In the fast-evolving landscape of tire maintenance, sourcing high-quality air hoses for tire inflators presents a significant challenge for international B2B buyers. The reliability and efficiency of these hoses can directly impact the performance of tire inflators, making informed purchasing decisions crucial for businesses across diverse markets, including Africa, South America, the Middle East, and Europe. This comprehensive guide is designed to equip buyers with essential insights into various types of air hoses, their applications, and the critical factors to consider when evaluating suppliers.

Understanding the different specifications and features of air hoses is vital for optimizing tire inflation processes. This guide covers an extensive range of products, including self-locking nozzles and quick-release connectors, providing clarity on how these innovations enhance usability and efficiency. Additionally, we delve into the importance of supplier vetting, offering strategies to assess quality, reliability, and compliance with international standards.

Moreover, we address cost considerations, helping buyers navigate pricing models and negotiate favorable terms. By leveraging this guide, businesses can confidently select the right air hoses for tire inflators, ensuring they meet operational demands while maximizing value. Whether you are in Nigeria or Saudi Arabia, understanding these dynamics will empower you to make strategic purchasing decisions that align with your business objectives.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rubber Air Hose | Flexible, lightweight, and cost-effective | General tire inflation | Pros: Affordable, easy to handle. Cons: Less durable under extreme conditions. |

| Braided Steel Hose | Reinforced with steel braiding for durability | Heavy-duty applications, commercial use | Pros: High durability, resistant to abrasion. Cons: Heavier, less flexible. |

| Coil Hose | Coiled design for compact storage and flexibility | Mobile tire service, automotive workshops | Pros: Space-saving, easy to store. Cons: Can tangle, limited reach. |

| Multi-Tire Inflation Kit | Designed for inflating multiple tires simultaneously | Fleet management, off-road vehicles | Pros: Efficient for multiple tires, time-saving. Cons: Higher initial investment. |

| Quick-Connect Hose Adapter | Allows for fast and easy connections | Tire shops, roadside assistance | Pros: Fast setup, reduces inflation time. Cons: May require specific compatibility. |

Standard rubber air hoses are widely used in tire inflators due to their flexibility and lightweight design. They are typically less expensive than other options, making them an attractive choice for businesses looking to manage costs. However, while they are suitable for general tire inflation tasks, they may not withstand harsh conditions or heavy use, which can be a concern for B2B buyers in demanding environments.

Braided steel hoses are reinforced with a steel mesh, offering exceptional durability and resistance to wear and tear. These hoses are ideal for heavy-duty applications such as commercial tire service or industrial settings. B2B buyers should consider the higher upfront cost as an investment in longevity and reliability, especially when frequent use is anticipated.

Illustrative image related to air hose for tire inflator

Coil hoses are designed for easy storage and transport, making them perfect for mobile tire service operations. Their coiled design allows for flexibility and quick deployment, which is essential for roadside assistance. However, buyers should be aware that coil hoses may tangle if not properly managed, and their reach can be limited compared to straight hoses.

Multi-tire inflation kits are specifically designed to inflate several tires simultaneously, which is a major advantage for businesses managing fleets or servicing off-road vehicles. These kits save time and enhance efficiency, making them a valuable investment for operations that require quick turnaround times. However, the initial cost may be higher than standard hoses, so buyers should assess their specific needs before purchasing.

Quick-connect hose adapters facilitate rapid connections between the inflator and tire valves, significantly reducing inflation times. This feature is particularly beneficial for tire shops and roadside assistance providers where speed is essential. While these adapters enhance efficiency, buyers need to ensure compatibility with their existing equipment to avoid potential issues.

| Industry/Sector | Specific Application of Air Hose for Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Routine tire maintenance and inflation services | Enhances customer satisfaction through quick service | Durable hoses that withstand frequent use and varying climates |

| Logistics and Transportation | Fleet tire inflation and maintenance | Reduces downtime and improves fleet efficiency | Long-lasting materials and compatibility with various tire types |

| Agriculture | Tire inflation for farming equipment | Ensures optimal performance of agricultural machinery | Lightweight and portable solutions for remote locations |

| Construction | Inflating tires for construction vehicles and equipment | Increases operational efficiency on job sites | Heavy-duty hoses that can endure rugged conditions |

| Automotive Manufacturing | Assembly line tire inflation for vehicles | Streamlines production processes and reduces errors | High-pressure capabilities and compliance with industry standards |

In automotive repair shops, air hoses for tire inflators are essential for conducting routine tire maintenance. These hoses facilitate the quick inflation of tires, enabling mechanics to provide timely service to customers. The ability to inflate tires efficiently reduces wait times, enhances customer satisfaction, and helps businesses maintain a steady flow of clients. For B2B buyers in regions like Nigeria or Saudi Arabia, sourcing durable hoses that can withstand the local climate and frequent use is crucial to ensuring long-term reliability.

In the logistics and transportation sector, air hoses for tire inflators are vital for maintaining the tires of fleet vehicles. Regular tire inflation is critical for optimizing fuel efficiency and ensuring safety on the road. By minimizing downtime associated with tire issues, businesses can improve overall fleet efficiency and reduce operational costs. Buyers in South America and the Middle East should consider sourcing hoses that are compatible with various tire types and designed for heavy-duty applications to meet their specific needs.

Agricultural businesses rely on air hoses for tire inflators to maintain the tires of their farming equipment. Proper tire inflation is essential for the optimal performance of tractors and other machinery, directly impacting productivity. In remote areas, lightweight and portable air hoses are particularly valuable, allowing farmers to perform maintenance on-site without the need for extensive equipment. Buyers in these sectors should prioritize sourcing hoses that offer flexibility and durability, suitable for use in rugged environments.

In the construction industry, air hoses for tire inflators are used to inflate tires on heavy machinery and vehicles. This application is crucial for ensuring that construction equipment operates efficiently and safely on job sites. A reliable air hose can help minimize downtime due to tire issues, allowing projects to stay on schedule. For B2B buyers in Europe, sourcing heavy-duty hoses that can endure the harsh conditions typical of construction sites is essential for maintaining operational efficiency.

Illustrative image related to air hose for tire inflator

Automotive manufacturing facilities utilize air hoses for tire inflators in assembly lines to ensure that vehicles are equipped with properly inflated tires. This process streamlines production and helps reduce errors associated with tire inflation. For international buyers, especially those in Europe, sourcing hoses that meet industry standards and can handle high-pressure requirements is vital to maintaining quality control and operational efficiency in the manufacturing process.

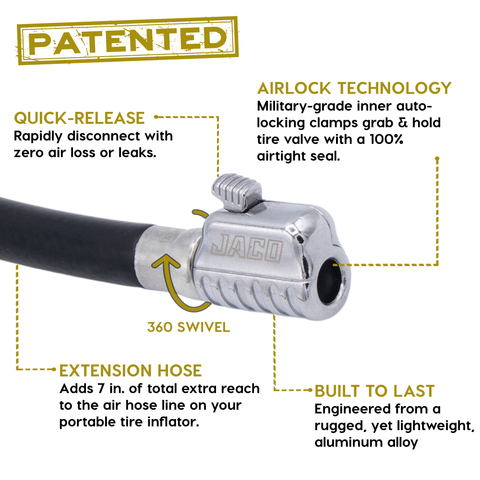

The Problem: B2B buyers often face challenges when trying to connect the air hose to various types of tire valves. Many inflators come with standard screw-on or clip-on fittings that can be cumbersome and time-consuming to attach, especially in a busy environment. This issue can lead to frustration, increased downtime, and ultimately, operational inefficiencies. In regions where quick tire maintenance is crucial—such as in fleet management or automotive repair—this problem becomes even more pronounced.

The Solution: To alleviate this issue, businesses should consider investing in air hoses that feature advanced connectors, such as self-locking or quick-release mechanisms. For instance, opting for a product like the Lightning S2X-Series self-locking nozzle can significantly enhance connection speed and reliability. This type of hose adapter allows for a swift attachment to the tire valve, reducing the time spent on each inflation task. Additionally, it’s essential to train staff on the proper techniques for connecting hoses to ensure they are familiar with the equipment’s functionality. This not only speeds up the process but also minimizes the risk of damage to both the tire and the inflator.

The Problem: Another common concern among B2B buyers is the durability of air hoses under various operational conditions. Many standard hoses may not withstand high pressure or harsh environmental factors such as extreme temperatures or rough handling, leading to leaks or ruptures. This can result in costly downtime and replacement costs, especially in industries such as transportation or construction where reliability is paramount.

The Solution: To address durability concerns, buyers should prioritize sourcing hoses made from high-quality materials, such as reinforced rubber or stainless steel braiding. These materials can withstand higher pressures and offer better resistance to wear and tear. Furthermore, it’s advisable to look for hoses that come with warranties or guarantees from manufacturers, indicating a commitment to quality. Regular maintenance checks can also prevent performance issues; businesses should implement a routine inspection schedule to identify any signs of wear early. By investing in durable air hoses and maintaining them properly, companies can enhance operational efficiency and reduce long-term costs.

The Problem: B2B buyers often encounter incompatibility issues between their existing tire inflator systems and the new air hoses they wish to purchase. This can lead to confusion and additional costs as adapters may be needed to ensure proper fitment. In markets that are rapidly evolving, such as those in Africa or South America, the diversity of equipment types can exacerbate this problem, leading to delays in service and frustration among employees.

The Solution: To avoid compatibility issues, businesses should conduct thorough assessments of their current equipment before purchasing new hoses. It is crucial to identify the specific types of fittings and pressure ratings required by existing inflators. Buyers should seek suppliers who offer a range of hoses with customizable options or provide comprehensive technical specifications. Additionally, investing in a universal tire inflator hose adapter can facilitate compatibility with various fittings, allowing for seamless integration across different equipment types. Training staff on the importance of checking compatibility before procurement can also prevent potential headaches down the line, ensuring smoother operations.

When selecting air hoses for tire inflators, the choice of material is crucial for performance, durability, and application suitability. Here, we analyze four common materials: rubber, PVC, polyurethane, and nylon, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Rubber is a traditional choice for air hoses due to its excellent flexibility and resilience. It typically has a high temperature and pressure rating, making it suitable for various environments. Rubber hoses are resistant to abrasion and can handle a wide range of temperatures, often from -40°F to 190°F (-40°C to 88°C).

Pros: Rubber hoses are durable and can withstand wear and tear, making them ideal for heavy-duty applications. They also provide good resistance to ozone and UV exposure, which is beneficial in outdoor settings.

Illustrative image related to air hose for tire inflator

Cons: The primary drawback of rubber is its cost, which is generally higher than synthetic alternatives. Additionally, rubber can be heavy and less flexible in colder temperatures, affecting ease of use.

Impact on Application: Rubber hoses are compatible with air and various gases, but may not be suitable for harsh chemicals.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or ISO. Additionally, rubber hoses may be subject to import tariffs that could affect overall costs.

Polyvinyl chloride (PVC) is a popular alternative to rubber, known for its lightweight and cost-effective properties. PVC hoses typically have a moderate temperature rating, usually between -20°F and 150°F (-29°C to 65°C), and can handle pressures up to 300 PSI.

Pros: PVC is less expensive than rubber and offers good resistance to abrasion and chemicals. Its lightweight nature makes it easier to handle and transport.

Illustrative image related to air hose for tire inflator

Cons: While PVC is cost-effective, it lacks the flexibility and durability of rubber, particularly in extreme temperatures. It can become brittle over time when exposed to UV light.

Impact on Application: PVC hoses are suitable for air and water but may not be ideal for high-pressure applications or extreme temperatures.

Considerations for International Buyers: Buyers should verify compliance with regional standards and consider the impact of UV exposure in sunny climates, which is common in many parts of Africa and the Middle East.

Polyurethane is increasingly popular for air hoses due to its superior flexibility and lightweight characteristics. It typically has a temperature range from -40°F to 180°F (-40°C to 82°C) and can handle pressures up to 300 PSI.

Pros: Polyurethane hoses are highly flexible, making them easy to maneuver. They also exhibit excellent abrasion resistance and are less prone to kinking.

Cons: The main limitation is the higher cost compared to PVC. Additionally, while polyurethane is resistant to many chemicals, it may not perform well in extreme heat.

Impact on Application: Polyurethane hoses are ideal for air applications and are often used in environments requiring high flexibility and durability.

Considerations for International Buyers: Compliance with international standards is crucial, especially in industrial applications. Buyers should also consider the cost implications when sourcing polyurethane hoses.

Nylon hoses are known for their strength and lightweight properties. They typically have a temperature rating of -40°F to 200°F (-40°C to 93°C) and can withstand pressures up to 300 PSI.

Illustrative image related to air hose for tire inflator

Pros: Nylon hoses are strong and resistant to abrasion, making them suitable for rugged environments. They also provide excellent resistance to chemicals.

Cons: The main disadvantage is their tendency to be less flexible than rubber or polyurethane, especially in colder temperatures. Additionally, nylon can be more expensive than PVC.

Impact on Application: Nylon hoses are suitable for air and gas applications, particularly in industries requiring chemical resistance.

Considerations for International Buyers: Buyers should ensure that nylon hoses meet local compliance standards, particularly in industries with strict regulations.

Illustrative image related to air hose for tire inflator

| Material | Typical Use Case for air hose for tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Heavy-duty tire inflators | Excellent durability | Higher cost | High |

| PVC | General-purpose tire inflators | Lightweight and cost-effective | Less flexible in extreme temps | Low |

| Polyurethane | Flexible air applications | Highly flexible and durable | Higher cost | Med |

| Nylon | Rugged industrial applications | Strong and chemical resistant | Less flexible in cold weather | Med |

This strategic material selection guide provides essential insights for B2B buyers in diverse markets, helping them make informed decisions when sourcing air hoses for tire inflators.

Manufacturing air hoses for tire inflators involves several critical stages, each contributing to the final product’s quality and reliability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: The manufacturing process begins with selecting high-quality raw materials, typically rubber or thermoplastic compounds, which are chosen for their durability and flexibility. Suppliers often conduct tests on these materials to ensure they meet specific performance and safety standards. For hoses, reinforcement materials such as nylon or polyester may also be included to enhance strength.

Forming: In this stage, the prepared materials are molded into the desired hose shape. Common techniques include extrusion and molding. Extrusion involves forcing the material through a die to create a continuous length of hose, while molding is used for specific shapes or fittings. Each method requires precise control of temperature and pressure to ensure optimal material properties.

Assembly: After forming, hoses undergo assembly, where connectors, fittings, and other components are attached. This may involve crimping, which secures the fittings to the hose, or using adhesives for a more permanent bond. Automated assembly lines are often employed to enhance efficiency and consistency.

Finishing: The final stage includes surface treatments, such as applying protective coatings or printing specifications on the hose. Quality checks are conducted to ensure that the hoses meet the specified dimensions and aesthetic requirements.

Quality assurance (QA) is a critical aspect of manufacturing air hoses, ensuring that products meet industry standards and customer expectations. Key elements of QA include adherence to international standards, quality checkpoints throughout the manufacturing process, and testing methods.

International Standards and Certifications: Manufacturers often comply with international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications, such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) certifications for hoses used in oil and gas, further validate product quality. Buyers should verify that suppliers hold relevant certifications to ensure compliance with their market requirements.

Quality Control Checkpoints: Quality control (QC) checkpoints are integrated into various stages of the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during production, where samples are tested for consistency and defects.

– Final Quality Control (FQC): Completed hoses undergo thorough inspection and testing to confirm they meet performance specifications before shipment.

Common Testing Methods: Several testing methods are employed to evaluate the performance of air hoses, including:

– Pressure Testing: Hoses are subjected to high-pressure conditions to ensure they can withstand operational stresses.

– Burst Testing: This test determines the maximum pressure a hose can handle before failure.

– Flexibility and Bend Testing: These tests assess the hose’s ability to withstand bending without damage, a crucial feature for ease of use in various environments.

B2B buyers can implement several strategies to verify a supplier’s quality control practices, ensuring they partner with reliable manufacturers.

Conducting Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request to review the supplier’s quality management systems and any relevant documentation, such as inspection reports and certifications.

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports, showcasing their QC processes, testing results, and compliance with international standards. Buyers should look for transparency in these documents, as they indicate a supplier’s commitment to quality.

Third-Party Inspections: Engaging a third-party inspection service can further validate a supplier’s claims regarding quality control. These independent entities can conduct assessments at various stages of production, ensuring that the supplier adheres to quality standards.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate additional complexities in quality control.

Understanding Regional Standards: Different regions may have varying standards for product quality and safety. For instance, products sold in Europe must comply with CE marking requirements, while those in the Middle East may need to meet specific local regulations. Buyers should familiarize themselves with these standards to ensure compliance.

Cultural and Communication Barriers: Language differences and cultural nuances can impact quality assurance processes. Buyers should establish clear communication channels and, if necessary, involve local representatives who understand the nuances of the market and can facilitate effective dialogue with suppliers.

Logistical Considerations: Shipping and handling can affect product quality. Buyers should consider the logistics involved in transporting air hoses and ensure that suppliers have adequate measures in place to protect products during transit. This includes appropriate packaging and handling instructions to minimize the risk of damage.

By understanding the manufacturing processes and quality assurance measures for air hoses used in tire inflators, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their quality and performance expectations. This knowledge not only enhances their purchasing strategy but also strengthens their supply chain resilience in an increasingly competitive global market.

Illustrative image related to air hose for tire inflator

This practical sourcing guide is designed for B2B buyers seeking to procure air hoses for tire inflators. With various specifications and supplier options available, this checklist will help streamline your purchasing process, ensuring you choose the right products that meet your operational needs.

Establishing your technical specifications is crucial for selecting the right air hose. Consider factors such as hose length, diameter, pressure rating, and compatibility with existing inflators.

– Hose Length: Ensure it fits your operational environment, allowing for easy maneuverability.

– Diameter and Pressure Rating: Choose a hose that can handle the required PSI for your tire inflator.

Conduct comprehensive research on potential suppliers to find those with a solid reputation in the industry. Utilize online directories, trade shows, and industry forums to gather information.

– Supplier Reviews: Look for feedback from previous clients to gauge reliability and product quality.

– Market Presence: A supplier with a robust international presence may offer better support and service.

Verify that your potential suppliers hold the necessary certifications and compliance with international standards. This ensures the quality and safety of the products you are purchasing.

– ISO Certifications: Suppliers with ISO certifications typically adhere to high-quality manufacturing practices.

– Local Compliance: Check for compliance with regional regulations, especially if sourcing from different countries.

Before finalizing your order, request samples of the air hoses you are considering. Testing these samples can provide valuable insights into their performance and durability under your specific conditions.

– Performance Testing: Assess how well the hose performs with your inflator, focusing on ease of connection and inflation speed.

– Material Quality: Evaluate the hose material for flexibility, resistance to wear, and overall durability.

Illustrative image related to air hose for tire inflator

Carefully analyze the pricing structures and payment terms offered by different suppliers. Look for transparency in costs and favorable terms that align with your financial practices.

– Bulk Discounts: Inquire about discounts for bulk orders or long-term contracts, which can significantly reduce costs.

– Payment Flexibility: Ensure the payment terms are manageable for your cash flow.

Evaluate the after-sales support and warranty policies of your chosen supplier. Reliable support can save time and resources in the long run.

– Warranty Coverage: A robust warranty indicates the supplier’s confidence in their product quality.

– Customer Service: Assess the supplier’s responsiveness and willingness to assist with any issues post-purchase.

After completing the previous steps, compile all gathered information and make an informed decision. Consider all aspects, including supplier reliability, product quality, and cost-effectiveness, to ensure you select the best air hose for your tire inflator needs.

When analyzing the cost structure for air hoses used in tire inflators, several critical components come into play. Materials are the foundation of any pricing strategy. Common materials include rubber, PVC, or reinforced nylon, which can vary significantly in cost based on quality and supplier relationships. Labor costs involve the wages paid to workers during the manufacturing process, which can differ based on the region and skill level required.

Manufacturing overhead encompasses expenses such as utilities, factory maintenance, and equipment depreciation. Additionally, tooling costs for molds or specialized machinery may be significant, especially for customized products. Quality Control (QC) measures are crucial for ensuring product reliability, which adds to the overall cost. Lastly, logistics costs, including transportation and warehousing, must be factored in, particularly for international shipments that may involve customs duties and tariffs.

Several factors can influence the pricing of air hoses for tire inflators. Volume or Minimum Order Quantities (MOQ) play a crucial role; larger orders generally benefit from lower per-unit costs due to economies of scale. Specific specifications and customization options, such as length, diameter, and connector types, can also lead to price variations. Higher quality materials or certifications, such as ISO or safety standards, typically increase costs but may be necessary for certain markets.

Supplier factors are significant in determining price, as established suppliers may charge a premium for their reliability and service. Understanding Incoterms is vital for international buyers; terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of products.

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency. Negotiation is essential; engaging suppliers in discussions about bulk discounts or alternative materials can yield favorable terms. Understanding the Total Cost of Ownership (TCO) is also critical. This includes not only the purchase price but also factors like maintenance, durability, and potential downtime costs associated with inferior products.

Buyers should be aware of pricing nuances in their respective regions. For example, in markets like Nigeria or Saudi Arabia, local regulations and import duties may affect pricing. Leveraging local suppliers might mitigate some of these costs, enhancing supply chain resilience.

Illustrative image related to air hose for tire inflator

While indicative prices can provide a general understanding of market rates, they should be approached with caution. Prices fluctuate based on market conditions, raw material availability, and geopolitical factors. It is advisable for buyers to request formal quotes from multiple suppliers to ensure they are making well-informed purchasing decisions.

In conclusion, understanding the comprehensive cost structure, pricing influencers, and strategic buyer tips can empower B2B buyers to navigate the complexities of sourcing air hoses for tire inflators effectively. By applying these insights, businesses can optimize their procurement processes and enhance their competitive edge in the market.

In the quest for efficient tire inflation, understanding the various alternatives to traditional air hoses is crucial for B2B buyers. Each alternative offers distinct advantages and drawbacks, which can affect operational efficiency and cost-effectiveness. This analysis will compare the standard air hose for tire inflators with two viable alternatives: tire inflator hose adapters and multi-tire inflation kits.

| Comparison Aspect | Air Hose For Tire Inflator | Tire Inflator Hose Adapter | Multi-Tire Inflation Kits |

|---|---|---|---|

| Performance | High, reliable for single tire inflation | Moderate, speeds up connection but limited to one tire at a time | Very high, inflates multiple tires simultaneously |

| Cost | $20 – $40 | $10 – $30 | $150 – $350 |

| Ease of Implementation | Simple, plug-and-play | Very easy, minimal setup required | Requires more setup and understanding |

| Maintenance | Low, occasional cleaning | Very low, minimal wear | Moderate, hoses may need replacing |

| Best Use Case | Individual tire inflation | Quick tire inflation for emergency situations | Off-road vehicles or fleet operations needing multiple tire inflation |

Tire inflator hose adapters convert standard twist-on connections to a more user-friendly press-on mechanism. This innovation can significantly reduce inflation time, making it ideal for emergencies or rapid refills. The primary advantage is ease of use; however, it is limited to one tire at a time. Additionally, while the cost is relatively low, the adapter may not provide the same reliability and durability as a traditional air hose for prolonged use.

Illustrative image related to air hose for tire inflator

Multi-tire inflation kits are designed for businesses that require the inflation of multiple tires simultaneously, such as those in the transportation and logistics sectors. These kits can save significant time and labor costs, particularly in environments where quick tire management is essential. While the initial investment is higher than standard hoses or adapters, the efficiency gains can offset this cost over time. However, these kits may require more maintenance and understanding of setup, which could be a barrier for some users.

When selecting the appropriate tire inflation solution, B2B buyers must consider their specific operational needs, budget constraints, and maintenance capabilities. For businesses focused on individual tire inflation with reliable performance, traditional air hoses remain a solid choice. Conversely, if speed and efficiency in emergency situations are paramount, tire inflator hose adapters could be more suitable. Finally, for organizations managing fleets or off-road vehicles requiring simultaneous inflation, investing in multi-tire inflation kits could yield substantial long-term benefits. Making an informed choice based on these factors will enhance overall operational efficiency and cost-effectiveness.

When sourcing air hoses for tire inflators, international B2B buyers should be aware of several critical technical specifications that can impact performance, durability, and usability. Understanding these properties can help in making informed purchasing decisions that align with specific operational requirements.

Air hoses are typically made from materials like rubber, PVC, or polyurethane. Rubber hoses offer flexibility and resistance to wear, while PVC hoses are lightweight and cost-effective. Polyurethane provides excellent durability and resistance to abrasion and weather conditions. The choice of material can influence both the performance and longevity of the hose, making it essential for buyers to match the hose material with their intended application.

Illustrative image related to air hose for tire inflator

The pressure rating, usually expressed in PSI (pounds per square inch), indicates the maximum pressure the hose can safely handle. A higher pressure rating allows for the use of the hose with various inflators and applications. Buyers should ensure that the hose they select meets or exceeds the pressure requirements of their inflator to avoid failures that could lead to operational downtime.

Temperature tolerance specifies the range of temperatures within which the hose can operate effectively. Hoses that can withstand extreme temperatures are crucial for outdoor applications, particularly in regions with variable climates. Buyers should consider both the minimum and maximum operating temperatures to ensure reliability in their specific environment.

The diameter of the hose affects the airflow and inflation speed. Common diameters range from 1/4 inch to 1/2 inch, with larger diameters allowing for faster inflation rates. Buyers should evaluate the compatibility of hose diameter with their tire inflators and the volume of air required for efficient operation.

The length of the hose determines how far the inflator can reach. Longer hoses offer flexibility in positioning the inflator, especially in larger vehicles or multi-tire inflation setups. Buyers must balance the need for length against the potential for increased pressure loss over longer distances.

The type of connector used on the hose can affect ease of use and compatibility with various inflators and tire valve stems. Common connector types include threaded, snap-on, and quick-release. Understanding the connector type is crucial for ensuring a secure and efficient connection during tire inflation.

Familiarity with industry-specific terminology is vital for B2B buyers to navigate procurement processes effectively. Here are several key terms often encountered in the air hose market:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the air hose market, sourcing from OEMs often ensures compatibility and quality assurance, as these products are designed to meet specific industry standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and ensure they meet supplier requirements while optimizing their purchase volumes.

Illustrative image related to air hose for tire inflator

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For air hoses, submitting an RFQ helps buyers gather competitive quotes and understand the market pricing, allowing for better budget planning.

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risks, and insurance responsibilities, ultimately aiding in smoother transactions across borders.

Lead time refers to the amount of time it takes for a supplier to deliver products after an order is placed. Understanding lead times is crucial for B2B buyers to plan their inventory and ensure they have the necessary materials when needed.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions that enhance their operational efficiency and product reliability when sourcing air hoses for tire inflators.

The global market for air hoses specifically designed for tire inflators is experiencing significant growth, driven by several key factors. The increasing prevalence of vehicle ownership in emerging markets across Africa, South America, and the Middle East is a primary driver. As more consumers and businesses prioritize vehicle maintenance, the demand for efficient tire inflation solutions is surging. Moreover, the expansion of e-commerce platforms has made these products more accessible to international B2B buyers, facilitating easier procurement processes.

Illustrative image related to air hose for tire inflator

Current trends indicate a marked shift towards innovative technology in air hose design. Features such as self-locking connectors, quick-release mechanisms, and multi-tire inflation capabilities are becoming standard. For instance, products like the Lightning S2X-Series self-locking hose extension are gaining popularity for their enhanced usability and efficiency. Additionally, the integration of smart technology, such as pressure monitoring systems, is emerging as a crucial differentiator in the market. Buyers from regions like Nigeria and Saudi Arabia are particularly inclined towards products that enhance operational efficiency and reduce downtime.

Sourcing strategies are also evolving. B2B buyers are increasingly focused on establishing long-term partnerships with suppliers who demonstrate reliability, quality, and the ability to adapt to changing market needs. This trend is further amplified by the need for competitive pricing, as buyers seek to optimize their procurement budgets while ensuring product quality.

The emphasis on sustainability is reshaping the air hose for tire inflator sector, compelling manufacturers and suppliers to adopt environmentally friendly practices. The environmental impact of production processes and material selection is under scrutiny, prompting a shift towards ‘green’ certifications and sustainable materials. B2B buyers are becoming more discerning, prioritizing suppliers who can demonstrate a commitment to sustainability through eco-friendly product lines.

Ethical sourcing is increasingly important as businesses recognize the value of transparent supply chains. Buyers are keen to partner with manufacturers who adhere to fair labor practices and environmental regulations. The use of recyclable materials in the production of air hoses is gaining traction, with companies leveraging this as a unique selling proposition. For instance, hoses made from recycled rubber or those that can be easily recycled at the end of their life cycle are becoming attractive options for environmentally conscious buyers.

Illustrative image related to air hose for tire inflator

Moreover, the demand for certification—such as ISO 14001 for environmental management—can significantly influence purchasing decisions. Buyers from regions such as Europe are particularly focused on these certifications, reflecting a broader commitment to sustainability and ethical practices within the global market.

The evolution of air hose technology for tire inflators has been marked by significant advancements aimed at enhancing efficiency and user experience. Initially, air hoses were rudimentary, primarily featuring simple screw-on connectors and basic materials that often limited their durability and usability. Over the years, innovations such as self-locking mechanisms and quick-connect adapters have transformed the landscape, allowing for faster and more reliable tire inflation.

In the last decade, the introduction of materials like braided nylon and reinforced rubber has improved the strength and flexibility of air hoses, catering to both consumer and industrial needs. The focus has now shifted towards multi-functional designs that support multiple tire inflations simultaneously, addressing the needs of commercial buyers and automotive service providers. As technology continues to evolve, the integration of smart features is expected to further enhance the functionality and appeal of air hoses in the tire inflator market.

Illustrative image related to air hose for tire inflator

1. How do I solve issues with air hose compatibility for tire inflators?

To address compatibility issues, first, identify the type of connection your tire inflator uses—be it a twist-on, clip-on, or push-on connector. Many manufacturers offer adapters to convert between different types of connections, enhancing versatility. Additionally, consider investing in hoses with universal fittings or those specifically designed for various inflators. Always verify compatibility with the supplier before purchasing to ensure seamless integration with your existing equipment, especially when sourcing from international suppliers.

2. What is the best air hose for tire inflators in terms of durability and performance?

The best air hoses for tire inflators are typically made from materials like rubber or reinforced PVC, which provide excellent durability and flexibility. Look for hoses with high burst pressure ratings and resistance to abrasion, UV, and oil. A braided or coil design can also enhance durability. For heavy-duty applications, consider hoses that are rated for both inflation and deflation, as they provide versatility in various tire maintenance tasks. Always assess the specific needs of your operations to select the most suitable option.

3. How can I vet international suppliers of air hoses for tire inflators?

When vetting international suppliers, start by checking their credentials and certifications, such as ISO or industry-specific standards. Request references from previous clients and assess their reputation through online reviews and industry forums. It’s also beneficial to evaluate their production capabilities, quality control processes, and after-sales support. Conducting a factory audit or visiting the supplier, if feasible, can provide valuable insights into their operations and reliability.

4. What customization options are available for air hoses for tire inflators?

Many manufacturers offer customization options, including varying lengths, colors, and fittings tailored to your specific requirements. You can also request branding options like your company logo on the hose. When discussing customization, be clear about your needs, including any specific standards or certifications required for your region. Remember to confirm lead times and any additional costs associated with custom orders to ensure they align with your budget and timeline.

5. What are the typical minimum order quantities (MOQs) for air hoses?

Minimum order quantities can vary widely depending on the supplier and the complexity of the product. For standard air hoses, MOQs might range from 100 to 500 units, while custom orders could require higher quantities. Always discuss MOQs upfront with your supplier to understand the implications for your budget and inventory management. Some suppliers may offer flexibility in MOQs for first-time orders or to establish long-term partnerships.

6. What payment terms should I expect when sourcing air hoses internationally?

Payment terms can differ significantly between suppliers. Common terms include upfront payment, partial payment upon order confirmation, and balance payment before shipping. It’s advisable to negotiate terms that protect your interests, such as using an escrow service for large orders. Additionally, consider the implications of currency exchange rates and transaction fees when dealing with international payments. Discuss these terms thoroughly to avoid misunderstandings and ensure smooth transactions.

7. How do I ensure quality assurance (QA) for air hoses sourced internationally?

To ensure quality assurance, request samples before placing bulk orders to evaluate the product’s performance and durability. Establish clear specifications and standards with your supplier, including testing protocols that align with international norms. It’s also beneficial to include QA clauses in your contract that outline acceptable quality levels and remedies for non-compliance. Consider third-party inspection services to assess quality before shipment, which can provide added peace of mind.

8. What logistics considerations should I keep in mind when importing air hoses?

When importing air hoses, consider factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable logistics partner experienced in handling international shipments. Understand the import regulations and tariffs in your country, as these can impact costs and lead times. It’s also wise to plan for potential delays and have contingency plans in place. Ensure that the supplier provides all necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs processing.

Domain: morrflate.com

Registered: 2019 (6 years)

Introduction: Multi Tire Inflation Deflation™ Kits by MORRFlate include both 4-way and 2-way tire hose kits. Customers can choose from pre-built kits or customize their own with various options for manifolds, gauges, hose lengths, and accessories. Key products include: 1. MORRFlate Braided Mega Quad (4-6 Tires, Up To 200″ Wheelbase) – Price: $245.00 – $285.00 2. MORRFlate Braided Quad Compact (4-Tire Hose Kit, …

In the competitive landscape of air hose sourcing for tire inflators, strategic procurement is essential for maximizing value and ensuring product quality. As international B2B buyers, understanding the diverse offerings—from self-locking nozzle extensions to multi-tire inflation kits—allows for tailored solutions that meet specific market demands across regions like Africa, South America, the Middle East, and Europe.

Investing in high-quality air hoses not only enhances operational efficiency but also supports safety and customer satisfaction. Prioritizing suppliers who offer innovative features, such as quick-connect systems and durable materials, can significantly improve user experience and reduce maintenance costs.

Looking ahead, the growing demand for portable and efficient tire inflation solutions presents a lucrative opportunity for businesses to expand their product lines. As you evaluate potential suppliers, consider engaging in strategic partnerships that leverage local expertise and distribution channels. This proactive approach will not only enhance your product offerings but also strengthen your market position. Embrace the future of tire inflator solutions by sourcing strategically and staying ahead of industry trends.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air hose for tire inflator

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.