigate the sourcing process for the DEWALT tire inflator with battery, ensuring they make informed decisions that support their business needs.

When analyzing the cost structure of the DeWalt tire inflator with battery, several critical components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The primary materials involved in the production of the inflator include high-quality plastics, metals for the motor and casing, rubber for hoses, and electronic components. Sourcing these materials from reliable suppliers can significantly impact cost.

Labor: Labor costs vary by region. In regions with higher labor costs, such as parts of Europe, manufacturers might incur greater expenses than in regions like South America or Africa, where labor is relatively cheaper.

Manufacturing Overhead: This encompasses the indirect costs associated with the production process, such as utilities, rent, and equipment depreciation. These costs can fluctuate based on the location of the manufacturing facility.

Tooling: The initial investment in tooling can be substantial, especially for custom designs or modifications. Buyers should consider whether they need standard products or if customization will be required.

Quality Control: Ensuring the inflator meets safety and performance standards is crucial. The costs associated with QC processes can vary based on regulatory requirements in different countries.

Logistics: Shipping costs, including freight, customs duties, and insurance, play a significant role in the overall cost structure. Incoterms will dictate who is responsible for these costs, which can vary greatly depending on the shipping terms agreed upon.

Margin: Suppliers will add a profit margin to cover their operational costs and ensure profitability. This margin can vary widely based on the competitive landscape and the specific market dynamics in the regions where the product is sold.

Several factors influence the pricing of the DeWalt tire inflator, particularly in international B2B markets.

Volume/MOQ: Minimum order quantities (MOQ) often affect pricing; larger orders typically result in lower per-unit costs. Buyers should evaluate their needs and consider bulk purchases to leverage better pricing.

Specifications and Customization: Custom features can increase costs. Buyers should carefully assess whether they need additional specifications that could raise the price.

Materials and Quality Certifications: The choice of materials directly impacts the inflator’s durability and performance, affecting the cost. Additionally, obtaining quality certifications may increase production costs but can enhance marketability.

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

Incoterms: The agreed-upon Incoterms will dictate the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties, impacting the total landed cost.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing is crucial for achieving cost efficiency.

Illustrative image related to dewalt tire inflator with battery

Negotiation: Engage in negotiations to secure better pricing. Suppliers often have flexibility, especially for larger orders or long-term partnerships.

Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime costs. A higher upfront cost may yield lower TCO over time due to better performance and reliability.

Pricing Nuances for International Buyers: Be aware of currency fluctuations and economic conditions in the supplier’s country, as these can affect pricing. Understanding local market conditions can help in negotiating better terms.

Leverage Local Partnerships: Establishing relationships with local distributors can facilitate smoother transactions and reduce logistics costs. Local partners may also provide insights into market trends and preferences.

Stay Informed: Keep abreast of industry trends, pricing changes, and new suppliers entering the market. This knowledge can empower buyers to make informed decisions and potentially find better pricing options.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and strategic negotiation techniques can significantly enhance the sourcing experience for international B2B buyers looking for the DeWalt tire inflator with battery.

When evaluating the Dewalt Tire Inflator with Battery, it’s essential to consider various alternatives that might meet similar needs. Different technologies and solutions can offer unique benefits and drawbacks, impacting their suitability for different applications. This analysis compares the Dewalt inflator with two viable alternatives: a traditional manual tire pump and a portable air compressor.

| Comparison Aspect | Dewalt Tire Inflator With Battery | Traditional Manual Tire Pump | Portable Air Compressor |

|---|---|---|---|

| Performance | Up to 160 PSI; quick inflation | Varies; slower than powered inflators | High PSI; fast inflation for multiple tires |

| Cost | Moderate (typically $169.99) | Low (typically $20 – $40) | Higher (typically $100 – $300) |

| Ease of Implementation | User-friendly with digital gauge and auto shutoff | Requires manual effort; no automation | Generally easy, but requires power source |

| Maintenance | Minimal; requires battery care | Minimal; no moving parts | Moderate; may need oiling and filter changes |

| Best Use Case | Best for on-the-go situations and multiple inflatables | Ideal for emergency situations or limited use | Best for frequent use and larger inflation tasks |

A traditional manual tire pump is a simple and cost-effective solution for inflating tires. The primary advantage is its low cost and portability—ideal for emergency situations where power sources are unavailable. However, it requires significant manual effort, making it less practical for frequent or larger inflation tasks. The performance is also limited, as it can take longer to achieve desired tire pressure compared to powered options.

A portable air compressor offers a high-performance solution for tire inflation, often providing higher PSI ratings and faster inflation times. It is versatile, capable of powering various pneumatic tools and inflating larger items like air mattresses. However, the cost is generally higher, and it often requires a power source, making it less convenient for on-the-go applications. Maintenance can also be more demanding, as regular upkeep is necessary to ensure optimal performance.

Selecting the right tire inflation solution depends on the specific requirements of the business or operation. For companies prioritizing portability and ease of use in various environments, the Dewalt Tire Inflator with Battery stands out as an excellent option. However, for those seeking a cost-effective solution for rare use, a manual pump may suffice. Alternatively, businesses that frequently require tire inflation and have the budget for it might consider a portable air compressor for its superior performance and versatility. Assessing factors such as budget, application frequency, and convenience will guide B2B buyers in making an informed choice.

Illustrative image related to dewalt tire inflator with battery

Understanding the essential technical properties of the DEWALT tire inflator with battery is crucial for B2B buyers, particularly when evaluating performance, reliability, and suitability for various applications. Below are some critical specifications:

Maximum Pressure (160 PSI)

The maximum pressure rating indicates the highest level of air pressure the inflator can achieve. This specification is vital for ensuring that the device can adequately inflate a wide range of items, from standard vehicle tires to high-pressure sports equipment. A higher PSI allows for versatility in applications, making it suitable for diverse markets.

Power Sources (20V MAX Battery, 12V DC, 110V AC)

The ability to operate on multiple power sources enhances the inflator’s versatility. This feature is particularly beneficial for international markets where power availability may vary. Buyers can use it in remote locations or on job sites without relying on a consistent power supply, increasing its utility across different environments.

Noise Level (77 dB)

The noise level rating is an important consideration for users who prioritize quieter operations, especially in residential or sensitive environments. Understanding the decibel level helps buyers select tools that meet local regulations or community standards, particularly in urban areas.

Weight (5.5 lbs)

The weight of the inflator impacts its portability and ease of use. A lighter device is more convenient for professionals who need to move it frequently or for end-users who may require it for personal use. Portability is a key selling point in markets where mobility and ease of transport are prioritized.

Digital Gauge with Auto Shutoff

The inclusion of a digital gauge and automatic shutoff feature enhances accuracy during inflation. This is especially important for B2B buyers concerned with efficiency and precision, as it minimizes the risk of over-inflation and potential damage to tires or other inflatables.

Heavy-Duty Rubber Feet

This feature helps stabilize the inflator during operation, reducing movement and enhancing user safety. For businesses that require consistent performance, this property ensures that the inflator remains reliable and effective even in challenging conditions.

Familiarity with industry terminology is essential for B2B transactions. Here are some common trade terms you may encounter:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of the DEWALT inflator, knowing the OEM can help buyers assess the quality and compatibility of replacement parts or accessories.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to negotiate terms and manage inventory effectively, particularly in regions where demand may fluctuate.

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. This process is vital for B2B negotiations, allowing buyers to compare offers and select the best supplier based on cost and service.

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms is essential for understanding shipping costs, risk management, and delivery obligations, especially for international buyers in Africa, South America, the Middle East, and Europe.

Warranty Terms

Warranty terms refer to the conditions under which a product can be repaired or replaced. For B2B buyers, understanding warranty coverage is critical for risk management, ensuring that investments are protected against manufacturing defects or failures.

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. This is a crucial factor for businesses that rely on timely deliveries to meet project deadlines or customer expectations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market requirements.

The global market for portable inflators, particularly the Dewalt tire inflator with battery, is experiencing significant growth driven by several key factors. The increasing demand for versatile, battery-operated tools in sectors like automotive, construction, and outdoor recreation is a primary driver. As urbanization and vehicle ownership rise in regions such as Africa, South America, and the Middle East, the need for reliable inflation solutions becomes paramount. Additionally, the trend toward DIY maintenance among consumers is pushing businesses to stock high-quality, user-friendly products like the Dewalt inflator.

Illustrative image related to dewalt tire inflator with battery

Emerging technologies are also shaping the market. Features such as digital pressure gauges, automatic shutoff capabilities, and multi-source power options (battery, DC, and AC) are becoming standard. These advancements enhance user experience and operational efficiency, making the inflator an indispensable tool for both professionals and consumers. Furthermore, the growing emphasis on e-commerce and online procurement platforms is facilitating easier access for international B2B buyers, allowing them to compare products and suppliers with greater ease.

As environmental concerns gain traction globally, the importance of sustainability and ethical sourcing in the manufacturing and distribution of products like the Dewalt tire inflator cannot be overstated. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their environmental footprint through sustainable practices. This includes using recyclable materials, reducing energy consumption during production, and ensuring responsible waste management.

Certifications such as ISO 14001 (Environmental Management) and adherence to green manufacturing standards are becoming crucial in the decision-making process for buyers. Suppliers that can showcase their commitment to sustainability not only enhance their reputation but also appeal to environmentally conscious consumers. Additionally, the trend towards battery-operated tools aligns with the broader push for reducing reliance on fossil fuels, making the Dewalt tire inflator an attractive option in a market that values eco-friendly products.

The Dewalt tire inflator has undergone significant evolution since its inception, reflecting advancements in technology and changing consumer needs. Initially designed for basic inflation tasks, modern versions like the 20V MAX Corded/Cordless Air Inflator now incorporate multiple power sources, including battery, DC, and AC, providing unprecedented versatility. The introduction of features such as digital gauges, automatic shutoff, and high-volume inflation modes has transformed the inflator from a simple tool into a sophisticated device that caters to a wide range of applications, from automotive maintenance to outdoor recreational use.

This evolution highlights a broader industry trend toward multifunctional tools that enhance user convenience and operational efficiency. As international B2B buyers continue to prioritize quality and innovation, the Dewalt tire inflator stands out as a prime example of how brands can adapt to meet market demands while ensuring reliability and performance.

How do I choose the right DeWalt tire inflator for my business needs?

Selecting the right DeWalt tire inflator involves assessing your specific requirements, such as the types of vehicles you service and the frequency of use. The 20V MAX Corded/Cordless Air Inflator is versatile, operating on battery, DC, or AC power, making it suitable for various environments, including job sites and mobile services. Consider factors like maximum pressure (up to 160 PSI), portability, and included accessories when making your decision. Additionally, evaluate the inflator’s durability and warranty options to ensure long-term reliability for your business.

What is the maximum pressure and volume capacity of the DeWalt tire inflator?

The DeWalt 20V MAX Corded/Cordless Air Inflator has a maximum pressure of 160 PSI, making it ideal for a wide range of inflation tasks, from tires to inflatable sports equipment. Its high-volume hose allows for quick inflation of larger items, such as air mattresses, with a simple push of a button. This combination of high-pressure capability and efficient volume delivery ensures that it meets the demands of both recreational and professional applications.

What are the payment terms typically offered for bulk purchases of DeWalt inflators?

Payment terms for bulk purchases can vary by supplier and region. Generally, B2B buyers may encounter options like net 30, net 60, or even cash on delivery (COD) arrangements. It’s essential to negotiate terms that suit your cash flow and inventory management needs. Additionally, inquire about discounts for larger orders, as many suppliers offer tiered pricing based on quantity, which can significantly affect overall costs.

How can I ensure the quality of the DeWalt tire inflators I purchase?

To guarantee quality, consider sourcing from authorized distributors or reputable suppliers with a proven track record. Request product samples and check for certifications or compliance with international standards. Additionally, review warranty terms; the DeWalt inflator comes with a 3-year limited warranty, which indicates the manufacturer’s confidence in their product. Conducting thorough supplier vetting and seeking feedback from previous customers can also provide insights into product reliability and performance.

What are the minimum order quantities (MOQ) for DeWalt tire inflators?

Minimum order quantities (MOQ) can vary widely depending on the supplier’s policies and your purchasing power. While some suppliers may allow small orders, others might set a higher MOQ to justify production and shipping costs. It’s advisable to discuss your needs directly with suppliers and explore options for flexibility, especially if you are looking to establish a long-term partnership. Larger orders often come with better pricing and terms.

What logistical considerations should I keep in mind when importing DeWalt tire inflators?

When importing DeWalt tire inflators, consider shipping methods, customs duties, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure compliance with local import regulations and tariffs to avoid unexpected fees. Additionally, work with a logistics provider experienced in international trade to streamline the process and mitigate potential delays.

Can I customize the DeWalt tire inflator for my brand?

Customization options for branding may depend on the supplier and the scale of your order. Some manufacturers offer private labeling or branding services for bulk orders. To explore these options, engage directly with your supplier to discuss minimum requirements, potential costs, and the customization process. This can enhance your brand visibility and make your offerings stand out in competitive markets.

What accessories are included with the DeWalt tire inflator, and are they customizable?

The DeWalt 20V MAX Corded/Cordless Air Inflator includes several accessories such as a high-pressure tapered nozzle, a Presta valve adapter, and an inflator needle, making it versatile for different inflation needs. While the standard accessories are fixed, some suppliers may offer customizable accessory kits for bulk orders. Inquire about available options to tailor the inflator to your specific requirements, which can enhance its utility for your business.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Dewalt tire inflator; compatible with Dewalt 20V MAX lithium-ion batteries; error code ‘BLO’ indicates battery issue; recommended battery capacity is at least 4Ah; 1.5Ah batteries may not provide sufficient power; inflator can be used for topping up car tires and inflating kayaks; some users report successful operation with 2Ah and 5Ah batteries.

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – DIY Tool Lifes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

The DEWALT 20V MAX Corded/Cordless Air Inflator exemplifies the importance of strategic sourcing in today’s competitive B2B landscape. Its versatility, powered by multiple sources—20V MAX battery, 12V DC, or 110V AC—ensures reliability across diverse applications, from tire inflation to recreational equipment. The built-in digital gauge and automatic shutoff feature enhance operational efficiency, allowing businesses to maintain productivity without compromising safety.

For international buyers, particularly in Africa, South America, the Middle East, and Europe, investing in such a high-quality inflator can significantly reduce downtime and improve service delivery. The robust design and user-friendly features cater to a range of industries, making it a valuable addition to any toolkit.

As market demands evolve, the DEWALT inflator stands out as a strategic asset, offering not only functionality but also cost-effectiveness in the long term. We encourage B2B buyers to consider how integrating this tool can enhance their operational capabilities and drive growth. Explore partnership opportunities with DEWALT to secure a competitive edge in your market.

Illustrative image related to dewalt tire inflator with battery

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.