In today’s fast-paced automotive landscape, sourcing reliable solutions such as the Slime portable tire inflator is critical for businesses aiming to enhance their service offerings and customer satisfaction. Flat tires remain one of the most common roadside emergencies, posing significant challenges for fleet managers, automotive retailers, and repair shops worldwide. This guide delves into the comprehensive landscape of portable tire inflators, focusing on their various types, applications, and the nuances of supplier vetting.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Brazil and Nigeria, will find actionable insights tailored to their unique needs. The guide emphasizes the importance of understanding product specifications, performance metrics, and pricing strategies to make informed purchasing decisions. With an array of options available—from basic models to advanced digital inflators equipped with smart technology—buyers will gain clarity on which features align best with their operational requirements.

By providing a thorough analysis of cost considerations and supplier reliability, this resource empowers businesses to navigate the global market confidently. Whether you’re looking to stock your inventory or enhance your service capabilities, understanding the landscape of Slime portable tire inflators will equip you with the knowledge to optimize your procurement strategy effectively.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12V Digital Tire Inflator | Compact design, auto shut-off, LED light, inflates in 6 minutes | Automotive service centers, roadside assistance | Pros: Quick inflation, user-friendly; Cons: Limited to 12V power sources. |

| Cordless Tire Inflator | Portable, battery-operated, lightweight | Fleet management, emergency kits | Pros: No power source needed; Cons: Limited battery life and capacity. |

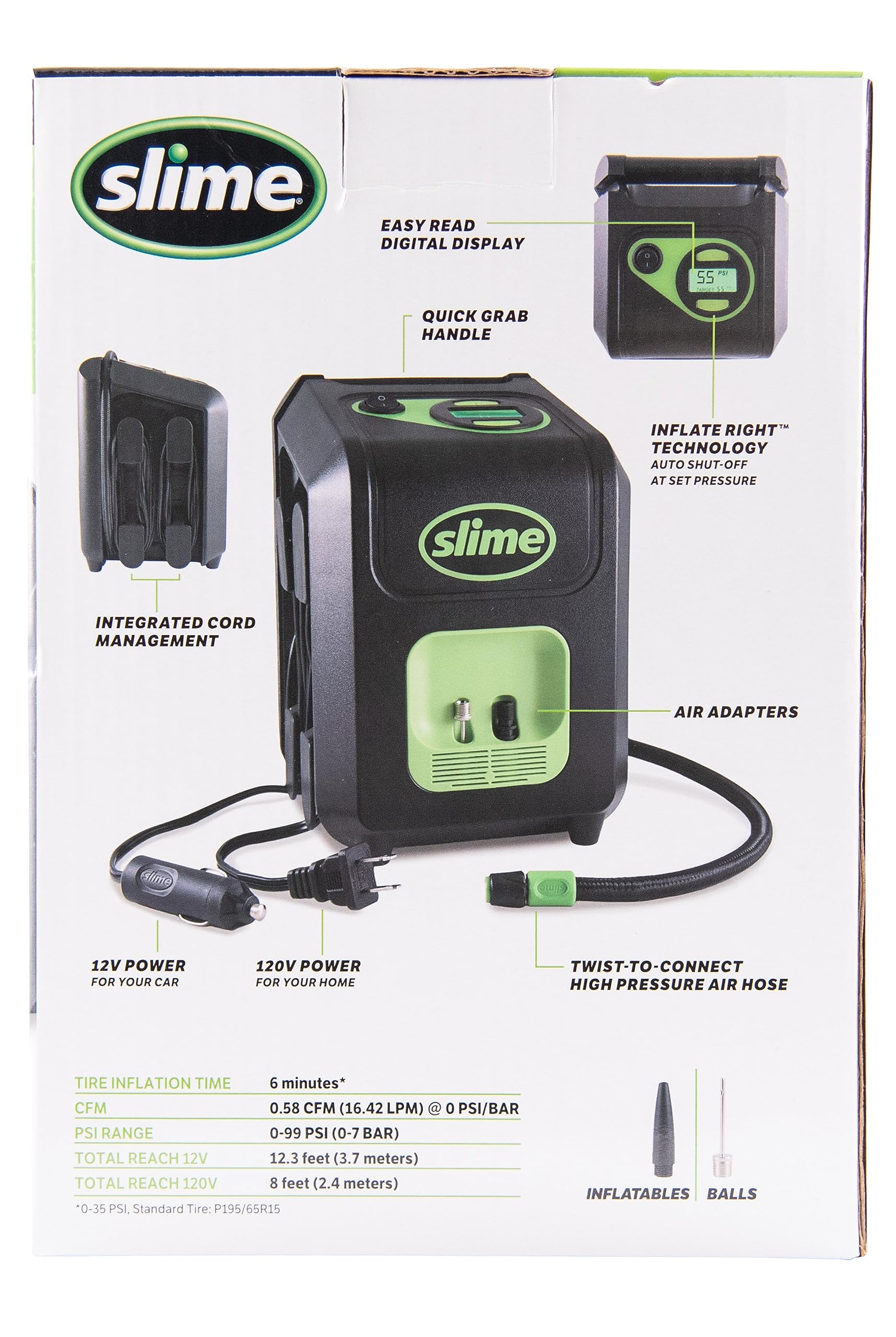

| Dual Power Tire Inflator | 120V and 12V compatibility, versatile for home and on-the-go use | Automotive workshops, home garages | Pros: Flexible power options; Cons: Bulkier than single-power models. |

| Rugged Digital Tire Inflator | Durable construction, designed for harsh conditions | Off-road vehicle maintenance, outdoor activities | Pros: Resilient design; Cons: Heavier, may not be as portable. |

| Multi-Purpose Inflator | Includes adapters for various inflatables, versatile functionality | Sports clubs, recreational vehicle maintenance | Pros: Multi-use capabilities; Cons: May lack specialized features for tire inflation. |

The 12V Digital Tire Inflator is characterized by its compact design and user-friendly interface. It features an automatic shut-off mechanism that prevents over-inflation, along with an LED light for nighttime use. This model is particularly suitable for automotive service centers and roadside assistance providers, offering quick inflation times of around six minutes for standard tires. B2B buyers should consider the inflator’s reliance on 12V power sources, which may limit its application in some settings.

Illustrative image related to slime portable tire inflator

The Cordless Tire Inflator stands out due to its portability and battery-operated design, making it ideal for fleet management and emergency kits. This model allows for inflation without the need for an external power source, enhancing convenience during roadside emergencies or in remote areas. However, buyers should be aware of its limited battery life and inflation capacity, which may require frequent recharging or replacement in high-demand situations.

The Dual Power Tire Inflator offers both 120V and 12V compatibility, making it a versatile choice for automotive workshops and home garages. This dual functionality enables users to switch between household power and vehicle power, catering to various operational needs. While this model is more versatile, its bulkier design compared to single-power options may be a consideration for B2B buyers with space constraints.

Designed for durability, the Rugged Digital Tire Inflator is ideal for off-road vehicle maintenance and outdoor activities. Its robust construction allows it to withstand harsh conditions, making it a reliable tool for businesses involved in rugged terrain operations. However, its heavier weight may limit portability, which is an important factor for buyers prioritizing ease of transport.

The Multi-Purpose Inflator is distinguished by its ability to inflate various items, including sports equipment and recreational vehicles, thanks to included adapters. This versatility makes it suitable for sports clubs and recreational vehicle maintenance. While it offers multi-use capabilities, B2B buyers should consider that it may lack specialized features for tire inflation, which could impact efficiency in tire-related tasks.

Illustrative image related to slime portable tire inflator

| Industry/Sector | Specific Application of Slime Portable Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Quick tire inflation during vehicle maintenance | Reduces downtime, enhances customer satisfaction | Reliability, ease of use, and compatibility with various tire types |

| Logistics and Transportation | On-the-road tire repairs for delivery vehicles | Minimizes delays and ensures timely deliveries | Portability, power source options, and inflation speed |

| Construction | Tire maintenance for heavy machinery and vehicles | Increases equipment uptime and operational efficiency | Durability, capacity for high-pressure inflations, and rugged design |

| Outdoor and Recreational | Inflating tires for ATVs, bikes, and camping gear | Enhances customer experience and convenience | Multi-purpose functionality and compact size |

| Emergency Services | Rapid tire inflation for emergency response vehicles | Ensures readiness and quick response capabilities | Fast inflation time, reliability under stress, and ease of storage |

In automotive repair shops, the Slime Portable Tire Inflator is an essential tool for quickly inflating tires during routine maintenance or after repairs. With its user-friendly design and rapid inflation capabilities, it reduces the time vehicles spend in the shop, enhancing overall customer satisfaction. For international buyers, especially in regions like Africa and South America, sourcing durable models that can withstand varying climates and conditions is vital. The ability to handle different tire types, including passenger vehicles and light trucks, is also a key consideration.

In the logistics and transportation sector, the Slime Portable Tire Inflator serves as a critical tool for on-the-road tire repairs. Delivery vehicles often face tire-related issues that can disrupt schedules. By enabling quick inflation, the inflator minimizes delays and maintains timely deliveries. Buyers in the Middle East and Europe should consider the inflator’s portability and power source options, ensuring it can be used in diverse environments and conditions encountered during transport.

In construction, maintaining the tires of heavy machinery and vehicles is crucial for operational efficiency. The Slime Portable Tire Inflator allows construction teams to perform tire maintenance swiftly, reducing equipment downtime. International buyers, particularly from regions with rough terrains, should focus on inflators that offer high-pressure capabilities and rugged designs to withstand demanding job site conditions. This ensures that machinery remains operational, thereby enhancing productivity.

For outdoor and recreational businesses, the Slime Portable Tire Inflator is invaluable for inflating tires on ATVs, bikes, and camping gear. It provides users with the convenience of quickly addressing tire issues, enhancing their overall experience. B2B buyers in Africa and South America should prioritize models that are compact and versatile, allowing for easy transport and use in remote locations. The ability to inflate various types of equipment can significantly improve customer satisfaction and loyalty.

Emergency services rely on the Slime Portable Tire Inflator to ensure that response vehicles are always ready for action. Rapid tire inflation capabilities are critical in emergencies where time is of the essence. Buyers in Europe and the Middle East should seek inflators that are reliable under pressure and easy to store within emergency response units. The ability to inflate tires quickly can be the difference between timely assistance and delays in critical situations.

The Problem: B2B buyers often face the challenge of sourcing reliable tire inflators that cater to diverse geographic markets, such as Africa and South America. Variability in infrastructure, climate, and vehicle types can complicate the selection process. Buyers may worry about the durability and performance of the inflators under different conditions, which can lead to increased operational costs and customer dissatisfaction if the product fails to meet expectations.

The Solution: To effectively source ‘slime portable tire inflators’, B2B buyers should conduct thorough market research to understand the specific needs of their target regions. This includes evaluating the average tire sizes and inflation pressures common in those markets. Buyers should consider partnering with local distributors who have insights into consumer preferences and can provide feedback on product performance. Additionally, opting for inflators with robust features—such as dual power sources (12V and 120V) and built-in LED lights for nighttime use—ensures adaptability in various environments. Establishing a solid relationship with manufacturers like Slime can also facilitate bulk purchasing options and better pricing structures, reducing overall costs while ensuring product reliability.

The Problem: Another significant pain point is the lack of user-friendly features and customer support for portable tire inflators. B2B buyers often deal with end-users who may not be familiar with how to operate these devices efficiently. Complicated interfaces or inadequate instructions can lead to frustration, increased return rates, and ultimately harm the brand’s reputation.

The Solution: When selecting ‘slime portable tire inflators’, B2B buyers should prioritize models that feature intuitive designs and clear operating instructions. For instance, inflators equipped with digital displays that show real-time pressure readings and automatic shut-off functions can enhance user experience significantly. To further support end-users, buyers can provide instructional videos or quick-start guides that accompany the product. Additionally, establishing a responsive customer support system to address user inquiries can enhance satisfaction and reduce return rates. Training staff or customers on how to use these inflators effectively can also mitigate issues, ensuring that users feel confident and empowered.

The Problem: B2B buyers frequently grapple with concerns about the long-term reliability and maintenance of portable tire inflators. In regions where tire issues are prevalent, a reliable inflator is essential for maintaining operational efficiency. Buyers may worry about the frequency of repairs or replacements, which can lead to unexpected costs and service interruptions.

The Solution: To address these concerns, B2B buyers should choose ‘slime portable tire inflators’ that come with warranties and robust customer service options. It is advisable to look for models that offer easy maintenance features, such as replaceable parts or serviceable components, which can extend the product’s lifespan. Furthermore, buyers should educate their customers on regular maintenance practices, such as checking the inflator for wear and tear and ensuring that all components are functioning correctly. Incorporating regular training sessions for users can also enhance the longevity of the inflators, reducing the likelihood of malfunction. By selecting durable products and promoting preventive maintenance, buyers can ensure that their investments yield long-term reliability and customer satisfaction.

When selecting materials for the Slime portable tire inflator, it is essential to consider various factors that affect performance, durability, and cost. The following analysis focuses on four common materials used in the construction of tire inflators: plastic, aluminum, rubber, and steel. Each material has unique properties that can significantly impact the product’s overall effectiveness and suitability for international markets.

Plastic is often used for the housing of tire inflators due to its lightweight nature and versatility. Common types include ABS (Acrylonitrile Butadiene Styrene) and polypropylene. These plastics can withstand moderate temperature ranges and have good impact resistance, making them suitable for portable applications.

Illustrative image related to slime portable tire inflator

Pros: Plastic is cost-effective and easy to mold into complex shapes, which simplifies manufacturing. Additionally, it is resistant to corrosion and can be produced in various colors and finishes.

Cons: While plastic is durable, it may not withstand extreme temperatures or prolonged exposure to UV light, leading to potential degradation over time.

Impact on Application: The compatibility of plastic with various chemicals is generally good, but it may not be suitable for high-pressure applications where metal components are preferred.

Considerations for International Buyers: Buyers should ensure compliance with regional standards such as ASTM or EN for material safety. In markets like Brazil and Nigeria, where environmental conditions may vary, selecting high-quality plastics that meet local regulations is crucial.

Aluminum is frequently utilized for components that require a balance of weight and strength, such as the inflator’s body or internal mechanisms. It has excellent thermal conductivity and can withstand high pressures, making it ideal for tire inflators.

Illustrative image related to slime portable tire inflator

Pros: Aluminum is lightweight, resistant to corrosion, and can be easily machined, allowing for precise manufacturing. Its thermal properties also enable efficient heat dissipation during operation.

Cons: The primary drawback is its cost compared to plastic, as aluminum can be more expensive to source and process.

Impact on Application: Aluminum is compatible with various media, including air and certain gases, making it a versatile choice for tire inflators.

Considerations for International Buyers: Buyers should verify that aluminum components meet international standards for pressure vessels, especially in regions with strict safety regulations, such as Europe.

Rubber is commonly used in seals and hoses within tire inflators due to its excellent elasticity and ability to withstand pressure. Natural rubber or synthetic variants like neoprene are often employed.

Illustrative image related to slime portable tire inflator

Pros: Rubber provides excellent sealing capabilities, ensuring that air does not escape during inflation. It is also resistant to wear and can handle a range of temperatures.

Cons: Rubber can degrade over time, especially when exposed to ozone or UV light, which may limit its lifespan compared to metal components.

Impact on Application: Rubber’s compatibility with air and other gases is high, making it suitable for tire inflation applications.

Considerations for International Buyers: Buyers should ensure that rubber components comply with local environmental regulations, particularly in regions where ozone levels may be higher, such as urban areas in Africa and South America.

Illustrative image related to slime portable tire inflator

Steel is often used for structural components of tire inflators, particularly in high-stress areas. It offers high strength and durability, making it suitable for heavy-duty applications.

Pros: Steel is incredibly strong and can withstand high pressures, making it ideal for inflators that need to perform under demanding conditions. It also has good resistance to impact and abrasion.

Cons: The primary disadvantage of steel is its weight, which can make the inflator less portable. Additionally, steel is prone to corrosion if not properly treated.

Illustrative image related to slime portable tire inflator

Impact on Application: Steel is highly compatible with air and other gases, making it a reliable choice for tire inflators.

Considerations for International Buyers: Buyers should consider the need for corrosion-resistant coatings, especially in humid or coastal regions, to ensure longevity and compliance with local standards.

| Material | Typical Use Case for slime portable tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and external components | Lightweight and corrosion-resistant | Limited temperature resistance | Low |

| Aluminum | Body and internal mechanisms | Excellent strength-to-weight ratio | Higher cost than plastic | Medium |

| Rubber | Seals and hoses | Superior sealing capabilities | Degrades under UV exposure | Low |

| Steel | Structural components | High strength and durability | Heavier and prone to corrosion | Medium |

In conclusion, selecting the right materials for the Slime portable tire inflator involves balancing performance, cost, and compliance with international standards. By understanding the properties, advantages, and limitations of each material, B2B buyers can make informed decisions that align with their operational needs and market conditions.

Manufacturing a reliable and efficient portable tire inflator involves several critical stages, each designed to ensure high-quality output. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to slime portable tire inflator

The first step in manufacturing Slime portable tire inflators is material preparation. This phase involves sourcing high-grade materials such as durable plastics for the casing, high-performance motors, and specialized rubber components for seals. Suppliers are carefully vetted to ensure compliance with international standards, such as ISO 9001, which governs quality management systems.

Once the materials are prepared, they undergo various forming techniques. For the casing, processes such as injection molding are commonly employed. This technique allows for the production of complex shapes with high precision, which is vital for ensuring a snug fit of internal components. Metal parts may be produced through stamping or CNC machining, providing the necessary strength and durability.

The assembly stage is where the inflator begins to take shape. Components are systematically brought together in a clean environment to minimize contamination. Skilled technicians perform assembly tasks, including integrating the motor with the casing and installing electronic components such as pressure gauges and LED lights. Automation is often utilized for repetitive tasks, increasing efficiency and ensuring consistency.

Finishing processes are crucial for both aesthetics and functionality. After assembly, inflators undergo surface treatments to enhance durability and resistance to wear and tear. This may include painting or applying protective coatings. Additionally, each unit is subjected to thorough cleaning to remove any residues from manufacturing.

Illustrative image related to slime portable tire inflator

Quality assurance (QA) is integral to the production of Slime portable tire inflators, ensuring that each unit meets stringent performance and safety standards.

For manufacturers targeting international markets, adhering to recognized quality standards is essential. ISO 9001 certification indicates a commitment to quality management and continuous improvement. Additionally, compliance with CE marking signifies that the inflator meets European safety requirements, while API standards may apply to components used in specific markets.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Suppliers are required to provide documentation and certificates of compliance.

In-Process Quality Control (IPQC): During assembly, random samples are taken to ensure that components meet specifications. This step helps identify issues early in the process.

Final Quality Control (FQC): After assembly, each inflator undergoes rigorous testing, including performance checks, pressure tests, and safety inspections. Units that fail these tests are either reworked or discarded.

Common testing methods for Slime tire inflators include:

Functional Testing: Each unit is tested for its ability to inflate a standard tire to the specified pressure within the required timeframe.

Durability Testing: Inflators are subjected to stress tests to simulate prolonged use, ensuring they can withstand real-world conditions.

Safety Testing: Compliance with safety standards is verified through tests that check for electrical hazards, overheating, and mechanical failures.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier QC practices is vital to ensuring product reliability.

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control systems. Buyers should develop a comprehensive audit checklist that includes:

Illustrative image related to slime portable tire inflator

Buyers should request detailed QC reports from suppliers to gain insights into their manufacturing processes. Additionally, engaging third-party inspection agencies can provide an unbiased assessment of the manufacturer’s capabilities and adherence to quality standards. These agencies can conduct inspections at various stages, from raw material sourcing to final product testing.

It’s essential for B2B buyers to understand that QC requirements and certifications may vary by region. For instance, buyers in Europe might prioritize CE marking, while those in Africa and South America may focus on local certifications that address specific market needs. Understanding these nuances can help buyers make informed purchasing decisions and mitigate risks associated with quality and compliance.

In conclusion, the manufacturing processes and quality assurance measures for Slime portable tire inflators are designed to deliver reliable and high-performance products. By understanding the key stages of manufacturing and the rigorous QC practices in place, B2B buyers can make informed decisions and establish partnerships with suppliers that prioritize quality and compliance. This knowledge is particularly valuable for international buyers navigating diverse markets with varying regulations and standards.

This practical sourcing guide is designed for B2B buyers looking to procure Slime portable tire inflators. By following this step-by-step checklist, you can ensure that you make informed decisions, select reliable suppliers, and secure high-quality products that meet your business needs.

Clearly outline the technical requirements for the tire inflators you intend to purchase. Consider aspects such as pressure range, inflation speed, power sources (e.g., 12V, cordless), and additional features like LED lights or multi-purpose adapters. Establishing these specifications will help you narrow down potential suppliers and ensure that the inflators meet your operational needs.

Illustrative image related to slime portable tire inflator

Conduct thorough market research to understand current trends and pricing in the tire inflator segment. Analyze competitor products and pricing strategies to gauge where your offerings might fit in. This step is crucial for negotiating favorable terms and ensuring you remain competitive in your market.

Compile a list of potential suppliers specializing in Slime portable tire inflators. Look for manufacturers with a strong reputation in the industry and positive customer reviews. Utilize platforms like Alibaba, TradeKey, and industry-specific directories to find reliable suppliers.

Before making any commitments, ensure that the suppliers you are considering have the necessary certifications and compliance standards. Check for ISO certifications, safety certifications, and any other relevant documentation. This verification helps mitigate risks associated with product quality and ensures compliance with international standards.

Request samples of the tire inflators from shortlisted suppliers. This allows you to evaluate the product quality firsthand and assess whether it meets your defined specifications. Pay attention to factors such as durability, functionality, and ease of use, as these elements can significantly impact customer satisfaction.

Illustrative image related to slime portable tire inflator

Once you have evaluated samples and selected a preferred supplier, engage in negotiations regarding pricing, minimum order quantities, delivery timelines, and payment terms. Clear communication during this phase is essential to ensure that both parties have aligned expectations and can build a long-term partnership.

Finally, set up a quality assurance process for ongoing shipments. This might include regular inspections, feedback loops, and a clear returns policy. Establishing this process ensures that you maintain high product standards and can quickly address any issues that may arise post-purchase, thereby protecting your investment and reputation.

By following this checklist, you can streamline your procurement process for Slime portable tire inflators and ensure a successful sourcing experience.

When evaluating the cost structure for sourcing Slime portable tire inflators, several components play a critical role. The primary cost elements include:

Materials: The materials used in tire inflators, such as plastics, metals, and electronic components, significantly influence the overall cost. High-quality materials can enhance durability and performance but may also increase the price.

Labor: Labor costs vary by region and can impact the final price of the inflators. In countries with higher labor costs, such as those in Europe, the manufacturing price may be higher compared to regions in Africa or South America, where labor costs are typically lower.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative support. Efficient manufacturing processes can reduce overhead costs, making it crucial to assess the supplier’s operational efficiency.

Tooling: The initial investment in tooling for production can be significant, especially for custom designs or specifications. Buyers should inquire about these costs, particularly if they require unique modifications to existing products.

Quality Control (QC): Implementing robust QC processes ensures product reliability and compliance with international standards. Suppliers may charge more for enhanced QC measures, but this investment can lead to reduced warranty claims and increased customer satisfaction.

Logistics: Shipping costs, including freight and insurance, are essential to consider. The location of the supplier and the destination market can significantly affect logistics costs, particularly for international shipping.

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market competition, brand positioning, and perceived product value. Understanding the supplier’s margin can help buyers negotiate better pricing.

Several factors can influence the pricing of Slime tire inflators in the B2B market:

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should assess their demand to negotiate favorable terms based on volume.

Specifications and Customization: Custom features, such as branding or specific technical specifications, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can enhance the product’s value but also increase costs. Buyers should balance quality needs with budget constraints.

Supplier Factors: The reputation, reliability, and financial stability of the supplier can affect pricing. Established suppliers may charge a premium for their experience and service.

Incoterms: Understanding the agreed Incoterms (International Commercial Terms) is crucial for determining who bears responsibility for shipping costs, insurance, and customs duties. This can significantly impact the total landed cost.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to optimize costs when sourcing Slime portable tire inflators:

Conduct Market Research: Understanding market trends and competitor pricing can provide leverage during negotiations. This knowledge enables buyers to make informed offers.

Negotiate Terms: Discuss payment terms, delivery schedules, and potential discounts for bulk purchases. A flexible approach can often lead to better pricing.

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, warranty, and operational costs. A slightly higher upfront cost may result in lower TCO if the product has superior reliability and performance.

Be Mindful of Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, tariffs, and shipping costs. Tailor your negotiation strategy accordingly.

Request Samples and Prototypes: Before placing large orders, requesting samples can help assess product quality and suitability, reducing the risk of costly returns.

The prices and cost structures discussed are indicative and may vary based on market conditions, supplier agreements, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure the best pricing strategy.

In the realm of tire inflation solutions, various products and technologies exist that serve similar purposes as the Slime Portable Tire Inflator. Understanding these alternatives can empower B2B buyers to make informed decisions based on specific needs, costs, and operational environments. Below is a comparative analysis of the Slime Portable Tire Inflator against two viable alternatives: a traditional manual pump and a high-performance electric tire inflator.

| Comparison Aspect | Slime Portable Tire Inflator | Manual Tire Pump | High-Performance Electric Tire Inflator |

|---|---|---|---|

| Performance | Fast inflation (6 mins for a standard car tire) | Slower; depends on user effort and type | Very fast; often inflates in under 3 mins |

| Cost | Mid-range ($40 – $60) | Low ($10 – $30) | Higher ($70 – $150) |

| Ease of Implementation | Easy to use, plug-and-play | Requires physical effort | Simple, usually just plug into a power source |

| Maintenance | Low; occasional cleaning required | Low; no mechanical parts | Moderate; may need regular checks for wear |

| Best Use Case | Roadside emergencies, quick fixes | Limited use; good for home | Ideal for frequent use, high volume needs |

A manual tire pump is a basic solution that relies on human effort to inflate tires. Its low cost makes it appealing, especially for budget-conscious buyers. However, the performance can be significantly slower than powered options, often taking much longer to achieve the desired pressure. Additionally, the physical exertion required can be a deterrent, especially in emergency situations. Manual pumps are best suited for infrequent use or as a backup option.

High-performance electric tire inflators offer rapid inflation times, often completing the task in under three minutes. They are designed for heavy-duty use, making them suitable for businesses that require frequent tire maintenance, such as logistics companies or automotive repair shops. However, these inflators come with a higher price tag and may require more maintenance due to the more complex mechanical components involved. While they provide excellent performance, they may not be the best fit for small businesses with limited budgets.

When selecting a tire inflation solution, B2B buyers should consider several factors, including budget, frequency of use, and operational environment. The Slime Portable Tire Inflator stands out for its balance of affordability and performance, making it an excellent choice for roadside emergencies and occasional tire maintenance. On the other hand, businesses that require quick turnaround times and high-volume tire services may benefit more from investing in a high-performance electric inflator. Manual pumps can serve as a cost-effective backup option but may lack the efficiency needed for urgent situations. By evaluating these alternatives based on their specific operational requirements, buyers can ensure they select the most suitable tire inflation solution for their needs.

When evaluating Slime portable tire inflators, several technical properties are crucial for B2B buyers. Understanding these specifications can help companies ensure they select the right product for their specific needs, whether for resale or fleet maintenance.

Illustrative image related to slime portable tire inflator

Inflation Time

This specification refers to the time taken to inflate a standard-sized tire. For example, Slime inflators can typically inflate a tire in approximately 6 minutes. This property is significant for businesses that prioritize efficiency, as quicker inflation times reduce downtime and enhance service delivery.

Pressure Range

The pressure range indicates the minimum and maximum PSI (pounds per square inch) the inflator can handle. Many Slime models feature a pressure range from 0 to 99 PSI. Understanding this range helps buyers ensure the inflator can accommodate various vehicle types, from cars to larger trucks, thus broadening their market appeal.

Power Source

Slime tire inflators often operate on a 12-volt power source, suitable for connection to a vehicle’s power outlet. Some models also offer dual power options (120V/12V), enhancing versatility for both home and on-the-go use. For B2B buyers, this flexibility can be a key selling point, especially in regions with limited access to traditional power supplies.

Material Quality

The materials used in manufacturing the inflator, such as high-grade plastics and durable metals, affect longevity and reliability. Buyers should look for products that are resistant to wear and tear, as this ensures lower replacement rates and better overall cost efficiency.

Built-in Features

Features such as automatic shut-off when the desired pressure is reached and built-in LED lights for nighttime use are essential for user convenience. These enhancements not only improve user experience but can also serve as unique selling points in competitive markets.

Understanding industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some key terms associated with the purchase of Slime portable tire inflators:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In this context, it could refer to Slime as the OEM for tire inflators, which is important for buyers seeking quality assurance and compatibility with their existing products.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory and cash flow, ensuring they do not overcommit to products that may not sell quickly.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. B2B buyers often use RFQs to compare prices and terms from multiple suppliers, aiding in informed purchasing decisions.

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with these terms is crucial for understanding shipping costs, risks, and responsibilities, particularly for international transactions involving Slime tire inflators.

Warranty Terms

Warranty terms outline the conditions under which a product is covered for defects or failures. Understanding these terms is essential for B2B buyers, as they impact long-term costs and customer satisfaction.

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Recognizing lead times is crucial for planning and inventory management, especially for businesses operating in markets with fluctuating demand.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market strategies.

The global portable tire inflator market is experiencing significant growth, propelled by rising vehicle ownership, increasing awareness of tire maintenance, and the growing trend of DIY vehicle care. In emerging markets like Africa and South America, where road conditions can be challenging, the demand for reliable and portable tire inflators is particularly high. Key trends include the shift towards advanced digital inflators that offer features such as automatic shut-off, digital pressure gauges, and built-in LED lights for night-time use. These innovations not only enhance user experience but also promote safety and efficiency.

Illustrative image related to slime portable tire inflator

Additionally, the integration of smart technology is becoming increasingly common. Manufacturers are exploring IoT-enabled devices that allow users to monitor tire pressure remotely via mobile applications. This trend resonates with tech-savvy consumers and businesses alike, offering a competitive edge in the market. For international B2B buyers, particularly in regions like the Middle East and Europe, understanding these dynamics is crucial for making informed sourcing decisions that align with market demands.

Sustainability has become a pivotal consideration in the B2B landscape, with businesses increasingly prioritizing ethical sourcing and environmental responsibility. The production of portable tire inflators, including the Slime brand, must consider the environmental impact of materials and manufacturing processes. Buyers are encouraged to seek products that utilize recycled materials, energy-efficient manufacturing techniques, and comply with eco-friendly certifications.

Moreover, the importance of transparent supply chains cannot be overstated. B2B buyers should inquire about the sourcing of components and the environmental policies of manufacturers. Certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as indicators of a company’s commitment to sustainability. By prioritizing ethical sourcing, buyers not only contribute to environmental preservation but also enhance their brand image, appealing to a growing demographic of environmentally conscious consumers.

The evolution of portable tire inflators has been marked by technological advancements and changing consumer needs. Initially, tire inflators were rudimentary devices that relied on manual operation and lacked the precision necessary for modern vehicles. However, as vehicle technology advanced, so did the demand for more sophisticated inflators.

Illustrative image related to slime portable tire inflator

The introduction of electric and digital inflators represented a significant leap forward, providing users with enhanced convenience and accuracy. Companies like Slime have consistently innovated, integrating features such as Inflate Right Technology, which automatically shuts off when the desired pressure is reached. This evolution reflects a broader trend in the automotive aftermarket, where consumers increasingly seek products that blend functionality with ease of use. Understanding this historical context can provide B2B buyers with insights into product development and the future direction of the portable tire inflator market.

In conclusion, the Slime portable tire inflator market is shaped by technological advancements, sustainability imperatives, and evolving consumer expectations. For international B2B buyers, staying abreast of these trends is essential for making strategic sourcing decisions that align with both market demands and ethical considerations.

How do I choose the right Slime portable tire inflator for my business needs?

When selecting a Slime portable tire inflator, consider the specific requirements of your business. Evaluate factors such as tire size compatibility, inflation speed, and power source (12V, cordless, or dual power). If your operations involve various vehicle types, a multi-purpose inflator with additional adapters may be beneficial. Additionally, assess the durability and warranty options to ensure long-term reliability, especially in demanding environments.

What is the best Slime tire inflator for commercial use?

For commercial applications, the Slime Pro Power Compact Tire Inflator stands out due to its robust construction and high performance. It can inflate tires quickly and efficiently, making it ideal for businesses that require frequent use, such as auto repair shops or fleet services. Its features include a powerful motor, a durable design, and multiple power options, ensuring versatility across various vehicles and applications.

How can I ensure quality when sourcing Slime tire inflators internationally?

To ensure quality when sourcing Slime tire inflators, conduct thorough supplier vetting. Look for manufacturers with a proven track record, positive customer reviews, and certifications that meet international standards. Request product samples to assess quality firsthand and consider visiting the supplier’s facility if possible. Engaging in regular communication and establishing clear quality assurance protocols can also help maintain high standards throughout the procurement process.

What are the typical minimum order quantities (MOQ) for Slime tire inflators?

Minimum order quantities for Slime tire inflators can vary based on the supplier and the specific model. Typically, MOQs range from 50 to 100 units for wholesale purchases. It’s advisable to discuss your requirements directly with potential suppliers to negotiate MOQs that align with your business needs. Understanding your sales projections can help you determine the appropriate quantity to order.

What payment terms should I expect when sourcing Slime tire inflators?

Payment terms for international orders of Slime tire inflators may include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers offer flexible terms based on the volume of the order and your relationship with them. Always clarify payment terms upfront and ensure that they are documented in the purchase agreement to avoid any misunderstandings later.

How do I handle logistics for importing Slime tire inflators?

When importing Slime tire inflators, it’s crucial to establish a reliable logistics plan. This includes selecting a freight forwarder experienced in international shipping, considering shipping methods (air vs. sea), and understanding customs regulations in your country. Ensure that all shipping documentation is complete and accurate to prevent delays. Additionally, factor in lead times and potential tariffs to calculate total import costs effectively.

Can I customize Slime tire inflators with my branding for resale?

Yes, many suppliers offer customization options for Slime tire inflators, allowing you to add your branding or private label the products. Discuss your branding requirements with the supplier during the negotiation phase. Be aware that customization may involve additional costs and longer lead times, so plan accordingly to align with your marketing strategy.

What are the warranty and after-sales support options for Slime tire inflators?

Slime typically offers a warranty on their tire inflators, which may cover defects in materials and workmanship for a specified period (often one year). It’s essential to verify the warranty details with your supplier and understand the claims process. Additionally, inquire about after-sales support, such as technical assistance and replacement parts availability, to ensure that you can provide reliable service to your customers.

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Slime Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “Slime 12V Digital Tire Inflator”, “Part No.”: “40051”, “Inflation Time”: “6 minutes”, “Pressure Range”: “0-99 PSI”, “Features”: [“Auto Shut-Off at Set PSI”, “Bright LED Light”, “Inflate Right Technology”], “Power Source”: “12-volt accessory power”, “Display”: “Easy to read digital display”, “Included Accessories”: [“Multi-purpose air adapters for rafts, balls, and other inflatabl…

In conclusion, the strategic sourcing of Slime portable tire inflators presents a compelling opportunity for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. The product’s robust features, such as rapid inflation capabilities, user-friendly design, and integrated safety technologies, make it a valuable addition to any automotive or emergency roadside assistance inventory.

Illustrative image related to slime portable tire inflator

By leveraging strategic sourcing, businesses can ensure a reliable supply of these essential tools, enhancing their service offerings and meeting the growing demand for efficient tire maintenance solutions. Moreover, engaging with a reputable supplier can lead to better pricing strategies, improved product availability, and enhanced customer satisfaction.

Looking ahead, as the automotive industry continues to evolve with increasing emphasis on convenience and safety, the demand for portable tire inflators is poised to rise. We encourage international buyers to act now—evaluate your sourcing strategies, align with trusted suppliers, and capitalize on the potential of Slime portable tire inflators to drive growth and innovation in your market. Seize the opportunity to enhance your product portfolio today!

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to slime portable tire inflator