- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the competitive landscape of the global cycling industry, sourcing effective solutions for inflating bike tires presents a unique challenge for B2B buyers. As international demand for bicycles continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of tire inflation technology becomes crucial. This guide comprehensively explores the various types of inflation devices, including manual pumps, CO2 inflators, and air compressors, along with their specific applications in diverse markets.

Navigating the complexities of supplier vetting is another essential focus of this guide. With the influx of new manufacturers and products, it is vital for businesses to assess quality, reliability, and pricing strategies to ensure they are making informed purchasing decisions. We delve into cost considerations, helping buyers evaluate the long-term value of their investments in tire inflation solutions.

This guide is designed to empower B2B buyers with the knowledge and insights necessary to select the best options for their operational needs. By addressing key factors such as product performance, supplier credibility, and market trends, we aim to facilitate a seamless purchasing experience. Whether you are a retailer, distributor, or fleet manager, this resource will equip you with the tools to make confident decisions in the dynamic world of bike tire inflation.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Floor Pump | Large volume, built-in gauge, high pressure | Retail bicycle shops, workshops | الإيجابيات: Fast and efficient; السلبيات: Bulky for transport. |

| Mini Pump | Compact, portable, lower volume and pressure | On-the-go retail, cycling tours | الإيجابيات: Lightweight and easy to carry; السلبيات: Slower inflation. |

| CO2 Inflator | Quick inflation using CO2 cartridges | Emergency kits, competitive cycling | الإيجابيات: Fast and lightweight; السلبيات: Higher long-term costs due to cartridge replacements. |

| Electric Pump | Automated inflation with adjustable pressure settings | Bike rental services, workshops | الإيجابيات: User-friendly and consistent pressure; السلبيات: Requires power source, bulkier. |

| Air Compressor | High volume, high pressure, often stationary | Large-scale repair shops, bike manufacturers | الإيجابيات: Extremely efficient for multiple tires; السلبيات: Not portable, high initial investment. |

Floor pumps are characterized by their large volume capacity and built-in pressure gauges, making them ideal for efficiently inflating bike tires to the required pressure. They are commonly used in retail bicycle shops and workshops where frequent tire inflation is necessary. When considering a floor pump for B2B applications, buyers should focus on the pump’s durability, ease of use, and the accuracy of the pressure gauge, which can significantly impact customer satisfaction.

Mini pumps are designed for portability, making them an excellent choice for cyclists on the go. These pumps are lightweight and can easily fit into a backpack or be attached to a bike frame. They are particularly suitable for retail environments that cater to touring cyclists or commuters. B2B buyers should consider the pump’s volume capacity and the ease of use, as some models may take longer to inflate tires compared to larger alternatives.

CO2 inflators are designed for rapid tire inflation, utilizing CO2 cartridges to achieve high pressure quickly. This type is especially popular among competitive cyclists and those who require a lightweight, compact solution for emergencies. For B2B buyers, the key considerations include the cost of cartridges and the need for quick refills during events or tours, making it essential to balance speed with long-term operational costs.

Electric pumps provide automated inflation, allowing users to set desired pressure levels easily. They are particularly beneficial for bike rental services and workshops, where consistent and accurate inflation is critical. B2B buyers should evaluate the availability of power sources and the pump’s capacity to handle various tire types, ensuring they choose a model that meets their operational needs without compromising efficiency.

Air compressors are powerful devices capable of inflating multiple tires quickly and efficiently, making them ideal for large-scale repair shops and bike manufacturers. While they offer significant advantages in terms of speed and efficiency, B2B buyers need to consider the initial investment and the lack of portability. Understanding the specific volume and pressure requirements for the types of bikes serviced can help in selecting the right compressor for operational needs.

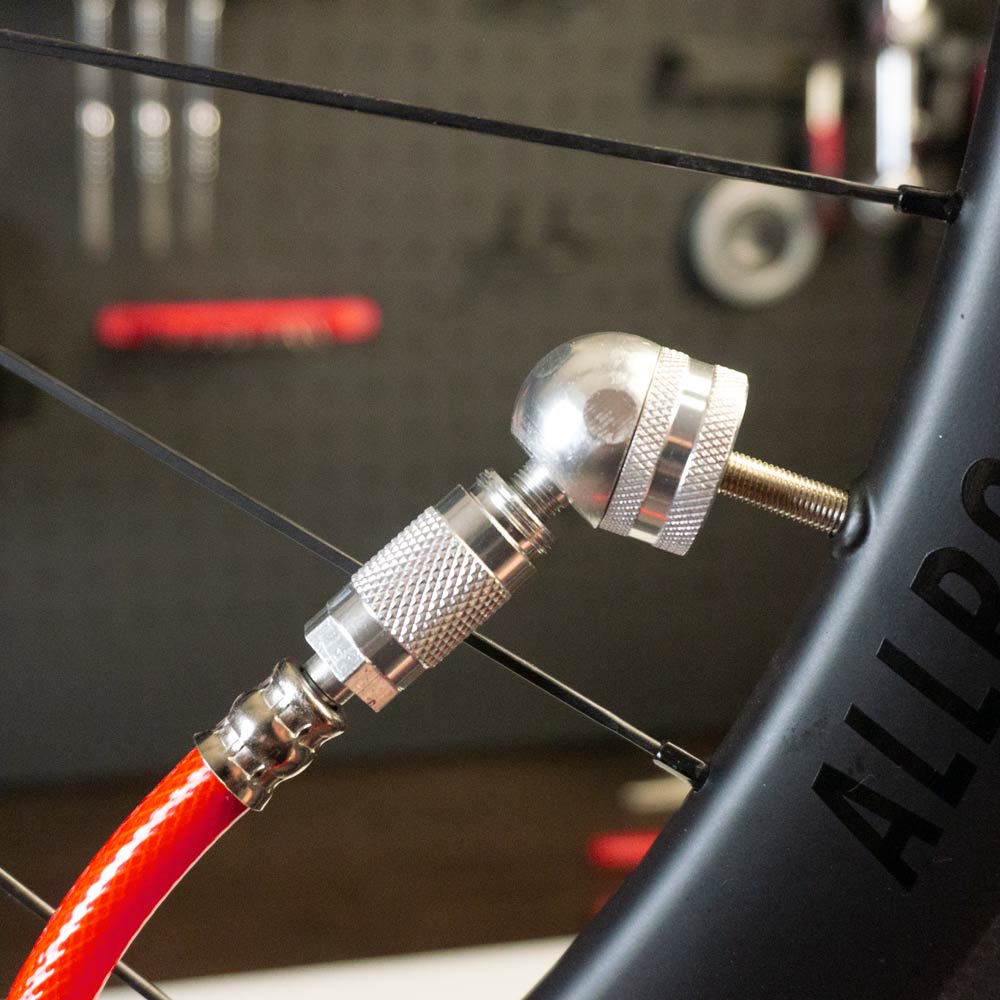

Illustrative image related to inflate bike tire

| الصناعة/القطاع | Specific Application of Inflate Bike Tire | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| الخدمات اللوجستية والتوصيل | Fleet maintenance for bicycle couriers | Ensures timely deliveries and reduces downtime | Reliable inflation solutions, portable pumps for on-site use |

| السياحة والترفيه | Bicycle rentals and guided tours | Enhances customer experience and safety | Lightweight and easy-to-use pumps, efficient service support |

| Manufacturing | Assembly line for bicycle production | Streamlined production and quality assurance | Industrial-grade inflators, bulk purchasing options |

| Urban Transport | Municipal bike-sharing programs | Promotes sustainable transport and reduces costs | Durable equipment, compatibility with various tire types |

In the logistics and delivery sector, bicycle couriers rely heavily on well-inflated tires to ensure their bikes operate efficiently. Regular inflation checks prevent flat tires, thus minimizing downtime and enhancing delivery speed. Businesses in this sector should consider portable inflation solutions that can be easily transported, allowing couriers to address tire issues on-the-go. Sourcing reliable pumps that can handle varying tire pressures is crucial, especially in diverse environments across Africa, South America, and Europe.

Bicycle rental services and guided tours in the tourism and recreation industry depend on maintaining optimal tire pressure for safety and performance. Inflated tires improve ride comfort and reduce the risk of punctures, significantly enhancing the customer experience. Businesses should focus on sourcing lightweight, easy-to-use pumps that can be integrated into rental setups. This is particularly important in regions with diverse terrains, such as mountainous areas in South America or urban environments in Europe.

In the manufacturing sector, particularly in bicycle production, maintaining the correct tire pressure is essential for quality assurance. Inflating tires accurately during assembly ensures that the final product meets safety and performance standards. Manufacturers should invest in industrial-grade inflators that provide consistent pressure and can accommodate high-volume production needs. When sourcing, companies should consider bulk purchasing options to optimize costs, especially in regions with growing bicycle markets like Africa and the Middle East.

Municipal bike-sharing programs are gaining traction as cities seek sustainable transport solutions. Regular tire inflation is vital to ensure the safety and reliability of shared bicycles. By implementing efficient inflation systems, municipalities can reduce operational costs and improve user satisfaction. Key sourcing considerations include durable and robust equipment that can withstand frequent use and compatibility with various tire types, crucial for serving diverse urban populations in Europe and beyond.

المشكلة For B2B buyers managing fleets of bicycles, ensuring consistent tire pressure can be a persistent challenge. Many buyers find that tires lose air pressure over time due to temperature changes, punctures, or even just natural permeability of the inner tubes. This leads to frequent maintenance checks and potential downtime, which can significantly affect operational efficiency and rider safety. Moreover, tires that are not properly inflated can lead to increased wear and tear, resulting in higher costs for replacements and repairs.

الحل: To combat this issue, buyers should invest in high-quality floor pumps equipped with pressure gauges for their maintenance teams. These pumps allow for quick and accurate inflation at a central maintenance location. Additionally, implementing a routine maintenance schedule where tires are checked weekly can help in identifying issues before they escalate. Buyers can also consider investing in advanced tire technology, such as self-sealing inner tubes that can automatically repair small punctures, thereby reducing the frequency of inflation and maintenance needs. Regular training for maintenance personnel on the importance of tire pressure and proper inflation techniques can further enhance operational efficiency.

المشكلة B2B buyers involved in bicycle rentals or logistics often face urgent situations where a flat tire can disrupt service and cause delays. When riders are on the go, they may lack the tools or time to properly inflate a tire, leading to frustration and potential loss of business. This is particularly critical in regions where access to repair shops or maintenance facilities is limited, making quick and effective solutions essential.

الحل: To address this pain point, buyers should equip their bicycles with portable, lightweight mini-pumps or CO2 inflators that can be easily carried by riders. These tools should be designed to work with both Schrader and Presta valves, ensuring compatibility with various bicycle types. Additionally, offering a simple instructional guide or video on how to use these inflators can empower riders to handle minor tire issues themselves, reducing downtime. Furthermore, establishing partnerships with local service providers for quick repairs can enhance service reliability and customer satisfaction.

المشكلة Many B2B buyers encounter issues with compatibility between different types of inflation equipment and bicycle valve systems. The presence of both Schrader and Presta valves in the market can create confusion and inefficiency, especially if the inflators or pumps provided do not accommodate both types. This not only leads to wasted time but can also result in damage to equipment or tires if improper inflation methods are used.

Illustrative image related to inflate bike tire

الحل: Buyers should take a proactive approach by standardizing equipment across their fleet. This includes selecting pumps and inflators that are versatile and can handle both valve types. Additionally, providing valve adapters for Presta valves can ensure that all bicycles in the fleet can be inflated quickly and easily, regardless of the equipment available. It may also be beneficial to include a variety of inflation options in the initial purchase, such as hand pumps, floor pumps, and CO2 inflators, to cater to different scenarios. Training staff and riders on the importance of knowing their bike’s valve type and the correct equipment to use will further enhance the efficiency of tire inflation processes.

When selecting materials for inflating bike tires, it is essential to consider the properties and performance of common materials. Here, we analyze four materials frequently used in this application: rubber, synthetic polymers, aluminum, and steel. Each material has unique characteristics that can significantly influence the performance and suitability of bike tires in various environments.

Rubber is the traditional material used in bike tire inner tubes. It offers excellent elasticity and flexibility, allowing it to withstand the high pressures required for inflation. The temperature rating of rubber can vary, but it generally performs well in a range of temperatures, making it suitable for diverse climates.

الإيجابيات: Rubber is durable and relatively inexpensive, making it a cost-effective choice for manufacturers. Its inherent flexibility allows it to conform to the tire shape, ensuring a tight seal and efficient inflation.

السلبيات: However, rubber can degrade over time, especially when exposed to UV light and ozone, leading to potential leaks. Additionally, its manufacturing process can be complex due to the need for vulcanization.

التأثير على التطبيق: Rubber is compatible with air and CO2, but it may not be suitable for certain chemicals or extreme temperatures.

اعتبارات للمشترين الدوليين: Buyers from regions like Africa or South America should ensure that the rubber meets local standards for durability and UV resistance, such as ASTM or ISO certifications.

Synthetic polymers, such as thermoplastic elastomers (TPE), are increasingly used in bike tire manufacturing. These materials provide enhanced durability and resistance to environmental factors compared to traditional rubber.

الإيجابيات: Synthetic polymers offer superior resistance to abrasion and aging, which can prolong the life of the tire. They are also lightweight, which can improve the overall performance of the bike.

السلبيات: The main drawback is the higher cost compared to rubber. Additionally, the manufacturing process can be more complex, requiring specialized equipment.

التأثير على التطبيق: Synthetic polymers are compatible with standard inflation methods and can withstand a wider range of temperatures and pressures.

اعتبارات للمشترين الدوليين: Buyers should be aware of the specific polymer grades and their compliance with international standards, as well as any regional preferences for materials.

Illustrative image related to inflate bike tire

Aluminum and steel are commonly used in the construction of tire inflation accessories, such as valves and pumps. Both materials offer distinct advantages and disadvantages.

Aluminum:

الإيجابيات: Aluminum is lightweight and resistant to corrosion, making it ideal for portable tire inflators. It also has good thermal conductivity, which can be beneficial in dissipating heat during inflation.

السلبيات: However, aluminum is generally more expensive than steel and can be less durable under extreme conditions.

التأثير على التطبيق: Aluminum is suitable for high-pressure applications but may not withstand heavy impacts as well as steel.

اعتبارات للمشترين الدوليين: Buyers should consider the availability and cost of aluminum in their regions, as well as compliance with relevant standards.

Steel:

الإيجابيات: Steel is known for its strength and durability, making it an excellent choice for heavy-duty applications. It is also more cost-effective than aluminum.

السلبيات: On the downside, steel is heavier and can be prone to rust if not properly coated.

التأثير على التطبيق: Steel components can handle high pressures but may require additional maintenance to prevent corrosion.

اعتبارات للمشترين الدوليين: Buyers should ensure that steel components are treated to resist corrosion, particularly in humid or coastal environments.

| المواد | Typical Use Case for inflate bike tire | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Inner tubes for bike tires | Cost-effective and flexible | Degrades over time and UV exposure | منخفضة |

| Synthetic Polymers | Advanced inner tubes and seals | Durable and lightweight | ارتفاع التكلفة والتصنيع المعقد | ميد |

| ألومنيوم | Tire inflation accessories (valves) | خفيف الوزن ومقاوم للتآكل | More expensive and less impact-resistant | عالية |

| الفولاذ | Heavy-duty tire inflation accessories | Strong and durable | أثقل وزناً وعرضة للصدأ | ميد |

This strategic material selection guide provides valuable insights for B2B buyers in various international markets, facilitating informed decisions when sourcing materials for bike tire inflation.

Illustrative image related to inflate bike tire

The manufacturing process for inflate bike tires involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers looking to source reliable products.

The first step in manufacturing inflate bike tires is material preparation. The primary materials used include rubber compounds, fabrics (such as polyester or nylon), and inner tubes. The rubber is often compounded with various additives to enhance properties like flexibility, durability, and resistance to environmental factors. Quality control begins here, as suppliers must ensure that the raw materials meet specified standards.

Following material preparation, the next stage is forming. This involves several techniques, including extrusion and calendering.

Both methods require precision to ensure uniformity in thickness and composition, critical for the performance of the tire.

The assembly stage integrates the formed components into a complete tire. This process typically includes:

Illustrative image related to inflate bike tire

Assembly is a critical phase that requires skilled labor and precise machinery to avoid defects that could compromise tire integrity.

Finishing involves curing the tire, a process where the assembled tire is heated in a mold to vulcanize the rubber. This step solidifies the shape and enhances the tire’s strength and elasticity. Post-curing inspections are essential to identify any defects, such as air pockets or uneven surfaces, which could affect performance.

Quality assurance (QA) is paramount in the manufacturing of bike tires, especially for international B2B buyers. Adhering to recognized standards ensures that products are reliable and safe for consumers.

Illustrative image related to inflate bike tire

International standards such as ISO 9001 are crucial for ensuring consistent quality in manufacturing processes. This standard focuses on various aspects, including quality management systems and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the tire’s intended use and market.

Quality control during manufacturing typically involves several checkpoints:

These checkpoints are designed to catch defects early in the manufacturing process, thereby reducing waste and ensuring product reliability.

Testing is an integral part of the quality assurance process. Various testing methods are employed to ensure that bike tires meet performance and safety standards.

Illustrative image related to inflate bike tire

By employing these testing methods, manufacturers can validate the performance characteristics of their tires before they reach the market.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is vital. Here are several strategies:

Conducting regular audits of suppliers can provide insight into their manufacturing processes and adherence to quality standards. Buyers should look for certifications such as ISO 9001 during these audits to ensure compliance with international quality standards.

Requesting quality control reports from suppliers can provide a detailed overview of their manufacturing processes and any issues encountered during production. These reports should outline results from IQC, IPQC, and FQC checkpoints, giving buyers confidence in the product’s quality.

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These organizations can conduct thorough inspections at various stages of production, providing an additional layer of assurance for buyers.

International B2B buyers must navigate various challenges related to quality control, especially when sourcing from different regions.

Different regions may have varying standards and regulations that impact quality assurance practices. B2B buyers should familiarize themselves with local regulations in the countries they are sourcing from, as compliance may differ from international standards.

Cultural attitudes toward quality can also influence manufacturing practices. Buyers should consider these differences when evaluating potential suppliers, ensuring that their quality expectations align with those of the manufacturer.

Illustrative image related to inflate bike tire

By understanding the manufacturing processes and quality assurance measures in place for inflate bike tires, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet their specific needs.

This guide serves as a practical sourcing checklist for B2B buyers interested in procuring solutions for inflating bike tires. Whether you are looking to purchase pumps, compressors, or related accessories, following this structured approach will help ensure you select the right products and suppliers that meet your operational needs.

Before sourcing, clearly define the specifications for the tire inflation equipment you need. Consider factors such as the type of bike tires (e.g., road, mountain, hybrid) and the required pressure levels. Understanding these requirements will help you narrow down your options and ensure compatibility with the bikes you are servicing.

Conduct thorough research on the different types of tire inflation solutions available in the market. Options may include floor pumps, mini-pumps, CO2 inflators, and electric air compressors. Evaluate the pros and cons of each type based on efficiency, ease of use, and maintenance needs to determine which best aligns with your operational context.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of reliability and quality to ensure you’re partnering with a reputable source.

Illustrative image related to inflate bike tire

Whenever possible, request samples or demonstrations of the products you are considering. This step allows you to evaluate the performance and usability of the inflation equipment firsthand. Pay attention to factors such as ease of operation, speed of inflation, and accuracy of pressure gauges.

Gather quotes from multiple suppliers to compare pricing structures. Look for transparent pricing that includes all costs, such as shipping and handling. Evaluate payment terms and conditions, ensuring they align with your budget and cash flow needs.

Understand the shipping and delivery options available from your chosen suppliers. Evaluate lead times, shipping costs, and the reliability of their logistics partners. Timely delivery can be crucial for maintaining your operations, especially in regions with limited access to local suppliers.

Illustrative image related to inflate bike tire

Once you have selected a supplier, finalize the purchase agreement. Ensure that all terms are clearly outlined, including pricing, delivery schedules, warranties, and return policies. Having a well-defined agreement will help mitigate risks and ensure accountability from both parties.

Following this checklist will streamline your procurement process, ensuring you acquire effective solutions for inflating bike tires that meet your business needs.

When sourcing inflate bike tires, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

المواد: The choice of materials significantly impacts the cost. Common materials include rubber for tires, nylon for inner linings, and various compounds for durability and performance. High-quality materials may have a higher upfront cost but can lead to long-term savings due to increased durability and reduced failure rates.

العمالة: Labor costs vary by region and are influenced by local wage standards. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level and training of the workforce, which can affect product quality.

نفقات التصنيع الزائدة: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, contributing to lower pricing.

الأدوات: Initial tooling costs can be significant, especially for custom designs. Buyers should inquire about tooling fees and how they impact overall pricing, particularly when considering lower-volume orders.

مراقبة الجودة (QC): Implementing stringent QC processes ensures product reliability. However, these practices can add to the cost. Buyers should weigh the benefits of QC against potential savings from less rigorous standards.

الخدمات اللوجستية: Shipping and handling costs vary based on the supplier’s location and the buyer’s destination. Factors such as shipping method, distance, and Incoterms (International Commercial Terms) play a crucial role in determining final costs.

الهامش: Suppliers typically include a margin to cover risks and ensure profitability. Understanding a supplier’s margin can aid in negotiations and help buyers identify potential cost-saving opportunities.

Several factors can influence pricing in the B2B bike tire market. Buyers should consider:

الحجم/الكمية (الحد الأدنى لكمية الطلب): Higher order volumes often lead to lower per-unit costs. Negotiating for bulk orders can yield significant savings.

المواصفات والتخصيص: Custom designs or specific performance specifications may increase costs. Buyers should clarify their needs upfront to avoid unexpected price hikes.

المواد وشهادات الجودة: Premium materials and certifications (like ISO or CE) can raise costs but may also enhance product value. Buyers should evaluate whether the benefits justify the additional expense.

عوامل الموردين: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge more due to their perceived value and quality assurance.

المصطلحات التجارية الدولية: These terms define the responsibilities of buyers and sellers in shipping. Understanding Incoterms is essential for assessing total landed costs, including tariffs, insurance, and shipping fees.

فهم التكلفة الإجمالية للملكية (TCO): Assess not just the purchase price but the total cost, including maintenance, logistics, and potential downtime. This comprehensive view can justify a higher upfront investment if long-term savings are evident.

Leverage Market Insights: Knowledge of prevailing market prices and competitor offerings can strengthen negotiation positions. Buyers should research and prepare data to support their requests for better pricing.

Build Long-term Relationships: Establishing rapport with suppliers can lead to better terms and pricing over time. Consistent orders may encourage suppliers to offer discounts or improved services.

Explore Local Options: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers can reduce shipping costs and lead times, offering a competitive advantage.

Be Open to Flexibility: Negotiating on order quantities, payment terms, and delivery schedules can create win-win scenarios that satisfy both parties’ needs.

Understanding the cost structure and pricing influencers in the inflate bike tire market is essential for B2B buyers. By focusing on cost components and applying strategic negotiation techniques, buyers can achieve optimal pricing while ensuring quality and reliability. Note that prices can vary widely based on the factors discussed, and buyers should always seek multiple quotes to ensure they are receiving competitive offers.

Illustrative image related to inflate bike tire

In the competitive landscape of bicycle maintenance solutions, understanding the various methods available for inflating bike tires is essential for B2B buyers. Each method presents its own set of advantages and disadvantages, which can significantly impact operational efficiency and cost-effectiveness. Below, we compare the traditional ‘inflate bike tire’ approach with two viable alternatives: CO2 inflators and electric pumps.

| جانب المقارنة | Inflate Bike Tire | CO2 Inflator | Electric Pump |

|---|---|---|---|

| الأداء | Reliable for regular use; manual effort required | Quick inflation, ideal for emergencies | High volume and consistent inflation |

| التكلفة | Low initial investment; no recurring costs | Moderate initial cost; recurring cost for cartridges | Higher upfront cost; low maintenance |

| سهولة التنفيذ | Simple to use; requires physical effort | Very easy; requires no power source | Plug-in or battery-operated; user-friendly |

| الصيانة | Minimal; mainly check for wear | Low; ensure cartridges are available | Moderate; requires occasional maintenance |

| أفضل حالة استخدام | Regular maintenance at home | Emergency situations or racing | Frequent use in workshops or commercial settings |

CO2 inflators are an excellent alternative for cyclists needing a quick tire inflation solution. They are particularly advantageous in emergency situations due to their speed; a flat tire can be inflated in seconds. However, the recurring cost of CO2 cartridges can add up over time, making them less economical for regular use. Additionally, CO2 can leak from the tire faster than air, which may necessitate follow-up inflations.

Electric pumps provide a highly efficient method for inflating bike tires, particularly in settings where high volume and consistent pressure are essential, such as bike shops or fleet maintenance. They typically feature automatic shut-off mechanisms, ensuring optimal tire pressure without user intervention. However, their higher initial cost and reliance on electricity may be drawbacks for users seeking portable or budget-friendly options. Maintenance is also required to keep the electric components in good working order.

Selecting the appropriate bike tire inflation solution depends on specific operational needs and budget considerations. Businesses that prioritize speed and efficiency may find electric pumps to be the best fit, particularly in high-demand environments. Conversely, those looking for cost-effective and reliable solutions for regular use might prefer traditional inflating methods or CO2 inflators for their convenience in emergencies. Ultimately, a careful assessment of performance, cost, and ease of use will guide B2B buyers in making the most informed choice for their unique situations.

When sourcing equipment for inflating bike tires, understanding the technical properties is crucial for ensuring performance and compatibility. Here are some essential specifications to consider:

Pressure Rating

The pressure rating indicates the maximum pressure a tire can withstand, typically measured in PSI (pounds per square inch) or BAR. For various bike types, such as road or mountain bikes, the required pressure can differ significantly. Knowing the pressure rating is vital for preventing blowouts and ensuring rider safety.

Valve Type Compatibility

Bike tires are equipped with either Presta or Schrader valves. Presta valves are narrower and commonly found on high-performance bikes, while Schrader valves are similar to those used in car tires. Understanding valve compatibility is essential for ensuring that the inflating equipment can be used effectively without the need for adapters, which can complicate the inflation process.

Material Quality

The materials used in the construction of pumps and hoses can affect durability and performance. High-grade plastics and metals are preferred for their resistance to wear and tear, especially in varying environmental conditions. This is particularly important in B2B transactions where reliability and longevity of equipment can impact operational efficiency.

Flow Rate

The flow rate measures the volume of air delivered per minute, usually expressed in liters per minute (L/min). A higher flow rate means faster inflation, which is beneficial in commercial settings where time is of the essence. Understanding flow rates can help buyers choose the right equipment to meet their specific operational needs.

Gauge Accuracy

An integrated pressure gauge provides real-time pressure readings, ensuring that tires are inflated to the correct specifications. Accurate gauges prevent over-inflation and potential damage to tires. For B2B buyers, investing in equipment with reliable gauges can reduce maintenance costs and enhance overall safety.

قابلية النقل

For businesses that require mobility, the weight and size of the inflating equipment are crucial. Portable pumps should be lightweight yet robust enough to handle frequent use. This characteristic is especially valuable for businesses operating in diverse environments, such as outdoor events or remote locations.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms to know:

OEM (الشركة المصنعة للمعدات الأصلية)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of bike tire inflation, understanding OEM relationships can help buyers identify quality products that meet industry standards.

موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for businesses to manage inventory effectively and minimize costs while ensuring they meet demand.

طلب عرض الأسعار (RFQ)

An RFQ is a formal request to suppliers to provide pricing for specific quantities of products. This process helps businesses compare offers and negotiate terms effectively, ensuring they receive competitive pricing for their tire inflation needs.

إنكوترمز (الشروط التجارية الدولية)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in a transaction. Familiarity with these terms is essential for understanding shipping costs, risks, and responsibilities, particularly in cross-border transactions.

المهلة الزمنية

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on timely delivery for operations, understanding lead times can aid in planning and inventory management.

PPE (Personal Protective Equipment)

While not directly related to tire inflation, PPE includes gear that protects workers from potential hazards. Ensuring that staff have appropriate PPE when handling tire inflation equipment is vital for maintaining workplace safety standards.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance operational efficiency and safety when inflating bike tires.

The global inflate bike tire market is experiencing dynamic shifts driven by several factors, including increasing urbanization, a growing emphasis on sustainable transport solutions, and the rise of cycling as a popular recreational activity. Urban areas in Africa, South America, the Middle East, and Europe are witnessing a surge in cycling infrastructure, leading to higher demand for reliable tire inflation solutions. As cities implement bike-sharing programs and promote cycling as an eco-friendly mode of transportation, the need for efficient inflate bike tire technologies becomes paramount.

Emerging technologies are reshaping how B2B buyers approach sourcing. Innovations such as smart pumps equipped with Bluetooth connectivity allow users to monitor tire pressure via mobile apps, enhancing the user experience and promoting preventative maintenance. Additionally, the introduction of portable CO2 inflators offers a quick and convenient solution for cyclists on the go, appealing to the growing market of casual and adventure cyclists.

Moreover, B2B buyers are increasingly prioritizing suppliers who offer comprehensive support services, including training on tire maintenance and inflation techniques. This trend highlights the importance of value-added services, which can differentiate suppliers in a competitive marketplace.

Illustrative image related to inflate bike tire

As environmental concerns continue to rise, sustainability has become a critical focus for B2B buyers in the inflate bike tire sector. The production and disposal of traditional bike tires can have significant environmental impacts, prompting a shift toward sustainable materials and practices. Suppliers that utilize recycled rubber, biodegradable materials, or eco-friendly manufacturing processes are gaining traction in the market.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their purchasing decisions. Ensuring that supply chains are transparent and that workers are treated fairly can enhance a brand’s reputation and attract conscientious consumers. Certifications such as Fair Trade or Global Organic Textile Standard (GOTS) can serve as valuable indicators of a supplier’s commitment to ethical practices.

Incorporating sustainability into product offerings not only meets growing consumer demand but also positions companies favorably in the eyes of investors and regulatory bodies focused on environmental stewardship. B2B buyers looking to partner with suppliers in this sector should evaluate their sustainability credentials and ethical sourcing practices to align with broader corporate social responsibility goals.

The evolution of the inflate bike tire industry reflects broader trends in cycling and transportation. Historically, the design of bike tires was straightforward, focusing primarily on functionality and durability. However, with the rise of cycling as a recreational activity and a viable commuting option, the demand for specialized tires has increased.

The introduction of advanced materials and technologies, such as puncture-resistant tires and lightweight inflation systems, has transformed the market landscape. Additionally, the integration of smart technology into tire inflation solutions has opened new avenues for innovation. These advancements not only enhance performance but also improve user convenience, which is essential for modern cyclists.

As the market continues to evolve, B2B buyers must stay attuned to these changes, ensuring they source products that meet the evolving needs of cyclists while aligning with sustainability and ethical sourcing goals.

How do I solve the problem of frequent tire deflation in my fleet?

To address frequent tire deflation, consider investing in high-quality inner tubes designed for durability and low air loss. Ensure that your tires are compatible with the inflation equipment you use. Regular maintenance checks can also help identify punctures or wear before they lead to significant air loss. Implementing a systematic approach to tire pressure checks—ideally weekly—will help maintain optimal performance. If you notice persistent issues, consult with your supplier about potential replacements or upgrades to your tire and tube options.

What is the best inflation method for bike tires in different environments?

The best inflation method depends on your specific circumstances. For stationary applications, such as workshops, a floor pump or air compressor with a pressure gauge is ideal. If inflating tires on-the-go, CO2 inflators offer quick solutions, though they may require frequent cartridge replacements. In areas with limited access to electricity or inflators, consider portable hand pumps that are compact and easy to use. Always ensure you have the necessary adapters for different valve types (Schrader and Presta) to avoid any compatibility issues.

What should I consider when vetting suppliers for bike tire inflators?

When vetting suppliers, assess their reputation by researching customer reviews and industry feedback. Check for certifications that indicate quality standards, such as ISO or CE markings. Request samples to evaluate the product quality firsthand. Additionally, consider the supplier’s capacity to provide customized solutions, including branding options. Communication and responsiveness are crucial; choose a supplier who is willing to address your inquiries promptly and clearly.

What are the typical minimum order quantities (MOQs) for tire inflation products?

MOQs for tire inflation products can vary significantly by supplier and product type. Generally, MOQs range from 100 to 1,000 units, depending on the complexity and customization of the product. It’s essential to discuss your specific needs with potential suppliers to find flexibility in MOQs, especially if you’re just starting to build your inventory. Some suppliers may offer lower MOQs for new customers or for trial orders, which can be beneficial for assessing product performance before committing to larger quantities.

What payment terms should I expect when purchasing bike tire inflators internationally?

International payment terms can vary widely, but common practices include 30% upfront payment with the remaining balance due before shipment. Some suppliers may offer net 30 or net 60 terms, allowing for more extended payment periods. It’s advisable to use secure payment methods such as letters of credit or escrow services for larger transactions to mitigate risks. Always clarify payment terms in the purchase agreement to avoid misunderstandings and ensure compliance with international trade regulations.

How can I ensure quality assurance for my tire inflation products?

To ensure quality assurance, establish clear specifications for your products before placing an order. Request a detailed quality control (QC) plan from your supplier that outlines their inspection processes and standards. Consider conducting factory audits or third-party inspections to verify product quality before shipment. Additionally, ask for samples to test the products in real-world conditions, ensuring they meet your performance expectations. Establishing a robust communication channel with your supplier will also help in addressing any quality concerns promptly.

What logistics considerations should I keep in mind when sourcing bike tire inflators?

Logistics plays a crucial role in the timely delivery of your tire inflation products. Evaluate the supplier’s shipping options and timelines, including express and standard shipping methods. Understand the customs regulations in your country to avoid unexpected delays or fees. Consider the total landed cost, which includes shipping, taxes, and duties, to accurately assess the financial implications of your purchase. Building a good relationship with your logistics provider can also enhance the efficiency of your supply chain management.

How can I customize tire inflators for my business needs?

Customization options for tire inflators may include branding with your company logo, unique color schemes, or tailored packaging. When discussing customization with your supplier, provide detailed specifications regarding your desired features. Some suppliers may offer modular designs that allow you to choose specific components or functionalities. Be aware that customization can affect lead times and costs, so it’s important to weigh the benefits against any potential delays in delivery. Always request prototypes or samples of customized products to ensure they align with your expectations before mass production.

المجال: bikeradar.com

مسجل: 2006 (19 سنة)

مقدمة: This company, BikeRadar – Tyre Inflation Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

المجال: bicycles.stackexchange.com

مسجل: 2009 (16 سنة)

مقدمة: 1. Air Compressor: Ideal for home use, easy and quick, often includes pressure gauges and controls for max pressure. 2. Portable Air Solutions: CO2 cannisters are quick but costly for refills; hand pumps are also available but not as quick. 3. Floor Pump: Recommended for home use, easy to use, includes a gauge for measuring pressure. 4. Mini-Pump: Suggested for road use, should be simple without e…

المجال: ternbicycles.com

مسجل: 2010 (15 سنة)

مقدمة: Proper tire pressure is key to a well-functioning bike. Recommended tire pressure range is printed on the tire’s sidewall. Factors influencing ideal tire pressure include riding surface, weather conditions, rider and cargo weight, and front vs. back tire pressure. Regularly check tire pressure, ideally using a thumb check before rides and a floor pump once a week. Avoid overinflating tires to main…

المجال: schwinnbikes.com

مسجل: 2003 (22 سنة)

مقدمة: 1. Recommended Inflation Pressure: Every tire has a maximum inflation recommendation (usually in PSI or bars) labeled on the side of the tire. 2. Valve Types: Presta valves (found on higher-end bikes and road bikes) and Schrader valves (used on cars and many bike tires, including mountain, hybrid, and kids bikes). 3. Pump Types: A good floor pump is recommended for home use, featuring a large easy…

المجال: wikihow.com

مسجل: 2004 (21 سنة)

مقدمة: Inflating bike tires involves identifying the valve type (Schrader or Presta), checking the recommended PSI printed on the tire’s side, and using an appropriate pump. For Schrader valves, no adapter is needed, and gas station pumps can be used with caution. For Presta valves, a Presta adapter may be required for gas station pumps. The process includes unscrewing the valve cap, attaching the pump, …

In conclusion, strategic sourcing in the bike tire inflation sector is essential for international B2B buyers looking to optimize their supply chains and enhance operational efficiency. By selecting high-quality, reliable inflation solutions—whether it be floor pumps, portable CO2 systems, or advanced air compressors—businesses can significantly improve customer satisfaction and retention. Understanding regional preferences and market demands in Africa, South America, the Middle East, and Europe will enable buyers to tailor their offerings effectively.

As the cycling industry continues to grow, staying ahead of trends in tire technology and inflation methods will be paramount. Investing in innovative products and sustainable practices not only aligns with consumer preferences but also sets businesses apart in a competitive marketplace.

Now is the time for B2B buyers to reevaluate their sourcing strategies, ensuring they partner with suppliers who offer not just products, but also comprehensive support and expertise. By leveraging strategic sourcing, businesses can position themselves for future success in an evolving market. Take proactive steps today to secure your supply chain and capitalize on the burgeoning demand for effective bike tire inflation solutions.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

Illustrative image related to inflate bike tire

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.