In today’s competitive landscape, sourcing reliable air for tires machines presents a significant challenge for international B2B buyers. With a myriad of options available, understanding the nuances of different types, applications, and supplier credentials can make all the difference in selecting the right equipment for your business needs. This comprehensive guide aims to demystify the complexities of the air for tires machine market, offering insights into various machine types, including pay and free models, as well as multi-functional units that combine air with additional services such as vacuuming and washing.

Navigating the global market involves not just selecting the right equipment but also evaluating suppliers effectively to ensure quality and reliability. This guide provides practical tips on vetting suppliers, understanding pricing structures, and assessing the total cost of ownership, from installation to maintenance.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, including emerging markets such as Vietnam and Brazil, having access to this information is crucial. By equipping yourself with knowledge about the latest trends, technologies, and best practices in the air for tires machine sector, you can make informed purchasing decisions that enhance your service offerings, attract more customers, and ultimately drive profitability. Whether you are looking to upgrade existing equipment or invest in new machines, this guide will serve as your go-to resource for navigating this vital aspect of automotive service.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pay Air Machines | Equipped with coin, bill, or credit card acceptors | Gas stations, car washes, convenience stores | Pros: Revenue generation, customer attraction. Cons: Initial investment and maintenance costs. |

| Free Air Machines | Simple push-button operation without payment mechanisms | Service stations, workshops, and retail shops | Pros: Enhances customer loyalty, low operational costs. Cons: No direct revenue generation. |

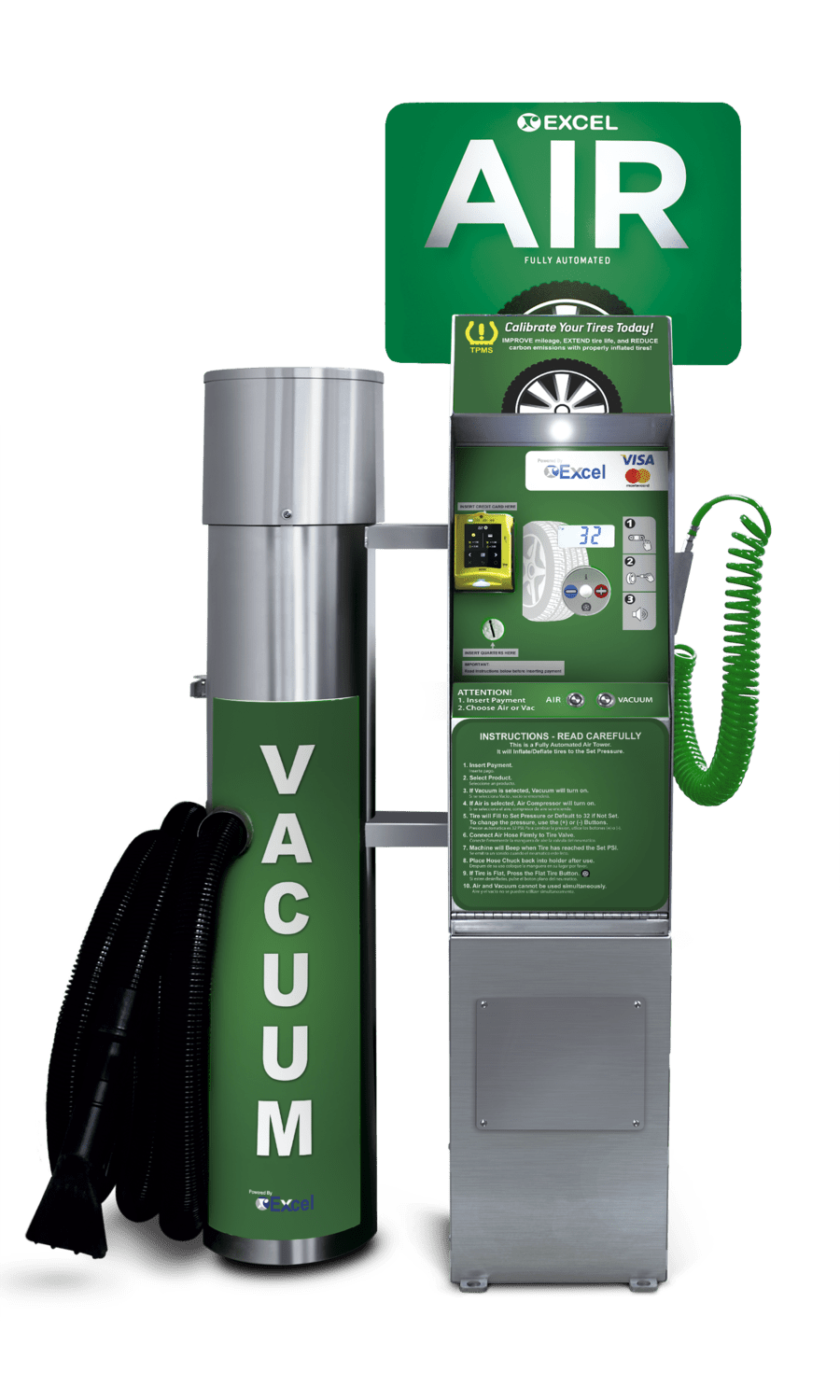

| Vacuum and Air Combo Machines | Integrates tire inflation and vacuum services | Car washes, auto detailing services | Pros: Multi-service convenience, increased foot traffic. Cons: Higher upfront costs due to multifunctionality. |

| Air and Water Combo Machines | Combines tire inflation with water services for cleaning | Auto service centers, car washes | Pros: Versatile service offering, attracts diverse customer needs. Cons: Requires more maintenance and space. |

| Portable Tire Inflators | Compact, battery-operated or plug-in devices | Automotive retailers, roadside assistance | Pros: Flexibility and convenience for users. Cons: Limited capacity and slower inflation rates compared to larger machines. |

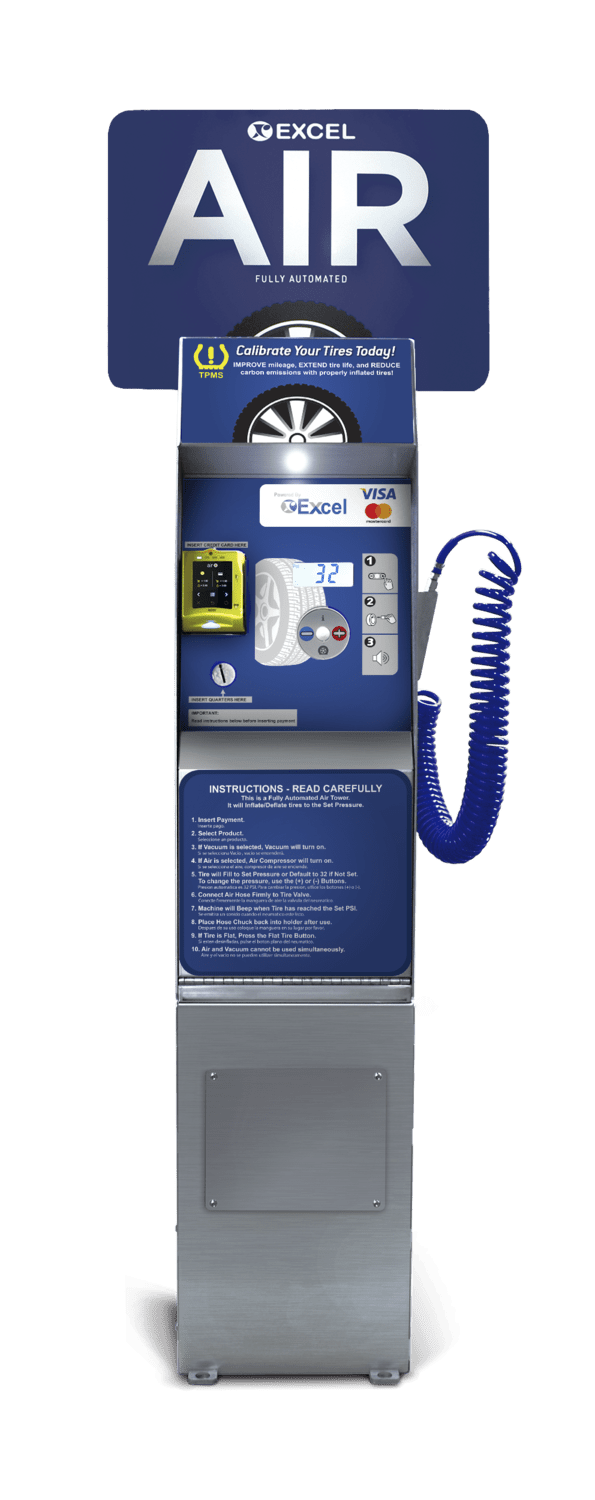

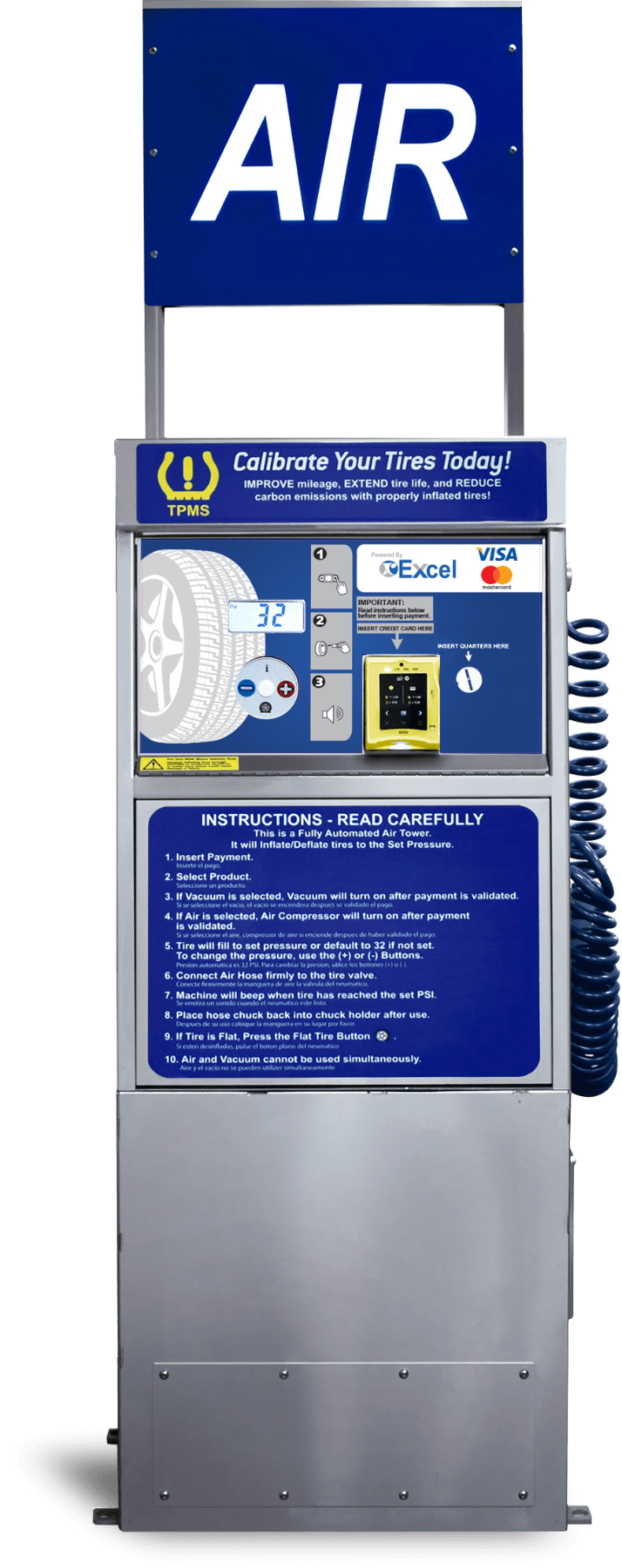

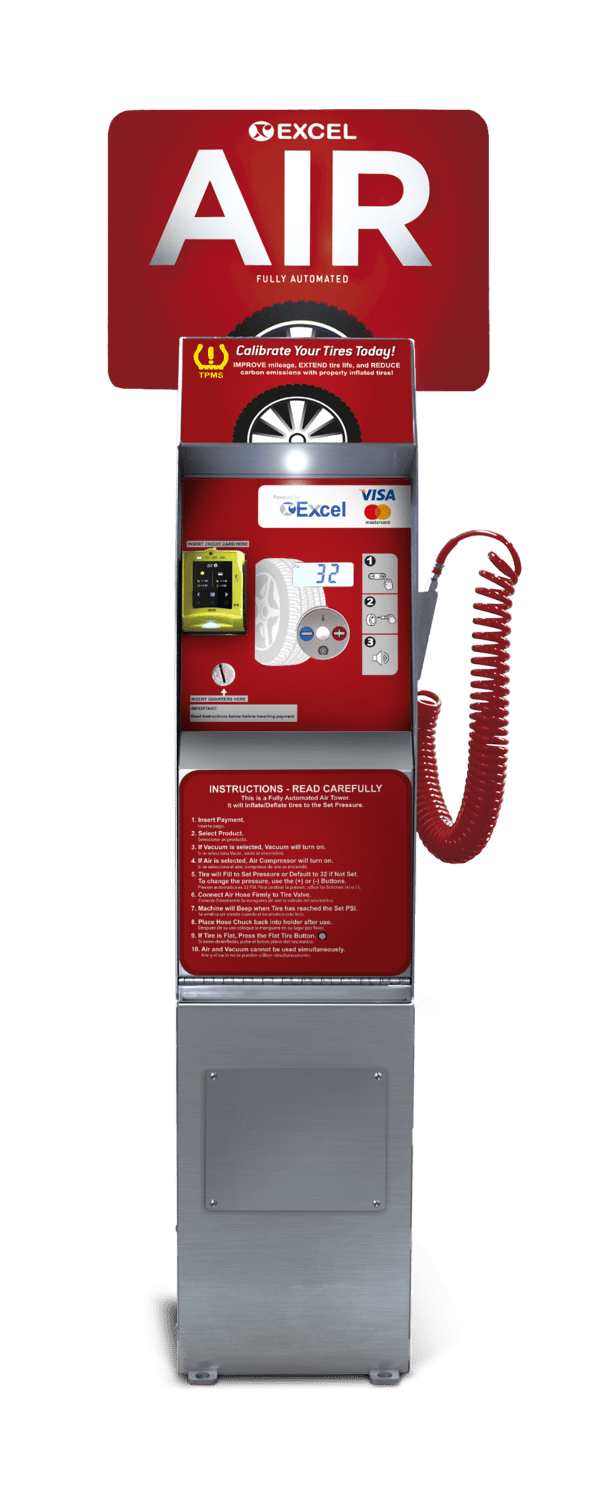

Pay air machines are designed to generate revenue by requiring customers to pay for air service. These machines typically feature coin, bill, or credit card acceptors, making them a popular choice for gas stations, car washes, and convenience stores. When considering a pay air machine, B2B buyers should evaluate factors such as initial investment, ongoing maintenance, and customer payment preferences. These machines can significantly boost foot traffic and service usage, translating to increased sales of complementary services.

Free air machines operate on a simple push-button mechanism, allowing customers to fill their tires without charge. These machines are ideal for service stations, workshops, and retail shops looking to enhance customer loyalty. For B2B buyers, the decision to invest in free air machines should consider the potential for increased customer satisfaction and repeat business, despite the lack of direct revenue generation. They provide a value-added service that can differentiate a business from competitors.

Illustrative image related to air for tires machine

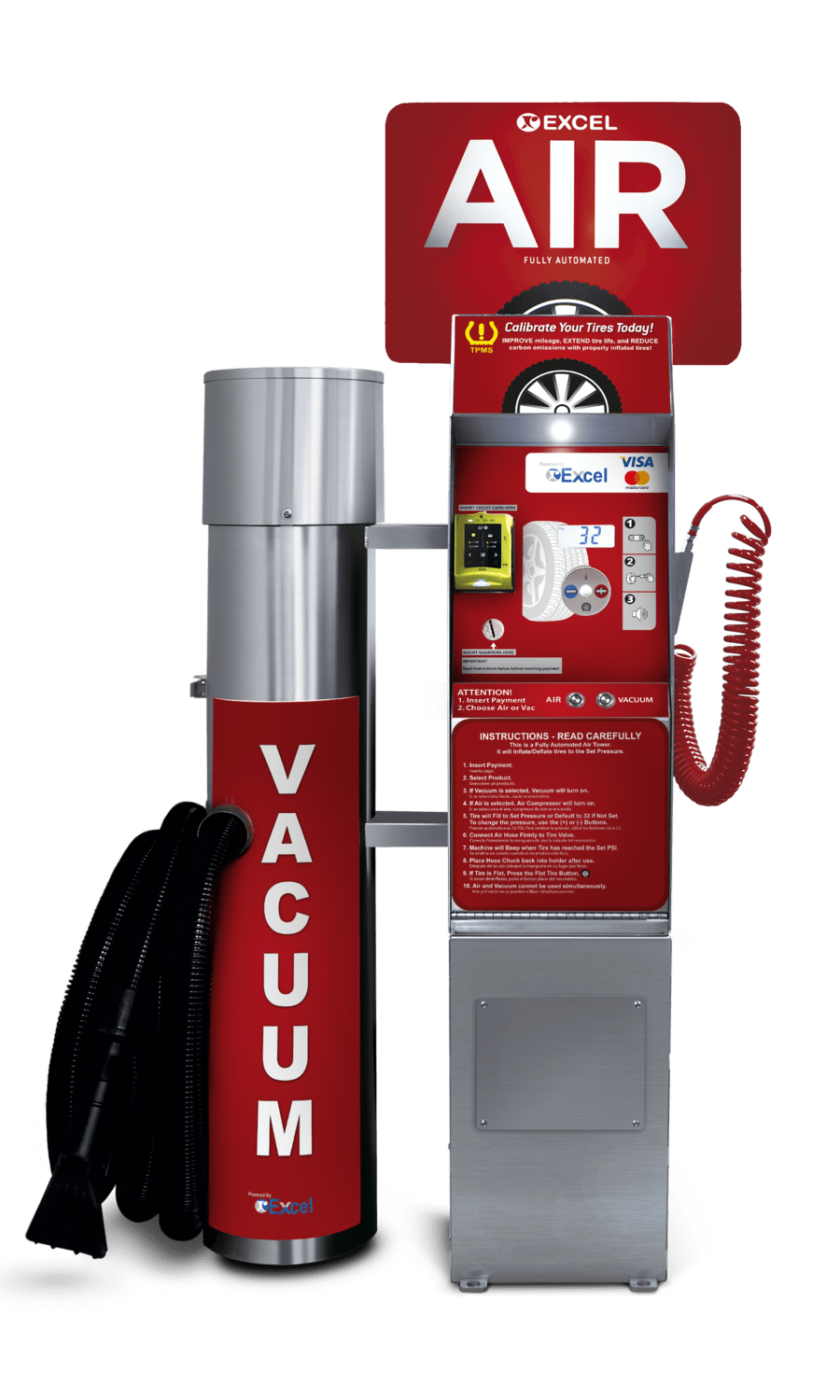

Vacuum and air combo machines offer both tire inflation and vacuuming services, creating a one-stop solution for customers. Commonly found in car washes and auto detailing services, these machines attract customers who may utilize multiple services during their visit. B2B buyers should weigh the higher upfront costs against the potential for increased customer retention and satisfaction. This dual functionality can lead to a more efficient service model, enhancing overall business performance.

Air and water combo machines provide the added benefit of integrating tire inflation with water services for quick vehicle cleaning. These machines are particularly suitable for auto service centers and car washes, offering versatile solutions that cater to various customer needs. When purchasing, B2B buyers should consider the additional maintenance requirements and space needed for installation. The ability to meet diverse customer demands can lead to higher satisfaction and loyalty.

Portable tire inflators are compact devices that can be battery-operated or plugged into a vehicle’s power source. They are ideal for automotive retailers and roadside assistance services, providing flexibility and convenience for users. While they are easy to transport and use, B2B buyers should note the limited capacity and slower inflation rates compared to larger machines. Evaluating the intended use and customer expectations is essential when considering portable options for tire inflation.

Illustrative image related to air for tires machine

| Industry/Sector | Specific Application of air for tires machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Tire inflation services for customer vehicles | Enhances customer service and retention | Reliability, ease of use, and compatibility with various tire types |

| Gas Stations | Paid air service for tire inflation | Generates additional revenue and attracts more customers | Payment options (coin, card), machine durability, and maintenance support |

| Car Wash Facilities | Multi-function air and vacuum machines | Offers convenience and encourages customers to use other services | Space requirements, installation ease, and machine features |

| Fleet Management | Regular tire maintenance and inflation | Reduces operational costs by extending tire life | Efficiency, speed of inflation, and integration with fleet management systems |

| Convenience Stores | Free air service to enhance customer loyalty | Differentiates the store from competitors | Cost of maintenance, machine aesthetics, and customer feedback mechanisms |

In automotive repair shops, air for tires machines are essential for providing tire inflation services. These machines allow mechanics to quickly and accurately inflate tires, enhancing customer satisfaction through efficient service. For international buyers, reliability and compatibility with various tire sizes are crucial, as shops often serve a diverse clientele with different vehicle types. Ensuring that machines are easy to operate and maintain can significantly improve the overall service experience.

Gas stations benefit significantly from installing air machines as a paid service. By offering tire inflation, they not only generate additional revenue but also attract customers who may purchase fuel or other items. International buyers should consider machines with robust payment systems (coin, bill, or card) that are durable enough to withstand high usage. Additionally, having machines that require minimal maintenance can save operational costs and ensure consistent service.

Car wash facilities can enhance their service offerings by incorporating multi-function air and vacuum machines. These units provide customers the convenience of inflating tires while also cleaning their vehicles, potentially increasing customer dwell time and spending. For B2B buyers, evaluating the space required for installation and the ease of integration with existing services is essential. Features that promote quick service turnaround can be a deciding factor in choosing the right machine.

In fleet management, regular tire maintenance is vital for reducing operational costs and ensuring vehicle safety. Air for tires machines enable fleet operators to maintain optimal tire pressure, which can extend tire life and improve fuel efficiency. When sourcing these machines, buyers should prioritize efficiency and speed, as well as the ability to integrate with fleet management systems for tracking maintenance schedules. Reliability is key, as downtime can lead to increased costs.

Illustrative image related to air for tires machine

Convenience stores that provide free air services can significantly enhance customer loyalty and differentiate themselves from competitors. This value-added service encourages customers to visit more frequently, potentially increasing sales of other products. For international buyers, factors such as the cost of maintenance, machine aesthetics, and customer feedback mechanisms are important considerations. Ensuring that the machines are user-friendly and reliable can further enhance customer satisfaction and retention.

The Problem: Many B2B buyers face the challenge of sourcing reliable and durable air for tires machines. This is particularly acute in emerging markets such as Africa and South America, where local suppliers may not offer high-quality products or after-sales support. Buyers often find themselves sifting through numerous suppliers, struggling to assess product quality and reliability. This uncertainty can lead to potential financial losses and operational downtime, as a malfunctioning air machine can disrupt services at gas stations, car washes, or convenience stores.

The Solution: To address this issue, B2B buyers should conduct thorough research to identify reputable manufacturers and suppliers known for their durability and reliability. Attending industry trade shows and exhibitions can provide firsthand experience with equipment and enable direct interactions with suppliers. Additionally, forming partnerships with well-established brands, such as JE Adams or Excel, can ensure access to high-quality machines and dependable customer service. Buyers should also seek testimonials and reviews from other businesses in their region to gauge performance and reliability. Establishing long-term relationships with suppliers can facilitate better pricing and more responsive service.

The Problem: B2B buyers often struggle to navigate the varying local regulations regarding air machine installations, especially in diverse markets like the Middle East and Europe. Compliance with safety standards and environmental regulations can be complex, leading to potential legal repercussions and costly fines if not adhered to. Buyers may be unaware of specific requirements related to electrical connections, installation locations, or machine certifications, putting their investment at risk.

Illustrative image related to air for tires machine

The Solution: To mitigate this risk, it is crucial for buyers to familiarize themselves with local regulations before purchasing an air for tires machine. Consulting with local authorities or industry experts can provide clarity on compliance requirements. Buyers should also request documentation from suppliers that confirms their machines meet local safety and environmental standards. Incorporating compliance checks into the procurement process can ensure that all necessary regulations are satisfied. Furthermore, investing in machines with built-in safety features and certifications can enhance compliance and reduce liability.

The Problem: Regular maintenance of air for tires machines is essential to ensure their longevity and performance; however, many B2B buyers overlook this aspect. Inadequate maintenance can lead to unexpected downtime, affecting business operations and customer satisfaction. Buyers often face the dilemma of either managing maintenance in-house, which can strain resources, or relying on external service providers, which may introduce variability in service quality and response times.

The Solution: To effectively manage maintenance, buyers should develop a structured maintenance plan tailored to their specific machines. This includes regular inspections, cleaning, and timely replacements of worn-out parts. Utilizing digital tracking systems can help monitor machine performance and alert management when maintenance is due. Furthermore, buyers should consider partnering with suppliers who offer maintenance contracts or service packages to ensure consistent support and minimize downtime. Training staff on basic maintenance procedures can also empower them to address minor issues before they escalate, thus prolonging the life of the machines and ensuring uninterrupted service for customers.

When selecting materials for air for tires machines, it is crucial to consider their properties, advantages, disadvantages, and the specific needs of international markets. Here, we analyze four common materials used in the construction of these machines: stainless steel, aluminum, plastic, and rubber.

Stainless steel is a popular choice for air for tires machines due to its excellent corrosion resistance and durability. It typically withstands high temperatures and pressures, making it suitable for commercial environments where machines operate continuously. The material’s non-reactive nature ensures that it does not contaminate the air supply, maintaining the integrity of the service provided.

Illustrative image related to air for tires machine

Pros & Cons: The primary advantage of stainless steel is its longevity and low maintenance requirements, which can lead to reduced operational costs over time. However, it is relatively expensive compared to other materials, which may be a consideration for budget-conscious buyers. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including air and water, making it versatile for machines offering multiple services.

International Considerations: Buyers from regions such as Africa and South America should ensure compliance with local standards, as stainless steel grades may vary. Understanding ASTM or DIN standards relevant to their market can help in selecting the right product.

Aluminum is another common material used in air for tires machines. It is lightweight and has good corrosion resistance, which makes it suitable for portable models. Aluminum can handle moderate pressures and is often used in components like casings and fittings.

Illustrative image related to air for tires machine

Pros & Cons: The key advantage of aluminum is its cost-effectiveness and ease of manufacturing, which allows for lower overall prices. However, aluminum is less durable than stainless steel and may not withstand harsh environments as effectively, potentially leading to a shorter lifespan.

Impact on Application: Aluminum’s compatibility with air makes it a suitable choice for machines that require frequent movement or relocation.

International Considerations: Buyers should be aware of the specific alloy types and their properties, as well as any regional regulations regarding aluminum usage in commercial applications.

Plastic is often used in non-structural components of air for tires machines, such as housing and controls. Its lightweight nature and resistance to corrosion make it an appealing choice for certain applications.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for quick production and customization. However, it is less durable than metals and can degrade over time, especially under UV exposure or extreme temperatures.

Illustrative image related to air for tires machine

Impact on Application: Plastic components are often used in areas where weight savings are critical, but they may not be suitable for high-pressure applications.

International Considerations: Buyers should consider the types of plastics used and their compliance with safety standards, particularly in regions with stringent regulations regarding material safety.

Rubber is primarily used in hoses and seals within air for tires machines. Its elasticity and ability to withstand pressure make it essential for maintaining airtight connections.

Illustrative image related to air for tires machine

Pros & Cons: The main advantage of rubber is its flexibility and ability to absorb vibrations, which enhances the durability of the machine. However, rubber can degrade over time due to exposure to ozone and UV light, necessitating regular replacement.

Impact on Application: Rubber is critical for ensuring that air remains contained and is delivered efficiently to tires, affecting overall performance.

International Considerations: Buyers should ensure that the rubber used meets local standards for durability and safety, particularly in regions with extreme weather conditions.

| Material | Typical Use Case for air for tires machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, cabinets | High durability and corrosion resistance | Higher initial cost | High |

| Aluminum | Casings, fittings | Lightweight and cost-effective | Less durable than steel | Medium |

| Plastic | Housing, controls | Low cost and easy to manufacture | Less durable than metals | Low |

| Rubber | Hoses, seals | Flexibility and vibration absorption | Degrades over time | Medium |

This guide provides a comprehensive overview of material options for air for tires machines, helping B2B buyers make informed decisions that align with their operational needs and regional standards.

Illustrative image related to air for tires machine

The manufacturing and quality assurance processes for air for tires machines are critical to ensuring that these devices meet the demands of commercial use and provide reliable performance. For B2B buyers, understanding these processes can inform purchasing decisions and help establish confidence in supplier capabilities.

The manufacturing process of air for tires machines typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques that contribute to the overall quality and functionality of the final product.

Material preparation begins with sourcing high-quality raw materials. Stainless steel is often the preferred choice due to its durability and resistance to corrosion, making it ideal for outdoor and commercial environments. Suppliers should ensure that materials meet international quality standards, such as ASTM or ISO specifications. Material inspection at this stage includes verifying the chemical composition and physical properties to ensure suitability for the intended application.

The forming stage involves shaping the raw materials into the required components. Common techniques include:

Stamping and Laser Cutting: These methods are used to create precise shapes and cutouts for the machine’s body and internal components. Laser cutting offers high precision and reduced waste, while stamping is efficient for high-volume production.

Bending and Welding: After cutting, components are bent into shape and welded together. Robotic welding systems are often employed for consistency and strength, ensuring that joints can withstand the operational stresses of frequent use.

Assembly is a critical phase where all components come together. This process typically involves:

Component Assembly: Individual parts such as the compressor, gauges, hoses, and payment systems are assembled in a specific order to ensure optimal performance and accessibility for maintenance.

Electrical Connections: As air machines often include electrical components, ensuring proper wiring and connections is essential. This includes installing pressure gauges and any electronic displays, which must be calibrated to ensure accurate readings.

Quality Checks During Assembly (IPQC): In-Process Quality Control (IPQC) involves checking components at various stages of assembly to catch defects early. This can include visual inspections and functional tests to confirm that each part meets specifications before moving to the next stage.

The finishing stage enhances the aesthetic and functional aspects of the air machines. Key techniques include:

Surface Treatment: Applying protective coatings or finishes to prevent rust and wear. Powder coating is common for aesthetic appeal and durability.

Final Assembly and Testing (FQC): Final assembly involves adding any additional features such as signage or branding. After assembly, Final Quality Control (FQC) tests are conducted to ensure that the machine operates correctly, including pressure testing and electrical safety checks.

Quality assurance in the manufacturing of air for tires machines is vital for compliance and performance. Key international standards include:

Illustrative image related to air for tires machine

ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate consistent quality in their products and processes.

CE Marking: For machines sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

API Standards: In some markets, adherence to American Petroleum Institute (API) standards may be relevant, particularly for machines used in gas stations.

Quality control (QC) is integrated at multiple stages throughout the manufacturing process:

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

In-Process Quality Control (IPQC): Regular checks during the assembly process help identify and rectify defects early, reducing waste and ensuring a higher quality final product.

Final Quality Control (FQC): Comprehensive testing of the finished product to verify that it meets all operational and safety requirements before being shipped to customers.

B2B buyers, especially those operating in diverse international markets, should take proactive steps to verify supplier quality control measures:

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the production processes and QC practices. This helps ensure that suppliers adhere to the necessary standards and practices.

Requesting Quality Reports: Buyers should ask for quality assurance reports that detail the results of IQC, IPQC, and FQC tests. This documentation should include any certifications, test results, and compliance with relevant standards.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s manufacturing processes and quality control systems. This is particularly important for international buyers who may not have the ability to conduct onsite audits.

International buyers must navigate various nuances when assessing QC and certifications:

Cultural and Regulatory Differences: Understanding local regulations and quality standards is crucial, especially in regions like Africa, South America, the Middle East, and Europe. Buyers should familiarize themselves with region-specific requirements that may differ from international standards.

Language Barriers: Communication can be a challenge in international transactions. Buyers should ensure that they receive documentation and reports in a language they understand to avoid misinterpretation of quality standards.

Logistical Considerations: Shipping and logistics can affect the integrity of the air machines. Buyers should confirm that suppliers have protocols in place to protect the machines during transport, ensuring they arrive in optimal condition.

By understanding the manufacturing processes and quality assurance practices for air for tires machines, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their operational needs. Investing time in verifying these processes can lead to long-term benefits, including reduced downtime and enhanced customer satisfaction.

This guide aims to provide a structured approach for B2B buyers looking to procure air machines for tires. Sourcing the right equipment is critical for ensuring customer satisfaction and operational efficiency. Follow these steps to streamline your purchasing process and make informed decisions.

Establishing clear technical specifications is vital to ensure the air machine meets your operational needs. Consider factors such as the machine’s pressure capacity, power source (electric or manual), and the type of payment system (coin, bill, or card). This clarity will help you target suppliers that can meet these specific requirements and avoid costly mismatches.

Understanding your customer base is crucial for selecting the right air machine. Analyze the demographics and preferences of your target market—whether they are consumers at gas stations, car washes, or convenience stores. This insight will guide you in choosing machines that enhance customer experience and drive additional revenue.

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, product specifications, and case studies to assess their credibility and experience. Pay special attention to customer reviews and testimonials from businesses in similar regions or industries to gauge reliability and service quality.

Ensure that the air machines comply with local regulations and industry standards. Check for certifications that confirm the machine’s safety and performance, such as CE marking in Europe or ISO certifications. Compliance not only protects your business from legal issues but also instills confidence in your customers.

Consider the maintenance requirements and support services offered by suppliers. Reliable air machines should have minimal maintenance needs, but it’s essential to verify the availability of spare parts and technical support. Check if the supplier provides training for your staff on machine operation and maintenance.

Illustrative image related to air for tires machine

Evaluate the total cost of ownership, which includes not just the initial purchase price but also installation, maintenance, and operational costs over time. Compare different models and brands to identify the best value for your investment. Keep in mind that higher upfront costs may result in lower maintenance expenses and better durability.

Once you’ve selected a supplier, ensure that the purchase agreement includes all essential terms, such as delivery timelines, warranty details, and return policies. Clear communication during this stage can prevent misunderstandings and ensure a smooth procurement process. Always read the fine print to avoid any hidden costs.

By following this checklist, B2B buyers can navigate the procurement process with confidence, ensuring they select the right air machines for their specific needs and business environment.

When sourcing air for tires machines, understanding the comprehensive cost structure and pricing dynamics is crucial for making informed purchasing decisions. This analysis delves into the key cost components, price influencers, and practical tips for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

The cost structure for air for tires machines typically comprises several components:

Materials: The quality of materials used significantly impacts pricing. For example, machines constructed from high-grade stainless steel are more durable and resistant to corrosion, leading to higher upfront costs but potentially lower long-term maintenance expenses.

Labor: Labor costs can vary widely depending on the manufacturing location. In regions with higher labor costs, such as Europe, the overall machine price may be elevated compared to production in lower-cost countries like Vietnam or Brazil.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can help keep these costs in check, influencing the final pricing.

Tooling: The initial investment in tooling for specific machine designs can be substantial. Customization often requires specialized tools, which can raise costs but may offer significant returns in terms of functionality and market appeal.

Quality Control (QC): Rigorous quality control measures ensure that machines meet safety and performance standards. While this adds to the cost, it is essential for maintaining reliability and customer satisfaction.

Logistics: Transportation costs can vary based on the shipping method and destination. Incoterms play a vital role here, affecting who bears the shipping costs and risks.

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary by supplier and market conditions.

Several factors can influence the pricing of air for tires machines:

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts, making it advantageous for businesses to negotiate higher MOQs when feasible.

Specifications and Customization: Custom features or specifications tailored to specific operational needs can significantly increase costs. Buyers should assess whether these enhancements justify the additional expense.

Materials and Quality Certifications: Machines with certifications for safety and performance (such as ISO standards) may carry a premium but can provide assurance of quality and reliability.

Supplier Factors: The reputation, reliability, and service offerings of suppliers can affect pricing. Established brands may charge more but often offer better support and warranty terms.

Incoterms: Understanding shipping terms (like FOB, CIF, etc.) can help buyers negotiate better deals. Different terms can significantly alter the total landed cost of the machines.

To maximize value when sourcing air for tires machines, buyers should consider the following strategies:

Illustrative image related to air for tires machine

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Leverage competitive offers from different suppliers to negotiate better terms.

Total Cost of Ownership (TCO): Evaluate not only the initial purchase price but also long-term costs, including maintenance, energy consumption, and potential downtime. A higher upfront cost may lead to lower operational expenses over time.

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, and the Middle East should be mindful of currency fluctuations, import duties, and local market conditions that can affect pricing. Building strong relationships with suppliers in these regions can also facilitate smoother transactions.

Stay Informed on Market Trends: Regularly monitoring industry trends and advancements in technology can provide insights into future pricing shifts and help buyers make timely purchasing decisions.

It is essential to note that prices for air for tires machines can vary widely based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

When considering tire inflation solutions, businesses have several options beyond traditional air for tires machines. Evaluating these alternatives is essential for B2B buyers looking to optimize their operations, enhance customer satisfaction, and ensure efficient maintenance. This analysis compares the air for tires machine with two viable alternatives: portable electric tire inflators and air compressor systems.

| Comparison Aspect | Air For Tires Machine | Portable Electric Tire Inflator | Air Compressor System |

|---|---|---|---|

| Performance | Quick inflation, high capacity | Slower, suitable for personal use | High pressure, versatile applications |

| Cost | Moderate initial investment | Low to moderate cost | Higher upfront and maintenance costs |

| Ease of Implementation | Requires installation and setup | Ready to use, no installation needed | Requires complex installation |

| Maintenance | Low maintenance, durable | Minimal maintenance required | Regular maintenance needed |

| Best Use Case | Gas stations, car washes | Personal vehicles, emergency kits | Workshops, industrial settings |

Portable electric tire inflators are compact devices designed for individual use, typically powered by a vehicle’s 12V outlet. They are particularly effective for personal vehicles and emergency situations where quick tire inflation is needed. The advantages of these inflators include their affordability and ease of use, as they require no installation and can be stored conveniently in a car. However, their performance is limited compared to air for tires machines, making them less suitable for high-volume environments like gas stations or car washes.

Air compressor systems offer a robust solution for tire inflation and various other pneumatic applications. These systems can generate higher pressure, making them ideal for workshops and industrial settings where multiple tires or tools need to be powered. While they provide excellent performance and versatility, the initial investment and installation complexity can be significant. Additionally, they require regular maintenance to ensure optimal functionality, which may not be feasible for all businesses. However, for operations with a high demand for air power, the return on investment can be substantial.

Illustrative image related to air for tires machine

Selecting the appropriate tire inflation solution involves assessing your specific operational needs, budget, and customer expectations. For businesses like gas stations or car washes aiming to attract customers and provide quick services, investing in a dedicated air for tires machine may be the best choice. Alternatively, if your operations are more focused on personal vehicle maintenance or emergency preparedness, portable electric tire inflators can offer a cost-effective and convenient option. For larger industrial operations, an air compressor system provides the power and versatility needed to support various pneumatic tools and applications.

Ultimately, understanding the strengths and limitations of each solution will enable B2B buyers to make informed decisions that align with their operational goals and customer service strategies.

When considering the purchase of air for tires machines, it is essential to understand their technical specifications. Here are some critical properties that influence performance and reliability:

The compressor is the heart of an air machine, determining how efficiently it can inflate tires. Common types include reciprocating and rotary screw compressors. The capacity, often measured in CFM (cubic feet per minute), indicates how quickly the machine can fill tires. A higher CFM means faster inflation, which is vital for businesses that cater to high traffic, such as gas stations or car washes.

Durability is paramount in commercial settings. Most air machines are constructed from stainless steel or heavy-duty powder-coated steel. Stainless steel offers greater resistance to corrosion and wear, ensuring a longer lifespan, which is crucial for minimizing downtime and maintenance costs.

Air machines typically require a specific voltage and amperage for optimal operation. Understanding these requirements is essential for proper installation and to ensure that the electrical infrastructure can support the machine. Machines with higher power needs may require dedicated circuits, influencing installation costs.

Illustrative image related to air for tires machine

The pressure gauge, whether analog or digital, must provide accurate readings to ensure proper tire inflation. Mismatched pressure can lead to safety issues and increased tire wear. B2B buyers should prioritize machines with high-precision gauges, as they enhance user experience and reduce liability risks.

For businesses looking to monetize their air service, machines can be equipped with various payment systems, including coin, bill, and card acceptors. Understanding these options is essential for aligning the machine’s functionality with the business model. Free air machines can also serve as value-added services, attracting more customers.

The frequency and type of maintenance needed can significantly affect operational costs. Machines designed for minimal upkeep can save businesses time and money. Buyers should inquire about the machine’s maintenance schedule and availability of replacement parts to ensure long-term viability.

Navigating the procurement process involves understanding specific industry terminology. Here are some key terms that B2B buyers should be familiar with:

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify trusted suppliers for parts or machines.

Illustrative image related to air for tires machine

MOQ is the smallest quantity of a product that a supplier is willing to sell. For air for tires machines, knowing the MOQ can help businesses manage inventory effectively and negotiate better pricing.

An RFQ is a document that buyers send to suppliers asking for a price quote on specific products or services. This process is essential for businesses to compare prices and terms before making a purchase decision.

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding these terms helps businesses clarify shipping costs, risk, and delivery obligations.

Illustrative image related to air for tires machine

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the context of air machines, knowing the lead time is crucial for planning installation and service operations.

These are contracts that outline the manufacturer’s responsibility for repairs and maintenance. A strong warranty can provide peace of mind and protect businesses from unexpected costs, making it an important factor in the purchasing decision.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when investing in air for tires machines, ensuring they select the best options for their operational needs.

The global market for air for tires machines is experiencing significant growth, driven by several key factors. The increasing vehicle ownership across developing regions such as Africa and South America is propelling demand for reliable tire inflation solutions. Additionally, the rise of electric vehicles (EVs) necessitates specialized air machines that accommodate higher pressure requirements. Technological advancements are also reshaping the landscape, with innovations like integrated digital gauges and payment systems that cater to both commercial and individual users.

Illustrative image related to air for tires machine

International B2B buyers should be aware of the emerging trend towards multifunctional machines that combine air inflation, vacuuming, and even water services. These units not only enhance customer experience but also optimize space and operational efficiency. Moreover, there is a growing preference for machines that accept various payment methods, reflecting shifts in consumer behavior towards cashless transactions. As markets evolve, suppliers must stay agile and adapt their offerings to meet changing customer expectations and preferences.

Sustainability has become a cornerstone of modern business practices, and the air for tires machine sector is no exception. The environmental impact of manufacturing processes and the lifecycle of machines is under scrutiny, prompting B2B buyers to prioritize suppliers that demonstrate commitment to sustainable practices. This includes using eco-friendly materials, reducing energy consumption, and implementing recycling programs for older machines.

Ethical sourcing is increasingly important, particularly for international buyers. Ensuring that suppliers adhere to labor laws and fair trade practices helps mitigate risks associated with supply chain disruptions and enhances brand reputation. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Buyers should actively seek out partners who prioritize these values, not only for compliance but also to appeal to a growing base of environmentally conscious consumers.

The evolution of air for tires machines traces back to simple manual pumps, which have transformed into sophisticated automated units. Initially designed for basic inflation, modern machines now incorporate advanced features such as digital displays, smart connectivity, and multifunctional capabilities. This evolution reflects broader technological advancements and changing consumer needs, emphasizing convenience and efficiency.

For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions. As the market grows increasingly competitive, buyers can leverage insights into historical trends to identify reliable suppliers and innovative products. Embracing modern air machines not only enhances service offerings but also positions businesses to capitalize on emerging market opportunities. Staying updated on these advancements can provide a competitive edge in a rapidly evolving landscape.

How do I select the right air for tires machine for my business?

Choosing the right air for tires machine involves assessing your specific business needs. Consider factors such as the expected volume of customers, desired features (like payment acceptance), and the available space for installation. Evaluate whether you need a pay-per-use model or a complimentary service for customer retention. Additionally, review the durability and reliability of different brands and models, as well as customer service and warranty options offered by suppliers.

What is the best air machine for tire inflation in commercial settings?

The best air machine for tire inflation in commercial settings typically combines durability, speed, and user-friendly features. Models from reputable brands like JE Adams or Excel are often recommended due to their robust construction and reliability. Look for machines that have a high PSI output, digital pressure gauges for accuracy, and options for coin, bill, or card payment systems to cater to your customer base. Evaluate models that also provide multi-function capabilities, such as air and vacuum or air and water combos, to maximize service offerings.

What should I consider when vetting suppliers for air machines?

When vetting suppliers for air machines, consider their industry reputation, product quality, and customer reviews. Request samples or case studies from similar businesses to gauge performance. Evaluate the supplier’s after-sales support, warranty terms, and availability of replacement parts. Additionally, inquire about their compliance with international safety standards and regulations, especially if you’re sourcing from abroad.

What are the minimum order quantities (MOQs) for air machines?

Minimum order quantities (MOQs) for air machines can vary significantly based on the supplier and the specific model. Some manufacturers may allow orders as low as one unit, particularly for customized machines, while others might require larger orders, ranging from 5 to 20 units, to meet production costs. It’s crucial to clarify MOQs upfront to ensure they align with your purchasing strategy and budget.

What payment terms are typically offered by suppliers of air machines?

Payment terms can vary widely among suppliers of air machines. Common options include full payment in advance, 30-60 days net, or even financing arrangements for larger orders. Some suppliers may offer discounts for upfront payments or bulk orders. It’s advisable to negotiate terms that suit your cash flow needs and ensure they are documented in your purchase agreement to avoid any misunderstandings.

How can I ensure quality assurance (QA) for my air machines?

To ensure quality assurance (QA) for your air machines, request detailed specifications and testing reports from the manufacturer. Consider suppliers that adhere to recognized quality standards, such as ISO certifications. It can also be beneficial to establish a pre-shipment inspection process, where a third-party service verifies the machines’ functionality and compliance before they leave the factory. This step can mitigate risks associated with defective products.

What logistics considerations should I keep in mind when importing air machines?

When importing air machines, logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with international shipping to handle documentation and customs clearance. Additionally, factor in lead times for production and shipping, and ensure you have a clear understanding of delivery terms (e.g., FOB, CIF) to avoid unexpected costs. Planning for storage and installation upon arrival is also essential.

Are there specific regulatory requirements for air machines in different regions?

Yes, regulatory requirements for air machines can vary by region. In many countries, compliance with safety and environmental standards is mandatory. For instance, machines may need to meet specific electrical safety certifications or emissions standards. Before importing, research the regulations in your target market—such as CE marking in Europe or specific certifications in African or South American countries—to ensure compliance and avoid potential fines or product recalls.

Domain: shop.exceltiregauge.com

Registered: 2004 (21 years)

Introduction: Air & Vacuum Machine: Excel Tire Gauge

– Categories: Air Machines & Tire Inflators

– Industries: Gas Stations & C-stores, Tire Shops, Auto Repairs & Quick Lubes, Car Washes, Fleets, Car Dealerships & Auto Rentals, Workplaces & Residentials

– Products: SC09-SS, SC05-SS, SCWM-23, PNT PRO, PNT 4

– Accessories: Hose Chucks, Hoses, Digital Head & Head Components, Internal Air Tower Parts, Communication…

In conclusion, strategic sourcing of air for tires machines represents a pivotal opportunity for businesses aiming to enhance customer experience and drive profitability. By selecting reliable and durable machines from trusted brands, such as JE Adams and Excel, B2B buyers can ensure consistent service delivery that meets the demands of their clientele. Offering air as a complimentary service or as a revenue-generating option can significantly increase foot traffic and ancillary sales, especially in high-traffic locations like gas stations and car washes.

Moreover, understanding the nuances of machine types—ranging from pay-per-use models to free air services—enables businesses to align their offerings with customer preferences and local market conditions. Proper installation and maintenance practices will further extend the lifespan of these machines, ensuring sustained operational efficiency.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe explore their sourcing options, they should consider not only the initial investment but also the long-term benefits of strategic partnerships with reputable suppliers. Embrace this opportunity to elevate your service offerings and secure a competitive advantage in the evolving automotive market. Begin your sourcing journey today, and unlock the potential of air for tires machines to drive your business forward.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.