In the ever-evolving global market, sourcing reliable tools such as the Harbor Freight tire inflator with gauge presents unique challenges for B2B buyers. Companies across various sectors, from automotive repair to logistics, face the critical task of ensuring their fleets and equipment are adequately maintained. A dependable tire inflator not only enhances operational efficiency but also extends the lifespan of tires, reducing overall costs. This guide serves as a comprehensive resource, addressing essential elements such as different types of tire inflators, their applications, and the intricacies of supplier vetting.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, will find valuable insights tailored to their needs. We delve into the specifications, performance metrics, and pricing strategies of various inflators, equipping decision-makers with the knowledge to make informed purchasing decisions. Additionally, we explore the importance of understanding local market dynamics and compliance requirements, ensuring that buyers can navigate potential pitfalls with confidence.

By providing detailed comparisons and expert recommendations, this guide empowers businesses to select the right tire inflator for their unique operational demands. Whether you are looking to enhance a service shop or maintain a fleet, understanding the nuances of tire inflators will position your business for success in the competitive global marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pistol-Grip Tire Inflator with Dial Gauge | Ergonomic pistol-grip design, rubberized gauge, 220 PSI max | Garages, repair shops, personal use | Pros: Easy handling, good pressure range. Cons: Limited to manual inflation. |

| Dual-Head Angle Chuck Inflator with Inline Gauge | Dual-head chuck for hard-to-reach areas, 160 PSI max | Fleet maintenance, commercial vehicle repair | Pros: Versatile for various wheel types. Cons: Slightly bulkier than standard inflators. |

| Digital Tire Inflator with Backlit Gauge | Large digital display, easy pressure adjustments, 255 PSI max | Automotive shops, emergency services | Pros: High accuracy, visibility in low light. Cons: Battery dependency for digital features. |

| Cordless Tire Inflator | Battery-operated, portable, various PSI settings | Fieldwork, remote locations | Pros: Mobility, no air compressor needed. Cons: Limited battery life under heavy use. |

| 12V Tire Inflator | Powered by vehicle’s 12V outlet, compact design, 100 PSI max | On-the-go tire inflation, personal vehicles | Pros: Convenient for travel, compact size. Cons: Limited inflation power compared to air compressors. |

Pistol-grip tire inflators with dial gauges are designed for ease of use, featuring an ergonomic grip that enhances control during inflation. With a maximum pressure of 220 PSI, these inflators are suitable for both personal and professional applications, such as garages and repair shops. Buyers should consider the durability and accuracy of the gauge, ensuring it meets their specific inflation needs.

Dual-head angle chuck inflators are particularly advantageous for reaching hard-to-access tires, such as those on dual-wheel configurations. With a maximum pressure of 160 PSI, these inflators are ideal for fleet maintenance and commercial vehicle repairs. When purchasing, B2B buyers should evaluate the flexibility of the hose and the ease of use for their specific tire types.

Digital tire inflators with backlit gauges offer enhanced visibility and precision, making them ideal for automotive shops and emergency services. With pressure readings up to 255 PSI, these inflators provide high accuracy and user-friendly features. B2B purchasers should weigh the benefits of digital accuracy against the potential drawbacks of battery dependency, especially in high-usage scenarios.

Cordless tire inflators are battery-operated, offering exceptional portability and convenience for fieldwork or remote locations. They typically feature various PSI settings, making them versatile for different inflation tasks. Businesses should consider the battery life and recharge time to ensure these inflators meet their operational demands.

12V tire inflators leverage a vehicle’s power outlet for operation, making them compact and convenient for on-the-go tire inflation. With a maximum pressure of 100 PSI, they are suitable for personal vehicles and emergency situations. Buyers should assess the inflator’s performance and durability, particularly for frequent use during travel.

| Industry/Sector | Specific Application of harbor freight tire inflator with gauge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Routine tire maintenance and repair for vehicles | Ensures optimal tire pressure, enhancing safety and fuel efficiency, and prolonging tire life. | Availability of compatible air compressors and ease of use in varied environments. |

| Transportation and Logistics | Fleet tire management for trucks and delivery vehicles | Reduces downtime due to tire issues, improving logistics efficiency and reducing operational costs. | Durability and reliability, especially under high-use conditions. |

| Construction | Tire inflation for construction equipment and machinery | Maintains equipment performance, reducing the risk of breakdowns and ensuring project timelines are met. | Compatibility with various machinery types and the ability to handle high PSI requirements. |

| Agriculture | Tire maintenance for farming vehicles and equipment | Enhances the performance of agricultural machinery, leading to better productivity and reduced costs. | Adaptability to different tire sizes and ease of use in remote locations. |

| Manufacturing | Inflating tires on material handling equipment (e.g., forklifts) | Improves safety and efficiency in manufacturing processes by ensuring equipment is always operational. | Consideration for noise levels and portability for use in confined spaces. |

In the automotive repair sector, the Harbor Freight tire inflator with gauge is essential for routine tire maintenance. Mechanics utilize this tool to ensure that tires are inflated to the correct PSI, which is crucial for vehicle safety and performance. Proper tire inflation can significantly enhance fuel efficiency and extend tire lifespan, leading to cost savings for both repair shops and customers. International buyers should consider the inflator’s compatibility with various air compressors and its usability in different environments to maximize its effectiveness.

For the transportation and logistics industry, maintaining optimal tire pressure in fleet vehicles is critical. The tire inflator helps logistics companies manage their fleets effectively by quickly addressing tire issues that could lead to downtime. This tool not only improves safety but also helps in reducing operational costs associated with tire wear and fuel inefficiency. When sourcing, businesses should prioritize the inflator’s reliability and durability, especially given the high usage rates in this sector.

In the construction field, the inflator is used to maintain tires on heavy machinery and equipment. Proper inflation is vital to avoid breakdowns and ensure that projects stay on schedule. The tool is designed to handle the high PSI requirements of construction equipment, making it a valuable asset on job sites. Buyers should assess the inflator’s compatibility with various machinery and its ability to perform under demanding conditions.

For the agriculture sector, the tire inflator is instrumental in maintaining the performance of farming vehicles. Ensuring that tractors and other equipment have properly inflated tires can lead to increased productivity and reduced operational costs. Given that agricultural operations often occur in remote areas, the inflator’s portability and ease of use are key considerations for buyers in this field.

In manufacturing, the inflator is crucial for inflating tires on material handling equipment such as forklifts. Keeping these vehicles properly inflated enhances safety and efficiency on the factory floor. When sourcing, manufacturers should consider the inflator’s noise levels and portability, as these factors can significantly impact operations in confined spaces.

The Problem: B2B buyers often face challenges with achieving precise tire pressure readings due to the limitations of standard gauges. This issue is particularly pronounced in environments such as automotive repair shops or fleet maintenance facilities, where accurate tire pressure is crucial for safety and efficiency. Inaccurate readings can lead to over-inflation or under-inflation, resulting in increased tire wear, reduced fuel efficiency, and potential safety hazards.

The Solution: To overcome this challenge, B2B buyers should consider investing in the Harbor Freight tire inflator with a gauge that features a high level of accuracy, such as the MERLIN Pistol-Grip Inflator with Digital Gauge. This model offers a +/- 1% accuracy rating, which is vital for precise inflation. Buyers should ensure that their team is trained on how to use the digital gauge effectively, including how to calibrate it periodically to maintain accuracy. Incorporating regular maintenance checks for the inflators and ensuring that they are stored in a controlled environment can further enhance their longevity and reliability.

The Problem: Many businesses operate vehicles with dual wheels or other configurations that make tire inflation difficult. This issue is common in logistics companies or construction fleets where vehicles may have limited access to tire valves. Trying to inflate these tires with standard inflators can lead to frustration and wasted time, negatively impacting operational efficiency.

The Solution: The Harbor Freight Dual-Head Angle Chuck Inflator with Inline Gauge is designed specifically to address this pain point. Its dual-head chuck allows access to hard-to-reach tire valves, making it an ideal tool for B2B buyers in industries with diverse vehicle types. When purchasing this inflator, businesses should prioritize training their staff on its use, emphasizing techniques for maneuvering the flexible hose to reach tight spaces. Additionally, setting up a dedicated tool station that includes this inflator can streamline the process, ensuring that all necessary tools are readily available when needed.

The Problem: In high-volume environments like tire repair shops or vehicle fleets, tools face considerable wear and tear. Buyers often express concerns about the durability of tire inflators, particularly when they are used frequently throughout the day. A less durable inflator can lead to frequent replacements, which increases operational costs and downtime.

The Solution: To address durability concerns, B2B buyers should opt for the MERLIN Pistol-Grip Inflator with Digital Gauge, which is constructed with robust materials designed to withstand daily use. When sourcing inflators, businesses should look for products that offer warranties and guarantees to safeguard their investment. Additionally, implementing a regular maintenance program that includes inspections and minor repairs can extend the life of the inflators. Training staff to handle the tools carefully and store them properly can further enhance their durability. Investing in high-quality inflators may require a higher upfront cost, but the long-term savings in maintenance and replacement will prove beneficial for any B2B operation.

When selecting materials for tire inflators, it is crucial to consider their properties, advantages, and limitations. The choice of materials not only affects the performance of the inflator but also its durability and cost-effectiveness. Below, we analyze several common materials used in Harbor Freight tire inflators, focusing on their relevance for international B2B buyers.

Aluminum is frequently used in tire inflators due to its lightweight and corrosion-resistant properties. It typically has a pressure rating that can exceed 200 PSI, making it suitable for most tire inflation applications.

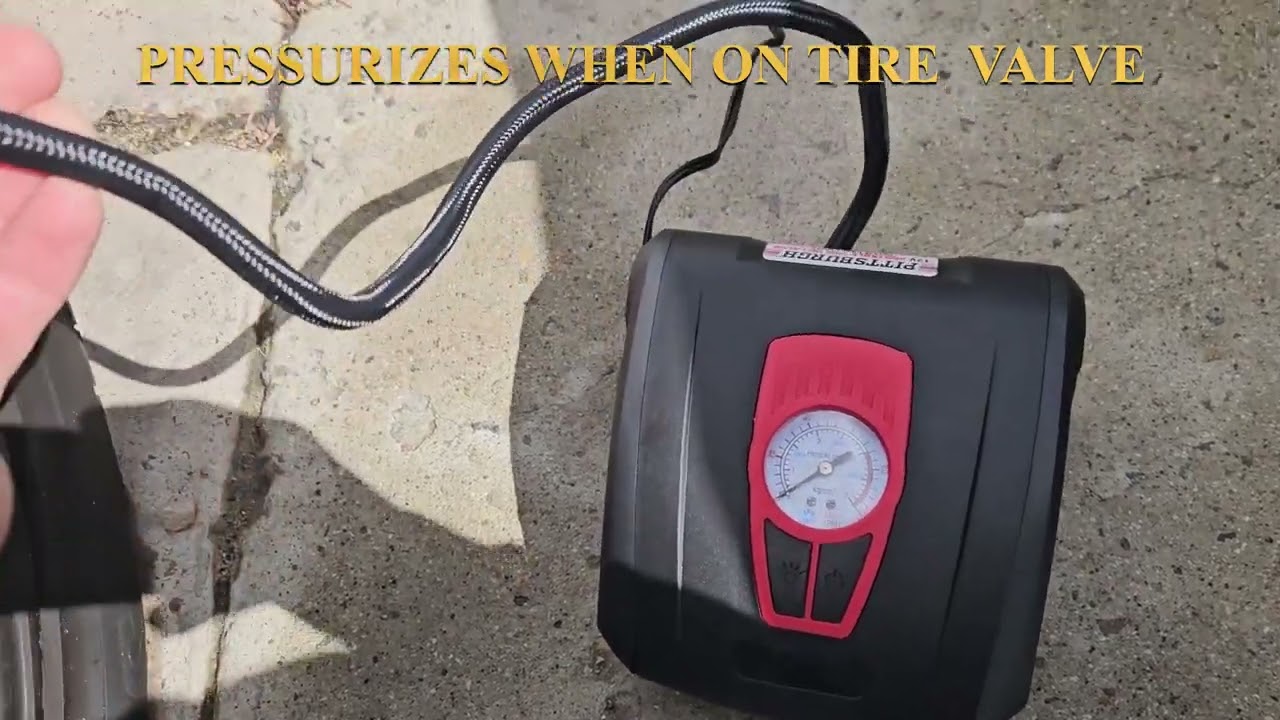

Illustrative image related to harbor freight tire inflator with gauge

Pros and Cons: Aluminum is durable and resistant to rust, which is essential for products used in various environmental conditions. However, it can be more expensive than other materials and may require more complex manufacturing processes.

Impact on Application: Aluminum is compatible with air and various gases, making it versatile for different types of inflators.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial, as is ensuring that the manufacturing process adheres to local regulations, especially in regions like Africa and the Middle East where environmental conditions can vary significantly.

Steel is another common material used in tire inflators, particularly for components like the body and the hose. It offers excellent strength and durability, with a high-temperature tolerance and pressure rating, often around 300 PSI.

Pros and Cons: Steel’s robustness makes it suitable for heavy-duty applications, but it is heavier than aluminum and can be prone to rust if not properly coated. The manufacturing complexity is moderate, as steel requires more energy to process than aluminum.

Impact on Application: Steel is suitable for high-pressure applications and can withstand harsher conditions, making it ideal for commercial use.

Considerations for International Buyers: Buyers should ensure that the steel used complies with international standards for pressure vessels and is treated to prevent corrosion, especially in humid climates.

Rubber is primarily used in seals and hoses within tire inflators. It provides excellent flexibility and is resistant to wear and tear, withstanding pressures typically up to 150 PSI.

Pros and Cons: Rubber is cost-effective and offers good insulation properties. However, it can degrade over time when exposed to UV light and extreme temperatures, which may limit its lifespan.

Impact on Application: Rubber is compatible with air and various gases, making it suitable for tire inflators.

Considerations for International Buyers: It is essential to ensure that rubber components meet specific international standards for durability and safety, particularly in regions with extreme weather conditions.

Illustrative image related to harbor freight tire inflator with gauge

Plastic is often used for gauges and various small components in tire inflators. It is lightweight and can be molded into complex shapes, offering design flexibility.

Pros and Cons: Plastic is inexpensive and resistant to corrosion, but it may not withstand high pressures as well as metal materials. Its durability can vary significantly based on the type of plastic used.

Impact on Application: While plastic can be suitable for low-pressure applications, it may not be ideal for all inflators, particularly those intended for heavy-duty use.

Considerations for International Buyers: Buyers should verify that the plastic used complies with relevant safety standards to avoid issues with durability and performance.

| Material | Typical Use Case for harbor freight tire inflator with gauge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body and housing of inflators | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Hoses and structural components | High strength and durability | Heavier and prone to rust | Medium |

| Rubber | Seals and hoses | Cost-effective and flexible | Degrades under UV and extreme temperatures | Low |

| Plastic | Gauges and small components | Lightweight and moldable | Limited pressure tolerance and variable durability | Low |

This guide provides insights into material selection for tire inflators, helping international B2B buyers make informed decisions that align with their operational needs and local conditions.

The manufacturing process for tire inflators, such as those offered by Harbor Freight, typically encompasses several critical stages: material preparation, forming, assembly, and finishing.

The first step involves sourcing high-quality materials, which primarily include metals like aluminum for the body, rubber for hoses, and various plastics for gauges and triggers. Suppliers must provide certifications confirming that materials meet international standards, ensuring durability and safety. For instance, rubber components should comply with standards like ASTM D2000 to guarantee resistance to heat and wear.

In the forming stage, raw materials undergo processes such as machining and molding. Machining is commonly used for metal components, where precision tools shape parts like the inflator body and chuck. For plastic parts, injection molding is often utilized, allowing for mass production with consistent quality. Advanced techniques, including CNC machining, are employed to achieve precise dimensions and tolerances critical for performance.

During assembly, various components, including gauges, hoses, and triggers, are systematically brought together. Automated assembly lines may be utilized to enhance efficiency and reduce human error. Each inflator is subjected to functional tests during assembly, ensuring that features like the trigger mechanism and gauge readability perform as intended.

The finishing stage includes surface treatments, such as anodizing for aluminum parts, to improve corrosion resistance. Final inspections are conducted to check for any defects in appearance or functionality. This stage is crucial for ensuring that the product not only meets aesthetic standards but also adheres to safety and performance requirements.

Quality assurance (QA) is an integral part of the manufacturing process for tire inflators, ensuring that every product meets established standards. This process typically follows international guidelines like ISO 9001, which outlines a framework for quality management systems.

ISO 9001 certification is essential for manufacturers targeting global markets, as it demonstrates a commitment to quality management practices. Additionally, for tire inflators, compliance with CE marking regulations is vital for entry into European markets, ensuring products meet health, safety, and environmental protection standards. In some regions, specific industry standards such as API specifications may also apply.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint ensures that all materials and components received from suppliers meet predefined quality standards. Verification includes checking material certifications and conducting random sampling tests.

In-Process Quality Control (IPQC): Throughout the manufacturing process, IPQC involves regular inspections and testing of components as they are being assembled. This step helps to identify any issues early, reducing rework and waste.

Final Quality Control (FQC): Once assembly is complete, FQC involves a thorough examination of the finished products. This may include pressure testing the inflators to ensure they can withstand operational demands and verifying gauge accuracy.

To ensure the quality and reliability of tire inflators, manufacturers employ several testing methods:

Pressure Testing: This is crucial for confirming that the inflator can handle the maximum pressure specified (e.g., 220 PSI for some models). Inflators are subjected to pressures beyond their rated limits to identify potential failure points.

Functional Testing: Each inflator is tested for operational efficiency, including trigger response, gauge readability, and air flow rate. This testing is critical for identifying any functional defects before products reach the market.

Durability Testing: Products may undergo accelerated life testing to simulate long-term usage. This helps identify any material fatigue or failure modes that could arise from regular use.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure product reliability.

One effective way to assess quality control is through supplier audits. Buyers can schedule on-site visits to evaluate the manufacturing processes, QA practices, and overall production environment. During these audits, buyers should look for evidence of compliance with international standards and the presence of documented quality procedures.

Buyers should request detailed quality assurance reports from suppliers. These documents should outline the results of various tests conducted during the manufacturing process, including IQC, IPQC, and FQC findings. Reports should also include any corrective actions taken in response to identified issues.

Illustrative image related to harbor freight tire inflator with gauge

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct independent audits and testing, offering buyers additional confidence in the reliability of the products they are sourcing.

For international buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, several quality control considerations should be taken into account:

Local Compliance: Understanding local regulations and standards is critical. Buyers should ensure that products not only comply with international standards but also meet any local requirements that may apply in their respective countries.

Cultural Differences in Quality Expectations: Quality perceptions can vary significantly between regions. Buyers must communicate their specific quality requirements clearly to avoid misunderstandings.

After-Sales Support and Warranty: Assessing the supplier’s after-sales support, including warranty terms and service availability, is essential. This consideration can significantly affect long-term satisfaction with the product.

By understanding the manufacturing processes and quality assurance measures in place for tire inflators, B2B buyers can make informed decisions that align with their operational needs and regional requirements. This knowledge ultimately helps to ensure that they source high-quality products that enhance their service offerings and customer satisfaction.

This practical sourcing guide is designed to assist B2B buyers in effectively procuring the Harbor Freight tire inflator with gauge. By following this step-by-step checklist, you can ensure that you make informed purchasing decisions, streamline your procurement process, and secure reliable inflators that meet your business needs.

Before beginning the sourcing process, it’s essential to establish clear technical specifications for the tire inflator. Consider factors such as maximum pressure capacity (e.g., 220 PSI for some models), hose length, and gauge type (analog vs. digital). Defining these specifications helps narrow down options and ensures that the product will meet the operational requirements of your business.

Conduct thorough research on potential suppliers that offer the Harbor Freight tire inflator. Look for suppliers with a strong reputation in the market, especially those that cater to your geographic region. Consider their experience, customer reviews, and product availability to ensure they can meet your needs effectively.

Take the time to assess the specific features of the inflators you are considering. Key features to evaluate include the type of gauge (analog or digital), ease of use (e.g., pistol-grip handle), and additional functionalities like bleed valves for excess pressure. Understanding these features helps ensure that the inflator aligns with your operational efficiency and user preferences.

Before finalizing your purchase, request samples from shortlisted suppliers. Testing the inflators allows you to assess their performance, durability, and ease of use in real-world conditions. It also provides an opportunity to evaluate customer service and responsiveness from the supplier, which is crucial for ongoing support.

Ensure that the suppliers you are considering have the necessary certifications and comply with international quality standards. Look for ISO certifications and other relevant industry standards that indicate a commitment to quality and safety. This step minimizes the risk of purchasing inferior products and protects your business reputation.

Engage in negotiations with your chosen suppliers to secure favorable pricing and terms. Discuss bulk purchase discounts, payment terms, and delivery schedules. A clear understanding of the financial aspects is critical to maintaining budget control and ensuring a smooth procurement process.

Before completing your order, confirm the warranty terms and after-sales support policies provided by the supplier. A robust warranty protects your investment, while reliable support ensures that any issues can be addressed promptly. This is particularly important for equipment that may require maintenance or repairs over time.

By following this checklist, B2B buyers can navigate the procurement process for Harbor Freight tire inflators with confidence, ensuring they select the best products for their operational needs.

When considering the cost structure for sourcing Harbor Freight tire inflators with gauges, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to harbor freight tire inflator with gauge

Materials: The construction of tire inflators typically involves metals (such as aluminum for the body), rubber for hoses and grips, and plastic for gauges. The choice of materials can significantly influence the cost; higher quality materials enhance durability but may increase the price.

Labor: Labor costs vary by region, affecting the overall price. In areas with higher labor costs, such as Europe, the manufacturing expenses will be elevated compared to regions with lower labor rates like parts of Africa and South America.

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Companies often distribute these costs across their product lines, impacting the pricing strategy for tire inflators.

Tooling: Initial tooling costs for molds and production equipment can be significant. These costs are typically amortized over the production volume, making them a critical factor for larger orders.

Quality Control (QC): Implementing rigorous QC processes ensures that inflators meet safety and performance standards. This adds to the cost but is essential for maintaining product integrity, especially in international markets where compliance with regulations is paramount.

Logistics: Transportation costs, including shipping and customs duties, can vary greatly depending on the destination. For international buyers, understanding Incoterms and associated logistics costs is crucial for accurate pricing.

Margin: Manufacturers typically include a profit margin in their pricing. This can fluctuate based on competitive pressures and market demand.

Several factors can influence the pricing of Harbor Freight tire inflators, which international buyers should consider:

Volume/MOQ: Minimum Order Quantities (MOQs) can impact the price per unit. Higher volumes often lead to lower costs, making it essential to assess your needs against potential bulk purchase opportunities.

Specifications/Customization: Custom features or specific technical specifications can increase costs. Buyers should weigh the necessity of customization against standard options available at lower prices.

Materials: As mentioned earlier, the choice of materials can affect both performance and cost. Buyers should evaluate whether premium materials are justified for their application.

Quality/Certifications: Products that meet specific international standards may carry a premium. Certifications can enhance marketability, particularly in regions with stringent safety regulations.

Supplier Factors: The reputation and reliability of suppliers can affect pricing and lead times. Engaging with reputable suppliers often ensures better quality and service but may come at a higher cost.

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential for calculating total landed costs. This will help avoid unexpected expenses that could erode profit margins.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance cost-efficiency:

Negotiation: Engage suppliers in negotiations. Building strong relationships can lead to better pricing and terms.

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost of ownership, including maintenance, operational efficiency, and potential downtime. This holistic view can lead to smarter purchasing decisions.

Pricing Nuances: Be aware of currency fluctuations and economic factors that might affect pricing. Establishing contracts that account for these variables can mitigate risks.

Market Research: Conduct thorough market research to understand prevailing prices and competitor offerings. This knowledge can empower negotiations and sourcing strategies.

Supplier Diversification: Consider multiple suppliers to avoid dependency on a single source and to foster competitive pricing.

Prices for Harbor Freight tire inflators with gauges are indicative and subject to change based on various factors, including market demand, material costs, and supplier pricing strategies. Buyers are encouraged to conduct their due diligence and obtain current pricing before making purchasing decisions.

In the competitive landscape of tire inflators, businesses must evaluate various options to find the most suitable solution for their needs. The Harbor Freight Tire Inflator with Gauge is a reliable choice, but several alternatives offer unique features and benefits that may better align with specific operational requirements. Below, we compare the Harbor Freight inflator with two viable alternatives to help B2B buyers make informed decisions.

| Comparison Aspect | Harbor Freight Tire Inflator With Gauge | Central Pneumatic Pistol-Grip Inflator | MERLIN Digital Tire Inflator |

|---|---|---|---|

| Performance | 220 PSI maximum; accurate readings | 220 PSI maximum; good for dual wheels | 255 PSI maximum; digital accuracy |

| Cost | $9.99 | $9.99 | $29.99 |

| Ease of Implementation | Simple design; user-friendly | Pistol grip for easy handling | Digital gauge for quick readouts |

| Maintenance | Low; requires occasional cleaning | Low; robust construction | Low; durable materials |

| Best Use Case | Home garages; small repair shops | Commercial garages; heavy-duty use | Professional workshops; precise applications |

The Central Pneumatic Pistol-Grip Inflator offers a sturdy design with a maximum pressure of 220 PSI, making it suitable for various tire types, including dual wheels. Its pistol-grip trigger allows for better control during inflation, enhancing user comfort. However, while it is cost-effective, its performance might be limited in more demanding commercial settings compared to digital alternatives. Additionally, it lacks advanced features like digital readouts, which may impact accuracy in low-light conditions.

The MERLIN Digital Tire Inflator is equipped with a backlit digital gauge that provides precise tire pressure readings, making it ideal for users who need quick and accurate measurements. With a maximum pressure of 255 PSI, it outperforms many traditional inflators, particularly in professional environments where accuracy is paramount. Despite its higher price point of $29.99, the added functionality and ease of use can justify the investment for businesses focused on efficiency. However, its reliance on battery power for the digital display can be seen as a downside in situations where power sources are limited.

When selecting a tire inflator, B2B buyers should consider their specific operational needs. For home garages or small repair shops, the Harbor Freight Tire Inflator and Central Pneumatic Pistol-Grip Inflator provide excellent value at a low cost. However, for professional environments requiring precision and reliability, the MERLIN Digital Tire Inflator may be the better option despite its higher price. Evaluating factors such as performance requirements, budget constraints, and ease of use will guide businesses in making the most suitable choice for their tire inflation needs.

When considering the procurement of tire inflators, several technical specifications are essential for ensuring product reliability and performance. Understanding these properties can help B2B buyers make informed decisions that align with their operational needs.

Illustrative image related to harbor freight tire inflator with gauge

The maximum pressure rating, often measured in pounds per square inch (PSI), indicates the highest pressure the inflator can achieve. For example, models may have ratings of up to 220 PSI. This specification is crucial for buyers who need to service a variety of vehicles, as different tire types have different inflation requirements. Ensuring the inflator can meet the highest demands will extend tire life and enhance vehicle performance.

The hose length, typically ranging from 12 to 16 inches, determines the reach and flexibility of the inflator during use. A longer hose allows easier access to hard-to-reach tire valves, especially in dual-wheel configurations. For B2B operations, this can improve efficiency and reduce the time spent on tire maintenance, which is particularly valuable in busy workshops or service centers.

The accuracy of the pressure gauge is vital for precise inflation. Many inflators offer accuracy ratings of +/- 1% to +/- 2.8 PSI, which is essential for ensuring that tires are inflated to the correct specifications. Accurate inflation helps prevent tire blowouts and improves fuel efficiency, making it a significant consideration for fleet operators and automotive service providers.

The air inlet size, usually specified as 1/4 inch, determines compatibility with air compressors and hoses. This specification is important for B2B buyers as it affects the inflator’s integration with existing equipment. Ensuring compatibility can streamline operations and reduce additional costs related to purchasing new accessories or adapters.

The materials used in the construction of the inflator, such as die-cast aluminum or rubberized components, influence durability and resistance to wear. A robust material composition is crucial for heavy-duty applications, particularly in professional settings where the inflator may be subjected to frequent use and rough handling. Investing in durable products can lead to lower replacement costs and increased operational efficiency over time.

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to tire inflators:

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a tire inflator is an OEM product can affect quality perceptions and compatibility with existing equipment.

MOQ indicates the smallest number of units a supplier is willing to sell. This is significant for buyers looking to optimize inventory costs and manage cash flow. Negotiating favorable MOQ terms can lead to cost savings for bulk purchases.

Illustrative image related to harbor freight tire inflator with gauge

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing RFQs can facilitate comparisons among suppliers and help secure the best possible deal for tire inflators.

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international buyers to understand their obligations and risks when importing tire inflators.

SKU is a unique identifier for each product variant. Knowing the SKU can streamline inventory management and assist in tracking sales data, which is important for businesses managing multiple product lines.

Understanding these technical properties and trade terminologies will empower B2B buyers to make informed decisions, ensuring they select the right tire inflators that meet their operational requirements and financial constraints.

The global market for tire inflators, particularly those equipped with gauges, is experiencing significant growth driven by several factors. First, the increasing number of vehicles on the road, especially in developing regions like Africa and South America, is fueling demand for reliable tire maintenance tools. Furthermore, rising awareness about vehicle safety and fuel efficiency is prompting consumers and businesses alike to ensure proper tire inflation.

Illustrative image related to harbor freight tire inflator with gauge

Emerging technologies are also reshaping the landscape of tire inflators. Digital gauges with backlit displays and integrated pressure sensors are becoming standard features, enhancing usability in various lighting conditions. Additionally, the trend toward cordless and portable inflators is gaining traction, catering to the needs of on-the-go consumers and businesses in industries such as logistics and transportation.

For international B2B buyers, particularly those from regions like Nigeria and Vietnam, sourcing strategies are evolving. Many buyers are prioritizing suppliers that offer competitive pricing without compromising quality, as seen with products like the Central Pneumatic Pistol-Grip Tire Inflator available for under $10. This price sensitivity is coupled with an increasing demand for diverse product ranges that can cater to different vehicle types and inflation needs, including options for dual wheels and specialized vehicles.

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the tire inflator market. The environmental impact of manufacturing processes is under scrutiny, and buyers are increasingly seeking suppliers that demonstrate a commitment to reducing their carbon footprint. This includes the use of recyclable materials in product construction and sustainable packaging solutions.

Furthermore, certifications such as ISO 14001 for environmental management systems are gaining importance. Suppliers who can provide proof of adherence to these standards are more likely to attract business from environmentally conscious buyers. In the tire inflator sector, incorporating ‘green’ materials not only enhances brand reputation but also aligns with the growing consumer preference for sustainable products.

For B2B buyers in Europe and the Middle East, the push for sustainable sourcing is also driven by regulatory frameworks that mandate environmentally friendly practices. As a result, businesses are increasingly looking for partnerships with manufacturers who prioritize eco-friendly materials and processes, ensuring that their supply chains are both ethical and compliant with international standards.

The evolution of tire inflators can be traced back to the early 20th century, when manual pumps were the primary tools for tire inflation. As automotive technology advanced, so did the need for more efficient inflation methods. The introduction of compressed air systems in the mid-20th century revolutionized tire maintenance, allowing for faster and more reliable inflation.

In recent decades, technological advancements have led to the development of electric and digital inflators, equipped with gauges for precise pressure readings. This evolution has not only improved the user experience but has also made tire maintenance more accessible and efficient for both consumers and businesses. As the market continues to grow, the focus on innovation, sustainability, and user-friendly designs will likely shape the future of tire inflators, providing new opportunities for B2B buyers to enhance their product offerings and meet changing consumer demands.

How can I ensure the quality of Harbor Freight tire inflators before purchasing?

To ensure the quality of Harbor Freight tire inflators, request samples from suppliers to conduct hands-on testing. Evaluate the inflator’s build quality, gauge accuracy, and performance under pressure. Additionally, verify supplier certifications, customer reviews, and warranty details. Engaging in discussions with previous customers or references can provide insights into the reliability of the product and the supplier’s commitment to quality control.

What is the best tire inflator for commercial use?

For commercial use, consider the MERLIN Pistol-Grip Inflator with Digital Gauge. It features a durable design, a large easy-to-read backlit display, and a deflate button for quick adjustments. With a maximum pressure of 255 PSI and a robust construction, it’s suitable for various tire sizes and types, making it ideal for garages and service stations. Always assess your specific needs and tire types before finalizing your purchase.

What are the typical payment terms for international orders of tire inflators?

Payment terms for international orders often include options like advance payment, letter of credit, or payment upon delivery. Common practices involve a 30-50% deposit upfront, with the balance due upon shipping or delivery. It’s crucial to negotiate favorable terms that align with your cash flow and risk tolerance while ensuring the supplier’s reliability. Always document the terms clearly in the purchase agreement to avoid misunderstandings.

What should I consider regarding minimum order quantities (MOQ)?

When sourcing tire inflators, MOQs can vary significantly between suppliers. Consider your inventory needs, storage capacity, and budget constraints. If you’re entering a new market, smaller MOQs may be beneficial to test demand without overcommitting. Discuss with suppliers about flexible MOQs or bulk discounts, especially for repeat orders, which can help you manage costs while ensuring product availability.

How do I vet suppliers for tire inflators effectively?

Vetting suppliers involves checking their business credentials, certifications, and production capabilities. Look for reviews from other B2B buyers and evaluate their communication responsiveness. Conduct background checks and, if possible, visit their facilities to assess their operations. Establishing a relationship with suppliers who have a track record in international trade can also enhance trust and reliability.

What logistics considerations should I keep in mind when importing tire inflators?

When importing tire inflators, consider shipping methods, lead times, and customs regulations specific to your country. Evaluate options like air freight for speed or sea freight for cost-effectiveness. Understanding import duties and taxes is essential for budgeting. Additionally, ensure the supplier provides proper documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance.

Can I customize tire inflators to suit my branding needs?

Many suppliers offer customization options for tire inflators, including branding with your logo or specific color schemes. Discuss your requirements with potential suppliers to understand their capabilities and any associated costs. Customization can enhance brand visibility and customer loyalty, particularly if you are targeting a niche market. Ensure that all customization details are agreed upon and documented in the contract.

What are common quality assurance practices for tire inflators?

Common quality assurance practices include conducting inspections at various production stages, from raw materials to final products. Request certification of compliance with international quality standards, such as ISO, to ensure the inflators meet safety and performance criteria. Additionally, consider implementing a final inspection before shipping to verify that the products meet your specifications and quality expectations.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: MERLIN Pistol Grip Inflator with Analog Gauge

The strategic sourcing of Harbor Freight tire inflators with gauges presents significant opportunities for international B2B buyers. Key insights reveal the importance of selecting inflators that not only meet performance standards but also offer cost efficiency, with options like the Central Pneumatic and Merlin lines providing robust features at competitive prices. Features such as durable construction, multiple pressure measurement scales, and user-friendly designs enhance their appeal for various markets, especially in regions with diverse vehicle specifications.

Investing in high-quality tire inflators is crucial for businesses involved in automotive maintenance and repair, as these tools directly contribute to operational efficiency and customer satisfaction. The affordability of these products allows businesses to maintain a competitive edge while ensuring the longevity of tires and overall vehicle safety.

As we look to the future, international B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to capitalize on the growing demand for reliable tire inflators. By strategically sourcing these products, businesses can enhance their service offerings and improve their bottom line. Explore the range of Harbor Freight tire inflators to find the perfect fit for your operational needs and position your business for success in the evolving automotive landscape.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to harbor freight tire inflator with gauge

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.