- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

Navigating the global market for self-inflating tires presents a unique set of challenges for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As the demand for innovative automotive solutions grows, sourcing self-inflating tires has become essential for businesses aiming to enhance vehicle safety, fuel efficiency, and overall performance. These advanced tires not only maintain optimal pressure automatically but also significantly reduce the risk of blowouts and enhance tire longevity, addressing critical concerns for fleet operators and vehicle manufacturers alike.

This comprehensive guide delves into the diverse types of self-inflating tire technologies available, including integrated and retrofit options, along with their various applications across different sectors. It also provides insights into supplier vetting processes, cost considerations, and the regulatory landscape impacting tire technologies globally. By equipping B2B buyers with actionable information and expert analysis, this guide empowers organizations to make informed purchasing decisions that align with their operational needs and market demands.

In a rapidly evolving automotive industry, understanding the nuances of self-inflating tires can offer a competitive edge. This guide serves as a vital resource for businesses looking to leverage innovative tire solutions to improve efficiency, sustainability, and safety in their operations, ultimately driving growth and success in their respective markets.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Integrated SIT | Built into tire during manufacturing, uses wheel energy | OEM partnerships, fleet vehicles | الإيجابيات: Seamless integration, reliable performance. السلبيات: Higher initial investment. |

| Retrofit SIT | Aftermarket solution that can be added to existing tires | Tire replacement markets, repair shops | الإيجابيات: Flexibility, lower entry cost. السلبيات: Compatibility issues with some tire models. |

| Military SIT | Designed for rugged terrains and extreme conditions | Military vehicles, off-road applications | الإيجابيات: Enhanced durability, reliability in harsh conditions. السلبيات: Limited availability for civilian use. |

| Smart SIT | Features integrated sensors for real-time monitoring | Logistics, fleet management | الإيجابيات: Data-driven insights, proactive maintenance. السلبيات: Higher complexity and cost. |

| Eco-friendly SIT | Focuses on sustainability, reduces waste and emissions | Green initiatives, corporate fleets | الإيجابيات: Environmental benefits, compliance with regulations. السلبيات: Potentially higher production costs. |

Integrated Self-Inflating Tires (SIT) are manufactured with self-inflation technology built directly into the tire structure. This type utilizes the energy generated from the tire’s movement to maintain optimal air pressure, ensuring consistent performance and safety. Ideal for Original Equipment Manufacturers (OEMs) and fleet vehicles, Integrated SIT offers reliability and lower long-term operational costs. B2B buyers should consider the initial investment against potential savings on maintenance and improved fuel efficiency.

Retrofit Self-Inflating Tires are designed as aftermarket solutions that can be installed on existing tires. This flexibility makes them particularly appealing to tire replacement markets and repair shops. Retrofit SIT allows businesses to enhance their current tire inventory without the need for complete replacements. While offering a lower entry cost, buyers should assess compatibility with different tire models to avoid installation challenges.

Military Self-Inflating Tires are engineered for extreme conditions, providing enhanced durability and reliability on rugged terrains. These tires are crucial for military vehicles that require consistent performance in challenging environments. B2B buyers in defense contracting and off-road applications should prioritize Military SIT for their robust design, although they may face limited availability for civilian use.

Illustrative image related to self inflating tires

Smart Self-Inflating Tires integrate sensors that monitor tire pressure and performance in real-time. This technology is particularly beneficial for logistics and fleet management companies, as it allows for proactive maintenance and data-driven decision-making. While offering significant advantages in operational efficiency, B2B buyers should be prepared for higher complexity and costs associated with these advanced systems.

Eco-friendly Self-Inflating Tires focus on sustainability by reducing waste and emissions. This type is increasingly relevant for businesses with green initiatives or those aiming to comply with environmental regulations. While they offer significant environmental benefits and can enhance corporate responsibility, potential buyers should consider the higher production costs associated with these eco-friendly technologies.

| الصناعة/القطاع | Specific Application of self inflating tires | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Manufacturing | Integration in passenger and commercial vehicles | Enhanced safety, fuel efficiency, and reduced maintenance costs | Licensing agreements, compatibility with existing models, production scalability |

| Logistics and Transportation | Fleet management for delivery and freight vehicles | Minimizes downtime due to tire issues, improves fuel economy | Retrofit options for existing fleets, availability of maintenance support |

| الزراعة | Use in agricultural machinery like tractors and harvesters | Improved performance on varying terrains, reduced tire wear | Adaptability to diverse agricultural environments, durability against harsh conditions |

| الجيش والدفاع | Deployment in tactical and support vehicles | Increased operational readiness and safety in challenging terrains | Compliance with military specifications, reliability in extreme conditions |

| Mining and Construction | Application in heavy equipment and vehicles | Enhanced safety and reduced risks of tire blowouts | Ability to withstand heavy loads, compatibility with existing machinery |

In the automotive manufacturing sector, self-inflating tires (SIT) can be integrated into both passenger and commercial vehicles during production. These tires automatically maintain optimal pressure, enhancing safety and fuel efficiency while reducing maintenance needs. For international B2B buyers, particularly in regions like Africa and South America, sourcing SIT technology involves understanding local manufacturing capabilities and ensuring compatibility with existing vehicle models. The ability to offer innovative products can significantly differentiate manufacturers in competitive markets.

In logistics and transportation, self-inflating tires are crucial for fleet management. They help minimize vehicle downtime due to tire-related issues, thereby enhancing operational efficiency. With improved fuel economy from properly inflated tires, companies can reduce overall operational costs. B2B buyers in the Middle East and Europe should consider retrofit options for existing fleets, as well as the availability of ongoing maintenance support, to maximize the benefits of implementing SIT technology.

Self-inflating tires are increasingly being utilized in agricultural machinery such as tractors and harvesters. They adapt to varying terrains, providing better traction and stability, which is essential for agricultural tasks. This technology also reduces tire wear, leading to lower replacement costs. Buyers in regions like Nigeria and Vietnam must assess the adaptability of SIT systems to diverse agricultural environments and ensure that the tires can withstand the harsh conditions often encountered in farming operations.

Illustrative image related to self inflating tires

In military and defense applications, self-inflating tires are deployed in tactical and support vehicles, significantly enhancing operational readiness. These tires ensure safety in challenging terrains, reducing the risk of blowouts during critical missions. For B2B buyers in this sector, compliance with military specifications and reliability in extreme conditions are paramount. The ability to source tires that meet these stringent requirements can be a decisive factor in procurement processes.

In mining and construction, self-inflating tires are applied to heavy equipment and vehicles, where safety and durability are crucial. These tires reduce the risk of blowouts, which can lead to costly downtime and safety hazards. Buyers in these industries should focus on sourcing SIT technology that can withstand heavy loads and is compatible with existing machinery. Understanding the specific requirements of the mining and construction sectors can help buyers make informed decisions when integrating this technology.

المشكلة B2B buyers in the transportation sector often face significant safety concerns due to under-inflated tires, which can lead to increased risk of accidents. This issue is particularly pronounced in regions with varying road conditions, such as Africa and South America, where maintaining optimal tire pressure can be challenging. Fleet managers are tasked with ensuring that vehicles are safe, reliable, and compliant with local regulations, yet manual tire checks are time-consuming and prone to human error.

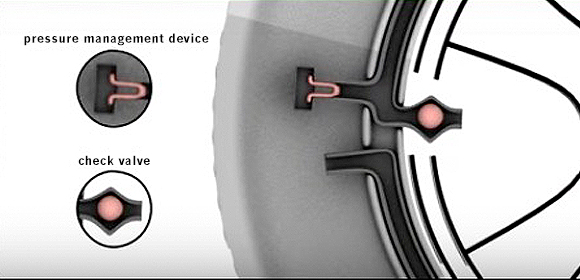

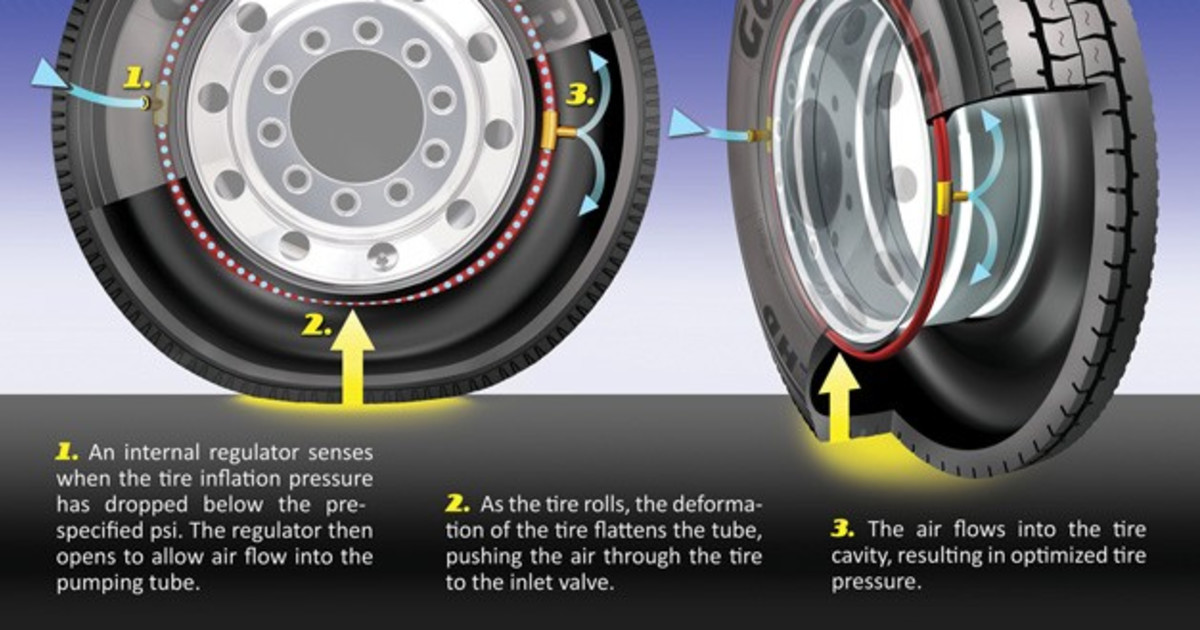

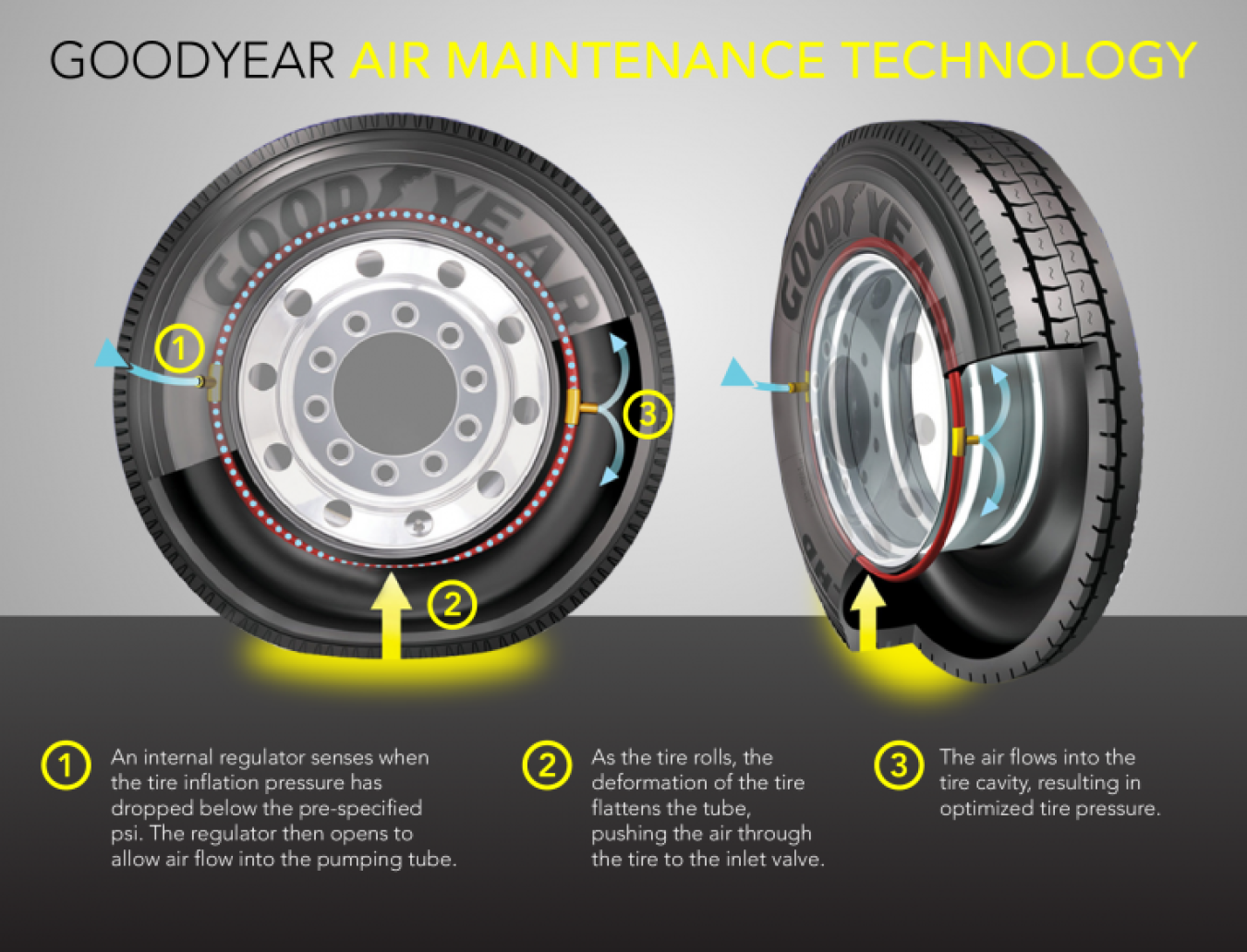

الحل: To mitigate these safety concerns, B2B buyers should consider integrating self-inflating tires (SIT) into their fleet management strategy. By sourcing tires equipped with SIT technology, fleet operators can ensure that tire pressure remains optimal at all times, significantly reducing the risk of blowouts and accidents. When selecting SIT solutions, it’s essential to work closely with manufacturers to understand the specific technology used, such as the peristaltic tube chamber design, which utilizes the energy of the wheel to maintain tire pressure. Additionally, incorporating a tire pressure monitoring system (TPMS) alongside SIT can provide an extra layer of safety by alerting drivers to any anomalies in real-time.

المشكلة Rising fuel costs present a major challenge for companies in logistics and transportation. Under-inflated tires can lead to increased rolling resistance, resulting in higher fuel consumption and operational costs. B2B buyers are often looking for solutions that not only enhance safety but also contribute to cost savings over time.

Illustrative image related to self inflating tires

الحل: Implementing self-inflating tires can play a pivotal role in reducing fuel expenses. By maintaining optimal tire pressure, these tires can lower rolling resistance, leading to improved fuel efficiency. B2B buyers should conduct a thorough cost-benefit analysis when considering the switch to SIT, factoring in potential fuel savings against the marginal increase in production costs. Additionally, it’s advisable to engage with tire manufacturers that offer retrofitting options, allowing companies to upgrade their existing tire inventory with SIT technology without the need for a complete overhaul. Such strategic investments can lead to significant long-term savings while also enhancing the overall performance of the fleet.

المشكلة As companies globally increasingly prioritize sustainability, B2B buyers are under pressure to adopt practices that minimize environmental impact. Conventional tire management practices often lead to higher rates of tire waste and CO2 emissions, which can undermine corporate sustainability goals.

الحل: Self-inflating tires contribute to sustainability by extending tire lifespan and reducing the frequency of replacements. B2B buyers should focus on sourcing SIT that incorporates eco-friendly materials and manufacturing processes. When evaluating potential suppliers, it’s crucial to examine their sustainability credentials and ensure that their products align with the company’s environmental commitments. Additionally, implementing a lifecycle management strategy for tires that includes SIT can further enhance sustainability efforts. This strategy should encompass regular monitoring of tire conditions, promoting proper tire maintenance, and recycling programs to manage end-of-life tires effectively. By aligning tire management with broader sustainability initiatives, companies can enhance their corporate social responsibility (CSR) profile while achieving compliance with regulatory standards in various regions.

Illustrative image related to self inflating tires

When selecting materials for self-inflating tires, it is crucial to consider properties that directly affect performance, durability, and manufacturing complexity. Here, we analyze four common materials used in the production of self-inflating tires: rubber, thermoplastic elastomers (TPE), nylon, and aluminum. Each material presents unique advantages and challenges that B2B buyers must weigh, particularly in diverse international markets.

Rubber is the primary material used in tire manufacturing due to its excellent elasticity and resilience. It can withstand a wide range of temperatures and pressures, making it suitable for various environmental conditions. The durability of rubber ensures longevity, which is essential for tires that must maintain optimal performance over time.

الإيجابيات: Rubber offers high durability and flexibility, which enhances tire performance and safety. It is also relatively cost-effective, making it a popular choice among manufacturers.

السلبيات: However, rubber can be susceptible to degradation from UV exposure and ozone, which may limit its lifespan in harsh climates. Additionally, the manufacturing process can be complex, requiring precise formulations to achieve the desired properties.

التأثير على التطبيق: In regions with extreme temperatures, such as parts of Africa and the Middle East, the formulation of rubber must account for thermal stability to prevent premature failure.

Illustrative image related to self inflating tires

Thermoplastic elastomers (TPE) are increasingly being used in self-inflating tires due to their combination of rubber-like elasticity and thermoplastic processing advantages. TPEs can be engineered to provide specific performance characteristics, such as improved chemical resistance and lower weight.

الإيجابيات: TPEs offer excellent resistance to chemicals and environmental factors, enhancing tire longevity. They are also easier to process than traditional rubber, which can streamline manufacturing.

السلبيات: The cost of TPEs can be higher than conventional rubber, which may impact overall production costs. Furthermore, TPEs may not provide the same level of durability under extreme conditions as traditional rubber.

التأثير على التطبيق: For manufacturers targeting markets in Europe, where environmental regulations are stringent, TPEs can help meet compliance standards while offering enhanced performance.

Nylon is often used in the construction of tire reinforcements due to its high tensile strength and resistance to abrasion. It plays a critical role in enhancing the structural integrity of self-inflating tires.

Illustrative image related to self inflating tires

الإيجابيات: Nylon’s strength-to-weight ratio allows for lighter tires without compromising durability. Its resistance to wear makes it suitable for various terrains, which is particularly beneficial for vehicles operating in rugged environments.

السلبيات: However, nylon can absorb moisture, which may lead to degradation over time. Additionally, it may require specialized processing techniques, increasing manufacturing complexity.

التأثير على التطبيق: In South American markets, where off-road driving is common, nylon-reinforced tires can provide the necessary durability and performance.

Illustrative image related to self inflating tires

Aluminum is often used for components such as the automatic pressure regulator in self-inflating tire systems. Its lightweight and corrosion-resistant properties make it an ideal choice for this application.

الإيجابيات: Aluminum’s low weight contributes to overall vehicle efficiency, while its corrosion resistance ensures longevity, especially in humid or saline environments.

السلبيات: The primary drawback is the higher cost of aluminum compared to other materials, which can affect the overall price of the tire. Additionally, aluminum components may require more complex manufacturing processes.

التأثير على التطبيق: In regions like Europe, where regulatory compliance for vehicle emissions is strict, the use of aluminum can enhance fuel efficiency, making it a valuable choice for manufacturers.

Illustrative image related to self inflating tires

| المواد | Typical Use Case for self inflating tires | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Tire tread and sidewalls | High durability and flexibility | Susceptible to UV and ozone degradation | منخفضة |

| Thermoplastic Elastomers | Tire components and seals | Excellent chemical resistance and processability | Higher cost compared to rubber | ميد |

| نايلون | Reinforcement layers | High tensile strength and abrasion resistance | Moisture absorption can lead to degradation | ميد |

| ألومنيوم | Pressure regulator components | خفيف الوزن ومقاوم للتآكل | ارتفاع التكلفة والتصنيع المعقد | عالية |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in self-inflating tires, enabling informed decision-making for diverse international markets.

The manufacturing of self-inflating tires (SIT) involves several key stages, each critical to ensuring the performance, safety, and longevity of the final product. The primary stages include material preparation, forming, assembly, and finishing.

Material preparation is the foundational step where raw materials are sourced and prepped for production. High-quality rubber compounds, reinforcing materials (like steel belts), and the specialized components for the self-inflating mechanism—such as the peristaltic tube chamber and automatic pressure regulator—are meticulously selected. Manufacturers often conduct tests on raw materials to verify their properties, ensuring they meet industry standards for durability and performance.

Once materials are prepared, the forming stage begins. This typically involves several techniques, including:

Assembly is the next phase, where the various components come together. Key processes include:

Quality assurance (QA) is essential in the manufacturing process of self-inflating tires to ensure they meet safety and performance standards. Relevant international and industry-specific standards include:

Quality control (QC) involves multiple checkpoints throughout the manufacturing process to ensure that each tire meets established standards. Key QC checkpoints include:

To ensure the reliability and safety of self-inflating tires, several common testing methods are employed:

Illustrative image related to self inflating tires

For B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring the reliability of self-inflating tires. Here are actionable steps to consider:

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may encounter unique challenges regarding quality control. Here are key nuances to consider:

In conclusion, the manufacturing processes and quality assurance for self-inflating tires are complex and multifaceted. By understanding these processes and implementing robust verification strategies, B2B buyers can ensure they procure high-quality, reliable products that meet their operational needs.

This practical sourcing guide is designed to assist B2B buyers in procuring self-inflating tires (SITs). As the automotive industry increasingly embraces innovations that enhance safety, efficiency, and sustainability, self-inflating tires represent a significant advancement. This checklist outlines essential steps to ensure that your procurement process is thorough and effective, ultimately leading to successful partnerships and product integration.

Before initiating the sourcing process, it’s crucial to establish clear technical specifications for the self-inflating tires you require. Consider factors such as tire size, load capacity, and intended applications (e.g., passenger vehicles, commercial fleets). Having well-defined specifications will help you communicate your needs effectively to potential suppliers and ensure compatibility with your existing fleet.

Illustrative image related to self inflating tires

Stay informed about current market trends and technological advancements related to self-inflating tires. Understanding innovations, such as the integration of SITs with vehicle telematics or advancements in energy efficiency, can provide you with a competitive edge. This knowledge will also help you identify suppliers who are at the forefront of the technology, allowing you to leverage cutting-edge solutions.

Conduct a thorough evaluation of potential suppliers before making a commitment. Request comprehensive company profiles, including their experience in manufacturing SITs, production capabilities, and any relevant certifications. Look for suppliers with a proven track record and positive references from other B2B buyers in your industry or region, as this can help mitigate risks associated with procurement.

Ensure that the suppliers you are considering adhere to international safety and quality standards, such as ISO certifications and compliance with local regulations. This step is vital for maintaining safety and reliability, particularly in regions where tire performance is critical due to varying road conditions. Additionally, check if the self-inflating tires meet any specific regulatory requirements in your target markets.

Before finalizing your order, request samples of the self-inflating tires for testing. This practical evaluation allows you to assess performance, durability, and compatibility with your vehicles. Conducting real-world tests can provide insights into how the tires perform under different conditions and help you make informed decisions based on empirical data.

Once you have identified a suitable supplier, proceed to negotiate favorable terms and conditions. Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Clear communication during this stage is crucial to establishing a mutually beneficial relationship and ensuring that both parties are aligned on expectations.

After procurement, consider how you will support and maintain the self-inflating tires over their lifecycle. Engage with your supplier regarding warranty terms, maintenance services, and training for your team on the technology. Establishing a plan for ongoing support will enhance the longevity of your investment and ensure that you maximize the benefits of self-inflating tire technology.

By following this checklist, B2B buyers can navigate the procurement process for self-inflating tires with confidence, ensuring that they make informed decisions that align with their operational needs and market demands.

Understanding the cost structure and pricing dynamics of self-inflating tires (SIT) is essential for international B2B buyers looking to make informed sourcing decisions. This analysis will break down the key cost components, price influencers, and provide actionable buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Illustrative image related to self inflating tires

المواد: The primary materials used in self-inflating tires include rubber compounds, the peristaltic tube chamber, and the automatic pressure regulator. These components must meet stringent quality and safety standards, which can affect material costs significantly.

العمل: Labor costs vary by region. In countries with lower labor costs, such as those in parts of Africa and South America, manufacturers may achieve lower overall production costs. However, skilled labor for quality assurance and engineering may still be a necessity.

نفقات التصنيع الزائدة: This includes expenses related to factory operations, utilities, and administrative costs. Companies should consider the efficiency of the manufacturing facility and the technology used, as advanced equipment may reduce production times and costs.

الأدوات: The initial investment in molds and machinery for producing self-inflating tires can be substantial. However, once the tooling is established, the marginal cost per unit decreases, benefiting larger production runs.

مراقبة الجودة (QC): Given the safety implications of tire performance, rigorous QC processes are essential. This can add to the cost but is necessary to ensure compliance with international safety standards.

Illustrative image related to self inflating tires

الخدمات اللوجستية: Transportation costs can vary widely depending on the distance from the manufacturing site to the buyer’s location. Factors such as shipping method, freight rates, and customs duties play a crucial role in the overall logistics cost.

الهامش: Manufacturers typically include a profit margin that can vary based on market competition and perceived value of the technology. Self-inflating tires, with their added benefits, may command higher margins compared to standard tires.

Volume and Minimum Order Quantity (MOQ): Pricing is often tiered based on order volume. Higher quantities typically attract lower per-unit costs, incentivizing larger purchases.

المواصفات والتخصيص: Buyers seeking specific tire dimensions, tread patterns, or features may face additional costs. Customization can significantly impact lead times and pricing.

Material Quality and Certifications: Tires that meet higher quality standards or have certifications (such as ISO or local safety certifications) may incur higher costs. Buyers should weigh the long-term benefits of investing in higher-quality products against initial expenses.

عوامل الموردين: The reputation, reliability, and financial stability of suppliers can influence pricing. Established manufacturers may charge a premium for their brand but often provide better quality assurance and service.

المصطلحات التجارية الدولية: The agreed-upon Incoterms (International Commercial Terms) can significantly affect pricing. Buyers should understand whether costs include shipping, insurance, and duties, as this will impact the total cost of ownership.

التفاوض: Engage in discussions with suppliers to explore pricing flexibility, especially for larger orders or long-term contracts. Understanding the supplier’s cost structure can provide leverage in negotiations.

Focus on Total Cost of Ownership: Consider not just the purchase price but also maintenance, fuel efficiency, and potential savings from reduced blowouts and increased tire longevity. Self-inflating tires can offer substantial long-term savings.

Understand Pricing Nuances for International Markets: Be aware of local market conditions, currency fluctuations, and trade tariffs that can affect costs. Buyers in regions like Africa and South America may face different challenges compared to their European counterparts.

Research and Due Diligence: Before committing, conduct thorough research on potential suppliers, their technologies, and their market reputation. Seek references and case studies to validate claims about performance and reliability.

While indicative prices can vary based on numerous factors, a comprehensive understanding of cost components, pricing influencers, and strategic buyer tips will empower B2B buyers to make informed sourcing decisions regarding self-inflating tires. By focusing on quality, negotiation, and total cost of ownership, buyers can ensure they select the best options for their specific needs and market conditions.

Illustrative image related to self inflating tires

In the quest for optimal tire performance and vehicle safety, various technologies have emerged to address the challenges associated with tire inflation. While self-inflating tires offer innovative solutions for maintaining optimal pressure, other alternatives exist that may cater to different operational needs, budgets, and vehicle types. This section provides a comparative analysis of self-inflating tires against two viable alternatives: Tire Pressure Monitoring Systems (TPMS) and traditional tire inflation methods.

| جانب المقارنة | Self Inflating Tires | Tire Pressure Monitoring Systems (TPMS) | Traditional Tire Inflation Methods |

|---|---|---|---|

| الأداء | Automatically maintains optimal pressure, enhancing safety and fuel efficiency. | Alerts drivers of under-inflation, but requires manual action to inflate. | Manual inflation can be effective but is dependent on user diligence. |

| التكلفة | Marginally higher production costs, but potential for higher profit margins due to added value. | Relatively low-cost technology, often integrated into vehicles. | Costs vary based on equipment (compressors, tools) and labor. |

| سهولة التنفيذ | Requires integration during manufacturing or retrofitting, which may be complex for some manufacturers. | Easy to implement as an aftermarket solution; does not require tire replacement. | Simple for consumers but requires regular attention and effort. |

| الصيانة | Low maintenance; system self-regulates and requires minimal oversight. | Requires occasional battery changes and monitoring for functionality. | High maintenance; dependent on user remembering to check and inflate tires regularly. |

| أفضل حالة استخدام | Ideal for fleets, autonomous vehicles, and regions with challenging terrains. | Suitable for standard vehicles where driver awareness is sufficient. | Best for occasional users or vehicles that are not used frequently. |

Tire Pressure Monitoring Systems (TPMS) provide a practical solution by alerting drivers when tire pressure drops below a set threshold. This technology is relatively inexpensive and easy to implement, making it a popular choice for many vehicle manufacturers. However, while TPMS alerts drivers to problems, it does not automatically rectify them; users must take action to inflate the tires. This reliance on driver initiative can lead to delays in addressing tire issues, potentially impacting safety and fuel efficiency.

Traditional tire inflation methods involve manually checking and inflating tires using air compressors or portable pumps. This approach can be cost-effective and straightforward for users familiar with tire maintenance. However, it demands consistent attention and effort from drivers, which can lead to under-inflation if neglected. Moreover, this method does not provide the same level of convenience or safety as self-inflating tires or TPMS, as it does not actively maintain optimal tire pressure.

When evaluating tire technologies, B2B buyers should consider several factors, including the specific operational context, vehicle types, and the importance of safety and efficiency in their fleet. Self-inflating tires are particularly advantageous for businesses operating in challenging environments or relying on autonomous vehicles, where maintaining optimal tire pressure is crucial for safety and performance. Conversely, TPMS may be suitable for standard fleet operations where cost is a significant consideration and driver engagement is sufficient for regular tire maintenance. Traditional methods may appeal to businesses that operate infrequently or have lower technological adoption rates. Ultimately, the right choice will depend on balancing cost, performance, and operational requirements.

Self-inflating tires (SIT) are engineered to enhance safety, fuel efficiency, and tire longevity. Understanding their critical technical properties is essential for B2B buyers looking to invest in this innovative technology.

The materials used in the construction of self-inflating tires are crucial for durability and performance. Typically, SITs utilize high-strength synthetic rubbers and polymers designed to withstand extreme conditions. The choice of material impacts the tire’s resilience against wear and tear, ensuring a longer lifespan and reduced failure rates. For manufacturers, selecting the right material grade can lead to significant cost savings in production and maintenance.

Pressure tolerance refers to the tire’s ability to maintain optimal air pressure under various conditions. A well-designed self-inflating tire can automatically adjust its pressure, accommodating fluctuations due to temperature changes or load variations. For B2B buyers, this feature is paramount as it directly influences vehicle safety, performance, and compliance with regulatory standards.

The efficiency of the inflation mechanism, which typically involves a peristaltic pump integrated within the tire, is a critical performance metric. This mechanism ensures that air is drawn in as needed, maintaining optimal pressure without excessive energy consumption. Understanding this property helps manufacturers assess the technology’s sustainability and operational cost-effectiveness.

Proper weight distribution in the tire design is vital for vehicle stability and handling. Self-inflating tires are engineered to distribute weight evenly, reducing the risk of blowouts and enhancing maneuverability. For buyers, this translates to improved safety metrics and reduced liability in fleet operations.

Illustrative image related to self inflating tires

Self-inflating tires are designed to minimize environmental impact by reducing CO2 emissions and waste from improperly maintained tires. By maintaining optimal tire pressure, these tires contribute to better fuel efficiency, which is increasingly important for companies aiming for sustainable practices. This property can enhance a brand’s reputation and appeal in markets focused on environmental responsibility.

The lifecycle cost of self-inflating tires encompasses initial investment, maintenance, and potential savings from improved fuel efficiency and tire longevity. Buyers need to evaluate this metric to make informed financial decisions that align with their operational budgets.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape.

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of self-inflating tires, OEMs often integrate SIT technology into their vehicles, making it crucial for tire manufacturers to establish partnerships with these companies to secure contracts.

Illustrative image related to self inflating tires

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory effectively and ensure they meet production demands without overcommitting resources.

An RFQ is a document that potential buyers send to suppliers to solicit pricing and terms for specific products. For self-inflating tires, an RFQ can help buyers compare offers from different manufacturers and negotiate better deals.

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. For companies importing self-inflating tires, understanding these terms is essential for managing shipping costs, delivery timelines, and risk allocation.

Illustrative image related to self inflating tires

TPMS is a technology that monitors the air pressure inside tires and alerts the driver when pressure falls below a certain threshold. While self-inflating tires can operate independently of TPMS, the integration of both technologies can enhance overall vehicle safety.

The aftermarket refers to the secondary market for parts and accessories following the sale of the vehicle. Understanding the aftermarket potential for self-inflating tires can help manufacturers identify new revenue streams and customer segments, particularly for retrofitting existing vehicles.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions about integrating self-inflating tire technology into their product offerings or vehicle fleets.

The self-inflating tire (SIT) sector is experiencing transformative growth driven by technological advancements and changing consumer expectations. Global demand for enhanced vehicle safety and fuel efficiency is propelling manufacturers to innovate. The increasing prevalence of electric and autonomous vehicles, particularly in regions like Europe and North America, is creating a fertile ground for SIT adoption. International B2B buyers in markets such as Africa, South America, the Middle East, and Europe should note that SIT technology not only addresses the issue of tire under-inflation—which is linked to numerous road accidents—but also enhances overall vehicle performance.

Emerging sourcing trends reflect a shift towards advanced manufacturing techniques. The integration of SIT systems into existing tire production processes is becoming more streamlined, reducing the associated costs and increasing profit margins for manufacturers. In addition, the growing emphasis on digital solutions in supply chain management is facilitating better tracking and forecasting of SIT demand, providing B2B buyers with valuable insights into inventory management. Companies looking to invest in SIT technology should prioritize partnerships with manufacturers who are early adopters of this innovation, as being first to market can provide a competitive edge.

Sustainability is a pivotal concern in the self-inflating tire sector, influencing both sourcing strategies and consumer preferences. The environmental impact of traditional tires, particularly in terms of waste generation and carbon emissions, has prompted the industry to seek more sustainable alternatives. Self-inflating tires contribute to environmental goals by reducing the frequency of tire replacement and minimizing fuel consumption through optimal inflation. This leads to lower greenhouse gas emissions, an essential consideration for businesses aiming to enhance their sustainability credentials.

Illustrative image related to self inflating tires

Ethical sourcing is increasingly important for B2B buyers, who are now more likely to favor suppliers that demonstrate a commitment to green practices. Certifications related to sustainable manufacturing processes and materials can enhance a company’s reputation and appeal in the marketplace. Buyers should look for manufacturers who utilize eco-friendly materials in their SIT production and those who have implemented responsible supply chain practices. By aligning with suppliers that prioritize sustainability, businesses can not only meet regulatory requirements but also cater to a growing segment of environmentally conscious consumers.

The evolution of self-inflating tire technology dates back several decades, with significant advancements occurring in the early 21st century. Initially developed for military and specialized vehicles, SIT technology has transitioned into the consumer market as a solution to common tire-related issues. The first commercially viable models began to emerge in the late 2000s, with patents filed for various innovations that enhance their functionality.

For B2B buyers, understanding the historical context of SIT is crucial. The technology’s maturation has been accompanied by a growing patent portfolio, which indicates robust intellectual property protection and ongoing innovation. This evolution not only assures buyers of the technology’s reliability but also highlights the competitive advantages available in a rapidly expanding market. As more manufacturers adopt SIT, the technology is likely to become a standard feature in new vehicles, making early investment in this area a strategic move for forward-thinking businesses.

How do I solve the issue of tire under-inflation for my fleet?

Self-inflating tires (SIT) provide a robust solution to the problem of tire under-inflation by automatically maintaining optimal air pressure. This technology integrates a peristaltic tube chamber within the tire, which uses the energy from the tire’s rotation to inflate as needed. By adopting SIT for your fleet, you can significantly reduce the risks associated with under-inflated tires, such as blowouts and reduced fuel efficiency, while enhancing overall vehicle safety and performance.

What is the best self-inflating tire technology for commercial vehicles?

The best self-inflating tire technology for commercial vehicles is the Integrated SIT, designed specifically for new tire manufacturing. This system offers seamless integration during production, providing a competitive edge in the marketplace. For existing fleets, the Retrofit SIT is an excellent choice, allowing you to upgrade standard tires without the need for new purchases. Both options ensure that your vehicles maintain optimal tire pressure, enhancing safety and fuel efficiency.

How can I ensure quality assurance (QA) when sourcing self-inflating tires?

To ensure quality assurance when sourcing self-inflating tires, it is crucial to partner with reputable manufacturers who adhere to international quality standards. Request certifications, such as ISO or other relevant industry qualifications, and conduct factory audits if possible. Additionally, consider requesting samples to evaluate tire performance and durability before placing a bulk order. Establishing clear communication about quality expectations and performance benchmarks will also help mitigate risks.

What are the minimum order quantities (MOQ) for self-inflating tires?

Minimum order quantities (MOQ) for self-inflating tires can vary significantly based on the manufacturer and the specific tire model. Generally, MOQs can range from a few hundred to several thousand units. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Some manufacturers may offer lower MOQs for first-time buyers or bulk purchase discounts, so be sure to explore these options to optimize your procurement strategy.

What payment terms should I expect when purchasing self-inflating tires?

Payment terms for self-inflating tires typically include options like upfront payment, partial payment with the balance on delivery, or credit terms based on established relationships. International buyers should be aware of currency exchange rates and potential transaction fees. It is beneficial to negotiate terms that suit your cash flow needs while ensuring the supplier’s confidence in fulfilling the order. Utilizing secure payment methods and escrow services can also provide additional protection.

How do logistics and shipping impact the procurement of self-inflating tires?

Logistics and shipping play a critical role in the procurement of self-inflating tires, particularly for international buyers. Factors such as shipping routes, customs regulations, and delivery times can affect overall costs and timelines. It’s essential to work with suppliers who have experience in international shipping and can provide detailed information on freight options. Additionally, consider the implications of tariffs and duties on imported goods to accurately budget for your procurement.

Can self-inflating tires be customized for specific vehicle applications?

Yes, self-inflating tires can often be customized to meet specific vehicle applications or performance requirements. Manufacturers may offer options for different tread patterns, sizes, and materials based on your fleet’s needs. Discuss your specific requirements with potential suppliers to explore available customization options and ensure that the tires align with the performance metrics necessary for your operations.

What are the regulatory considerations for importing self-inflating tires?

When importing self-inflating tires, it is essential to comply with local and international regulations governing tire safety and environmental standards. Each country may have specific certifications or testing requirements that tires must meet to be sold legally. Research the regulations in your target markets, and ensure that your supplier can provide the necessary documentation to facilitate a smooth import process. Engaging with a customs broker can also help navigate complex regulatory environments.

المجال: selfinflatingtire.com

مسجل: 2003 (22 سنة)

مقدمة: SIT – Self Inflating Tire Technology

Key Benefits:

– Safety: Properly inflated tires increase car stability, reduce blowout danger, and ensure proper braking distance and vehicle handling.

– Fuel Efficiency: Correct tire pressure lowers rolling resistance, improving fuel efficiency.

– Tire Longevity: Proper inflation extends tire lifespan.

– Environmental Friendliness: Reduces CO2 emissions, tire …

المجال: auto.howstuffworks.com

مسجل: 1998 (27 سنة)

مقدمة: Self-inflating tires allow vehicles to adjust to current terrain for optimal performance and safety. They are commonly used in military and commercial applications, with the CTIS system on Hummers being a notable exception for consumer vehicles. Underinflated tires, which affect 80% of cars on the road, can lead to decreased gas mileage, poor handling, and increased tire wear. Tires can lose air d…

المجال: continental-tires.com

مسجل: 2000 (25 سنة)

مقدمة: The tire that regulates its own pressure utilizes smart tire technology to automatically adapt tire pressure, enhancing driving performance, reducing car maintenance costs, minimizing maintenance time, and optimizing rolling resistance, comfort, and efficiency.

المجال: reddit.com

مسجل: 2005 (20 سنة)

مقدمة: Auto inflating tires are a technology that exists but are not commonly used in passenger cars due to several factors: 1) High cost of implementation (estimated $2000-$3000 extra per vehicle). 2) Complexity of adding an onboard air system, which is already present in trucks but not in cars. 3) The technology is already utilized in military vehicles like US Army Humvees. 4) Most passenger vehicles d…

المجال: rockystirepros.com

مسجل: 2010 (15 سنة)

مقدمة: Self-inflating tires are designed to automatically maintain proper tire pressure, addressing the issue of underinflated tires which can lead to decreased fuel efficiency and increased risk of tire failure. Two innovative designs are highlighted: 1) The SIT system uses a tube chamber near the tire bead that, when tire pressure drops, activates sensors and an automatic pressure regulator to draw in …

In conclusion, the evolution of self-inflating tire technology presents a unique opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By strategically sourcing self-inflating tires, manufacturers can enhance product differentiation, ensuring they remain competitive in a rapidly evolving automotive landscape. The benefits of this technology—ranging from improved safety and fuel efficiency to environmental sustainability—align with increasing consumer demand for innovative solutions.

Moreover, self-inflating tires offer manufacturers lower production costs and higher profit margins, making them an attractive investment. As regulations around tire pressure monitoring become stricter globally, the integration of self-inflating systems not only meets compliance but also directly addresses the critical issue of tire under-inflation, enhancing vehicle safety.

International B2B buyers should consider engaging with manufacturers who hold patents in this domain, such as CODA Development, to explore licensing opportunities. By doing so, companies can capitalize on this pioneering technology and cater to a market increasingly focused on safety and efficiency.

As the automotive industry moves towards autonomous driving and smarter vehicle technologies, self-inflating tires are poised to become a standard feature. Now is the time for strategic sourcing—partner with innovators in this field to secure a competitive edge and drive your business forward in the global marketplace.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.