- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In today’s fast-paced cycling industry, sourcing reliable CO2 tire inflators presents a significant challenge for B2B buyers. With the increasing demand for efficient and user-friendly solutions, companies must navigate a complex landscape of products that vary in design, compatibility, and performance. This guide serves as an invaluable resource, offering insights into the diverse types of CO2 tire inflators available in the global market, their applications across different cycling contexts, and strategies for supplier vetting.

From compact inflators suitable for road cyclists to robust options designed for mountain biking, understanding the nuances of each type can lead to more informed purchasing decisions. Additionally, we delve into cost considerations, ensuring that buyers can evaluate products not just on price but on overall value and performance.

Targeted specifically at international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Nigeria—this guide empowers businesses to select the right products that meet their specific needs. By providing a comprehensive overview of features, advantages, and potential pitfalls, we aim to enhance your purchasing strategy, ensuring that your offerings stand out in a competitive marketplace.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Stand-Alone Chucks | Simple design, lightweight, easy to use | Bike shops, emergency kits | الإيجابيات: Cost-effective, portable. السلبيات: Limited features, may require practice. |

| Inline Inflators | Integrated design with control for gas flow | High-end cycling retailers, sports events | الإيجابيات: Precise inflation, compact. السلبيات: Slightly more complex, potential for leaks. |

| Multi-Tool Inflators | Combines CO2 inflator with other tools | Mechanic shops, cycling tours | الإيجابيات: Versatile, space-saving. السلبيات: Heavier, may lack dedicated inflator features. |

| Electric CO2 Pumps | Battery-operated, automated inflation | High-volume retailers, repair shops | الإيجابيات: Quick inflation, no manual effort. السلبيات: Higher initial investment, requires charging. |

| Cartridge Variants | Compatibility with various cartridge types | Wholesale distributors, specialty retailers | الإيجابيات: Flexible options, suitable for diverse applications. السلبيات: Storage and disposal concerns. |

Stand-alone chucks are the most basic type of CO2 tire inflator, designed for straightforward inflation tasks. Their lightweight and portable nature makes them ideal for bike shops and emergency kits. B2B buyers appreciate their cost-effectiveness and ease of use, but they may require practice to master the inflation technique. For businesses targeting casual cyclists, these inflators represent a low-risk investment.

Inline inflators offer a more sophisticated design, featuring controls that allow users to manage the flow of gas during inflation. This precision makes them suitable for high-end cycling retailers and sports events where performance is critical. While they provide compactness and reliability, businesses should consider potential complexities and the risk of leaks. Buyers focused on quality and user experience may find these inflators highly beneficial.

Multi-tool inflators combine the functionality of a CO2 inflator with other essential tools, making them a practical choice for mechanic shops and cycling tours. Their versatility allows users to carry fewer items, saving space and weight. However, businesses should note that these inflators can be heavier and may not perform as efficiently as dedicated inflators. For shops targeting adventure cyclists, these tools can be a strong selling point.

Electric CO2 pumps represent a modern evolution in tire inflation technology, allowing for quick and automated inflation. These pumps are particularly advantageous for high-volume retailers and repair shops, where speed and efficiency are paramount. While they require a higher initial investment and regular charging, their convenience can attract customers looking for advanced solutions. Retailers should assess their clientele’s needs when considering these options.

Cartridge variants of CO2 inflators are designed to accommodate different types of CO2 cartridges, making them flexible for various applications. This adaptability is particularly appealing to wholesale distributors and specialty retailers serving diverse customer bases. While they offer a range of options for inflation, businesses must also consider the implications of storage and disposal of cartridges. Retailers can benefit from promoting the environmental aspects of cartridge recycling to appeal to eco-conscious consumers.

| الصناعة/القطاع | Specific Application of CO2 Tire Inflator | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Quick tire inflation for roadside assistance services | Reduces downtime and improves customer satisfaction | Ensure compatibility with various tire valves and CO2 cartridge types. |

| Cycling and Outdoor Sports | Portable inflators for cycling events and competitions | Enhances performance and convenience for athletes | Focus on lightweight and compact designs for ease of transport. |

| Logistics and Transportation | Emergency tire inflation for delivery vehicles | Minimizes delays and ensures timely deliveries | Look for robust and reliable inflators that can withstand frequent use. |

| Manufacturing | Maintenance of pneumatic tools and machinery | Ensures operational efficiency and reduces equipment failure | Choose inflators with precise flow control for accurate inflation. |

| Recreational Vehicles | Tire inflation for RVs and off-road vehicles | Provides convenience for travelers in remote locations | Consider durability and ease of use in challenging environments. |

In the automotive repair sector, CO2 tire inflators serve as essential tools for roadside assistance services. These inflators allow technicians to quickly and efficiently inflate tires on-site, significantly reducing vehicle downtime. This capability is vital in enhancing customer satisfaction, as it minimizes wait times for repairs. Buyers in this industry should prioritize inflators that are compatible with various tire valve types and CO2 cartridge configurations to ensure versatility in service offerings.

For cycling and outdoor sports, CO2 tire inflators are indispensable during events and competitions. Athletes often face tire punctures, and the ability to inflate tires swiftly can make a significant difference in performance. These inflators are designed to be portable, allowing cyclists to carry them easily in their gear. B2B buyers in this sector should focus on lightweight and compact designs that facilitate easy transport while ensuring efficient inflation capabilities.

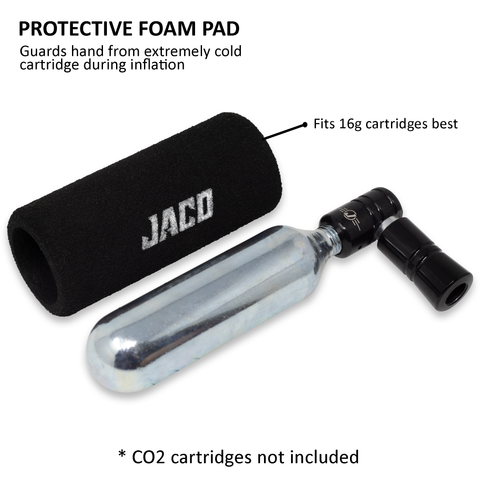

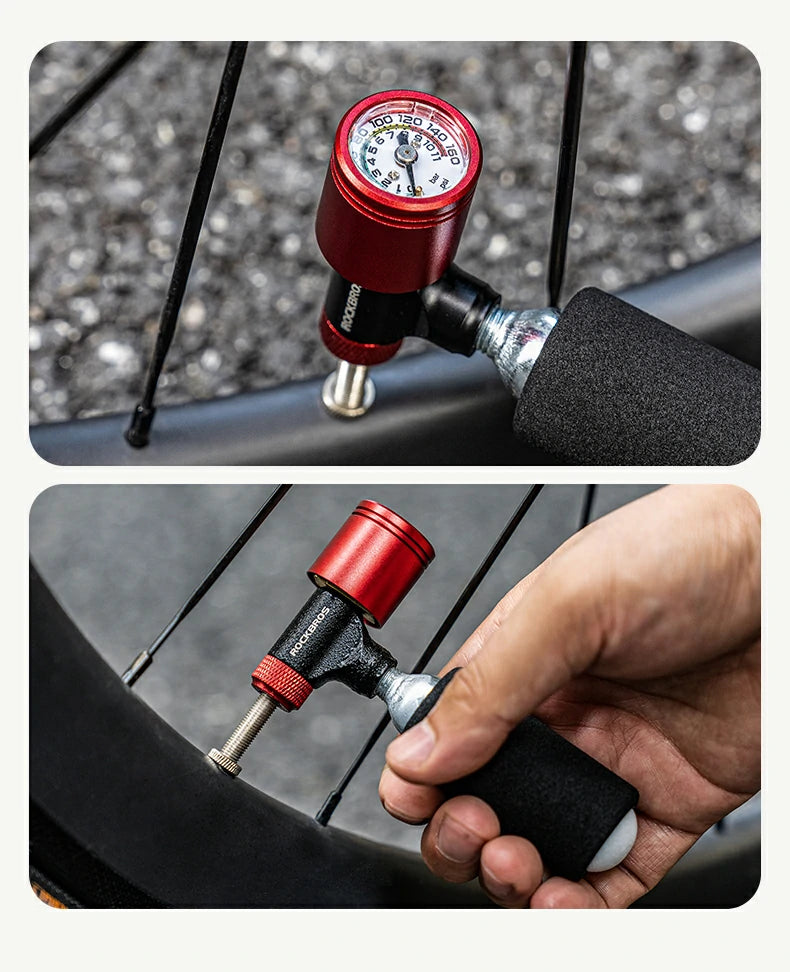

Illustrative image related to co2 tire inflator

In logistics and transportation, CO2 tire inflators are utilized for emergency tire inflation in delivery vehicles. Quick inflation solutions are crucial in minimizing delays and ensuring that deliveries are made on time. Businesses in this sector benefit from inflators that are robust and reliable, capable of withstanding frequent use in various conditions. Buyers should consider the durability and ease of use of these inflators, as they are often used in high-pressure situations.

Manufacturing environments often rely on pneumatic tools and machinery, which require regular maintenance and inflation. CO2 tire inflators can be employed to maintain optimal pressure in these tools, ensuring operational efficiency and reducing the likelihood of equipment failure. For B2B buyers in this industry, selecting inflators with precise flow control is essential to achieve accurate inflation, thereby enhancing tool performance and longevity.

In the recreational vehicle (RV) sector, CO2 tire inflators offer vital convenience for travelers, especially in remote locations where traditional air sources may be unavailable. The ability to quickly inflate tires can prevent potentially hazardous situations and enhance safety on the road. Buyers looking to source inflators for this application should focus on models that are durable and easy to use, ensuring they can withstand the challenges of outdoor environments while providing reliable performance.

المشكلة B2B buyers often struggle to select the appropriate CO2 tire inflator that meets the varying demands of their customers or fleet. Different types of bicycles and vehicles require distinct inflation mechanisms, particularly when considering valve types (Presta vs. Schrader) and compatibility with various CO2 cartridge sizes. This challenge can lead to customer dissatisfaction if the wrong inflator is provided, resulting in lost sales and damaged reputations.

Illustrative image related to co2 tire inflator

الحل: To effectively address this issue, B2B buyers should conduct a thorough analysis of the specific needs of their target market. This includes assessing the types of bicycles or vehicles most commonly used by their customers and the prevalent valve types in their region. Buyers can enhance their product offerings by sourcing inflators that are versatile, such as those compatible with both Presta and Schrader valves, and that accept a range of CO2 cartridge sizes. Additionally, consider providing a selection of inflators with features such as flow control to cater to different user preferences and inflation scenarios. Establishing relationships with reliable suppliers who offer customizable options can also facilitate a tailored inventory that meets diverse customer needs.

المشكلة As global awareness of environmental issues increases, B2B buyers face pressure from customers who are concerned about the sustainability of CO2 cartridges. The reliance on disposable cartridges can be perceived as wasteful, potentially affecting brand image and customer loyalty. Moreover, supply chain disruptions can lead to shortages, making it challenging for businesses to maintain adequate stock for their customers.

الحل: Buyers can alleviate these concerns by diversifying their product range to include eco-friendly alternatives, such as rechargeable electric pumps or hybrid systems that combine CO2 inflators with manual pumps. This approach not only addresses environmental concerns but also provides customers with options that may reduce long-term costs. Additionally, establishing partnerships with suppliers who prioritize sustainability can ensure a steady supply of cartridges made from recyclable materials. Providing educational resources to customers about the environmental impact of their choices can further enhance brand loyalty and position the business as a responsible industry leader.

المشكلة Many users encounter difficulties when using CO2 tire inflators, which can result in improper inflation and user frustration. Common issues include difficulty attaching the inflator to the valve, loss of CO2 during inflation, and insufficient control over the inflation process. These problems can lead to negative feedback from customers, impacting sales and brand reputation.

الحل: To improve user experience, B2B buyers should prioritize sourcing inflators that are designed with user-friendly features. This includes inflators with clear instructions, ergonomic designs for easy handling, and flow control mechanisms that allow users to manage the inflation process effectively. Offering demonstration sessions or instructional materials can further help users understand how to use the product correctly. Additionally, incorporating customer feedback into product selection can guide buyers in choosing inflators that address common pain points, ensuring that the products they offer enhance the overall user experience and encourage repeat business.

When selecting materials for CO2 tire inflators, several options are commonly considered, each with distinct properties and implications for performance, durability, and cost. Here, we analyze four prevalent materials: aluminum, plastic, stainless steel, and brass.

Aluminum is a popular choice for CO2 tire inflators due to its lightweight nature and excellent strength-to-weight ratio. It typically exhibits good corrosion resistance, particularly when anodized, making it suitable for various environmental conditions. The temperature and pressure ratings of aluminum are generally adequate for CO2 applications, allowing it to handle the rapid gas expansion without compromising safety.

Illustrative image related to co2 tire inflator

الإيجابيات: Aluminum is durable, lightweight, and relatively inexpensive compared to other metals. Its ease of machining and forming allows for complex designs, which can enhance functionality.

السلبيات: While aluminum is resistant to corrosion, it can be prone to scratches and dents, which may affect its aesthetic appeal and long-term performance. Additionally, the manufacturing complexity can increase costs if intricate designs are required.

التأثير على التطبيق: Aluminum’s compatibility with CO2 makes it an excellent choice for inflators. However, international buyers should ensure that the aluminum used meets specific standards for pressure vessels, such as those outlined by ASTM or DIN.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is often used for components like grips or protective sleeves in CO2 inflators. These materials are lightweight and can provide adequate insulation against the cold generated during CO2 release.

الإيجابيات: Plastics are generally less expensive than metals and can be molded into complex shapes, allowing for innovative designs. They also offer excellent resistance to corrosion and chemical exposure.

السلبيات: Plastics may not withstand high pressures as effectively as metals, which could limit their use in critical components of the inflator. Additionally, they are less durable and can degrade over time when exposed to UV light or extreme temperatures.

التأثير على التطبيق: While suitable for non-structural components, buyers must consider the pressure ratings of plastic materials. Compliance with safety standards is crucial, especially in regions with stringent regulations.

Stainless steel is another viable option for CO2 inflators, particularly for components that require high strength and corrosion resistance. It can withstand higher pressures and temperatures, making it suitable for heavy-duty applications.

الإيجابيات: Stainless steel is extremely durable and resistant to corrosion, ensuring a long lifespan even in harsh environments. Its aesthetic appeal is also a plus for premium products.

السلبيات: The primary drawback is its weight; stainless steel inflators can be significantly heavier than their aluminum counterparts. Additionally, the cost of stainless steel can be higher, impacting the overall price point of the inflator.

التأثير على التطبيق: Given its robustness, stainless steel is often preferred for high-performance inflators. Buyers in regions with variable climates, like the Middle East or South America, should consider its superior durability.

Brass is often used for valve fittings and connectors in CO2 inflators due to its excellent corrosion resistance and mechanical properties. It can handle the pressures associated with CO2 gas effectively.

الإيجابيات: Brass offers good machinability and is less likely to corrode than other metals, making it a reliable choice for fittings that require a tight seal.

السلبيات: Brass can be heavier than aluminum and may be more expensive. Additionally, it is susceptible to dezincification in certain environments, which could compromise its integrity.

التأثير على التطبيق: Brass components must meet specific international standards for pressure fittings. Buyers should ensure that the brass used is of high quality and suitable for the intended application.

| المواد | Typical Use Case for CO2 Tire Inflator | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | Body and housing | خفيفة الوزن ومتينة | Prone to scratches and dents | متوسط |

| بلاستيك | Grips and protective sleeves | Cost-effective and moldable | Limited pressure resistance | منخفضة |

| الفولاذ المقاوم للصدأ | High-pressure components | Excellent durability | أثقل وزناً وأغلى ثمناً | عالية |

| Brass | Valve fittings and connectors | Corrosion-resistant | Can be heavy and susceptible to dezincification | متوسط |

This guide provides B2B buyers with insights into material selection for CO2 tire inflators, helping them make informed decisions based on performance, cost, and regional compliance standards.

Illustrative image related to co2 tire inflator

The manufacturing of CO2 tire inflators involves several critical stages, each designed to ensure the product meets both performance and safety standards.

The first stage in manufacturing CO2 tire inflators is material preparation. Typically, high-grade aluminum is used due to its lightweight and corrosion-resistant properties. In some cases, durable plastics may be incorporated for specific components. The materials undergo rigorous quality checks to ensure they meet specified standards for strength and durability. Suppliers must provide certificates of compliance that detail the material properties, which are crucial for B2B buyers seeking reliability in performance.

Once the materials are approved, they proceed to the forming stage. Techniques such as CNC machining and extrusion are commonly employed to create the inflator components. CNC machining is particularly favored for producing precise parts like valve heads and attachment threads, ensuring a snug fit for both Presta and Schrader valves. The use of advanced forming technologies reduces waste and enhances dimensional accuracy, which is crucial for the inflator’s operation.

The assembly process is where individual components come together to form the final product. This stage often utilizes automated assembly lines to enhance efficiency while minimizing human error. Manual assembly may still play a role in quality-sensitive areas, such as ensuring the proper sealing of gas cartridges and checking the functionality of flow control mechanisms. Each inflator typically undergoes a functional test at this stage to verify that it can effectively inflate tires without leaks or malfunctions.

Finishing processes such as anodizing or powder coating are used to enhance the aesthetic appeal and corrosion resistance of the inflators. These techniques not only improve the product’s longevity but also contribute to its marketability. The finishing stage is vital for B2B buyers, as a well-finished product can lead to higher customer satisfaction and brand loyalty.

Quality assurance is critical in the manufacturing of CO2 tire inflators, especially given their role in safety and performance. International and industry-specific standards guide these processes.

ISO 9001 is a globally recognized standard for quality management systems (QMS). Manufacturers of CO2 tire inflators should be certified to this standard, which emphasizes the importance of consistent quality and customer satisfaction. The CE marking is particularly relevant in the European market, indicating that the product meets EU safety and environmental requirements. For B2B buyers, verifying that suppliers have these certifications can mitigate risks associated with product quality.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

مراقبة الجودة الواردة (IQC): This step verifies the quality of raw materials before they enter production. It includes testing for material properties and adherence to specifications.

مراقبة الجودة أثناء العملية (IPQC): During manufacturing, various inspections are conducted to ensure each stage meets quality standards. This includes checking the accuracy of CNC machining and verifying assembly integrity.

مراقبة الجودة النهائية (FQC): Before packaging, each inflator undergoes a final inspection and testing phase. This includes functional tests to ensure proper inflation and leak detection.

To ensure the reliability and safety of CO2 tire inflators, manufacturers employ several testing methods:

Illustrative image related to co2 tire inflator

Leak Testing: This is vital for confirming that the inflator does not lose gas during operation. Techniques include pressure decay testing and bubble tests.

الاختبار الوظيفي: Each unit is tested to ensure it can inflate a tire to the required pressure within a specified time frame.

اختبار المتانة: This involves simulating prolonged use and exposure to varying environmental conditions to assess the inflator’s longevity.

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers:

عمليات تدقيق الموردين: Conducting on-site audits can provide insights into the manufacturing environment and QC practices. This is particularly important for international buyers who may not be familiar with local suppliers.

Reviewing QC Reports: Suppliers should provide detailed QC reports documenting test results and compliance with international standards. These reports can serve as a basis for assessing product reliability.

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing process and the quality of finished products. This is especially valuable for buyers in regions like Africa and South America, where local compliance may vary.

International B2B buyers must navigate various nuances in QC and certification processes:

Cultural and Regulatory Differences: Buyers should be aware of regional regulations and certifications that may differ from their own. For instance, while CE marking is essential in Europe, other regions may have different compliance standards.

Supply Chain Transparency: Ensuring transparency in the supply chain can help buyers understand where and how products are manufactured. This is particularly relevant for buyers from emerging markets who may face challenges related to quality consistency.

Environmental Considerations: With rising awareness of environmental issues, buyers should consider the ecological impact of CO2 canisters. Manufacturers that adhere to sustainable practices and offer recyclable products can be more appealing to conscientious buyers.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing CO2 tire inflators, ultimately ensuring they choose reliable products that meet their operational needs.

This practical sourcing guide is designed to assist B2B buyers in the effective procurement of CO2 tire inflators. Given the growing demand for efficient and portable inflation solutions in diverse markets, understanding the key factors in selecting the right inflator is essential. This checklist will streamline the sourcing process and help ensure that you acquire a high-quality product that meets your specific needs.

Before diving into the market, clearly outline the technical specifications required for your CO2 tire inflators. Consider factors such as:

– Valve Compatibility: Ensure the inflator supports both Presta and Schrader valves to cater to a broader range of bicycles.

– Cartridge Size: Determine if you need inflators that accept 16g or 25g cartridges, as this will impact the inflation speed and efficiency.

Illustrative image related to co2 tire inflator

Stay informed about the latest trends and innovations in CO2 tire inflators. This step is crucial for understanding the competitive landscape and identifying features that may enhance your product offering. Look for:

– User Reviews: Analyze feedback on functionality, ease of use, and durability from cyclists and businesses.

– Emerging Technologies: Pay attention to advancements such as integrated flow control systems or environmentally friendly cartridge options.

Before committing to a supplier, conduct thorough evaluations. This ensures you align with reputable manufacturers that can consistently deliver quality products. Focus on:

– Company Credentials: Request documentation of certifications, such as ISO or industry-specific standards.

– Track Record: Ask for case studies or references from other businesses, particularly those in your target market regions.

Understanding the pricing structure is essential for budget management. Compare various suppliers to find a balance between quality and cost. Consider:

– خصومات الشراء بالجملة: Inquire if suppliers offer discounts for larger orders, which can significantly reduce costs.

– Payment Terms: Evaluate the payment options available, ensuring they align with your financial strategy and cash flow management.

Before finalizing your order, always request product samples. This step allows you to verify the quality and functionality of the inflators firsthand. Look for:

– سهولة الاستخدام: Test the inflator’s operation to ensure it meets user expectations.

– Build Quality: Assess the materials used in the inflator to ensure durability and reliability in various conditions.

Illustrative image related to co2 tire inflator

After-sales support is a crucial aspect of your procurement process. Ensure the supplier provides adequate support and warranty options. Consider:

– Customer Service Availability: Check if they offer responsive customer service for troubleshooting or product inquiries.

– Warranty Terms: Review warranty policies to understand coverage on defects or malfunctions, which can affect long-term satisfaction.

Once you’ve completed the above steps, draft a procurement agreement that encapsulates all terms discussed. This contract should include:

– Delivery Timelines: Specify expected delivery dates to align with your inventory needs.

– Quality Assurance Measures: Outline quality checks and protocols to be followed upon receipt of the inflators.

By following this checklist, B2B buyers can effectively navigate the procurement process for CO2 tire inflators, ensuring they make informed decisions that align with their operational requirements and market expectations.

When considering the sourcing of CO2 tire inflators, a thorough understanding of the cost structure and pricing dynamics is essential for international B2B buyers. This guide provides a detailed analysis of the various cost components, price influencers, and practical tips to maximize value while navigating the global market.

Illustrative image related to co2 tire inflator

المواد: The primary materials used in CO2 tire inflators include lightweight metals like aluminum, plastics, and rubber for seals. The choice of materials significantly affects durability and overall performance, impacting the final price.

العمالة: Labor costs vary by region and depend on the complexity of the manufacturing process. Automated production can reduce labor costs, while manual assembly might drive them higher, particularly in regions with higher wage standards.

نفقات التصنيع الزائدة: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can minimize these costs, making it essential for buyers to assess suppliers’ operational efficiencies.

الأدوات: The cost of molds and tools used in production is a significant factor, especially for customized inflators. High-quality tooling can enhance product precision but may require a larger upfront investment.

مراقبة الجودة (QC): Implementing stringent QC measures ensures product reliability, which is vital for customer satisfaction. However, these processes add to the overall cost, and buyers should consider the balance between quality and price.

الخدمات اللوجستية: Shipping costs are influenced by the distance from the manufacturer to the buyer, the mode of transportation, and the weight of the products. For bulk orders, freight costs can be negotiated, but buyers should be mindful of potential delays.

الهامش: Suppliers typically apply a profit margin to cover their costs and earn a profit. Understanding the competitive landscape can provide leverage in negotiations, especially for bulk orders.

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capacity to optimize pricing.

المواصفات والتخصيص: Tailoring inflators to specific requirements can increase costs. Buyers should weigh the benefits of customization against the additional expenses it incurs.

المواد وشهادات الجودة: The use of high-grade materials and certifications (e.g., ISO, CE) can enhance product value but also raise costs. Buyers in markets with stringent regulations should prioritize certified products to ensure compliance.

عوامل الموردين: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may command higher prices due to their reliability and quality assurance.

المصطلحات التجارية الدولية: Understanding Incoterms (International Commercial Terms) is crucial, as they dictate responsibilities between buyers and sellers regarding shipping, insurance, and tariffs. This can impact the total cost of ownership significantly.

Leverage Negotiation: Engage in discussions with multiple suppliers to obtain competitive quotes. Highlighting potential long-term partnerships can incentivize suppliers to offer better pricing.

التركيز على كفاءة التكلفة: Assess the total cost of ownership rather than just the purchase price. Consider factors like durability, warranty, and potential replacement costs over time.

فهم الفروق الدقيقة في التسعير للأسواق الدولية: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, exchange rates, and import tariffs that can influence pricing. Custom duties can vary significantly, impacting the overall cost.

البحث والعناية الواجبة: Conduct thorough research on potential suppliers, including their production capabilities, financial stability, and customer reviews. This knowledge can empower buyers to make informed decisions and negotiate effectively.

In conclusion, a comprehensive understanding of the cost structure and pricing dynamics of CO2 tire inflators is vital for international B2B buyers. By considering these elements and leveraging negotiation strategies, buyers can secure optimal pricing and enhance their procurement processes.

In the realm of tire inflation, particularly for bicycles and vehicles, CO2 tire inflators are a popular choice due to their convenience and speed. However, there are several alternative solutions that businesses may consider when evaluating their options for tire inflation. This analysis compares CO2 tire inflators with two viable alternatives: manual hand pumps and electric tire pumps. Each solution offers distinct advantages and disadvantages, making it crucial for B2B buyers to choose based on their specific requirements.

| جانب المقارنة | CO2 Tire Inflator | Manual Hand Pump | Electric Tire Pump |

|---|---|---|---|

| الأداء | Quick inflation, suitable for emergency use | Slower inflation, requires physical effort | Fast inflation, can handle multiple tires |

| التكلفة | Moderate initial cost, ongoing cost for cartridges | Low initial cost, no ongoing costs | Higher initial investment, low maintenance costs |

| سهولة التنفيذ | Simple to use, requires CO2 cartridges | Requires physical effort, user skill | Plug-and-play operation, minimal user skill needed |

| الصيانة | Minimal maintenance, cartridge replacement needed | Low maintenance, occasional lubrication | Low maintenance, requires electrical checks |

| أفضل حالة استخدام | Emergency situations, racing scenarios | Everyday use, casual cycling | Frequent use, workshops, or commercial settings |

Manual hand pumps are a traditional and cost-effective option for tire inflation. They are lightweight, portable, and require no additional consumables, making them ideal for everyday use. However, their performance is slower compared to CO2 inflators, and they demand physical effort from the user, which may not be ideal in emergency situations or for those with limited strength. While they are reliable for casual cycling, they may not be the best choice for competitive settings where speed is essential.

Electric tire pumps provide a modern solution to tire inflation, offering the advantage of quick and efficient inflation without the need for manual effort. They are particularly useful for frequent users, such as workshops or commercial settings, where multiple tires may need to be inflated in a short time. However, electric pumps typically come with a higher initial investment and may require electrical maintenance. They are less portable than CO2 inflators and can be overkill for casual cyclists who may only need to inflate a tire occasionally.

When considering which tire inflation solution to adopt, B2B buyers should evaluate their specific needs. If speed and convenience are paramount—especially in emergency scenarios—CO2 tire inflators are a compelling choice. For businesses focused on cost-effectiveness and everyday use, manual hand pumps may suffice. Conversely, electric tire pumps serve as an excellent option for operations requiring regular, high-volume tire inflation. Ultimately, the decision should align with the operational requirements, budget constraints, and the intended use cases of the business. By carefully assessing these factors, buyers can select the most suitable tire inflation technology for their needs.

When evaluating CO2 tire inflators, several critical specifications must be considered to ensure product efficacy and reliability. Here are the key technical properties that B2B buyers should focus on:

Illustrative image related to co2 tire inflator

The most common materials used in CO2 tire inflators are aluminum and high-grade plastics. Aluminum is favored for its lightweight yet durable properties, which are essential for portability. The choice of material affects the inflator’s resistance to corrosion and wear, crucial for products sold in varying climates, particularly in regions like Africa and the Middle East where humidity and temperature fluctuations can be significant.

Most CO2 inflators are designed to accommodate either threaded or non-threaded cartridges, typically in 16g sizes. This compatibility is vital as it ensures that users can find suitable cartridges easily, minimizing downtime during emergencies. Buyers should ensure that the inflator they choose can handle multiple cartridge types to cater to different market preferences.

CO2 tire inflators must be compatible with both Presta and Schrader valves. This dual compatibility allows the inflator to be used with a wider range of bicycles, which is particularly important in diverse markets where different valve types are prevalent. Ensuring that the inflator can easily switch between these valves without requiring additional adapters can enhance user experience.

A good inflator should feature a flow control mechanism, allowing users to adjust the rate of CO2 release. This feature is essential for achieving the desired tire pressure and helps prevent over-inflation, which can lead to tire damage. In competitive cycling markets, the ability to finely control inflation can be a significant selling point.

Illustrative image related to co2 tire inflator

Compact design is crucial for portability, especially for cyclists who may carry inflators in small bags or jersey pockets. Inflators weighing around 100 grams and measuring less than 130 mm in length are generally considered optimal. Buyers should assess the size-to-weight ratio, as this impacts both shipping costs and user convenience.

Safety features, such as protective sleeves for cartridges, are essential to prevent cold burns from the CO2 release. Additionally, features that prevent accidental discharge when cartridges are loaded are important for user safety and should be highlighted in product specifications.

Understanding industry terminology is crucial for effective communication between buyers and suppliers. Here are several key terms frequently encountered in the CO2 tire inflator market:

This term refers to companies that manufacture products based on specifications provided by another company. In the context of CO2 inflators, an OEM may produce inflators under another brand’s label, allowing for cost-effective production and branding strategies.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is critical for budgeting and inventory planning. Suppliers may have different MOQs based on production capabilities, which can affect order sizes and pricing.

An RFQ is a formal process where buyers request pricing information and terms from suppliers. This is particularly useful in B2B transactions for CO2 tire inflators, allowing buyers to compare offers and negotiate terms effectively.

Incoterms define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs, which is essential for B2B transactions involving CO2 tire inflators, especially when dealing with international suppliers from regions like Europe and South America.

Lead time refers to the time it takes from placing an order to receiving it. Understanding lead times is crucial for B2B buyers to manage inventory levels and ensure timely availability of CO2 tire inflators, particularly in markets with high demand.

Illustrative image related to co2 tire inflator

Certification standards, such as ISO or CE marking, ensure that products meet specific safety and quality benchmarks. For B2B buyers, verifying these certifications can help guarantee that the CO2 tire inflators they purchase are reliable and safe for end-users.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing CO2 tire inflators, ensuring they meet market needs and regulatory requirements.

The global market for CO2 tire inflators is witnessing significant growth, driven by the increasing adoption of cycling as a sustainable mode of transportation and recreational activity. In regions such as Africa, South America, the Middle East, and Europe, the demand for portable and efficient inflation solutions is surging. Factors such as urbanization, an expanding cycling culture, and rising awareness about the need for quick tire repairs are propelling this trend. Notably, the emergence of electric bicycles is also influencing the market, as these bikes often require lightweight and user-friendly inflators that can be easily carried.

Technological advancements are shaping the sourcing landscape, with innovations in materials and design enhancing the functionality of CO2 inflators. Manufacturers are increasingly focusing on producing inflators that are compatible with both Presta and Schrader valves, providing versatility for users. Furthermore, the integration of flow control mechanisms is becoming a standard feature, allowing cyclists to achieve precise tire pressure. As B2B buyers seek to differentiate their offerings, sourcing products that leverage these technologies will be crucial.

International B2B buyers should also consider the implications of fluctuating raw material costs and supply chain disruptions. The COVID-19 pandemic highlighted vulnerabilities in global supply chains, prompting many companies to explore local sourcing options. Buyers from emerging markets like Nigeria and Saudi Arabia may find opportunities in partnering with local manufacturers who can provide competitive pricing and faster delivery times, thus enhancing their market responsiveness.

Sustainability has become a cornerstone of B2B purchasing decisions, particularly in the cycling industry. The environmental impact of CO2 cartridges, primarily made from aluminum, necessitates responsible sourcing practices. As global awareness about climate change grows, buyers are increasingly looking for suppliers who prioritize sustainable materials and manufacturing processes.

Ethical sourcing is also critical in the CO2 tire inflator sector. B2B buyers should seek partnerships with manufacturers who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001, which focuses on effective environmental management systems, and the Global Recycle Standard, which ensures recycled materials are used responsibly, can serve as benchmarks for sustainability.

Furthermore, the growing trend of eco-friendly products is influencing consumer preferences, prompting manufacturers to explore biodegradable or recyclable packaging solutions. Buyers can leverage these trends by sourcing inflators that highlight their sustainable attributes, enhancing their brand reputation and appeal among environmentally conscious consumers.

The evolution of CO2 tire inflators can be traced back to the late 20th century when cycling enthusiasts began seeking efficient solutions for puncture repairs. Initially, inflators were rudimentary, often lacking the precision and reliability that modern cyclists expect. Over the years, advancements in materials and design have led to the development of lightweight, compact inflators that can inflate tires in seconds.

Illustrative image related to co2 tire inflator

The introduction of threaded and non-threaded CO2 cartridges significantly improved usability, allowing users to quickly switch between different types of valves. Today, CO2 inflators are a staple in the cycling accessories market, with ongoing innovations focusing on enhancing user experience and environmental sustainability. For B2B buyers, understanding this historical context is vital for recognizing the value proposition of modern CO2 inflators and making informed sourcing decisions that align with current market demands.

How do I choose the right CO2 tire inflator for my business needs?

Choosing the right CO2 tire inflator involves considering several factors, including compatibility with valve types (Presta and Schrader), size, weight, and ease of use. Evaluate the inflator’s construction material; lightweight aluminum is preferred for portability. Additionally, consider flow control features that allow precise inflation, as this can reduce CO2 waste. Assess your target market’s needs and preferences, which may vary by region, particularly in Africa, South America, the Middle East, and Europe.

What is the best CO2 tire inflator for commercial use?

The best CO2 tire inflator for commercial use is one that offers reliability, speed, and ease of operation. Models such as the Muc-Off Road Inflator Kit and Lezyne Control Drive are highly recommended due to their robust build quality, compatibility with both Presta and Schrader valves, and effective flow control. Ensure that the inflator can handle a high volume of use, as this will be crucial for businesses catering to cyclists or automotive customers.

How do I vet suppliers for CO2 tire inflators?

When vetting suppliers for CO2 tire inflators, prioritize those with a solid reputation and verified credentials. Request samples to assess product quality and ensure compliance with international safety and environmental standards. Check for certifications, such as ISO, and seek reviews or references from other B2B buyers. Engaging in direct communication can also help gauge the supplier’s responsiveness and willingness to customize products according to your specifications.

What are common payment terms for international purchases of CO2 tire inflators?

Payment terms for international purchases can vary significantly but often include options like advance payment, letter of credit, or net 30/60/90 days, depending on the supplier’s policies and the buyer’s creditworthiness. It is advisable to clarify payment methods upfront and consider using secure platforms that protect both parties. Understand any currency conversion implications, especially when dealing with suppliers across different regions.

What is the minimum order quantity (MOQ) for CO2 tire inflators?

The minimum order quantity (MOQ) for CO2 tire inflators can vary based on the supplier and the product specifications. Typically, MOQs can range from 100 to 1,000 units. Larger orders often lead to better pricing, so it’s beneficial to discuss potential discounts for bulk purchases. If your business model involves retail or distribution, consider negotiating lower MOQs to test market demand without significant upfront investment.

How do I ensure quality assurance (QA) for CO2 tire inflators?

To ensure quality assurance for CO2 tire inflators, establish clear specifications with your supplier regarding materials, performance, and safety standards. Conduct regular inspections during production and upon receipt of goods. It’s also advisable to request third-party testing reports to verify compliance with relevant regulations. Implementing a quality control checklist can help maintain consistency in product quality across shipments.

What logistics considerations should I keep in mind when importing CO2 tire inflators?

When importing CO2 tire inflators, consider logistics aspects such as shipping methods, customs clearance, and potential tariffs. Evaluate different shipping options (air, sea, or land) based on cost, speed, and reliability. Ensure that your supplier provides all necessary documentation for customs, including bills of lading and certificates of origin. Additionally, factor in storage and distribution logistics within your target market to optimize delivery times.

Can I customize CO2 tire inflators for my brand?

Yes, many suppliers offer customization options for CO2 tire inflators, allowing you to incorporate your branding, such as logos or specific color schemes. Discuss your requirements early in the sourcing process to determine the feasibility of customization and any associated costs. Customization can enhance brand visibility and differentiate your products in competitive markets, particularly in regions like Africa and South America where branding can significantly influence purchasing decisions.

المجال: planetbike.com

مسجل: 1997 (28 سنة)

مقدمة: {“Product Name”: “Airship 2.0 CO2 Bike Inflator”, “Brand”: “Planet Bike”, “SKU”: “1025”, “Price”: “$20.00”, “Condition”: “New”, “Color”: “Black”, “Pump Type”: “CO2 Inflator”, “Valve Type”: “Presta and Schrader”, “CO2 Cartridge Compatibility”: “Accepts 16g THREADED and NON-THREADED CO2 cartridges”, “Construction”: “Lightweight aluminum design stores cartridge and protects from cold cartridge when i…

المجال: ride.lezyne.com

مسجل: 2007 (18 سنة)

مقدمة: Lezyne CO2 inflators provide instant, reliable tire inflation in seconds, ideal for road bikes and mountain bikes. Key products include: PRESSURE DRIVE CFH ($43.99, regular price $54.99), CLIK™ DRIVE CO2 WITH 20G CARTRIDGE ($37.99), CADDY KIT ($26.39, regular price $32.99), CONTROL DRIVE CO2 (from $23.99, regular price $29.99), TWIN KIT (from $23.99, regular price $29.99), 25G CO2 – 5 PACK ($22.39…

المجال: genuineinnovations.com

مسجل: 2004 (21 سنة)

مقدمة: Reliable and durable CO2 tire inflators for cyclists of all experience levels. Products include inflators, CO2 cartridges, and tools & accessories. All products come with a lifetime guarantee.

المجال: ridepdw.com

مسجل: 2008 (17 سنة)

مقدمة: Bike Pumps & CO2 Tire Inflators include various models such as:

– Timber to Town: Cloud Cap CO2 Inflator – $39.00

– Shiny Object – from $19.00

– Tiny Object – $22.00

– Fatty Object – from $19.00

– Timber to Town: Cloud Cap Gravel Pump + CO2 Inflator – $89.00

– Ninja Pump – $35.00

– 38g CO2 Cartridge – $15.00

– 16g CO2 Cartridge Packs – from $10.00

– Leather CO2 Cartridge Sleeve – $5.00

-…

As the demand for CO2 tire inflators continues to rise across global markets, strategic sourcing becomes essential for B2B buyers looking to enhance their product offerings. Key takeaways from our analysis emphasize the importance of selecting high-quality, reliable inflators that cater to diverse consumer needs. Buyers should prioritize compatibility with both Presta and Schrader valves, ease of use, and the availability of replacement cartridges to ensure customer satisfaction and product longevity.

Investing in CO2 tire inflators not only addresses immediate consumer needs during emergencies but also positions businesses to capitalize on the growing cycling trend, particularly in regions like Africa, South America, the Middle East, and Europe. By sourcing from reputable manufacturers, businesses can secure competitive pricing and improve their supply chain resilience.

Looking ahead, the market for CO2 inflators is poised for growth, driven by the increasing popularity of cycling as a sustainable mode of transport. We encourage international B2B buyers to explore partnerships with innovative suppliers to stay ahead of market trends and meet evolving customer demands. Embrace strategic sourcing today to elevate your product range and drive business success in the coming years.

Illustrative image related to co2 tire inflator

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.