- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

Navigating the complexities of bike tire inflation can be a daunting challenge for B2B buyers in the global market, especially when sourcing reliable products across diverse regions such as Africa, South America, the Middle East, and Europe. Ensuring optimal tire pressure is not just about comfort or speed; it directly impacts safety and performance, making it crucial for businesses to understand the nuances of tire inflation. This comprehensive guide delves into various types of bike tires, their recommended inflation pressures, and the specific applications suitable for different biking environments.

We will also explore essential factors that influence tire performance, such as rider weight, temperature, and the implications of over or under-inflation. Additionally, the guide provides actionable insights on vetting suppliers, assessing costs, and identifying the best products that align with your business needs.

By empowering international B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to facilitate smoother operations and enhance customer satisfaction. Whether you are in Brazil looking for high-performance tires for competitive cycling or in Saudi Arabia sourcing durable options for rugged terrains, understanding bike tire inflation is a key component to driving success in your market.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Manual Pumps | Hand-operated, portable, versatile | Retail bike shops, cycling events | الإيجابيات: Affordable, easy to use. السلبيات: تضخم كثيف العمالة وبطيء التضخم. |

| Floor Pumps | Stationary, high-efficiency, often with gauges | Bicycle repair shops, workshops | الإيجابيات: Fast inflation, accurate pressure measurement. السلبيات: Bulky, less portable. |

| CO2 Inflators | Compact, quick inflation using CO2 cartridges | Emergency kits, competitive cycling | الإيجابيات: Lightweight, rapid inflation. السلبيات: Limited use per cartridge, ongoing costs. |

| Electric Pumps | Automated, consistent pressure control | Bike manufacturers, rental services | الإيجابيات: Effortless operation, precise inflation. السلبيات: Higher upfront cost, requires power source. |

| Air Compressors | High-volume air delivery, suitable for multiple tires | Large-scale bike retailers, workshops | الإيجابيات: Fast inflation for multiple tires, powerful. السلبيات: Not portable, risk of overinflation. |

Manual pumps are a staple in the cycling industry due to their portability and versatility. They are ideal for individual cyclists and small bike shops, allowing for on-the-go inflation without the need for electricity. However, they require physical effort and can be slower compared to other methods. B2B buyers should consider the frequency of use and the volume of customers when deciding on stocking manual pumps, as they can be an affordable solution for casual cyclists.

Floor pumps are designed for efficiency and accuracy, often equipped with built-in gauges to monitor tire pressure. They are predominantly used in bike repair shops and workshops, where quick and accurate inflation is essential for customer satisfaction. While they take up more space and are less portable, their ability to inflate tires rapidly makes them invaluable for businesses focused on high-volume service. Buyers should evaluate the balance between price and features, such as gauge accuracy and durability.

CO2 inflators are compact devices that allow cyclists to quickly inflate tires using CO2 cartridges. They are particularly popular in competitive cycling and emergency repair kits due to their lightweight and rapid inflation capabilities. However, they come with the downside of requiring ongoing purchases for cartridges, which can add to long-term costs. B2B buyers should assess the market demand for quick-fix solutions and consider stocking these inflators for performance-oriented customers.

Electric pumps represent a modern solution for bike tire inflation, providing automated and consistent pressure control. They are especially beneficial for bike manufacturers and rental services, where efficiency and ease of use are paramount. While they typically have a higher upfront cost and require a power source, their ability to deliver precise inflation can enhance customer experience. B2B buyers should consider the potential return on investment based on their customer demographics and service offerings.

Air compressors are powerful tools capable of delivering high-volume air, making them suitable for large-scale bike retailers and workshops that service multiple bikes at once. They offer rapid inflation but are not portable and carry the risk of overinflating tires if not monitored carefully. B2B buyers should weigh the benefits of speed and efficiency against the costs and space requirements, ensuring they meet the needs of their operational scale.

| الصناعة/القطاع | Specific Application of bike tire inflation | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Bicycle Manufacturing | Quality control in production | Ensures optimal tire performance and safety for end users | Reliable inflation equipment and accurate pressure gauges |

| التوصيل والخدمات اللوجستية | Fleet maintenance for delivery bikes | Reduces downtime and improves delivery efficiency | Durable and portable inflation solutions for remote locations |

| السياحة والترفيه | Rental bike services | Enhances customer satisfaction through well-maintained bikes | Cost-effective inflation systems for high turnover rates |

| Sports and Fitness | Performance optimization for competitive cycling | Maximizes speed and handling for athletes | High-precision inflators suitable for varied PSI requirements |

| خدمات الطوارئ | Quick inflation solutions for rescue bikes | Ensures readiness and reliability in critical situations | Compact, reliable inflators for rapid deployment |

In the bicycle manufacturing sector, tire inflation is a critical part of quality control. Ensuring that tires are inflated to the correct PSI during production guarantees optimal performance and safety for consumers. Manufacturers must invest in reliable inflation equipment and accurate pressure gauges to maintain consistency across their product lines. This attention to detail not only enhances product quality but also helps in building brand reputation in competitive markets across regions like Europe and South America.

In the delivery and logistics industry, especially where bicycles are used for last-mile delivery, proper tire inflation is essential for fleet maintenance. Regular inflation checks reduce the risk of flat tires, minimizing downtime and improving overall delivery efficiency. B2B buyers in this sector should consider durable and portable inflation solutions that can be easily used in various locations, including urban environments in Africa and the Middle East, where access to traditional inflating equipment may be limited.

For rental bike services in the tourism and recreation sector, maintaining the correct tire pressure is vital for customer satisfaction. Well-inflated bikes provide a smoother and safer riding experience, which is crucial for attracting repeat customers. B2B buyers in this market should focus on cost-effective inflation systems that can handle high turnover rates, ensuring that bikes are always ready for use. This is particularly important in popular tourist destinations across South America and Europe.

In the sports and fitness industry, particularly for competitive cycling, precise tire inflation is crucial for performance optimization. Athletes rely on specific PSI levels to maximize speed and handling during races. B2B buyers in this sector should seek high-precision inflators that can accommodate varied PSI requirements for different bike types. This attention to detail can significantly impact an athlete’s performance, making it an essential investment for cycling teams and sports organizations across Europe and other competitive markets.

Emergency services that utilize bikes for rapid response need quick inflation solutions to ensure their vehicles are always ready for action. Properly inflated tires enhance reliability and performance in critical situations, which can be life-saving. Buyers in this sector should prioritize compact and reliable inflators that can be deployed quickly, particularly in regions like Africa and the Middle East, where timely responses are essential. Investing in quality inflation equipment can directly affect operational efficiency and service delivery in emergencies.

المشكلة B2B buyers managing bike fleets often face the challenge of inconsistent tire pressure due to varying environmental conditions. For example, in regions with extreme temperatures, like the Middle East, air pressure in tires can fluctuate significantly. This inconsistency leads to performance issues such as reduced speed, increased wear on tires, and even safety risks for cyclists. Buyers may struggle to maintain optimal pressure levels across diverse terrains and climates, resulting in downtime and additional maintenance costs.

الحل: To effectively address this issue, buyers should invest in high-quality, accurate tire pressure gauges and educate their teams on the importance of regular tire pressure checks. Implementing a standardized protocol for checking tire pressure before each ride can ensure that tires are inflated to the recommended PSI for the specific environment. Additionally, consider sourcing tires designed with adaptive pressure technology that can withstand temperature fluctuations, maintaining optimal performance regardless of external conditions. Establishing a regular maintenance schedule can also help mitigate these issues, ensuring that all bikes are consistently monitored and serviced.

المشكلة For businesses operating bike rental services or bike shops, training staff to inflate tires correctly can be a significant hurdle. New employees may struggle with understanding the nuances of different tire types, PSI recommendations, and the consequences of overinflation or underinflation. This lack of knowledge can lead to frequent tire-related issues, impacting customer satisfaction and operational efficiency.

الحل: To enhance staff training on tire inflation, create a comprehensive training program that includes hands-on workshops and instructional materials. Utilize visual aids like charts that outline the recommended PSI for various bike types and tire conditions. Incorporating practical demonstrations using different types of pumps can also build confidence among employees. Additionally, consider developing a quick reference guide or mobile app that staff can consult while inflating tires, ensuring they have the right information at their fingertips. Regular refresher courses can keep the team updated on best practices, ultimately leading to improved service quality.

المشكلة B2B buyers often face challenges in managing inventory for tire inflation equipment, such as pumps and gauges. Inadequate inventory can lead to delays in service or the inability to meet customer demands, especially during peak seasons. Conversely, overstocking can result in increased carrying costs and wasted resources, particularly in regions with fluctuating demand.

الحل: To optimize inventory management for tire inflation equipment, implement a just-in-time (JIT) inventory system. This approach allows businesses to maintain minimal stock levels while ensuring that they can quickly replenish supplies as needed. Use data analytics to forecast demand based on historical usage patterns and seasonal trends, enabling more accurate purchasing decisions. Collaborate with reliable suppliers who can provide quick turnaround times for orders, ensuring that essential equipment is always on hand without overstocking. Additionally, consider conducting regular audits of your inventory to identify slow-moving items that may need to be phased out or promoted to enhance turnover.

When it comes to bike tire inflation, the choice of materials significantly impacts performance, durability, and overall user experience. This analysis covers four common materials used in bike tire inflation systems: rubber, thermoplastic elastomers (TPE), aluminum, and steel. Each material has unique properties that cater to specific needs in the biking industry, particularly for B2B buyers operating in diverse international markets.

Rubber is the most traditional material used in bike tires due to its excellent elasticity and ability to withstand varying pressure levels. Its temperature rating typically ranges from -30°C to 80°C, making it suitable for most climates. Rubber also exhibits good corrosion resistance, particularly when treated with additives.

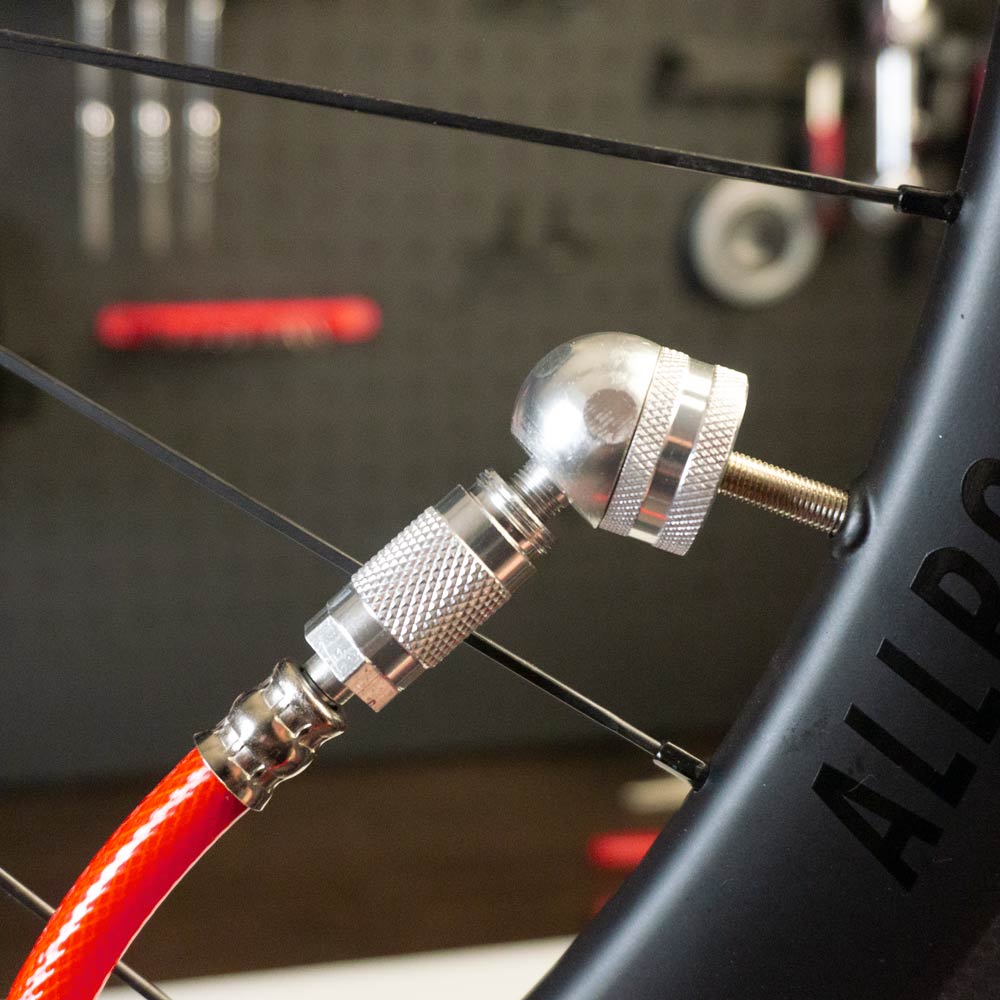

Illustrative image related to bike tire inflation

الإيجابيات: Rubber is highly durable and provides a comfortable ride due to its shock-absorbing properties. It is also relatively inexpensive and easy to manufacture, making it a cost-effective option for mass production.

السلبيات: While rubber is durable, it can degrade over time, especially when exposed to UV light and extreme temperatures. Additionally, its performance can vary based on the quality of the rubber used, which may affect consistency across different suppliers.

التأثير على التطبيق: Rubber is compatible with air and is the standard material for inner tubes. However, B2B buyers should ensure that the rubber used meets local compliance standards, particularly in regions with stringent regulations.

Illustrative image related to bike tire inflation

Thermoplastic elastomers (TPE) are increasingly being used in bike tire applications due to their flexibility and recyclability. TPEs can withstand a wide range of temperatures (typically -40°C to 100°C) and offer excellent pressure ratings.

الإيجابيات: TPEs are lightweight and provide good resistance to wear and tear. They can also be processed easily, allowing for complex designs and shapes, which can enhance the end product’s performance.

السلبيات: While TPEs are more environmentally friendly, they can be more expensive than traditional rubber. Additionally, TPEs may not provide the same level of shock absorption as rubber, which could affect rider comfort.

التأثير على التطبيق: TPEs can be used in both inner tubes and tire casings. International buyers should consider local preferences for sustainability, as TPEs may align better with eco-conscious markets in Europe and certain parts of South America.

Aluminum and steel are commonly used for components like valves and rims in bike tire inflation systems. Aluminum is lightweight and offers good corrosion resistance, while steel is known for its strength and durability.

مزايا الألومنيوم: Aluminum is lightweight, reducing the overall weight of the bike. It also has excellent resistance to corrosion, making it suitable for various climates.

سلبيات الألومنيوم: Although durable, aluminum can be more expensive than steel and may not withstand as much impact without bending.

مزايا الفولاذ: Steel is incredibly strong and cost-effective, making it a popular choice for manufacturers. It can handle high pressures without deforming.

سلبيات الفولاذ: Steel is heavier than aluminum and is prone to rust if not properly coated, which could be a concern in humid environments.

Illustrative image related to bike tire inflation

التأثير على التطبيق: Both materials are suitable for high-pressure applications, but international buyers should consider local climate conditions when selecting materials. For instance, buyers in humid regions like parts of Africa and South America may prefer aluminum for its corrosion resistance.

| المواد | Typical Use Case for bike tire inflation | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Inner tubes and tire casings | Excellent elasticity and shock absorption | Degrades over time in UV exposure | منخفضة |

| اللدائن البلاستيكية الحرارية (TPE) | Inner tubes and tire casings | Lightweight and recyclable | More expensive than rubber | متوسط |

| ألومنيوم | Valves and rims | خفيف الوزن ومقاوم للتآكل | More expensive, can bend under impact | متوسط |

| الفولاذ | Valves and rims | High strength and cost-effective | أثقل وزناً وعرضة للصدأ | منخفضة |

This strategic material selection guide provides B2B buyers with critical insights into the various materials used in bike tire inflation. Understanding the properties, pros and cons, and regional considerations can help businesses make informed decisions that align with their operational needs and market demands.

The manufacturing process for bike tire inflation equipment involves several key stages that ensure the production of high-quality pumps, gauges, and other inflation devices. Understanding these stages is essential for B2B buyers looking to source reliable products.

The first stage in the manufacturing process is material preparation. Manufacturers typically use durable materials such as rubber, plastic, aluminum, and steel. Rubber is primarily used for seals and hoses due to its flexibility and resilience, while aluminum and steel are common for the structural components of pumps. Ensuring the quality of these raw materials is crucial, as subpar materials can lead to product failures.

The forming stage involves shaping the raw materials into usable components. Techniques such as injection molding, extrusion, and stamping are commonly employed. For example, injection molding is used to create plastic parts like pump bodies and gauges, while extrusion is used for hoses. Precision in this stage is vital, as any defects can compromise the functionality and reliability of the inflation equipment.

Once the components are formed, they are assembled into the final products. This stage often includes integrating various parts, such as connecting hoses to pumps and installing pressure gauges. Automated assembly lines are increasingly common, allowing for higher efficiency and consistency. Manual assembly may also be employed for more complex products, where skilled workers ensure that components fit together seamlessly.

The finishing stage involves applying any necessary coatings, decals, or branding to the products. This can also include quality checks to ensure that all components are functioning correctly. Finishing touches not only enhance the aesthetic appeal of the products but also contribute to their durability and resistance to wear and tear.

Quality assurance is paramount in the manufacturing of bike tire inflation equipment, particularly for international B2B buyers. Understanding the relevant standards can help buyers make informed decisions.

ISO 9001 is one of the most widely recognized international quality management standards. It ensures that manufacturers have a systematic approach to managing their processes and meeting customer expectations. Compliance with ISO 9001 can serve as a strong indicator of a manufacturer’s commitment to quality.

Illustrative image related to bike tire inflation

In addition to general quality standards, industry-specific certifications such as CE marking (European Conformity) and API (American Petroleum Institute) certification can be crucial. CE marking indicates that the product meets EU safety, health, and environmental protection requirements, while API certification ensures that equipment meets specific industry standards. These certifications can significantly influence a buyer’s decision, particularly in regions with strict regulatory requirements.

Quality control (QC) is integrated at various stages of the manufacturing process to ensure that the final products meet the required specifications and standards.

مراقبة الجودة الواردة (IQC): This is the initial inspection of raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specified standards is essential for preventing defects in the final product.

مراقبة الجودة أثناء العملية (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the quality of work in progress. This allows for immediate corrective actions to be taken if any deviations from standards are detected.

مراقبة الجودة النهائية (FQC): After assembly, the final products undergo a comprehensive inspection to verify that they meet all specifications and performance criteria. This may include functional tests, pressure tests, and visual inspections.

Various testing methods are employed to validate the quality and performance of bike tire inflation equipment.

Pressure Testing: This method involves subjecting the products to various pressure levels to ensure they can withstand the intended use without failure.

اختبار المتانة: Products are tested for longevity by simulating extended use conditions, ensuring they maintain performance over time.

الاختبار الوظيفي: This involves checking the operational capabilities of pumps and gauges to confirm they provide accurate readings and effective inflation.

For international B2B buyers, verifying the quality control practices of suppliers is essential for ensuring product reliability and compliance with standards.

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request to see audit reports and certifications.

Request Quality Reports: Suppliers should be able to provide documentation that details their quality control processes, including testing methods and results.

Utilize Third-Party Inspection Services: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and quality assurance practices. This is particularly useful for buyers in regions like Africa and South America, where local standards may differ.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control and certification processes.

Different regions may have unique regulatory requirements that impact the manufacturing and quality assurance processes. For instance, products sold in the EU must comply with CE marking, while products intended for the U.S. market may need to meet different standards. Understanding these regulations is crucial for ensuring compliance and avoiding potential legal issues.

Building strong relationships with suppliers is vital for navigating the complexities of international trade. Buyers should communicate their quality expectations clearly and establish a framework for ongoing quality assessments. This proactive approach can help mitigate risks and ensure a steady supply of reliable products.

By understanding the manufacturing processes and quality assurance measures involved in bike tire inflation equipment, B2B buyers can make informed decisions that align with their operational needs and market requirements.

This practical sourcing guide aims to provide B2B buyers with a comprehensive checklist for procuring bike tire inflation solutions. Understanding the nuances of tire inflation, including pressure specifications and supplier evaluation, is essential for ensuring optimal performance and safety in biking. This guide will facilitate informed purchasing decisions, catering specifically to international markets in Africa, South America, the Middle East, and Europe.

Establish clear technical specifications based on the types of bikes your target market uses. Different bikes require varying PSI ranges for optimal performance, so it’s vital to align your sourcing with these needs. Consider factors such as the weight of the rider and the intended use (e.g., racing vs. casual riding).

Before engaging with suppliers, verify their credentials and industry experience. Look for certifications such as ISO 9001 or other relevant quality assurance standards that demonstrate their commitment to manufacturing excellence. A well-established supplier will also have a history of reliability and customer satisfaction.

Thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request company profiles, case studies, and references from buyers in similar industries or regions. This step will help you gauge the supplier’s reliability and capability to fulfill your specific demands.

Illustrative image related to bike tire inflation

Investigate the quality of the products being offered, including the types of pumps, gauges, and inflation systems available. Check for durability, ease of use, and compatibility with various bike types. A diverse product range is advantageous, as it allows you to cater to a broader customer base.

Once you have shortlisted potential suppliers, request samples of their products for testing. This is crucial for assessing performance, ease of use, and overall quality. Testing samples can also help identify any issues before making a bulk purchase, minimizing risk and ensuring customer satisfaction.

Engage in discussions about pricing structures, including bulk order discounts and payment terms. Understanding the financial aspects is key to maintaining profitability. Be aware of any hidden costs, such as shipping or customs fees, especially when sourcing internationally.

Evaluate the after-sales support offered by suppliers, including warranty terms and customer service availability. A reliable supplier should provide comprehensive support for any issues that arise post-purchase. Clear warranty policies can protect your investment and foster long-term relationships with your customers.

By following this checklist, B2B buyers can streamline the procurement process for bike tire inflation solutions, ensuring that they meet the diverse needs of their customers while maintaining high-quality standards.

When evaluating the cost structure and pricing for bike tire inflation sourcing, it is essential to consider various components that contribute to the overall expenditure. This analysis will provide B2B buyers with insights into the intricacies of pricing, enabling informed decision-making.

Understanding the cost components involved in bike tire inflation is crucial for accurate budgeting. The primary elements include:

المواد: The type of materials used in tire production significantly impacts costs. Natural rubber, synthetic compounds, and reinforcements vary in price, affecting the final cost of the tires. High-quality materials may lead to higher initial costs but can enhance durability and performance.

العمالة: Labor costs vary by region and influence the overall manufacturing expenses. Automated processes can reduce labor costs but may require significant initial investment in machinery.

نفقات التصنيع الزائدة: This encompasses the indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient operational practices can help mitigate these costs.

الأدوات: Custom molds and specialized machinery for tire production require upfront investment. These costs should be factored into the pricing, especially for custom designs.

مراقبة الجودة (QC): Ensuring tires meet safety and performance standards is paramount. The costs associated with testing and quality assurance processes must be considered in the pricing structure.

الخدمات اللوجستية: Transporting materials and finished products can significantly impact costs, especially for international shipments. Factors such as shipping methods, distances, and tariffs must be evaluated.

الهامش: Suppliers typically add a margin to cover risks and profit. Understanding the expected margin in your region can help in negotiation and budgeting.

Several factors can influence pricing in the bike tire inflation market:

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs against MOQ requirements to optimize costs.

المواصفات والتخصيص: Tailoring products to specific requirements can lead to increased costs. Buyers should weigh the benefits of customization against budget constraints.

المواد وشهادات الجودة: High-quality materials and certifications (e.g., ISO, CE) can elevate prices but may also enhance product reliability. Buyers should consider the long-term benefits of investing in quality.

عوامل الموردين: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more, but they often provide superior service and quality assurance.

المصطلحات التجارية الدولية: Understanding Incoterms is crucial for managing shipping costs and responsibilities. Different terms (e.g., FOB, CIF) affect pricing based on who bears the costs at various stages of transport.

To achieve cost-efficiency in bike tire inflation sourcing, buyers should consider the following strategies:

Illustrative image related to bike tire inflation

التفاوض بفعالية: Leverage bulk purchasing power to negotiate better rates. Establishing long-term relationships with suppliers can also lead to more favorable terms.

تقييم التكلفة الإجمالية للملكية (TCO): Consider not just the purchase price but also long-term costs related to maintenance, durability, and performance. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

فهم الفروق الدقيقة في التسعير: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import duties, and local market conditions that can affect pricing.

Stay Informed on Market Trends: Keeping abreast of market trends and competitor pricing can enhance negotiation leverage and help identify the best sourcing opportunities.

Navigating the complexities of bike tire inflation sourcing requires a thorough understanding of cost components, pricing influencers, and effective negotiation strategies. By applying these insights, B2B buyers can make informed decisions that align with their operational needs and budget constraints. As with any sourcing endeavor, it is important to remain adaptable and responsive to market conditions to optimize costs effectively.

In the realm of cycling, ensuring optimal tire performance is crucial for safety, efficiency, and rider comfort. While traditional bike tire inflation methods are widely used, several alternative solutions exist that can also achieve effective tire management. This section delves into a comparison of standard bike tire inflation techniques against two viable alternatives: self-sealing tires and tire pressure monitoring systems (TPMS).

| جانب المقارنة | Bike Tire Inflation | Self-Sealing Tires | Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| الأداء | Highly effective with proper PSI | Reduces flat risks, maintains PSI | Provides real-time pressure data |

| التكلفة | Low (manual pumps are inexpensive) | Higher upfront cost | Moderate (installation and maintenance costs) |

| سهولة التنفيذ | Simple, requires basic tools | Requires specialized tires | Involves installation and setup |

| الصيانة | Regular checks needed | Minimal, mostly self-sustaining | Regular battery checks for sensors |

| أفضل حالة استخدام | General cycling, diverse terrains | Urban commuting, puncture-prone areas | Long-distance rides, performance cycling |

Self-sealing tires utilize a special sealant that automatically fills punctures as they occur. This technology greatly reduces the risk of flats, making it an attractive option for urban cyclists or those riding in puncture-prone environments. The major advantage is convenience; riders can continue their journey without the immediate need for repair. However, the initial cost is higher than traditional tires, and they may not perform as well in extreme conditions, such as off-road biking.

A Tire Pressure Monitoring System (TPMS) is designed to provide real-time data on tire pressure, alerting riders to any significant drops that could affect performance and safety. This system is particularly useful for long-distance cyclists who want to ensure optimal pressure throughout their ride. The main drawback is the need for installation, which can be complex, and the ongoing maintenance required for sensor batteries. However, the benefits of enhanced safety and performance monitoring often outweigh these challenges for serious cyclists.

When choosing the right tire management solution, B2B buyers should consider their specific needs and usage scenarios. For companies involved in urban cycling or delivery services, self-sealing tires may provide the best balance of convenience and performance. Conversely, businesses focused on long-distance cycling or performance-oriented activities may find that investing in a TPMS offers greater safety and efficiency. Ultimately, understanding the unique requirements of your cycling operations will guide you in selecting the most appropriate solution for bike tire inflation and management.

Illustrative image related to bike tire inflation

When dealing with bike tire inflation, understanding the technical specifications is crucial for ensuring optimal performance and safety. Here are several critical specifications that B2B buyers should be familiar with:

Pound Per Square Inch (PSI)

– التعريف: PSI measures the inflation pressure within the tire. This value is critical for determining the tire’s performance and safety.

– الأهمية: Ensuring the correct PSI is vital for rider comfort, tire longevity, and overall handling of the bike. Overinflated tires can lead to blowouts, while underinflated tires may cause pinch flats.

Tire Size and Type

– التعريف: This includes the width, diameter, and type of tire (e.g., road, mountain, hybrid).

– الأهمية: Different bikes require specific tire sizes and types to perform well under various conditions. Understanding these specifications helps buyers select appropriate tires for their target markets, ensuring compatibility and customer satisfaction.

التركيب المادي

– التعريف: Tires are typically made from a blend of rubber compounds, including natural and synthetic rubber, along with reinforcing materials like nylon or polyester.

– الأهمية: The material affects durability, traction, and puncture resistance. Buyers should consider the balance between performance and cost when selecting tires made from different materials.

Tread Pattern

– التعريف: The design of the tire’s surface, which can vary significantly between types of bikes.

– الأهمية: Tread patterns influence grip, rolling resistance, and handling in different conditions (wet, dry, off-road). Understanding tread design helps businesses cater to specific riding needs in different markets.

سعة الوزن

– التعريف: This indicates the maximum load a tire can safely support, often denoted in pounds or kilograms.

– الأهمية: Knowing the weight capacity ensures that tires can handle the loads of various riders and cargo, which is essential for safety and performance in commercial applications.

Temperature Tolerance

– التعريف: The range of temperatures within which a tire can operate effectively without compromising performance.

– الأهمية: Different regions experience varying climates, and tires must perform reliably under these conditions. This specification is crucial for B2B buyers in diverse geographical markets.

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common trade terms related to bike tire inflation:

OEM (الشركة المصنعة للمعدات الأصلية)

– التعريف: Refers to companies that produce parts or equipment that may be marketed by another manufacturer.

– Context: Buyers often seek OEM tires to ensure compatibility and quality, as these products meet the original specifications set by bike manufacturers.

موك (الحد الأدنى لكمية الطلب)

– التعريف: أصغر عدد من الوحدات التي يرغب المورد في بيعها.

– Context: Understanding MOQ is crucial for inventory management and cost calculations. Buyers should negotiate MOQs that align with their sales forecasts.

طلب عرض الأسعار (RFQ)

– التعريف: A document issued by a buyer to invite suppliers to bid on specific products or services.

– Context: An RFQ is essential for comparing pricing and terms from different suppliers, allowing buyers to make informed purchasing decisions.

إنكوترمز (الشروط التجارية الدولية)

– التعريف: A set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers.

– Context: Familiarity with Incoterms helps buyers understand shipping responsibilities, insurance, and risk management in international trade.

Tire Pressure Monitoring System (TPMS)

– التعريف: An electronic system that monitors tire pressure and alerts the rider when pressure falls below a set threshold.

– Context: TPMS is becoming increasingly relevant in bike design, especially for high-performance models. Buyers should consider these features for their product offerings.

Treadwear Indicator

– التعريف: A feature on tires that shows the level of tread wear and indicates when a tire needs to be replaced.

– Context: Treadwear indicators enhance safety and performance monitoring. Buyers should prioritize tires with clear indicators to help their customers maintain optimal tire conditions.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions, ultimately enhancing their product offerings and customer satisfaction.

The global bike tire inflation market is experiencing significant growth, driven by increasing urbanization, rising health consciousness, and a shift towards sustainable transportation. With more individuals opting for bicycles as a primary mode of transport, particularly in urban areas across Africa, South America, the Middle East, and Europe, the demand for reliable tire inflation solutions is on the rise. Additionally, the booming e-commerce sector is facilitating easier access to specialized bike maintenance tools, including tire inflators, thereby enhancing market dynamics.

Emerging technologies are reshaping sourcing trends within the bike tire inflation sector. Smart tire inflation systems equipped with IoT technology are gaining traction, allowing riders to monitor tire pressure through mobile applications. This trend not only enhances rider safety but also optimizes tire performance, making it essential for B2B buyers to consider these innovations in their procurement strategies. Furthermore, the integration of automatic tire inflation systems is becoming increasingly popular, particularly in commercial fleets and bike-sharing programs, which underscores the need for international buyers to remain attuned to these advancements.

Illustrative image related to bike tire inflation

In terms of regional dynamics, markets in Brazil and Saudi Arabia are witnessing a surge in demand for high-performance tire inflation systems. As cycling cultures evolve, B2B buyers in these regions are prioritizing quality and innovation, seeking partnerships with manufacturers that can provide cutting-edge products. Understanding these dynamics is crucial for businesses looking to capitalize on the growing demand in the bike tire inflation sector.

The importance of sustainability and ethical sourcing in the bike tire inflation sector cannot be overstated. Environmental concerns are prompting manufacturers to adopt greener practices, leading to innovations in tire materials and inflation technology. B2B buyers are increasingly seeking products that minimize environmental impact, such as tire inflators made from recycled materials or those that promote energy efficiency.

Ethical supply chains are becoming a priority, as buyers demand transparency regarding sourcing practices. Companies that prioritize ethical labor practices and sustainable materials are not only enhancing their brand reputation but are also gaining a competitive edge in the market. Certifications like ISO 14001 for environmental management and Fair Trade for ethical practices are increasingly influencing purchasing decisions among B2B buyers.

Illustrative image related to bike tire inflation

Moreover, the shift towards electric bicycles (e-bikes) is driving demand for more efficient tire inflation solutions. E-bike tires require specific inflation strategies to optimize performance and longevity, and this has led to the development of specialized inflation tools. B2B buyers must consider these factors when sourcing products, as the emphasis on sustainability and ethical sourcing continues to shape market trends.

The evolution of bike tire inflation technologies has been marked by significant advancements aimed at improving efficiency and user experience. Traditionally, manual pumps dominated the market, but as cycling gained popularity, especially in urban settings, the need for more efficient solutions became apparent. The introduction of floor pumps revolutionized the inflation process, allowing for quicker and more accurate tire pressure adjustments.

In recent years, the emergence of portable electric pumps has further transformed the landscape. These devices cater to the needs of modern cyclists, offering convenience and ease of use. Furthermore, the integration of smart technology into tire inflation solutions, such as Bluetooth connectivity and mobile apps, has made it easier for cyclists to monitor tire pressure and optimize performance.

As the market continues to evolve, B2B buyers should stay informed about these technological advancements, as they present new opportunities for product differentiation and customer engagement. Understanding the historical context of bike tire inflation technologies can provide valuable insights for strategic sourcing decisions in the rapidly changing landscape of the cycling industry.

How do I determine the correct PSI for different bike tire types?

To determine the correct PSI (pounds per square inch) for bike tires, refer to the manufacturer’s specifications printed on the tire sidewall. Generally, narrow tires for road bikes require 80-130 PSI, while hybrid tires typically need 50-70 PSI. Mountain bikes have a wider range due to varying terrain, often between 30-50 PSI. It’s essential to consider rider weight and riding conditions, as heavier riders may need higher pressure, and different terrains may necessitate adjustments for optimal performance.

What are the best practices for maintaining bike tire pressure?

Regular maintenance of bike tire pressure includes checking PSI before each ride, especially after periods of inactivity. Air naturally seeps out over time, and environmental factors like temperature can affect pressure. Use a reliable gauge to ensure accuracy, and adjust as necessary based on riding conditions. It’s advisable to inflate tires to the higher end of the recommended range for speed and performance, while lower pressure can enhance comfort and traction on rough terrains.

What should I consider when sourcing bike tire inflation equipment internationally?

When sourcing bike tire inflation equipment internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. It’s crucial to vet suppliers thoroughly—request samples, check references, and review their certifications. Additionally, consider the logistics of shipping, including customs duties and delivery timelines. Building relationships with suppliers who understand regional demands can also facilitate smoother transactions and better pricing.

How can I customize bike tire inflation products for my market?

Customization options for bike tire inflation products may include branding, size adjustments, and features tailored to specific regional needs. Engage with suppliers early in the sourcing process to discuss potential modifications. Conduct market research to understand consumer preferences in your target regions, such as preferred tire types and inflation methods. Collaborating with manufacturers who offer flexibility in production can lead to successful product launches tailored to your market.

What are typical minimum order quantities (MOQs) for bike tire inflation products?

Minimum order quantities (MOQs) for bike tire inflation products can vary significantly based on the supplier and product type. Generally, MOQs may range from a few hundred units to several thousand. Suppliers often set MOQs to ensure cost-effectiveness in production. It’s beneficial to negotiate with suppliers and explore the possibility of smaller initial orders, especially if you are testing new products or entering new markets.

What payment terms should I expect when dealing with international suppliers?

Payment terms with international suppliers can vary widely. Common arrangements include upfront payments, letters of credit, or payment upon delivery. It’s essential to establish clear terms during negotiations to protect both parties. Consider using secure payment methods like PayPal or escrow services for larger transactions. Additionally, be aware of currency exchange rates and potential fees that may affect the overall cost of your purchase.

How can I ensure quality assurance (QA) for bike tire inflation products?

To ensure quality assurance for bike tire inflation products, establish clear quality standards with your suppliers before production begins. Request samples for testing and conduct thorough inspections upon delivery. Consider implementing a third-party inspection service to verify quality standards, especially when dealing with large orders. Regular communication with suppliers during the production process can also help address any issues promptly, ensuring you receive products that meet your expectations.

What logistics considerations should I keep in mind for importing bike tire inflation products?

When importing bike tire inflation products, consider logistics aspects such as shipping methods, transit times, and customs regulations. Choose reliable freight forwarders familiar with your target market to streamline the process. Understand the import duties and taxes applicable in your country, as these can significantly impact overall costs. Additionally, maintaining open lines of communication with suppliers and logistics partners can help mitigate delays and ensure timely deliveries.

المجال: silca.cc

مسجل: 2013 (12 سنة)

مقدمة: SILCA Pro Tire Pressure Calculator; Input: Total System Weight (75-450 lbs or 34-205 kg); Surface Condition options: Track (Indoor/Outdoor), New/Worn Pavement, Various Gravel Categories; Measured Tire Width selection; Wheel Diameter options: 700C/29″, 650C, 650B/27.5″, 26″; Tire Type options: High performance tubeless/latex, Mid Range tubeless/latex, Mid-Range butyl, Puncture resistant tubeless/la…

المجال: thebikesmiths.com

مسجل: 2003 (22 سنة)

مقدمة: Road Bike: 85-110 PSI for tube-type clincher tires, 150-200 PSI for tubular tires. Hybrid Bike: 60-85 PSI. Mountain Bike: 35-65 PSI.

المجال: dedhambike.com

مسجل: 2000 (25 سنة)

مقدمة: Bicycle tire pump; Price range: $50 to $300; Fits both Schrader and Presta valves; Recommended features: built-in gauge; CO2 cartridges for on-the-go inflation; Recommended tire pressure: Road bikes 80-100 PSI, Mountain bikes 30-50 PSI, Gravel bikes 25-40 PSI; Importance of maintaining proper tire pressure for performance and safety.

المجال: trekbikes.com

مسجل: 1995 (30 سنة)

مقدمة: Best selling pumps: Bontrager TLR Flash Charger Floor Pump, Bontrager Charger Floor Pump, Bontrager Dual Charger Floor Pump. Additional products: Bontrager Flat Pack, Bontrager Air Rush Road CO2 Pump.

المجال: radpowerbikes.com

مسجل: 2015 (10 سنوات)

مقدمة: This company, Rad Power Bikes – Tire Pressure Guidelines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the dynamic landscape of bike tire inflation, strategic sourcing remains a crucial component for international B2B buyers. Understanding the specific pressure requirements for various bike types—ranging from road to mountain bikes—empowers businesses to optimize product offerings and enhance customer satisfaction. By aligning sourcing strategies with regional preferences and climatic conditions, such as temperature variations in Africa or humidity levels in South America, companies can ensure that their products meet the unique needs of their target markets.

Illustrative image related to bike tire inflation

Moreover, the importance of reliable inflation equipment cannot be overstated. Investing in high-quality pumps and gauges not only reduces the risk of tire damage but also fosters a reputation for excellence among customers. As the cycling market continues to expand, particularly in emerging economies, the potential for growth is significant.

Looking ahead, B2B buyers are encouraged to adopt a proactive approach to sourcing, focusing on innovation and sustainability. Engaging with local suppliers and leveraging technological advancements can facilitate better product performance and customer loyalty. Embrace the future of bike tire inflation by making informed sourcing decisions that cater to the evolving demands of your market.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

Illustrative image related to bike tire inflation

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.