- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the competitive landscape of automotive parts, sourcing an AutoZone compressor can present significant challenges for international B2B buyers. With the air conditioning compressor being a critical component that ensures optimal vehicle performance and comfort, understanding its various types, applications, and maintenance requirements is essential for making informed purchasing decisions. This comprehensive guide delves into the intricacies of AutoZone compressors, offering insights into the different models available, their specific uses across diverse vehicle types, and the importance of selecting the right components for effective air conditioning systems.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Germany—will benefit from our detailed examination of supplier vetting processes. We will also explore cost considerations, highlighting factors that influence pricing and potential savings for bulk purchases. Additionally, we aim to equip buyers with practical tips for navigating local regulations and logistics, ensuring a seamless procurement experience. By providing actionable insights and comprehensive data, this guide empowers B2B buyers to make strategic decisions, ultimately enhancing their operational efficiency and customer satisfaction in the automotive sector.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Reciprocating Compressor | Uses pistons to compress refrigerant; common in older models | Repair shops, automotive maintenance | الإيجابيات: High efficiency, reliable. السلبيات: Noisy, requires more maintenance. |

| Scroll Compressor | Features spiral design; compact and efficient | OEMs, aftermarket replacements | الإيجابيات: Quiet operation, fewer moving parts. السلبيات: تكلفة أولية أعلى. |

| Rotary Compressor | Utilizes rotating vanes; compact and lightweight | Small vehicles, motorcycles | الإيجابيات: Lightweight, efficient. السلبيات: Limited cooling capacity for larger vehicles. |

| Variable Displacement Compressor | Adjusts output based on cooling demand; enhances efficiency | Luxury vehicles, heavy-duty applications | الإيجابيات: Energy-efficient, reduces wear. السلبيات: Complex installation and higher cost. |

| Electric Compressor | Powered by electricity; no reliance on engine RPM | Hybrid and electric vehicles | الإيجابيات: Environmentally friendly, versatile. السلبيات: More expensive, requires specialized components. |

Reciprocating compressors are traditional units that utilize pistons to compress refrigerant. They are commonly found in older vehicle models and are favored for their reliability and efficiency in cooling. B2B buyers should consider the maintenance requirements and noise levels associated with these compressors. While they are generally cost-effective, the need for regular upkeep can impact overall operational costs.

Scroll compressors employ a spiral design that enhances efficiency and minimizes noise. Their compact size makes them suitable for a variety of applications, particularly in OEM and aftermarket replacements. For B2B buyers, the initial investment might be higher, but the long-term savings in energy costs and reduced maintenance make them an attractive option. Their quiet operation also adds value in customer-facing environments.

Rotary compressors are characterized by their lightweight and compact design, making them ideal for small vehicles and motorcycles. They operate using rotating vanes, which provide efficient cooling. B2B buyers should consider their application needs, as rotary compressors may have limitations in cooling capacity for larger vehicles. However, their efficiency and ease of installation can make them appealing for businesses focused on smaller automotive solutions.

Variable displacement compressors offer advanced technology that adjusts output based on the vehicle’s cooling demand. This feature enhances energy efficiency and prolongs the lifespan of the compressor. They are often found in luxury and heavy-duty vehicles. B2B buyers should weigh the benefits of lower operational costs against the complexities of installation and higher initial costs. Their ability to reduce wear on the vehicle’s system can be a significant selling point.

Electric compressors are increasingly relevant in the context of hybrid and electric vehicles. They operate independently of the engine, providing cooling without the need for mechanical energy. This makes them environmentally friendly and versatile. For B2B buyers, the cost of electric compressors can be higher, and they require specialized components. However, as the market shifts towards more sustainable options, electric compressors represent a forward-thinking investment.

| الصناعة/القطاع | Specific Application of autozone compressor | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Air Conditioning Systems in Vehicles | Enhances customer satisfaction with reliable cooling. | Ensure compatibility with various vehicle models. |

| Refrigeration | Commercial Refrigeration Units | Maintains product integrity through consistent cooling. | Look for energy-efficient models to reduce operational costs. |

| Manufacturing | Climate Control in Production Facilities | Improves worker comfort and productivity. | Consider durability and ease of maintenance. |

| Transportation | HVAC Systems in Transport Vehicles | Ensures passenger comfort, leading to better service. | Assess the compressor’s performance under varying climates. |

| Agricultural Equipment | Cooling Systems for Produce Storage | Reduces spoilage and extends shelf life of goods. | Verify compliance with local regulations and standards. |

In the automotive repair industry, the autozone compressor is essential for maintaining air conditioning systems in vehicles. By compressing refrigerant, it ensures the effective cooling of the vehicle’s cabin, which is crucial for customer satisfaction, especially in hot climates. For international B2B buyers, selecting a compressor that fits various vehicle models is vital. They should consider the compressor’s compatibility with different refrigerants and the availability of replacement parts to minimize downtime in repairs.

In commercial refrigeration, the autozone compressor is pivotal for maintaining the temperature of perishable goods. It ensures consistent cooling, preventing spoilage and maintaining product integrity. Businesses benefit from increased customer trust and reduced waste. Buyers should prioritize energy-efficient models that comply with local environmental regulations. Additionally, understanding the compressor’s capacity and maintenance requirements is crucial for maximizing operational efficiency.

In manufacturing, the autozone compressor is utilized in climate control systems to regulate temperature and humidity levels within production facilities. This regulation is essential for worker comfort and productivity, directly impacting output quality. For B2B buyers, durability and ease of maintenance are critical factors, as equipment downtime can lead to significant losses. Buyers should also consider compressors that can operate efficiently under varying load conditions.

In the transportation sector, the autozone compressor is integral to HVAC systems in vehicles, ensuring passenger comfort during transit. A well-functioning compressor enhances the overall travel experience, which is vital for service-oriented businesses like public transport and logistics. Buyers should assess the compressor’s performance in diverse climates, ensuring reliability and efficiency. Moreover, compatibility with various vehicle types is essential for fleet operators.

The autozone compressor is crucial in agricultural equipment, particularly in cooling systems for produce storage. It helps reduce spoilage and extends the shelf life of agricultural products, which is essential for maintaining market value. B2B buyers in agriculture must verify that compressors comply with local regulations and standards regarding food safety. Additionally, understanding the specific cooling requirements for different types of produce can guide buyers in selecting the right compressor for their operations.

المشكلة B2B buyers, particularly those in automotive repair and parts distribution, often face challenges in estimating the total cost associated with replacing an AC compressor. This uncertainty can arise from the need to understand not only the price of the compressor itself but also the additional components that may need to be replaced during the service. Buyers may also struggle to find reliable pricing information, leading to underbidding or overbidding on projects, which can significantly affect profit margins.

الحل: To accurately estimate the cost of replacing an AutoZone compressor, buyers should develop a comprehensive checklist that includes the compressor, necessary seals, the accumulator or receiver drier, and the orifice tube. It is advisable to engage with suppliers who provide detailed breakdowns of costs for each component, including potential labor fees if outsourcing the work. Additionally, creating relationships with local repair shops can provide insights into common pricing in the area, allowing for better project estimates. Buyers should also consider bulk purchasing agreements with suppliers to secure better pricing on components, which can enhance profitability when servicing multiple vehicles.

المشكلة B2B buyers in automotive repair often encounter the challenge of diagnosing AC system failures effectively. When a vehicle’s air conditioning system is not functioning, it could be due to a variety of issues, not just a faulty compressor. This ambiguity can lead to increased downtime for vehicles, frustrated customers, and ultimately a loss of revenue for repair shops.

الحل: Implementing a systematic diagnostic approach can significantly enhance efficiency in identifying AC system issues. Buyers should invest in specialized diagnostic tools, such as manifold gauges and electronic leak detectors, to assess system performance accurately. Training technicians on the importance of a thorough diagnostic process is critical. For instance, they should check refrigerant levels, evaluate the compressor clutch’s operation, and inspect for leaks before concluding that the compressor needs replacement. This structured approach not only reduces unnecessary component replacements but also builds trust with customers, as they receive precise and efficient service.

المشكلة Another common pain point for B2B buyers is the proper installation of AutoZone compressors. Misinstallation can lead to premature failure of the compressor and other components in the AC system, resulting in increased warranty claims and dissatisfied customers. This issue is particularly prevalent in regions where technicians may lack experience or proper training.

الحل: To mitigate installation challenges, buyers should prioritize technician training and adherence to manufacturer guidelines during the installation process. Investing in training programs that cover the specifics of compressor installation, including the importance of flushing the AC system to eliminate contaminants, can greatly enhance installation success. Additionally, providing comprehensive installation manuals and checklists can serve as valuable resources for technicians. Encouraging the use of OEM (Original Equipment Manufacturer) parts for replacement components can also ensure compatibility and reliability, thus reducing the likelihood of future issues. Establishing a feedback loop with technicians can help identify common installation challenges and address them proactively, further improving service quality.

When selecting materials for the AutoZone compressor, it is essential to consider properties that directly influence performance, durability, and compatibility with various environments. The following analysis covers four common materials used in the manufacturing of compressors, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum is a prevalent material in compressor construction due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels. Aluminum also exhibits good corrosion resistance, particularly when anodized, making it suitable for humid or coastal environments.

Pros and Cons of Using Aluminum:

Aluminum’s lightweight characteristic enhances fuel efficiency in vehicles, while its thermal properties allow for effective heat dissipation. However, it may not be as durable as other metals, leading to potential wear over time. Additionally, manufacturing processes involving aluminum can be more complex, affecting overall production costs.

التأثير على التطبيق:

Aluminum is compatible with various refrigerants, including R134a, making it a versatile choice for different compressor designs. However, its susceptibility to wear necessitates regular maintenance and monitoring.

الاعتبارات الدولية:

For buyers in regions like Europe and the Middle East, compliance with standards such as ASTM and DIN is crucial. Anodized aluminum finishes may be preferred in these markets to enhance corrosion resistance.

Steel, particularly stainless steel, is another common material used in compressor construction. It boasts a high-temperature rating (up to 300°C) and excellent pressure resistance, making it ideal for high-performance applications. Steel also offers superior durability and strength compared to aluminum.

Pros and Cons of Using Steel:

The primary advantage of steel is its robustness, which translates to a longer lifespan for the compressor. However, it is heavier than aluminum, potentially impacting vehicle efficiency. Additionally, the manufacturing process for steel can be more expensive due to the need for advanced machining techniques.

التأثير على التطبيق:

Steel’s high resistance to corrosion makes it suitable for harsh environments, particularly in regions with extreme weather conditions. It is compatible with various refrigerants but may require specific seals to prevent leaks.

الاعتبارات الدولية:

In markets such as South America and Africa, where environmental conditions can vary significantly, the durability of steel may be a selling point. Buyers should ensure compliance with local standards and consider the availability of replacement parts.

Plastic is often used for non-structural components in compressors, such as housings and seals. It typically has a temperature rating of around 80°C and can handle moderate pressure. Certain plastics, like polyamide (nylon), offer good chemical resistance.

Pros and Cons of Using Plastic:

The lightweight nature of plastic can reduce overall compressor weight, contributing to vehicle efficiency. However, plastics may not withstand high temperatures or pressures as effectively as metals, leading to potential failures in extreme conditions.

التأثير على التطبيق:

Plastic components are particularly useful in reducing noise and vibration, enhancing user comfort. However, compatibility with refrigerants must be assessed to avoid degradation over time.

الاعتبارات الدولية:

For buyers in regions with stringent environmental regulations, the recyclability of plastic components may be a significant factor. Compliance with standards like JIS in Japan may also influence material selection.

Copper is commonly used in the tubing and fittings of compressors due to its excellent thermal and electrical conductivity. It can handle high temperatures (up to 200°C) and pressures, making it suitable for refrigerant flow.

Pros and Cons of Using Copper:

Copper’s superior thermal properties enhance the efficiency of the compressor. However, it is more expensive than aluminum and can be prone to corrosion if not properly treated.

التأثير على التطبيق:

Copper is compatible with most refrigerants and is often used in high-performance applications. Its ability to resist thermal expansion makes it ideal for maintaining system integrity.

الاعتبارات الدولية:

In Europe, compliance with regulations regarding copper usage in refrigeration systems is critical. Buyers should also consider the availability of copper components in their region to ensure timely repairs.

| المواد | Typical Use Case for autozone compressor | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | Compressor housing and components | Lightweight and good thermal conductivity | Less durable than steel | متوسط |

| الفولاذ | Structural components and casings | قوة ومتانة عالية | Heavier, more expensive to manufacture | عالية |

| بلاستيك | Non-structural components (housings, seals) | Reduces weight and noise | Limited temperature/pressure resistance | منخفضة |

| Copper | Tubing and fittings | Excellent thermal conductivity | More expensive, prone to corrosion | متوسط |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance considerations.

The manufacturing process of an AutoZone compressor involves several critical stages that ensure the final product meets both performance and reliability standards. Each stage is meticulously designed to optimize efficiency and effectiveness.

The process begins with the selection and preparation of high-quality materials. Common materials for compressors include aluminum for the housing due to its lightweight and corrosion-resistant properties, and high-strength steel for internal components that require durability. The materials undergo rigorous testing for composition and quality to ensure they meet the required specifications. This stage is crucial, as the integrity of the materials directly affects the performance and longevity of the compressor.

Following material preparation, the forming stage employs advanced techniques such as die casting, machining, and stamping to create the various components of the compressor. Die casting is particularly effective for producing complex shapes with high precision, while machining ensures that parts fit together seamlessly. Stamping is used for creating flat components that will be later assembled. This stage emphasizes precision, as even minor deviations can lead to inefficiencies or failures in the compressor’s operation.

Once the individual components are shaped, they move to the assembly stage. Automated assembly lines are often utilized to enhance speed and consistency. Key techniques include robotic arms for precise placement of parts and torque wrenches for ensuring that all fasteners are tightened to the specified torque. The assembly process is closely monitored to prevent errors, and workers are trained to identify potential issues during assembly, such as misalignment or incomplete fittings.

The finishing stage involves surface treatments, such as anodizing or powder coating, to enhance corrosion resistance and improve aesthetic appeal. This stage also includes the installation of seals and gaskets to prevent refrigerant leaks, which are critical for the compressor’s functionality. Final inspections are conducted to ensure that all components meet quality standards before the compressor is packaged and shipped.

Quality assurance is an integral part of the manufacturing process, ensuring that each compressor meets international standards and performs reliably under various conditions.

Manufacturers of AutoZone compressors typically adhere to international quality management standards such as ISO 9001, which focuses on consistent quality and customer satisfaction. Compliance with CE marking requirements is also essential, particularly for products sold in Europe, as it indicates conformity with health, safety, and environmental protection standards. Additionally, industry-specific standards like those from the American Petroleum Institute (API) may apply, especially if the compressors are used in petroleum applications.

Quality control (QC) is implemented at multiple checkpoints throughout the manufacturing process, including:

مراقبة الجودة الواردة (IQC): This initial checkpoint assesses the quality of raw materials and components before they are used in production. It ensures that only materials meeting strict specifications enter the manufacturing process.

مراقبة الجودة أثناء العملية (IPQC): During manufacturing, IPQC monitors various stages of production to identify and rectify issues in real-time. This includes checking dimensional tolerances and assessing the quality of assembled components.

مراقبة الجودة النهائية (FQC): Before packaging, a comprehensive inspection is conducted to verify the overall quality and performance of the finished compressor. This includes functional testing to ensure the compressor operates within specified parameters.

Manufacturers employ various testing methods to validate the performance and reliability of compressors. Common tests include:

Leak Testing: To ensure that the compressor is airtight and will not leak refrigerants, manufacturers often use pressure testing methods.

اختبار الأداء: This involves running the compressor under simulated operational conditions to measure its efficiency, cooling capacity, and noise levels.

اختبار المتانة: Compressors may be subjected to accelerated life testing to simulate years of use in a short timeframe, ensuring they can withstand the stresses of real-world applications.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability and compliance.

Buyers should request detailed quality assurance reports from suppliers, including audits of their manufacturing processes and quality control measures. Third-party audits can provide an unbiased assessment of the supplier’s adherence to quality standards. Additionally, buyers should inquire about certifications and compliance with international standards like ISO 9001 and CE marking.

Utilizing third-party inspection services can further enhance quality assurance. These organizations conduct independent evaluations of the manufacturing process, ensuring that the supplier meets all necessary quality and compliance standards. This is particularly important for B2B buyers who may not have direct access to the manufacturing facilities.

Understanding the nuances of quality control is vital for international buyers. Each region may have different regulatory requirements and standards that affect the importation and use of compressors. For instance, compressors sold in Europe must comply with CE standards, while those intended for the Middle Eastern market may need to meet local certification requirements.

Buyers should also consider the warranty and after-sales support provided by the supplier. A robust warranty can serve as an indicator of the manufacturer’s confidence in their product quality. Additionally, effective after-sales support is essential for addressing any issues that may arise post-purchase, particularly in regions where technical support may be limited.

In conclusion, the manufacturing processes and quality assurance measures for AutoZone compressors are designed to ensure that they meet the highest standards of performance and reliability. By understanding these processes, B2B buyers can make informed decisions and establish strong partnerships with suppliers.

This sourcing guide provides a practical checklist for B2B buyers seeking to procure AutoZone compressors. Whether you’re a distributor, automotive repair shop, or fleet manager, following these steps will ensure you make informed purchasing decisions, maximize efficiency, and maintain quality in your operations.

Before initiating the procurement process, clearly outline the technical specifications required for the AutoZone compressor. Identify the type of compressor that suits your vehicle models, including compatibility with refrigerants (e.g., R134a) and any specific performance metrics. This step is crucial to avoid purchasing incompatible parts, which could lead to costly repairs or downtime.

Conduct thorough research to identify suppliers with a strong reputation in the market. Look for suppliers who specialize in automotive components and have positive reviews from other businesses in your region. A solid supplier relationship can lead to better pricing, reliable service, and access to a wider range of products.

Verify that potential suppliers adhere to recognized quality standards and possess necessary certifications. Certifications such as ISO 9001 demonstrate a commitment to quality management systems, which can significantly affect the reliability of the compressors you receive.

Once you’ve identified suitable suppliers, request detailed quotes for the compressors. Ensure that each quote includes not only the price of the compressor but also associated costs, such as shipping and potential import duties. Comparing quotes will help you identify the best value without compromising quality.

Evaluate the after-sales support offered by suppliers, including warranty policies and return procedures. A strong warranty can provide peace of mind, ensuring that you are protected against defects or premature failures. Additionally, good after-sales support can assist in maintenance and troubleshooting.

Perform a risk assessment to understand potential challenges associated with your procurement process. Consider factors such as supplier reliability, geopolitical risks affecting shipping, and potential fluctuations in pricing. This analysis helps in developing contingency plans that can mitigate risks.

Once you’ve completed your evaluations and selected a supplier, draft a purchase agreement outlining all terms, conditions, and responsibilities. This agreement should include delivery timelines, payment terms, and quality assurance expectations. A well-defined contract protects both parties and clarifies expectations.

By following this checklist, B2B buyers can streamline their procurement process for AutoZone compressors, ensuring they secure reliable products while minimizing risks and maximizing value.

When evaluating the total cost of sourcing Autozone compressors, several cost components come into play. First, materials account for a significant portion of the total expense. The compressor’s construction typically involves high-quality metals and specialized components, such as the compressor clutch and seals, which can vary based on the model and specifications.

Labor costs also play a crucial role in the pricing structure. This includes not just the assembly labor in manufacturing but also the skilled labor required for installation and maintenance. Additionally, manufacturing overhead such as utilities, rent, and administrative expenses is factored into the overall cost.

الأدوات costs are another consideration, particularly for manufacturers that require specialized equipment to produce customized compressors. Quality control (QC) processes ensure that each unit meets industry standards, adding another layer of expense. Finally, logistics costs, including shipping and handling, are essential to consider, especially for international buyers who may face additional tariffs or import duties.

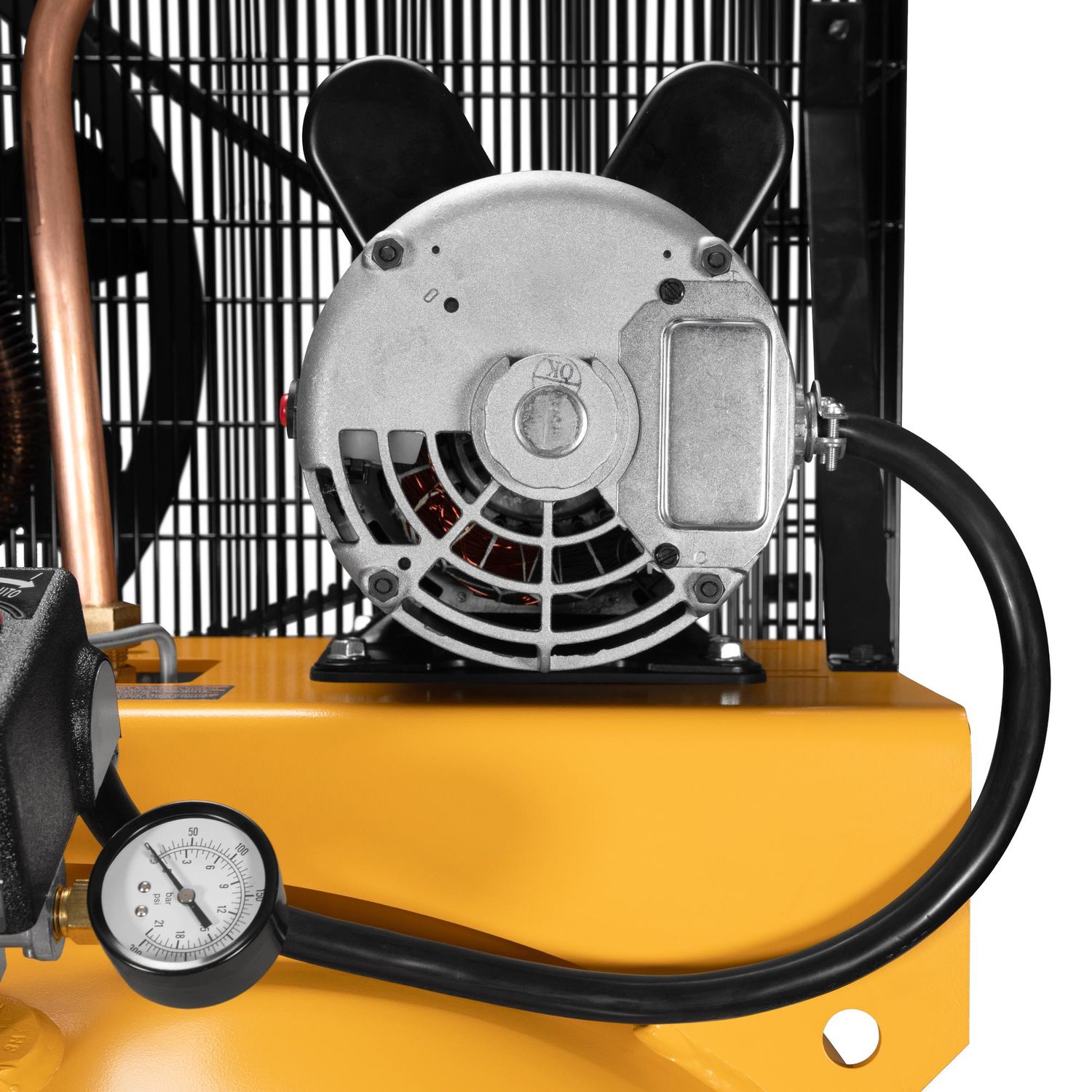

Illustrative image related to autozone compressor

Several factors influence the pricing of Autozone compressors. Volume and minimum order quantities (MOQ) can significantly affect unit prices; larger orders often result in bulk discounts. Customization options, such as specific specifications or features, can also increase costs due to the need for specialized manufacturing processes.

The choice of materials impacts both quality and price; higher-quality components often lead to better performance and durability, justifying a higher price point. Additionally, certifications and compliance with international quality standards can also drive up costs but are essential for ensuring product reliability.

عوامل الموردين are critical as well. The reputation, reliability, and geographical location of suppliers can affect both pricing and shipping times. Understanding المصطلحات التجارية الدولية (International Commercial Terms) is vital for international buyers, as they define responsibilities regarding shipping, insurance, and tariffs.

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to cost savings. Start by researching the market to understand average pricing and competitor offerings. Highlighting your potential for repeat business can be a persuasive factor in negotiations.

Consider discussing التكلفة الإجمالية للملكية (TCO) rather than just the initial purchase price. Emphasizing long-term value, including durability and lower maintenance costs, can encourage suppliers to offer more competitive pricing. Don’t hesitate to ask for better terms, especially if you are considering a larger order or a long-term partnership.

International buyers must navigate various pricing nuances when sourcing Autozone compressors. Currency fluctuations can impact overall costs, so consider negotiating in a stable currency to mitigate risks. Additionally, understand local regulations and potential tariffs that may affect pricing when importing compressors.

Be aware of the logistics costs that can arise from longer shipping times, especially when sourcing from distant suppliers. Selecting suppliers with a strong logistics network can help minimize these costs. Finally, always clarify payment terms and delivery timelines upfront to avoid unexpected charges or delays.

While this analysis provides a comprehensive overview of cost components and pricing strategies for Autozone compressors, actual prices may vary based on specific models, market conditions, and supplier negotiations. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing and to verify all costs associated with sourcing and importing compressors.

When evaluating air conditioning compressor options for vehicles, it is essential to explore various solutions that can meet diverse operational needs and preferences. The AutoZone compressor is a well-known choice, but other alternatives may offer distinct advantages depending on specific requirements, such as cost, performance, and maintenance. This analysis will compare the AutoZone compressor with two viable alternatives: aftermarket compressors and remanufactured compressors.

Illustrative image related to autozone compressor

| جانب المقارنة | AutoZone Compressor | Aftermarket Compressor | Remanufactured Compressor |

|---|---|---|---|

| الأداء | Reliable and efficient, designed for specific vehicle models | Varies widely; some may perform better than OEM | Generally restored to OEM specifications, reliable |

| التكلفة | Moderate, typically ranges from $350 – $650 for parts | Can be lower, often under $300, but quality varies | Usually priced between $250 – $500, competitive |

| سهولة التنفيذ | Requires specialized tools and knowledge for installation | May be easier for DIYers, depending on design | Similar installation complexity as new compressors |

| الصيانة | Standard maintenance; may require system flush during replacement | Can vary; some cheaper models may require more frequent replacement | Typically low maintenance if restored correctly |

| أفضل حالة استخدام | Ideal for those seeking a reliable, model-specific solution | Suitable for budget-conscious buyers, with varying quality | Best for buyers wanting a cost-effective, reliable option |

Aftermarket compressors can be an attractive option for buyers seeking lower prices. These compressors are produced by third-party manufacturers and can often be found at competitive rates, sometimes below $300. However, the performance and reliability of aftermarket compressors can vary significantly, as they may not always meet OEM specifications. While they can be appealing for budget-sensitive projects, buyers should be cautious and conduct thorough research on the manufacturer’s reputation to avoid quality issues.

Remanufactured compressors present a middle ground between new and used options. These compressors are restored to meet OEM specifications, ensuring a level of reliability and performance similar to new units. The cost typically ranges between $250 and $500, making them a cost-effective solution compared to brand-new compressors. Buyers can benefit from a lower price point while still receiving a reliable product. However, remanufactured compressors may still carry some risk if the restoration process is not thorough, so it’s important to choose reputable suppliers.

Selecting the appropriate compressor solution involves a careful assessment of your specific needs, budget, and the intended application. For businesses in regions such as Africa, South America, the Middle East, and Europe, it is crucial to consider not only the initial cost but also the long-term reliability and maintenance implications of each option. The AutoZone compressor is a solid choice for those seeking reliability tailored to specific vehicles. In contrast, aftermarket and remanufactured compressors can provide more budget-friendly alternatives, albeit with varying degrees of risk regarding quality. Ultimately, conducting thorough research and considering both performance and cost will empower B2B buyers to make informed decisions that align with their operational goals.

When considering an Autozone compressor for your business needs, understanding its technical properties is essential. Here are some critical specifications that can influence purchasing decisions:

درجة المادة

The materials used in the compressor, typically aluminum or high-grade steel, determine durability and resistance to corrosion. A higher material grade signifies a more robust product, which is crucial for compressors that may be exposed to varying environmental conditions, particularly in regions with extreme weather, like the Middle East or South America.

Operating Pressure

This specification indicates the maximum pressure the compressor can handle, typically measured in psi (pounds per square inch). Knowing the operating pressure is vital for ensuring compatibility with your vehicle’s AC system. A compressor with a higher operating pressure can offer better performance and efficiency, which is essential for commercial fleets.

Refrigerant Type

Most modern compressors use R134a refrigerant, but some may be compatible with newer alternatives like R1234yf. Understanding refrigerant compatibility is crucial for compliance with environmental regulations and for the overall efficiency of the cooling system. Buyers must ensure that the compressor they select aligns with their specific refrigerant needs to avoid costly retrofits.

Compressor Clutch Type

The clutch engages and disengages the compressor as needed. There are two main types: electromagnetic and variable displacement. The choice between these options affects the compressor’s efficiency and responsiveness, impacting fuel economy and overall vehicle performance. Businesses must consider the type of clutch that best fits their operational requirements.

Warranty and Service Life

A compressor’s warranty period and expected service life (typically around 10-12 years) are critical for B2B buyers, as they directly affect the total cost of ownership. Longer warranties can indicate higher quality and reliability, which can translate to lower maintenance costs and less downtime for vehicles.

Familiarity with industry jargon can significantly enhance communication and negotiation processes in B2B transactions. Here are some essential terms:

OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to companies that produce parts that are used in the original manufacturing of a vehicle. When sourcing compressors, understanding whether a part is OEM or aftermarket can impact quality and compatibility. OEM parts are often preferred for their guaranteed fit and performance.

موك (الحد الأدنى لكمية الطلب)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget accordingly. It’s particularly relevant for international buyers who may need to balance shipping costs with order sizes.

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers requesting price quotes for specific quantities of products. This process is essential for ensuring competitive pricing and understanding the market rates for compressors. A well-structured RFQ can streamline procurement processes.

إنكوترمز (الشروط التجارية الدولية)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that dictate the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping logistics and costs, especially for international buyers in Africa and Europe.

المهلة الزمنية

This term refers to the amount of time it takes from placing an order to receiving it. Understanding lead times is essential for planning inventory and ensuring that operations are not disrupted. Longer lead times can affect project timelines, particularly in regions with complex supply chains.

Aftermarket

This term refers to parts made by companies other than the original manufacturer. Aftermarket compressors can often be more cost-effective but may vary in quality and performance. B2B buyers need to weigh the pros and cons of aftermarket options versus OEM products based on their specific needs and budget.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when procuring Autozone compressors, ultimately enhancing operational efficiency and reducing costs.

Illustrative image related to autozone compressor

The global autozone compressor market is witnessing significant growth driven by several factors. Increasing temperatures across regions such as Africa, the Middle East, and parts of South America are leading to heightened demand for efficient automotive air conditioning systems. Additionally, the surge in vehicle ownership in emerging markets is propelling the need for reliable and cost-effective compressors. Technological advancements, particularly in energy-efficient compressor designs and variable displacement technology, are reshaping the landscape, offering B2B buyers enhanced options for their fleets.

Moreover, the integration of smart technologies and IoT in vehicle systems is influencing sourcing strategies. International B2B buyers are increasingly looking for suppliers that can provide compressors equipped with smart diagnostics capabilities, allowing for predictive maintenance and minimizing downtime. This trend is particularly relevant for buyers in Europe, where regulatory frameworks are pushing for more sustainable and efficient automotive solutions.

Supply chain dynamics also play a crucial role in this sector. The ongoing disruptions caused by global events have prompted buyers to diversify their supplier base and seek local sourcing options to mitigate risks. Establishing partnerships with manufacturers that can ensure timely delivery and quality assurance is essential for maintaining operational efficiency, especially in regions like Saudi Arabia and Germany, where automotive markets are rapidly evolving.

Sustainability is becoming a critical concern for B2B buyers in the autozone compressor sector. The environmental impact of manufacturing processes, particularly concerning refrigerants and energy consumption, is under scrutiny. Buyers are increasingly seeking compressors that utilize eco-friendly refrigerants, such as R-1234yf, which have a lower global warming potential compared to traditional options like R-134a.

Ethical sourcing is also gaining traction, with buyers prioritizing suppliers that adhere to sustainable practices throughout their supply chains. This includes ensuring that raw materials are sourced responsibly, and that labor practices meet international standards. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are becoming important criteria for selecting suppliers.

Furthermore, B2B buyers are exploring partnerships with manufacturers that commit to reducing their carbon footprint and implementing circular economy principles. This shift not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products. Engaging with suppliers who invest in ‘green’ technologies and materials can provide a competitive edge in the marketplace.

The autozone compressor market has evolved significantly over the last few decades. Initially, air conditioning systems were considered luxury features in vehicles, leading to limited compressor availability. However, as consumer expectations shifted and climate control became standard in vehicles worldwide, the demand for compressors surged.

The 1990s saw advancements in compressor technology, particularly with the introduction of variable displacement compressors that improved efficiency and performance. This innovation allowed manufacturers to meet the growing environmental regulations while enhancing the comfort and convenience of vehicle occupants.

In the early 2000s, the market experienced another transformation with the shift towards more environmentally friendly refrigerants and energy-efficient designs. As a result, manufacturers began to focus on sustainability, leading to the emergence of compressors that not only performed better but also minimized their ecological impact.

Today, the autozone compressor market stands at the intersection of technology, sustainability, and consumer demand, shaping a future where efficiency and environmental responsibility are paramount for B2B buyers across various global markets.

How do I solve issues with a malfunctioning AC compressor?

To address a malfunctioning AC compressor, start by diagnosing the problem accurately. Common issues include electrical failures, refrigerant leaks, and mechanical wear. If the compressor is not engaging, check the electrical connections and the compressor clutch. For leaks, inspect the seals and hoses. If internal damage is suspected, a complete system flush may be necessary to avoid contaminating a new compressor. Depending on your expertise, you may choose to repair the unit or replace it entirely, considering the cost-effectiveness of both options.

What is the best compressor for high-temperature climates?

For high-temperature environments often found in regions like Africa and the Middle East, select a robust AC compressor designed for efficiency and durability. Look for compressors with high thermal resistance and those compatible with R134a or R1234yf refrigerants. Brands known for reliability in extreme conditions, such as AutoZone, typically offer products that can withstand elevated temperatures while maintaining optimal cooling performance. Always ensure the chosen compressor meets the specifications required for your specific vehicle model.

What factors should I consider when sourcing autozone compressors internationally?

When sourcing AutoZone compressors internationally, consider factors such as supplier reputation, compliance with international quality standards, and warranty terms. Evaluate the supplier’s ability to provide timely delivery, especially for urgent needs. Additionally, assess their experience in shipping to your region and their understanding of local regulations regarding automotive parts. Establish clear communication channels to ensure that all specifications and expectations are met, minimizing potential misunderstandings.

How can I vet suppliers for autozone compressors?

To vet suppliers for AutoZone compressors, conduct thorough research on their background, including years in business, customer reviews, and industry certifications. Request references from other clients and check their compliance with international quality standards such as ISO certifications. Engage in direct communication to assess their responsiveness and willingness to provide detailed product information. Additionally, consider ordering samples to evaluate product quality before committing to larger orders.

What is the minimum order quantity (MOQ) for autozone compressors?

Minimum order quantities (MOQ) for AutoZone compressors can vary significantly based on the supplier and the specific product. Typically, MOQs can range from a single unit for trial orders to several dozen for bulk purchases. It’s essential to discuss these terms directly with your supplier to negotiate favorable conditions that suit your purchasing strategy. Some suppliers may offer flexibility on MOQs for new clients or bulk agreements.

What payment terms are common for international B2B transactions?

Common payment terms for international B2B transactions include options such as Letters of Credit (LC), advance payments, and payment upon delivery. Many suppliers may request a deposit upfront, with the balance payable upon shipment or delivery. It’s crucial to establish clear payment terms before finalizing agreements to avoid misunderstandings. Additionally, consider using secure payment platforms that offer buyer protection, especially for larger transactions.

How can I ensure quality assurance (QA) for my compressor orders?

To ensure quality assurance for your compressor orders, implement a comprehensive QA process that includes pre-shipment inspections, compliance checks against specifications, and testing of samples. Request certificates of authenticity and quality from the supplier. Additionally, consider working with third-party inspection services that can validate product quality before shipment. Establishing clear expectations regarding quality standards in your contract will also help mitigate risks.

What logistics considerations should I keep in mind when importing compressors?

When importing compressors, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling automotive parts to ensure timely and safe delivery. Be aware of the import duties applicable in your region and factor these into your overall cost. Additionally, maintain clear communication with your supplier regarding shipping timelines to manage your inventory effectively and avoid disruptions in your supply chain.

Could not verify enough suppliers for autozone compressor to create a list at this time.

In the evolving landscape of automotive parts, the strategic sourcing of AutoZone compressors emerges as a vital consideration for international B2B buyers. Understanding the critical role of the AC compressor in vehicle performance not only enhances purchasing decisions but also fosters long-term supplier relationships. The insights gathered regarding replacement costs, necessary components, and maintenance best practices underscore the importance of thorough evaluation when selecting suppliers.

For businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, sourcing quality compressors can significantly impact operational efficiency and customer satisfaction. By prioritizing suppliers who provide comprehensive solutions—including essential parts and support services—buyers can mitigate risks and ensure seamless integration into their supply chains.

As the automotive sector continues to advance, it is essential for B2B buyers to stay informed about emerging technologies and trends. Embrace the opportunity to collaborate with reliable suppliers who understand your specific market needs. This proactive approach will not only enhance your competitive edge but also position your business for sustained success in the global marketplace.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.