The demand for pocket tire inflators is surging as international B2B buyers seek reliable, portable solutions for maintaining tire pressure across various vehicles. Sourcing high-quality pocket tire inflators can be challenging, particularly when balancing cost, functionality, and supplier reliability. This guide addresses these challenges by providing a comprehensive overview of the different types of pocket tire inflators available on the market, their applications, and critical factors to consider when selecting the right product for your business needs.

In the coming sections, we will delve into the specific features that make pocket tire inflators indispensable for diverse markets, including e-bikes, motorcycles, and passenger vehicles. We will also explore the nuances of supplier vetting processes, ensuring that you can confidently partner with reputable manufacturers. Furthermore, we will provide insights into pricing structures and trends specific to regions such as Africa, South America, the Middle East, and Europe, including key markets like Brazil and Saudi Arabia.

By the end of this guide, you will be equipped with the knowledge necessary to make informed purchasing decisions, optimizing your investment in pocket tire inflators. Whether you are a distributor looking to expand your product line or a retailer seeking reliable inflator solutions, this resource is designed to empower your business in navigating the global market effectively.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Electric Inflator | Battery-powered, portable, often with digital gauges | Automotive repair shops, bike retailers | Pros: Portable, quick inflation. Cons: Limited charge duration. |

| Compact Manual Inflator | Hand-operated, lightweight, no power source needed | Outdoor retailers, emergency kits | Pros: No battery required, very lightweight. Cons: Labor-intensive, slower inflation. |

| High-Pressure Inflator | Capable of inflating to high PSI levels, often with adapters | Trucking companies, industrial applications | Pros: Versatile for various vehicles. Cons: Bulkier, often requires a power outlet. |

| Multi-Function Inflator | Includes features like USB charging, LED lights | Camping suppliers, adventure gear retailers | Pros: Multi-use device, convenient. Cons: Can be pricier, may have complex features. |

| Smart Digital Inflator | Connects to smartphones, offers pressure monitoring | Fleet management, logistics companies | Pros: Real-time monitoring, data tracking. Cons: Higher cost, dependency on technology. |

Cordless electric inflators are designed for maximum portability, powered by rechargeable batteries, making them ideal for on-the-go applications. They typically feature digital pressure gauges for precise inflation and can inflate tires quickly, often within minutes. These inflators are suitable for automotive repair shops and bike retailers, where efficiency is key. When purchasing, consider battery life, maximum PSI, and ease of use, as well as compatibility with different valve types.

Compact manual inflators are lightweight and do not require any power source, making them an essential tool for outdoor retailers and emergency kits. They are particularly effective for quick fixes in remote locations. However, they require manual effort, which can be a drawback for some users. B2B buyers should evaluate the balance between portability and the physical effort required for inflation, as well as the target market’s needs.

High-pressure inflators are capable of achieving higher PSI levels, making them suitable for heavy-duty vehicles like trucks and industrial equipment. They often come with various adapters for different types of tires, enhancing their versatility. These inflators are particularly valuable for trucking companies and industrial applications where tire performance is critical. Buyers should focus on the inflator’s durability, power source, and PSI capabilities to meet their specific needs.

Illustrative image related to pocket tire inflator

Multi-function inflators incorporate additional features such as USB charging ports and LED lights, catering to camping suppliers and adventure gear retailers. They serve not only as tire inflators but also as power banks for electronic devices, adding significant value. However, they may come at a higher price point and can have more complex features. B2B buyers should weigh the benefits of versatility against the potential for increased costs and user complexity.

Smart digital inflators connect to smartphones and provide real-time pressure monitoring, making them ideal for fleet management and logistics companies. They enhance operational efficiency by allowing for proactive tire maintenance through data tracking. While they offer advanced features, they generally come at a higher cost and may depend on technology reliability. B2B purchasers should consider the long-term benefits of data-driven maintenance against initial investment and technology integration challenges.

| Industry/Sector | Specific Application of Pocket Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Quick tire inflation for customer vehicles | Reduces downtime for vehicle servicing | Consider battery life, inflation speed, and compatibility with various tire valves. |

| E-Bike Manufacturing | On-the-go inflation solutions for e-bike customers | Enhances customer satisfaction with fast service | Look for compact size, PSI capacity, and ease of use for end-users. |

| Logistics and Transportation | Maintenance of fleet vehicles’ tire pressures | Improves fuel efficiency and extends tire lifespan | Ensure durability, reliability, and the ability to handle multiple tire types. |

| Outdoor Adventure Retail | Portable inflators for camping and outdoor activities | Attracts customers seeking convenience in emergencies | Evaluate weight, battery capacity, and included accessories for diverse applications. |

| Sports Equipment Retail | Inflation of sports balls and recreational items | Offers added value to customers purchasing equipment | Assess compatibility with various adapters and ease of storage. |

Automotive repair shops utilize pocket tire inflators for quickly addressing tire-related issues in customer vehicles. These compact devices enable technicians to efficiently inflate tires, reducing the time vehicles spend in the shop. This not only enhances customer satisfaction but also boosts the shop’s overall productivity. B2B buyers in this sector should prioritize inflators with long battery life, quick inflation capabilities, and compatibility with different tire valves to meet diverse customer needs.

Illustrative image related to pocket tire inflator

In the e-bike manufacturing industry, pocket tire inflators serve as essential tools for providing on-the-go inflation solutions. Retailers can offer these inflators to customers, ensuring they can maintain optimal tire pressure during rides. This convenience significantly enhances the customer experience, fostering brand loyalty. Buyers in this sector should consider models that are compact, lightweight, and capable of inflating tires to the required PSI levels quickly, as this will appeal to the active lifestyle of e-bike users.

Logistics and transportation companies rely on pocket tire inflators to maintain the tire pressures of their fleet vehicles. Proper tire inflation is crucial for optimizing fuel efficiency and prolonging the lifespan of tires, directly impacting operational costs. These companies should look for durable inflators that can withstand heavy use, have a reliable power source, and can accommodate various tire sizes and types to ensure all vehicles can be serviced efficiently.

Outdoor adventure retailers can leverage pocket tire inflators to provide customers with portable inflation solutions for camping and other outdoor activities. These devices are invaluable during emergencies when quick tire inflation is necessary. By offering inflators, retailers can enhance customer satisfaction and differentiate themselves from competitors. Sourcing considerations should include the inflator’s weight, battery capacity, and the variety of included accessories, ensuring customers have everything needed for their outdoor adventures.

Illustrative image related to pocket tire inflator

Sports equipment retailers can utilize pocket tire inflators for inflating sports balls and recreational items, providing an additional service to their customers. This added convenience can encourage purchases and enhance the shopping experience. Buyers in this sector should focus on inflators that come with multiple adapters for different sports equipment, are easy to store, and offer reliable performance, ensuring they meet the diverse needs of their clientele.

The Problem: B2B buyers often face challenges with pocket tire inflators that have limited battery life, especially when used in high-demand environments like automotive repair shops or roadside assistance services. A short battery duration can lead to inefficiencies, requiring frequent recharging or additional equipment on hand. This can be particularly frustrating when multiple tires need inflation, leading to downtime and potentially dissatisfied customers.

The Solution: To overcome this issue, buyers should prioritize inflators with a robust battery capacity—ideally, models that offer at least 2,000 mAh or more. When sourcing pocket tire inflators, look for those that provide rapid charging capabilities, allowing for quick turnaround times between uses. Additionally, consider investing in models that can also serve as power banks to charge other devices, providing dual functionality. Implementing a regular maintenance schedule to check battery health and performance will also ensure that the inflator remains reliable over time. This proactive approach can help maintain consistent operational efficiency.

Illustrative image related to pocket tire inflator

The Problem: Another common pain point arises when B2B buyers encounter pocket tire inflators that lack versatility in terms of compatibility with different tire types and valve systems. For businesses dealing with a variety of vehicles—from cars and trucks to bicycles and motorcycles—having an inflator that can accommodate both Schrader and Presta valves is crucial. Incompatibility can lead to delays in service and increased frustration for customers.

The Solution: When selecting a pocket tire inflator, ensure it includes a range of adapters to accommodate various valve types, including Presta, Schrader, and other specialized fittings. Look for inflators that are marketed specifically as versatile or multifunctional, often featuring multiple nozzles and attachments. This will enable your business to serve a wider range of customers effectively. Additionally, training your staff on how to switch between adapters quickly can improve service times and customer satisfaction, ensuring that you can handle any tire inflation need that arises.

The Problem: Inaccurate tire pressure readings can lead to significant issues, including reduced vehicle performance, increased fuel consumption, and safety hazards. B2B buyers often struggle with pocket tire inflators that do not provide reliable pressure readings, which can compromise the quality of service offered to clients, especially in sectors like transportation and logistics where vehicle reliability is paramount.

The Solution: To mitigate this risk, prioritize pocket tire inflators that feature built-in digital pressure gauges with high accuracy ratings (±1 psi is ideal). Ensure that the inflator has an auto shut-off feature that stops inflation once the desired pressure is reached. When procuring these devices, it’s beneficial to conduct thorough testing of the inflators in real-world scenarios to verify their accuracy and reliability. Additionally, consider incorporating regular calibration checks into your operational processes to ensure that all inflators maintain their precision over time. This attention to detail not only enhances service quality but also builds trust with clients who rely on accurate tire maintenance for their operations.

Illustrative image related to pocket tire inflator

When selecting materials for pocket tire inflators, various factors such as performance, durability, cost, and regional preferences must be considered. Here, we analyze four common materials used in the construction of these devices: plastic, aluminum, rubber, and stainless steel.

Key Properties: Plastic is lightweight and can be engineered for high impact resistance. It typically has a temperature rating of -40°C to 80°C and is resistant to many chemicals, making it suitable for various environments.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for complex shapes and designs. However, it may not withstand high-pressure applications as effectively as metals, leading to potential durability issues over time.

Illustrative image related to pocket tire inflator

Impact on Application: Plastic components are often used in the housing of inflators, which must be lightweight yet sturdy enough to protect internal mechanisms. Compatibility with specific media is generally good, but care must be taken with aggressive chemicals.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the plastic used meets local safety and environmental regulations. Compliance with standards such as ASTM can be crucial for market acceptance.

Key Properties: Aluminum is known for its excellent strength-to-weight ratio and corrosion resistance. It can handle pressures up to 150 PSI and performs well in both high and low-temperature environments.

Illustrative image related to pocket tire inflator

Pros & Cons: The key advantage of aluminum is its durability and lightweight nature, making it ideal for portable applications. However, the manufacturing process can be more complex and costly compared to plastic.

Impact on Application: Aluminum is often used for the body and structural components of inflators, providing a robust framework that enhances the device’s longevity. Its compatibility with various gases makes it suitable for tire inflation.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer aluminum for its premium feel and performance. Compliance with regulations such as DIN can enhance product credibility.

Key Properties: Rubber is highly flexible and can withstand a range of temperatures (-30°C to 100°C). It is also resistant to wear and tear, making it ideal for seals and hoses.

Illustrative image related to pocket tire inflator

Pros & Cons: The flexibility of rubber allows for effective sealing and pressure retention, which is crucial for tire inflators. However, it can degrade over time when exposed to UV light and certain chemicals, limiting its lifespan.

Impact on Application: Rubber components are essential for creating airtight seals in the inflator, ensuring efficient operation. Compatibility with air and various gases is excellent, but buyers should be cautious about rubber quality.

Considerations for International Buyers: In regions with high UV exposure, such as parts of Africa and the Middle East, selecting UV-resistant rubber can significantly enhance product longevity. Compliance with JIS standards can also be a selling point.

Key Properties: Stainless steel is known for its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures.

Illustrative image related to pocket tire inflator

Pros & Cons: The main advantage of stainless steel is its durability and long lifespan, making it ideal for high-performance applications. However, it is heavier and more expensive than other materials, which may affect portability.

Impact on Application: Stainless steel is often used in high-pressure components, such as valves and connectors, where reliability is critical. Its compatibility with various gases is excellent, ensuring safe operation.

Considerations for International Buyers: Buyers in Europe may favor stainless steel for its premium quality and compliance with stringent safety regulations. Ensuring that the material meets ASTM standards can facilitate market entry.

Illustrative image related to pocket tire inflator

| Material | Typical Use Case for pocket tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and external components | Lightweight and cost-effective | Less durable under high pressure | Low |

| Aluminum | Body and structural components | Durable and corrosion-resistant | Higher manufacturing complexity | Medium |

| Rubber | Seals and hoses | Excellent flexibility and sealing | UV degradation over time | Low |

| Stainless Steel | High-pressure components (valves, etc.) | High strength and long lifespan | Heavier and more expensive | High |

This analysis provides a comprehensive overview of material considerations for pocket tire inflators, enabling international B2B buyers to make informed decisions based on performance, cost, and regional standards.

The manufacturing process of pocket tire inflators involves several key stages, each critical to ensuring the final product meets performance and quality expectations. These stages are:

The first stage in manufacturing pocket tire inflators is material preparation. Common materials include high-grade plastics for the body, rubber for seals and hoses, and metals such as aluminum or stainless steel for internal components. Suppliers must ensure that materials meet specific standards for durability and safety, which can vary by region. For instance, materials may need to comply with environmental regulations such as RoHS in Europe or similar standards in other regions.

Once materials are prepared, the next step is forming. This involves various techniques such as injection molding for plastic components and metal stamping for internal parts. Advanced manufacturing processes, including CNC machining and 3D printing, may also be employed to create precise and complex shapes. The choice of forming technique can significantly influence the strength, weight, and overall performance of the inflator.

Illustrative image related to pocket tire inflator

The assembly stage is where all individual components come together. This process often employs automated machinery for efficiency, but skilled labor is equally important for quality assurance. Components such as the motor, battery, and digital display are assembled in a clean and controlled environment to minimize contamination. Manufacturers may implement modular assembly lines to facilitate quick changes in production based on market demands.

Finishing is the final stage before packaging and shipping. This stage can include surface treatments, painting, or the application of protective coatings to enhance durability. Additionally, quality checks are performed to ensure that each inflator meets design specifications and functional requirements. The finishing stage is crucial for aesthetics and functionality, as it can affect user experience and product longevity.

Quality assurance (QA) is critical in the manufacturing of pocket tire inflators, ensuring that products are safe, reliable, and meet customer expectations. Several international and industry-specific standards play a role in this process.

ISO 9001 is one of the most recognized quality management standards globally. It provides a framework for consistent quality in manufacturing processes. Compliance with ISO 9001 demonstrates a manufacturer’s commitment to quality and continuous improvement. Additionally, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

Industry-specific certifications may also be necessary. For instance, the American Petroleum Institute (API) certification can be relevant if the inflators are designed for use in specific heavy-duty applications. Other certifications may pertain to battery safety, electromagnetic compatibility, and environmental impact. Manufacturers targeting markets in Africa, South America, the Middle East, and Europe should be aware of the specific certifications required in each region.

Quality control (QC) checkpoints throughout the manufacturing process are vital for ensuring product integrity. These checkpoints are designed to catch defects early and ensure compliance with established standards.

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. This stage ensures that materials meet specified quality standards before they enter the production line.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC monitors production to ensure that each stage adheres to quality standards. This may involve regular checks of dimensions, assembly accuracy, and performance tests of components.

Final Quality Control (FQC): The final checkpoint occurs after assembly. Here, the completed inflators undergo rigorous testing, including functionality checks, pressure testing, and safety assessments. Any units that do not meet quality standards are either reworked or discarded.

Testing methods play a crucial role in the QC process, ensuring that pocket tire inflators perform as expected. Common testing methods include:

Illustrative image related to pocket tire inflator

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are some effective strategies:

Conducting supplier audits is one of the most effective ways to assess quality control practices. Buyers should look for:

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality assurance processes. These inspections typically cover material quality, production practices, and compliance with relevant standards. Third-party certifications can enhance trust and credibility in international markets, particularly in regions like Africa and South America, where regulatory requirements may differ significantly.

International B2B buyers should be aware of specific nuances that may affect their purchasing decisions.

Regulatory frameworks can vary widely between regions. For instance, products sold in Europe must comply with CE marking requirements, while different standards may apply in Africa or South America. Buyers should familiarize themselves with the specific regulations in their target markets to ensure compliance and avoid costly delays.

Understanding warranty terms and post-purchase support is crucial for B2B buyers. Manufacturers should provide clear information regarding warranty coverage, including duration and conditions for claims. Buyers should also inquire about the availability of technical support and spare parts to ensure long-term satisfaction with their investment.

Illustrative image related to pocket tire inflator

By thoroughly understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing pocket tire inflators, ensuring they select suppliers who prioritize quality and compliance.

This sourcing guide is designed to assist B2B buyers in the procurement of pocket tire inflators. As a crucial tool for maintaining tire pressure across various vehicles, selecting the right inflator involves careful consideration of technical specifications, supplier reliability, and additional features. This checklist will help ensure that your purchasing decisions align with your operational needs and standards.

Understanding the specific technical requirements for the pocket tire inflator is essential. Determine the maximum PSI needed for your applications, as different vehicles may require varying levels of inflation pressure.

– Consider compatibility: Ensure the inflator can accommodate different valve types (e.g., Schrader and Presta).

– Assess power options: Decide whether a battery-operated model or one that plugs into a vehicle’s power outlet suits your needs better.

Illustrative image related to pocket tire inflator

Set a clear budget for the procurement process. Pocket tire inflators can vary significantly in price based on features and brand reputation.

– Evaluate total cost of ownership: Consider not just the initial purchase price, but also potential maintenance costs and the longevity of the product.

– Look for bulk purchase discounts: Many suppliers offer price reductions for bulk orders, which can be beneficial for larger organizations.

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Assess supplier reliability: Look for suppliers with a proven track record of quality and service.

– Check for certifications: Ensure suppliers comply with international quality standards, which can reflect their commitment to product excellence.

Examine the features offered by different pocket tire inflators. Key attributes to assess include:

– Inflation speed: Consider how quickly the inflator can fill a tire, which is vital for operational efficiency.

– Battery life and charging options: A long-lasting battery is crucial for repeated use, especially in remote areas. Investigate the charging time and whether it supports USB charging.

Before finalizing your order, request samples from shortlisted suppliers. Testing the product firsthand can reveal insights that specifications alone may not provide.

– Conduct real-world evaluations: Test the inflators on various tire types to assess performance and reliability.

– Gather user feedback: Share samples with team members who will use the inflators, and collect their feedback on usability and effectiveness.

Illustrative image related to pocket tire inflator

Once you’ve selected a supplier, it’s time to negotiate terms. This includes pricing, delivery schedules, and warranty agreements.

– Clarify payment terms: Understand the payment options available and any potential discounts for early payment.

– Set delivery expectations: Ensure that the supplier can meet your timelines, particularly if you require the inflators for a specific project or event.

After negotiating, finalize the purchase agreement with your chosen supplier. Ensure that all details are clearly documented, including specifications, pricing, and delivery terms.

– Include warranty details: A robust warranty can protect your investment and ensure support in case of defects.

– Establish a communication plan: Determine how you will communicate with the supplier throughout the order process to address any issues that may arise.

By following these steps, B2B buyers can confidently source pocket tire inflators that meet their operational needs while ensuring supplier reliability and product quality.

When sourcing pocket tire inflators, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The core materials for pocket tire inflators typically involve high-grade plastics, metal components for valves and motors, and lithium-ion batteries. The choice of materials can significantly influence the durability and performance of the product. Higher-quality materials may lead to increased initial costs but can reduce long-term failures and warranty claims.

Labor: Labor costs vary based on the manufacturing location. Countries with lower wage rates may offer more competitive pricing, but this can sometimes come at the expense of quality. It’s essential to balance cost with the expertise of the workforce in producing high-quality inflators.

Manufacturing Overhead: This includes costs related to factory operation such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, positively impacting the overall pricing of the product.

Tooling: Initial investments in tooling can be substantial, especially for custom designs. Buyers should consider whether they require standard models or if customization is necessary, as this will affect the tooling costs and overall pricing.

Quality Control: Implementing robust QC processes ensures that products meet specifications and reduce defects. The costs associated with QC should be factored into the pricing, as they are critical for maintaining brand reputation and customer satisfaction.

Logistics: Transportation costs, including shipping and customs duties, significantly affect the final price. Buyers should assess the logistics involved in getting the product from the manufacturer to their location, especially when sourcing internationally.

Margin: Manufacturers set margins based on their overall costs, market demand, and competitive landscape. Understanding the margin can help buyers negotiate better pricing.

Several key factors can influence pricing, particularly for international buyers:

Volume/MOQ: Larger order volumes often qualify for better pricing. Minimum Order Quantities (MOQs) can vary by supplier, impacting total costs. Negotiating for lower MOQs or tiered pricing based on volume can lead to significant savings.

Specifications and Customization: Custom features or specifications can raise costs. Buyers should evaluate whether standard models meet their needs or if the added investment in customization is justified.

Materials and Quality Certifications: Products made with premium materials or those that meet specific certifications (e.g., CE, ISO) may command higher prices. International buyers should weigh the benefits of such certifications against their budget constraints.

Supplier Factors: Supplier reliability, reputation, and location can also affect pricing. Established suppliers with a track record of quality may charge more, but the assurance of product reliability can offset these costs in the long run.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining shipping responsibilities and costs. Buyers should negotiate terms that minimize their exposure to unexpected charges.

Conduct Thorough Market Research: Understanding the average market price and competitor offerings can provide leverage during negotiations.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, warranty, and potential replacement costs over the product’s lifecycle. This holistic view can justify higher upfront costs for better quality products.

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns and might incentivize suppliers to offer better pricing.

Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better pricing, priority service, and improved communication.

Leverage Local Expertise: When sourcing in regions like Africa, South America, or the Middle East, local partners can provide valuable insights into market dynamics and help navigate logistical challenges.

Prices for pocket tire inflators can vary significantly based on market conditions, supplier negotiations, and specific requirements. The information provided is indicative and should be validated through direct supplier engagement and market research.

In the realm of tire maintenance, pocket tire inflators have gained popularity for their compact design and convenience. However, businesses may seek alternative solutions that cater to specific needs or applications. Evaluating these alternatives can provide insights into performance, cost-effectiveness, and ease of use, ensuring that buyers select the most suitable option for their operations.

| Comparison Aspect | Pocket Tire Inflator | Bullseye Pocket Air Inflator | AstroAI Cordless Tire Inflator |

|---|---|---|---|

| Performance | Up to 150 PSI, fast inflation (25 sec for bike tires) | Up to 100 PSI, suitable for various vehicles | Up to 160 PSI, effective for cars and bikes |

| Cost | $59.99 | $59.95 | $65.99 |

| Ease of Implementation | User-friendly, compact, portable | Easy to use, includes multiple adapters | Cordless with multiple power options |

| Maintenance | Minimal, rechargeable battery | Low, rechargeable with long lifespan | Low, with battery management features |

| Best Use Case | Ideal for cyclists and light vehicles | Great for camping, commuting, and emergencies | Versatile for cars, bikes, and sports equipment |

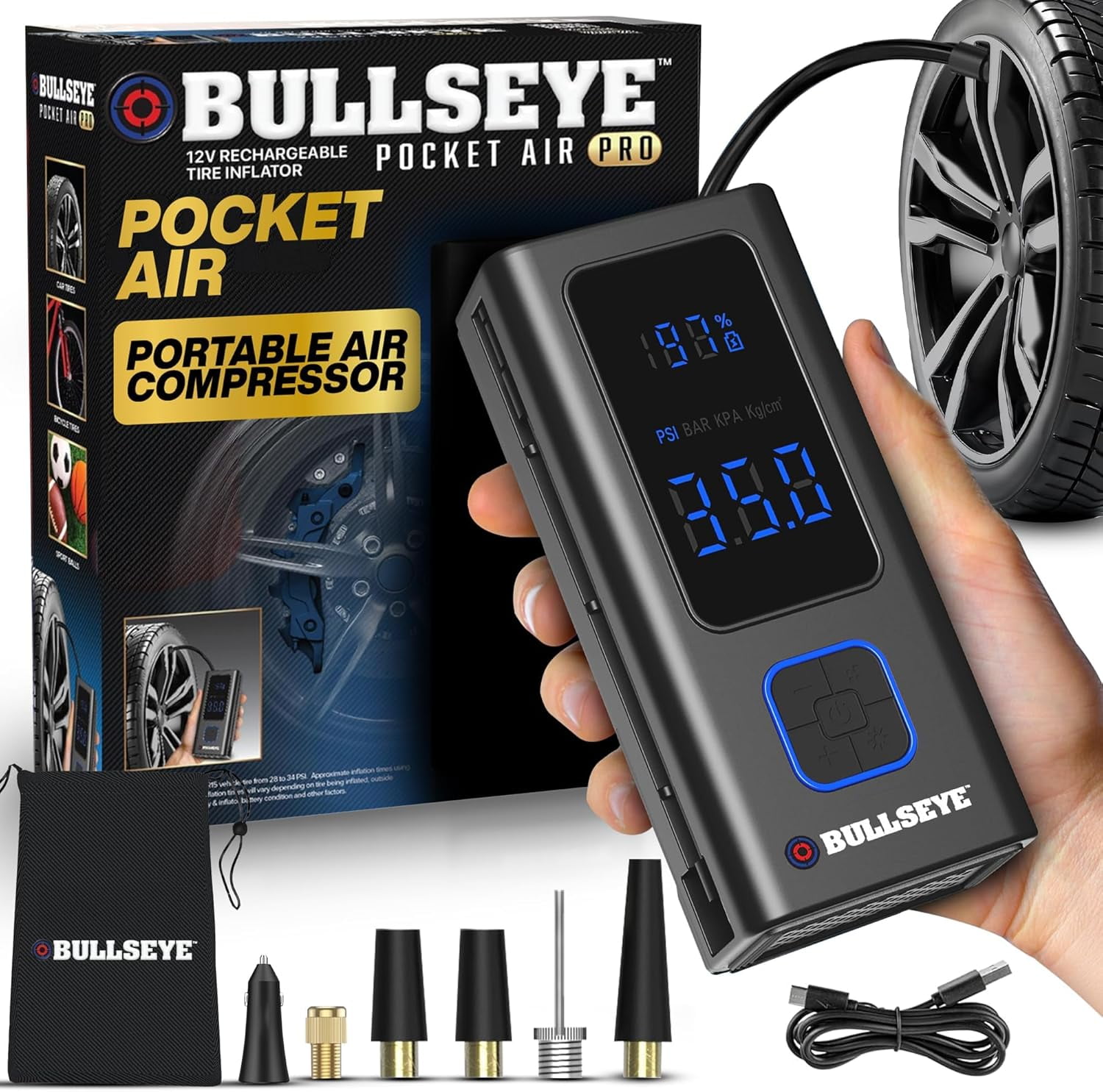

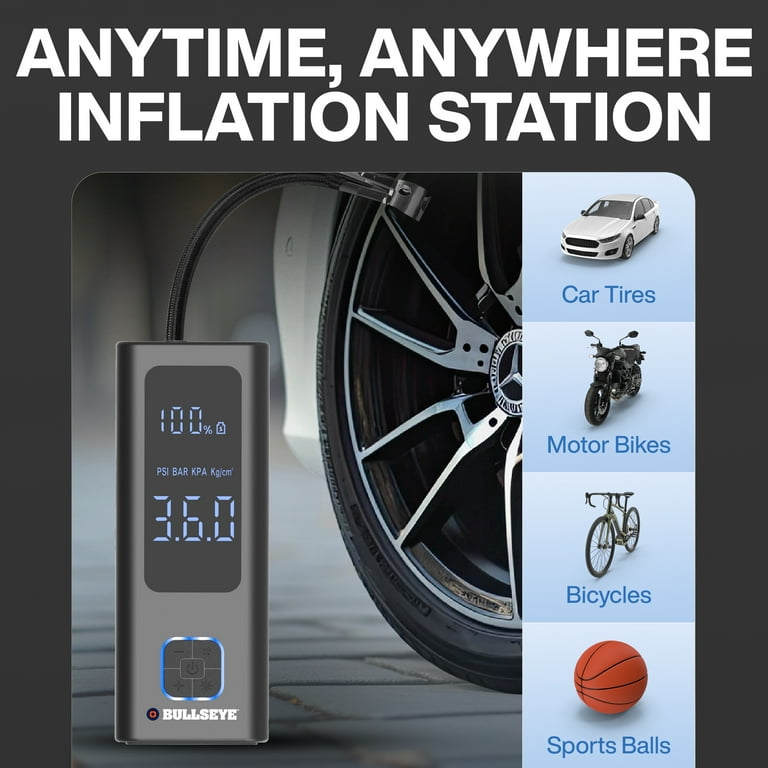

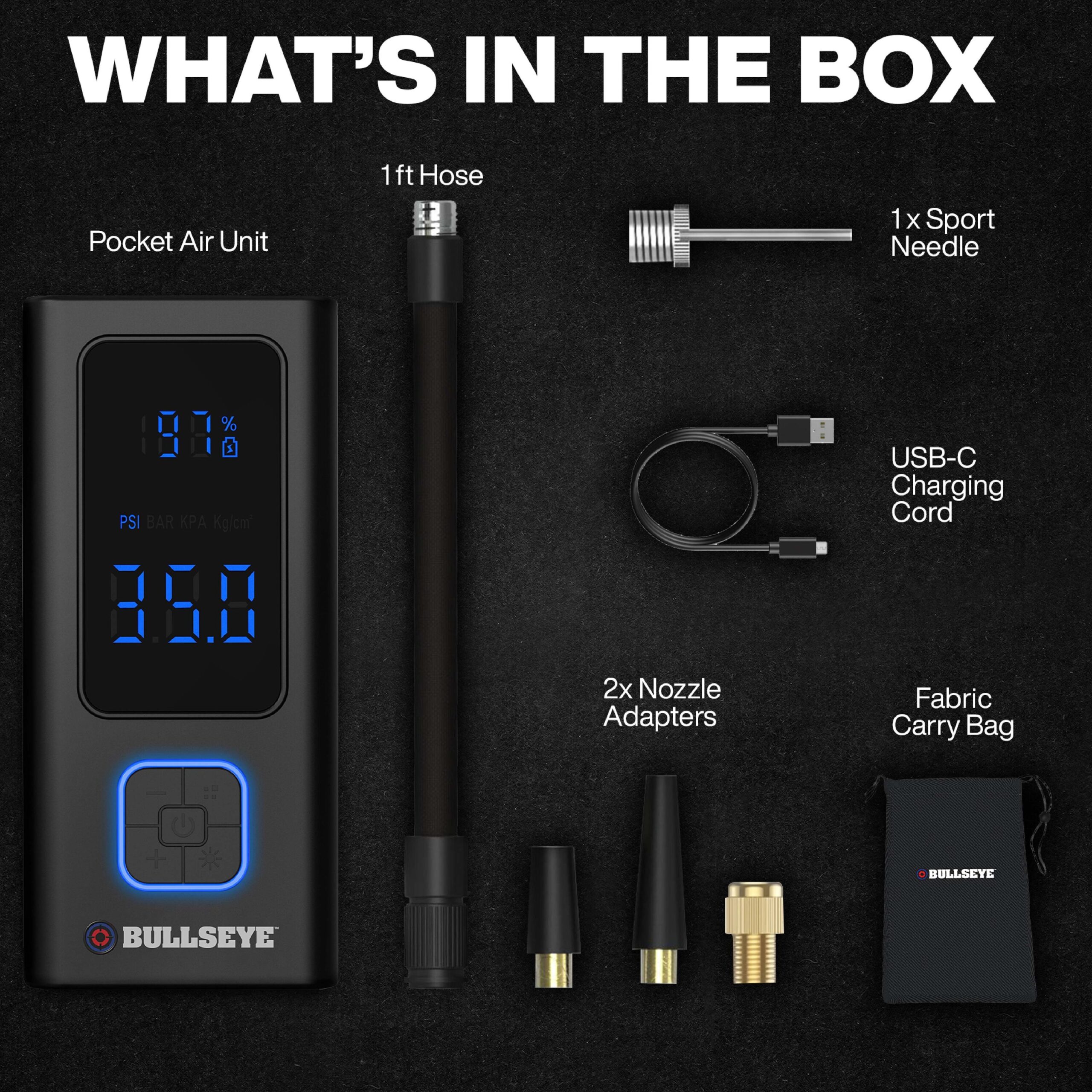

Bullseye Pocket Air Inflator

The Bullseye Pocket Air Inflator is designed for portability and convenience. It can inflate tires up to 100 PSI and includes a built-in power bank to charge electronic devices, making it ideal for outdoor activities like camping. However, its lower PSI limit compared to pocket tire inflators may be a drawback for users needing higher pressure for larger tires. The compact design fits easily in vehicle storage, but its reliance on battery power means users should monitor charge levels for consistent performance.

AstroAI Cordless Tire Inflator

The AstroAI Cordless Tire Inflator stands out as a powerful alternative, capable of reaching up to 160 PSI. It offers multiple power options, including a rechargeable battery and a 12-volt outlet, enhancing versatility. This inflator is suitable for various applications, from cars to sports equipment. However, its slightly higher price point may be a consideration for budget-conscious buyers. Additionally, the unique design may not appeal to everyone, but its efficient performance and additional features, like a flashlight and USB ports, provide added value.

When selecting a tire inflation solution, B2B buyers should consider their specific operational needs, including the types of vehicles or equipment they maintain, budget constraints, and the environments in which they operate. Pocket tire inflators offer unparalleled portability and rapid inflation for cyclists and light vehicles, while alternatives like the Bullseye and AstroAI inflators provide additional features and functionalities for diverse applications. By assessing performance, cost, and ease of use, businesses can make informed decisions that optimize their tire maintenance processes.

When sourcing pocket tire inflators, understanding the key technical properties is vital for making informed purchasing decisions. Here are some essential specifications to consider:

Inflation Pressure (PSI)

The maximum inflation pressure, typically measured in pounds per square inch (PSI), indicates the pump’s capability to inflate different types of tires. For example, many pocket tire inflators can achieve pressures of up to 150 PSI. This is crucial for B2B buyers targeting markets that require high-performance tires, such as motorcycles or e-bikes, ensuring the inflator meets diverse inflation needs.

Battery Capacity (mAh)

Battery capacity, measured in milliamp hours (mAh), determines how many times the inflator can operate before needing a recharge. A typical capacity for a pocket tire inflator is around 2000 mAh, allowing it to inflate multiple tires on a single charge. This property is essential for businesses that require efficiency and reliability, especially in remote areas where power sources may be limited.

Charging Time

The time required to fully charge the inflator significantly impacts its usability. A fast charging time, such as 1.5 hours, allows for quick turnaround, which is vital for businesses needing to minimize downtime. Quick charging also enhances user satisfaction, making it an attractive feature for B2B buyers.

Weight and Dimensions

The overall weight (often less than 1 lb) and compact dimensions (approximately 4x2x2 inches) are critical for portability. Lightweight and compact designs make it easier for users to store and transport the inflator, especially for businesses in logistics or outdoor activities. This property ensures that the inflator can be easily integrated into vehicle kits or carried by technicians.

Material Quality

The materials used in manufacturing the inflator affect durability and performance. High-grade plastics and metal components ensure longevity and resistance to wear and tear. Understanding material specifications helps B2B buyers assess product quality and longevity, which is crucial for investment decisions.

Familiarizing yourself with industry jargon is essential for effective communication and negotiation. Here are some common terms relevant to pocket tire inflators:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help B2B buyers identify reliable suppliers and ensure they are sourcing quality products that meet industry standards.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory planning. For pocket tire inflators, this could range from 50 to several hundred units, depending on the supplier and product line.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. B2B buyers should prepare RFQs to compare quotes from multiple suppliers, ensuring competitive pricing and terms for pocket tire inflators.

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and delivery responsibilities, particularly when sourcing products from global suppliers.

Warranty Period

This term refers to the time frame during which a product is guaranteed against defects. Understanding warranty terms is important for evaluating long-term reliability and support, ensuring that your investment in pocket tire inflators is protected.

Digital Display

This feature indicates that the inflator has an electronic interface to show pressure readings. Digital displays enhance user experience by providing accurate and easy-to-read data, making it a selling point for B2B buyers focused on user-friendly products.

By grasping these technical properties and industry terms, B2B buyers can navigate the market for pocket tire inflators more effectively, ensuring they select products that meet their operational needs.

The pocket tire inflator market is experiencing significant growth, driven by several global factors. First, the increasing adoption of electric vehicles, especially in regions like Europe and the Middle East, has heightened the demand for portable tire maintenance solutions. B2B buyers are particularly interested in compact and efficient inflators that can cater to diverse vehicle types, from e-bikes to SUVs. Furthermore, the rise in outdoor recreational activities in South America and Africa has led to a surge in demand for portable inflators that can be easily transported for camping and road trips.

Illustrative image related to pocket tire inflator

Emerging technologies also play a crucial role in shaping market dynamics. Innovations such as smart digital displays, customizable presets, and high-capacity batteries are becoming standard features, enhancing user convenience and performance. International buyers are increasingly looking for products that offer quick inflation times and multiple functionalities, such as charging capabilities for mobile devices, which are essential for on-the-go usage.

Moreover, the competitive landscape is evolving, with new entrants focusing on eco-friendly designs and sustainable materials. This trend aligns with the growing consumer preference for environmentally responsible products. As a result, B2B buyers are encouraged to explore partnerships with manufacturers that prioritize innovation and sustainability in their product offerings.

Sustainability is becoming a pivotal consideration for B2B buyers in the pocket tire inflator sector. As environmental concerns continue to rise globally, businesses are increasingly prioritizing ethical sourcing and sustainable manufacturing processes. The production of inflators often involves materials and components that can have significant environmental impacts, making it essential for companies to evaluate their supply chains.

Buyers should seek manufacturers that utilize recycled materials and implement energy-efficient production methods. Certifications such as ISO 14001 (Environmental Management) and eco-labels can guide B2B buyers in identifying partners committed to sustainability. Additionally, companies that emphasize product longevity and reparability contribute positively to environmental goals by reducing waste.

Incorporating sustainability into sourcing strategies not only enhances brand reputation but also meets the growing consumer demand for responsible products. By aligning with suppliers that share these values, international B2B buyers can ensure compliance with regulations and consumer expectations while fostering a positive impact on the environment.

The evolution of the pocket tire inflator reflects broader technological advancements and changing consumer needs. Initially designed as manual pumps, these devices have transformed significantly with the advent of electric and battery-operated models. Early inflators were often bulky and limited in functionality, primarily serving basic inflation needs.

Over the years, the integration of digital technology has revolutionized the sector. Modern inflators now feature digital pressure gauges, automatic shut-off functions, and the ability to connect to various valve types, enhancing usability. The focus has shifted towards compact designs that prioritize portability without sacrificing power, catering to the demands of both individual consumers and B2B buyers.

As the market continues to evolve, the incorporation of smart technology and sustainable practices will likely define the next phase of development in the pocket tire inflator sector, presenting new opportunities for international buyers seeking innovative solutions.

How do I choose the right pocket tire inflator for my business needs?

Selecting the right pocket tire inflator involves assessing your target market and their specific requirements. Consider factors such as maximum PSI, inflation speed, and compatibility with various tire valves. Additionally, evaluate the product’s battery life and portability, especially if your customers are likely to use it for travel or outdoor activities. Research user reviews and ratings to gauge performance reliability. Lastly, ensure the inflator meets safety and quality standards relevant to your region.

What are the key features to look for in a pocket tire inflator?

When sourcing pocket tire inflators, prioritize features such as maximum pressure capability, rapid inflation times, and battery capacity. Look for built-in pressure gauges for accuracy, and consider models that offer multiple power options, such as USB charging. Additional functionalities like LED lights, auto shut-off features, and compatibility with various valve types (Presta, Schrader) can enhance user experience and satisfaction. Compact design and lightweight construction are also essential for portability.

What are the common customization options for pocket tire inflators?

Many manufacturers offer customization options for pocket tire inflators, including branding, color schemes, and packaging. You can also inquire about specific features tailored to your target market, such as enhanced battery life or additional adapters for various tire types. Discussing minimum order quantities (MOQs) for customized products is crucial, as this can influence your sourcing strategy and cost-effectiveness. Ensure that the customization aligns with your brand’s identity and customer preferences.

What are the typical minimum order quantities (MOQs) for pocket tire inflators?

MOQs for pocket tire inflators can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from 100 to 1,000 units for standard products, while customized inflators may require higher quantities. It’s essential to communicate your needs clearly to suppliers and negotiate terms that suit your business model. Smaller businesses may consider collaborating with distributors to meet MOQ requirements or explore suppliers that cater to lower-volume orders.

How can I vet suppliers for pocket tire inflators?

Vetting suppliers is critical to ensuring product quality and reliability. Begin by researching the supplier’s reputation, reading reviews, and checking their business credentials. Request samples to assess product quality and performance. Verify their compliance with international standards and certifications relevant to your market. Additionally, inquire about their manufacturing processes, lead times, and after-sales support. Establishing communication channels and discussing terms upfront can also help build a trustworthy partnership.

What payment terms should I expect when sourcing pocket tire inflators internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit (typically 30-50%) upon order confirmation and the balance before shipping. Some suppliers may offer flexible payment options, including letters of credit or PayPal. It’s essential to clarify terms before finalizing agreements to avoid misunderstandings. Additionally, consider factors such as currency exchange rates, transaction fees, and potential tariffs that could affect your overall costs.

What quality assurance measures should I implement when sourcing pocket tire inflators?

Implementing quality assurance (QA) measures is vital to ensure the inflators meet your standards. Start by defining clear specifications and performance criteria. Conduct inspections at different stages of production, including pre-shipment checks. Utilize third-party inspection services if necessary to verify compliance with safety and quality standards. Establish a return policy and warranty terms to protect your business from defective products. Regular communication with your supplier can also help address any quality concerns promptly.

How do logistics affect the sourcing of pocket tire inflators?

Logistics play a crucial role in the sourcing process, impacting delivery times, costs, and overall supply chain efficiency. When sourcing pocket tire inflators, consider shipping methods, transit times, and customs regulations in your country. Engage with reliable logistics partners to ensure timely deliveries and proper handling of goods. Assess the total landed cost, which includes shipping, duties, and taxes, to better understand your budget. Effective logistics management can enhance your ability to meet customer demands and maintain stock levels.

Domain: sportys.com

Registered: 1998 (27 years)

Introduction: Bullseye Pocket Air Inflator, Price: $59.95, SKU: 4930, Features: Compact and portable, rechargeable pump, digital control with auto shut-off, pressure up to 100 PSI, bright LED light, 4,000 mAh power bank for charging electronics, includes USB-C charging cable, storage bag, air hose, sports ball needle, Presta valve, narrow and wide adapter, dimensions: 7″h x 2 3/4″w x 2″d, weight: under 2 lb, 5-…

Domain: automoblog.com

Registered: 2004 (21 years)

Introduction: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX – Robust and powerful with four memory settings. 5. Milwaukee M18 – Durable with multiple memory settings. Price range: $80 to $180. Features include robust material co…

In the competitive landscape of pocket tire inflators, strategic sourcing emerges as a critical component for international B2B buyers. By understanding the diverse features and specifications of products like the HOTO Air Pump Pocket and the Bullseye Pocket Air Inflator, buyers can make informed decisions that align with their market needs. Prioritizing attributes such as portability, inflation speed, and battery capacity not only enhances customer satisfaction but also fosters brand loyalty.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for compact and efficient tire inflators is set to rise. Buyers should focus on sourcing products that provide robust performance while being adaptable to various vehicle types, ensuring they meet the needs of a broad customer base.

Looking ahead, the integration of innovative features such as smart technology and multi-functional capabilities will likely redefine the pocket tire inflator market. To remain competitive, international buyers are encouraged to engage with suppliers who prioritize quality and adaptability. Embrace this opportunity to enhance your product offerings and meet the increasing demand for reliable tire maintenance solutions.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.