- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In today’s fast-paced global market, sourcing effective solutions like air in a can for tires presents a unique challenge for international B2B buyers. As tire maintenance becomes increasingly critical to operational efficiency and safety, understanding the diverse range of products available—from emergency tire inflators to specialized seasonal air formulations—is essential. This guide offers a comprehensive exploration of the air in a can market, detailing various product types, their applications across different vehicle categories, and considerations for supplier vetting and cost analysis.

For businesses operating in regions such as Africa, South America, the Middle East, and Europe, the decision-making process can be complex. Factors such as local regulations, environmental standards, and logistical considerations significantly influence purchasing decisions. By equipping buyers with actionable insights into product specifications, market trends, and best practices for sourcing, this guide aims to empower businesses to make informed choices that enhance their operational reliability and customer satisfaction.

Whether you are a fleet manager seeking rapid solutions for tire emergencies or a retailer looking to expand your inventory, understanding the nuances of air in a can will position you to meet market demands effectively. Join us as we navigate the global landscape of tire inflation solutions, ensuring your business remains competitive and well-prepared for any challenge on the road.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Emergency Tire Sealant | Quick application, seals punctures up to 1/4″, eco-friendly | Automotive repair shops, fleets | الإيجابيات: Fast and easy to use; السلبيات: Temporary fix, requires follow-up repair. |

| Seasonal Tire Inflator | Formulated for temperature variations (e.g., summer air) | Tire retailers, automotive service | الإيجابيات: Optimizes pressure management; السلبيات: Limited to specific seasons. |

| CO2 Inflator Kits | Compact, battery-free operation with CO2 cartridges | Off-road vehicle supply, outdoor sports | الإيجابيات: Portable and efficient; السلبيات: Limited inflation capacity per cartridge. |

| Standard Air in a Can | Basic inflation for standard tires, simple aerosol format | General automotive retailers | الإيجابيات: Widely available and easy to use; السلبيات: May not seal punctures effectively. |

| Specialty Tire Inflation Solutions | Tailored formulations for specific vehicle types (e.g., heavy-duty) | Commercial vehicle fleets | الإيجابيات: Designed for high-performance needs; السلبيات: Higher cost and specific application. |

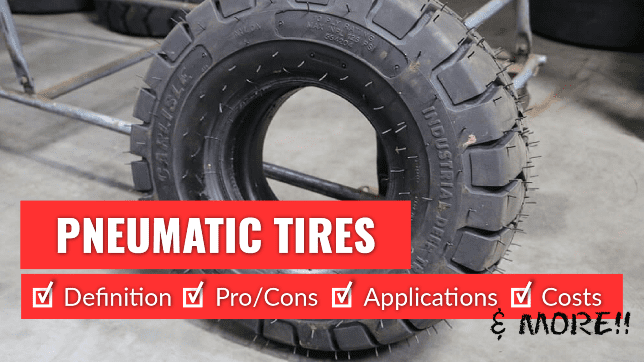

Emergency tire sealants are designed for rapid application during roadside emergencies. They can seal punctures up to 1/4 inch in diameter and are typically eco-friendly, making them a safe choice for users. B2B buyers should consider the product’s ease of use, as many sealants require no tools or jacks for application. These products are ideal for automotive repair shops and fleet operators who need to provide quick solutions to customers.

Seasonal tire inflators are formulated to address the challenges posed by temperature fluctuations, particularly in summer. They help maintain optimal tire pressure, preventing over-inflation due to heat expansion. This type of product is particularly relevant for tire retailers and automotive service centers that cater to customers in regions with significant seasonal temperature changes. Buyers should evaluate the product’s compatibility with various tire types and its environmental impact.

CO2 inflator kits are compact and easy to use, making them an excellent choice for off-road enthusiasts and outdoor sports applications. These kits come with CO2 cartridges that can inflate tires quickly without the need for electricity or batteries. B2B buyers in the outdoor equipment market will appreciate the portability and efficiency of these kits. However, they should be aware of the limited inflation capacity and ensure that the cartridges are suitable for their specific tire sizes.

Standard air in a can is the most basic option for tire inflation, typically available in aerosol format. It is widely accessible and suitable for general automotive retailers. While it provides a straightforward solution for tire inflation, its effectiveness in sealing punctures is limited compared to sealants. Buyers should consider the trade-off between convenience and performance when selecting this type of product.

Specialty tire inflation solutions are tailored for specific vehicle types, including heavy-duty trucks and performance vehicles. These formulations are designed to meet the high demands of commercial vehicle fleets. B2B buyers in this sector should assess the unique requirements of their vehicles and the potential return on investment when opting for these specialized solutions. While they may come at a higher price point, the performance benefits can justify the cost.

| الصناعة/القطاع | Specific Application of air in a can for tires | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Emergency tire inflation for workshops | Reduces downtime for customers, enhancing service speed | Quality assurance, eco-friendly formulations, pricing |

| النقل والخدمات اللوجستية | On-road tire maintenance for fleets | Minimizes vehicle downtime, ensuring operational efficiency | Bulk purchasing options, compatibility with various tire types |

| Construction | Tire inflation for heavy machinery and equipment | Ensures equipment reliability, reducing project delays | Can size options, temperature range suitability |

| الاستجمام في الهواء الطلق | Tire inflation for off-road vehicles | Enhances safety and performance during outdoor activities | Portable solutions, ease of use, environmental impact |

| Retail & Distribution | Consumer sales of tire inflators in automotive shops | Increases customer satisfaction and repeat business | Branding, marketing support, product availability |

In automotive repair, air in a can serves as a quick solution for tire inflation during emergencies. Repair shops utilize these products to provide immediate assistance to customers with flat tires, significantly reducing their wait time. The ability to seal punctures and inflate tires without the need for tools or jacks enhances service efficiency. For international buyers, sourcing eco-friendly and safe formulations is crucial to comply with local regulations and to appeal to environmentally conscious consumers.

In the transportation and logistics sector, fleets often encounter tire-related issues that can lead to costly downtime. Air in a can allows for rapid tire inflation on the road, ensuring that vehicles remain operational and deliveries are not delayed. This is particularly beneficial in regions with challenging terrains or where access to repair services is limited. Buyers should consider the compatibility of the product with various tire types and the availability of bulk purchasing options to optimize their supply chain.

Construction sites heavily rely on heavy machinery that requires consistent tire maintenance. Air in a can is essential for quickly inflating tires on construction equipment, ensuring that operations run smoothly without unnecessary interruptions. This product not only improves equipment reliability but also helps in adhering to project timelines. Buyers in this sector should focus on can size options and the product’s suitability for various temperature ranges to ensure performance under different environmental conditions.

Outdoor enthusiasts, particularly those using off-road vehicles, benefit from having air in a can readily available for tire inflation. This product enhances safety and performance by allowing users to quickly inflate tires on the go, which is critical in remote areas. Sourcing portable and user-friendly solutions is vital for this market, alongside considerations for environmental impact, as many consumers prioritize eco-friendly products for recreational use.

Retailers in the automotive sector can enhance customer satisfaction by offering air in a can as a convenient solution for tire maintenance. This product not only meets consumer needs but also encourages repeat business. For B2B buyers, considerations should include branding opportunities, marketing support, and the availability of stock to ensure that they can meet consumer demand effectively.

المشكلة

B2B buyers often struggle with maintaining an adequate inventory of tire inflators. In regions with fluctuating demand, such as Africa and South America, seasonal variations and local economic conditions can lead to overstocking or stockouts. This unpredictability can result in lost sales opportunities or increased holding costs, ultimately impacting profitability. Buyers may also face challenges in sourcing reliable suppliers who can provide consistent quality and timely deliveries, complicating inventory management further.

الحل:

To effectively manage inventory, B2B buyers should implement a data-driven approach to forecast demand. Utilizing historical sales data and market trends can help identify peak seasons for tire inflator sales. Establishing relationships with multiple suppliers can also mitigate risks associated with stockouts. Consider using a just-in-time (JIT) inventory system that allows for more flexible purchasing based on real-time demand signals. Additionally, suppliers should provide clear lead times and stock availability updates to assist in planning. Setting up automated reordering processes when stock levels fall below a certain threshold can streamline operations and ensure that you always have sufficient stock on hand.

Illustrative image related to air in a can for tires

المشكلة

In markets across Europe and the Middle East, compliance with safety and environmental regulations is critical. Buyers face the challenge of ensuring that air in a can products meet these stringent standards. Non-compliance can lead to costly penalties, product recalls, and damage to brand reputation. Furthermore, varying regulations across different countries can complicate the sourcing process, making it essential for buyers to stay informed about local laws and standards.

الحل:

B2B buyers should conduct thorough due diligence on potential suppliers by requesting documentation that proves compliance with relevant regulations. This includes safety data sheets (SDS), certifications for eco-friendliness, and any other relevant compliance information. Engaging in regular audits of suppliers can also ensure that they adhere to required standards. It is advisable to work with suppliers who are familiar with the regulatory landscape of your target markets and who can provide ongoing support in navigating compliance issues. Additionally, investing in training for your team about regulatory requirements can enhance your ability to manage these challenges effectively.

المشكلة

B2B buyers must consider the performance of air in a can products under varying environmental conditions, particularly in regions that experience extreme temperatures, such as the Middle East and parts of Africa. Products that work well in moderate conditions may fail in extreme heat or cold, leading to customer dissatisfaction and returns. This variability can create concerns over the reliability of the product, especially for businesses that depend on a dependable supply for customer satisfaction.

الحل:

To address this issue, buyers should prioritize sourcing products that are specifically formulated to withstand extreme temperatures. Look for tire inflators that have been tested and certified for performance in both high and low-temperature ranges. This information should be readily available from reputable manufacturers. Additionally, conducting field tests in your target market can help assess the performance of these products under real-world conditions. Collaborating with manufacturers to develop customized solutions that cater to the specific needs of your market can also enhance product reliability and customer satisfaction. Offering clear guidelines on how to properly use these products in extreme conditions can further reduce the likelihood of performance issues.

When selecting materials for air in a can for tires, it’s essential to consider properties that affect performance, durability, and compatibility with various applications. Here, we analyze four common materials used in the production of tire inflators and their implications for international B2B buyers.

Illustrative image related to air in a can for tires

Compressed Air

– الخصائص الرئيسية: Compressed air is a mixture of gases, primarily nitrogen (N2), oxygen (O2), and trace gases. It typically operates effectively within a temperature range of -20°C to 50°C and can handle pressures up to 100 psi.

– الإيجابيات والسلبيات: Compressed air is cost-effective and widely available, making it a popular choice for tire inflation. However, it is susceptible to moisture, which can lead to corrosion within the tire. The manufacturing process is relatively straightforward, but quality control is essential to ensure moisture is minimized.

– التأثير على التطبيق: While suitable for standard passenger tires, it may not be ideal for high-performance or off-road vehicles that demand more specialized inflation solutions.

– اعتبارات للمشترين الدوليين: Compliance with local regulations regarding emissions and safety standards is crucial. Buyers from regions like Europe may prefer products that meet DIN standards for environmental safety.

Nitrogen Gas

– الخصائص الرئيسية: Nitrogen is inert, non-flammable, and has a lower permeability than air, which helps maintain tire pressure longer. It operates effectively in a temperature range of -40°C to 70°C.

– الإيجابيات والسلبيات: The primary advantage of nitrogen is its ability to reduce oxidation and moisture within the tire, leading to longer tire life and improved fuel efficiency. However, nitrogen inflation systems can be more expensive to set up, and sourcing nitrogen may be less straightforward in some regions.

– التأثير على التطبيق: Ideal for high-performance vehicles and aircraft, nitrogen is increasingly being adopted in commercial fleets, particularly in Europe and North America.

– اعتبارات للمشترين الدوليين: Buyers should assess the availability of nitrogen inflation services in their region and consider the potential for increased operational costs.

CO2 Gas

– الخصائص الرئيسية: Carbon dioxide is a versatile gas with a temperature range of -78°C to 30°C and can handle moderate pressures (up to 60 psi). It is often used in portable tire inflators.

– الإيجابيات والسلبيات: CO2 is compact and easy to store in canisters, making it convenient for emergency tire inflation. However, it can lead to a rapid loss of pressure due to its higher permeability compared to nitrogen.

– التأثير على التطبيق: CO2 is suitable for temporary fixes and emergency situations, particularly for off-road and recreational vehicles.

– اعتبارات للمشترين الدوليين: Compliance with safety regulations regarding the use and storage of CO2 canisters is essential, especially in regions with stringent environmental laws.

Aerosol Propellants

– الخصائص الرئيسية: Commonly used as propellants in tire inflators, aerosol propellants can include hydrocarbons or compressed gases. They typically function effectively within a temperature range of -10°C to 50°C.

– الإيجابيات والسلبيات: Aerosol propellants allow for easy application and portability. However, they may pose environmental risks if not managed correctly, leading to stricter regulations in various markets.

– التأثير على التطبيق: Suitable for quick, on-the-go repairs, aerosol propellants are widely used in consumer products but may face regulatory scrutiny in certain regions.

– اعتبارات للمشترين الدوليين: Buyers must ensure compliance with local environmental regulations, particularly in Europe, where REACH and CLP regulations apply.

| المواد | Typical Use Case for air in a can for tires | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| Compressed Air | Standard passenger tires | Cost-effective and widely available | Susceptible to moisture and corrosion | منخفضة |

| Nitrogen Gas | High-performance and aircraft tires | Reduces oxidation, maintains pressure longer | Higher setup costs, sourcing challenges | ميد |

| CO2 Gas | Emergency inflators for off-road vehicles | Compact and portable | Rapid pressure loss | ميد |

| Aerosol Propellants | Quick repairs in consumer products | Easy application and portability | Environmental risks | منخفضة |

This strategic material selection guide provides insights into the various materials used in air in a can for tires, helping B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

The manufacturing of air in a can for tires involves several critical stages, ensuring that the final product meets both performance and safety standards. The key stages include material preparation, forming, assembly, and finishing.

The primary materials utilized in the production of tire inflators typically include propellants, sealing agents, and the aerosol can itself. Propellants are often blends of gases like Nitrogen (N2), Oxygen (O2), and Carbon Dioxide (CO2). The selection of eco-friendly materials is becoming increasingly important due to regulatory pressures and consumer preferences. Quality suppliers ensure that all materials meet international safety and environmental standards.

The forming stage involves creating the aerosol can from metal or plastic materials. This process often employs techniques such as stamping and welding to ensure the can is airtight and can withstand high pressures. The assembly stage involves filling the can with the prepared air mixture and sealing it securely. Manufacturers must adhere to strict safety protocols to prevent leaks and ensure the can withstands operational pressures.

Finishing processes may include labeling, painting, and packaging. These processes are crucial for both branding and compliance with regulatory requirements. The cans must be labeled with usage instructions, safety warnings, and compliance marks (like CE or ISO certifications). Quality control during this phase ensures that all products are visually appealing and correctly labeled.

Illustrative image related to air in a can for tires

Quality assurance in the manufacturing of air in a can is vital to ensure that products are safe, effective, and compliant with various international standards. Implementing a robust quality control (QC) system can help B2B buyers mitigate risks associated with product failures.

Manufacturers of air in a can typically adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) standards are also relevant. B2B buyers should verify that their suppliers possess these certifications to ensure product reliability and safety.

Quality control checkpoints are critical for maintaining product integrity. Common checkpoints include:

Illustrative image related to air in a can for tires

These checkpoints help identify issues early in the manufacturing process, reducing the likelihood of defective products reaching the market.

Manufacturers employ various testing methods to validate the performance and safety of air in a can for tires. Common testing methods include:

B2B buyers should request detailed testing reports from suppliers to confirm that these tests have been conducted and passed.

To ensure their suppliers are adhering to the necessary quality control measures, B2B buyers can take several steps:

Buyers should conduct regular audits of their suppliers’ manufacturing facilities. These audits can help verify compliance with international standards and the effectiveness of the QC processes in place. Additionally, requesting quality assurance reports and certifications can provide insights into the supplier’s quality management practices.

Engaging third-party inspection services can further validate the quality of the products. These organizations provide unbiased assessments of the manufacturing processes and the final products. B2B buyers should consider using third-party inspections, especially when dealing with suppliers from regions where regulatory oversight may be less stringent.

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and certifications is crucial. Different countries may have varying requirements for product safety and environmental impact.

Buyers should familiarize themselves with the local regulatory landscape of the regions they are purchasing from. This includes understanding the certifications required in their home country and ensuring that their suppliers can provide products that meet these standards. For example, while CE marking is critical in Europe, other regions may require different certifications.

Illustrative image related to air in a can for tires

By maintaining a thorough understanding of the manufacturing processes, quality control measures, and regulatory nuances, B2B buyers can make informed decisions when sourcing air in a can for tires, ultimately ensuring product reliability and customer satisfaction.

In the competitive landscape of tire maintenance products, sourcing ‘air in a can’ for tires requires a strategic approach to ensure quality, compliance, and value. This guide provides a practical checklist for B2B buyers looking to procure these essential products effectively.

Understanding the specific requirements of your target market is crucial. Different regions may have varying preferences based on climate, vehicle types, and consumer behavior. Research local regulations and market demands to tailor your offerings, ensuring that your product aligns with the expectations of buyers in Africa, South America, the Middle East, and Europe.

Illustrative image related to air in a can for tires

Establishing clear technical specifications will help you identify suitable products. Consider factors such as:

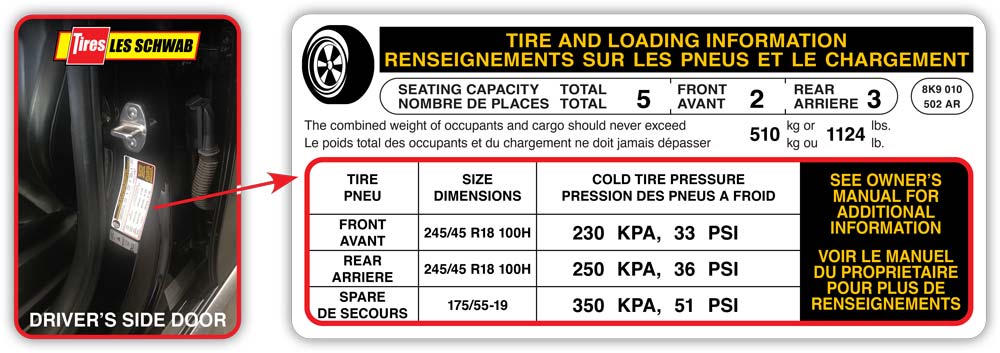

– Can Size and Volume: Determine the appropriate can size based on the typical tire sizes in your market (e.g., sedan, SUV, truck).

– Inflation Pressure Range: Ensure the product can effectively inflate tires to the required pressure levels for various vehicle types.

Before committing to a supplier, thorough vetting is essential. Look for suppliers with a proven track record in the industry. Key considerations include:

– Company Profile and Experience: Investigate their history and experience in manufacturing tire inflators.

– References and Case Studies: Request testimonials from clients in similar industries or regions to gauge reliability and product performance.

Compliance with local and international safety and environmental regulations is paramount. Check for:

– Safety Certifications: Ensure the product meets safety standards, such as those set by the Rubber Manufacturers Association or equivalent organizations.

– Eco-Friendly Formulations: Look for products with eco-friendly certifications, as these are increasingly important to consumers and regulatory bodies.

Pricing will significantly affect your bottom line, so compare quotes from multiple suppliers. Consider:

– Cost-Effectiveness: Analyze the cost per unit against the quality and features offered.

– Payment Flexibility: Negotiate terms that align with your cash flow needs, such as payment schedules or bulk purchase discounts.

Illustrative image related to air in a can for tires

The efficiency of logistics can impact your ability to deliver products on time. Evaluate:

– خيارات الشحن: Understand the shipping methods available and their costs to your target markets.

– المهلة الزمنية: Confirm lead times for production and delivery to ensure you can meet your customers’ demands promptly.

Implementing a quality assurance process is vital for maintaining product standards. Consider:

– Testing Procedures: Ensure that products undergo rigorous testing to verify performance claims.

– Return and Warranty Policies: Establish clear return policies and warranties to build trust with your clients.

By following this checklist, B2B buyers can navigate the sourcing process for ‘air in a can’ for tires with confidence, ensuring they procure high-quality products that meet market demands and regulatory standards.

When sourcing air in a can for tires, understanding the cost structure is essential for B2B buyers. The primary cost components include:

المواد: The formulation of the air mixture itself, which may include various gases such as nitrogen, oxygen, and proprietary additives for performance. Higher-quality materials often lead to better product efficacy but also increase costs.

العمالة: This encompasses the workforce involved in production, from assembly line workers to quality control personnel. Labor costs can vary significantly based on the region, impacting overall pricing.

نفقات التصنيع الزائدة: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help lower these overhead costs, benefiting pricing strategies.

الأدوات: Custom tooling may be required for specific can sizes or features. This is a one-time investment but can significantly affect initial pricing, especially for custom orders.

مراقبة الجودة (QC): Ensuring product safety and effectiveness is crucial, particularly for products used in emergency situations. Robust QC measures may add to the production cost but are essential for maintaining brand reputation.

الخدمات اللوجستية: Transportation costs for raw materials and finished products can vary widely based on geographic location and shipping methods. Efficient logistics can mitigate costs, especially for international shipments.

الهامش: Suppliers typically include a margin that reflects the risk and investment associated with their products. This margin can vary based on market demand and competition.

Several factors influence the pricing of air in a can for tires:

الحجم/معدل العرض/الطلب: Suppliers often provide better pricing for larger order quantities. Understanding Minimum Order Quantities (MOQ) can help buyers negotiate more favorable terms.

المواصفات/التخصيص: Custom formulations or packaging can increase costs. Buyers should evaluate the necessity of these specifications against their budget constraints.

Material Quality/Certifications: Higher-quality materials often come with certifications, which can enhance product reliability but also lead to increased costs. Buyers should balance the need for quality with budgetary limits.

عوامل الموردين: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers may charge a premium due to their reliability and proven track record.

المصطلحات التجارية الدولية: Understanding shipping terms (e.g., FOB, CIF) is crucial for international buyers. These terms can significantly affect the total landed cost of goods.

B2B buyers should consider several strategies when negotiating prices for air in a can for tires:

أسعار سوق الأبحاث: Familiarize yourself with the current market rates and competitor offerings. This knowledge can empower you during negotiations.

Leverage Volume Discounts: If your purchasing strategy allows, consolidate orders to meet or exceed MOQs to secure better pricing.

تقييم التكلفة الإجمالية للملكية (TCO): Consider not just the purchase price but also potential logistics, storage, and disposal costs when assessing offers. A cheaper upfront price may not always result in lower overall costs.

Seek Long-term Partnerships: Establishing a long-term relationship with suppliers can lead to better pricing and priority service, especially in times of high demand.

Be Open to Alternatives: If a supplier’s price is too high, don’t hesitate to explore other vendors or negotiate terms that may lower the overall cost, such as extended payment terms.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, various pricing nuances must be accounted for:

Currency Fluctuations: Exchange rates can impact costs significantly. It’s advisable to lock in prices or negotiate in a stable currency when possible.

Import Duties and Taxes: Be aware of any tariffs or taxes that may apply when importing products, as these can add to the overall cost.

الاختلافات الثقافية: Negotiation styles and expectations can vary by region. Understanding these nuances can facilitate smoother transactions.

الامتثال التنظيمي: Ensure that products meet the regulatory standards of your target market, as non-compliance can lead to additional costs or product recalls.

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and geographic factors. Always verify with suppliers for the most accurate pricing tailored to specific needs.

When considering tire inflation solutions, businesses must evaluate various options to determine the most effective method for their needs. While air in a can is a popular choice for quickly inflating tires, several alternatives offer unique advantages and may be more suitable depending on specific operational contexts. Below, we compare air in a can with two viable alternatives: traditional tire pumps and CO2 inflators.

| جانب المقارنة | Air In A Can For Tires | Traditional Tire Pump | CO2 Inflator |

|---|---|---|---|

| الأداء | Seals and inflates punctures quickly; effective for small holes. | Inflates tires but requires manual effort and time. | Rapid inflation with CO2 cartridges; ideal for quick roadside repairs. |

| التكلفة | Moderate, typically around $15-$20 per can. | Low initial cost, but requires effort; long-term savings on tire repairs. | Moderate cost, around $35 for a complete kit. |

| سهولة التنفيذ | User-friendly; requires no tools. | Requires physical effort and may need an electrical source. | Simple operation; requires no power source, compact design. |

| الصيانة | Minimal; single-use product. | Requires periodic maintenance and checks. | Requires replacement cartridges but minimal upkeep. |

| أفضل حالة استخدام | Emergency situations; quick fix for small punctures. | Regular use for maintaining tire pressure; ideal for workshops. | Off-road or roadside emergencies; compact and portable. |

Traditional tire pumps are a staple in many garages and workshops. They provide a reliable means of inflating tires and can be used repeatedly. The primary advantage is their low cost and the fact that they can be used without any ongoing expenses after the initial purchase. However, they require manual effort and can be cumbersome, especially in emergency situations where time is of the essence. Additionally, some models may require access to a power source, limiting their use in certain environments.

CO2 inflators offer a rapid solution for tire inflation, particularly in off-road or emergency contexts. These devices utilize CO2 cartridges to inflate tires quickly, making them ideal for roadside repairs. They are compact and easy to carry, providing a significant advantage over traditional pumps in terms of portability. However, the ongoing cost of replacing CO2 cartridges can add up, and they may not seal punctures as effectively as air in a can products, which are specifically designed to fill and seal tire leaks.

When selecting a tire inflation solution, B2B buyers should consider their specific operational needs, including the typical conditions under which their vehicles operate. For businesses prioritizing quick emergency responses, air in a can or CO2 inflators may be the best fit. Conversely, companies focused on routine maintenance and cost-effectiveness might find traditional tire pumps to be more advantageous. Ultimately, evaluating performance, cost, ease of implementation, and maintenance will guide buyers in making an informed decision that aligns with their operational requirements and budget constraints.

When considering ‘air in a can’ products for tire inflation, several technical properties play a crucial role in ensuring performance, safety, and compatibility with various tire types. Here are essential specifications that B2B buyers should understand:

Can Size and Capacity

The size of the can, typically ranging from 12 oz to 24 oz, directly impacts its inflation capability. Larger cans can provide more air pressure and volume, making them suitable for larger tires such as those found on SUVs or trucks. Understanding the appropriate can size for specific applications is vital for effective inventory management and customer satisfaction.

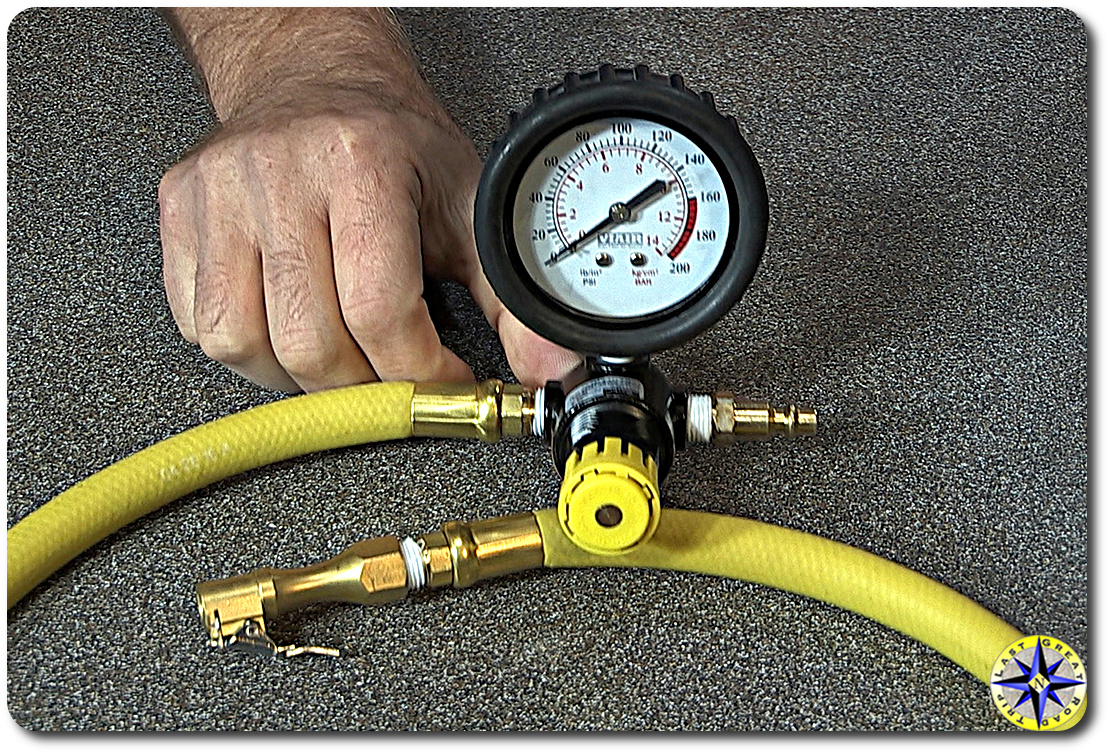

Inflation Pressure

Measured in PSI (pounds per square inch), the inflation pressure indicates how much air the canister can deliver into the tire. For instance, most products provide inflation pressure ranging from 30 to 40 PSI, which is essential for achieving optimal tire performance. B2B buyers must ensure that the inflation pressure meets the requirements of the vehicles their customers use.

Temperature Range

The operating temperature range indicates the conditions under which the product can function effectively. For example, some products are designed to operate between -2°C to 45°C (28.4°F to 113°F). This property is particularly relevant for regions with extreme temperature variations, influencing product selection and inventory management.

Eco-Friendly Formulation

An increasing number of products are now marketed as eco-friendly, using non-toxic and non-corrosive ingredients. This is important not only for regulatory compliance but also for meeting consumer demands for sustainable products. B2B buyers should consider the environmental impact of the products they offer and the growing market trend towards eco-conscious purchasing.

Puncture Sealing Capability

The ability to seal punctures is a critical property, with some products capable of sealing larger punctures (up to 1/4″ in diameter). This feature enhances the product’s value proposition, especially for emergency tire repair solutions. Buyers should understand the sealing effectiveness to position these products appropriately in their market.

Understanding industry-specific terminology is essential for effective communication and negotiation in the B2B landscape. Here are some key terms relevant to air in a can for tires:

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. In the context of air in a can, understanding OEM specifications can help buyers ensure compatibility with existing tire products.

موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for inventory management and cost control. Buyers should negotiate MOQs that align with their sales forecasts and financial goals.

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers to request pricing for specific products. It is an important tool in procurement, allowing buyers to compare costs and terms across different suppliers effectively.

إنكوترمز (الشروط التجارية الدولية)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers navigate logistics and avoid unexpected costs.

CFC-Free

CFC (chlorofluorocarbon)-free products are essential for compliance with environmental regulations. Buyers should seek out CFC-free options to ensure that their products are not only effective but also align with sustainability goals.

Aerosol Technology

This term refers to the mechanism through which the air is dispensed from the can. Understanding aerosol technology can help buyers evaluate product performance and safety standards.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ultimately leading to enhanced customer satisfaction and business growth.

The air in a can for tires market is experiencing notable growth driven by several global factors. Firstly, increasing vehicle ownership in emerging markets, particularly in Africa and South America, is creating a rising demand for convenient tire repair solutions. As urbanization accelerates, the need for quick and efficient roadside assistance products becomes paramount, making air in a can a viable option for both personal and commercial vehicles.

Another significant trend is the integration of technology in sourcing and distribution processes. Suppliers are leveraging e-commerce platforms and digital marketing strategies to reach international B2B buyers more effectively. This shift is particularly evident in Europe and the Middle East, where buyers are increasingly seeking online solutions for purchasing tire maintenance products. Additionally, the adoption of mobile applications for tire monitoring and maintenance has created new opportunities for air in a can products, as consumers look for integrated solutions that enhance vehicle safety and performance.

Market dynamics are also influenced by competitive pricing and innovation. With several players entering the market, businesses must differentiate their offerings through unique selling propositions such as eco-friendly formulations, ease of use, and compatibility with various tire types. For instance, products like Fix-a-Flat and specialized inflators for different tire sizes cater to diverse consumer needs, enhancing their appeal across various markets.

Sustainability has become a cornerstone for businesses in the air in a can for tires sector, driven by increasing consumer awareness and regulatory demands. The environmental impact of traditional tire repair methods and products has prompted companies to innovate, leading to the development of eco-friendly formulations. For example, brands are now offering products that are non-toxic, non-corrosive, and free from harmful chemicals, which not only protect the environment but also ensure consumer safety.

Illustrative image related to air in a can for tires

Ethical sourcing is equally crucial in this sector. International B2B buyers are increasingly prioritizing suppliers that maintain transparent supply chains and adhere to sustainability standards. This includes sourcing raw materials from certified suppliers who follow environmentally responsible practices. Certifications like Green Seal or EcoLabel can serve as important indicators of a product’s environmental impact, allowing buyers to make informed purchasing decisions that align with their corporate social responsibility goals.

Moreover, as sustainability becomes more integrated into purchasing criteria, companies that prioritize green initiatives may find themselves with a competitive edge. By promoting environmentally friendly products and practices, suppliers can attract conscientious buyers, particularly in regions like Europe, where sustainability is a key factor in consumer decision-making.

The concept of air in a can for tires has evolved significantly over the past few decades. Initially introduced as a quick-fix solution for flat tires, these products have transformed from basic inflators into sophisticated, multi-functional tools designed for various tire types and sizes. The early versions primarily focused on sealing small punctures, but advancements in technology have led to the development of formulations that cater to larger punctures and provide longer-lasting solutions.

Illustrative image related to air in a can for tires

Over the years, the market has witnessed the introduction of innovative features, such as eco-friendly formulations and specialized products for different weather conditions, like summer or winter air in a can. This evolution reflects a broader trend in the automotive sector towards convenience, safety, and environmental consciousness. As a result, the air in a can for tires has not only become a staple for individual consumers but also a crucial product for fleet managers and commercial vehicle operators, underscoring its importance in the global automotive maintenance market.

How do I choose the right air in a can product for my tire repair needs?

Selecting the appropriate air in a can product hinges on several factors, including tire type, puncture size, and environmental conditions. For standard passenger vehicles, products like Fix-a-Flat are effective for sealing punctures up to 1/4 inch. If you operate in extreme temperatures, consider specialized formulations like Summer Air in a Can, designed to maintain optimal tire pressure in varying climates. It’s crucial to evaluate the product specifications and compatibility with your tire’s requirements, ensuring you have an effective solution tailored to your needs.

What types of tire inflators are available for B2B buyers?

B2B buyers can access various tire inflators, including aerosol canisters, CO2 cartridge systems, and portable electric inflators. Aerosol products like Fix-a-Flat offer quick, tool-free repairs, while CO2 inflators are compact and ideal for off-road applications. Electric inflators provide sustained air supply but require power sources. When sourcing, consider your target market’s preferences, product reliability, and ease of use to ensure customer satisfaction.

What are the minimum order quantities (MOQ) for air in a can products?

Minimum order quantities for air in a can products can vary significantly by supplier and region. Typically, manufacturers may set MOQs ranging from 500 to 5,000 units, depending on the product type and packaging. It’s advisable to discuss MOQs directly with potential suppliers to negotiate terms that align with your inventory and sales strategy. Consider your market demand and storage capabilities when determining the optimal order size.

What payment terms should I expect when sourcing air in a can products internationally?

Payment terms in international trade for air in a can products can vary widely. Common arrangements include upfront payments, net 30/60/90 days, or letters of credit. Some suppliers may offer discounts for early payments or bulk orders. It’s essential to establish clear payment terms before finalizing any contracts to mitigate risks and ensure smooth transactions. Always verify the supplier’s payment methods and currency preferences to facilitate seamless financial exchanges.

How can I vet suppliers of air in a can products?

Vetting suppliers involves a thorough evaluation of their manufacturing capabilities, certifications, and track record. Check for compliance with international safety and quality standards, such as ISO certifications. Request product samples to assess quality firsthand and read reviews or testimonials from other clients. Additionally, consider conducting a factory audit if feasible, as this can provide insights into the supplier’s operations and reliability.

What quality assurance measures should I consider when sourcing air in a can products?

Quality assurance (QA) measures are critical when sourcing air in a can products to ensure product safety and effectiveness. Look for suppliers who implement rigorous testing protocols for their products, including pressure tests and safety evaluations. Certifications from relevant authorities, like the Rubber Manufacturers Association, can indicate adherence to industry standards. Establish a QA agreement that outlines testing procedures, acceptance criteria, and responsibilities to safeguard your interests.

What logistics considerations should I be aware of when importing air in a can?

Logistics for importing air in a can involve understanding shipping regulations, especially since aerosol products are classified as hazardous materials. Ensure compliance with international shipping laws and carrier requirements to avoid delays. Consider factors like shipping costs, transit times, and customs duties. Partnering with a reliable freight forwarder can streamline the process and help navigate the complexities of international logistics, ensuring timely delivery to your market.

How can I customize air in a can products for my brand?

Customization options for air in a can products often include private labeling, formulation adjustments, and packaging design. Many manufacturers offer branding opportunities that allow you to differentiate your product in the market. Discuss your specific requirements with potential suppliers, including desired can sizes, branding elements, and eco-friendly formulations. Be prepared to meet minimum order requirements for customized products and factor in longer lead times for design and production adjustments.

المجال: petroleumservicecompany.com

مسجل: 2004 (21 سنة)

مقدمة: Product Name: Summer Air in a Can

SKU: 8PRLF00LZ2

Weight: 1.00 LBS

Price: $1.99 (MSRP)

Size: 12 oz can

Description: Aerosol tire inflator formulated to withstand temperature increases during summer months. Contains a pollutant-free additive package. Suitable for cars, trucks, and off-road vehicles. Features a natural fresh air scent and is CFC free.

Key Benefits: Helps maintain proper tire pressu…

المجال: community.cartalk.com

مسجل: 1995 (30 سنة)

مقدمة: Sentry Pack Tire Inflator; purchased 2 years ago; contents are “extremely flammable”; contains propane or butane; suggests inflating and deflating several times in the open before removing from rim; potential tire damage not mentioned on can; may cause issues with tire pressure monitoring systems.

المجال: reddit.com

مسجل: 2005 (20 سنة)

مقدمة: Nitrogen vs Compressed Air for Tires: Nitrogen is often used in racing due to its stability under high temperatures, while compressed air is sufficient for daily driving. Nitrogen can reduce moisture and pressure fluctuations, but many users find the cost and effort to fill tires with nitrogen unnecessary for regular use.

In conclusion, the strategic sourcing of air in a can for tires presents a lucrative opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. As the demand for quick, effective, and eco-friendly tire solutions continues to rise, suppliers who prioritize innovation and sustainability will stand out in the marketplace. Key takeaways include the importance of selecting products that not only meet performance standards but also align with environmental regulations and consumer expectations.

Investing in reliable tire inflators, such as those offering eco-friendly formulations or advanced sealing capabilities, will enhance customer satisfaction and operational efficiency. Moreover, understanding regional market dynamics—such as temperature fluctuations that affect tire pressure—can inform product selection and marketing strategies.

Illustrative image related to air in a can for tires

As the global automotive landscape evolves, staying ahead of trends in tire maintenance solutions will be crucial. International buyers are encouraged to engage with reputable suppliers who offer competitive pricing and robust support. Embrace the future of tire care by prioritizing strategic sourcing decisions that enhance safety, convenience, and sustainability for your business and customers alike.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.