The global market for slime portable air compressors presents a unique challenge for B2B buyers seeking reliable and efficient tire inflators. With the increasing demand for versatile and portable solutions, sourcing the right air compressor can significantly impact operational efficiency, especially in regions like Africa, South America, the Middle East, and Europe, including key markets such as Saudi Arabia and Germany. This guide aims to equip international buyers with essential insights into the diverse types of slime portable air compressors available, their various applications, and the critical factors to consider during the supplier vetting process.

Navigating the complexities of the global supply chain can be daunting, but understanding product specifications, pricing structures, and supplier reputations can empower businesses to make informed purchasing decisions. This comprehensive resource will delve into the latest innovations in tire inflators, explore their practical applications across different sectors, and provide actionable strategies for evaluating potential suppliers.

By arming B2B buyers with the necessary knowledge and tools, this guide facilitates smarter investment choices, ensuring that companies can procure the most suitable slime portable air compressors to meet their specific needs. Whether you are involved in automotive services, construction, or outdoor recreational activities, our insights will help streamline your sourcing process and enhance your operational capabilities.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12V Tire Inflator | Compact, powered by vehicle’s battery, ideal for on-the-go needs | Automotive repair shops, roadside assistance | Pros: Portable, cost-effective. Cons: Limited power for larger tires. |

| Cordless Tire Inflator | Battery-operated, offers mobility without cords | Emergency services, outdoor equipment rental | Pros: High portability, no need for an external power source. Cons: Battery life may be limited. |

| Dual Power Tire Inflator | Operates on both 120V AC and 12V DC, versatile for home and road use | Fleet management, automotive service centers | Pros: Flexible power options, ideal for various settings. Cons: Heavier due to dual power capability. |

| Digital Tire Inflator | Features digital display for accurate pressure readings | Tire shops, automotive manufacturing | Pros: Precision in inflation, easy-to-use interface. Cons: May be more expensive than analog models. |

| Multi-Purpose Inflator | Versatile design for inflating tires, sports equipment, and more | Sporting goods stores, event organizers | Pros: Multifunctional, suitable for diverse applications. Cons: May lack specialized features for tire inflation. |

The 12V Tire Inflator is a compact solution primarily designed for quick inflations using a vehicle’s battery. This type is particularly suitable for automotive repair shops and roadside assistance services, where rapid response is crucial. B2B buyers should consider its portability and affordability, but note that it may struggle with larger tires due to limited power output.

Cordless Tire Inflators provide unmatched mobility, allowing users to inflate tires without being tethered to an electrical outlet. This feature is especially beneficial for emergency services and outdoor equipment rental businesses. While they offer significant advantages in portability, potential buyers should evaluate battery life and charging time to ensure they meet operational demands.

The Dual Power Tire Inflator can operate on both 120V AC and 12V DC, making it a versatile option for various environments, from home garages to roadside settings. This flexibility makes it ideal for fleet management and automotive service centers. Buyers should be aware that while it offers great functionality, its dual power capabilities may result in a heavier unit, impacting portability.

Digital Tire Inflators are equipped with a digital display that provides accurate pressure readings, making them ideal for tire shops and automotive manufacturing environments where precision is paramount. While they enhance user experience with easy-to-read interfaces, buyers should consider the higher investment compared to traditional analog inflators.

Multi-Purpose Inflators are designed to cater to a variety of inflating needs, including tires and sports equipment, making them suitable for sporting goods stores and event organizers. Their versatility is a significant advantage, but potential buyers should assess whether they require specialized features for tire inflation, as these may be lacking in more generalized models.

| Industry/Sector | Specific Application of slime portable air compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and emergency roadside assistance | Reduces downtime and improves customer satisfaction | Durability, portability, and ease of use in various conditions |

| Construction | Inflating construction equipment tires | Ensures equipment readiness and minimizes project delays | Power supply options, rugged design for job site use |

| Fleet Management | Regular maintenance of vehicle tire pressure | Enhances vehicle performance and fuel efficiency | Bulk purchasing, compatibility with diverse vehicle types |

| Outdoor Recreation | Inflation of recreational vehicle tires and gear | Supports customer engagement and enhances outdoor experiences | Lightweight, compact design for portability |

| Agriculture | Maintaining tire pressure of farm equipment | Increases efficiency and productivity of farming operations | Adaptability to various farm equipment and conditions |

In automotive repair, the slime portable air compressor is essential for tire inflation and emergency roadside assistance. It enables quick repairs, reducing vehicle downtime, which is crucial for maintaining a steady flow of customers. For international buyers, especially in regions like Africa and the Middle East, the compressor’s durability and ease of use in diverse weather conditions are significant considerations. The ability to operate on both 12V and 120V power sources adds to its versatility, allowing for use in a wide range of settings.

In the construction sector, the slime portable air compressor is vital for inflating tires on various heavy machinery, ensuring that equipment is always ready for operation. This capability minimizes project delays caused by equipment failures, thus enhancing overall productivity. Buyers in South America and Europe should focus on sourcing models that are rugged and capable of withstanding the demanding environments typical of construction sites. Additionally, features like a dual power supply can be advantageous for flexibility on-site.

Fleet management companies rely on slime portable air compressors for regular tire pressure maintenance across their vehicles. Proper tire inflation is crucial for optimizing fuel efficiency and enhancing vehicle performance. For B2B buyers in regions such as Germany, considerations should include the compressor’s compatibility with a variety of vehicle types and the ability to handle high usage rates. Bulk purchasing options can also provide cost savings for large fleets.

In the outdoor recreation industry, the slime portable air compressor is used to inflate tires for recreational vehicles, bicycles, and various gear. This application enhances customer engagement by ensuring that users are ready for their adventures without unnecessary delays. International buyers, particularly in the Middle East and Africa, should prioritize lightweight and compact models that are easy to transport. The ability to operate without a direct power source can also be a significant advantage in remote locations.

In agriculture, maintaining proper tire pressure on farm equipment is critical for efficiency and productivity. The slime portable air compressor allows farmers to quickly inflate tires on tractors and other machinery, reducing downtime during critical planting and harvesting periods. Buyers in agricultural sectors should look for compressors that can adapt to various equipment types and withstand harsh outdoor conditions. Additionally, features that enhance portability will enable farmers to address tire issues quickly, ensuring continuous operation.

The Problem: B2B buyers, particularly those in sectors like automotive services or logistics, often face challenges when sourcing reliable portable air compressors. With numerous brands and models available, it can be overwhelming to find a product that meets the quality and performance standards required for their operations. This is particularly true in regions such as Africa and the Middle East, where access to dependable supply chains may be limited. Buyers may also struggle with ensuring that the products are compatible with local power standards, leading to potential operational downtime.

The Solution: To address sourcing challenges, B2B buyers should conduct thorough market research and establish relationships with reputable suppliers of slime portable air compressors. This includes evaluating suppliers’ certifications, customer reviews, and product warranties. Additionally, buyers should seek out models that offer dual power options (e.g., 12V and 120V), as this versatility allows for use in various environments and reduces compatibility issues. Engaging in direct conversations with manufacturers can provide insight into product specifications and performance metrics, ensuring the selected compressor meets the specific needs of their operations.

The Problem: Businesses operating in harsh climates, such as the extreme heat of Saudi Arabia or the humid conditions in parts of South America, often encounter performance issues with portable air compressors. These environmental factors can lead to overheating, reduced efficiency, and even equipment failure. B2B buyers may find that many compressors are not designed to withstand such conditions, leading to increased maintenance costs and operational disruptions.

The Solution: To mitigate performance issues, B2B buyers should prioritize models specifically designed for rugged use, like the Slime Pro Power Compact Tire Inflator, which is engineered to handle extreme temperatures and demanding conditions. Buyers should also consider investing in additional accessories such as cooling fans or insulated storage solutions to protect the compressors when not in use. Furthermore, implementing a regular maintenance schedule that includes checking for wear and tear can help prolong the lifespan of the equipment and ensure consistent performance.

The Problem: A common pain point for B2B buyers is ensuring that their team is adequately trained to use portable air compressors efficiently. In many cases, inadequate training can lead to improper usage, resulting in damage to the equipment or ineffective inflation. This is particularly critical in industries where time is money, as downtime due to operator error can significantly impact productivity.

The Solution: To enhance operational efficiency, companies should develop a comprehensive training program focused on the proper use and maintenance of slime portable air compressors. This program could include hands-on workshops and detailed manuals that cover troubleshooting common issues and optimizing compressor settings for different applications. Additionally, leveraging digital platforms for training can facilitate ongoing education and allow new employees to learn at their own pace. By investing in training, companies can minimize operational risks and ensure that their teams are proficient in using the equipment, ultimately leading to improved productivity and reduced costs.

When selecting materials for slime portable air compressors, it is essential to consider factors such as durability, performance, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of these compressors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

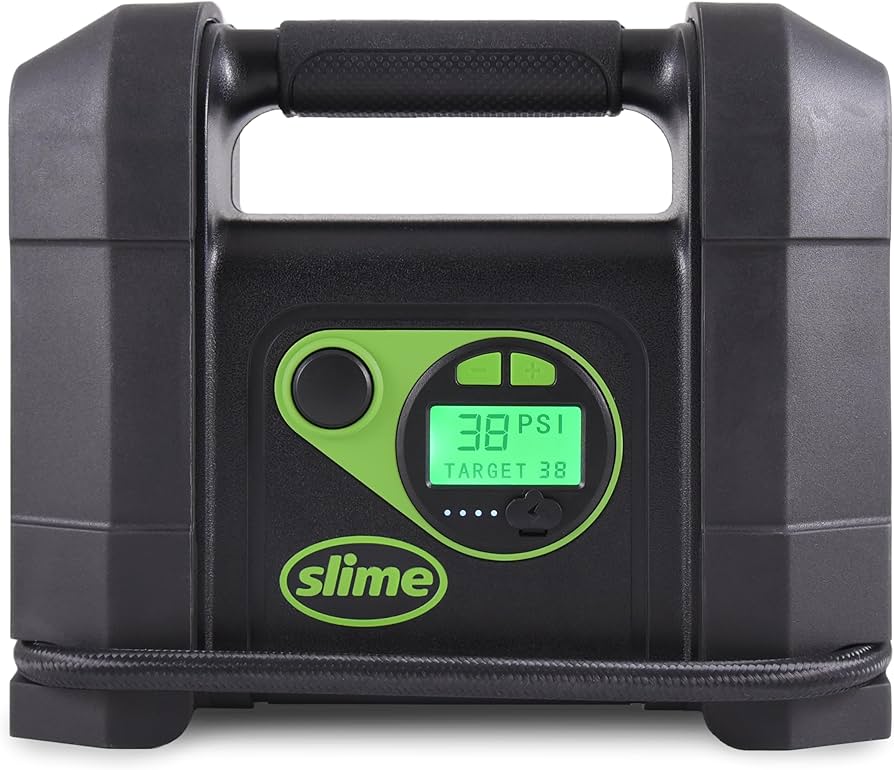

Illustrative image related to slime portable air compressor

Plastic is often used in the casing and certain internal components of portable air compressors. Key properties include lightweight nature, resistance to corrosion, and good thermal stability. Plastics like ABS (Acrylonitrile Butadiene Styrene) can withstand moderate temperatures and pressures, making them suitable for housing and non-structural components.

Pros: Plastics are generally cost-effective, lightweight, and easy to mold into complex shapes, which simplifies manufacturing. They also provide good insulation against heat and electricity.

Cons: However, plastics may not withstand high temperatures or pressures as effectively as metals. They can be prone to degradation under UV exposure and may not be suitable for heavy-duty applications.

Impact on Application: Plastic components are often used in consumer-grade compressors where weight and cost are critical. However, they may not be ideal for industrial applications requiring high durability.

Illustrative image related to slime portable air compressor

Considerations for International Buyers: Buyers from regions with high UV exposure, such as parts of Africa and the Middle East, should consider UV-resistant plastics. Compliance with international standards like ASTM for material properties is also essential.

Aluminum is frequently used in the construction of compressor housings and internal components due to its favorable strength-to-weight ratio and corrosion resistance. It can typically handle moderate pressure and temperature levels, making it a versatile choice.

Pros: Aluminum is lightweight, resistant to corrosion, and offers good thermal conductivity. Its strength allows for a compact design, which is vital for portable applications.

Cons: The primary drawback is that aluminum can be more expensive than plastic and may require additional surface treatments to enhance corrosion resistance.

Impact on Application: Aluminum is suitable for both consumer and light industrial applications, providing a balance between performance and weight.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure that the aluminum used meets local standards such as DIN or JIS. Additionally, the cost of aluminum may fluctuate based on global market conditions, affecting pricing strategies.

Steel is often utilized for structural components and high-stress parts of portable air compressors. Its key properties include high tensile strength, excellent durability, and resistance to deformation under pressure.

Pros: Steel is known for its robustness and longevity, making it ideal for heavy-duty applications. It can withstand high temperatures and pressures, ensuring reliability in demanding environments.

Cons: The main disadvantages include susceptibility to rust and corrosion if not properly treated, as well as a heavier weight compared to aluminum or plastic.

Impact on Application: Steel components are ideal for industrial-grade compressors that require high durability and performance. However, the added weight may be a concern for portable applications.

Considerations for International Buyers: Buyers should ensure that steel components comply with relevant standards, such as ASTM for the U.S. market or EN standards for Europe. Corrosion resistance treatments may also be necessary for regions with high humidity.

Rubber is commonly used in seals, gaskets, and hoses within portable air compressors. Its key properties include flexibility, resistance to wear, and the ability to maintain a seal under varying pressure conditions.

Pros: Rubber provides excellent sealing capabilities and can withstand a range of temperatures and pressures. It is also relatively inexpensive and easy to manufacture.

Cons: However, rubber can degrade over time, especially when exposed to oils, fuels, and UV light. This limits its lifespan and may necessitate more frequent replacements.

Impact on Application: Rubber components are essential for ensuring airtight seals in compressors, which is critical for performance.

Considerations for International Buyers: Buyers should consider the specific rubber grades used, as some may be more suitable for tropical climates found in Africa and South America. Compliance with international standards for material safety and performance is also crucial.

Illustrative image related to slime portable air compressor

| Material | Typical Use Case for slime portable air compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-structural components | Lightweight and cost-effective | Limited durability under high stress | Low |

| Aluminum | Housing and internal components | Corrosion-resistant and strong | Higher cost and requires treatments | Medium |

| Steel | Structural and high-stress components | High durability and strength | Susceptible to rust if untreated | Medium |

| Rubber | Seals, gaskets, and hoses | Excellent sealing capabilities | Degrades over time with exposure | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with their operational needs and regional compliance requirements.

The manufacturing of Slime portable air compressors involves a systematic approach to ensure durability, efficiency, and user satisfaction. The primary stages in the manufacturing process include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the careful selection and preparation of raw materials, such as high-grade plastics, metals, and electronic components. Manufacturers typically source these materials from reputable suppliers who adhere to international quality standards. This stage often includes inspections of incoming materials to verify their compliance with specifications.

Forming: In this stage, raw materials are transformed into usable components through techniques such as injection molding, stamping, and machining. Injection molding is particularly common for creating plastic casings, ensuring that parts are lightweight yet robust. For metal components, processes like CNC machining guarantee precision and durability, essential for the compressor’s performance.

Assembly: The assembly stage involves the integration of all components into a finished product. This is often done on an assembly line where skilled workers or automated systems ensure that each unit is assembled to specification. Quality control is integrated into this stage, with checkpoints to catch defects early.

Finishing: Finally, the compressors undergo finishing processes, which may include painting, labeling, and packaging. This stage not only enhances the product’s aesthetic appeal but also adds protective coatings that can improve durability. The compressors are then prepared for shipment, ensuring that they meet all regulatory requirements.

Quality assurance is a critical component of the manufacturing process, especially for products that demand reliability and safety. Manufacturers typically follow international standards such as ISO 9001, which outlines a framework for quality management systems.

International Standards: Compliance with ISO 9001 ensures that manufacturing processes are consistent and meet customer expectations. Additionally, certifications such as CE mark for the European market and API standards for specific industrial applications provide further assurance of quality and safety.

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection checks raw materials against predefined criteria.

– In-Process Quality Control (IPQC): During the assembly phase, random checks are performed to ensure that manufacturing processes are being followed and that products meet specified standards.

– Final Quality Control (FQC): Before packaging, each air compressor undergoes a thorough inspection to verify functionality and safety, including performance tests to ensure they meet inflation and pressure specifications.

Testing Methods: Common testing methods include pressure testing, durability testing, and performance evaluation under various conditions. These tests are crucial in identifying any potential failures before the product reaches the market.

For international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality management systems. This can be done through on-site visits or by reviewing their quality assurance documentation.

Requesting Quality Reports: Buyers should request detailed quality control reports that outline the results of inspections and testing. These documents should provide evidence of compliance with international standards and highlight any corrective actions taken for non-conformities.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s manufacturing capabilities and quality standards. These services can also verify certifications and compliance with relevant industry standards.

Navigating quality control nuances is particularly important for international buyers who may face challenges such as varying standards and regulations across different regions.

Understanding Regional Standards: Buyers must be aware of the specific quality standards applicable in their regions. For example, products sold in Europe must comply with CE marking requirements, while those in the Middle East may need to meet specific local regulations.

Cultural and Language Barriers: Effective communication is key in ensuring that quality expectations are understood and met. Buyers should consider working with local representatives who can bridge any cultural or language gaps.

Logistics and Supply Chain Considerations: The logistics of transporting products across borders can impact quality. Buyers should ensure that their suppliers have robust logistics and handling processes to prevent damage during transport.

The manufacturing processes and quality assurance protocols for Slime portable air compressors are designed to deliver reliable, high-quality products that meet the needs of B2B buyers. By understanding the stages of manufacturing, quality control measures, and verification strategies, international buyers can make informed purchasing decisions that ensure they receive products that align with their business standards and customer expectations. As markets continue to evolve, maintaining a focus on quality and compliance will be essential for success in the global marketplace.

To assist B2B buyers in the procurement of Slime portable air compressors, this guide outlines a practical checklist that ensures a successful sourcing process. By following these steps, you can make informed decisions that align with your operational needs and market demands.

Establishing clear technical specifications is the foundation of your procurement process. Consider the power source (12V, cordless), pressure capacity, and intended use (automotive, multi-purpose). This will help narrow down your options and ensure that the compressors you evaluate meet the requirements of your target market.

Understanding market trends is crucial to sourcing the right product. Research the specific needs of your target regions, such as Africa, South America, the Middle East, and Europe. Evaluate factors like consumer preferences for portability, power options, and additional features, which can significantly impact your sales strategy.

Before making any commitments, conduct thorough evaluations of potential suppliers. Request detailed company profiles, product catalogs, and case studies to understand their capabilities. Look for reviews or references from other buyers in your region to gauge reliability and customer satisfaction.

Ensure that any suppliers you consider have the necessary certifications and compliance with international standards. This includes safety certifications and quality management systems such as ISO 9001. Compliance not only ensures product safety but also enhances your credibility when reselling in your market.

Before finalizing a supplier, request samples of the Slime portable air compressors you are interested in. Testing samples allows you to evaluate performance, durability, and ease of use. Pay attention to factors like inflation speed, noise levels, and user-friendliness, as these will influence customer satisfaction.

Pricing is a critical factor in your procurement decision. Compare quotes from multiple suppliers while considering total cost, including shipping and any additional fees. Additionally, review payment terms to ensure they align with your budget and cash flow requirements.

Illustrative image related to slime portable air compressor

Once you have selected a supplier, outline your logistics and distribution strategy. Consider factors such as shipping methods, lead times, and warehousing solutions. A clear logistics plan will ensure timely delivery and maintain customer satisfaction, which is crucial for repeat business.

By following this checklist, you can streamline your sourcing process for Slime portable air compressors, ensuring that you meet both your operational needs and market demands effectively.

When sourcing Slime portable air compressors, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The quality of materials used significantly impacts costs. High-quality plastics and metals are essential for durability and efficiency, but they also raise the base cost of the product. Buyers should consider suppliers that offer a balance between quality and cost.

Labor: Labor costs can vary based on the manufacturing location. For instance, labor in Southeast Asia may be lower than in Europe or the U.S., but this can also affect quality. Evaluating the labor practices of a supplier can provide insights into the overall quality and ethical standards of the product.

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance costs incurred during production. Buyers should inquire about the supplier’s operational efficiencies, which can influence pricing.

Tooling: Customization often requires specialized tooling, which can be a significant upfront investment. Understanding the tooling costs can help buyers gauge the potential for additional charges related to customized orders.

Quality Control (QC): Robust QC measures ensure product reliability and safety. Suppliers with stringent QC practices may charge higher prices, but this often translates into fewer defects and lower warranty claims.

Logistics: Transportation and shipping costs can vary based on the origin of the product and the destination. Consideration of local tariffs, import duties, and shipping methods is crucial for accurate total cost calculations.

Margin: Suppliers typically build a profit margin into the pricing structure. This margin can vary widely, influenced by brand reputation, market demand, and competitive landscape.

Several factors can influence the pricing of Slime portable air compressors, impacting the overall cost for B2B buyers.

Volume/MOQ: Buying in bulk often reduces the per-unit cost. Understanding the minimum order quantities (MOQ) set by suppliers can enable buyers to negotiate better pricing.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials: The choice of materials not only affects the cost but also the product’s performance and longevity. Buyers should weigh the benefits of premium materials against budget constraints.

Quality Certifications: Products that meet international quality standards may come at a premium but can be crucial for market acceptance, especially in regulated markets.

Supplier Factors: The reputation and reliability of the supplier can greatly influence pricing. Well-established suppliers may charge more due to their track record of quality and service.

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks during shipping. This knowledge can help buyers make informed decisions about their total landed costs.

B2B buyers should adopt effective negotiation strategies to ensure cost-efficiency when sourcing Slime portable air compressors.

Illustrative image related to slime portable air compressor

Research and Benchmarking: Buyers should conduct thorough market research to understand average pricing and industry standards. This knowledge provides leverage in negotiations.

Building Relationships: Establishing strong relationships with suppliers can lead to better pricing and more favorable terms. Long-term partnerships often yield discounts and improved service.

Discussing Total Cost of Ownership: Buyers should consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, warranties, and potential downtime costs.

Flexibility in Order Size: Negotiating terms based on flexibility with order sizes can lead to better pricing structures. Suppliers may offer discounts for larger orders or allow for staggered deliveries to reduce upfront costs.

Understanding Pricing Nuances: International buyers should be aware of pricing nuances influenced by currency fluctuations, local market conditions, and regional economic factors.

Prices for Slime portable air compressors can fluctuate based on the aforementioned factors, including market demand and supplier pricing strategies. It is advisable for buyers to obtain quotes from multiple suppliers and consider all cost components to arrive at a well-informed decision.

In the realm of tire inflation solutions, the Slime Portable Air Compressor stands out as a popular choice among B2B buyers. However, various alternatives exist that may better suit specific operational needs and preferences. This analysis compares the Slime Portable Air Compressor with two viable alternatives: the traditional air compressor and the battery-operated tire inflator. Each option has distinct characteristics that can influence purchasing decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Slime Portable Air Compressor | Traditional Air Compressor | Battery-Operated Tire Inflator |

|---|---|---|---|

| Performance | Quick inflation for small tires, reliable for emergencies | High airflow, suitable for larger tires and multiple uses | Convenient for small jobs, portable but limited power |

| Cost | Moderate (approx. $50-$100) | Higher initial investment (approx. $200-$500) | Low to moderate (approx. $30-$80) |

| Ease of Implementation | Plug-and-play; user-friendly | Requires setup and space | Simple to use; no cords needed |

| Maintenance | Low maintenance; occasional sealant replacement | Regular maintenance needed for optimal performance | Minimal maintenance; battery replacement as needed |

| Best Use Case | Roadside emergencies, personal vehicles | Garage use, heavy-duty applications | Light tasks, personal vehicles, and emergencies |

1. Traditional Air Compressor

Traditional air compressors are robust machines designed for extensive use in both commercial and personal settings. They deliver high air pressure and volume, making them ideal for inflating larger tires or multiple tires simultaneously. However, they come with a higher upfront cost and require more space, which can be a limitation for some businesses. Additionally, regular maintenance is necessary to ensure efficiency, which could lead to increased operational costs. They are best suited for workshops or garages where heavy-duty inflation is frequent.

2. Battery-Operated Tire Inflator

Battery-operated tire inflators offer a portable and convenient solution for quick inflation tasks. They are lightweight and do not require any external power source, making them ideal for roadside emergencies or personal use. However, their performance may be limited by battery life and power, making them less effective for larger vehicles. The lower cost makes them accessible for small businesses or individuals, but they may not be suitable for heavy-duty applications. Maintenance is minimal, requiring only occasional battery replacements.

When selecting the appropriate tire inflation solution, B2B buyers must consider their specific operational needs. The Slime Portable Air Compressor is excellent for quick, emergency inflation tasks, particularly in regions where roadside assistance may not be readily available. For businesses requiring high-performance capabilities, a traditional air compressor may be more suitable despite its higher cost and maintenance requirements. Conversely, battery-operated tire inflators provide a cost-effective and portable option, ideal for light tasks and personal use. By evaluating these factors, businesses can make informed decisions that align with their operational requirements and budget constraints.

When assessing the Slime portable air compressor, several technical properties are critical for B2B buyers to consider:

Power Source

Slime compressors are typically powered by 12V DC or 120V AC, with some models offering dual power options. Understanding the power source is essential for businesses operating in diverse markets, as it influences usability in various environments. For instance, a 12V model is ideal for automotive applications, while a 120V model suits home or garage settings.

Inflation Rate

Measured in liters per minute (L/min), the inflation rate indicates how quickly a tire can be inflated. A higher inflation rate reduces downtime for vehicles, making it a crucial factor for businesses in logistics or transportation. Buyers should evaluate their specific needs based on vehicle types and tire sizes to ensure optimal performance.

Maximum Pressure

The maximum pressure, typically measured in PSI (pounds per square inch), determines the compressor’s capability to inflate various tire types. Most Slime models can reach pressures of 30 to 150 PSI. This specification is vital for B2B buyers, particularly those in industries like automotive repair or fleet management, where different tire pressures are required.

Durability and Build Quality

The material used in the compressor’s housing and internal components affects its longevity and reliability. Buyers should look for models constructed from high-grade plastics or metals that can withstand harsh environments, especially in markets with extreme weather conditions. A durable compressor translates to lower replacement costs and enhanced reliability.

Portability Features

Weight, size, and the presence of built-in handles or storage compartments are important for ease of transport. A lightweight and compact design is essential for businesses that require frequent mobility, such as roadside assistance services. Ensuring that the compressor is easy to store and carry can significantly enhance operational efficiency.

Noise Level

Measured in decibels (dB), the noise level of a compressor can impact user comfort and compliance with local regulations, especially in residential areas. Lower noise levels are preferable for B2B applications that involve customer interactions or work in noise-sensitive environments.

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are several key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Slime compressors, understanding OEM relationships is vital for buyers looking for authentic parts or seeking to establish partnerships with manufacturers for resale.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products a supplier is willing to sell. This term is essential for B2B buyers to understand as it affects inventory management and initial investment costs. Buyers should negotiate MOQs that align with their sales forecasts to optimize cash flow.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request price and delivery information for specific products. This term is important for B2B buyers as it helps streamline the procurement process, ensuring that they receive competitive pricing and terms from multiple suppliers.

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. These terms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding Incoterms is critical for B2B buyers engaged in cross-border transactions involving Slime portable air compressors.

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This is crucial for B2B buyers as it affects inventory levels and operational efficiency. Knowing the lead times for different suppliers can help businesses plan their inventory more effectively.

Warranty Period

The warranty period is the duration during which a product is guaranteed against defects. For Slime compressors, understanding warranty terms can protect B2B buyers from unforeseen repair costs and influence purchasing decisions based on reliability and support.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions regarding the procurement of Slime portable air compressors, ultimately enhancing their operational efficiency and customer satisfaction.

The global market for portable air compressors, particularly the Slime brand, is experiencing notable growth driven by several factors. First, the increasing prevalence of road travel and outdoor activities is boosting demand for tire maintenance products. As international markets in Africa, South America, the Middle East, and Europe expand, the need for reliable, portable solutions for tire inflation is becoming critical. In regions like Saudi Arabia and Germany, where vehicular travel is integral, the demand for efficient and durable tire inflators is particularly pronounced.

Emerging technologies are reshaping sourcing trends in this sector. The rise of smart technology integration into portable air compressors—such as Bluetooth connectivity for monitoring tire pressure—offers significant value to B2B buyers seeking innovative solutions. Additionally, the trend towards multi-functional devices, such as those that combine inflating capabilities with battery charging or emergency lighting, is appealing to diverse market segments. Buyers are increasingly looking for products that not only serve a singular purpose but can also provide added convenience and safety features.

Moreover, the competitive landscape is evolving as new entrants and established brands innovate to capture market share. B2B buyers must stay informed about these dynamics, focusing on suppliers who demonstrate adaptability and responsiveness to changing consumer preferences. Collaboration with manufacturers who prioritize quality assurance and customer service will be essential for securing reliable sourcing channels.

Sustainability is no longer just a buzzword; it has become a critical consideration for B2B buyers, especially in the portable air compressor sector. Environmental impact assessments are increasingly influencing purchasing decisions, with buyers prioritizing products that minimize ecological footprints. The use of eco-friendly materials and energy-efficient technologies in the production of Slime portable air compressors is vital for meeting the expectations of environmentally-conscious consumers.

Ethical sourcing practices also play a significant role in the decision-making process. Buyers are keen on partnering with suppliers who uphold fair labor practices and transparency throughout their supply chains. This is particularly relevant in regions where regulatory frameworks may vary, and suppliers must demonstrate compliance with international standards. B2B buyers should seek out manufacturers that possess certifications indicating sustainable practices, such as ISO 14001 for environmental management or certifications related to recycled materials.

Illustrative image related to slime portable air compressor

Furthermore, the shift towards circular economy principles is gaining traction. Products designed for longevity, reparability, and recyclability not only appeal to consumers but also enhance brand reputation. For international buyers, aligning with suppliers that prioritize sustainability can lead to enhanced market positioning and customer loyalty.

The evolution of the Slime portable air compressor reflects broader trends in consumer needs and technological advancements. Initially designed primarily for basic tire inflation, these compressors have transformed into multifunctional devices that cater to a variety of automotive and recreational needs. The introduction of digital pressure gauges and automatic shut-off features has significantly improved user experience, making it easier for consumers to achieve optimal tire pressure without guesswork.

Over the years, Slime has expanded its product line to include cordless options and models that cater to specific markets, such as off-road enthusiasts and cyclists. This adaptability has allowed the brand to maintain relevance in a competitive market, appealing to a diverse audience across different regions. As B2B buyers look for reliable products, understanding this evolution can inform their sourcing strategies and highlight the importance of choosing established brands with a history of innovation.

Illustrative image related to slime portable air compressor

How do I determine the right slime portable air compressor for my business needs?

To choose the right slime portable air compressor, assess your specific applications, such as tire inflation for vehicles or bicycles. Consider factors like power source (12V, cordless), pressure capacity, and portability. Evaluate the frequency of use and required features, such as built-in gauges or emergency sealants. Additionally, consulting with your suppliers about their recommendations based on your operational demands can provide insights tailored to your business.

What are the key features to look for in a portable air compressor for commercial use?

When sourcing a portable air compressor for commercial applications, prioritize features such as durability, ease of use, and versatile power options (12V, 120V, cordless). Look for compressors with built-in safety mechanisms, accurate pressure gauges, and quick inflation times. Compatibility with various tire sizes and the inclusion of accessories like hoses and adapters can also enhance the value of the product, making it suitable for a wider range of applications.

What is the minimum order quantity (MOQ) for slime portable air compressors?

The minimum order quantity for slime portable air compressors varies by supplier and region. Typically, manufacturers may set an MOQ ranging from 50 to 500 units, depending on production capabilities and shipping logistics. It’s advisable to communicate directly with potential suppliers to negotiate terms that align with your business needs, as some may offer flexibility based on your purchasing power or long-term relationship potential.

What payment terms are commonly offered for international B2B transactions?

Payment terms in international B2B transactions often include options like advance payment, letters of credit, or payment upon delivery. Common terms such as Net 30 or Net 60 may also apply, allowing for payment after receipt of goods. Ensure to clarify payment methods accepted by suppliers, including bank transfers or online payment platforms, and consider discussing potential discounts for early payments or bulk orders to enhance cash flow management.

How can I assess the quality assurance (QA) processes of a supplier?

To evaluate a supplier’s quality assurance processes, request documentation of their QA protocols, certifications (e.g., ISO), and product testing procedures. Conduct factory audits or request samples to assess product quality firsthand. Engaging with past customers for testimonials or reviews can also provide insight into the reliability and consistency of the supplier’s products. Establishing clear communication about your quality expectations is crucial for successful partnerships.

What are the logistics considerations when importing slime portable air compressors?

When importing slime portable air compressors, consider shipping methods (air freight vs. sea freight), customs regulations, and potential tariffs in your region. Understand the lead times associated with different shipping options and plan accordingly to avoid delays. Engaging a freight forwarder can simplify the logistics process, ensuring that all necessary documentation is in order and helping you navigate any challenges that may arise during transit.

Are there customization options available for slime portable air compressors?

Many suppliers offer customization options for slime portable air compressors, allowing businesses to tailor products to their brand or specific needs. Customizations may include branding with logos, color variations, or modifications to technical specifications. Discuss your requirements with potential suppliers to explore available options, timelines for production, and any additional costs associated with customization.

What warranties or guarantees are typically offered with slime portable air compressors?

Most reputable suppliers provide warranties or guarantees with their slime portable air compressors, covering defects in materials or workmanship for a specific period, often ranging from one to three years. Review the warranty terms carefully, noting what is covered and any limitations. Understanding the warranty process for repairs or replacements is essential for managing risks and ensuring the longevity of your investment.

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Slime Automotive Air Compressors for sale on eBay include various models such as the Slime 300PSI Portable 12 Volt Compressor with Flashlight, Slime 50123 Flat Tire Puncture Emergency Kit with Sealant & 12V Tire Inflator Pump, and Slime 40050 Tire Inflator Pump. Prices range from $20.00 to $479.99, with options for new, used, and pre-owned conditions. Many listings feature free shipping and top-ra…

In today’s competitive landscape, strategic sourcing of Slime portable air compressors presents a unique opportunity for international buyers. By focusing on quality, reliability, and versatility, these products cater to diverse markets across Africa, South America, the Middle East, and Europe. Notably, the range of Slime tire inflators—from cordless models to dual-power options—ensures that businesses can meet varying customer needs while enhancing their service offerings.

Investing in Slime’s portable air compressors not only supports operational efficiency but also strengthens customer satisfaction through dependable performance. As businesses navigate supply chain complexities, establishing strong partnerships with reputable manufacturers like Slime can lead to improved procurement processes and cost-effectiveness.

Looking ahead, the demand for portable air compressors is poised to grow, driven by increasing vehicle ownership and the necessity for reliable roadside assistance. B2B buyers are encouraged to leverage this trend by integrating Slime products into their portfolios. Now is the time to act—forge strategic alliances that will enhance your market position and drive sustainable growth in this essential sector.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to slime portable air compressor

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.