- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the rapidly evolving landscape of automotive accessories, sourcing a reliable 12V auto air compressor can present a significant challenge for international B2B buyers. Whether you’re operating in bustling markets in Nigeria or navigating the competitive automotive sectors in Germany, understanding the nuances of these vital tools is essential for making informed purchasing decisions. This comprehensive guide delves into the various types of 12V auto air compressors available, their diverse applications—from tire inflation to powering air suspension systems—and the critical factors to consider when selecting a supplier.

Navigating the global market requires a strategic approach, particularly when it comes to vetting suppliers and evaluating costs. This guide empowers buyers by providing actionable insights into performance specifications, portability, and duty cycles, ensuring that you can identify the best options tailored to your operational needs. Furthermore, it emphasizes the importance of additional features such as thermal protection and automatic shut-off systems, which enhance reliability and safety during use. By equipping yourself with this knowledge, you can confidently engage with suppliers, negotiate better terms, and ultimately secure the right 12V auto air compressor for your business, regardless of your geographic location.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Portable 12V Air Compressors | Compact, lightweight, easy to transport | Tire inflation, recreational vehicles | الإيجابيات: Highly portable, versatile; السلبيات: Limited power output, not suitable for heavy-duty tasks. |

| Heavy-Duty 12V Air Compressors | Designed for continuous duty, high PSI output | Air suspension systems, commercial vehicles | الإيجابيات: High performance, durable; السلبيات: أثقل وزناً وأغلى ثمناً. |

| Onboard Air Systems | Fixed installations, integrated with vehicles | Off-road vehicles, fleet management | الإيجابيات: Always ready, supports multiple functions; السلبيات: Installation complexity, space requirement. |

| Rechargeable 12V Air Compressors | Battery-operated, no vehicle power needed | Emergency kits, remote locations | الإيجابيات: Great for emergencies, portable; السلبيات: Limited run time, lower pressure output. |

| Industrial 12V Air Compressors | High CFM output, robust construction | Construction sites, automotive repair shops | الإيجابيات: Suitable for heavy tools, high efficiency; السلبيات: Higher cost, requires more maintenance. |

Portable 12V air compressors are lightweight and designed for ease of transport, making them ideal for quick tire inflation and recreational uses. They typically connect directly to a vehicle’s battery, allowing for immediate use without needing a power outlet. B2B buyers should consider their portability and versatility, as these compressors are suitable for various applications, from personal vehicles to small trailers. However, their limited power output may restrict their use for more demanding tasks.

Heavy-duty 12V air compressors are engineered for continuous operation, delivering high PSI output essential for applications like air suspension adjustments and powering air horns. These compressors are built for durability and reliability, making them suitable for commercial vehicles and demanding off-road applications. B2B purchasers should evaluate their performance specifications, as these models often come at a higher price point but provide significant long-term value due to their robust construction.

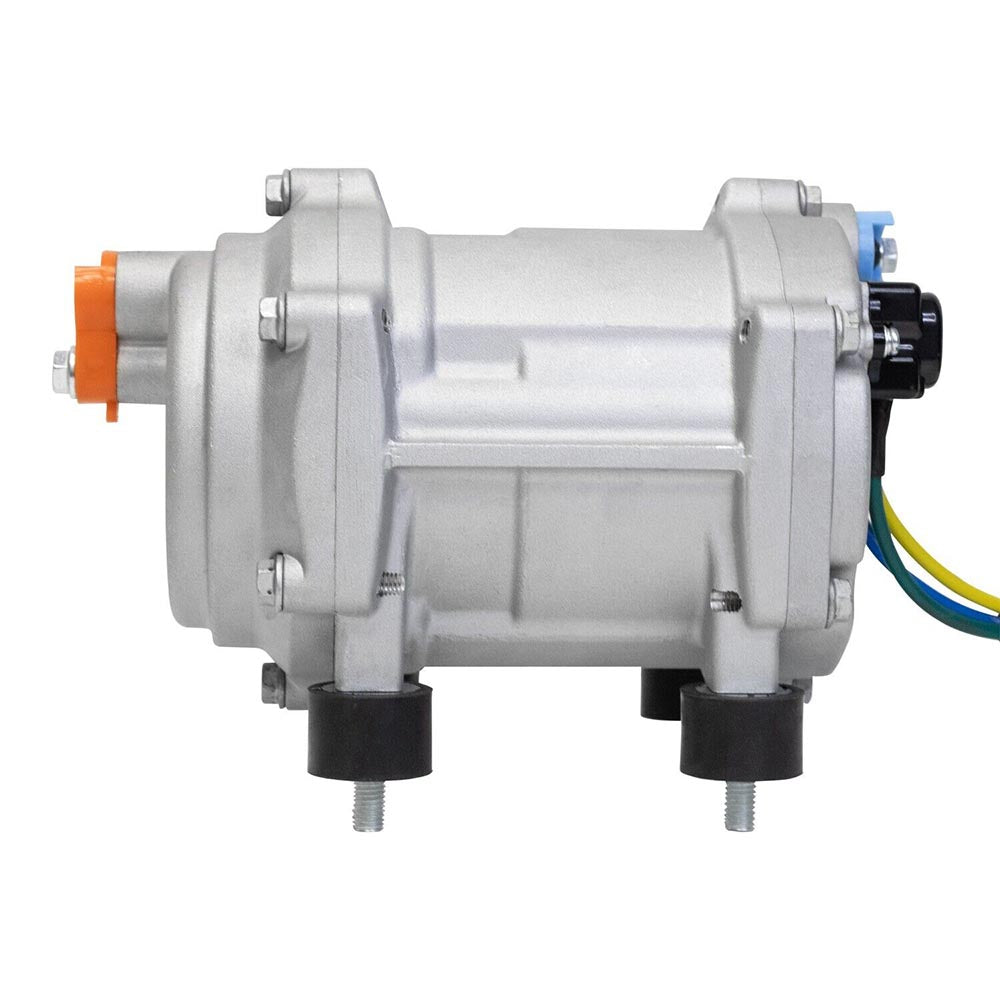

Illustrative image related to 12v auto air compressor

Onboard air systems are integrated into vehicles, providing a permanent air supply for various applications, including air suspension and pneumatic tools. Their fixed installation means they are always ready for use, making them particularly advantageous for fleet management and off-road vehicles. Buyers must consider the installation requirements and the space available in their vehicles, as these systems can be more complex than portable options but offer unmatched convenience and performance.

Rechargeable 12V air compressors operate independently of a vehicle’s power supply, making them a valuable addition to emergency kits or for use in remote locations. These compressors are typically compact and easy to store, ensuring they are readily available when needed. However, buyers should be aware of their limited run time and lower pressure output compared to traditional models, making them best suited for lighter tasks.

Industrial 12V air compressors are designed for high-volume output and robust construction, making them suitable for demanding environments like construction sites and automotive repair shops. They can power a range of heavy tools and equipment efficiently, providing a reliable air supply for various applications. B2B buyers should consider the higher initial investment and maintenance requirements, but the efficiency and performance they offer can justify the cost in high-demand scenarios.

| الصناعة/القطاع | Specific Application of 12v auto air compressor | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Tire Inflation and Repair | Enhances service efficiency by quickly inflating tires, reducing downtime for customers. | Ensure compatibility with various tire sizes and types; look for portable options for service vans. |

| Construction | Powering Pneumatic Tools | Increases productivity by enabling the use of air tools on job sites without needing a stationary compressor. | Consider the CFM and PSI ratings to match tool requirements; durability against harsh conditions is crucial. |

| Transportation and Logistics | Air Suspension Adjustment | Improves vehicle performance and safety by allowing quick adjustments to air suspension systems. | Look for compressors with a long duty cycle and reliability for continuous use; check for ease of installation. |

| Recreational Vehicles (RVs) | Inflating Air Mattresses and Sports Equipment | Provides convenience for outdoor activities, enhancing customer satisfaction and experience. | Portability and compact design are essential; battery compatibility with RV systems should be verified. |

| Agricultural Equipment | Inflating Tires on Farm Equipment | Ensures operational efficiency by maintaining proper tire pressure, reducing wear and tear. | Assess compatibility with various agricultural vehicles; durability and weather resistance are key factors. |

In automotive repair shops, 12v auto air compressors are essential for tire inflation and repair tasks. These compressors enable technicians to quickly inflate tires, ensuring minimal downtime for customers. The ability to operate directly from a vehicle’s battery makes them particularly useful for mobile service units. Buyers in this sector should prioritize compressors that can handle a range of tire sizes and have a robust construction for daily use.

In the construction industry, 12v auto air compressors are employed to power pneumatic tools, such as nail guns and air hammers, on job sites. Their portability allows workers to utilize air tools without being tethered to a stationary compressor, significantly enhancing productivity. For international buyers, especially in regions with varying power supply reliability, selecting a durable compressor with sufficient CFM and PSI ratings to match the tools’ requirements is crucial.

Illustrative image related to 12v auto air compressor

Transportation companies utilize 12v auto air compressors for air suspension adjustments, which are critical for maintaining vehicle performance and safety. These compressors allow drivers to quickly adjust the air pressure in their suspension systems, ensuring optimal handling and comfort. Buyers should consider compressors with a long duty cycle and reliability for continuous use, as well as ease of installation to minimize service interruptions.

For recreational vehicle (RV) owners, 12v auto air compressors are invaluable for inflating air mattresses and sports equipment. Their compact and portable design makes them ideal for outdoor activities, providing convenience and enhancing the overall experience. Buyers should focus on models that are lightweight, easy to store, and compatible with RV battery systems to ensure seamless operation during trips.

In agriculture, 12v auto air compressors are crucial for inflating tires on farm equipment, ensuring that machinery operates efficiently. Proper tire pressure helps reduce wear and tear, contributing to the longevity of expensive equipment. Buyers in this sector should assess the compatibility of compressors with various agricultural vehicles and prioritize models that are durable and weather-resistant to withstand outdoor conditions.

المشكلة B2B buyers often encounter challenges with air compressors that fail to maintain consistent air pressure. This inconsistency can lead to inefficiencies, especially in applications requiring precise air pressure, such as tire inflation for fleet vehicles or powering pneumatic tools. The frustration of having to repeatedly adjust or replace compressors not only wastes time but also incurs additional costs for businesses, particularly in sectors like transportation and logistics.

Illustrative image related to 12v auto air compressor

الحل: To address this issue, buyers should prioritize sourcing compressors with robust performance specifications. Look for models that explicitly detail their maximum pressure (PSI) and airflow (CFM) ratings. Brands that offer heavy-duty 12V compressors designed for continuous duty cycles are often more reliable. Ensure that the compressor features advanced technologies like automatic shut-off and thermal protection, which can prevent overheating and pressure drops during prolonged use. When selecting a unit, consider conducting performance tests or requesting demonstrations to verify pressure consistency before purchase, ensuring it meets the specific requirements of your operations.

المشكلة Many B2B buyers face difficulties when their 12V air compressors lack portability or usability across various environments. For example, companies in the construction or outdoor recreation sectors often require compressors that can easily transition between different job sites or terrains. A bulky or heavy compressor can hinder productivity, making it challenging to perform tasks efficiently in the field.

الحل: To overcome portability challenges, buyers should focus on compact and lightweight models that do not compromise on performance. Look for portable 12V compressors designed with ergonomic features, such as built-in handles and robust wheels for easy transportation. Additionally, consider compressors with versatile power options—those that can connect to vehicle batteries or include rechargeable batteries for use in locations without direct power access. Ensuring that the compressor comes with a comprehensive set of accessories, such as hoses and adapters, will enhance usability across a wide range of applications, from tire inflation to powering tools.

المشكلة Another common pain point for B2B buyers is the compatibility of 12V air compressors with existing vehicle power systems. Businesses operating a fleet of vehicles may find that certain compressors do not integrate well with their power setups, leading to operational delays and increased maintenance costs. This challenge is especially prevalent in regions with varying vehicle models and electrical configurations, like Africa and South America.

Illustrative image related to 12v auto air compressor

الحل: To ensure compatibility, buyers should conduct thorough research on the electrical specifications of their vehicles before selecting a compressor. Focus on 12V compressors that are explicitly designed to connect directly to vehicle batteries, providing clear compatibility information in their product specifications. It is also advisable to engage with suppliers who can offer customized solutions or expert advice on compatible models for specific vehicle types. Additionally, investing in compressors that feature multi-vehicle compatibility or adjustable power inputs can significantly reduce future procurement challenges and streamline operations across a diverse fleet.

When selecting materials for 12V auto air compressors, several factors come into play, including performance, durability, cost, and regional compliance standards. Below, we analyze four common materials used in the construction of these compressors, focusing on their properties, advantages and disadvantages, and considerations for international buyers.

الخصائص الرئيسية: Aluminum is lightweight yet strong, with good corrosion resistance and a temperature rating suitable for most automotive applications. It can withstand pressures typically encountered in air compression, making it a popular choice for compressor housings and components.

الإيجابيات والسلبيات: The primary advantage of aluminum is its low weight, which enhances portability. Additionally, its corrosion resistance extends the lifespan of the compressor. However, aluminum can be more expensive than other materials, and its manufacturing processes can be complex, requiring specialized techniques.

التأثير على التطبيق: Aluminum is compatible with various media, including air and some gases, making it versatile for different compressor applications. However, its lower strength compared to steel might limit its use in high-pressure scenarios.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM and DIN is essential, particularly for buyers in Europe and Germany. Buyers should also consider the availability of aluminum in their region, as it may affect lead times and costs.

الخصائص الرئيسية: Steel offers high tensile strength and excellent durability, with a temperature and pressure rating that can exceed those of aluminum. It is also highly resistant to deformation under stress.

Illustrative image related to 12v auto air compressor

الإيجابيات والسلبيات: The main advantage of steel is its robustness, making it suitable for high-pressure applications. However, it is heavier than aluminum, which may reduce portability. Additionally, steel is prone to rust if not properly coated or treated.

التأثير على التطبيق: Steel is ideal for applications requiring high strength, such as heavy-duty compressors used in off-road vehicles or industrial settings. Its compatibility with various media is broad, but care must be taken to prevent corrosion.

اعتبارات للمشترين الدوليين: Buyers from regions with high humidity or coastal areas, such as parts of Africa and South America, should prioritize corrosion-resistant coatings. Compliance with local manufacturing standards will also be crucial for ensuring product reliability.

الخصائص الرئيسية: Plastics are lightweight and can be molded into complex shapes, making them suitable for components like casings and housing. They generally have lower temperature and pressure ratings compared to metals.

Illustrative image related to 12v auto air compressor

الإيجابيات والسلبيات: The key advantage of plastic is its low cost and ease of manufacturing. However, plastics often have lower durability and can be susceptible to degradation from UV exposure and high temperatures.

التأثير على التطبيق: While plastics are suitable for non-structural components, they may not be appropriate for high-pressure applications. Their compatibility with air is generally good, but specific plastics may not withstand certain chemicals.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastics used comply with relevant safety and environmental standards, particularly in Europe, where regulations can be stringent.

Illustrative image related to 12v auto air compressor

الخصائص الرئيسية: Copper is an excellent conductor of heat and electricity, with good corrosion resistance. It can handle high temperatures and pressures, making it suitable for certain components like wiring and fittings.

الإيجابيات والسلبيات: The primary advantage of copper is its conductivity, which enhances the efficiency of electric components. However, it is more expensive than other materials and can be heavy, potentially impacting the overall weight of the compressor.

التأثير على التطبيق: Copper is ideal for electrical connections and heat exchangers within compressors. Its compatibility with air and various gases is excellent, but care must be taken to prevent galvanic corrosion when used with dissimilar metals.

Illustrative image related to 12v auto air compressor

اعتبارات للمشترين الدوليين: Compliance with electrical standards is critical for buyers in regions like the Middle East and Europe. Additionally, the cost of copper can fluctuate, impacting overall pricing.

| المواد | Typical Use Case for 12v Auto Air Compressor | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | Compressor housings and components | خفيف الوزن ومقاوم للتآكل | ارتفاع التكلفة والتصنيع المعقد | متوسط |

| الفولاذ | Heavy-duty applications and structural components | قوة ومتانة عالية | أثقل وزناً وعرضة للصدأ | متوسط |

| بلاستيك | Non-structural components like casings | Low cost and easy to manufacture | Lower durability and UV sensitivity | منخفضة |

| Copper | Electrical connections and heat exchangers | Excellent conductivity | Higher cost and heavy | عالية |

This analysis provides a comprehensive overview of the materials used in 12V auto air compressors, focusing on their properties, advantages, and implications for international buyers. Understanding these factors will aid B2B buyers in making informed decisions that align with their operational needs and regional standards.

The manufacturing process of a 12V auto air compressor involves several critical stages, each designed to ensure high performance and durability. Here’s a detailed breakdown:

The initial stage focuses on sourcing high-quality materials, which typically include metals like aluminum or steel for the housing and components, as well as durable plastics for non-structural parts. Material integrity is vital, and suppliers often provide certificates of compliance to international standards. Rigorous testing for corrosion resistance and mechanical properties is conducted to ensure that the materials can withstand varying environmental conditions.

In this stage, the prepared materials undergo various forming processes, such as machining, stamping, and casting. CNC (Computer Numerical Control) machining is frequently used for precision parts, ensuring that components meet exact specifications. Techniques like injection molding may be employed for plastic components, allowing for complex designs that enhance functionality and reduce weight.

Illustrative image related to 12v auto air compressor

The assembly process combines all the manufactured parts into a complete unit. This stage often uses automated assembly lines to enhance efficiency and minimize human error. Key components, such as the motor, pressure switch, and air tank, are assembled with precision. Additionally, torque specifications are strictly adhered to for all fastenings, and assembly jigs are utilized to maintain consistency.

Finishing processes include surface treatments like anodizing or powder coating, which not only enhance aesthetic appeal but also provide protection against environmental factors such as moisture and corrosion. Final inspections are conducted at this stage to ensure all components are correctly installed and that the unit meets performance specifications.

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that the final product meets both customer expectations and international standards.

Manufacturers of 12V auto air compressors often adhere to international quality management standards such as ISO 9001. This standard focuses on a process-oriented approach and continuous improvement, which is essential for maintaining product consistency and reliability. Additionally, compliance with CE marking indicates that the product meets EU safety, health, and environmental protection standards, while API (American Petroleum Institute) standards may apply for compressors used in specialized applications.

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and ensure quality. Key checkpoints include:

Illustrative image related to 12v auto air compressor

مراقبة الجودة الواردة (IQC): Inspection of raw materials and components upon arrival to verify compliance with specifications.

مراقبة الجودة أثناء العملية (IPQC): Ongoing inspections during the manufacturing process, including checks on dimensions, assembly accuracy, and performance of individual components.

مراقبة الجودة النهائية (FQC): A comprehensive evaluation of the assembled unit, including performance testing under various conditions to ensure it meets specified pressure and airflow ratings.

To guarantee the performance and safety of 12V auto air compressors, various testing methods are employed:

الاختبار الوظيفي: Each compressor undergoes a series of functional tests to verify its operational efficiency, including airflow and pressure output.

اختبار المتانة: Units are subjected to prolonged operational cycles to simulate real-world usage and identify any potential points of failure.

الاختبار البيئي: Compressors may be tested under extreme temperatures and humidity levels to ensure reliability in various climates, which is particularly important for international markets.

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are effective strategies:

عمليات تدقيق الموردين: Conduct regular audits of suppliers’ manufacturing facilities to assess adherence to quality standards and processes.

Request Quality Assurance Reports: Suppliers should provide documented evidence of their quality control processes, including results from IQC, IPQC, and FQC.

عمليات التفتيش من طرف ثالث: Engage third-party inspection agencies to independently verify the quality of products before shipment. These agencies can provide unbiased reports regarding compliance with international standards.

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and regulations.

Compliance with Local Regulations: Buyers from Africa, South America, the Middle East, and Europe should ensure that the compressors they source comply with local regulations and standards. For example, in Europe, the CE marking is mandatory, while in the US, compliance with UL (Underwriters Laboratories) standards may be required.

Cultural and Business Practices: Recognize that quality assurance practices may differ significantly across regions. Building strong relationships with suppliers can facilitate better communication regarding quality standards and expectations.

الاعتبارات اللوجستية: Quality assurance doesn’t stop at manufacturing. International shipping and handling can impact product integrity. Ensure that suppliers have protocols in place to protect the products during transit, such as proper packaging and handling instructions.

In summary, a robust understanding of manufacturing processes and quality assurance protocols is essential for B2B buyers in the 12V auto air compressor market. By focusing on these aspects, buyers can make informed decisions that align with their operational needs and market standards.

In today’s competitive marketplace, sourcing a reliable 12V auto air compressor is essential for businesses involved in automotive service, transportation, and outdoor activities. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively, ensuring they select the right product for their needs.

Illustrative image related to 12v auto air compressor

Begin by clearly outlining the technical requirements for the air compressor. Consider factors such as maximum pressure (PSI), airflow (CFM), and intended applications (e.g., tire inflation, powering air horns, etc.). Knowing your specifications will help you narrow down options and communicate effectively with potential suppliers.

Understanding the current market landscape and the various applications of 12V air compressors is crucial. Different regions may have specific demands based on local automotive standards and usage scenarios.

Before finalizing a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and references from other businesses in similar industries.

Once you have a list of potential suppliers, compare their pricing structures and payment terms. It is important to look beyond the sticker price and consider overall value, including warranty and after-sales support.

Ensure that the air compressors meet relevant international and local standards. This is crucial for maintaining quality and safety in your operations.

Before making a large purchase, request samples or demonstrations of the compressors. Testing the product in real-world conditions can reveal potential issues that may not be apparent through specifications alone.

Once satisfied with your selection, finalize the purchase agreement. Ensure that all terms, including delivery timelines, payment schedules, and return policies, are clearly outlined.

By following these steps, B2B buyers can confidently source a 12V auto air compressor that meets their operational needs while ensuring quality and reliability.

When evaluating the cost structure for sourcing 12V auto air compressors, several components contribute to the overall pricing. These include:

المواد: The quality and type of materials used significantly affect costs. High-grade metals and durable plastics can increase the price but enhance longevity and performance. Components like motors, valves, and hoses also vary in price based on specifications and supplier quality.

العمالة: Labor costs can vary widely based on the location of manufacturing. Regions with higher labor costs, such as Europe, may see increased prices, whereas manufacturers in countries with lower wages may offer more competitive rates. Understanding the labor market in the supplier’s region can help in negotiating costs.

نفقات التصنيع الزائدة: This includes utilities, rent, equipment depreciation, and other indirect costs associated with production. Suppliers with efficient manufacturing processes may pass savings on to buyers, while those with outdated facilities may have higher overheads, impacting pricing.

الأدوات: Initial costs for molds and tools can be substantial, particularly for customized or specialized compressors. Buyers should consider whether the supplier has the necessary tooling capabilities, as this can influence lead times and costs.

مراقبة الجودة (QC): Implementing rigorous QC processes can add to costs but ensures product reliability and compliance with international standards. Buyers should inquire about the QC measures in place and the potential costs associated with them.

الخدمات اللوجستية: Shipping costs can fluctuate based on distance, volume, and chosen logistics partners. Understanding the Incoterms agreed upon in contracts can clarify responsibilities for shipping costs, duties, and insurance.

الهامش: Suppliers often mark up prices to cover overhead and profit. Understanding the market landscape and comparing multiple suppliers can help buyers negotiate better margins.

Several factors influence pricing in the B2B landscape for 12V auto air compressors:

الحجم/الكمية (الحد الأدنى لكمية الطلب): Larger orders typically result in lower per-unit costs. Buyers should negotiate volume discounts to maximize cost-efficiency.

المواصفات والتخصيص: Customized units tailored to specific requirements will generally incur higher costs. Buyers should weigh the need for custom features against the potential price increase.

المواد وشهادات الجودة: Products with certifications (e.g., ISO, CE) may command higher prices due to the assurance of quality and compliance. Buyers should evaluate whether these certifications are necessary for their markets.

عوامل الموردين: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better reliability and support.

المصطلحات التجارية الدولية: The choice of Incoterms can significantly affect landed costs. Understanding terms like FOB (Free on Board) and CIF (Cost Insurance and Freight) can help buyers manage costs effectively.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance negotiation outcomes:

Research and Benchmarking: Understand the market price range for similar products. This knowledge can empower buyers during negotiations and help identify fair pricing.

التكلفة الإجمالية للملكية (TCO): Evaluate not just the purchase price but the total cost of ownership, including maintenance, operational costs, and potential downtime. Highlighting TCO can be a persuasive argument for cost reduction.

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Frequent communication and a clear understanding of mutual goals can foster collaboration.

Flexibility in Terms: Be open to negotiating payment terms, delivery schedules, and other contractual elements. Flexibility can lead to more favorable pricing arrangements.

Cultural Sensitivity: Understanding cultural nuances in negotiation styles can be crucial, especially when dealing with suppliers from different regions. Approach negotiations with respect and adaptability to local customs.

While indicative prices for 12V auto air compressors can vary widely—from budget models starting around $50 to high-end units exceeding $2,500—buyers should focus on the comprehensive cost structure and the factors influencing pricing. By approaching sourcing with a strategic mindset, international buyers can optimize their purchasing decisions and secure favorable terms in the competitive landscape of automotive equipment.

In the automotive and outdoor industries, the need for efficient inflation solutions is paramount. While 12V auto air compressors are popular for their portability and convenience, several alternative solutions can also meet the demands of various applications. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their specific operational needs.

| جانب المقارنة | 12V Auto Air Compressor | Portable AC Air Compressor | Manual Foot Pump |

|---|---|---|---|

| الأداء | Up to 200 PSI, varies by model | Up to 150 PSI, continuous operation | Varies, generally lower than 30 PSI |

| التكلفة | Moderate ($100 – $600) | Higher ($200 – $1,000) | Low ($20 – $50) |

| سهولة التنفيذ | Simple, connects to vehicle battery | Requires power source, often requires installation | Very simple, no setup required |

| الصيانة | Moderate, depends on usage | High, regular servicing needed | Minimal, very few parts |

| أفضل حالة استخدام | Tire inflation, air horns, air suspension | Heavy-duty applications, continuous use | Occasional tire inflation, low-volume tasks |

Portable AC air compressors are designed for heavier-duty applications and can deliver consistent air pressure for prolonged periods. They are often used in professional settings, such as construction sites or automotive shops, where high airflow and pressure are crucial. However, their higher cost and need for a dedicated power source can be limiting factors for some businesses. Maintenance is also more demanding, requiring regular checks to ensure optimal performance. For companies with significant air needs, this option is robust and efficient.

Manual foot pumps represent a cost-effective and environmentally friendly alternative for infrequent or emergency tire inflation. They are lightweight and require no power source, making them easy to transport and use anywhere. However, their performance is limited, typically providing lower PSI, which may not be adequate for larger vehicles or heavy-duty applications. While they require minimal maintenance, their effectiveness diminishes with frequent use, making them less suitable for businesses that require consistent and reliable air pressure solutions.

Illustrative image related to 12v auto air compressor

For B2B buyers assessing air inflation solutions, the choice between a 12V auto air compressor, a portable AC compressor, and a manual foot pump hinges on several factors, including performance requirements, budget constraints, and maintenance capabilities. The 12V auto air compressor offers a versatile balance of portability and performance for automotive needs, while portable AC compressors serve well in professional environments requiring higher air demands. Meanwhile, manual foot pumps are ideal for occasional use and budget-conscious buyers. Evaluating these aspects will enable businesses to select the most suitable solution to enhance operational efficiency and meet specific inflation tasks effectively.

When sourcing a 12V auto air compressor, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

The maximum pressure, measured in pounds per square inch (PSI), indicates the compressor’s ability to inflate tires or power pneumatic tools. A higher PSI rating is essential for applications requiring rapid inflation or for powering air horns and air suspension systems. For B2B buyers, selecting a compressor with the appropriate PSI ensures it meets operational needs without risking equipment failure.

Cubic feet per minute (CFM) measures the volume of air the compressor can deliver. This specification is critical for determining how quickly a compressor can inflate tires or operate air tools. For businesses involved in automotive services or off-road vehicle modifications, selecting a compressor with the right CFM rating can optimize workflow efficiency and reduce downtime.

The duty cycle percentage indicates the amount of time a compressor can run continuously before needing to cool down. A higher duty cycle is advantageous for businesses that require prolonged use, such as tire shops or service centers. Understanding the duty cycle helps buyers choose a compressor that aligns with their operational intensity and prevents overheating.

Most 12V compressors connect directly to a vehicle’s battery. Ensuring compatibility with the vehicle’s electrical system is vital for seamless operation. Buyers should confirm that the compressor’s voltage and amperage ratings are suitable for their vehicle to avoid electrical issues that could lead to operational interruptions.

For mobile applications, the size and weight of the compressor are significant factors. A compact and lightweight design facilitates ease of transport, which is especially important for businesses operating in varied environments. Buyers should assess whether the compressor’s dimensions fit their storage and mobility requirements.

Understanding industry jargon can enhance communication and negotiation with suppliers. Here are several key terms:

OEM refers to companies that manufacture products that are marketed under another company’s brand. In the context of 12V air compressors, knowing whether a product is OEM can affect quality assurance and compatibility with existing equipment. B2B buyers often prefer OEM parts for their reliability and performance consistency.

MOQ indicates the smallest number of units a supplier is willing to sell. For international buyers, especially in regions like Africa and South America, understanding MOQ is crucial for budgeting and inventory management. Negotiating MOQs can lead to cost savings and better stock management for businesses.

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. B2B buyers should utilize RFQs to compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms for 12V auto air compressors.

Illustrative image related to 12v auto air compressor

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international trade, including shipping, risk, and insurance. Familiarity with Incoterms helps businesses avoid disputes and understand their obligations in cross-border transactions.

Warranties outline the manufacturer’s commitment to repair or replace defective products within a certain timeframe. Service agreements often accompany warranties, detailing maintenance and support services. Understanding these terms is essential for buyers to protect their investment and ensure the longevity of the compressors.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting 12V auto air compressors, ensuring they meet their operational needs and business objectives effectively.

The 12V auto air compressor market is witnessing robust growth driven by several global factors. The rising demand for portable and efficient inflation solutions, especially in the automotive sector, is a significant driver. As more consumers engage in outdoor and recreational activities, the need for versatile air compressors capable of inflating various equipment—from tires to sports gear—has surged. Additionally, the expansion of e-commerce platforms facilitates easy access to diverse models, making it easier for international B2B buyers in regions like Africa, South America, the Middle East, and Europe to source products that meet their specific needs.

Illustrative image related to 12v auto air compressor

Emerging technologies are also reshaping the landscape. Smart air compressors equipped with digital interfaces and automatic shut-off features are becoming increasingly popular, enhancing user experience and safety. Furthermore, the trend toward hybrid and electric vehicles is prompting manufacturers to innovate 12V compressors that are lightweight and energy-efficient, appealing to eco-conscious buyers. In terms of market dynamics, B2B buyers should be aware of fluctuating raw material costs and supply chain disruptions, which could affect pricing and availability. Staying informed about these trends can aid in making strategic sourcing decisions.

Sustainability has become a cornerstone of modern business practices, and the 12V auto air compressor sector is no exception. The environmental impact of manufacturing processes and product lifecycle management is increasingly under scrutiny. B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of recycled materials and energy-efficient manufacturing processes.

Ethical sourcing is also paramount, as companies strive to ensure that their supply chains are free from human rights violations and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations can serve as important indicators of a supplier’s commitment to sustainability. By partnering with manufacturers who prioritize ethical practices and sustainability, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable future.

The evolution of the 12V auto air compressor can be traced back to the mid-20th century when portable air compressors began to gain traction in the automotive industry. Initially designed for basic tire inflation, these devices have transformed dramatically over the decades. Technological advancements have led to the development of more compact, efficient, and powerful models, catering to a broader range of applications beyond just tires, such as air suspension systems and pneumatic tools.

As consumer demand for convenience and performance grew, manufacturers began integrating features like automatic shut-off, digital pressure gauges, and enhanced portability into their designs. This evolution has made 12V auto air compressors indispensable tools for both everyday drivers and outdoor enthusiasts, solidifying their place in the global market. Today, as buyers seek products that combine performance with sustainability, the focus is shifting toward innovations that align with eco-friendly practices and ethical sourcing, setting the stage for the next phase of growth in this sector.

How do I choose the right 12V air compressor for my business needs?

When selecting a 12V air compressor, focus on key performance specifications such as maximum pressure (PSI) and airflow (CFM) ratings to match your applications. Consider the intended use, whether for tire inflation, powering air tools, or operating air horns. Evaluate portability versus mounting options based on your operational needs. Additionally, assess the duty cycle for continuous use and look for features like automatic shut-off and thermal protection for enhanced reliability. Research different brands and models to ensure you find a balance between performance, durability, and cost-effectiveness.

What are the typical applications for a 12V air compressor in a B2B context?

12V air compressors are versatile tools commonly used in various industries. They are ideal for inflating tires of vehicles, motorcycles, and trailers, as well as for powering pneumatic tools in workshops. Additionally, they can be used in recreational settings for inflating sports equipment and camping gear. In sectors like automotive and construction, these compressors assist with air suspension adjustments and other pneumatic applications, making them valuable assets for businesses focused on vehicle maintenance and outdoor activities.

What should I consider when vetting suppliers for 12V air compressors?

When vetting suppliers, assess their reputation and reliability by checking customer reviews and testimonials. Verify their compliance with international quality standards and certifications to ensure product safety and performance. Evaluate their manufacturing capabilities, including technology and workforce expertise. Request samples to gauge product quality firsthand. Additionally, inquire about their ability to provide after-sales support, warranty terms, and responsiveness to queries. Establishing a solid relationship with a reputable supplier can significantly impact your business’s operational efficiency.

What is the typical minimum order quantity (MOQ) for 12V air compressors?

Minimum order quantities (MOQs) for 12V air compressors can vary widely depending on the supplier and product specifications. Generally, MOQs can range from as low as 50 units to several hundred. Factors influencing MOQ include production costs, customization options, and shipping logistics. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ policies and negotiate terms that align with your business requirements. Establishing a strong partnership can often lead to more favorable terms.

How can I customize a 12V air compressor for my brand?

Customization options for 12V air compressors may include branding, color schemes, and packaging. Many manufacturers offer OEM (Original Equipment Manufacturer) services, allowing you to incorporate your logo and branding elements. Discuss your specific customization needs with potential suppliers and inquire about their capabilities. Be sure to clarify any associated costs, lead times, and minimum order requirements for customized products. Customization can enhance your brand visibility and provide a competitive edge in your market.

What payment terms should I expect when sourcing 12V air compressors internationally?

Payment terms can vary significantly among suppliers and depend on the relationship established. Common terms include a deposit (typically 30% upfront) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment through platforms like PayPal or escrow services for added security. It’s crucial to clearly outline and agree on payment terms before finalizing orders to avoid any misunderstandings. Always consider the impact of currency exchange rates and transaction fees in your budgeting.

How do I ensure quality assurance for 12V air compressors sourced from suppliers?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Consider implementing a quality control process that includes pre-shipment inspections and testing for performance metrics like PSI and CFM. Establish clear quality standards and communicate them with your supplier to ensure compliance. Additionally, building a long-term relationship with a reliable supplier can facilitate ongoing quality improvements and responsiveness to any issues that may arise post-purchase.

What logistics considerations should I keep in mind when importing 12V air compressors?

When importing 12V air compressors, consider logistics factors such as shipping methods, costs, and delivery times. Assess whether air freight or sea freight is more suitable based on your urgency and budget. Be aware of customs regulations and tariffs in your country, as these can impact total import costs. Establish a reliable shipping partner to manage documentation and ensure compliance with international trade laws. Additionally, plan for warehousing and distribution within your region to optimize inventory management.

المجال: thorslightningairsystems.com

مسجل: 2022 (3 سنوات)

مقدمة: 12v Portable Air Compressors from Thor’s Lightning include:

– Thor’s Lightning Strike Compressor: FROM $449.99 (originally $499.00)

– Jeep® Thor’s Lightning Strike Compressor: FROM $449.99 (originally $599.99)

– Customize Your Compressor: FROM $0.00

– Thor’s Lightning Bolt TrueDual Air Compressor TotalControl: FROM $255.99 (originally $319.99)

– Thor’s Lightning Bolt Portable 12v True Dual Air Com…

المجال: hornblasters.com

مسجل: 2003 (22 سنة)

مقدمة: Heavy-Duty 12V Air Compressors – Reliable & Powerful

المجال: griotsgarage.com

مسجل: 1996 (29 سنة)

مقدمة: 12V Car Tire Air Compressor – Portable & Efficient\n- Item# 10285\n- UPC: Not specified\n- MSRP: $74.99\n- Fills typical car tire in 2 minutes\n- Power cord and hose will reach all four tires\n- Outstanding build quality\n- Compact size\n- Quiet operation\n- Free shipping on orders over $49\n- 100% Satisfaction Guarantee\n- Current Stock: 79\n- Available for backorder

In conclusion, strategic sourcing of 12V auto air compressors offers substantial benefits for international B2B buyers. By focusing on performance specifications, power compatibility, and portability, companies can ensure they select compressors that meet their operational needs while maximizing efficiency. The versatility of these compressors—ranging from tire inflation to powering pneumatic tools—enhances their appeal across various sectors, including automotive, recreational, and industrial applications.

As global markets continue to evolve, particularly in Africa, South America, the Middle East, and Europe, the demand for reliable and durable air compressors is set to increase. Buyers should prioritize suppliers that demonstrate commitment to quality and innovation, ensuring they stay ahead in competitive markets.

Now is the time to leverage strategic sourcing to enhance your supply chain, reduce costs, and improve product offerings. Engage with reputable manufacturers and distributors to explore the latest advancements in 12V auto air compressors. By doing so, you position your business for success in an ever-changing landscape. Take the next step in optimizing your operations today.

Illustrative image related to 12v auto air compressor

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.