In today’s competitive industrial landscape, sourcing an air compressor with pressure gauge can be a daunting task for B2B buyers, especially when navigating the diverse options available across global markets. The challenge lies not only in identifying the right specifications but also in ensuring the product meets quality standards and operational requirements. This comprehensive guide is designed to illuminate the complexities of the air compressor market, providing invaluable insights into various types, applications, and key features that can significantly impact your purchasing decisions.

Throughout this guide, you will explore the different categories of air compressors, from portable models ideal for fieldwork to heavy-duty variants suited for industrial applications. We will delve into the significance of pressure gauges, highlighting how precision in pressure measurement can enhance operational efficiency and safety. Additionally, we will cover essential aspects of supplier vetting, including evaluating reliability, service support, and compliance with regional standards, particularly important for buyers from Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria.

By equipping you with detailed knowledge on costs, features, and supplier qualifications, this guide empowers you to make informed purchasing decisions. Whether you are looking to enhance productivity or ensure safety in your operations, understanding the landscape of air compressors with pressure gauges is crucial for optimizing your business’s performance.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Piston Air Compressors | High pressure, robust design, mechanical operation | Automotive repair, manufacturing | Pros: High efficiency, suitable for heavy-duty tasks. Cons: Noisy, requires maintenance. |

| Rotary Screw Compressors | Continuous operation, lower noise, energy-efficient | Industrial applications, HVAC systems | Pros: Long lifespan, low operational costs. Cons: Higher initial investment. |

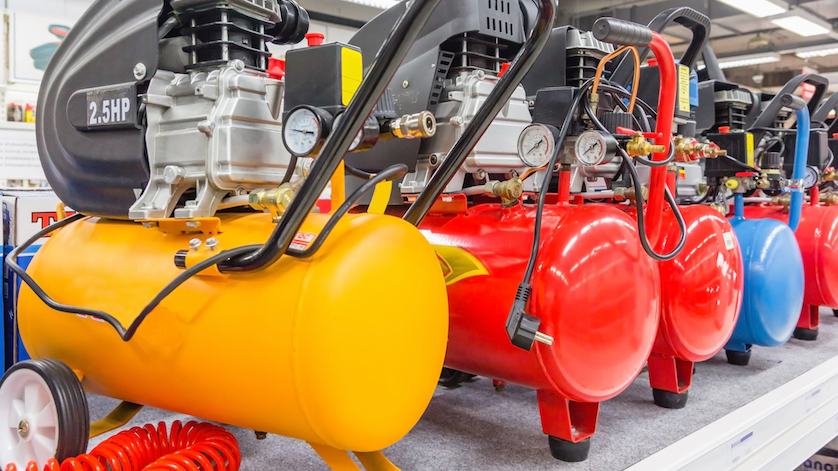

| Portable Air Compressors | Compact, lightweight, battery-operated options | Construction sites, automotive service | Pros: Versatile, easy to transport. Cons: Limited power for heavy tasks. |

| Oil-Free Air Compressors | Clean air output, minimal maintenance | Food processing, medical equipment | Pros: No oil contamination, lower maintenance. Cons: Lower pressure capabilities. |

| Digital Inflators | Built-in digital pressure gauge, preset features | Tire inflation, small inflatables | Pros: Accurate readings, user-friendly. Cons: Limited to lower pressure applications. |

Piston air compressors are known for their high-pressure output and robust construction, making them ideal for demanding applications in automotive repair and manufacturing. They operate using a reciprocating motion, which allows them to generate significant pressure. Buyers in industries requiring heavy-duty performance often favor these compressors, but they should be aware of their noisy operation and the need for regular maintenance to ensure optimal performance.

Rotary screw compressors are designed for continuous operation and are recognized for their energy efficiency and lower noise levels. These compressors are particularly suitable for industrial applications, such as HVAC systems and large-scale manufacturing. Their ability to operate for extended periods with minimal downtime makes them a valuable investment, although the initial cost can be higher compared to other types. Buyers should consider long-term operational savings against the upfront investment.

Portable air compressors are compact and lightweight, often powered by batteries or 12V systems, making them ideal for construction sites and automotive service. Their versatility allows for easy transport and use in various locations. However, potential buyers should note that these compressors typically have limited power and may not be suitable for heavy-duty tasks. They are best suited for smaller inflation jobs or light-duty applications.

Oil-free air compressors are specifically designed to produce clean air without oil contamination, making them essential in industries such as food processing and medical equipment. Their low maintenance requirements are a significant advantage, as they eliminate the need for oil changes. However, these compressors generally have lower pressure capabilities than their oil-lubricated counterparts, which may limit their use in high-demand applications. Buyers should assess their specific air quality needs when considering this type.

Digital inflators are equipped with built-in digital pressure gauges and preset features, allowing for precise inflation of tires and small inflatables. Their user-friendly design makes them accessible for non-professionals, while their accuracy is beneficial for ensuring proper inflation levels. However, these inflators are typically limited to lower pressure applications and may not meet the needs of more demanding industrial tasks. B2B buyers should consider their specific inflation needs when selecting this type.

| Industry/Sector | Specific Application of air compressor with pressure gauge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for vehicles | Ensures optimal tire pressure for safety and fuel efficiency | Durability, ease of use, and compatibility with various tire sizes |

| Manufacturing | Powering pneumatic tools in assembly lines | Increases productivity and reduces manual labor costs | Flow rate, pressure capacity, and energy efficiency |

| Construction | Operating air-powered tools such as nail guns | Enhances speed and efficiency in construction tasks | Portability, pressure regulation accuracy, and ruggedness |

| Food and Beverage | Cleaning and sanitizing equipment | Maintains hygiene standards and prevents contamination | Compliance with safety standards, pressure control features |

| Agriculture | Inflating agricultural tires and operating irrigation systems | Supports efficient farming operations and reduces downtime | Reliability, pressure gauge accuracy, and maintenance support |

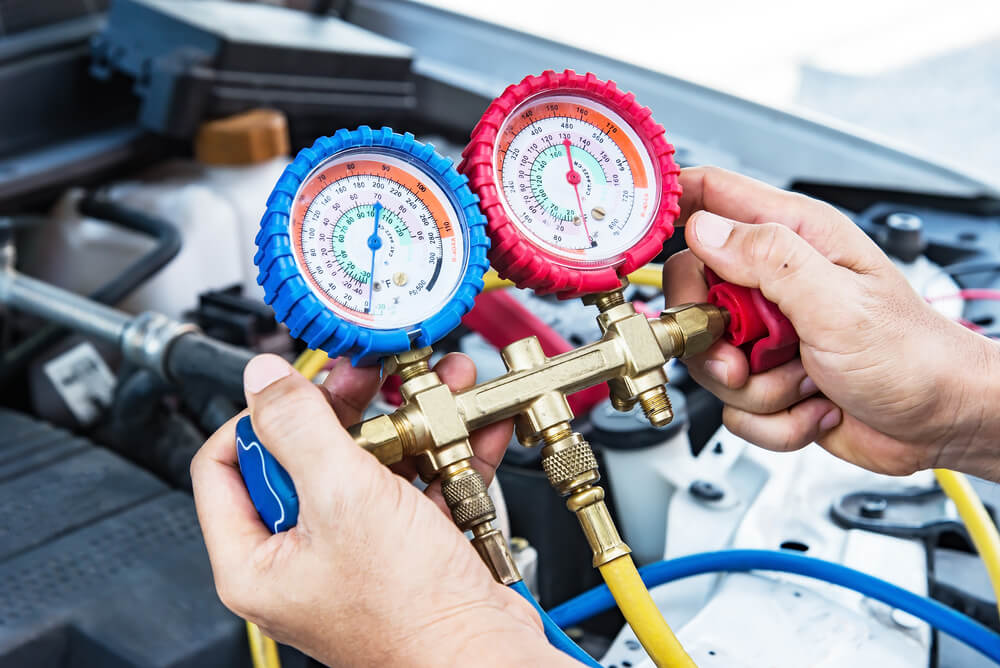

In the automotive repair industry, air compressors equipped with pressure gauges are essential for tire inflation and maintenance. These compressors allow technicians to accurately monitor tire pressure, ensuring vehicles operate safely and efficiently. The precise regulation of pressure helps in extending tire life and optimizing fuel consumption. B2B buyers in this sector should prioritize compressors that offer durability and compatibility with a variety of tire sizes to meet diverse customer needs.

In manufacturing, air compressors are pivotal in powering pneumatic tools used on assembly lines, enhancing productivity by facilitating faster operations. The pressure gauge ensures that tools operate within the optimal pressure range, preventing damage and ensuring safety. For international buyers, especially from regions with varying electricity standards, sourcing compressors that are energy-efficient and capable of handling fluctuating power supplies is critical.

Construction sites frequently utilize air compressors to operate tools such as nail guns and pneumatic drills. An air compressor with a pressure gauge allows workers to adjust the pressure according to specific tool requirements, increasing speed and efficiency. Buyers in this sector should consider the portability and ruggedness of compressors, as construction environments can be demanding and require equipment that can withstand harsh conditions.

In the food and beverage industry, maintaining hygiene is paramount. Air compressors are used for cleaning and sanitizing equipment, and having a pressure gauge ensures that the air pressure is adequate for effective cleaning without damaging sensitive machinery. B2B buyers should focus on compressors that comply with safety standards and offer features for precise pressure control to ensure food safety.

In agriculture, air compressors are utilized for inflating tires on machinery and operating irrigation systems. The ability to monitor and adjust pressure accurately is vital for ensuring that equipment functions efficiently, thus minimizing downtime during critical farming operations. When sourcing compressors, agricultural buyers should look for reliable models that provide consistent performance and accurate pressure readings, along with robust maintenance support.

The Problem: B2B buyers often encounter issues with air compressors providing inaccurate pressure readings. This can lead to improper inflation of tires or equipment, risking damage and safety concerns. For instance, a manufacturing facility in Germany may rely on an air compressor to maintain specific pressure levels in pneumatic tools. If the pressure gauge malfunctions or is improperly calibrated, it could result in the tools operating outside their optimal pressure range, leading to equipment failure or decreased operational efficiency.

Illustrative image related to air compressor with pressure gauge

The Solution: To mitigate this risk, buyers should prioritize air compressors equipped with high-quality, digital pressure gauges that allow for precise readings. Additionally, establishing a routine maintenance schedule that includes regular calibration of the pressure gauges can prevent inaccuracies. When sourcing compressors, look for models that feature user-friendly interfaces for easy adjustment and monitoring of pressure levels. It’s also advisable to choose suppliers that offer comprehensive warranties and customer support, ensuring that any issues with the pressure gauge can be promptly addressed. Investing in reliable, well-reviewed models with advanced pressure regulation technology can significantly enhance operational safety and efficiency.

The Problem: Many businesses face challenges when integrating new air compressors with existing pneumatic systems. This is especially true for companies in regions like Nigeria or Brazil, where equipment standards may vary. An air compressor with a pressure gauge that doesn’t match the existing connectors or pressure requirements can cause significant downtime, leading to lost productivity and increased costs.

The Solution: Before purchasing an air compressor, buyers should conduct a thorough compatibility assessment of their current pneumatic systems. This includes checking specifications for connector sizes, pressure ratings, and any unique requirements that may exist. Opting for air compressors that come with multiple adapter options or those that feature standard connection sizes can alleviate compatibility issues. Furthermore, partnering with suppliers who understand local market standards and can provide tailored solutions will ensure that the selected air compressor integrates seamlessly with existing systems, minimizing operational disruptions.

The Problem: Noise pollution from air compressors can significantly impact workplace conditions, particularly in environments where employees need to maintain focus, such as in assembly lines or automotive workshops. For businesses in the Middle East, where open spaces are common, excessive noise can lead to decreased employee productivity and potential hearing damage over time.

The Solution: To address noise concerns, businesses should invest in air compressors specifically designed for quieter operation. Look for models with sound-dampening features or those labeled as “low-noise” compressors. Additionally, consider the placement of the compressor; positioning it in sound-insulated rooms or using noise barriers can further reduce sound levels. Buyers should also assess the compressor’s duty cycle and select units that operate efficiently without excessive noise. Engaging with manufacturers that offer detailed specifications on noise levels can help ensure the selected equipment aligns with workplace comfort standards, ultimately enhancing employee satisfaction and productivity.

When selecting materials for air compressors equipped with pressure gauges, it’s essential to consider the properties and performance characteristics that align with the specific requirements of various applications. Below, we analyze four common materials used in the construction of air compressors and their respective pressure gauges, focusing on their suitability for international B2B buyers.

Aluminum is a widely used material in air compressor construction due to its favorable properties. It boasts a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. Aluminum can typically withstand temperatures up to 150°C (302°F) and pressures of around 150 PSI, making it suitable for various applications.

Pros: Aluminum is lightweight, which enhances portability, especially for mobile air compressors. Its corrosion resistance reduces maintenance needs, leading to lower long-term costs. Additionally, aluminum is relatively easy to manufacture, allowing for complex designs.

Cons: While durable, aluminum can be more expensive than steel and may not be suitable for high-pressure applications beyond its rating. Moreover, it can be prone to scratches and dents, which can affect performance over time.

Impact on Application: Aluminum is compatible with a wide range of media, including air and certain gases, making it versatile for different industries.

Illustrative image related to air compressor with pressure gauge

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure that aluminum components comply with international standards like ASTM or ISO, particularly regarding safety and performance.

Steel, particularly carbon steel, is another popular choice for air compressors. It offers high tensile strength and can handle high pressures, often exceeding 200 PSI. Steel’s resistance to deformation under stress makes it ideal for heavy-duty applications.

Pros: Steel is highly durable and can withstand harsh environmental conditions, making it suitable for industrial applications. It is also generally less expensive than aluminum, which can be a significant factor for budget-conscious buyers.

Cons: Steel is heavier than aluminum, which may affect the portability of the compressor. Additionally, it is susceptible to rust and corrosion unless properly treated or coated, leading to higher maintenance costs.

Illustrative image related to air compressor with pressure gauge

Impact on Application: Steel is compatible with various media, including air and oil, but its susceptibility to corrosion may limit its use in humid or corrosive environments.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the corrosion resistance of steel, especially in coastal areas. Compliance with local standards, such as DIN for Germany, is crucial.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are often used in the construction of pressure gauges. These materials are lightweight, resistant to corrosion, and can handle moderate pressure levels.

Pros: Plastics are cost-effective and can be molded into complex shapes, allowing for innovative designs. They are also resistant to many chemicals, which is beneficial in various industrial applications.

Cons: Plastic materials may not withstand high temperatures or pressures as effectively as metals. They can also become brittle over time, particularly when exposed to UV light or extreme temperatures.

Illustrative image related to air compressor with pressure gauge

Impact on Application: Plastics are suitable for non-corrosive media but may not be ideal for high-pressure applications.

Considerations for International Buyers: Buyers should verify that plastic components meet safety and performance standards relevant to their region, such as JIS standards in Japan.

Brass is commonly used for fittings and connections in air compressors due to its excellent corrosion resistance and good mechanical properties. It can handle pressures up to 200 PSI and is often used in environments where durability is essential.

Pros: Brass is highly resistant to corrosion, making it ideal for humid conditions. Its malleability allows for easy machining and forming, which is beneficial for creating precise fittings.

Cons: Brass can be more expensive than steel and aluminum, impacting overall costs. It is also heavier, which may affect the weight of portable compressors.

Impact on Application: Brass is compatible with air and various gases, making it suitable for a wide range of applications.

Considerations for International Buyers: Compliance with international standards is essential, particularly for buyers in Europe and Africa, where regulations may vary.

| Material | Typical Use Case for air compressor with pressure gauge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable air compressors, automotive applications | Lightweight and corrosion-resistant | More expensive, prone to scratches | Medium |

| Steel | Industrial air compressors, heavy-duty applications | High durability and cost-effective | Heavier, susceptible to rust | Low |

| Plastic | Pressure gauges and non-critical components | Cost-effective and moldable | Limited pressure and temperature resistance | Low |

| Brass | Fittings and connections in compressors | Excellent corrosion resistance | Heavier and more expensive | Medium |

This material selection guide provides valuable insights for B2B buyers, enabling them to make informed decisions based on their specific application needs and regional standards.

The manufacturing of air compressors with pressure gauges involves several critical stages, each contributing to the overall quality and performance of the final product.

The first step in the manufacturing process involves sourcing high-quality materials. Common materials include aluminum for the cylinder, steel for structural components, and durable plastics for housing and gauges. Suppliers must ensure that materials meet industry standards for strength and corrosion resistance. Material testing is often conducted to verify properties such as tensile strength and fatigue resistance before proceeding.

Once the materials are prepared, forming techniques come into play. This stage typically involves processes like casting, machining, and stamping. For example, aluminum cylinders may be produced through die casting, while steel components are often machined to precise specifications. Advanced technologies, such as CNC (Computer Numerical Control) machining, enhance accuracy and repeatability, ensuring that parts fit together seamlessly.

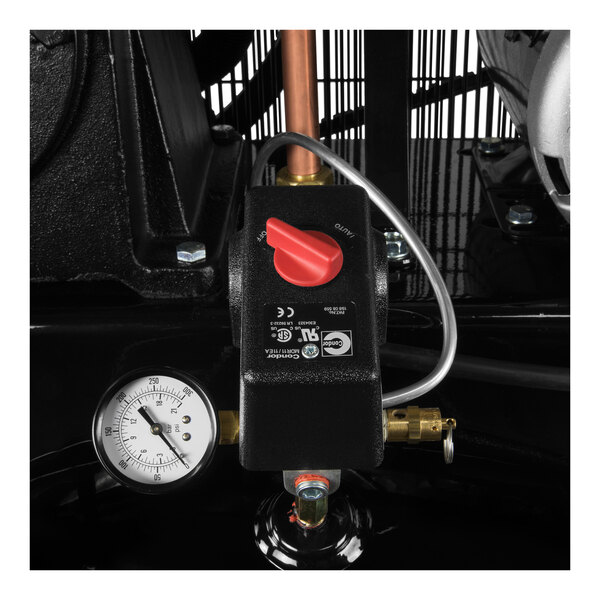

The assembly of air compressors is a pivotal phase where all components come together. This includes integrating the motor, pressure gauge, and control systems. Automated assembly lines may be employed to boost efficiency, but skilled technicians also play a critical role in ensuring that each unit is assembled correctly. During this stage, specific attention is given to the integration of the pressure gauge with the compressor, as accuracy in pressure readings is essential for user safety and performance.

After assembly, finishing processes enhance the durability and aesthetics of the air compressors. This may involve powder coating for corrosion resistance, as well as the installation of protective casings. Additionally, quality control checks are conducted to ensure that all components function properly and meet specified tolerances.

Quality assurance is integral to the manufacturing process of air compressors with pressure gauges. This ensures that products not only meet but exceed the expectations of B2B buyers.

Compliance with international standards, such as ISO 9001, is crucial for manufacturers looking to export their products globally. ISO 9001 sets the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement. Other industry-specific certifications, such as CE marking for the European market and API standards for performance and safety, add further assurance for buyers.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process.

Incoming Quality Control (IQC): This checkpoint assesses the quality of incoming materials. Suppliers provide certification and testing reports that demonstrate compliance with material specifications.

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to ensure that processes are followed and products meet design specifications. This includes monitoring machining tolerances and assembly procedures.

Final Quality Control (FQC): Before shipment, each compressor undergoes thorough testing. This includes functional tests of the pressure gauge, leak tests, and performance assessments under simulated operating conditions.

Testing methods play a vital role in ensuring the reliability and safety of air compressors with pressure gauges. Common methods include:

Pressure Testing: This involves subjecting the compressor to pressures exceeding its rated capacity to ensure structural integrity and safety.

Performance Testing: Evaluates the compressor’s efficiency, flow rate, and pressure output. This is crucial for validating the accuracy of the integrated pressure gauge.

Durability Testing: Simulates prolonged use to identify potential failure points in the compressor design or materials.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential.

Conducting supplier audits is an effective way to assess manufacturing processes and quality assurance protocols. Buyers can request detailed reports that outline quality management systems, testing methodologies, and compliance with international standards. Regular audits can also foster strong relationships and enhance trust between buyers and suppliers.

Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing processes and final products. These inspections can be conducted at various stages, from material sourcing to final assembly, ensuring adherence to quality standards.

Illustrative image related to air compressor with pressure gauge

Understanding the quality control nuances specific to different regions is crucial for international buyers. For instance, European standards may require more stringent testing and documentation compared to other regions. Buyers should familiarize themselves with the regulatory requirements in their target markets, ensuring that their suppliers can meet these standards.

In addition, cultural differences can impact communication and expectations regarding quality. Establishing clear quality agreements and specifications at the outset can mitigate misunderstandings and ensure that both parties are aligned on quality expectations.

The manufacturing processes and quality assurance practices for air compressors with pressure gauges are complex and multifaceted. By understanding these processes and the importance of quality control, B2B buyers can make informed decisions when selecting suppliers. Ensuring compliance with international standards and conducting thorough due diligence will ultimately lead to more reliable partnerships and superior products in the marketplace.

This guide provides a comprehensive checklist for B2B buyers looking to procure air compressors with pressure gauges. By following these steps, you can ensure that your sourcing process is thorough and that you select the right equipment to meet your operational needs.

Illustrative image related to air compressor with pressure gauge

Before starting your search for an air compressor, it’s essential to clearly outline your technical requirements. Consider the necessary pressure range (e.g., PSI), flow rate (CFM), and intended applications such as tire inflation or powering tools.

Conduct thorough research on various marketplaces and platforms that specialize in industrial equipment. This will help you gather a list of potential suppliers who offer air compressors with pressure gauges.

It’s crucial to vet suppliers thoroughly before making a commitment. Request company profiles, case studies, and references from buyers in similar industries or regions.

Once you’ve shortlisted suppliers, verify the specific features of the air compressors they offer. Pay attention to the pressure gauge’s accuracy, durability, and compatibility with other equipment you use.

Good after-sales support can save you time and money in the long run. Ensure that the supplier provides robust customer service and a reasonable warranty period.

Illustrative image related to air compressor with pressure gauge

After narrowing down your options, request detailed quotes from your selected suppliers. This allows you to compare not just pricing, but also the value offered in terms of features, warranty, and after-sales service.

Finally, based on your evaluations and comparisons, make an informed decision about which air compressor with pressure gauge to purchase. Consider not only the cost but also the long-term benefits and reliability of the equipment.

By following this checklist, you can streamline your procurement process and ensure that you invest in an air compressor that meets your business requirements effectively.

When sourcing air compressors with integrated pressure gauges, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

Illustrative image related to air compressor with pressure gauge

Materials: The choice of materials significantly affects the price. High-quality components, such as aluminum for the casing and brass for the pressure gauge fittings, can drive costs up. Conversely, opting for lower-grade materials may reduce initial expenses but could lead to increased maintenance costs over time.

Labor: Labor costs vary by region and can be influenced by local wage standards. In manufacturing hubs, labor costs might be lower, but this can affect the quality of craftsmanship. Understanding the labor market in the supplier’s location is essential for evaluating overall costs.

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Suppliers with efficient operations may offer better pricing, as lower overhead can be passed on to buyers.

Tooling: Specialized tooling for the production of air compressors and gauges can be a significant upfront investment. If a buyer requires customized products, the tooling costs may increase, which will be reflected in the pricing.

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the cost. Certifications such as ISO or CE can also influence pricing, as they require additional processes and documentation.

Logistics: Transportation costs vary based on the shipping method, distance, and weight of the products. International buyers should consider the implications of shipping delays, customs duties, and tariffs that can affect the total cost of ownership.

Margin: Finally, suppliers will add their profit margin to the total cost. This can vary widely based on the supplier’s market positioning and competitive landscape.

Several factors can influence the final pricing of air compressors with pressure gauges, particularly for international B2B buyers.

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to discounts, as suppliers benefit from economies of scale. Negotiating for bulk purchases can significantly reduce unit costs.

Specifications and Customization: Customized products or specific performance specifications can lead to increased costs. Buyers should clearly define their needs to avoid unnecessary expenses.

Material Quality and Certifications: Premium materials and compliance with international standards (such as CE, UL, etc.) can justify higher prices. Buyers should assess whether the additional cost aligns with their operational requirements.

Supplier Factors: The reputation, reliability, and location of the supplier can also impact pricing. Suppliers with a proven track record in quality and service may command higher prices but offer greater peace of mind.

Incoterms: Understanding international shipping terms is crucial. Incoterms dictate responsibilities for shipping, insurance, and tariffs, which can significantly affect the total landed cost.

To ensure a cost-effective procurement process, buyers should consider the following strategies:

Negotiation: Leverage volume purchases and long-term contracts to negotiate better terms. Building strong relationships with suppliers can lead to favorable pricing and service agreements.

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, energy consumption, and operational costs over the product’s lifespan. This holistic approach can reveal hidden costs.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import regulations, and local market conditions that can influence pricing. Establishing contracts in stable currencies and considering local suppliers can mitigate risks.

Market Research: Conduct thorough market research to understand price trends and competitor offerings. This knowledge will empower buyers during negotiations and help in making informed purchasing decisions.

By considering these cost components and pricing influencers, B2B buyers can make strategic sourcing decisions that align with their operational goals and budgetary constraints.

In the realm of industrial and automotive applications, the need for efficient inflation and pressure monitoring solutions is paramount. While air compressors equipped with pressure gauges are a popular choice for many businesses, various alternatives can also meet similar needs effectively. This section delves into a comparative analysis of air compressors with pressure gauges against two viable alternatives: portable battery-operated inflators and manual hand pumps.

| Comparison Aspect | Air Compressor With Pressure Gauge | Portable Battery-Operated Inflator | Manual Hand Pump |

|---|---|---|---|

| Performance | High air flow, consistent pressure | Moderate air flow, variable pressure | Low air flow, manual effort |

| Cost | Moderate to high investment | Low to moderate investment | Low investment |

| Ease of Implementation | Requires power source, setup | Simple setup, battery-operated | Very easy, no setup required |

| Maintenance | Regular checks and servicing | Minimal maintenance | Low maintenance |

| Best Use Case | Heavy-duty applications, multiple tires | Light to medium use, emergencies | Occasional use, single tire inflation |

Portable battery-operated inflators represent a modern solution for inflation needs, especially in automotive settings. They typically offer a compact design, making them easy to transport and store. Their operation is straightforward, requiring minimal setup—often just the push of a button. However, while they are convenient, they may not deliver the same level of air flow as traditional compressors, making them less suitable for heavy-duty applications. The reliance on batteries can also present challenges, particularly in scenarios where prolonged use is required, necessitating frequent recharging.

Manual hand pumps are the most basic option available for inflation tasks. They are cost-effective and require no electricity or batteries, making them highly portable and always ready for use. However, their performance is significantly limited compared to powered alternatives, as they require physical effort to operate. This can be a drawback for users needing to inflate multiple tires or larger items quickly. Nonetheless, they are ideal for occasional use and emergency situations where other options may not be accessible.

Illustrative image related to air compressor with pressure gauge

When selecting between an air compressor with a pressure gauge and its alternatives, it is essential for B2B buyers to consider their specific operational requirements. For industries demanding high performance and continuous use, air compressors remain the optimal choice due to their power and efficiency. Conversely, businesses with lighter inflation needs or those prioritizing cost-effectiveness may find battery-operated inflators or manual pumps more suitable. Ultimately, understanding the unique demands of your operations will guide you in selecting the most appropriate inflation solution, ensuring efficiency and reliability in your processes.

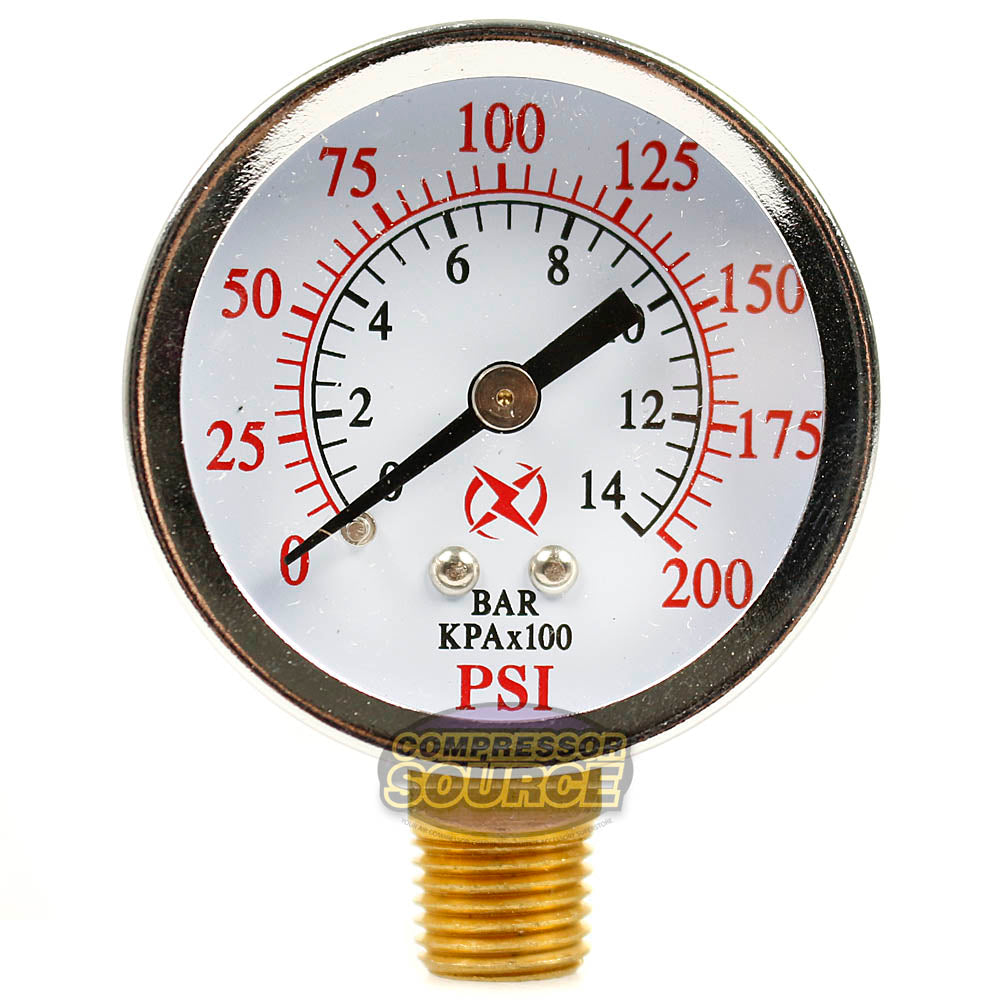

Air compressors with pressure gauges are critical tools in various industries, from automotive to manufacturing. Understanding the technical properties of these devices is essential for B2B buyers making informed purchasing decisions. Here are some key specifications:

Maximum Pressure Rating (PSI)

The maximum pressure rating, measured in pounds per square inch (PSI), indicates the highest pressure the compressor can safely handle. A higher PSI allows for more versatile applications, such as inflating tires or powering pneumatic tools. For instance, compressors rated at 150 PSI are suitable for most automotive needs, while those reaching 300 PSI cater to more demanding industrial applications.

Air Flow Rate (CFM)

The air flow rate, expressed in cubic feet per minute (CFM), measures the volume of air the compressor can deliver. This specification is crucial when selecting a compressor for tasks that require continuous air supply. Higher CFM ratings are essential for powering multiple tools simultaneously or for tasks requiring quick inflation, such as tire servicing.

Tank Size (Gallons)

The tank size, measured in gallons, determines how much compressed air the unit can store. A larger tank size means longer periods of operation without needing to restart the compressor, which is especially important for high-demand applications. For example, a 6-gallon tank may suffice for occasional home use, while a 20-gallon tank is better suited for commercial settings.

Power Source (Voltage and Amperage)

Understanding the power requirements of an air compressor is vital for ensuring compatibility with existing electrical systems. Most portable compressors operate on 12V DC or 110-120V AC power. Buyers should consider their power source and the amperage requirements, as inadequate power can hinder performance or cause damage.

Material Construction

The materials used in the compressor’s construction, such as aluminum or steel, affect durability and weight. Aluminum compressors are lighter and more portable, while steel options are typically more robust and suited for heavy-duty applications. Material choice impacts not only performance but also maintenance costs and lifespan.

Safety Features

Safety features, such as pressure relief valves and thermal overload protection, are crucial for preventing accidents and prolonging the compressor’s life. These features help mitigate risks associated with high-pressure systems, ensuring safe operation in various environments.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air compressors, an OEM might supply specific pressure gauges or components used in compressor assemblies. Understanding OEM relationships can help buyers ensure quality and compatibility.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For air compressors, knowing the MOQ is crucial for budgeting and inventory planning. Buyers must evaluate whether they can meet the MOQ without overcommitting resources.

RFQ (Request for Quotation)

An RFQ is a formal document that solicits price quotes from suppliers. For B2B buyers, submitting an RFQ for air compressors with specific technical requirements allows for better comparison and negotiation of prices and terms.

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping. These terms clarify who pays for shipping, insurance, and tariffs, which is vital for international buyers. Understanding Incoterms can help avoid disputes and ensure smoother transactions.

Duty Cycle

The duty cycle indicates how long a compressor can run before it needs a cooldown period. This is essential for buyers to ensure that the compressor meets their operational needs without overheating or failing prematurely.

Calibration

Calibration refers to the process of adjusting the pressure gauge to ensure accurate readings. Regular calibration is essential for maintaining the reliability of the pressure gauge, which directly affects the performance of the air compressor in various applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing air compressors with pressure gauges, ensuring they select the right equipment for their operational needs.

The air compressor with pressure gauge sector is currently experiencing notable growth driven by a variety of global factors. The increasing demand for compressed air across industries such as automotive, manufacturing, and construction is a primary driver. As companies strive for efficiency, the need for reliable and accurate pressure gauges becomes paramount. Emerging technologies, such as IoT-enabled air compressors that offer real-time monitoring and analytics, are transforming the landscape, allowing businesses to optimize operations and reduce downtime.

Illustrative image related to air compressor with pressure gauge

In markets like Africa and South America, infrastructure projects are spurring demand, particularly in construction and mining sectors. Meanwhile, in Europe and the Middle East, there is a significant push towards portable and energy-efficient models, catering to both commercial and residential needs. Additionally, the rise of e-commerce platforms is simplifying the sourcing process for international buyers, enabling them to access a broader range of products and suppliers.

Current sourcing trends highlight a shift towards integrated solutions that combine compressors with digital pressure gauges, enhancing user experience and operational efficiency. Buyers are increasingly looking for products that offer ease of use, such as automatic shutoff features, digital displays, and compatibility with various applications. This trend emphasizes the importance of suppliers who can provide innovative and user-friendly solutions tailored to diverse market needs.

The environmental impact of manufacturing processes is becoming a focal point for international B2B buyers. Companies are increasingly prioritizing ethical sourcing and sustainability in their procurement strategies. This trend is especially evident in the air compressor sector, where the demand for energy-efficient models is on the rise. Buyers are seeking products that minimize energy consumption and carbon footprints, aligning with global sustainability goals.

Ethical supply chains are crucial, particularly in regions like Africa and South America, where sourcing practices can significantly affect local communities. Buyers should look for suppliers who demonstrate transparency in their sourcing methods and adhere to international standards. Certifications such as ISO 14001 (Environmental Management) and Energy Star ratings can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of eco-friendly materials in the manufacturing of air compressors is gaining traction. For example, compressors that utilize recyclable materials or have lower emissions during production can appeal to environmentally conscious buyers. As sustainability becomes a core component of corporate strategies, B2B buyers must assess not only the product quality but also the environmental credentials of their suppliers.

The evolution of the air compressor market reflects significant technological advancements and changing consumer demands. Historically, air compressors were primarily mechanical devices used for simple tasks. Over the decades, they have transformed into sophisticated machines equipped with digital pressure gauges and smart technologies. This evolution has been driven by the need for precision and efficiency in various applications.

The introduction of digital pressure gauges has enhanced the accuracy of air compressors, enabling users to monitor and control pressure levels more effectively. This technological shift has been particularly beneficial for industries that require stringent quality control, such as automotive manufacturing and food processing. Furthermore, the rise of portable and battery-operated compressors has expanded their usage beyond industrial settings to personal applications, catering to a broader audience.

As the market continues to evolve, the integration of IoT and automation technologies is expected to further revolutionize the sector. These advancements not only enhance functionality but also provide users with valuable data for informed decision-making. In this dynamic landscape, international B2B buyers must remain attuned to these trends to ensure they source products that meet their operational needs while aligning with future market developments.

How do I choose the right air compressor with a pressure gauge for my business needs?

Choosing the right air compressor involves assessing your specific application requirements, such as the type of tools you’ll be using, the required PSI (pounds per square inch), and airflow rate (CFM – cubic feet per minute). For industrial applications, a higher PSI and CFM will be necessary, while smaller operations may only need a compact model. Additionally, consider the compressor’s power source (electric vs. gas), portability, and maintenance requirements to ensure it aligns with your business operations.

What are the key features to look for in an air compressor with a pressure gauge?

When sourcing an air compressor, prioritize features like a reliable pressure gauge for accurate monitoring, an automatic shut-off function to prevent over-inflation, and a durable build to withstand heavy usage. Other important features include ease of maintenance, noise level, and whether it has additional functionalities such as a digital display or built-in inflation tools. Ensure that it meets the specific needs of your industry, whether for tire inflation, pneumatic tools, or other applications.

What is the typical lead time for air compressor orders in international trade?

Lead times for air compressors can vary significantly based on the supplier’s location, manufacturing capacity, and your order size. Typically, expect a lead time of 4 to 12 weeks for international shipments. It’s crucial to discuss lead times upfront with suppliers, especially if you have a specific project timeline. Planning for potential delays due to customs clearance or logistics can help you manage your supply chain more effectively.

What minimum order quantities (MOQs) should I expect when sourcing air compressors?

Minimum order quantities for air compressors can differ widely among suppliers, often ranging from one unit for small manufacturers to several hundred for larger companies. When negotiating with suppliers, inquire about the possibility of lower MOQs, especially if you are a new buyer. Some manufacturers may offer flexibility for first-time orders or allow a mix of models to meet MOQ requirements, which can be beneficial for startups or smaller businesses.

How do I vet suppliers for air compressors with pressure gauges?

To effectively vet suppliers, conduct thorough research by checking their industry reputation, certifications, and customer reviews. Request references from previous clients and verify their experience in your specific market. Additionally, consider visiting their manufacturing facility if possible, or use third-party inspection services to assess product quality and compliance with international standards. Establishing clear communication about expectations and quality assurance processes is also critical in supplier selection.

What payment terms are commonly offered for international purchases of air compressors?

Payment terms can vary based on the supplier and the nature of the transaction. Commonly, suppliers may require a deposit (typically 30-50%) upon order confirmation, with the balance due before shipping. Some suppliers may offer letter of credit or net payment terms for established relationships. Always negotiate terms that align with your cash flow and risk management strategies, and ensure that all agreements are documented to avoid misunderstandings.

What quality assurance measures should I expect from manufacturers of air compressors?

Reputable manufacturers should have stringent quality assurance measures in place, including ISO certification and compliance with industry standards. Ask about their testing processes for air compressors, which should include pressure testing, safety checks, and performance evaluations. Additionally, inquire about warranty terms and post-sale support to ensure you have recourse if the product does not meet your expectations. Regular audits and quality control measures are indicators of a reliable supplier.

What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider shipping methods, customs regulations, and potential tariffs that may affect your overall costs. Choose a reliable freight forwarder familiar with your destination’s import laws to navigate the logistics smoothly. Additionally, ensure that the packaging is robust enough to withstand transport, and verify that all necessary documentation, such as bills of lading and commercial invoices, is accurate and complete to avoid delays in customs clearance.

Domain: alltopusa.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “Air Compressor Kit Dual Cylinder – w/ Digital Pressure Gauge”, “Air Flow”: “12.35 ft³/min”, “Max Pressure”: “150 PSI”, “Power Source”: “12V DC”, “Included Components”: [“Heavy Duty Double Cylinder Air Compressor”, “6.5ft Heavy Power Cord”, “Digital Tire Inflator with Pressure Gauge”, “26ft Rubber Air Hose”, “3 Nozzle Adapters”, “Thumb Lock Adapter”], “Weight”: “11.72 Kilograms (2…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Milton Standard Air Pressure Gauge – recommended for reliability.

2. Jaco Flow Pro with Digital Gauge – noted for accuracy and performance.

3. Sealey SA302 Tyre Inflator with Gauge – includes brass tyre valve air pump clip and various nozzle adapters.

Domain: astroai.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “AstroAI Tire Inflator with Pressure Gauge 120PSI”, “price”: “$30.99”, “rating”: “4.6”, “pressure_range”: “0-60PSI, 6-170PSI, 10-120PSI, 0-230PSI, 3-250PSI”, “accuracy”: “±0.5%PSI”, “warranty_period”: “36 MONTHS”, “features”: [“Fast, Free Shipping”, “30-Day Money-Back Guarantee”, “Hassle-Free Warranty”, “Lifetime Customer Support”], “compatibility”: “Works on Schrader valves, comp…

As international B2B buyers explore the landscape of air compressors with pressure gauges, strategic sourcing emerges as a critical component for optimizing procurement processes. The integration of advanced features such as digital pressure gauges and automatic shutoff systems enhances operational efficiency and safety, particularly in industries ranging from automotive to manufacturing. Understanding the specifications and capabilities of various models—like those offering high PSI ratings and quick inflation times—can significantly influence purchasing decisions.

Value-driven sourcing ensures that companies not only acquire high-quality equipment but also benefit from long-term partnerships with reliable suppliers. This approach allows buyers to negotiate better terms, access innovative technologies, and secure after-sales support, which is vital in regions like Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for versatile and efficient air compressors is expected to rise, driven by industrial growth and technological advancements. Now is the time for B2B buyers to leverage strategic sourcing practices, aligning procurement strategies with their operational goals. Embrace the opportunity to enhance your supply chain and ensure your organization stays ahead in a competitive market by investing in top-notch air compressor solutions.

Illustrative image related to air compressor with pressure gauge

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.