In today’s dynamic global marketplace, sourcing the right pump car can be a significant challenge for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With a myriad of options available, understanding the unique features, applications, and supplier standards of pump cars is essential for making informed purchasing decisions. This comprehensive guide aims to demystify the complexities surrounding pump cars by covering various types, their applications in different industries, effective supplier vetting processes, and cost considerations.

As you navigate through this guide, you will gain insights into the latest innovations in pump car technology, ensuring that you are well-equipped to choose products that meet your operational needs and budget constraints. We will also highlight best practices for evaluating potential suppliers, including their reliability, certifications, and customer service capabilities, enabling you to forge partnerships that enhance your supply chain resilience.

Whether you are looking to invest in pump cars for construction, agricultural, or industrial applications, this guide empowers you to make strategic decisions that drive efficiency and success. By leveraging the information presented here, you can confidently approach your sourcing process, ensuring that your investments contribute to your organization’s growth and operational excellence.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Tire Inflators | Compact design, battery-operated or 12V powered, quick inflation | Automotive repair shops, roadside assistance | Pros: Easy to transport; quick inflation. Cons: Limited power for larger tires. |

| Heavy-Duty Air Compressors | High PSI capacity, often stationary, larger tanks | Industrial applications, workshops | Pros: Suitable for high-volume inflation; durable. Cons: Requires significant space and power. |

| Dual-Cylinder Compressors | Faster inflation rates, robust construction | Off-road vehicle support, fleet maintenance | Pros: Efficient for large tires; quicker inflation. Cons: Heavier and pricier than single-cylinder models. |

| Cordless Air Compressors | Rechargeable batteries, lightweight, versatile attachments | Mobile mechanics, emergency services | Pros: Convenient for remote locations; no power source needed. Cons: Battery life may limit usage duration. |

| Multi-Purpose Inflators | Adaptable for various inflatables, includes multiple nozzles | Sporting goods, recreational vehicle maintenance | Pros: Versatile for different applications; compact. Cons: May lack power for heavy-duty tasks. |

Portable tire inflators are compact devices primarily designed for quick inflation of vehicle tires. They are typically powered by a 12V connection or rechargeable batteries, making them suitable for emergency roadside assistance or routine maintenance in automotive repair shops. B2B buyers should consider the inflator’s PSI capacity and inflation speed, which can significantly affect service efficiency. Their lightweight design allows for easy transportation, but their limited power may restrict use for larger vehicles.

Heavy-duty air compressors are powerful machines designed for high PSI applications, often found in industrial settings or workshops. They typically feature larger tanks that enable extended use without frequent refills. For B2B buyers, the durability and high-volume inflation capabilities of these compressors make them ideal for businesses that require consistent performance. However, they require more space and power, which can be a consideration for smaller operations.

Illustrative image related to pump car

Dual-cylinder compressors are engineered for rapid inflation and are particularly beneficial for off-road vehicles with larger tires. Their robust construction allows them to handle demanding conditions, making them suitable for fleet maintenance or off-road support services. B2B buyers should focus on the compressor’s inflation rate and maximum PSI to ensure it meets the needs of their vehicles. While they provide faster inflation, their heavier weight and higher price point may be drawbacks for some buyers.

Cordless air compressors are designed with rechargeable batteries, making them highly portable and convenient for mobile mechanics and emergency services. Their versatility allows them to inflate tires, sports equipment, and more without the need for a direct power source. B2B buyers should evaluate battery life and charging time, as these factors can impact operational efficiency. While their convenience is a significant advantage, the limited battery life may restrict prolonged use.

Multi-purpose inflators are adaptable devices that come with various nozzles to accommodate different types of inflatables, including tires, sports gear, and recreational vehicles. Their compact design makes them an excellent choice for businesses involved in sports or outdoor activities. Buyers should consider the inflator’s versatility and ease of use, as these features can enhance customer satisfaction. However, their power may not be sufficient for heavy-duty tasks, so understanding the intended application is crucial for B2B buyers.

| Industry/Sector | Specific Application of pump car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting water for concrete mixing | Enhances project efficiency and quality | Look for durability, pump capacity, and compatibility with construction equipment. |

| Agriculture | Irrigation and pesticide application | Increases crop yield and reduces labor costs | Ensure adaptability to local soil conditions and water sources, and consider energy efficiency. |

| Mining | Dewatering and slurry transport | Prevents flooding and maintains operational flow | Focus on pump reliability under harsh conditions and ease of maintenance. |

| Oil & Gas | Fluid transfer for drilling and production | Optimizes extraction processes and safety | Evaluate pump materials for corrosion resistance and compliance with industry standards. |

| Emergency Services | Rapid water supply for firefighting | Critical for emergency response effectiveness | Ensure portability, ease of operation, and compatibility with existing emergency equipment. |

In the construction sector, pump cars are essential for transporting water to mix concrete, ensuring the right consistency and quality for structural integrity. They address challenges like water scarcity at job sites and reduce the need for manual labor, thereby enhancing overall project efficiency. For international buyers, particularly in regions like Africa and South America, sourcing pump cars that can withstand diverse environmental conditions and integrate seamlessly with existing machinery is crucial. Additionally, understanding local regulations regarding construction practices is vital to ensure compliance.

Illustrative image related to pump car

In agriculture, pump cars are utilized for irrigation and pesticide application, facilitating efficient water management and crop protection. By automating these processes, farmers can increase crop yield while minimizing labor costs and resource waste. For B2B buyers in the Middle East and Europe, selecting pump cars that are adaptable to varying soil types and local water sources is essential. Energy efficiency and the ability to operate under different climatic conditions are also key factors to consider when sourcing these vehicles.

The mining industry employs pump cars primarily for dewatering and transporting slurry, which is crucial for maintaining safe working conditions and operational flow. These vehicles help prevent flooding in mining sites and ensure that materials can be moved efficiently. Buyers from regions like Africa and South America should prioritize sourcing robust pump cars that can withstand harsh environments and require minimal maintenance. Additionally, understanding the specific demands of local mining operations can inform better purchasing decisions.

In the oil and gas sector, pump cars are integral for the transfer of fluids during drilling and production processes. They enhance operational efficiency and safety by ensuring that fluids are moved quickly and reliably. For international buyers, especially in regions with strict regulatory standards like Europe, it’s essential to source pump cars made from corrosion-resistant materials and compliant with safety regulations. Assessing the compatibility of these vehicles with existing infrastructure is also a key consideration.

Emergency services utilize pump cars to provide rapid water supply for firefighting, making them a critical asset in crisis situations. Their ability to deliver water quickly can mean the difference between life and death during emergencies. For B2B buyers in regions prone to natural disasters, such as the Middle East, sourcing portable and easy-to-operate pump cars is vital. Additionally, ensuring compatibility with existing emergency response equipment can enhance operational readiness and effectiveness in critical situations.

The Problem: Maintaining proper tire pressure is a critical concern for B2B buyers managing fleets or operating in industries reliant on vehicles, such as logistics or transportation. Inconsistent tire pressure can lead to increased fuel consumption, reduced safety, and premature tire wear. Buyers often struggle with the challenge of ensuring that all vehicles in their fleet are regularly checked and maintained, particularly in remote locations or areas with limited access to service stations. This inconsistency can result in operational inefficiencies and higher costs.

The Solution: To address this issue, B2B buyers should invest in a robust fleet of portable tire inflators that are easy to use and maintain. When sourcing these devices, opt for models that feature smart technology, such as preset pressure settings and auto shut-off functions, to eliminate guesswork. Incorporating a routine maintenance schedule where drivers are trained to check and inflate tires using these portable inflators can greatly enhance efficiency. Additionally, consider implementing a centralized digital system to monitor tire pressures across the fleet, allowing for proactive maintenance and minimizing downtime. This approach not only ensures consistent tire pressure but also promotes fuel efficiency and extends the lifespan of tires.

The Problem: For businesses that operate with a diverse range of vehicles, such as delivery services or construction companies, dealing with varying tire types and sizes can be a logistical headache. This diversity complicates the selection of appropriate tire inflators and pumps. Buyers may find themselves confused about which equipment to purchase, leading to potential mismatches that can result in inefficiencies and increased costs.

The Solution: A comprehensive analysis of the fleet’s tire specifications is essential before making purchasing decisions. B2B buyers should prioritize tire inflators that come with multiple adaptors and are compatible with various tire types, including heavy-duty vehicles, motorcycles, and standard passenger cars. Choosing inflators with adjustable pressure settings and different inflation modes can ensure versatility across a fleet. Furthermore, training staff on the proper use of these inflators and maintaining an inventory of adaptors can streamline operations. This proactive approach not only enhances flexibility but also reduces the risk of tire damage from incorrect inflation.

The Problem: Many businesses operate in remote locations where access to reliable tire inflation solutions is limited. This situation can be particularly challenging for industries like mining or agriculture, where downtime due to flat tires can severely impact productivity. Buyers often face the dilemma of choosing between bulky, stationary air compressors or less effective portable options that may not meet their needs.

The Solution: B2B buyers should focus on sourcing high-performance, portable tire inflators designed for rugged use in remote environments. When selecting these devices, look for models that are battery-operated or have dual power capabilities (AC/DC) to ensure they can function without a constant power source. Additionally, consider inflators that feature robust construction to withstand harsh conditions. Providing operators with training on how to effectively use these inflators and establishing a regular maintenance schedule can further enhance reliability. By investing in quality portable inflators tailored to their operational context, businesses can minimize downtime and maintain productivity in challenging environments.

In the manufacturing of pump cars, material selection is critical for ensuring optimal performance and longevity. Here, we analyze four common materials used in pump car construction, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Steel is a widely used material in pump car manufacturing due to its excellent strength and durability. It typically offers high temperature and pressure ratings, making it suitable for various applications. Steel’s corrosion resistance can be enhanced through galvanization or coating, which is essential in environments where exposure to moisture or chemicals is prevalent.

Illustrative image related to pump car

Pros: Steel is relatively inexpensive compared to other materials and can be easily fabricated, making it a cost-effective choice for manufacturers. Its strength allows for the construction of robust pump components that can withstand high operational demands.

Cons: The primary drawback of steel is its susceptibility to corrosion if not properly treated. Additionally, the weight of steel can be a disadvantage in applications where weight reduction is crucial.

Impact on Application: Steel is compatible with a wide range of media, including water, oil, and various chemicals, provided appropriate corrosion-resistant treatments are applied.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN for steel grades. Additionally, understanding the local climate’s impact on material performance is vital.

Aluminum is another popular choice for pump car components, known for its lightweight properties and resistance to corrosion. It typically has a lower density than steel, which can enhance fuel efficiency in vehicles.

Pros: Aluminum’s lightweight nature makes it easier to handle and reduces overall vehicle weight, contributing to better fuel economy. It also has excellent corrosion resistance, which is beneficial in harsh environments.

Cons: The primary limitation of aluminum is its lower strength compared to steel, which may require thicker components to achieve the same load-bearing capacity. This can offset some weight advantages.

Impact on Application: Aluminum is suitable for applications involving water and certain chemicals but may not be ideal for high-pressure systems without additional reinforcement.

Considerations for International Buyers: Buyers should verify compliance with international standards like JIS for aluminum alloys. Additionally, the cost of aluminum can vary significantly based on global market conditions, affecting budget considerations.

Plastics, particularly engineered thermoplastics, are increasingly used in pump car components due to their lightweight and corrosion-resistant properties. They can be molded into complex shapes, allowing for innovative designs.

Pros: Plastics are often less expensive than metals and can be produced with high precision. They also provide excellent resistance to corrosion and chemical attack, making them suitable for a wide range of applications.

Cons: The main drawback is that plastics generally have lower strength and temperature resistance compared to metals, which may limit their use in high-pressure or high-temperature applications.

Impact on Application: Plastics are compatible with various media, including water and some chemicals, but may not be suitable for oils or solvents that can degrade certain types of plastic.

Considerations for International Buyers: Buyers should ensure that the selected plastic meets relevant standards for safety and performance, as regulations can vary significantly between regions.

Stainless steel is a premium material choice for pump cars, known for its exceptional corrosion resistance and durability. It is particularly suitable for applications where hygiene and cleanliness are paramount, such as in food processing or pharmaceutical industries.

Pros: The primary advantage of stainless steel is its resistance to corrosion, which makes it ideal for harsh environments. It also maintains strength at high temperatures, making it versatile for various applications.

Cons: The cost of stainless steel is significantly higher than that of carbon steel and plastics, which can impact budget considerations. Additionally, manufacturing processes for stainless steel can be more complex.

Illustrative image related to pump car

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive chemicals, making it suitable for specialized applications.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel required for their applications and ensure compliance with international standards such as ASTM or ISO.

| Material | Typical Use Case for pump car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastic | Non-structural components | Cost-effective and easy to mold | Lower strength and temperature limits | Low |

| Stainless Steel | Corrosive environments | Excellent corrosion resistance | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material selection for pump cars, helping international B2B buyers make informed decisions that align with their operational needs and regional standards.

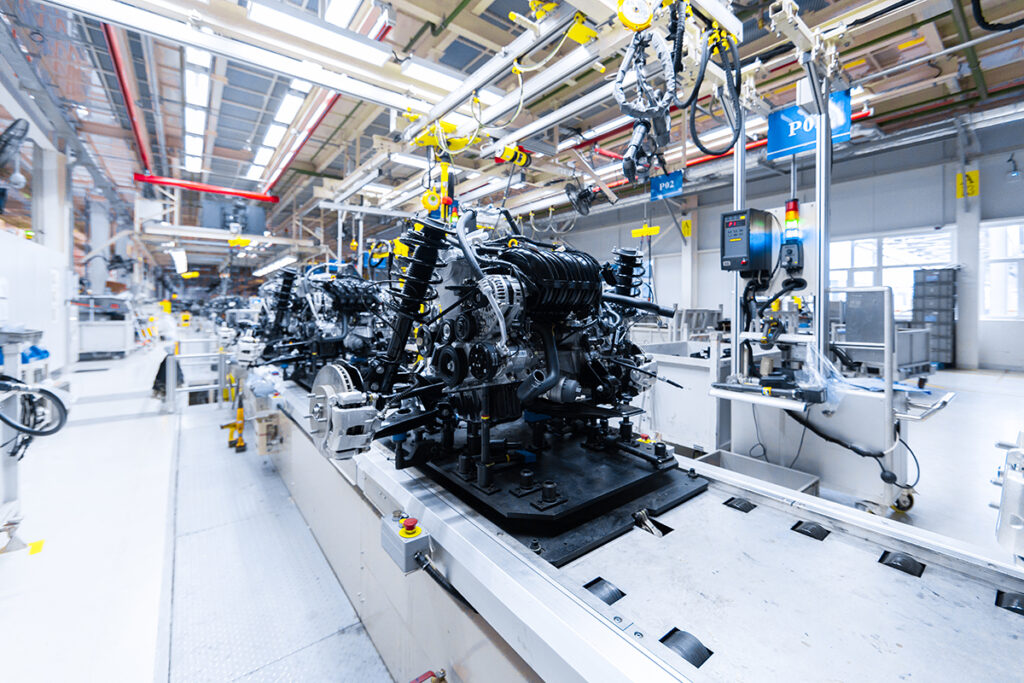

The manufacturing process for pump cars involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

The first step in manufacturing a pump car is material preparation. High-quality raw materials, such as steel, aluminum, and plastic composites, are essential for durability and performance. Suppliers typically source these materials from reputable vendors who adhere to international standards. During this stage, materials undergo inspection to ensure they meet specified chemical and physical properties.

Once materials are prepared, the forming process begins. Techniques such as stamping, casting, and machining are employed to shape components. For instance, metal parts may be stamped from sheets or cast into specific forms, while precision machining is used for critical components like pump housings and engine parts. Advanced technologies such as CNC machining and 3D printing are increasingly being utilized to enhance precision and reduce waste.

The assembly stage involves bringing together all the individual components to create a complete pump car. This process typically occurs on an assembly line, where workers or robotic systems meticulously fit parts together. Key considerations during assembly include ensuring that all connections are secure, verifying alignment, and integrating systems such as hydraulics and electronics. Quality assurance checkpoints are often established at this stage to catch any discrepancies early.

After assembly, the finishing process ensures the pump car meets aesthetic and functional standards. This may include painting, coating, or polishing components. Finishing not only enhances the appearance but also provides protection against environmental factors such as corrosion. Additionally, thorough cleaning is conducted to remove any contaminants that may have accumulated during manufacturing.

Quality assurance (QA) is critical in the pump car manufacturing process. B2B buyers should be aware of relevant international standards and industry-specific certifications that suppliers must adhere to.

ISO 9001 is the most widely recognized quality management standard, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements. Compliance with ISO 9001 signifies a commitment to continual improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking for European markets and API standards for oil and gas applications are crucial. These certifications indicate that the pump car meets safety and performance criteria established by regulatory bodies.

Quality control (QC) is implemented throughout the manufacturing process to ensure that the final product meets established standards. Key checkpoints include:

Incoming Quality Control (IQC) involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide certificates of compliance, and materials are tested for quality before being accepted into the production line. This step is crucial for preventing defects in the final product.

In-Process Quality Control (IPQC) occurs during the manufacturing stages. This includes monitoring processes such as welding, machining, and assembly. Regular inspections and testing at various stages help identify issues early, allowing for corrective actions to be taken promptly.

Final Quality Control (FQC) is conducted once the pump car is fully assembled. This comprehensive inspection ensures that all specifications are met and that the product functions correctly. Common tests include pressure testing, performance evaluations, and safety checks. Documentation of FQC results is essential for traceability.

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some actionable strategies:

Conducting supplier audits is one of the most effective ways to assess quality control processes. Audits provide insights into a supplier’s manufacturing practices, adherence to standards, and overall operational efficiency. Buyers should establish a schedule for regular audits to ensure ongoing compliance.

Buyers should request detailed quality control reports from suppliers, including IQC, IPQC, and FQC documentation. These reports should outline testing methods, results, and any corrective actions taken. This transparency is crucial for building trust and ensuring accountability.

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. Third-party inspectors can conduct audits, perform testing, and validate compliance with international standards. This added layer of scrutiny helps buyers mitigate risks associated with sourcing from international suppliers.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific quality control nuances when engaging with international suppliers.

Cultural differences can affect communication and expectations regarding quality assurance. Buyers should be clear about their quality requirements and ensure that suppliers understand these standards. Establishing a collaborative relationship can facilitate better alignment on quality goals.

Navigating different international standards can be complex. Buyers should familiarize themselves with the certifications and regulations relevant to their target markets. Working with suppliers who have experience in exporting to specific regions can help streamline compliance efforts.

By understanding the manufacturing processes and quality assurance practices involved in pump car production, B2B buyers can make informed decisions and establish reliable partnerships with suppliers. Emphasizing quality control not only enhances product reliability but also strengthens the overall supply chain.

To assist B2B buyers in procuring pump cars effectively, this guide provides a clear checklist to ensure that all critical aspects are considered. Following these steps will help streamline the sourcing process and enhance the likelihood of a successful purchase.

Illustrative image related to pump car

Before engaging with suppliers, it’s essential to establish the technical requirements for the pump car you need. Consider factors such as the intended application, capacity, and any specific features required (e.g., fuel type, power output, or operational capabilities). This clarity will help you communicate effectively with suppliers and ensure they meet your operational needs.

Identifying reputable suppliers is crucial for a successful procurement process. Look for companies with a proven track record in manufacturing or distributing pump cars. Utilize online resources, industry directories, and trade shows to gather a list of potential suppliers. Check their websites for product catalogs, certifications, and client testimonials to gauge their reliability.

Ensure that potential suppliers hold the necessary certifications and comply with industry standards. This may include ISO certifications, safety regulations, and environmental compliance. Valid certifications not only signify quality but also reduce the risk of operational disruptions due to non-compliance with local regulations in your region.

Once you have narrowed down potential suppliers, request detailed quotations that outline pricing, payment terms, and delivery schedules. A comprehensive quote will enable you to compare offers effectively. Pay attention to the terms of warranty and after-sales support, as these can significantly impact your long-term satisfaction with the pump car.

Illustrative image related to pump car

Evaluate the after-sales support offered by suppliers, as this is critical for the long-term performance of your pump car. Inquire about the availability of spare parts, service contracts, and technical support. A supplier that provides robust after-sales services can greatly reduce downtime and maintenance costs.

Before finalizing your decision, ask for references and case studies from suppliers to verify their credibility. Speaking with other clients who have purchased similar pump cars can provide valuable insights into the supplier’s reliability, product performance, and customer service. This step can reveal potential issues and help you make a more informed decision.

Once you have selected a supplier, engage in negotiations to finalize terms and conditions. Ensure that all aspects, including delivery timelines, payment schedules, and warranties, are clearly defined in the contract. A well-structured agreement will safeguard your interests and provide clarity on both sides.

By following this step-by-step checklist, B2B buyers can navigate the procurement process for pump cars with confidence, ensuring they make informed decisions that align with their operational requirements and business goals.

When sourcing pump cars, understanding the cost structure is crucial for making informed purchasing decisions. The primary components of cost include:

Materials: The choice of materials significantly impacts the overall cost. High-quality metals and durable plastics may raise the price but can lead to longer product life and reduced maintenance costs.

Labor: Labor costs can vary widely depending on the region and the complexity of manufacturing processes. Skilled labor may command higher wages but can also lead to superior craftsmanship.

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs.

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs, lowering per-unit costs.

Quality Control (QC): Investing in QC ensures that the pump cars meet industry standards and customer expectations. While this may add to upfront costs, it can prevent costly returns and rework.

Logistics: Transportation and warehousing are critical in determining the final cost. Factors such as shipping distances, fuel prices, and customs duties should be considered, particularly for international sourcing.

Margin: Suppliers will incorporate a margin into their pricing to cover risks and ensure profitability. Understanding typical margins in the industry can aid in negotiating better prices.

Several factors can influence pricing dynamics in pump car sourcing:

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to lower per-unit costs. Suppliers may offer discounts based on order size, making it advantageous for buyers to consolidate their purchases.

Specifications/Customization: Custom features or specifications can significantly impact pricing. While tailored solutions may come at a premium, they can provide competitive advantages in specific markets.

Materials: The choice of materials not only affects cost but also the performance and durability of the pump cars. Higher-grade materials typically command higher prices but can enhance product longevity.

Quality and Certifications: Certifications (e.g., ISO, CE) can be critical for international markets. Products with recognized quality certifications may have higher initial costs but can lead to lower total cost of ownership through reduced failures and warranty claims.

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established suppliers with a track record of quality may charge more but can offer peace of mind regarding product performance and service.

Incoterms: Understanding Incoterms is essential for managing shipping costs and responsibilities. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the products.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

Negotiate Wisely: Leverage volume purchasing power to negotiate better terms. Building a good relationship with suppliers can also yield favorable pricing and terms.

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also factors like maintenance, warranty, and energy consumption over the product’s lifespan. A lower upfront cost may not always translate to savings if the product requires frequent repairs.

Understand Pricing Nuances: Be aware that international pricing can vary due to tariffs, taxes, and currency fluctuations. Engaging with local experts or consultants can provide insights into market trends and pricing strategies.

Conduct Market Research: Investigate local suppliers and compare their offerings with international options. Sometimes local sourcing can provide cost advantages due to lower shipping and logistics costs.

Pricing for pump cars can fluctuate based on market conditions, raw material costs, and geopolitical factors. The prices mentioned herein are indicative and may not reflect the current market rates. Always conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

In the realm of transportation and logistics, pump cars serve a specific purpose, primarily in the construction and industrial sectors, where fluid movement is essential. However, businesses often seek alternative solutions that can provide similar or enhanced benefits. This section will analyze the pump car against two viable alternatives: the traditional truck-mounted pump and the newer vacuum truck technology. By comparing these options, B2B buyers can make informed decisions based on their operational needs.

| Comparison Aspect | Pump Car | Truck-Mounted Pump | Vacuum Truck |

|---|---|---|---|

| Performance | High efficiency in fluid transfer | Moderate efficiency, limited by hose length | High efficiency in both liquid and solid waste management |

| Cost | Moderate initial investment | Lower initial cost but higher operational costs | Higher initial investment but lower long-term costs |

| Ease of Implementation | Requires specialized training for operators | Easier for general drivers to operate | Requires specialized training for both operation and maintenance |

| Maintenance | Moderate maintenance requirements | Low maintenance, but wear on hoses can add costs | High maintenance due to complex systems |

| Best Use Case | Ideal for construction and pumping large volumes | Suitable for smaller jobs and general construction | Best for waste removal and diverse fluid transfer tasks |

Truck-mounted pumps are a common alternative to pump cars, especially in smaller construction projects. They are equipped with hoses that can reach a limited distance, making them suitable for localized tasks. The initial cost is generally lower than pump cars, but operational costs can accumulate due to wear and tear on hoses. Additionally, while they are relatively easy to operate, they may not provide the same level of efficiency as pump cars for larger projects.

Vacuum trucks represent a more advanced alternative, combining the capabilities of both liquid and solid waste management. They are effective for transporting fluids and can handle various materials, including sludge and debris. Although the initial investment is higher, vacuum trucks often result in lower long-term costs due to their versatility and efficiency. However, they require specialized training for operators and maintenance staff, which may pose a barrier for some companies. The complexity of their systems can lead to higher maintenance requirements compared to simpler solutions.

When evaluating whether to invest in a pump car or consider alternatives like truck-mounted pumps or vacuum trucks, businesses must weigh several factors. Understanding the specific operational requirements, budget constraints, and workforce capabilities is crucial in making an informed decision. For construction firms focusing on large-scale projects, pump cars may offer the best performance. In contrast, companies needing flexibility in waste management might find vacuum trucks to be the superior choice. Ultimately, aligning the choice with the company’s long-term strategy and immediate needs will lead to the most effective investment.

Understanding the essential technical properties of pump cars is crucial for B2B buyers, particularly in international markets where specifications can vary significantly. Here are several critical specifications to consider:

Material Grade

– Definition: The material grade indicates the type and quality of materials used in constructing the pump car, which can include metals, plastics, and composites.

– Importance: Higher-grade materials can enhance durability and performance, making them essential for heavy-duty applications. For buyers, selecting the right material grade ensures that the pump car can withstand specific operational conditions, such as temperature fluctuations and corrosive environments.

Flow Rate

– Definition: The flow rate measures the volume of fluid that the pump can move over a specific period, usually expressed in liters per minute (L/min) or gallons per minute (GPM).

– Importance: A higher flow rate is vital for applications requiring rapid fluid transfer. Buyers must assess their operational needs to choose a pump car with an appropriate flow rate to optimize efficiency and productivity.

Pressure Rating

– Definition: The pressure rating indicates the maximum pressure the pump can handle, typically measured in pounds per square inch (PSI) or bar.

– Importance: This specification is crucial for ensuring that the pump can perform effectively without risk of failure. B2B buyers need to match the pressure rating with their specific applications to prevent damage or operational downtime.

Tolerance Levels

– Definition: Tolerance levels refer to the permissible limits of variation in the dimensions and performance of the pump components.

– Importance: High tolerance levels ensure better fitting and operation, which can lead to improved reliability and less maintenance. Buyers should consider tolerance specifications to ensure compatibility with existing systems and components.

Energy Efficiency Rating

– Definition: This rating assesses how effectively the pump converts energy into hydraulic power, often expressed in terms of a percentage.

– Importance: Energy-efficient pumps can significantly reduce operational costs and environmental impact. For B2B buyers, selecting pumps with higher energy efficiency ratings aligns with sustainability goals and can lead to long-term savings.

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are several common trade terms relevant to pump cars:

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Buyers often prefer OEM parts for their reliability and compatibility. Understanding OEM specifications can help buyers make informed decisions about sourcing and quality.

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory planning. Buyers must evaluate whether the MOQ aligns with their purchasing needs and storage capabilities.

RFQ (Request for Quotation)

– Definition: An RFQ is a business document used to invite suppliers to provide a price estimate for specific products or services.

– Importance: Submitting an RFQ helps buyers compare costs and negotiate better deals. This process is particularly valuable for large orders or customized pump car specifications.

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms helps buyers manage shipping, delivery, and risk. This knowledge is crucial for international transactions, ensuring all parties are aligned on terms of delivery and liability.

Lead Time

– Definition: Lead time is the amount of time that passes from the initiation of a process until its completion, particularly in production and delivery.

– Importance: Knowing the lead time is vital for planning and inventory management. Buyers should factor lead times into their project timelines to avoid delays and ensure timely project execution.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, optimize procurement strategies, and enhance their operational efficiency when sourcing pump cars.

The pump car sector is experiencing significant transformation driven by various global factors. One of the primary market dynamics is the increasing demand for efficient transportation solutions across developing regions, particularly in Africa, South America, and the Middle East. These areas are witnessing rapid urbanization and infrastructure development, creating a robust market for pump cars that facilitate the movement of goods and people.

Emerging B2B technologies are also reshaping the sector. The integration of IoT (Internet of Things) in pump car systems allows for real-time monitoring and data analytics, enabling companies to optimize fleet management and reduce operational costs. Furthermore, automation and electric vehicles are gaining traction, reflecting a broader shift towards sustainable transportation solutions. International buyers, especially from regions like Vietnam and Saudi Arabia, are increasingly seeking partners that can provide innovative and reliable pump car solutions tailored to local conditions.

Moreover, fluctuating raw material prices and supply chain disruptions have prompted businesses to adopt agile sourcing strategies. Companies are prioritizing suppliers that demonstrate flexibility and reliability, ensuring they can meet changing market demands swiftly. The focus on total cost of ownership (TCO) is becoming essential, with buyers looking beyond initial acquisition costs to consider long-term maintenance and operational efficiency.

Sustainability is becoming a critical consideration for B2B buyers in the pump car sector. The environmental impact of production processes, resource consumption, and end-of-life disposal of vehicles is under scrutiny. Buyers are increasingly aware of the carbon footprint associated with their purchases and are seeking suppliers who prioritize eco-friendly practices.

Illustrative image related to pump car

Ethical sourcing is equally important, as companies strive to ensure their supply chains are transparent and responsible. This includes verifying that materials are sourced from suppliers who adhere to labor rights and environmental regulations. Certifications such as ISO 14001 for environmental management systems and ISO 26000 for social responsibility are becoming essential criteria for suppliers.

Additionally, the use of ‘green’ materials in the manufacturing of pump cars is gaining traction. Manufacturers that incorporate recycled or sustainably sourced materials not only reduce their environmental impact but also appeal to a growing segment of eco-conscious buyers. Implementing sustainable practices can enhance brand reputation and foster loyalty among customers who value corporate social responsibility.

The pump car, originally designed for transporting personnel and equipment along railway tracks, has evolved significantly since its inception in the 19th century. Initially, these vehicles were manually operated, but advancements in technology have led to the development of motorized versions, enhancing efficiency and safety.

Over the decades, the pump car has transitioned from a niche utility vehicle to an integral part of modern transportation networks, particularly in regions undergoing rapid industrialization. This evolution reflects broader trends in transportation, including the move towards automation and electric power, which are now shaping the future of the pump car market. For international B2B buyers, understanding this historical context is crucial for making informed sourcing decisions that align with current market trends and future innovations.

How do I solve issues related to pump car performance?

To address performance issues with pump cars, start by conducting a thorough inspection of the vehicle’s components, including the pump, hoses, and engine. Ensure that all mechanical parts are in good condition and free of leaks. Regular maintenance checks, including oil changes and filter replacements, can prevent many performance-related problems. If issues persist, consult with the manufacturer or a professional mechanic who specializes in pump cars for detailed diagnostics and solutions tailored to your specific model.

What is the best pump car for construction projects?

The best pump car for construction projects should be durable, versatile, and capable of handling various terrains. Look for models equipped with high-capacity pumps, strong engines, and rugged tires designed for off-road conditions. Additionally, consider vehicles that offer customizable features to suit specific project needs, such as adjustable pump settings and enhanced load-bearing capabilities. Research brands with a proven track record in construction to ensure reliability and support.

What are the key factors to consider when sourcing a pump car supplier?

When sourcing a pump car supplier, evaluate their reputation in the industry, customer reviews, and the quality of their products. Verify their manufacturing certifications and compliance with international safety standards. Assess their capacity for customization to meet your specific needs, and inquire about their supply chain reliability. Establishing clear communication and a good relationship with the supplier can also enhance collaboration and ensure timely delivery.

What customization options are available for pump cars?

Customization options for pump cars often include modifications to engine power, pump capacity, and vehicle size. Buyers can also request features like enhanced safety equipment, specialized control systems, or additional storage compartments. Discuss your specific requirements with potential suppliers to explore available configurations. Customization can significantly improve operational efficiency and ensure the vehicle meets the unique demands of your projects.

What is the minimum order quantity (MOQ) for pump cars?

The minimum order quantity (MOQ) for pump cars can vary significantly between manufacturers and models. Generally, larger manufacturers may require higher MOQs, while smaller suppliers might be more flexible. It’s advisable to communicate your needs directly with suppliers to negotiate the best terms. Some manufacturers may offer sample units or lower quantities for first-time buyers, allowing you to evaluate the product before committing to a larger order.

What payment terms should I expect when purchasing a pump car?

Payment terms for pump cars typically include options such as upfront payments, installment plans, or letters of credit. Many suppliers prefer a deposit to secure the order, followed by the balance upon delivery or within a specified period after receipt. Always clarify the payment terms before finalizing the purchase to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and payment processing fees, especially in international transactions.

How can I ensure quality assurance (QA) for pump cars?

To ensure quality assurance (QA) for pump cars, request documentation of the manufacturer’s quality control processes and certifications. Conduct factory visits if possible, or arrange for third-party inspections to verify the vehicle’s compliance with industry standards. Establish a clear agreement on warranty terms and after-sales support. Regular maintenance and service checks post-purchase are also crucial for maintaining the vehicle’s performance over time.

What logistics considerations should I keep in mind when importing pump cars?

When importing pump cars, consider logistics factors such as shipping methods, customs regulations, and transportation costs. Ensure that you have all necessary documentation, including import permits and compliance certificates. Partnering with a reliable logistics provider can streamline the shipping process and help navigate any potential challenges. Additionally, factor in lead times for delivery and any potential delays at customs to better plan your project timelines.

Domain: lasfit.com

Registered: 2016 (9 years)

Introduction: Lasfit Tire Inflator | Portable Tire Pumps for Pickup Trucks & Large SUVs & Off-Road Vehicles. Key features include fast inflation, accurate pressure readings, compact design for easy storage, multi-purpose use for car tires, bikes, motorcycles, and more, digital display with auto shut-off for precise inflation. Designed for 12V DC outlets, built with durable components for long-lasting performanc…

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Car Pumps & Air Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: jdpower.com

Registered: 1995 (30 years)

Introduction: A water pump in a car is a component of the vehicle’s cooling system that circulates coolant through the engine to help regulate its temperature. It is typically located near the front of the engine block and is driven by the engine’s belts. The water pump plays a critical role in maintaining the engine’s proper operating temperature; if it fails, the engine can become damaged or seized.

Functio…

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car Tire Inflator for sale on eBay. Brands include Craftsman, DEWALT, Hitachi, Ingersoll Rand, Campbell Hausfeld, Milwaukee, VIAIR, Unbranded, PORTER-CABLE, Makita, Ryobi. Voltage options available: 120 V, 12 V, 110 V, 220 V, 230 V, 240 V, 18 V, 115 V, 460 V, 24 V. Related products include Portable Air Compressors, Portable Tank Air Compressors, Air Compressors Tanks, Automotive Air Chucks, Pressu…

In today’s competitive landscape, strategic sourcing is essential for maximizing value in the pump car market. By carefully evaluating suppliers, assessing total cost of ownership, and prioritizing quality and reliability, international B2B buyers can enhance their operational efficiency and reduce long-term expenses. The integration of advanced technology in pump car design—such as digital displays and auto shut-off features—underscores the importance of sourcing innovative products that meet evolving market demands.

As businesses expand into regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics and regulatory standards becomes crucial. Collaborating with trusted suppliers who have a strong presence in these regions can facilitate smoother transactions and ensure compliance with local regulations.

Looking ahead, the pump car industry is poised for growth, driven by increasing infrastructure investments and the need for reliable transportation solutions. International buyers are encouraged to leverage strategic sourcing practices to not only navigate current challenges but also position themselves for future opportunities. Embrace this chance to enhance your supply chain and stay ahead of the competition by sourcing high-quality pump cars that align with your business objectives.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.