- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In today’s competitive landscape, sourcing the right air chuck digital solutions can be a formidable challenge for international B2B buyers. Whether you’re operating in the bustling markets of Africa, South America, the Middle East, or Europe, the need for reliable and efficient tire inflation systems is paramount. This guide aims to demystify the complexities of the air chuck digital market, offering insights into various types, their applications across different industries, and essential supplier vetting strategies.

As businesses strive to enhance operational efficiency, understanding the nuances of digital tire inflators—ranging from portable units to advanced inflator gauges—becomes critical. This comprehensive resource will delve into key considerations, including cost factors, performance benchmarks, and best practices for integration into existing workflows.

By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide empowers you to navigate the global market with confidence. With a focus on practical applications and supplier evaluations, you will be better positioned to select air chuck digital solutions that not only meet your operational needs but also drive long-term value for your business. Join us as we explore the essentials of digital tire inflation technology and its impact on your bottom line.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Digital Tire Inflator with Gauge | Integrated pressure gauge, automatic shut-off | Automotive service centers, tire shops | الإيجابيات: Accurate readings, reduces risk of over-inflation. السلبيات: Higher initial investment. |

| Pre-Set Digital Tire Inflator | Programmable pressure settings, audible alerts | Heavy equipment maintenance, fleet services | الإيجابيات: Saves time, enhances safety with automatic shut-off. السلبيات: Complexity may deter some users. |

| Portable Digital Air Compressor | Compact design, dual power source (AC/DC) | Mobile tire repair services, roadside assistance | الإيجابيات: Versatile use, easy transport. السلبيات: Lower power compared to stationary units. |

| Lock-on Digital Air Chuck | Hands-free operation, leak-proof design | Professional garages, tire installation services | الإيجابيات: Increases efficiency, minimizes air loss. السلبيات: May require additional training for optimal use. |

| Heavy-Duty Digital Inflator | High PSI capacity, rugged construction | Off-road vehicle maintenance, industrial applications | الإيجابيات: Durable, suitable for tough environments. السلبيات: Bulkier, may not be ideal for all users. |

Digital tire inflators with integrated gauges are essential tools for automotive service centers and tire shops. They allow technicians to monitor tire pressure accurately and prevent over-inflation. These devices often feature automatic shut-off capabilities, making them user-friendly and enhancing safety. When considering a purchase, B2B buyers should evaluate the inflator’s PSI capacity, durability, and ease of use, as these factors directly impact operational efficiency.

Pre-set digital tire inflators are designed for businesses that require consistent tire pressure settings, such as heavy equipment maintenance and fleet services. These inflators allow users to program desired pressures, automatically stopping once the target is reached. This feature not only saves time but also minimizes the risk of tire damage. B2B buyers should consider the inflator’s range of pressure settings and ease of programming when making their selection.

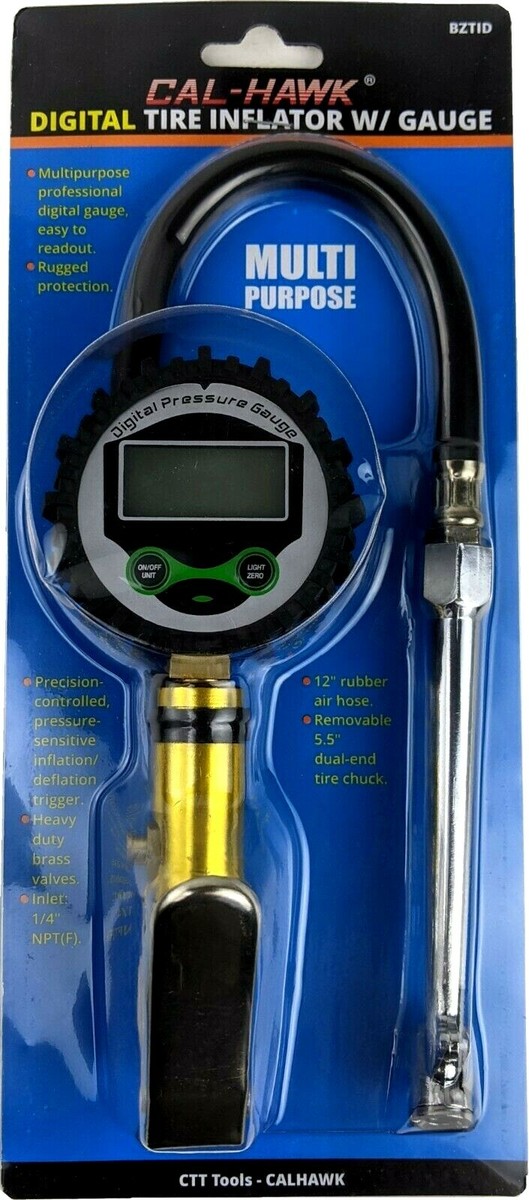

Illustrative image related to air chuck digital

Portable digital air compressors are ideal for mobile tire repair services and roadside assistance due to their compact design and dual power options (AC/DC). Their versatility allows businesses to provide on-the-go services without sacrificing performance. However, buyers should be aware that while these units are convenient, they may offer lower power than stationary alternatives. Evaluating the compressor’s PSI ratings and battery life is crucial for ensuring it meets operational needs.

Lock-on digital air chucks provide hands-free operation and a leak-proof design, making them popular in professional garages and tire installation services. Their ability to secure the connection without requiring constant manual pressure allows technicians to focus on other tasks, enhancing productivity. When purchasing, businesses should consider the chuck’s compatibility with existing equipment and the training required for staff to use it effectively.

Heavy-duty digital inflators are built to withstand tough environments, making them suitable for off-road vehicle maintenance and industrial applications. With high PSI capacities and rugged construction, these inflators can handle the demands of commercial use. However, their bulkier design may not be ideal for all users. B2B buyers should assess the specific needs of their operations, including the types of vehicles serviced and the frequency of use, to determine the best fit.

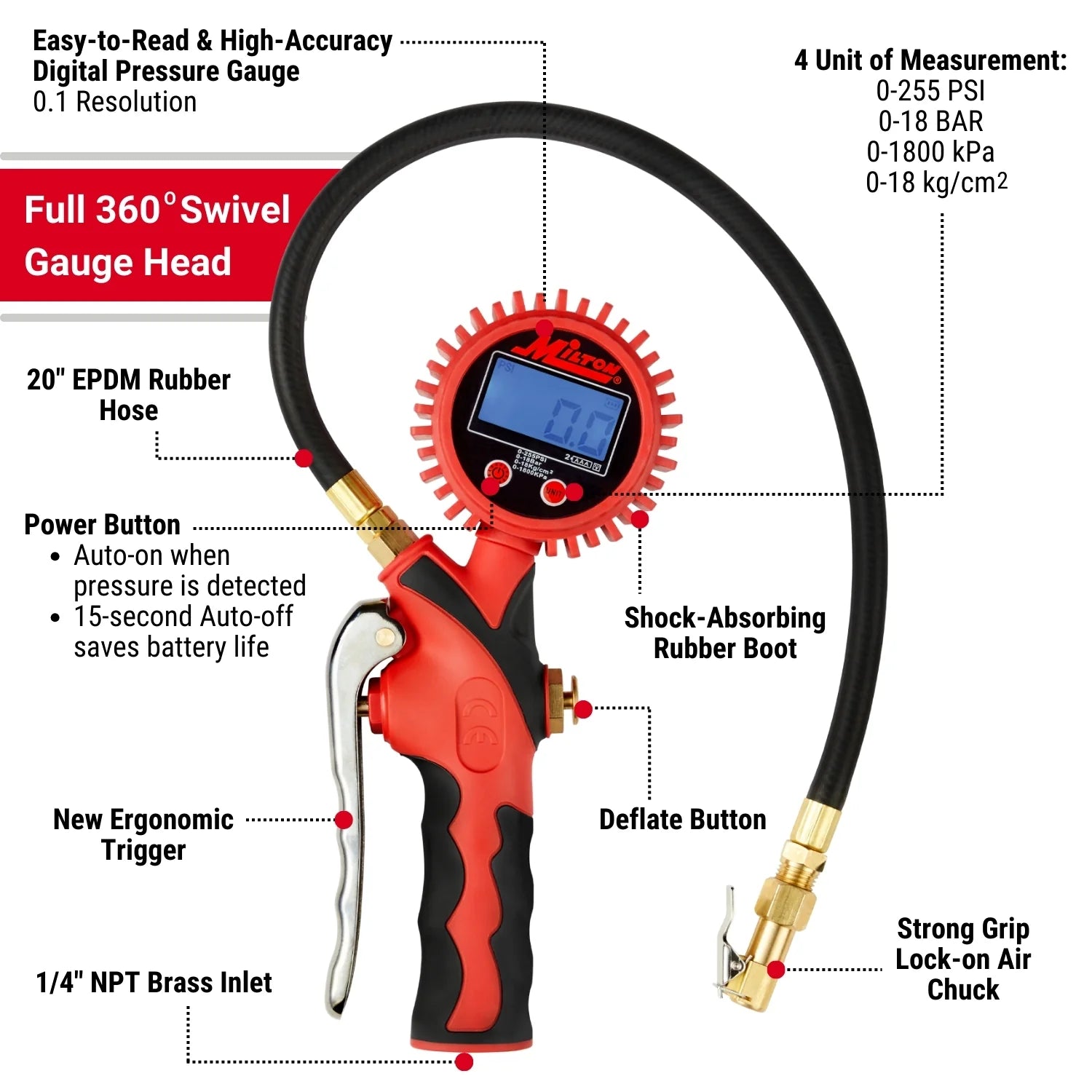

Illustrative image related to air chuck digital

| الصناعة/القطاع | Specific Application of air chuck digital | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Manufacturing | Tire assembly and quality control | Ensures precise tire pressure for safety and performance | Calibration accuracy, compatibility with existing systems |

| النقل والخدمات اللوجستية | Fleet maintenance and tire inflation | Reduces downtime through efficient tire management | Portability, ease of use, and durability in rugged conditions |

| الزراعة | Maintenance of agricultural vehicles and equipment | Enhances operational efficiency and safety | Resistance to harsh environments, battery life, and pressure range |

| Construction | Inflation of heavy machinery tires | Improves safety and performance on construction sites | Robust design, ease of handling, and accurate pressure settings |

| Aviation | Pre-flight tire checks and maintenance | Enhances safety and compliance with aviation standards | High precision, multiple pressure units, and ease of storage |

In automotive manufacturing, air chuck digital devices are pivotal during the tire assembly process. These tools ensure that tires are inflated to the precise specifications required for optimal performance and safety. The accuracy of digital air chucks minimizes the risk of over-inflation or under-inflation, which can lead to tire failure. Buyers in this sector must prioritize calibration accuracy and compatibility with existing tire assembly systems to maintain production efficiency.

In the transportation and logistics sector, air chuck digital devices streamline fleet maintenance by facilitating quick and accurate tire inflation. This efficiency reduces vehicle downtime, allowing for more effective route management and cost savings. Businesses should consider the portability and ease of use of these devices, especially in remote locations, as well as their durability to withstand various weather conditions encountered during operations.

For agricultural applications, air chuck digital tools are essential for maintaining the tire pressure of various vehicles and equipment, such as tractors and harvesters. Proper tire inflation enhances fuel efficiency and ensures safety while operating heavy machinery in challenging terrains. Buyers in the agricultural sector should look for devices that can endure harsh environmental conditions, have long battery life, and offer a wide range of pressure settings to cater to different equipment types.

In construction, air chuck digital devices are crucial for inflating tires on heavy machinery like excavators and bulldozers. Accurate tire pressure is vital for the performance and safety of these machines on uneven job sites. Construction firms should focus on sourcing robust air chuck digital tools that are easy to handle and provide precise pressure readings to enhance operational efficiency and worker safety.

In the aviation industry, air chuck digital devices are utilized for pre-flight tire checks to ensure compliance with safety regulations. Accurate tire pressure is critical for aircraft performance and safety during takeoff and landing. Buyers in this sector must prioritize high precision, the ability to measure in multiple units, and compact storage options for these tools, given the stringent safety requirements and limited space in aviation environments.

المشكلة Many B2B buyers in industries such as transportation or automotive services face challenges in obtaining precise tire pressure readings. This is particularly true when using traditional air chuck devices, which can often lead to under-inflation or over-inflation. Inaccurate pressure readings can not only affect vehicle performance but also compromise safety, leading to potential accidents or costly repairs. This scenario is especially critical for businesses operating fleets where tire maintenance is paramount for operational efficiency and safety.

Illustrative image related to air chuck digital

الحل: To address this issue, B2B buyers should consider investing in high-quality digital air chucks equipped with advanced pressure sensors. Models that feature real-time digital readouts provide immediate feedback on tire pressure, significantly reducing the risk of error. When sourcing these devices, look for features such as calibration options and a wide pressure range to ensure compatibility with various tire sizes. Additionally, integrating digital air chucks with tire pressure monitoring systems (TPMS) can automate readings, alerting operators to any discrepancies in real-time. Regular training on the proper usage of these tools will further enhance accuracy and operational safety.

المشكلة In high-demand environments, such as automotive service centers or logistics companies, the efficiency of tire inflation processes is crucial. Traditional air chuck systems often require manual handling, leading to delays and increased labor costs. These inefficiencies can result in longer turnaround times for vehicles, ultimately impacting productivity and customer satisfaction.

الحل: B2B buyers can streamline their tire inflation processes by selecting automated digital air chuck systems that feature preset functions. These advanced models allow users to set desired pressure levels, automatically stopping inflation once the target is reached. This hands-free operation not only saves time but also minimizes the risk of human error. When purchasing, consider systems that offer various inflation modes (e.g., fast inflation, slow fill) to cater to different tire types and sizes. Implementing these systems can drastically reduce time spent on tire maintenance, allowing staff to focus on other essential tasks.

المشكلة In industries that operate in harsh environments—such as construction or off-road vehicle maintenance—standard air chuck devices may suffer from wear and tear. This can lead to frequent breakdowns, costly repairs, and downtime, which can be detrimental to business operations. B2B buyers need reliable equipment that can withstand tough conditions without compromising performance.

الحل: To combat durability issues, B2B buyers should prioritize sourcing air chucks made from high-quality materials, such as reinforced polycarbonate or stainless steel. These materials enhance the longevity of the devices, reducing the frequency of replacements. Additionally, consider models with protective features like shock resistance and weatherproofing to ensure functionality in extreme conditions. Regular maintenance, such as cleaning and lubricating moving parts, will also extend the lifespan of the equipment. Buyers should also establish a routine inspection schedule to identify any potential issues before they escalate, ensuring that their operations remain uninterrupted.

Illustrative image related to air chuck digital

When selecting materials for air chuck digital components, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. The following analysis focuses on four common materials used in air chuck digital manufacturing: aluminum, brass, stainless steel, and plastic.

Aluminum is a lightweight, corrosion-resistant metal often used in air chuck digital applications. Its key properties include a temperature rating of up to 150°C and a pressure rating that can exceed 200 PSI, making it suitable for various tire inflation tasks.

الإيجابيات: Aluminum is cost-effective and easy to manufacture, allowing for complex shapes and designs. Its lightweight nature reduces shipping costs and enhances user convenience.

السلبيات: While aluminum offers good corrosion resistance, it can be less durable than other metals under extreme conditions. It may also be prone to deformation under high pressure if not properly engineered.

Illustrative image related to air chuck digital

التأثير على التطبيق: Aluminum is compatible with air and nitrogen, making it suitable for most tire inflation applications. However, care must be taken to ensure that it can withstand the specific environmental conditions of the target market.

اعتبارات للمشترين الدوليين: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and ISO, which may affect material selection and performance expectations.

Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and mechanical properties. It typically has a temperature rating of up to 200°C and can handle pressures up to 300 PSI.

Illustrative image related to air chuck digital

الإيجابيات: Brass offers superior durability and resistance to corrosion, making it ideal for environments where moisture or chemicals are present. Its machinability allows for intricate designs and precise fittings.

السلبيات: Brass can be more expensive than aluminum, which may impact overall product pricing. Additionally, it is heavier, potentially increasing shipping costs.

التأثير على التطبيق: Brass is highly compatible with various gases and fluids, making it suitable for diverse applications, including automotive and industrial uses.

اعتبارات للمشترين الدوليين: Compliance with local standards is crucial, especially in regions with stringent regulations. Buyers should verify that brass components meet the required certifications.

Illustrative image related to air chuck digital

Stainless steel is renowned for its strength, durability, and corrosion resistance, making it a popular choice for air chuck digital applications. It can withstand temperatures up to 250°C and pressures exceeding 400 PSI.

الإيجابيات: Stainless steel’s robustness ensures long-lasting performance, even in harsh environments. Its resistance to rust and corrosion makes it suitable for use in wet or humid conditions.

السلبيات: The primary drawback of stainless steel is its cost, which is generally higher than aluminum and brass. Additionally, its weight can be a disadvantage for portable applications.

التأثير على التطبيق: Stainless steel is compatible with air, nitrogen, and other gases, making it versatile for various applications. Its durability ensures reliability in demanding conditions.

اعتبارات للمشترين الدوليين: Buyers should be aware of different grades of stainless steel and their respective properties. Compliance with international standards is also essential to ensure product quality.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is increasingly used in air chuck digital manufacturing due to its lightweight and cost-effective nature. It can typically handle temperatures up to 80°C and pressures around 150 PSI.

الإيجابيات: Plastic is highly resistant to corrosion and chemical damage, making it suitable for various environments. Its lightweight nature reduces shipping costs, and it can be molded into complex shapes easily.

السلبيات: Plastic may not offer the same level of durability as metals, particularly under extreme pressure or temperature conditions. Its lifespan may be shorter compared to metal alternatives.

Illustrative image related to air chuck digital

التأثير على التطبيق: Plastic is best suited for low-pressure applications and environments where weight is a critical factor. However, it may not be ideal for high-performance or heavy-duty uses.

اعتبارات للمشترين الدوليين: Buyers should ensure that the selected plastic meets relevant safety and performance standards, especially in regions with strict regulatory requirements.

| المواد | Typical Use Case for air chuck digital | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | General tire inflation | خفيفة الوزن وفعالة من حيث التكلفة | Less durable under extreme conditions | منخفضة |

| Brass | Automotive and industrial applications | Excellent corrosion resistance | Higher cost and weight | متوسط |

| الفولاذ المقاوم للصدأ | Heavy-duty and harsh environments | قوة ومتانة عالية | Expensive and heavier | عالية |

| بلاستيك | Low-pressure and portable applications | خفيف الوزن ومقاوم للتآكل | Shorter lifespan and lower durability | منخفضة |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance requirements and regional compliance standards.

Illustrative image related to air chuck digital

The manufacturing process and quality assurance protocols for digital air chucks are crucial elements that B2B buyers must understand to make informed purchasing decisions. This section outlines the main stages of manufacturing, key techniques employed, and the quality control measures that ensure the reliability and safety of these products.

The manufacturing process begins with the careful selection of materials. Digital air chucks typically utilize high-quality metals such as stainless steel and aluminum due to their durability, corrosion resistance, and lightweight properties. These materials are often sourced from reputable suppliers who comply with international standards to ensure consistency in quality. Buyers should look for suppliers that provide material certifications to confirm compliance with standards like ISO 9001.

The next stage involves forming the components of the air chuck. This process may include techniques such as machining, casting, and forging. CNC (Computer Numerical Control) machining is commonly used to achieve precise dimensions and tolerances. Advanced techniques like laser cutting and 3D printing may also be employed for intricate designs, particularly in the development of digital displays and electronic components.

Illustrative image related to air chuck digital

Assembly is a critical phase where the individual components are brought together to create the final product. This step often involves both manual and automated processes to ensure efficiency and precision. Key components such as the air chuck body, digital pressure gauge, and electronic circuitry are assembled in controlled environments to prevent contamination and ensure the integrity of the electronic systems.

The finishing stage focuses on enhancing both the functionality and appearance of the air chuck. This may include anodizing for corrosion resistance, polishing for aesthetic appeal, and applying protective coatings. Quality assurance checks are integrated into this stage to ensure that all components meet specified standards before moving to packaging.

B2B buyers must be aware of relevant international standards that govern manufacturing quality. ISO 9001 is a critical standard that outlines the requirements for a quality management system. Compliance with this standard indicates that the manufacturer has established processes for consistent quality, customer satisfaction, and continuous improvement.

In addition to ISO 9001, industry-specific certifications such as CE marking for products sold in Europe or API standards for oil and gas applications may be relevant. These certifications signal compliance with safety and performance regulations, which are particularly important for buyers in sectors requiring rigorous safety standards.

Illustrative image related to air chuck digital

Quality control (QC) is integral throughout the manufacturing process. Key checkpoints include:

مراقبة الجودة الواردة (IQC): This is the first line of defense, where raw materials and components are inspected upon arrival. This step ensures that only materials that meet quality standards proceed to the next stages of production.

مراقبة الجودة أثناء العملية (IPQC): During the manufacturing process, various checks are performed to monitor the production line. This includes dimensional checks, functional tests, and visual inspections to catch defects early.

مراقبة الجودة النهائية (FQC): Once the assembly is complete, the final product undergoes comprehensive testing. This may involve pressure testing, electronic functionality checks, and performance assessments to ensure that the digital air chuck operates as intended.

Testing methods can vary depending on the specific requirements of the air chuck. Common methods include:

Pressure Testing: Evaluates the integrity of the air chuck under various pressure levels to ensure it can withstand operational demands without leaking.

Electrical Testing: Checks the functionality of digital displays and sensors to ensure accurate pressure readings.

اختبار المتانة: Simulates real-world conditions to assess the product’s performance over time, including exposure to environmental factors like temperature and humidity.

B2B buyers should conduct thorough audits of potential suppliers to verify their quality control processes. This can include:

عمليات تدقيق الموردين: On-site inspections can reveal much about a manufacturer’s capabilities and adherence to quality standards. Buyers should inquire about the supplier’s quality management practices, equipment, and workforce training.

Reviewing Quality Reports: Suppliers should provide documentation that outlines their quality control measures, including testing results and compliance with international standards.

Third-party inspections can serve as an impartial verification of a supplier’s quality control processes. These inspections can be particularly valuable for international buyers who may not be able to conduct on-site audits. Engaging a reputable third-party organization to evaluate a supplier’s manufacturing and QC practices can enhance buyer confidence.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific certification requirements in their markets. Different countries may have unique regulatory demands, such as local certifications or additional testing. It is advisable for buyers to familiarize themselves with these requirements to ensure compliance and avoid delays in shipping or customs.

Illustrative image related to air chuck digital

Additionally, language barriers and cultural differences may affect communication regarding quality expectations. Establishing clear communication channels and setting explicit quality benchmarks from the outset can mitigate misunderstandings.

Understanding the manufacturing processes and quality assurance measures for digital air chucks is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and robust quality control practices, buyers can ensure they are partnering with reputable suppliers that meet their standards for quality and reliability. Armed with this knowledge, international buyers can make informed purchasing decisions that align with their business needs and regulatory requirements.

To effectively source air chuck digital products for your business needs, it is essential to follow a structured approach. This guide will provide you with actionable steps to ensure that you procure high-quality digital air chucks that meet your specifications and requirements.

Before beginning your sourcing process, clearly outline the technical requirements for the air chuck digital you need. Consider factors such as pressure range, compatibility with existing equipment, and whether you require features like automatic shut-off or preset pressure settings. A well-defined specification will help you communicate effectively with suppliers and avoid costly misalignments.

Illustrative image related to air chuck digital

Conduct thorough research to identify suppliers that specialize in digital air chucks. Utilize online directories, trade shows, and industry forums to compile a list of potential vendors. Pay attention to their reputation, product offerings, and experience in the market. A diverse list will provide you with options and leverage in negotiations.

It’s crucial to verify that your chosen suppliers adhere to industry standards and regulations. Look for certifications such as ISO 9001 or relevant local certifications that indicate quality assurance. These certifications not only reflect the supplier’s commitment to quality but also ensure compliance with international standards, which is particularly important for international transactions.

Before making a bulk purchase, request samples of the digital air chucks you are considering. This allows you to evaluate the quality and functionality firsthand. Check for essential features such as accuracy, durability, and ease of use. Testing samples can prevent potential issues down the line and ensures that the product meets your expectations.

Once you have narrowed down your options, compare pricing structures and payment terms. Be aware of the total cost of ownership, which includes shipping, duties, and potential after-sales support. Negotiate terms that work for your budget while ensuring the supplier can still deliver on quality and service.

Illustrative image related to air chuck digital

Inquire about the after-sales support offered by the supplier. A reliable supplier should provide warranty information and have a clear process for handling returns or repairs. This is vital for maintaining operational efficiency, especially if the equipment is critical to your business operations.

Building a long-term relationship with your supplier can yield significant benefits, such as better pricing, priority service, and access to new products. After the initial purchase, maintain communication to discuss future needs and opportunities for collaboration. A strong partnership can enhance your supply chain resilience and competitiveness.

By following this checklist, you will be well-prepared to source digital air chucks that not only meet your technical requirements but also align with your business goals.

When sourcing digital air chucks, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

المواد: The choice of materials significantly impacts the price. High-quality metals and plastics enhance durability and functionality but also increase costs. For instance, air chucks made from aluminum may be lighter and more resistant to corrosion compared to those made from lower-grade steel.

العمالة: Labor costs vary by region and depend on the skill level required for assembly and quality control. In countries with higher labor costs, such as parts of Europe, the overall cost of production may increase.

نفقات التصنيع الزائدة: This includes expenses related to utilities, rent, and administrative costs associated with production facilities. Efficient manufacturing processes can help mitigate these costs.

الأدوات: Initial tooling costs can be substantial, particularly for custom designs or high-precision air chucks. This upfront investment often influences pricing, especially for low-volume orders.

مراقبة الجودة (QC): Investing in quality assurance processes ensures that the products meet safety and performance standards, which can also add to the overall cost.

الخدمات اللوجستية: Shipping and handling costs vary based on the origin and destination of the products. Factors such as freight rates and customs duties can significantly impact the final price.

الهامش: Suppliers typically include a profit margin that reflects their operational risks and market positioning. This margin can fluctuate based on competition and demand.

Several factors can influence the pricing of digital air chucks, including:

الحجم/معدل العرض/الطلب: Minimum order quantities (MOQs) often dictate the price per unit. Larger orders typically result in lower costs due to economies of scale.

المواصفات والتخصيص: Customized products that meet specific buyer requirements can incur additional costs. Standardized models are generally more cost-effective.

المواد وشهادات الجودة: Products that meet international quality standards (ISO, CE) may command higher prices. Buyers should weigh the importance of certifications against their budget constraints.

عوامل الموردين: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge premium prices due to their proven track record and customer service.

المصطلحات التجارية الدولية: Understanding the chosen Incoterms (e.g., FOB, CIF) is critical, as they define the responsibilities of buyers and sellers regarding shipping costs and risks, which can affect overall pricing.

B2B buyers can employ several strategies to enhance cost-efficiency:

التفاوض: Engage suppliers in discussions about pricing, especially for bulk orders. Many suppliers may offer discounts or flexible payment terms to secure larger contracts.

التكلفة الإجمالية للملكية (TCO): Assess the TCO rather than just the initial purchase price. Consider factors like maintenance, energy efficiency, and longevity of the air chuck, which can lead to long-term savings.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and potential tariffs that may affect the final cost. Building strong relationships with local suppliers can also reduce logistics costs and lead times.

Research and Compare Suppliers: Conduct thorough market research to compare prices, quality, and service levels among different suppliers. Leverage online platforms and trade shows to gather information.

Sourcing digital air chucks requires a keen understanding of various cost components and pricing influencers. By strategically negotiating and considering the total cost of ownership, B2B buyers can make informed decisions that align with their budget and operational needs. Always be aware that indicative prices can vary based on the aforementioned factors, and it is prudent to seek quotations tailored to specific requirements.

Illustrative image related to air chuck digital

In today’s competitive market, B2B buyers must evaluate various tools to optimize tire inflation and maintenance processes. The ‘air chuck digital’ is an innovative solution that enhances efficiency and accuracy, but it’s essential to consider alternatives that might better fit specific operational needs. This analysis presents a comparison between the air chuck digital and two viable alternatives: traditional manual tire inflators and advanced pre-set digital tire inflator gauges.

| جانب المقارنة | Air Chuck Digital | Traditional Manual Tire Inflator | Pre-Set Digital Tire Inflator Gauge |

|---|---|---|---|

| الأداء | High accuracy, real-time digital readouts | Varies, relies on user skill | High accuracy, auto shut-off feature |

| التكلفة | Moderate price range (approx. $40 – $100) | Low cost (approx. $20 – $50) | Higher cost (approx. $300) |

| سهولة التنفيذ | Simple connection to air compressor | Basic operation, requires manual effort | User-friendly, minimal training needed |

| الصيانة | Low maintenance, durable materials | Moderate, depends on usage | Low, built to withstand rough use |

| أفضل حالة استخدام | Professional garages, high-volume operations | Home use, occasional tire checks | Workshops requiring precision and speed |

1. Traditional Manual Tire Inflators

Traditional manual tire inflators are a cost-effective solution for basic tire inflation needs. These devices are often less expensive and straightforward, making them accessible for casual users. However, they require manual effort and skill to achieve accurate pressure readings, which can lead to inconsistent results. For businesses with low tire maintenance demands, this option can suffice, but it lacks the precision and efficiency necessary for high-volume operations.

2. Pre-Set Digital Tire Inflator Gauges

Pre-set digital tire inflator gauges represent a significant advancement in tire maintenance technology. These devices allow users to set desired pressure levels, automatically shutting off once the target is reached. This feature not only saves time but also minimizes the risk of over-inflation, which can damage tires. While they come at a higher price point, their accuracy and ease of use make them ideal for professional settings where tire safety is paramount. The included air chuck design enhances convenience, allowing for hands-free operation.

When selecting the best tire inflation solution, B2B buyers should consider their specific operational requirements and budget constraints. The air chuck digital offers a robust balance of performance and cost-effectiveness for many professional applications. However, businesses that prioritize low initial investment may find traditional manual inflators adequate for infrequent use. Conversely, organizations that demand high precision and efficiency will benefit from investing in pre-set digital inflator gauges, despite the higher upfront cost. Ultimately, understanding the unique needs of your operations will guide you to the most suitable tire inflation solution.

Digital air chucks are essential tools in tire maintenance and inflation, offering precision and efficiency. Understanding their technical properties can significantly impact purchasing decisions for B2B buyers. Here are some critical specifications to consider:

Illustrative image related to air chuck digital

The pressure range typically indicates the minimum and maximum pressure the air chuck can handle, usually measured in PSI (pounds per square inch). Common ranges include 0-100 PSI or 0-200 PSI. For B2B buyers, selecting an air chuck with an appropriate pressure range is vital to ensure compatibility with various vehicle types, from passenger cars to heavy-duty trucks.

Accuracy, often expressed as a percentage (e.g., ±1 PSI), refers to the precision of the air chuck’s pressure readings. High accuracy is crucial for preventing under-inflation or over-inflation, which can lead to safety issues and premature tire wear. For businesses, this means fewer maintenance costs and improved vehicle performance.

The material used in the construction of digital air chucks can vary, with options including brass, stainless steel, and high-grade plastics. Durable materials enhance longevity and resistance to wear and tear, making them suitable for high-volume environments like workshops and garages. For B2B buyers, investing in robust materials can reduce replacement frequency and overall costs.

Different air chucks feature various connection types, such as 1/4″ NPT (National Pipe Thread) or other fittings. Understanding the connection type is essential for ensuring compatibility with existing air compressor systems. This compatibility minimizes installation costs and avoids downtime, which is particularly important for businesses operating in industries where efficiency is paramount.

Many digital air chucks come with advanced display features, including backlit screens and multiple measurement units (e.g., PSI, BAR, KPA). These features enhance usability, particularly in low-light conditions or when quick readings are required. For B2B buyers, selecting models with user-friendly displays can streamline operations and improve productivity in busy environments.

Illustrative image related to air chuck digital

A locking mechanism is a critical feature that allows the air chuck to securely attach to the tire valve without the need for manual holding. This hands-free operation not only saves time but also enhances safety by allowing users to stand back during inflation. For businesses, this feature can lead to increased efficiency and reduced risk of accidents.

Familiarizing oneself with industry jargon can facilitate smoother transactions and clearer communication. Here are essential terms related to digital air chucks:

OEM refers to companies that produce components that are used in another company’s end product. In the context of air chucks, sourcing from an OEM can ensure high-quality parts that meet specific performance standards, beneficial for businesses looking for reliable equipment.

Illustrative image related to air chuck digital

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and cash flow effectively, especially when ordering specialized equipment like digital air chucks.

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. This process is essential for B2B buyers to ensure competitive pricing and evaluate different suppliers before making purchasing decisions.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Familiarity with these terms can help B2B buyers understand shipping responsibilities, insurance, and risk, ultimately facilitating smoother international transactions.

Lead time refers to the period between placing an order and receiving it. Understanding lead times is essential for B2B buyers to plan operations and avoid disruptions in service, particularly in industries reliant on timely maintenance.

Calibration is the process of adjusting the air chuck to ensure accurate pressure readings. Regular calibration is crucial for maintaining performance standards and safety. B2B buyers should consider the calibration capabilities of the equipment they purchase to ensure long-term reliability.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and safety in their tire maintenance processes.

The digital air chuck market is witnessing significant growth driven by several global factors. Increasing vehicle ownership, particularly in emerging markets across Africa, South America, and the Middle East, is fueling demand for reliable tire inflation solutions. Technological advancements, such as the integration of digital pressure gauges and automatic shut-off features, are becoming essential selling points, enhancing the user experience and safety. Additionally, the rise of e-commerce platforms has transformed sourcing practices, allowing international B2B buyers to access a broader range of products and suppliers with ease.

Emerging trends highlight a shift towards more advanced inflator technologies, such as portable and battery-operated models that cater to both consumer and commercial sectors. The demand for multi-functional devices, which combine tire inflation with other capabilities like pressure monitoring, is on the rise. Furthermore, the growing focus on precision and efficiency in tire maintenance is reshaping buyer preferences, leading to increased interest in high-quality, durable products that offer better long-term value.

Illustrative image related to air chuck digital

For international buyers, understanding regional market dynamics is crucial. In Africa and South America, for instance, local sourcing strategies are increasingly important due to logistical challenges and fluctuating currency values. Buyers from these regions may benefit from partnerships with suppliers who offer tailored solutions that address local needs, such as robust, all-terrain inflators. In Europe and the Middle East, regulatory compliance and certifications are more prominent, necessitating a focus on quality assurance and adherence to safety standards.

Sustainability has emerged as a key concern in the B2B landscape, influencing sourcing decisions across various sectors, including the air chuck digital market. The environmental impact of manufacturing processes, particularly in terms of waste generation and carbon emissions, is prompting buyers to seek suppliers committed to sustainable practices. This trend is particularly relevant for international buyers who are increasingly scrutinizing supply chains for ethical sourcing and environmental stewardship.

The importance of ethical supply chains cannot be overstated. Buyers are now prioritizing partnerships with manufacturers that demonstrate transparency in their sourcing and production methods. This includes a focus on materials that are recyclable or made from sustainable sources. Additionally, certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential indicators of a supplier’s commitment to sustainability.

In the digital air chuck sector, innovations in product design are also contributing to environmental efforts. For instance, manufacturers are exploring the use of eco-friendly materials and energy-efficient production techniques. As buyers become more aware of their environmental footprint, they are likely to favor products that not only meet performance standards but also align with their values regarding sustainability.

The evolution of digital air chucks can be traced back to the need for precision in tire maintenance. Traditionally, manual air chucks were prone to inaccuracies and required constant monitoring, leading to potential safety hazards and inefficiencies. The introduction of digital technology revolutionized this sector by providing real-time pressure readings and automated inflation capabilities.

Over the years, advancements in sensor technology and digital displays have led to the development of more sophisticated inflators that cater to a wide range of vehicles, including passenger cars, trucks, and heavy equipment. The integration of features such as preset pressure settings and audible alerts has further enhanced user convenience and safety, making digital air chucks an essential tool for both professional technicians and everyday consumers.

Today, as the market continues to evolve, the focus is shifting towards creating multifunctional devices that not only inflate tires but also monitor pressure and provide diagnostic information. This evolution reflects a broader trend in the automotive industry towards smart technology and integrated solutions, positioning digital air chucks as critical components in modern vehicle maintenance practices.

1. How do I choose the right digital air chuck for my needs?

Selecting the right digital air chuck involves evaluating your specific requirements. Consider the types of vehicles or machinery you will be servicing, as different models may accommodate various pressure ranges and connections. Assess features like accuracy, ease of use, and durability, especially if used in harsh environments. Additionally, look for options with hands-free operation and auto shut-off to enhance safety and efficiency during tire inflation. Consulting with suppliers for recommendations based on your operational needs can also be beneficial.

Illustrative image related to air chuck digital

2. What features should I look for in a digital air chuck?

Key features to consider when purchasing a digital air chuck include accuracy (ideally ±1 PSI), a large and easy-to-read display, and the ability to switch between pressure measurement units (e.g., PSI, BAR). Look for models with automatic shut-off to prevent over-inflation and those that offer a locking mechanism for hands-free operation. Durability is crucial, so opt for a chuck made from robust materials that can withstand frequent use. Battery life is also important if choosing a rechargeable model; ensure it can operate for extended periods without needing a recharge.

3. What are the common payment terms for international B2B transactions?

Payment terms can vary widely among suppliers, but common practices include upfront payment, partial payment before shipment, or net payment terms (e.g., Net 30, Net 60). For international transactions, options like Letters of Credit (LC) or escrow services can provide added security for both parties. It’s essential to clarify payment methods accepted (such as bank transfer, PayPal, or credit cards) and any additional fees associated with currency conversion. Always negotiate terms that are favorable and ensure they are documented in the purchase agreement.

4. What is the typical minimum order quantity (MOQ) for digital air chucks?

Minimum order quantities (MOQ) for digital air chucks can range from as low as 10 units to several hundred, depending on the manufacturer and the specific product. Larger manufacturers may have higher MOQs due to production costs, while smaller or specialized suppliers might offer more flexibility. It’s advisable to discuss your needs with potential suppliers to find a balance between your inventory requirements and their MOQ policies. Some suppliers may also provide sample orders to help you assess product quality before committing to larger quantities.

5. How can I ensure quality assurance for digital air chucks?

To ensure quality assurance, request certifications and quality control documents from the supplier, such as ISO certification or product testing reports. Establish clear quality standards before placing an order and communicate these expectations with the supplier. Consider implementing a third-party inspection service to assess the products before shipment, particularly if sourcing from international suppliers. Additionally, inquire about the warranty and return policies, which can provide further assurance regarding the product’s reliability and performance.

6. What logistics considerations should I keep in mind when sourcing digital air chucks?

Logistics play a critical role in international sourcing. Consider shipping options, transit times, and costs associated with freight forwarding, customs clearance, and insurance. Ensure that the supplier can provide the necessary documentation for smooth customs processing, including invoices and certificates of origin. Evaluate the reliability of the supplier’s shipping partners and their experience in handling international shipments. Additionally, consider potential tariffs and taxes that may apply to your order, which could affect overall costs.

7. How do I vet suppliers for digital air chucks effectively?

Effective supplier vetting involves researching the supplier’s reputation, experience, and product quality. Start by checking online reviews and ratings, and ask for references from other clients. Conduct a factory visit if possible, or request a virtual tour to assess their manufacturing capabilities. Verify their certifications and compliance with international standards. It’s also wise to compare multiple suppliers to gauge pricing, terms, and customer service levels. Establishing a strong communication line can also help in assessing their responsiveness and reliability.

8. Can digital air chucks be customized for specific applications?

Yes, many manufacturers offer customization options for digital air chucks to meet specific application requirements. This can include modifications in size, pressure ranges, connection types, and additional features such as integrated gauges or preset functions. When considering customization, communicate your specifications clearly to the supplier and inquire about any additional costs or minimum order requirements associated with custom products. Custom solutions can enhance efficiency and effectiveness, ensuring the tool meets the unique demands of your operations.

المجال: jacosuperiorproducts.com

مسجل: 2014 (11 سنة)

مقدمة: FlowPro® Digital Tire Inflator with Pressure Gauge – 200 PSI: $39.95 (originally $89.99), rated “Best Inline Tire Pressure Gauge” by Car and Driver Magazine. FlowPro® Tire Inflator with Pressure Gauge – 100 PSI: $35.95 (originally $79.99). FlowPro® 2.0 Digital Tire Inflator with Pressure Gauge – 200 PSI: $39.95 (originally $89.99), features patented Lightning® Air Chuck. FlowPro® Digital Tire Infl…

المجال: zeeline.com

مسجل: 1999 (26 سنة)

مقدمة: Heavy Duty Digital Tire Inflator and Air Pressure Gauge, Clip-On Chuck, 1/4″ NPT, 20″ Rubber Hose, 0-255 PSI

المجال: steckmfg.com

مسجل: 1998 (27 سنة)

مقدمة: {“product_name”: “Precision Digital Tire Inflator Pressure Gauge”, “pressure_range”: “0-160 psi”, “accuracy”: “0.25 psi”, “model”: “S-581E”}

المجال: locknlube.com

مسجل: 2013 (12 سنة)

مقدمة: Pre-Set Digital Tire Inflator Gauge – SKU: LNL65302-KIT – Price: $299.99 (Regular price: $399.99) – Includes LockNFlate® Air Chuck – Inflation Range: 7-174 PSI (0.5-12 BAR / 50-1200 kPa / 0.5-12 kgf) – Accuracy: ±1 PSI (±0.08 BAR) – Gauge Type: Digital – Inlet/Outlet: 1/4″ – Battery: 12V DC rechargeable lithium-ion – Continuous Working Time: 10-15 hours – Auto Shut Off: After 90 seconds – Working …

المجال: mactools.com

مسجل: 1997 (28 سنة)

مقدمة: This company, MacTools – Digital Tire Gauge & Air Chuck, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

المجال: matcotools.com

مسجل: 1996 (29 سنة)

مقدمة: This company, Matco Tools – Rechargeable Digital Tire Inflator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In conclusion, the strategic sourcing of digital air chucks is a pivotal decision for businesses focused on enhancing operational efficiency and ensuring tire safety. With advancements in technology, products like the FlowPro® and LockNLube® inflators not only deliver precision and speed but also reduce the risk of over-inflation, thereby minimizing maintenance costs and downtime. For international buyers from Africa, South America, the Middle East, and Europe, investing in high-quality digital air inflators translates into long-term savings and increased customer satisfaction.

Strategic sourcing involves more than just procurement; it encompasses understanding market trends, evaluating supplier capabilities, and aligning product features with your specific needs. By leveraging these insights, businesses can secure reliable partnerships that foster innovation and adaptability in a competitive landscape.

As the demand for efficient tire management solutions continues to grow, now is the opportune moment to explore the latest offerings in digital air chucks. Equip your operations with cutting-edge technology that not only meets but exceeds industry standards. Engage with suppliers who prioritize quality and innovation, and position your business for success in the evolving marketplace.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.