Inflating a Presta bike tire can present a significant challenge for businesses operating in diverse markets, especially for B2B buyers in regions such as Africa, South America, the Middle East, and Europe. Understanding the nuances of this specific valve type is crucial for sourcing reliable pumps and accessories that can meet the demands of varying tire specifications and pressures. This guide provides a comprehensive overview of the essential techniques, tools, and considerations necessary for efficiently inflating Presta tires.

From exploring different types of pumps compatible with Presta valves to assessing the appropriate accessories like valve extenders and adapters, this guide equips international buyers with the knowledge needed to make informed purchasing decisions. We delve into the specific applications of Presta valves, their advantages in high-pressure situations, and potential challenges faced by users in different geographic markets.

Moreover, supplier vetting processes are discussed, ensuring that buyers can identify reputable manufacturers and distributors that offer quality products tailored to their needs. By providing insights into cost factors, maintenance tips, and troubleshooting common issues, this guide empowers B2B buyers to enhance their operational efficiency, streamline their supply chains, and ultimately improve customer satisfaction in their respective markets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Floor Pump | Utilizes a lever mechanism for inflation, requires physical effort. | Bicycle repair shops, retail outlets. | Pros: Cost-effective, no need for power. Cons: Labor-intensive, less efficient for high-volume operations. |

| Electric Pump | Battery or AC powered, offers automatic inflation. | Large bicycle rental services, workshops. | Pros: Quick and easy, consistent pressure. Cons: Higher initial investment, maintenance required. |

| CO2 Inflator | Uses CO2 cartridges for rapid inflation. | Competitive cycling teams, emergency kits. | Pros: Compact, fast inflation. Cons: Single-use cartridges, ongoing supply costs. |

| Valve Adapter | Connects Presta valves to Schrader pumps or compressors. | Retailers, repair shops requiring versatility. | Pros: Increases compatibility, versatile use. Cons: Additional accessory cost, potential for loss. |

| Tubeless Tire Setup | Involves sealing rim and tire without a tube, often requires specific inflation methods. | Advanced bicycle manufacturers, performance shops. | Pros: Reduced puncture risk, lower rolling resistance. Cons: More complex setup, requires specialized knowledge. |

Manual floor pumps are a staple in many bicycle repair shops and retail outlets due to their simplicity and cost-effectiveness. They operate on a lever mechanism that requires physical effort to inflate tires. While they are highly reliable and do not require power sources, they can be labor-intensive, making them less suitable for high-volume operations. Buyers should consider the ease of use and durability of the pump, especially in environments where frequent tire inflation is necessary.

Electric pumps are powered by batteries or AC sources, providing a convenient option for quick and consistent tire inflation. They are particularly beneficial for large bicycle rental services and workshops that need to inflate multiple tires efficiently. Although they come with a higher initial investment and require regular maintenance, their ability to save time and reduce labor costs makes them an attractive option for businesses focused on efficiency.

CO2 inflators are designed for rapid tire inflation using CO2 cartridges, making them a popular choice among competitive cycling teams and emergency kits. Their compact size allows for easy transport, and they can inflate a tire in seconds, which is crucial during races. However, the ongoing costs associated with purchasing CO2 cartridges and their single-use nature can be a drawback for businesses looking to minimize expenses.

Valve adapters play a critical role in connecting Presta valves to Schrader pumps or compressors, increasing compatibility across different tire types. This versatility is essential for retailers and repair shops that service a wide range of bicycles. While they add an additional cost, the ability to accommodate various valve types can enhance service offerings and customer satisfaction.

The tubeless tire setup eliminates the need for traditional inner tubes, relying on a sealant to maintain pressure. This method can reduce the risk of punctures and lower rolling resistance, appealing to advanced bicycle manufacturers and performance shops. However, the complexity of the setup and the need for specialized knowledge may deter some buyers. Businesses must weigh the benefits of improved performance against the challenges of implementation and maintenance.

| Industry/Sector | Specific Application of how to inflate a presta bike tire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Manufacturing | Quality control during production of bicycles | Ensures optimal performance and safety of bicycles produced | Sourcing reliable inflation tools and quality control equipment |

| Bike Rentals | Regular maintenance for rental fleets | Enhances customer experience through well-maintained bikes | Durable pumps and valve adapters to accommodate various tire types |

| Sports Retail | Customer service in retail settings | Increases customer satisfaction and encourages repeat business | Training staff on proper inflation techniques and equipment sales |

| Cycle Touring Services | Pre-ride inspections and maintenance | Reduces the risk of tire failure during tours, ensuring safety | Portable inflation solutions for on-the-go maintenance |

| Logistics and Shipping | Preparing bikes for shipment | Minimizes damage during transport by ensuring proper tire pressure | Reliable inflation tools that are easy to use in warehouse settings |

In the bicycle manufacturing sector, understanding how to inflate a Presta bike tire is critical for quality control. Manufacturers must ensure that all bikes meet safety standards, which includes proper tire inflation. By utilizing appropriate inflation techniques, manufacturers can verify that tires are capable of handling the specified pressure, thereby enhancing performance and safety. International buyers should consider sourcing high-quality inflation tools and equipment to maintain consistent production standards.

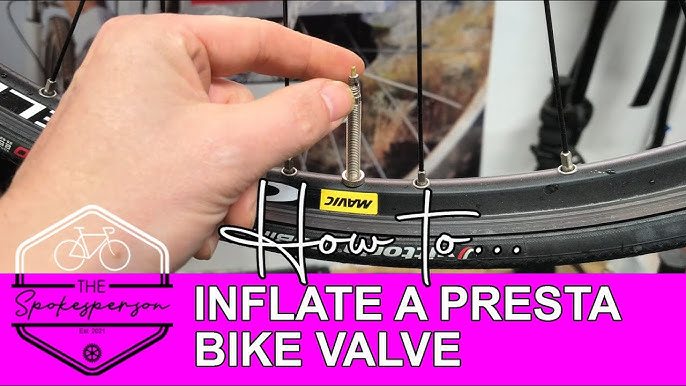

Illustrative image related to how to inflate a presta bike tire

For bike rental companies, regular maintenance, including tire inflation, is essential to ensure customer satisfaction. Properly inflated tires enhance the riding experience, reduce the risk of flats, and promote safety. Rental operations need reliable pumps and valve adapters to accommodate various tire types. Additionally, staff should be trained in effective inflation techniques to streamline maintenance processes and provide excellent customer service, particularly in regions with diverse cycling conditions.

In sports retail, understanding how to inflate a Presta bike tire directly impacts customer service. Retail staff equipped with the knowledge of proper inflation techniques can assist customers in maintaining their bikes, leading to increased satisfaction and loyalty. Retailers must also consider stocking a range of inflation tools and accessories, ensuring that customers have access to the right equipment for their needs. Training staff on these techniques can further enhance the in-store experience, fostering a knowledgeable environment for cyclists.

Cycle touring services rely on proper bike maintenance, including tire inflation, to minimize the risk of tire failure during tours. Regular inspections before rides ensure that all bikes are in optimal condition, enhancing the safety of participants. Portable inflation solutions are vital for on-the-go maintenance, allowing guides to quickly address any tire issues during tours. International buyers in this sector should prioritize sourcing reliable and easy-to-use inflation equipment to ensure a seamless touring experience.

In logistics and shipping, preparing bikes for transport includes ensuring proper tire pressure. Correct inflation minimizes the risk of damage during transit and ensures that bikes arrive in optimal condition. Logistics companies should invest in reliable inflation tools that are easy to use in warehouse settings. Understanding the nuances of Presta valve inflation is crucial for international buyers, as it allows for efficient operations and reduces the likelihood of costly shipping errors.

The Problem: Many B2B buyers, especially those managing bike rental or repair businesses, encounter frustration when trying to attach a pump to Presta valves. The unique design of these valves can lead to air leaks if not connected correctly, causing wasted time and potential customer dissatisfaction. For instance, a bike rental manager may find that their staff struggles to inflate tires quickly, leading to longer wait times for customers and decreased operational efficiency. This issue is particularly pronounced with shorter valve stems on deep-section rims, making it nearly impossible to achieve a secure connection without special techniques or tools.

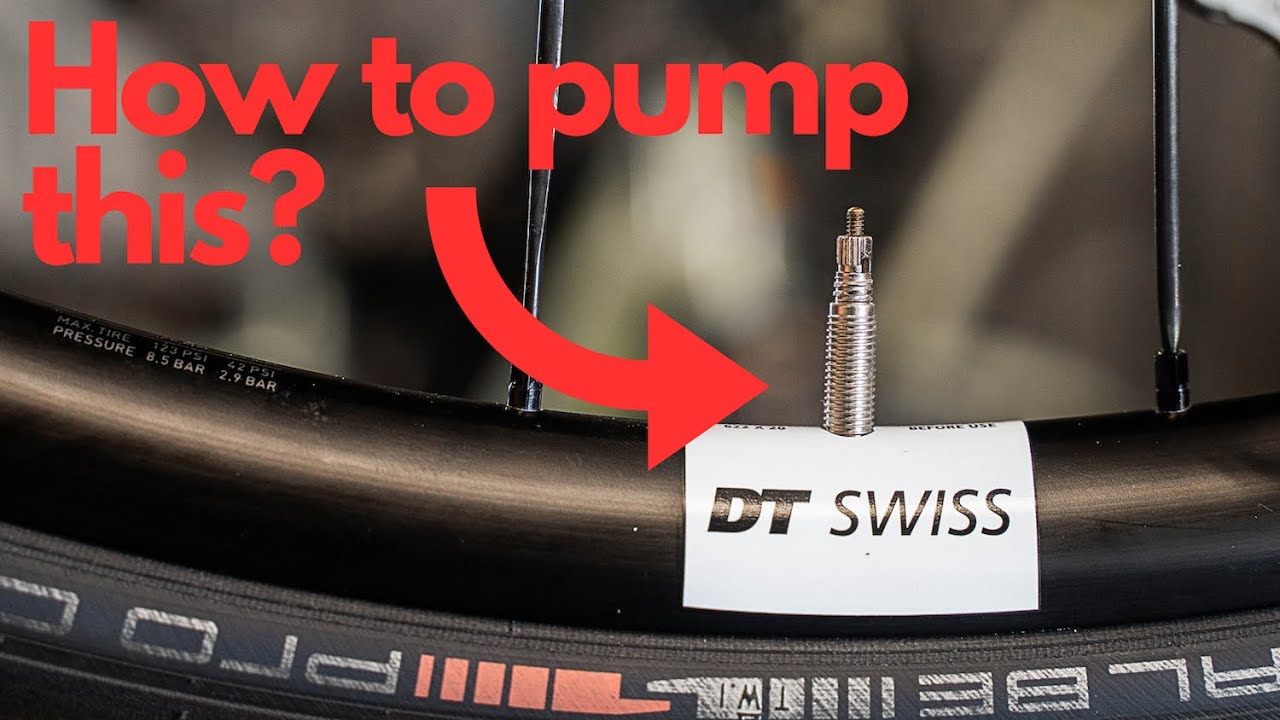

Illustrative image related to how to inflate a presta bike tire

The Solution: To effectively address this challenge, it is crucial to invest in high-quality pumps specifically designed for Presta valves, which often feature a more accommodating design. Buyers should consider pumps that have a dual-head feature allowing for easy switching between Presta and Schrader valves. Additionally, providing staff training on proper techniques—such as ensuring the valve is in the correct position and using a valve extender if necessary—can significantly reduce inflation time. For businesses dealing with deep-section rims, stocking valve extenders can ensure that even shorter stems are accessible for inflation, thereby enhancing service efficiency and customer satisfaction.

The Problem: Another common pain point for B2B buyers is the difficulty in obtaining accurate pressure readings during the inflation process. Many pumps may not display pressure accurately or may fail to register any pressure at all, leading to inflated tires that are under- or over-pressured. This scenario can be particularly problematic for businesses that rely on precise tire pressure for performance and safety, such as cycling clubs or bike shops that cater to competitive cyclists.

The Solution: To mitigate this issue, businesses should consider investing in digital pressure gauges or pumps with integrated digital displays that provide clear and accurate readings. These tools can significantly enhance reliability and ease of use. Additionally, staff should be trained to perform manual pressure checks with a separate gauge after inflation to ensure accuracy, particularly when using pumps that may not be reliable. Encouraging regular maintenance of inflating equipment, including checking for wear and tear on the pressure gauge, will also help maintain accuracy and prolong the life of the equipment.

The Problem: B2B buyers often face confusion regarding the appropriate tire pressure for various bike models, especially when dealing with a diverse fleet. This challenge can lead to inconsistent inflation practices, resulting in tires that are either too soft—leading to increased wear and risk of flats—or too hard, which can compromise ride quality and safety. For example, a bike rental service with a mix of road and mountain bikes may struggle to find a balance, impacting customer experience and operational costs.

The Solution: To streamline the inflation process, businesses should develop a standardized reference guide that outlines the recommended tire pressures for each bike type within their fleet. This guide should be easily accessible to staff and could be printed and displayed near the inflation area. Additionally, implementing a color-coded system for tire pressures—using stickers or tags on each bike—can provide a quick visual reference for employees, reducing the chances of human error. Regular training sessions can also reinforce this knowledge and ensure that all team members are updated on any changes to tire specifications, thus enhancing safety and performance across the board.

When selecting materials for inflating Presta bike tires, it is essential to consider the properties and performance of various components involved in the process. The most common materials include rubber, plastic, aluminum, and brass. Each material has distinct characteristics that affect their suitability for different applications, particularly in international markets.

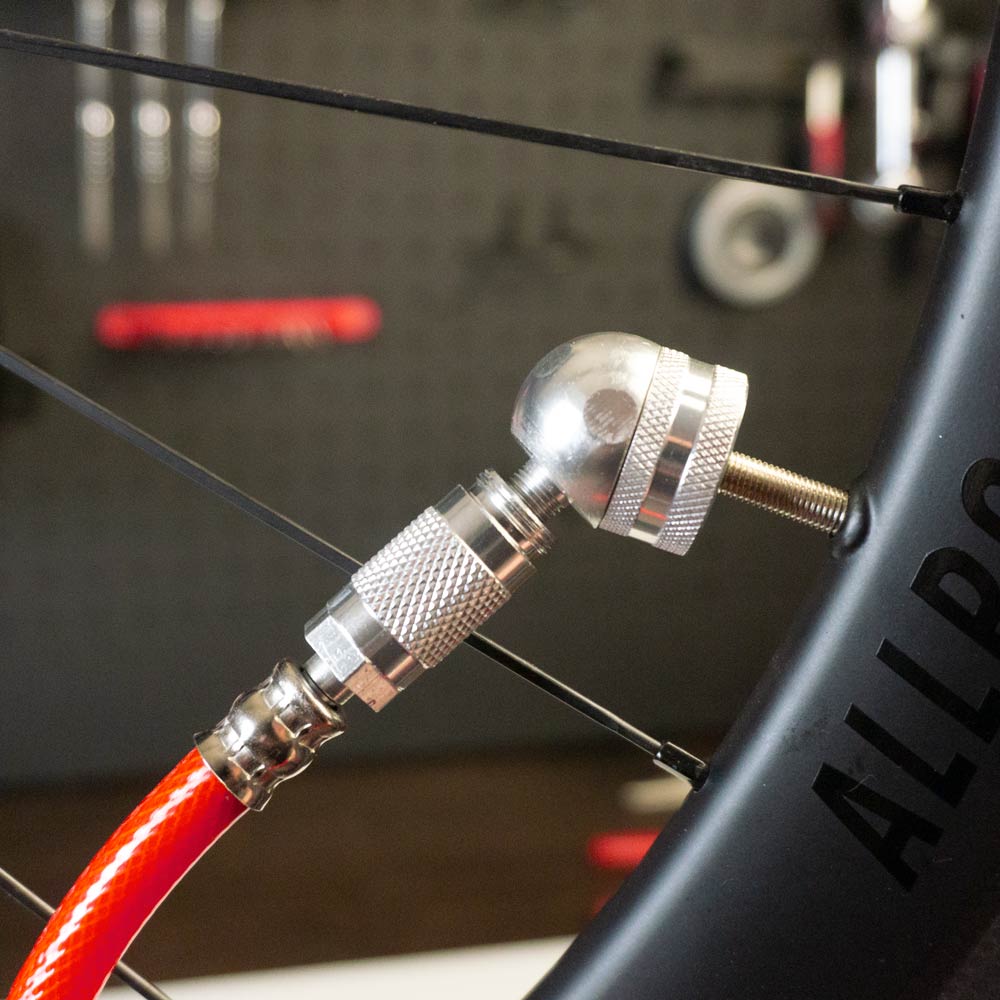

Illustrative image related to how to inflate a presta bike tire

Key Properties: Rubber is known for its excellent elasticity and ability to form airtight seals, making it ideal for tire tubes and valve gaskets. It can typically withstand temperatures ranging from -40°C to 100°C and pressure ratings up to 120 PSI.

Pros & Cons: Rubber is durable and cost-effective, but it can degrade over time due to exposure to UV light and ozone. Manufacturing complexity is low, as rubber can be molded into various shapes. However, its longevity may be a concern in harsh environments.

Impact on Application: Rubber is compatible with air and other gases, making it suitable for tire inflation. However, it may not perform well in extreme temperatures or corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with local standards (like ASTM or DIN) regarding rubber quality. In regions with high UV exposure, such as parts of Africa and South America, UV-resistant rubber may be preferred.

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are lightweight and resistant to corrosion. They can handle moderate pressure and temperatures, typically up to 80°C.

Pros & Cons: The primary advantage of plastic is its lightweight nature, which is beneficial for portable pumps. However, plastics can be less durable than metals and may not withstand high pressures as effectively. Manufacturing complexity can vary based on the design.

Impact on Application: Plastic components are often used in pump heads and adapters. They are suitable for air but may not be ideal for high-pressure applications.

Considerations for International Buyers: Compliance with international plastic standards (like ISO) is crucial. Buyers in Europe and the Middle East may prefer recyclable plastics, aligning with sustainability trends.

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It can handle high pressures (up to 200 PSI) and has a temperature tolerance ranging from -50°C to 150°C.

Pros & Cons: The strength-to-weight ratio of aluminum makes it suitable for high-performance pumps. However, it is generally more expensive than plastic or rubber. Manufacturing processes can be more complex due to the need for precision machining.

Impact on Application: Aluminum is often used in high-end pumps and valve components, providing durability and performance. It is compatible with air and does not react with common gases.

Considerations for International Buyers: Buyers should look for aluminum components that meet international standards (like ASTM or JIS). In regions with high humidity, such as parts of Southeast Asia, corrosion-resistant coatings may be necessary.

Key Properties: Brass is known for its excellent strength and corrosion resistance, particularly in humid environments. It can withstand high pressures and has a temperature tolerance similar to aluminum.

Pros & Cons: Brass components are durable and provide a reliable seal. However, they are heavier and generally more expensive than plastic alternatives. The manufacturing process can be complex due to the need for precise machining.

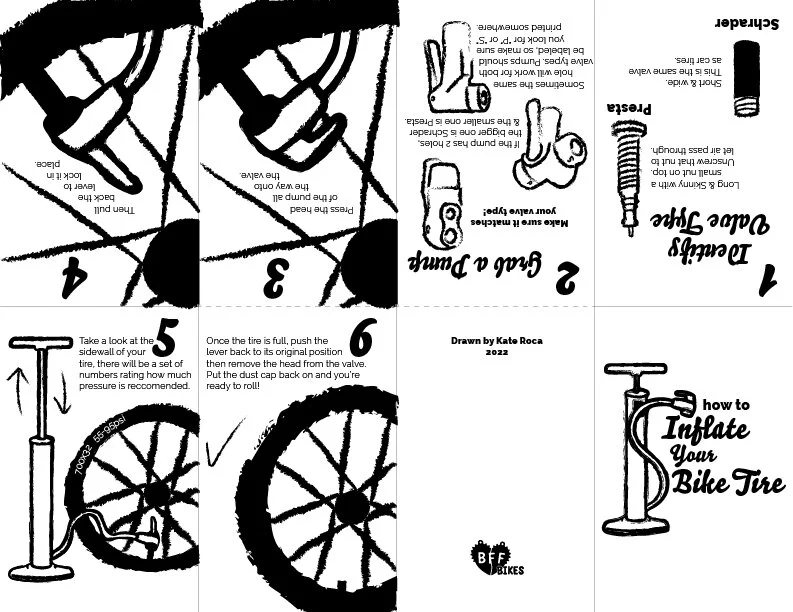

Illustrative image related to how to inflate a presta bike tire

Impact on Application: Brass is commonly used in valve fittings and connectors, ensuring a secure connection during inflation. It is compatible with air and can handle high-pressure applications effectively.

Considerations for International Buyers: Compliance with local standards is essential, especially in regions with strict regulations on metal content. Buyers in Europe may prefer lead-free brass to meet health and safety standards.

| Material | Typical Use Case for how to inflate a presta bike tire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Tire tubes and valve gaskets | Excellent elasticity and airtight seal | Degrades over time in UV exposure | Low |

| Plastic | Pump heads and adapters | Lightweight and corrosion-resistant | Less durable under high pressure | Medium |

| Aluminum | High-performance pumps and valve components | Strong and corrosion-resistant | More expensive and complex to manufacture | High |

| Brass | Valve fittings and connectors | Durable and reliable seal | Heavier and more costly than plastic | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their processes for inflating Presta bike tires, ensuring they choose the right materials for their specific needs and regional considerations.

Manufacturing Presta valve bike tires involves several critical stages, ensuring that the final product meets high standards of performance and durability. Each stage of production requires careful attention to detail and adherence to quality control measures.

The manufacturing process begins with material preparation, where raw materials such as rubber compounds, fabric, and metal components for the valves are sourced. The rubber is typically formulated to achieve the desired balance of elasticity and durability. Manufacturers often employ advanced compounding techniques to enhance the rubber’s properties, ensuring it can withstand high pressures and various environmental conditions.

The metal components, particularly the Presta valve stems, are usually made from lightweight materials such as aluminum or brass. These materials are selected for their strength-to-weight ratios and resistance to corrosion. The preparation phase also includes inspecting raw materials for defects, which is crucial to maintaining the integrity of the final product.

Once materials are prepared, the next stage is forming. This involves molding the rubber into tire shapes and crafting the Presta valves. For tires, the rubber is heated and placed into molds that shape it into the desired profile. The manufacturing process may use techniques such as extrusion and calendaring to ensure uniform thickness and consistency across the tire.

For Presta valves, the components are formed through processes like machining and stamping. Precision is key here, as the valve must fit securely into the tire without any leaks. Manufacturers often utilize Computer Numerical Control (CNC) machines for high precision in producing valve components, which enhances the overall quality and performance of the tire.

Illustrative image related to how to inflate a presta bike tire

Assembly is a critical phase where the various components come together. The tire is typically assembled in layers, with the inner lining, fabric, and outer tread being combined. The Presta valve is installed during this stage, requiring accurate positioning to ensure it functions correctly.

Finishing processes include curing, where the assembled tire is heated to solidify the rubber and bond the components. Quality checks during this phase often involve visual inspections and tests for air retention and structural integrity. After curing, tires are inflated to verify that they can hold the specified pressure without any leaks, ensuring they meet safety standards.

Quality assurance is paramount in the production of Presta valve bike tires, as it directly impacts performance and safety. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system, ensuring consistent product quality and continuous improvement.

B2B buyers should look for certifications that indicate compliance with international standards. For Presta valve bike tires, relevant certifications include:

These certifications provide assurance that the products have been manufactured following strict guidelines, reducing the risk of defects.

Quality control checkpoints are integrated throughout the manufacturing process, including:

B2B buyers should inquire about these checkpoints to understand how manufacturers maintain quality throughout production.

To ensure suppliers adhere to high-quality standards, B2B buyers can take several steps:

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and identify areas for improvement.

Request Quality Reports: Suppliers should be able to provide documentation of quality control processes, including results from inspections and tests. Reviewing these reports can help buyers gauge the reliability of the supplier.

Engage Third-Party Inspectors: Utilizing independent third-party inspectors can add an extra layer of assurance. These inspectors can evaluate the manufacturing processes and confirm that products meet specified standards before they are shipped.

Evaluate Certifications: Buyers should verify the authenticity of the certifications provided by suppliers. This can often be done through the certifying bodies or by checking with industry associations.

For international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential. Variations in regulatory standards and market expectations can influence product specifications and quality requirements.

Regional Standards: Buyers should familiarize themselves with local regulations that may apply to the importation and sale of bike tires. For example, certain regions may have stricter environmental regulations affecting material choices.

Cultural Considerations: Cultural differences can impact communication and expectations regarding quality. Establishing clear guidelines and open lines of communication with suppliers can help bridge any gaps.

Supply Chain Logistics: Understanding the logistics involved in international shipping is crucial. Delays or mishandling during transport can affect product quality, making it important to work with reliable logistics partners.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance for Presta valve bike tires is essential for B2B buyers. By focusing on quality control measures, international standards, and supplier verification, businesses can make informed purchasing decisions that enhance their product offerings and meet market demands.

This guide serves as a practical checklist for B2B buyers seeking effective methods to inflate Presta bike tires. Understanding the nuances of this process is essential for ensuring optimal tire performance and prolonging the lifespan of bike equipment. By following these steps, businesses can streamline their procurement processes and make informed decisions when sourcing products and services related to tire inflation.

Before purchasing any inflation equipment, familiarize yourself with the specifications of Presta valves. These valves are typically used for high-pressure tires and have a narrower diameter compared to Schrader valves. Ensure that the inflation products you consider are compatible with Presta valves to avoid operational inefficiencies.

Choose a pump that is specifically designed for Presta valves, as this will ensure a secure fit and efficient inflation. Floor pumps with a dual-head or dedicated Presta valve chuck are recommended for ease of use and effectiveness.

Invest in high-quality pumps and accessories to minimize the risk of leaks and ensure durability. Poor-quality equipment can lead to frustration and inefficiency during the inflation process.

Ensure that your suppliers adhere to international standards for quality and safety in manufacturing tire inflation equipment. This is particularly important for businesses operating in multiple regions, where compliance may vary.

Before finalizing your purchase, ask suppliers for demonstrations or samples of their inflation equipment. This allows you to evaluate the functionality and ease of use firsthand.

Consider the after-sales support provided by your suppliers, as this can be critical for the long-term success of your tire inflation operations. Regular maintenance and access to replacement parts can prevent downtime.

By following this checklist, B2B buyers can effectively navigate the procurement process for inflating Presta bike tires. Prioritizing compatibility, quality, and support will lead to successful sourcing decisions and improved operational efficiency.

Illustrative image related to how to inflate a presta bike tire

When analyzing the cost structure for inflating Presta bike tires, several components come into play. Materials encompass the cost of valves, tubes, and pumps. The choice of materials significantly impacts durability and performance; for example, high-quality rubber valves may cost more but ensure longevity and reliability. Labor costs are influenced by the skill level required to manufacture and assemble these components. Skilled labor can enhance product quality, which is crucial for maintaining safety and performance standards.

Manufacturing overhead includes expenses related to facilities, utilities, and equipment maintenance. These fixed costs are distributed across production volume, affecting per-unit pricing. Tooling costs, particularly for custom or specialized components, also play a critical role. Investments in high-precision tooling can enhance production efficiency, but they require upfront capital.

Quality Control (QC) is essential to ensure that products meet safety and performance standards. Implementing stringent QC processes can increase costs but reduce the risk of product failures and subsequent liability. Lastly, logistics costs, including shipping and handling, must be factored in, especially for international transactions where tariffs and import duties can significantly affect overall pricing.

Illustrative image related to how to inflate a presta bike tire

Several factors influence the pricing of Presta tire inflation solutions. Volume/MOQ (Minimum Order Quantity) is a primary driver; larger orders often lead to discounts. Suppliers may offer tiered pricing structures that reward bulk purchases, making it crucial for buyers to understand their needs and plan accordingly.

Specifications and customization can also affect pricing. Custom components, such as specific valve lengths or colors, often incur additional costs. Buyers should assess whether these specifications are essential for their target market or if standard options suffice.

Materials used in the production of pumps and valves significantly impact pricing as well. Higher-quality materials might come with a premium but can lead to better performance and customer satisfaction. Furthermore, quality certifications can influence both cost and price; products that meet international standards may be priced higher due to the costs associated with obtaining these certifications.

Supplier factors, such as reputation and reliability, also play a crucial role in pricing. Established suppliers may command higher prices but typically offer better quality assurance and customer service. Lastly, Incoterms dictate the responsibilities of buyers and sellers in international transactions, affecting overall costs and risk management.

Illustrative image related to how to inflate a presta bike tire

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to substantial cost savings. Understanding the Total Cost of Ownership (TCO) is vital; this includes not only the purchase price but also costs related to maintenance, operation, and potential downtime. Buyers should inquire about warranties and after-sales support, which can significantly impact TCO.

Pricing nuances for international buyers can also pose challenges. Currency fluctuations, local taxes, and import duties must be considered when calculating the final price. It is advisable to work with suppliers who offer transparent pricing and clear terms to avoid unexpected costs.

Buyers should leverage their purchasing power by exploring multiple suppliers and obtaining quotes to ensure competitive pricing. Additionally, forming long-term relationships with reliable suppliers can lead to better pricing agreements and priority service.

It is essential to note that prices can vary significantly based on factors like market conditions, supplier negotiations, and specific buyer requirements. Therefore, this analysis serves as a guideline rather than a fixed pricing structure. Always conduct thorough market research and consult with suppliers for the most accurate and up-to-date pricing information.

Illustrative image related to how to inflate a presta bike tire

When it comes to inflating Presta bike tires, several methods exist beyond the traditional use of a floor pump. Each alternative offers unique benefits and challenges that can impact performance, cost, and user experience. B2B buyers in the cycling industry, particularly those in Africa, South America, the Middle East, and Europe, must consider these alternatives when sourcing equipment for their businesses.

| Comparison Aspect | How To Inflate A Presta Bike Tire | CO2 Inflator | Electric Air Pump |

|---|---|---|---|

| Performance | High PSI capability, can reach 110 PSI | Quick inflation, typically up to 120 PSI | Moderate PSI capability, often limited to 100 PSI |

| Cost | Affordable, typically $30-$50 for quality pumps | Moderate, around $15-$30 for inflators (excluding cartridges) | Higher initial investment, generally $50-$150 |

| Ease of Implementation | Requires manual effort and technique | Very easy, one-step inflation | Easy, just plug in and press a button |

| Maintenance | Minimal, occasional lubrication needed | Low, replace CO2 cartridges as needed | Moderate, requires checking battery and motor function |

| Best Use Case | Regular maintenance for avid cyclists | Quick roadside fixes for competitive cyclists | Home or shop use, convenient for frequent use |

CO2 inflators provide a rapid solution for inflating Presta valves, making them ideal for competitive cyclists who need quick fixes during races or training sessions. The convenience of a small, portable device allows cyclists to carry multiple cartridges for extended journeys. However, the recurring cost of CO2 cartridges can add up, and once the gas is released, it cannot be reused. Additionally, cyclists must be cautious about over-inflation, as the lack of a pressure gauge can lead to tire damage.

Electric air pumps present a more automated option for inflating Presta bike tires. They are user-friendly, requiring minimal effort—just plug in and press a button. This makes them ideal for less experienced users or those who may struggle with manual pumps. However, electric pumps typically have a higher upfront cost and may be less portable compared to other options. Additionally, reliance on electricity or batteries can limit their use in remote locations, making them less suitable for on-the-go repairs.

For B2B buyers, the choice of inflation method hinges on the specific needs of their customer base. If the target market consists of competitive cyclists who prioritize speed and efficiency, CO2 inflators may be the best option. Conversely, for businesses focused on casual riders or those requiring regular maintenance, investing in high-quality floor pumps or electric air pumps could enhance customer satisfaction. Ultimately, understanding the needs and preferences of the target audience is essential for making the right purchasing decision.

When considering the inflation of Presta bike tires, several technical specifications play a crucial role in ensuring efficiency and reliability. Understanding these properties can significantly enhance procurement decisions for B2B buyers involved in the cycling industry.

Valve Stem Length

The length of the Presta valve stem is critical, especially for deep-section rims. Longer stems (e.g., 60mm or more) are essential for compatibility with various rim depths, allowing adequate access for pumps. Buyers should prioritize tires with appropriately sized stems to avoid inflation difficulties, ensuring smooth operations in the field.

Material Composition

Presta valves are typically made from brass or aluminum, impacting durability and weight. Brass valves offer superior strength and resistance to corrosion, making them suitable for harsh environmental conditions. In contrast, aluminum valves are lighter, enhancing performance in competitive settings. B2B buyers should consider the material based on the intended use of the bike, whether for leisure or high-performance cycling.

Pressure Rating

The maximum inflation pressure of a Presta valve is often indicated on the tire sidewall (e.g., 110 PSI). It is vital for B2B buyers to ensure that pumps used in conjunction with these tires can achieve the required pressure. Misalignment between tire specifications and pump capabilities can lead to inefficiencies and potential product failures.

Seal Integrity

The sealing mechanism within the Presta valve prevents air leakage during inflation. The quality of the rubber gasket and the valve core’s design directly affect the sealing performance. Buyers should prioritize products that demonstrate high seal integrity, minimizing maintenance and ensuring consistent tire performance.

Compatibility with Pump Types

Not all pumps are designed to accommodate Presta valves effectively. The pump head must securely attach to the valve without air escaping during inflation. Buyers should assess the pump design, focusing on features that ensure compatibility and ease of use, such as lever mechanisms that engage the valve securely.

In the B2B context, familiarizing oneself with industry jargon enhances communication and decision-making processes. Here are several common terms relevant to the inflation of Presta bike tires:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Presta valves, an OEM might provide high-quality valve systems that meet specific industry standards, ensuring reliability for end-users.

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers to manage inventory effectively and negotiate favorable terms with suppliers, especially when sourcing specialized components like Presta valves.

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. B2B buyers should utilize RFQs when seeking to understand pricing structures for bulk purchases of Presta valve systems, enabling them to compare options and negotiate better deals.

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is crucial when importing components, as they dictate who bears the risk and costs associated with shipping and delivery, impacting overall procurement strategies.

TPI (Threads Per Inch)

This specification refers to the density of threads in the tire’s casing, affecting its flexibility and durability. A higher TPI generally indicates a lighter and more supple tire, which can enhance performance. B2B buyers should consider TPI ratings when sourcing tires to meet specific performance criteria.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance their product offerings and improve customer satisfaction in the cycling market.

The global market for bicycle accessories, including those related to inflating Presta bike tires, is experiencing significant growth driven by increased cycling popularity and a shift towards sustainable transportation. In regions such as Africa, South America, the Middle East, and Europe, the demand for bicycles has surged due to urbanization, rising fuel costs, and environmental awareness. This trend is bolstered by innovations in tire technology, including the development of high-pressure tires that require Presta valves, making them essential for performance-oriented cycling.

Emerging B2B technologies, such as smart pumps that integrate with mobile applications for pressure monitoring, are reshaping the landscape. These technologies offer buyers enhanced functionalities, such as automatic pressure adjustments and alerts, thereby improving user experience and safety. Additionally, the rise of e-commerce platforms has facilitated access to specialized tools and pumps for international buyers, allowing them to source quality products from diverse markets.

As the market evolves, international buyers should keep an eye on the growing trend of local sourcing. This shift is driven by the desire to minimize logistics costs and reduce carbon footprints, aligning with global sustainability goals. Understanding regional preferences and local supply chains can provide a competitive edge in sourcing strategies.

Sustainability is becoming a pivotal factor in the sourcing decisions of B2B buyers in the bicycle accessories sector. The environmental impact of manufacturing processes and materials is under scrutiny, prompting buyers to seek out products that minimize ecological footprints. For Presta bike tire inflation, this means sourcing pumps and accessories made from recycled materials or designed for longevity to reduce waste.

Ethical sourcing practices are also gaining traction, with buyers increasingly prioritizing suppliers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and Fair Trade can be significant indicators of a supplier’s commitment to sustainability. These certifications not only enhance brand reputation but also resonate with consumers who are becoming more environmentally conscious.

Moreover, the adoption of “green” materials, such as biodegradable plastics and energy-efficient manufacturing processes, is increasingly important. B2B buyers should evaluate their supply chains for these sustainable practices, ensuring that they align with their corporate social responsibility goals while meeting the demands of eco-conscious consumers.

The inflation process for Presta tires has evolved significantly since their introduction, primarily due to advancements in technology and changes in consumer preferences. Initially, Presta valves were favored in high-performance cycling circles due to their ability to withstand higher pressures and provide a more reliable seal compared to Schrader valves. Over time, as cycling has grown in popularity across various demographics, the need for simpler and more user-friendly inflation methods has emerged.

Modern innovations include specialized pumps designed for Presta valves, which often feature ergonomic designs and enhanced sealing mechanisms that make inflation easier and more efficient. The introduction of digital pressure gauges and smart pumps has further transformed the inflation process, allowing cyclists to accurately monitor tire pressure and inflate tires to optimal levels without the guesswork.

These advancements reflect a broader trend in the cycling industry towards improving user experience and safety. As the market continues to expand, international B2B buyers must stay informed about these developments to ensure they are sourcing the most effective and efficient products for their customers.

1. How do I solve the issue of air leaking when inflating a Presta valve?

To address air leakage during inflation, ensure that the pump head is securely attached to the valve. If air escapes, it may indicate that the pump head is not fully engaging the valve or that the valve is damaged. Start by removing the valve cap and slightly unscrewing the valve core to release any pressure. Then, position the valve at the 6 o’clock position for stability and firmly press the pump head onto the valve before flipping the lever to create a seal. If problems persist, consider using a valve extender or a different pump compatible with Presta valves.

2. What is the best pump for inflating Presta bike tires?

The best pump for Presta valves is a high-quality floor pump with a dual-head design that accommodates both Presta and Schrader valves. Look for features such as a pressure gauge for accurate readings and a lever lock mechanism for a secure fit. Brands like Topeak and Lezyne offer reliable options that are durable and user-friendly. Additionally, for portability, consider a compact hand pump with a built-in gauge. Ensure the pump can handle the required PSI for your tires, as many Presta setups require higher pressures.

3. How can I check the pressure of a Presta valve tire accurately?

To accurately check the pressure of a tire with a Presta valve, first, attach a compatible pump or pressure gauge to the valve. Before connecting, unscrew the small valve nut to allow air to escape slightly, which ensures the valve is not stuck. When you attach the pump, the gauge should indicate the current pressure; if it reads zero, the pump may not be engaging properly. If the gauge is still unresponsive, consider using a dedicated pressure gauge to avoid confusion caused by the pump’s design.

4. What are the key considerations when sourcing Presta valve pumps for international trade?

When sourcing Presta valve pumps internationally, consider factors such as compliance with local regulations, quality assurance certifications, and the reliability of the supplier. Evaluate the supplier’s production capacity and lead times to ensure they can meet your demand. Additionally, inquire about customization options to align the products with your branding. Establish clear communication regarding minimum order quantities (MOQs), payment terms, and logistics to avoid complications during the shipping process.

5. How do I vet suppliers for Presta valve products?

Vetting suppliers for Presta valve products involves assessing their experience, reputation, and product quality. Check for customer reviews and ratings on platforms such as Alibaba or industry-specific trade sites. Request samples to evaluate the product quality firsthand and ensure it meets your specifications. Conduct background checks to verify business credentials and certifications. Building a relationship through regular communication can also provide insights into the supplier’s reliability and responsiveness.

6. What customization options are typically available for Presta valve pumps?

Customization options for Presta valve pumps often include branding with your logo, color variations, and packaging designs. Some suppliers may offer the ability to modify the pump’s features, such as adding a digital gauge or a specific nozzle type. Discuss your requirements with the supplier during the initial sourcing phase to understand what customization is feasible and any additional costs involved. Ensure that the final product aligns with your marketing strategy and target audience’s preferences.

7. What payment terms should I expect when importing Presta valve pumps?

Payment terms for importing Presta valve pumps can vary significantly by supplier and region. Common arrangements include upfront payments, a deposit followed by balance upon shipment, or payment through letters of credit for larger orders. Negotiate terms that provide security for both parties, and consider using escrow services for high-value transactions. Always clarify the currency used, potential additional fees, and the timeline for payment to avoid misunderstandings that could delay the order.

8. How do logistics impact the import of Presta valve products?

Logistics play a crucial role in the timely and cost-effective import of Presta valve products. Factors such as shipping methods, customs regulations, and potential tariffs can significantly affect overall costs and delivery times. Work closely with your supplier to understand their shipping options and choose the best method based on your urgency and budget. Additionally, ensure that all paperwork is in order to facilitate smooth customs clearance and avoid unexpected delays. Consider partnering with a reliable freight forwarder to manage the logistics process efficiently.

Domain: bicycles.stackexchange.com

Registered: 2009 (16 years)

Introduction: Presta valve, tire pressure 110 psi (7.5 atm), floor pump, valve cap, valve stem, pump head, valve adapter, jam nut, 60 mm valve, 42 mm valve, deep rims.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Presta valve, bike pump, adapter for Presta valve, air compressor.

In summary, effectively inflating a Presta bike tire requires a clear understanding of the valve’s unique design and operational requirements. Businesses should prioritize sourcing high-quality pumps that are compatible with Presta valves, ensuring that their teams can efficiently manage tire maintenance. Additionally, investing in valve extenders or adapters can significantly enhance usability for various rim depths, reducing frustration and downtime.

Illustrative image related to how to inflate a presta bike tire

Strategic sourcing is essential for optimizing the procurement of bicycle maintenance tools and accessories. By establishing reliable partnerships with suppliers who understand the specific needs of your market—whether in Africa, South America, the Middle East, or Europe—you can secure better pricing, quality, and support. This proactive approach not only streamlines operations but also positions your business as a knowledgeable leader in the cycling industry.

Looking ahead, it is crucial for international B2B buyers to stay informed about the latest innovations in bicycle maintenance products. Engaging with suppliers who offer comprehensive training and resources on tire inflation techniques will empower your team to enhance service delivery. Embrace these opportunities to elevate your operational efficiency and customer satisfaction, ensuring that your business remains competitive in the evolving cycling market.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to inflate a presta bike tire

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.