Navigating the global market for air compressor tire attachments presents a unique set of challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. With the rising demand for reliable tire inflation solutions across various industries, sourcing the right air compressor tire attachment can be daunting. Factors such as compatibility, efficiency, and cost-effectiveness must be carefully considered to ensure optimal performance and value.

This comprehensive guide addresses these challenges by delving into the diverse types of air compressor tire attachments available, including tire inflators, blow guns, and specialized couplers. Each section is designed to provide insights into their applications, ensuring that buyers can select the most suitable products for their specific needs. Additionally, the guide covers critical aspects of supplier vetting, helping businesses identify reputable manufacturers and distributors who meet international quality standards.

By equipping B2B buyers with detailed information on pricing structures, market trends, and the latest innovations in air compressor technology, this guide empowers informed purchasing decisions. Whether you are based in Nigeria, Germany, or elsewhere, understanding the nuances of air compressor tire attachments will enable you to enhance operational efficiency and meet your tire maintenance requirements with confidence.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tire Inflator Chucks | Varying designs (single/double head), pressure gauges | Automotive repair shops, fleet services | Pros: Accurate inflation; easy to use. Cons: Can be bulky; gauge accuracy may vary. |

| Portable Tire Inflators | Battery-operated, compact, often cordless | Emergency services, roadside assistance | Pros: Highly portable; quick inflation. Cons: Limited power; may require frequent recharging. |

| Electric Tire Pumps | Plug-in with high PSI ratings, suitable for heavy use | Industrial tire maintenance, workshops | Pros: Fast inflation; ideal for larger tires. Cons: Requires power source; less portable. |

| Hand and Foot Pumps | Manual operation, low PSI capability | Home workshops, small vehicle maintenance | Pros: Economical; no power needed. Cons: Labor-intensive; slower inflation rate. |

| Tire Repair Kits | Includes sealants, patches, and tools | Tire service centers, automotive workshops | Pros: Comprehensive solutions; versatile. Cons: Not suitable for all tire types; repair quality varies. |

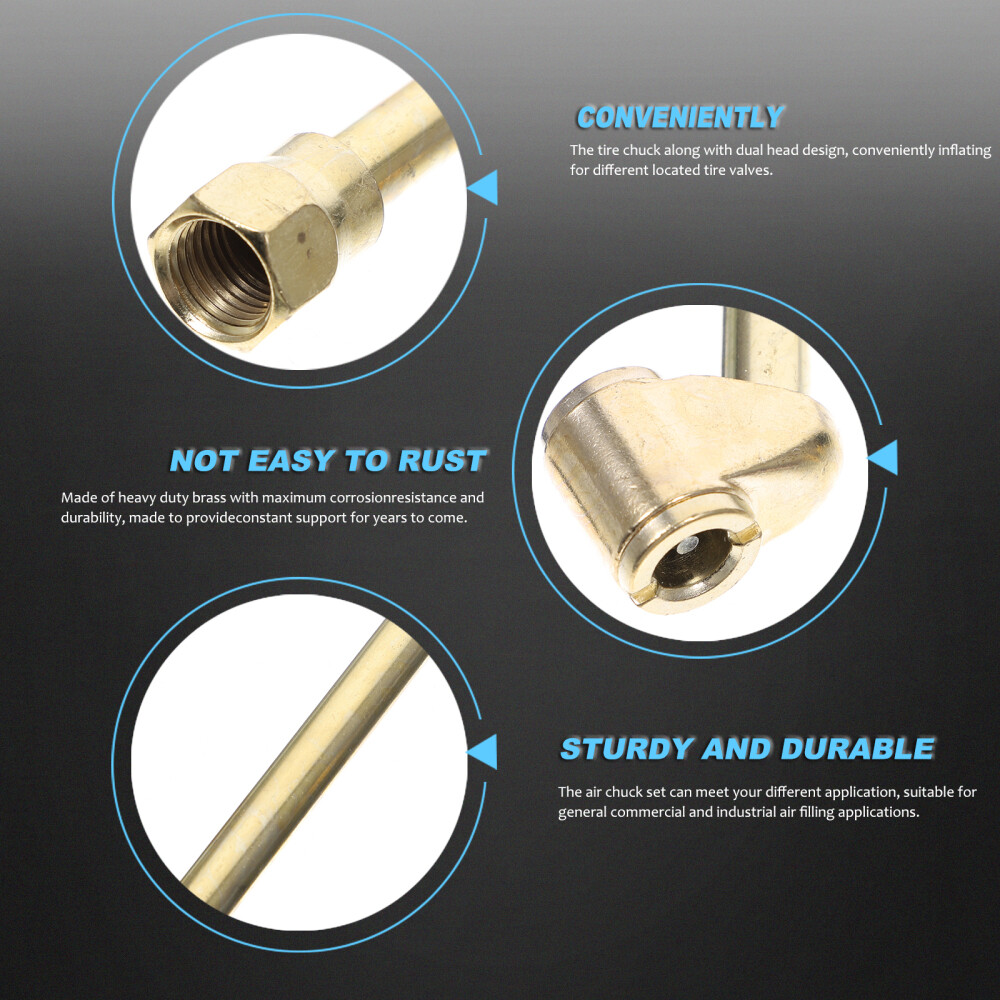

Tire inflator chucks are essential attachments for connecting air compressors to tires. They come in various designs, such as single or dual-head configurations, often featuring built-in pressure gauges. These tools are primarily used in automotive repair shops and fleet maintenance services, where accurate tire inflation is critical. Buyers should consider the chuck’s compatibility with different tire valves and its ease of use, as well as the gauge’s accuracy, which can significantly impact operational efficiency.

Portable tire inflators are battery-operated devices designed for convenience and quick inflation. Their compact size makes them ideal for emergency services and roadside assistance, where immediate tire inflation is necessary. When purchasing, businesses should assess the inflator’s battery life, PSI capacity, and ease of transport. While they offer excellent portability, their reliance on batteries may limit their usage duration, requiring careful consideration of operational needs.

Electric tire pumps are powerful tools that connect to a standard electrical outlet, providing high-pressure inflation suitable for heavy-duty applications. These pumps are commonly used in industrial tire maintenance and workshops, where efficiency and speed are paramount. Buyers should evaluate the pump’s PSI rating and compatibility with different tire sizes. Although electric pumps excel in performance, their dependency on power sources can restrict mobility, making them less suitable for on-the-go applications.

Hand and foot pumps remain a cost-effective solution for tire inflation, especially for small workshops and home maintenance. These manual devices operate without electricity and are ideal for inflating bicycle tires or sports equipment. While they are economical and easy to store, buyers must consider their labor-intensive operation and slower inflation rates compared to powered options. Businesses focusing on budget constraints may find these tools particularly appealing.

Tire repair kits provide a comprehensive solution for addressing tire punctures and leaks. They typically include sealants, patches, and essential tools for effective repairs, making them valuable for tire service centers and automotive workshops. When selecting a kit, businesses should assess the range of repairs it can handle and the quality of the included components. While these kits offer versatility, they may not be suitable for all tire types, necessitating careful evaluation of their intended applications.

| Industry/Sector | Specific Application of air compressor tire attachment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for vehicles | Enhances operational efficiency and reduces downtime | Look for compatibility with various tire sizes and pressure ratings |

| Construction | Inflating tires on heavy machinery and equipment | Ensures equipment mobility and reduces maintenance costs | Consider durability and portability for on-site use |

| Logistics and Transport | Regular tire maintenance for fleet vehicles | Improves safety and extends tire lifespan | Evaluate ease of use and speed of inflation |

| Agriculture | Tire inflation for agricultural machinery | Increases productivity and reduces equipment failures | Source attachments that can withstand harsh outdoor conditions |

| Manufacturing | Tire inflation for conveyor systems and transport vehicles | Enhances operational reliability and efficiency | Ensure compatibility with existing air compressor systems |

In the automotive repair sector, air compressor tire attachments are vital for tire inflation and maintenance. They enable technicians to quickly and accurately inflate tires to the manufacturer-recommended pressure, which is essential for vehicle safety and performance. This application reduces downtime, allowing repair shops to serve more customers efficiently. International B2B buyers should seek attachments that are compatible with various tire sizes and feature durable construction to withstand frequent use in busy automotive environments.

Illustrative image related to air compressor tire attachment

In construction, air compressor tire attachments are crucial for inflating tires on heavy machinery and equipment, such as excavators and bulldozers. Maintaining optimal tire pressure ensures that machinery operates smoothly, enhancing mobility on job sites and reducing the risk of tire blowouts. Buyers in this sector should prioritize sourcing attachments that are durable and portable, as they need to withstand rugged conditions and be easily transported between various locations.

For logistics and transport businesses, regular tire maintenance is critical for fleet vehicles. Air compressor tire attachments facilitate quick tire inflation, which is essential for maintaining safety standards and optimizing fuel efficiency. A well-maintained fleet reduces the likelihood of road incidents and extends the lifespan of tires, ultimately saving costs. When sourcing these attachments, logistics companies should evaluate ease of use and inflation speed to ensure minimal disruption to their operations.

In the agriculture sector, air compressor tire attachments are utilized for inflating tires on tractors and other agricultural machinery. Proper tire pressure is crucial for maximizing productivity and minimizing equipment failures during peak seasons. International buyers should consider sourcing attachments designed to endure harsh outdoor conditions, ensuring reliability even in the most challenging environments. This reliability directly impacts farming efficiency and operational costs.

In manufacturing, air compressor tire attachments are employed for maintaining tire pressure in conveyor systems and transport vehicles within the facility. Consistent tire pressure enhances operational reliability, contributing to smoother production processes and reduced equipment downtime. When sourcing these attachments, manufacturers should ensure compatibility with existing air compressor systems and focus on quality to prevent frequent replacements, thereby optimizing long-term operational costs.

The Problem: B2B buyers often face challenges when the air compressor they purchased does not seamlessly work with their tire attachments. This can be particularly problematic for businesses in sectors such as automotive repair or logistics, where time is crucial. For instance, a fleet manager in Nigeria may find that their air compressor’s fittings do not match the standard tire inflators, leading to delays in maintenance and operational inefficiencies. This incompatibility can result in lost productivity and increased costs, as alternative methods must be employed to inflate tires.

The Solution: To mitigate compatibility issues, it is essential for buyers to conduct thorough research before purchasing air compressor tire attachments. When sourcing these products, buyers should verify the specifications of their existing air compressor, including the size of the fittings and the pressure ratings. It is advisable to consult with suppliers or manufacturers to ensure that the attachments are designed to work with their specific models. Additionally, investing in universal couplers or adapters can provide flexibility, allowing different attachments to be used with various air compressor brands. This proactive approach will not only streamline operations but also enhance overall efficiency.

The Problem: Another common pain point is the lack of effective tire pressure monitoring solutions integrated with air compressor tire attachments. Many businesses, especially in the transportation and logistics sectors, need to maintain precise tire pressure to ensure safety and fuel efficiency. However, without reliable monitoring tools, workers may inadvertently overinflate or underinflate tires, leading to potential safety hazards and increased operational costs. For example, a logistics company in South America may struggle with inconsistent tire pressures, affecting delivery schedules and increasing fuel consumption.

The Solution: To address this issue, businesses should prioritize attachments that come equipped with built-in tire pressure gauges or consider purchasing separate high-quality pressure monitoring tools. When selecting tire inflators, look for models that offer real-time pressure readings and automatic shut-off features to prevent overinflation. Furthermore, establishing a routine maintenance schedule that includes regular pressure checks will promote better tire health and longevity. By integrating effective monitoring solutions, companies can optimize tire performance, enhance safety, and reduce operational costs.

The Problem: B2B buyers frequently encounter difficulties in sourcing durable and reliable air compressor tire attachments, especially in regions with limited access to high-quality products. This is particularly true for businesses involved in heavy-duty applications, such as construction or mining, where equipment must withstand harsh conditions. For instance, a construction firm in the Middle East may find that low-quality attachments fail under pressure, leading to costly downtime and safety risks on job sites.

Illustrative image related to air compressor tire attachment

The Solution: To overcome this challenge, buyers should focus on sourcing air compressor tire attachments from reputable manufacturers known for their quality and durability. Engaging with local suppliers who specialize in industrial-grade products can provide insights into the best options available for specific applications. Additionally, buyers should look for warranties or guarantees that cover defects and performance issues, as this indicates confidence in product reliability. Investing in high-quality attachments, even if the upfront costs are higher, will ultimately save businesses money by reducing the frequency of replacements and minimizing downtime due to equipment failure.

When selecting materials for air compressor tire attachments, it’s essential to consider factors such as performance, durability, and cost. The following analysis covers four common materials used in these applications: rubber, aluminum, steel, and plastic. Each material has distinct properties that influence its suitability for various operational environments and applications.

Rubber is a popular choice for air compressor tire attachments due to its excellent flexibility and sealing properties. It can withstand moderate pressure and temperature variations, typically rated up to 100 PSI and temperatures ranging from -20°F to 180°F.

Pros: Rubber is highly durable and resistant to wear and tear, making it ideal for frequent use. Its ability to create airtight seals also enhances efficiency in tire inflation.

Cons: However, rubber can degrade over time when exposed to UV light and certain chemicals, which may limit its lifespan in harsh environments. Additionally, while generally cost-effective, high-quality rubber may be more expensive than other materials.

Impact on Application: Rubber is compatible with air and non-corrosive gases but may not perform well with oils or solvents.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the rubber meets local compliance standards, such as ASTM or JIS, particularly in terms of temperature and pressure ratings.

Aluminum is often chosen for its lightweight and corrosion-resistant properties. It can handle pressures up to 250 PSI and operates effectively in temperatures ranging from -40°F to 400°F.

Pros: The primary advantage of aluminum is its resistance to corrosion, which makes it suitable for humid or saline environments. Its lightweight nature also contributes to ease of handling and installation.

Cons: On the downside, aluminum can be more expensive than rubber and may require more complex manufacturing processes. It is also less durable than steel, making it less suitable for heavy-duty applications.

Impact on Application: Aluminum is compatible with air and non-corrosive gases, making it a versatile option for various applications.

Illustrative image related to air compressor tire attachment

Considerations for International Buyers: Buyers in Europe, particularly Germany, should look for compliance with DIN standards to ensure quality and safety.

Steel is widely used in air compressor tire attachments due to its strength and durability. It can withstand high pressures, typically rated up to 300 PSI, and operates effectively in a broad temperature range from -40°F to 500°F.

Pros: Steel’s high tensile strength makes it ideal for heavy-duty applications, and it is generally less expensive than aluminum.

Cons: However, steel is prone to corrosion if not properly treated, and it is heavier than both rubber and aluminum, which can complicate installation and handling.

Impact on Application: Steel is suitable for high-pressure applications but may require protective coatings to prevent rust, especially in humid climates.

Considerations for International Buyers: Buyers in the Middle East should ensure that steel components comply with local standards for corrosion resistance, as environmental conditions can be harsh.

Illustrative image related to air compressor tire attachment

Plastic, particularly high-density polyethylene (HDPE) or polyvinyl chloride (PVC), is increasingly being used in air compressor tire attachments due to its lightweight and cost-effectiveness. It typically handles pressures up to 150 PSI and operates effectively in temperatures from -20°F to 180°F.

Pros: Plastic is resistant to corrosion and chemicals, making it ideal for various environments. It is also lightweight, which simplifies installation.

Cons: The main disadvantage is its lower durability compared to metals, making it less suitable for heavy-duty applications. Plastic can also become brittle over time, especially under UV exposure.

Impact on Application: Plastic is compatible with air and non-corrosive gases but may not withstand high-pressure applications effectively.

Considerations for International Buyers: Buyers from regions like Africa should verify that plastic components meet local safety and performance standards.

| Material | Typical Use Case for air compressor tire attachment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Tire inflators and seals | Excellent flexibility and sealing | Degrades under UV and chemicals | Medium |

| Aluminum | Lightweight tire attachments | Corrosion-resistant and lightweight | More expensive, less durable than steel | High |

| Steel | Heavy-duty tire attachments | High tensile strength | Prone to corrosion, heavier | Medium |

| Plastic | Lightweight, low-pressure applications | Cost-effective and corrosion-resistant | Lower durability, can become brittle | Low |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for air compressor tire attachments, enabling informed decision-making based on specific application needs and regional compliance requirements.

When considering the manufacturing processes and quality assurance for air compressor tire attachments, it is essential for B2B buyers to understand the intricate steps involved and the standards that govern quality control. This knowledge not only aids in selecting the right suppliers but also ensures that the products meet the necessary performance and safety requirements.

The first stage in the manufacturing process involves selecting high-quality raw materials, typically metals like steel or aluminum, and durable plastics. These materials are sourced based on their strength, corrosion resistance, and ability to withstand high-pressure environments. After sourcing, materials undergo rigorous testing to confirm their properties.

Once materials are verified, they are prepared for forming. This can involve cutting, machining, or molding the raw materials into specific shapes required for the tire attachment components, such as chucks, hoses, and connectors. Advanced technologies such as CNC machining or injection molding are often utilized to ensure precision and reduce waste.

The forming stage is crucial as it defines the physical characteristics of the tire attachment. Techniques such as stamping, forging, or extrusion are commonly employed. For instance, metal components may be stamped out of sheets and then heat-treated to enhance strength and durability.

Illustrative image related to air compressor tire attachment

After the initial shaping, components are assembled. This can involve manual labor or automated assembly lines, depending on the complexity of the product. For instance, tire inflators may require the integration of gauges, hoses, and valves, which need to be assembled in a way that ensures airtight connections and functionality.

The finishing stage involves applying coatings or treatments to enhance the durability and aesthetics of the tire attachments. Common techniques include powder coating, anodizing, or galvanizing, which provide corrosion resistance and improve the overall look of the product.

In this phase, components are also subjected to surface treatments that may include polishing or sanding to eliminate any sharp edges and improve user safety. A thorough inspection is conducted post-finishing to ensure that all components meet design specifications.

Quality assurance in the manufacturing of air compressor tire attachments typically adheres to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with such standards ensures that manufacturers maintain consistent quality in their processes and products.

Additionally, industry-specific certifications, such as CE marking for products sold in Europe and API standards for petroleum and natural gas equipment, are critical. These certifications indicate that products meet safety and performance requirements relevant to their respective markets.

Quality control is integrated into various stages of the manufacturing process, typically categorized into several checkpoints:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before production begins. Materials are tested for compliance with specifications, and any non-conforming materials are rejected.

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors critical parameters and processes to ensure they remain within specified limits. This includes measuring dimensions, checking for defects, and ensuring proper assembly techniques are followed.

Final Quality Control (FQC): Once production is complete, FQC involves comprehensive testing of finished products. This includes functional testing, pressure testing, and visual inspections to ensure that the final product meets all quality and safety standards.

B2B buyers should be familiar with several common testing methods employed during quality assurance:

Functional Testing: This verifies that the air compressor tire attachment operates as intended under various conditions. For example, a tire inflator would be tested for its ability to reach specified pressure levels quickly and reliably.

Pressure Testing: Given the high-pressure environment in which these attachments operate, pressure testing is essential. This method involves subjecting the product to pressures exceeding normal operating conditions to identify any weaknesses or potential failure points.

Durability Testing: This assesses how well the product withstands wear and tear over time. It can include repeated cycling through operational states or exposure to environmental conditions like humidity and temperature variations.

To ensure that suppliers adhere to quality control standards, B2B buyers can take several proactive steps:

Conduct Supplier Audits: Regular audits of suppliers can reveal their adherence to quality management systems and manufacturing processes. This can be done through on-site visits or requesting audit reports from third-party certification bodies.

Request Quality Control Documentation: Suppliers should provide documentation that outlines their quality assurance processes, including inspection reports, testing results, and certifications. This transparency is vital for building trust and ensuring compliance.

Engage Third-Party Inspection Services: Utilizing third-party inspectors can offer an unbiased assessment of a supplier’s quality control practices. These services can conduct random inspections of products during production and prior to shipment.

For international buyers, understanding the nuances of quality control is critical. Regulations and standards may vary significantly between regions. For example, while CE marking is essential for products sold in Europe, similar certifications may not be required in other markets like Africa or South America.

Additionally, buyers should be aware of the logistics involved in shipping products internationally, as this can impact quality. Components may be exposed to varying conditions during transit, which can affect their performance upon arrival. Thus, it is prudent to discuss packaging and shipping methods with suppliers to ensure product integrity.

In conclusion, understanding the manufacturing processes and quality assurance practices for air compressor tire attachments is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control measures, buyers can make informed decisions and ensure they receive reliable, high-quality products.

In the competitive landscape of air compressor accessories, particularly tire attachments, making informed purchasing decisions is crucial for maximizing your investment. This guide provides a structured checklist designed for B2B buyers seeking to procure air compressor tire attachments effectively. Follow these steps to ensure you choose the right products and suppliers for your business needs.

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the required pressure ratings, compatibility with existing equipment, and intended applications (e.g., automotive, industrial). This clarity will guide your selection and help avoid costly mismatches.

A comprehensive supplier evaluation is vital to ensure you are partnering with reliable manufacturers. Look for suppliers with a proven track record in the industry and positive customer feedback. Conduct market research to identify established brands and emerging players.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage in direct communication to gauge their responsiveness and expertise.

Understanding pricing structures and payment terms is essential for budgeting and financial planning. Compare pricing across different suppliers but be cautious of prices that seem too low, as they may indicate compromised quality.

Confirm the supplier’s ability to meet your order volume and timeline requirements. This step is critical to avoid disruptions in your supply chain.

Illustrative image related to air compressor tire attachment

Shipping logistics can significantly impact your total cost and delivery times. Clarify the supplier’s shipping policies, including costs and available options for international shipping, especially if you are sourcing from different continents.

Effective communication is vital for a successful partnership. Set expectations for regular updates on order status, product availability, and any potential issues that may arise.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement process for air compressor tire attachments, ensuring that they make informed decisions that align with their operational needs and budget constraints.

When sourcing air compressor tire attachments, understanding the cost structure is crucial. The primary cost components include:

Materials: The choice of materials significantly impacts pricing. High-quality metals or durable plastics may increase initial costs but can enhance longevity and performance, reducing the need for replacements.

Labor: Labor costs vary by region and the complexity of manufacturing. Regions with lower labor costs may offer competitive pricing, but this must be weighed against potential quality differences.

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities and facility maintenance. Efficient manufacturing processes can help keep these costs lower.

Tooling: Custom tooling can be a significant upfront investment, particularly for specialized attachments. The cost may be amortized over larger production runs, making it essential to consider order volume.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, but it adds to overall costs. Certifications (e.g., ISO) can also influence the price due to the associated compliance requirements.

Logistics: Shipping and handling costs are vital in the total cost calculation. Factors such as distance, transportation mode, and customs duties can vary widely, especially for international transactions.

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding this margin can help buyers negotiate more effectively.

Several factors can influence the final pricing of air compressor tire attachments:

Volume/MOQ: Minimum order quantities (MOQ) often determine the pricing structure. Larger orders can lead to discounts, making it essential for buyers to assess their needs carefully.

Specifications and Customization: Custom designs or specific performance requirements can lead to higher costs due to additional engineering and production complexities. Clear communication of specifications can help avoid unexpected expenses.

Materials: The choice of materials directly affects the cost. Options that offer better performance or durability will usually come at a premium.

Quality and Certifications: Products with industry certifications tend to command higher prices due to the assurance of quality and compliance. Buyers should weigh the benefits of certified products against their cost.

Supplier Factors: The reputation, reliability, and experience of the supplier can impact pricing. Established suppliers may offer better warranties and support, justifying a higher price.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining responsibilities for shipping costs and risks. This knowledge can help buyers negotiate better terms and avoid hidden costs.

B2B buyers should employ strategic approaches to enhance cost-efficiency when sourcing air compressor tire attachments:

Illustrative image related to air compressor tire attachment

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leveraging competitive quotes can yield better deals.

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and operational costs over the product’s lifespan. Opting for slightly more expensive but durable attachments can result in savings over time.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should consider local market conditions, currency fluctuations, and import tariffs when assessing costs. Understanding these nuances can help in making informed purchasing decisions.

Research and Compare: Conduct thorough market research to compare prices and specifications across different suppliers. This helps in identifying the best value offerings.

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and insights into market trends that can benefit procurement strategies.

Pricing for air compressor tire attachments can vary widely based on the factors discussed. The information provided here is intended as a guideline. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

In the realm of tire inflation, businesses often face a choice between various tools and technologies. While air compressor tire attachments are a popular option, alternatives exist that may better suit specific operational needs, budgets, or environments. This analysis will compare air compressor tire attachments with electric tire inflators and manual pumps, providing insights to help B2B buyers make informed decisions.

| Comparison Aspect | Air Compressor Tire Attachment | Electric Tire Inflator | Manual Pump |

|---|---|---|---|

| Performance | High PSI; suitable for heavy-duty applications | Moderate PSI; ideal for light to medium tasks | Low PSI; best for bicycles and small items |

| Cost | Moderate; varies by brand and type | Moderate to high; depending on features | Low; generally budget-friendly |

| Ease of Implementation | Requires air compressor setup; may need additional accessories | Plug-and-play; easy to use with minimal setup | Simple to use; no power needed |

| Maintenance | Requires regular maintenance of compressor and attachments | Minimal maintenance; mainly battery care | Minimal; no mechanical parts |

| Best Use Case | Automotive and industrial applications requiring quick inflation | Roadside emergencies and home use | Light-duty inflation tasks like bicycles and sports equipment |

Electric tire inflators provide a convenient alternative to air compressor tire attachments. They typically offer a decent PSI range sufficient for most passenger vehicles, making them suitable for roadside emergencies and home use. Their plug-and-play nature allows for quick deployment without the need for an air compressor. However, they may not deliver the high performance required for heavy-duty applications, and their reliance on electrical power can limit usability in remote areas. Additionally, higher-end models can be quite expensive, which may be a consideration for budget-conscious buyers.

Illustrative image related to air compressor tire attachment

Manual pumps, including foot and hand-operated options, present a cost-effective solution for tire inflation. They are lightweight, portable, and require no power source, making them ideal for bicycles, sports equipment, and small inflatables. However, their performance in terms of PSI is limited, which may not suffice for larger tires or heavy-duty applications. The physical effort required for operation can also be a drawback for some users. Despite these limitations, manual pumps remain a practical choice for light-duty tasks, especially in regions where access to electricity is inconsistent.

When selecting a tire inflation solution, B2B buyers should consider their specific use cases, budget constraints, and operational environments. Air compressor tire attachments excel in high-performance scenarios and industrial settings, while electric tire inflators provide convenience for everyday use. Manual pumps are best for light-duty tasks and scenarios where portability and cost are paramount. By evaluating the pros and cons of each alternative, businesses can make strategic purchasing decisions that align with their operational requirements and enhance overall efficiency.

Understanding the essential technical properties of air compressor tire attachments is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications that should be considered:

Material Grade

Air compressor tire attachments are typically made from materials such as steel, aluminum, or high-grade plastics. The material grade affects durability, corrosion resistance, and overall performance. For instance, high-grade steel is often preferred for its strength and longevity, making it suitable for heavy-duty applications. Buyers should ensure the material meets their operational requirements, particularly in harsh environments.

Pressure Rating

The pressure rating, measured in PSI (pounds per square inch), indicates the maximum pressure the attachment can safely handle. This specification is vital for ensuring that the attachment can efficiently perform its intended function without risk of failure or accidents. For example, a tire inflator with a rating of 150 PSI is suitable for most passenger vehicles, while industrial applications may require attachments rated at 250 PSI or higher.

Compatibility Standards

Compatibility with various air compressor models and tire valve types is essential. Attachments should adhere to industry standards such as the American National Standards Institute (ANSI) or International Organization for Standardization (ISO) specifications. This ensures that the attachment can be used universally across different equipment, minimizing the need for multiple tools and simplifying inventory management.

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. High tolerance levels ensure precision in fit and function, which is particularly important in high-pressure applications. For B2B buyers, selecting attachments with lower tolerance levels can lead to improved efficiency and reduced wear on equipment, ultimately leading to cost savings.

Durability Rating

Durability ratings often consider factors such as wear resistance, temperature range, and impact resistance. Buyers should assess these ratings based on the intended use of the attachment, as higher durability ratings typically correlate with longer service life and decreased maintenance costs. This is especially important in commercial settings where equipment is used frequently.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms relevant to air compressor tire attachments:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing attachments, buyers may choose OEM products for guaranteed compatibility and quality assurance, as these parts are designed specifically for certain air compressor models.

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers as it affects inventory management and budgeting. Suppliers often set MOQs to ensure profitability, so buyers need to negotiate effectively to meet their operational needs without overcommitting.

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers for specific products. This is an essential step in the procurement process, allowing businesses to compare pricing, terms, and conditions. A well-prepared RFQ can lead to better pricing negotiations and ensure that the buyer receives the best value.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and import duties. Understanding these terms is crucial for B2B buyers to clarify risks and costs associated with the procurement of air compressor tire attachments, especially when dealing with international suppliers.

Lead Time

Lead time refers to the time taken from placing an order to its delivery. For businesses operating on tight schedules, understanding lead times helps in planning and ensures that operations remain uninterrupted. Buyers should inquire about lead times during negotiations to align their procurement timelines with operational needs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing air compressor tire attachments, ultimately enhancing operational efficiency and profitability.

Global drivers in the air compressor tire attachment sector are largely influenced by the growing demand for efficient tire maintenance solutions across various industries, including automotive, transportation, and agriculture. As the global economy continues to recover post-pandemic, international B2B buyers are increasingly seeking reliable and durable tire attachments that can enhance productivity and reduce downtime. Key trends include the adoption of smart technology, such as digital pressure monitoring systems, which provide real-time data and improve the accuracy of tire inflation. This trend is particularly significant in regions like Europe and North America, where advanced automotive technology is prevalent.

Moreover, the rise of e-commerce platforms is reshaping how businesses source air compressor tire attachments. B2B buyers from Africa and South America are leveraging online marketplaces to access a wider range of products and suppliers, driving competition and innovation. Additionally, sustainability is becoming a focal point, with an increasing number of buyers favoring suppliers that offer eco-friendly products and practices. Emerging markets in Africa and the Middle East are also witnessing a surge in the demand for affordable yet high-quality tire maintenance solutions, leading to a diversification of sourcing strategies.

The environmental impact of manufacturing processes and materials used in air compressor tire attachments is drawing increased scrutiny from B2B buyers. Companies are recognizing the importance of ethical sourcing to mitigate risks associated with environmental degradation and to enhance their brand reputation. Sustainability in this sector is often measured through the use of recycled materials, energy-efficient manufacturing processes, and reduced carbon footprints.

Buyers are now prioritizing suppliers that possess certifications such as ISO 14001 (Environmental Management Systems) or those that utilize green materials in their products. This shift not only supports global sustainability efforts but also appeals to environmentally conscious consumers. In regions like Europe, where strict environmental regulations are in place, suppliers that align with these standards can gain a competitive advantage. Furthermore, the adoption of circular economy principles—where products are designed for reuse and recycling—is gaining traction, prompting B2B buyers to seek innovative solutions that contribute to a more sustainable future.

The evolution of air compressor tire attachments can be traced back to the early 20th century when basic tire inflation devices emerged. Initially, these tools were rudimentary, primarily designed for manual operation. Over the decades, advancements in pneumatic technology led to the development of more sophisticated attachments, such as automatic inflators and digital gauges.

Illustrative image related to air compressor tire attachment

The introduction of portable air compressors in the late 20th century marked a significant milestone, allowing users to inflate tires conveniently at home or on the go. This innovation spurred a shift in consumer behavior, as individuals and businesses alike began to prioritize efficiency and convenience in tire maintenance. Today, the market continues to evolve with the integration of smart technology, reflecting a broader trend towards automation and connectivity in industrial applications. Understanding this historical context helps B2B buyers appreciate the advancements and innovations that shape the current landscape of air compressor tire attachments.

How do I select the right air compressor tire attachment for my business needs?

Choosing the right air compressor tire attachment depends on your specific requirements, including the type of vehicles or equipment you service and the air pressure levels needed. Consider factors such as the attachment’s compatibility with your existing compressor, ease of use, and durability. Additionally, evaluate whether you need a manual or automatic inflator, and if portability is essential for your operations. Consulting with suppliers who understand your industry can also provide valuable insights into the best options available.

What is the best air compressor tire attachment for high-pressure applications?

For high-pressure applications, a dual-head tire inflator gauge with a robust build is recommended. Look for attachments that can handle pressures exceeding 150 PSI, which are suitable for both automotive and industrial uses. Brands like Milton and Ingersoll-Rand offer reliable options with durable materials that ensure longevity and accuracy. Additionally, ensure that the attachment is compatible with your air compressor’s specifications to avoid performance issues.

What are the key factors to consider when sourcing air compressor tire attachments internationally?

When sourcing air compressor tire attachments internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Verify their certifications and request product samples to assess quality firsthand. Additionally, evaluate logistics capabilities, including shipping times and costs, as well as potential customs duties. Understanding local regulations in your market, such as safety standards, is also crucial to ensure compliance and avoid delays.

How can I vet suppliers for air compressor tire attachments?

To vet suppliers, start by checking their track record and client testimonials. Request references from other B2B buyers who have purchased similar products. Additionally, assess their production capabilities, quality assurance processes, and certifications. Engaging in a trial order can help evaluate their reliability and product quality. If possible, visit their manufacturing facilities to gain insights into their operations and standards.

What are the typical minimum order quantities (MOQs) for air compressor tire attachments?

MOQs for air compressor tire attachments can vary significantly based on the supplier and the type of product. Typically, MOQs range from 50 to 500 units, depending on the complexity and customization of the attachments. It’s essential to discuss your specific needs with suppliers to negotiate favorable terms that align with your business volume. Some suppliers may offer flexibility for first-time buyers or larger orders.

What payment terms should I expect when purchasing air compressor tire attachments?

Payment terms can vary widely among suppliers but typically include options such as advance payment, net 30/60/90 days, or letter of credit. It’s advisable to negotiate terms that suit your cash flow and risk management strategies. Some suppliers may require a deposit upfront, especially for larger orders or customized products. Always ensure that payment methods are secure and that you have a clear agreement in place to protect both parties.

How can I ensure quality assurance (QA) for air compressor tire attachments?

Implement a QA process by requesting detailed product specifications and compliance certifications from your supplier. Establish clear quality standards and inspection criteria before production begins. Consider hiring a third-party inspection service to verify the quality of products before shipment. Regular communication with suppliers during the production process can also help address any potential issues early on.

What logistics considerations should I keep in mind when importing air compressor tire attachments?

Logistics considerations include understanding shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder who can assist with documentation and compliance with import regulations in your country. Be aware of potential tariffs and duties that may affect your total cost. Planning for storage and distribution once the products arrive is also crucial to maintain operational efficiency.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Attachment for air compressor to allow for on-demand use, specifically an air gun or air blow nozzle. Requires matching the tire chuck to the air hose connector.

Domain: robidouxinc.com

Registered: 2003 (22 years)

Introduction: Tire Fillers & Air Chucks available online or at the Lincoln, NE showroom. Range includes standard air chucks, air chucks with pressure gauges, and pneumatic tire fillers. Brands include RapidAir, Milton Industries, Grip Tools, and more. Local pickup or fast shipping options available. In stock products. Knowledgeable customer support. Secure payments for online shopping.

As the global market for air compressor tire attachments continues to evolve, strategic sourcing remains a critical component for B2B buyers in sectors ranging from automotive to industrial applications. By focusing on quality, compatibility, and supplier reliability, businesses can ensure they procure the most effective tools for tire maintenance and inflation. Key takeaways include the importance of selecting attachments that align with specific operational needs and the value of investing in durable and efficient products that enhance productivity.

With a diverse array of options available, international buyers—particularly in regions like Africa, South America, the Middle East, and Europe—should prioritize partnerships with reputable suppliers that offer comprehensive support and service. As you navigate this landscape, consider the long-term benefits of establishing strong relationships with manufacturers who understand the regional market dynamics and can provide customized solutions.

Looking ahead, the demand for innovative and efficient air compressor tire attachments is set to grow. Embrace this opportunity to enhance your operational capabilities by sourcing strategically. Engage with leading suppliers today to ensure your business remains competitive in this dynamic marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air compressor tire attachment

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.