In an increasingly globalized marketplace, sourcing reliable air fillers for tires poses significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The demand for efficient tire inflation solutions is critical not only for vehicle performance but also for cost-effective maintenance practices. This comprehensive guide delves into the multifaceted world of air fillers, examining various types, applications, and the nuances of supplier vetting.

From portable inflators to industrial-grade compressors, we address key considerations that influence purchasing decisions, such as performance specifications, pricing structures, and after-sales support. Additionally, we provide insights into the regulatory landscape affecting import and export practices, ensuring compliance with international standards.

By equipping buyers with actionable intelligence, this guide empowers them to make informed decisions that align with their operational needs and budget constraints. Whether you’re a distributor in Brazil or a fleet manager in Vietnam, understanding the intricacies of air filler technologies will enable you to enhance your product offerings and improve customer satisfaction. Join us as we navigate this essential component of tire maintenance, ensuring your business remains competitive in a rapidly evolving market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Electric Inflators | Battery-operated, compact, suitable for light vehicles | Automotive repair shops, fleet management | Pros: Easy to use, portable; Cons: Limited battery life for heavy-duty tasks. |

| Heavy-Duty Air Compressors | High PSI capabilities, often stationary, powerful motors | Commercial garages, tire service centers | Pros: Fast inflation, suitable for large tires; Cons: Higher initial investment, requires space. |

| Cordless Tire Inflators | Rechargeable, lightweight, often includes digital gauges | Retail automotive outlets, mobile mechanics | Pros: Great for emergencies, easy to store; Cons: Less powerful than corded options. |

| 12V Car Tire Inflators | Plugs into vehicle’s power outlet, often portable | Roadside assistance, personal vehicle owners | Pros: Convenient for on-the-go inflation; Cons: Performance may vary with vehicle power supply. |

| Industrial Tire Inflators | Designed for high-volume use, robust construction | Manufacturing, logistics, heavy equipment | Pros: Durable, efficient for large fleets; Cons: Higher maintenance costs, specialized training may be needed. |

Portable electric inflators are compact, battery-operated devices designed for convenience and ease of use. They are particularly suitable for light vehicles and are commonly used in automotive repair shops and fleet management operations. When considering a purchase, B2B buyers should assess battery life, inflation speed, and ease of storage, as these factors significantly impact operational efficiency.

Heavy-duty air compressors are characterized by their high PSI capabilities and powerful motors, making them ideal for commercial garages and tire service centers. These compressors can inflate tires quickly and efficiently, accommodating larger vehicles and heavy-duty applications. Buyers should weigh the initial investment against long-term benefits, including speed and durability, as well as the need for adequate space in their operations.

Cordless tire inflators are rechargeable and lightweight, often featuring digital gauges for precise inflation. They are particularly beneficial for retail automotive outlets and mobile mechanics, providing a quick solution for roadside emergencies. B2B buyers should consider battery life and the range of features offered, such as preset pressure settings, which can enhance usability and customer satisfaction.

12V car tire inflators are designed to plug into a vehicle’s power outlet, making them a convenient option for roadside assistance and personal vehicle owners. These inflators are typically portable and easy to use, but their performance can vary depending on the vehicle’s power supply. Buyers should evaluate the inflator’s compatibility with their fleet and the expected frequency of use to ensure optimal performance.

Industrial tire inflators are built for high-volume use and feature robust construction to withstand demanding environments. They are essential for businesses in manufacturing, logistics, and heavy equipment sectors that require reliable inflation solutions for large fleets. B2B buyers should consider the durability, efficiency, and potential maintenance costs associated with these inflators to make informed purchasing decisions that align with their operational needs.

| Industry/Sector | Specific Application of air filler for tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Fleet Maintenance for Commercial Vehicles | Reduces downtime and maintenance costs | Reliability, ease of use, compatibility with various vehicles |

| Agriculture | Tire Maintenance for Agricultural Equipment | Enhances productivity by minimizing equipment failures | Durability, pressure capacity, and weather resistance |

| Construction | Inflating Heavy-Duty Tires for Construction Vehicles | Ensures safety and efficiency on job sites | Power source options, portability, and inflation speed |

| Logistics & Warehousing | Maintaining Tire Pressure for Delivery Trucks | Increases fuel efficiency and reduces tire wear | Accuracy of pressure gauges, size, and weight of the inflator |

| Mining | Tire Inflation for Heavy Machinery | Improves operational efficiency and reduces downtime | Robustness, ability to handle high-pressure requirements |

In the transportation sector, air fillers for tires are crucial for maintaining the performance of commercial vehicle fleets. Regular tire inflation helps prevent flats and extends tire life, leading to reduced operational costs. Businesses benefit from minimized downtime and enhanced fuel efficiency due to properly inflated tires. Buyers should consider reliability, ease of use, and compatibility with various vehicle types when sourcing inflators, especially in regions like Africa and South America, where road conditions can vary significantly.

In agriculture, air fillers are essential for maintaining the tires of tractors and other heavy equipment. Proper tire inflation enhances the performance and safety of these machines, directly impacting productivity. Inflators must be durable and capable of withstanding harsh environments, with features that allow for high-pressure inflation. For international buyers in regions such as Brazil and the Middle East, sourcing equipment that is resistant to dust and moisture is vital to ensure longevity and reliability.

Construction companies rely on air fillers to maintain the tires of heavy-duty vehicles and equipment. Properly inflated tires are crucial for safety and efficiency on job sites, helping to prevent accidents and equipment failures. When sourcing inflators, businesses should prioritize options that offer a robust power source, portability for job site mobility, and quick inflation speeds to keep operations running smoothly. This is particularly important for buyers in Europe, where construction regulations often emphasize safety standards.

In logistics and warehousing, maintaining tire pressure in delivery trucks is vital for operational efficiency. Properly inflated tires improve fuel efficiency and reduce wear, leading to lower costs and enhanced delivery reliability. Buyers should focus on the accuracy of pressure gauges, as well as the size and weight of the inflators, to ensure they meet the demands of busy logistics operations. In regions like Africa and the Middle East, where logistics networks are rapidly developing, sourcing durable and efficient tire inflators can significantly impact business success.

The mining industry often employs heavy machinery that requires precise tire inflation to operate effectively. Air fillers help improve operational efficiency and reduce downtime due to tire issues. Buyers in this sector need to consider the robustness of inflators, as well as their ability to handle high-pressure requirements common in mining applications. In regions with challenging mining conditions, such as South America, sourcing equipment that can withstand extreme environments is crucial for maintaining productivity.

The Problem: For businesses that operate a fleet of vehicles, maintaining consistent tire pressure is crucial for optimizing fuel efficiency and ensuring safety. However, many B2B buyers encounter the challenge of regularly checking and inflating tires, particularly in regions where tire pressure can fluctuate due to extreme weather conditions. A failure to monitor this can lead to uneven wear, increased fuel costs, and potential safety hazards, ultimately impacting operational efficiency and bottom-line profitability.

The Solution: To effectively manage tire pressure across a fleet, B2B buyers should consider investing in high-quality, portable air fillers that offer automatic shut-off features and built-in pressure gauges. These devices allow for quick and easy inflation, ensuring that tires are maintained at the recommended PSI without the risk of over-inflation. Buyers should also implement a scheduled maintenance system, equipping fleet managers with the necessary tools to regularly check tire pressures. Additionally, leveraging technology such as tire pressure monitoring systems (TPMS) can provide real-time data, allowing businesses to proactively address any tire-related issues before they escalate.

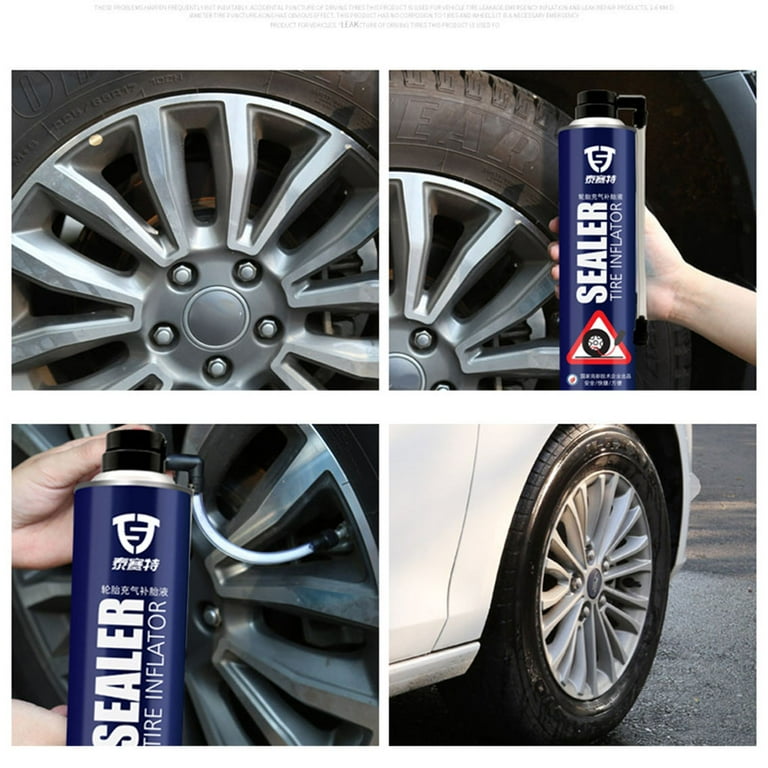

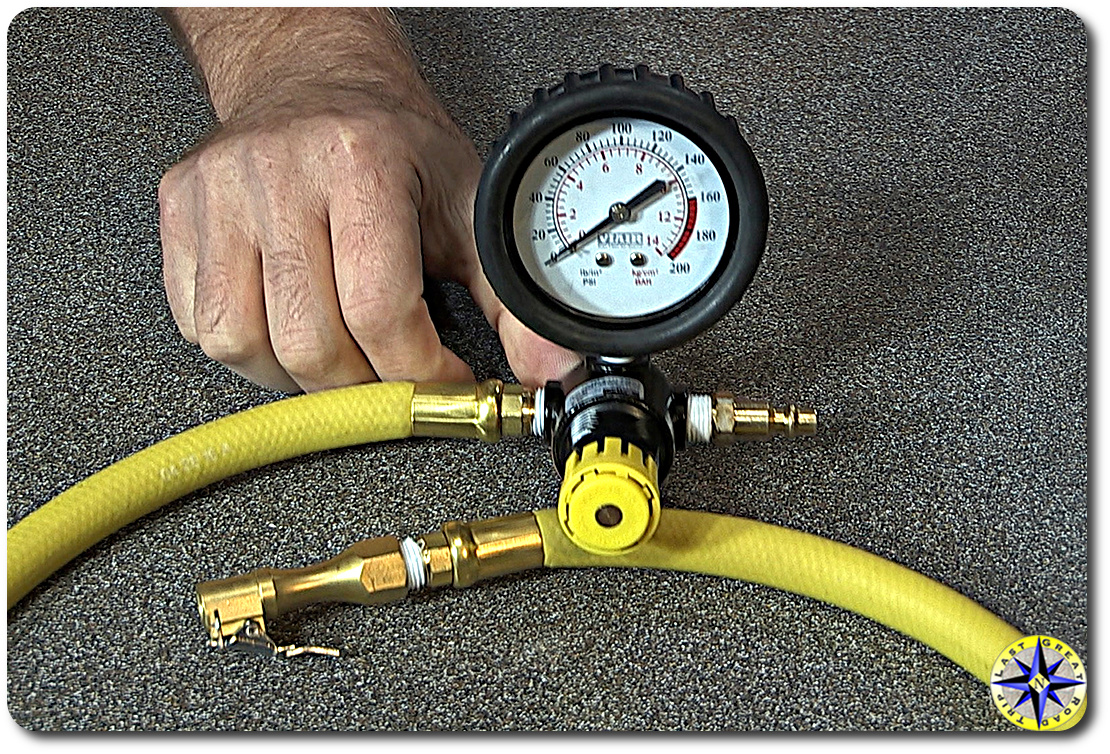

Illustrative image related to air filler for tires

The Problem: Businesses operating in remote areas often face challenges in accessing traditional power sources for tire inflation. This situation is particularly common in industries such as construction or mining, where vehicles frequently operate far from electrical outlets. As a result, employees may find themselves stranded with flat tires, leading to costly downtime and delays in operations.

The Solution: A practical solution for this scenario is to invest in cordless tire inflators that come with rechargeable batteries. These units should have sufficient battery life to inflate multiple tires on a single charge, ensuring that teams can address tire issues without needing immediate access to power sources. It’s essential for B2B buyers to evaluate the battery specifications and choose inflators with robust performance metrics, such as the ability to inflate tires to high pressures quickly. Additionally, establishing a protocol for regularly charging these devices and ensuring they are included in vehicle kits can help mitigate potential downtime.

The Problem: With the vast array of tire inflators available in the market, B2B buyers often struggle to identify reliable products that meet their specific needs. This challenge can lead to purchasing decisions that result in subpar performance, frequent breakdowns, and ultimately, wasted resources. Furthermore, buyers may be unsure of which features are essential for their operations, complicating the procurement process.

Illustrative image related to air filler for tires

The Solution: To navigate the complexities of sourcing tire inflators, B2B buyers should conduct thorough market research, focusing on product reviews, user testimonials, and performance metrics. Engaging with suppliers who specialize in automotive tools and equipment can provide valuable insights into which models are best suited for heavy-duty use. It’s also advisable to prioritize inflators that offer a combination of features such as fast inflation times, accuracy in pressure measurement, and versatility in usage (e.g., compatibility with various tire types). Creating a checklist of required features tailored to specific operational needs will help streamline the purchasing process, ensuring that the selected inflators deliver reliability and efficiency in the long run.

When selecting materials for air fillers in tires, several factors must be considered, including performance characteristics, compatibility with different tire types, and regional compliance standards. Below, we analyze four common materials used in air fillers, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

Rubber is a widely used material for air fillers due to its elasticity and ability to maintain air pressure effectively.

Thermoplastic elastomers (TPEs) are increasingly being used in air fillers due to their versatility and performance.

Metal-based fillers, such as aluminum or steel, are less common but can be used in specialized applications.

Composite materials, which combine various materials to enhance performance, are becoming popular in air fillers.

| Material | Typical Use Case for air filler for tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Passenger and heavy-duty tires | Excellent elasticity and durability | Moderate to high manufacturing complexity | Medium to High |

| Thermoplastic Elastomers | Passenger and light truck tires | Lightweight and cost-effective | Lower chemical resistance | Medium |

| Metal | Off-road and industrial tires | High strength and durability | Increased weight and manufacturing complexity | High |

| Composites | High-performance and specialized tires | Tailored performance characteristics | Higher production costs and complexity | High |

This analysis provides B2B buyers with actionable insights into material selection for air fillers in tires, ensuring they make informed decisions that align with their operational needs and regional compliance requirements.

Illustrative image related to air filler for tires

The manufacturing process of air fillers for tires involves several critical stages, each designed to ensure that the final product meets the required performance and safety standards. Understanding these stages is essential for B2B buyers looking for high-quality tire inflators.

The first stage in the manufacturing process is material preparation. Common materials used in air fillers include:

These materials must be sourced from reputable suppliers who adhere to international quality standards. Buyers should verify the material specifications and ensure they are suitable for the intended application, especially in regions with diverse environmental conditions.

Once materials are prepared, the next stage involves forming and assembling the components. Key techniques include:

The assembly process typically follows a modular approach, where components are assembled in stages, allowing for easier quality checks and adjustments. This modularity can also facilitate repairs and replacements, enhancing product longevity.

Illustrative image related to air filler for tires

The final stage of manufacturing is finishing, which includes processes that enhance the appearance and functionality of the air fillers. Common finishing techniques include:

These finishing touches not only improve the product’s appearance but also its performance and lifespan, making them crucial for B2B buyers seeking reliable products.

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that air fillers meet both international and industry-specific standards. B2B buyers must be aware of these practices to make informed purchasing decisions.

Manufacturers of tire inflators should comply with several international standards to ensure product quality and safety. Key standards include:

B2B buyers should request certification documents from suppliers to verify compliance with these standards, as adherence can significantly impact product reliability and marketability.

Illustrative image related to air filler for tires

Quality control (QC) is integrated throughout the manufacturing process and includes several checkpoints to ensure that products meet specified standards. Common QC checkpoints include:

Implementing these checkpoints helps to minimize defects and ensure that only high-quality products reach the market.

Verifying the quality control practices of suppliers is crucial for B2B buyers, especially in international markets where standards may vary. Here are some effective methods:

These methods help mitigate risks associated with sourcing from international suppliers, ensuring that the products meet necessary quality standards.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

By considering these factors, international B2B buyers can enhance their sourcing strategies, ensuring they procure high-quality tire inflators that meet their specific needs and standards.

This guide serves as a practical resource for B2B buyers in the tire industry, specifically focusing on the procurement of air fillers for tires. Whether you are sourcing for a retail business, a fleet, or a service center, following these steps will ensure you make informed decisions that meet your operational needs.

Begin by determining the technical requirements for the air fillers you intend to purchase. Consider factors such as maximum pressure (psi), power source (cordless, battery-operated, or AC), and size. Understanding these specifications will help you narrow down options that are not only suitable for your applications but also compatible with the types of vehicles you service.

Illustrative image related to air filler for tires

Evaluate the needs of your target market, which may vary by region. For instance, customers in off-road regions may require heavy-duty inflators capable of handling larger tires. Conduct market research to identify common vehicle types and tire sizes in your area, ensuring the products you source are relevant and desirable.

Before finalizing suppliers, check their certifications and compliance with international standards. This may include ISO certifications or safety standards specific to the automotive industry. Reliable suppliers should also provide proof of quality assurance processes, ensuring the products meet safety and performance requirements.

Conduct a thorough evaluation of potential suppliers. Request company profiles, product samples, and references from existing clients. Look for suppliers who have experience in your target market and can provide case studies demonstrating successful partnerships within similar industries.

Comparatively analyze pricing structures across different suppliers, taking into account not only the purchase price but also shipping costs and potential tariffs. Additionally, review payment terms, including options for bulk discounts and credit terms, to ensure that the financial arrangements align with your budget and cash flow requirements.

Illustrative image related to air filler for tires

Confirm the level of after-sales support offered by your suppliers. This includes warranty terms, availability of spare parts, and customer service responsiveness. Effective after-sales support can significantly impact your operational efficiency, especially if you encounter issues with the products post-purchase.

Once you have selected a supplier, consider placing a trial order to test the products in real-world conditions. This will allow you to assess the performance of the air fillers and gauge customer satisfaction before making a larger commitment. Use this opportunity to gather feedback from your team and customers, informing future purchasing decisions.

By following this structured approach, you can confidently navigate the procurement process for air fillers for tires, ensuring that your selections meet both your operational needs and those of your market.

Illustrative image related to air filler for tires

In the competitive landscape of air fillers for tires, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This analysis breaks down the components that influence costs and pricing, enabling informed sourcing decisions.

The cost structure for tire inflators typically includes several key components:

Materials: The primary materials used in tire inflators include plastic casings, metal components, motors, and electronic parts. The choice of materials significantly impacts the durability and performance of the product. Higher-quality materials may increase upfront costs but can lead to better longevity and reliability.

Labor: Labor costs can vary based on geographic location. For instance, manufacturing in regions with higher wages (like parts of Europe) may lead to increased overall costs compared to lower-wage regions (such as parts of Africa or South America).

Manufacturing Overhead: This encompasses factory costs, utilities, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, impacting the final pricing of the product.

Tooling: The initial investment in tooling and equipment for production can be substantial. This cost is often amortized over the volume of production, making it essential for suppliers to produce at scale to lower per-unit costs.

Quality Control (QC): Rigorous testing and quality assurance processes ensure that products meet safety and performance standards. These processes add to the cost but are crucial, especially for international markets that may have stringent regulations.

Logistics: Shipping and handling costs are significant, particularly for international buyers. Factors such as distance, shipping method, and customs duties can affect overall logistics costs.

Margin: Suppliers typically apply a markup to cover their costs and generate profit. This margin can vary widely based on competition and market demand.

Several factors influence the pricing of air fillers for tires:

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often yield better pricing due to economies of scale.

Specifications and Customization: Custom features, such as advanced digital displays or specific PSI capabilities, can increase costs. Buyers should assess whether these features are necessary for their target market.

Materials and Quality Certifications: The use of premium materials and compliance with international quality certifications can raise prices but may be necessary for certain markets.

Supplier Factors: Supplier reputation and reliability can impact pricing. Established suppliers may charge more due to their track record of quality and service.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers as they dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs.

Negotiation: Engage suppliers in discussions about pricing and terms. Leveraging volume commitments can often lead to better rates.

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance and operational costs over the product’s lifecycle.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local regulations that may affect final costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand local demand and pricing structures.

Disclaimer on Indicative Prices: Always approach pricing with caution. Prices can fluctuate based on market conditions, supplier relationships, and geopolitical factors. Request detailed quotes and consider all cost components when making decisions.

By understanding these elements, B2B buyers can better navigate the complexities of sourcing air fillers for tires, ensuring they make informed purchasing decisions that align with their business needs.

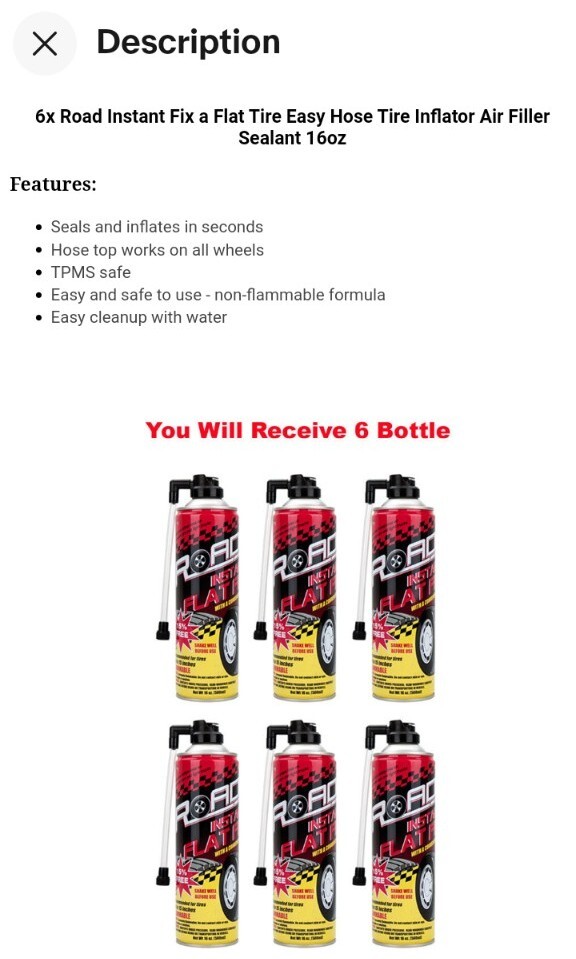

When it comes to maintaining optimal tire pressure, businesses have several options beyond traditional air fillers. Understanding the different methods available can help B2B buyers make informed decisions based on their specific operational needs. This analysis compares air fillers for tires with alternative solutions, including tire sealants and inflators, to provide a comprehensive view of their effectiveness, cost, and ease of use.

| Comparison Aspect | Air Filler For Tires | Tire Sealants | Portable Tire Inflators |

|---|---|---|---|

| Performance | Effective for inflation | Prevents slow leaks | Quick inflation for flat tires |

| Cost | Moderate ($40 – $90) | Low to Moderate ($10 – $30) | Moderate to High ($30 – $90) |

| Ease of Implementation | Simple setup | Easy to apply, no tools needed | Requires time for setup |

| Maintenance | Minimal (periodic checks) | Low (once applied) | Regular charging/checks needed |

| Best Use Case | Routine tire maintenance | Emergency situations | On-the-go inflation needs |

Tire sealants, such as those made from liquid rubber, are designed to be applied to tires to seal punctures and prevent air loss. These products are particularly effective for small leaks, providing a quick and often permanent solution without the need for immediate inflation. The primary advantage of tire sealants is their ease of application; they can be added to tires without special tools, making them ideal for emergency situations. However, they may not be suitable for larger punctures and can complicate tire repairs in the long run, as they can create a mess when a tire is dismounted.

Illustrative image related to air filler for tires

Portable tire inflators are compact devices that allow users to inflate tires quickly and efficiently. They are available in various forms, including battery-powered and plug-in models, making them versatile for different settings. The key benefits of portable inflators include their speed and convenience, especially in roadside emergencies. However, they can be costly and require regular maintenance, such as battery charging or keeping cords untangled. While they excel in quickly bringing flat tires back to operational pressure, they do not address slow leaks as effectively as tire sealants.

For B2B buyers, selecting the appropriate tire inflation solution hinges on understanding their specific needs and operational contexts. Air fillers are ideal for routine maintenance and ensuring tire health, while tire sealants offer a quick fix for emergency situations. On the other hand, portable tire inflators provide rapid inflation but require ongoing maintenance. By evaluating performance, cost, and ease of implementation, businesses can choose the most effective solution to enhance their fleet’s reliability and safety.

When sourcing air fillers for tires, understanding their technical specifications is crucial for ensuring product quality and performance. Here are some critical specs to consider:

Max PSI (Pounds per Square Inch)

This specification indicates the maximum pressure that the inflator can achieve. For heavy-duty applications, such as trucks or SUVs, a higher max PSI (often up to 160 PSI) is essential. Understanding this property helps buyers select products that meet the requirements of various tire types, ensuring safety and performance.

Duty Cycle

The duty cycle refers to the duration an inflator can operate before needing a cool-down period. For instance, a 20-minute duty cycle means the inflator can run for 20 minutes before it requires a break. This property is important for B2B buyers who expect continuous use, particularly in commercial settings where efficiency is critical.

Power Source

Air fillers can be powered by various sources, including rechargeable batteries, 12-volt outlets, or direct battery clamps. Knowing the power source can influence purchasing decisions based on the intended use case, whether it’s for emergency roadside assistance or regular maintenance in a garage.

Hose Length

The length of the hose affects the inflator’s versatility and ease of use. Longer hoses can reach more tires or awkward positions without needing to reposition the inflator. This specification is particularly relevant for B2B buyers in industries where convenience and time efficiency are paramount.

Weight and Portability

The weight of the inflator impacts its portability, especially for on-the-go applications. Lightweight models are favored for personal vehicles, while heavier, robust inflators might be necessary for workshop settings. Buyers must consider the balance between durability and ease of transport.

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers looking for high-quality components that meet specific tire inflator standards.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as it helps determine the cost-effectiveness of sourcing products in bulk versus individual units.

RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to solicit pricing and terms for specific products. In the tire inflator market, issuing an RFQ can help buyers compare offers from multiple suppliers, ensuring they get the best deal.

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Understanding Incoterms is essential for B2B buyers involved in international trade, as they clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

Lead Time

Lead time is the period between the initiation of an order and the delivery of the product. In the tire inflator sector, knowing the lead time is important for planning inventory and ensuring that products are available when needed.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they choose the right air fillers for tires that meet their operational needs and standards.

The air filler for tires market is witnessing significant transformation driven by advancements in technology, rising consumer expectations, and a growing emphasis on sustainability. One of the primary global drivers is the increasing awareness of vehicle maintenance and safety, leading to a surge in demand for efficient and user-friendly tire inflators. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking products that blend performance with convenience, such as cordless inflators and models equipped with smart technology for real-time pressure monitoring.

Emerging B2B tech trends include the integration of IoT capabilities, enabling tire inflators to connect with mobile apps for tracking tire pressure and maintenance schedules. This shift towards smart technology not only enhances user experience but also appeals to tech-savvy consumers who prioritize convenience. Furthermore, the rise of e-commerce platforms has transformed sourcing strategies, allowing international buyers to access a broader range of products and suppliers, thus fostering competitive pricing.

Market dynamics are also influenced by regulatory frameworks promoting energy efficiency and emissions reduction. Countries are introducing stricter regulations on vehicle emissions, driving the demand for high-performance inflators that can accommodate various tire sizes, from standard passenger vehicles to heavy-duty trucks and SUVs. Buyers in emerging markets must navigate these regulations while ensuring they source products that comply with international standards.

Illustrative image related to air filler for tires

Sustainability is becoming a critical consideration in the sourcing of air fillers for tires. The environmental impact of manufacturing processes and the materials used in tire inflators is under scrutiny, prompting buyers to seek products that align with eco-friendly practices. This trend is particularly relevant for B2B buyers from regions like Europe, where consumers increasingly demand transparency regarding the sustainability of products.

Ethical sourcing is gaining traction as companies prioritize supply chains that adhere to sustainable practices, such as using recycled materials or manufacturing processes that minimize waste. B2B buyers are looking for suppliers who can provide certifications that demonstrate compliance with environmental standards, such as ISO 14001 for environmental management or certifications indicating the use of recycled materials.

Moreover, the shift towards “green” certifications is influencing purchasing decisions. Buyers are more inclined to partner with manufacturers that can prove their commitment to sustainability through verified claims. This not only helps in enhancing brand reputation but also meets the growing consumer demand for environmentally responsible products.

Illustrative image related to air filler for tires

The air filler for tires market has evolved significantly over the past few decades. Initially dominated by manual pumps and basic electric inflators, the industry has seen a shift towards more sophisticated technology. The introduction of portable, battery-operated inflators has revolutionized consumer access to tire maintenance, offering convenience and efficiency.

As vehicle technology advanced, so did tire designs, necessitating more powerful and versatile inflators capable of handling diverse tire pressures. The emergence of smart tire technology and IoT-connected devices has further transformed the landscape, allowing users to monitor tire health and maintenance needs proactively.

In summary, the evolution of the air filler for tires market reflects broader trends in technology, consumer behavior, and sustainability, providing B2B buyers with opportunities to source innovative and eco-friendly solutions that meet the demands of modern vehicle maintenance.

1. How do I choose the right air filler for tires for my business?

Selecting the right air filler involves assessing your specific needs, such as the types of vehicles you service and the volume of tire inflations required. Consider factors like the inflator’s power source (cordless vs. corded), maximum PSI capability, portability, and additional features (e.g., built-in pressure gauges, adapters). Additionally, evaluate the inflator’s performance in real-world conditions through product reviews and testing data. It’s also advisable to reach out to suppliers for demonstrations or trial periods before committing to a purchase.

2. What is the best tire inflator for commercial use?

For commercial applications, the AstroAI Cordless Tire Inflator is highly recommended due to its robust performance, which allows it to efficiently inflate multiple tires on a single charge. It features a digital pressure gauge for accuracy, a compact design for easy storage, and multiple power options (battery and 12-volt). The Viair 88P is another strong contender, especially for larger vehicles, as it can inflate tires quickly but requires direct battery connection, which may be less convenient in some settings.

3. What should I look for when vetting suppliers for tire inflators?

When vetting suppliers, prioritize those with a strong reputation in the industry, evidenced by customer reviews and testimonials. Verify their certifications and compliance with international standards to ensure product quality. Request samples to assess product performance and reliability before making bulk purchases. Additionally, inquire about their after-sales support, warranty policies, and responsiveness to inquiries, as these factors can significantly impact your long-term partnership.

4. What are the typical minimum order quantities (MOQs) for air fillers?

Minimum order quantities for air fillers can vary significantly based on the supplier and product type. Generally, MOQs range from 50 to 500 units for B2B purchases. Some suppliers may offer flexibility for first-time buyers or allow smaller orders for specific models. It’s important to discuss your needs with the supplier to find a mutually beneficial arrangement, especially if you’re testing a new product or entering a new market.

5. What payment terms should I expect when sourcing tire inflators internationally?

Payment terms can vary widely among suppliers, but common options include upfront payments, letter of credit, or payment upon delivery. Many suppliers may require a deposit (typically 30-50%) before production, with the balance due upon shipment or delivery. It’s critical to negotiate terms that align with your cash flow and risk management strategies. Additionally, ensure that all payment methods are secure and offer recourse in case of disputes.

6. How can I ensure quality assurance (QA) for tire inflators?

To maintain quality assurance, establish clear quality standards with your supplier before production begins. Request certifications or reports from third-party testing organizations that validate product quality and safety. Implement regular inspections during the production process and conduct a final quality check before shipment. Additionally, consider setting up a feedback loop post-delivery to address any product issues and improve future orders.

7. What logistics considerations should I keep in mind when importing tire inflators?

Logistics are crucial when importing tire inflators, particularly regarding shipping methods, customs clearance, and storage. Choose a reliable logistics partner experienced in handling automotive products to ensure timely delivery. Understand the customs regulations and duties applicable in your country to avoid unexpected costs. Additionally, plan for adequate storage facilities to manage inventory effectively upon arrival.

8. How can I customize air fillers for my brand?

Customization options for air fillers may include branding (logos and colors), packaging design, and specific features tailored to your business needs. Many manufacturers offer OEM (Original Equipment Manufacturer) services that allow you to request modifications to existing models or create entirely new designs. Discuss your requirements with potential suppliers, and ensure they have the capability and experience to meet your customization needs while adhering to quality standards.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Viair 88p: Recommended by users for its performance. 2. Ridgid Tire Inflator: $70 kit from Home Depot, includes battery and charger, can connect to 12v car outlet, features automatic setting for specific PSI with auto-off function.

Domain: lowes.com

Registered: 1995 (30 years)

Introduction: This company, Lowe’s – Portable Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: fanttik.com

Registered: 2020 (5 years)

Introduction: 2X Faster Electric Tire Inflators; Models: X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross; Sale prices range from $48.99 to $199.97; Discounts up to 50% off during Black Friday Sale; Ratings: Most models rated 4.8; Regular prices range from $59.97 to $129.99; Extra coupons available for additional savings.

In navigating the complexities of sourcing air fillers for tires, international B2B buyers must prioritize quality, efficiency, and supplier reliability. The diverse landscape of tire inflators—from compact models to robust units designed for heavy-duty use—highlights the importance of aligning product specifications with market demands. Buyers should leverage strategic sourcing to identify suppliers that not only meet regulatory standards but also offer innovative features that enhance user convenience, such as built-in pressure gauges and multiple power options.

As the automotive industry continues to evolve, so too does the need for efficient tire maintenance solutions. Investing in high-quality air fillers can lead to significant cost savings through improved fuel efficiency and extended tire life. Moreover, buyers from regions like Africa, South America, the Middle East, and Europe should consider establishing long-term partnerships with manufacturers to ensure a steady supply of reliable products.

Illustrative image related to air filler for tires

Looking ahead, the demand for versatile and efficient tire inflators will likely increase. Buyers are encouraged to explore emerging technologies and trends in the market to stay ahead of the competition. By fostering strategic relationships with suppliers, businesses can not only enhance their product offerings but also contribute to a more sustainable automotive ecosystem.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.