- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In today’s fast-paced global market, sourcing the right slime compressor can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany. The demand for efficient and reliable tire inflation solutions is on the rise, and understanding the variety of products available—from portable inflators to advanced digital compressors—can be overwhelming. This guide aims to demystify the sourcing process by providing a comprehensive overview of slime compressors, detailing their types, applications, and key features that matter most to your business needs.

Navigating the complexities of supplier vetting, pricing structures, and regional availability is crucial for making informed purchasing decisions. This guide empowers international buyers by offering actionable insights into selecting the right slime compressor tailored to specific operational requirements. Whether you’re looking for a robust compressor for heavy-duty use or a compact solution for emergency roadside assistance, our resource will equip you with the knowledge necessary to enhance your procurement strategy. By focusing on quality, functionality, and cost-effectiveness, you can confidently invest in products that meet your business’s demands while ensuring customer satisfaction.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| 12V Tire Inflator | Powered by a vehicle’s 12V outlet; compact design | Automotive repair shops, fleet services | الإيجابيات: Portable, easy to use. السلبيات: Limited power for larger tires. |

| Cordless Tire Inflator | Battery-operated; offers freedom from cords | Roadside assistance, emergency kits | الإيجابيات: Highly portable, no power source needed. السلبيات: Battery life may limit usage. |

| Digital Tire Inflator | Features digital pressure gauge and auto shut-off | Automotive retail, service centers | الإيجابيات: Accurate pressure settings, user-friendly. السلبيات: Typically more expensive. |

| Pro Power Tire Inflator | High CFM output; suitable for larger tires | Heavy-duty vehicles, off-road applications | الإيجابيات: Fast inflation, robust design. السلبيات: Bulkier, may require more storage space. |

| Multi-Purpose Inflator | Versatile attachments for various applications | Sports facilities, event organizers | الإيجابيات: Can inflate multiple items (balls, pool toys). السلبيات: May lack power for heavy-duty use. |

The 12V Tire Inflator is a staple in automotive settings, utilizing a vehicle’s 12V power outlet for operation. Its compact design makes it ideal for automotive repair shops and fleet services, where space and efficiency are crucial. Buyers should consider its portability and ease of use, although its power limitations may hinder performance with larger tires.

Cordless Tire Inflators offer unmatched portability, powered by rechargeable batteries. This type is particularly beneficial for roadside assistance and emergency kits, allowing users to inflate tires without needing a power source. While the convenience of mobility is a significant advantage, potential buyers should assess battery life, as it may restrict the number of uses before needing a recharge.

Digital Tire Inflators are equipped with features like digital pressure gauges and automatic shut-off, making them suitable for automotive retail and service centers. Their accuracy in setting desired pressure levels enhances user experience and efficiency. However, these units often come at a higher price point, which should be factored into purchasing decisions.

The Pro Power Tire Inflator is designed for high airflow output (CFM), making it ideal for larger tires found in heavy-duty vehicles and off-road applications. Its robust construction ensures durability under demanding conditions. However, its bulkier size may require additional storage considerations, which buyers need to keep in mind when evaluating their needs.

Multi-Purpose Inflators are versatile devices that come with various attachments for inflating sports equipment, pool toys, and more. This adaptability makes them valuable for sports facilities and event organizers. While they excel in versatility, they may not provide the power necessary for heavy-duty tire inflation, which buyers should consider based on their primary use cases.

| الصناعة/القطاع | Specific Application of Slime Compressor | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Tire maintenance and emergency repairs | Reduces downtime and enhances customer satisfaction | Availability of models suitable for various vehicle types |

| النقل والخدمات اللوجستية | Fleet tire management | Increases fleet efficiency and reduces operational costs | Power source compatibility and portability |

| الزراعة | Inflating tires for agricultural machinery | Ensures timely operations and minimizes delays | Durability in harsh environments and repair capabilities |

| Construction | Tire inflation for heavy machinery | Enhances productivity and reduces equipment failure | Robustness and ease of use in rugged conditions |

| Recreational Vehicles | Tire inflation for off-road vehicles | Improves safety and reliability during excursions | Lightweight models for easy transport and storage |

In the automotive repair sector, slime compressors are essential for tire maintenance and emergency repairs. They allow mechanics to quickly inflate tires on-site, ensuring that vehicles can be serviced without delay. This capability not only reduces downtime but also enhances customer satisfaction, as vehicles can be returned to service more rapidly. International buyers, particularly from Africa and South America, should consider the compressor’s compatibility with various vehicle types and its ability to handle high-pressure demands.

In the transportation and logistics industry, slime compressors are critical for managing fleet tire health. They enable fleet operators to maintain optimal tire pressure, which is crucial for fuel efficiency and safety. This proactive approach can significantly reduce operational costs by preventing tire blowouts and extending tire lifespan. Buyers in the Middle East and Europe should prioritize models that offer power source compatibility and portability, ensuring they can be used across diverse vehicles in the fleet.

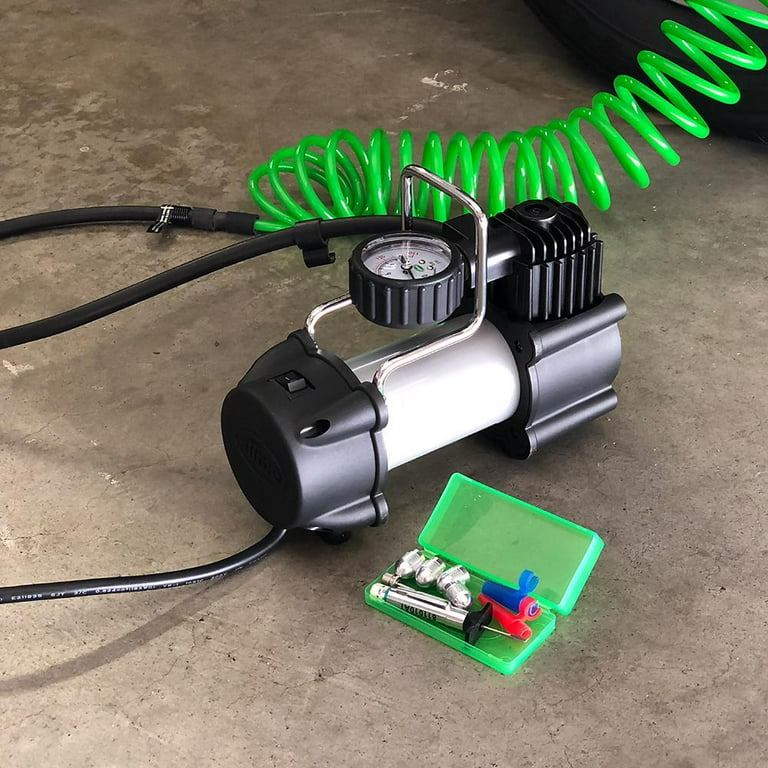

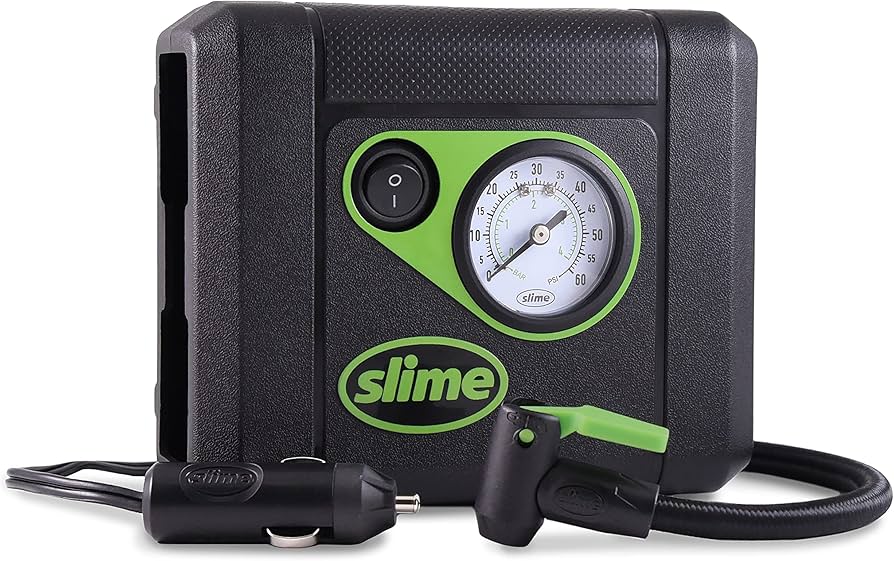

Illustrative image related to slime compressor

For the agriculture sector, slime compressors are invaluable for inflating tires on tractors and other heavy machinery. Timely inflation ensures that farming operations run smoothly, preventing delays during critical planting and harvesting seasons. The durability of the compressor in harsh outdoor conditions is a significant consideration for agricultural buyers, especially in regions like Africa where equipment is subjected to rugged terrain and variable weather.

In construction, slime compressors are used to inflate tires on heavy machinery such as bulldozers and excavators. Proper tire inflation enhances machinery productivity and reduces the risk of equipment failure, which can lead to costly project delays. Buyers should look for compressors that are robust and easy to use in rugged conditions, ensuring they can withstand the demands of a busy construction site, particularly in regions like the Middle East where extreme weather can be a factor.

For recreational vehicles (RVs), slime compressors are crucial for tire inflation before and during trips. They provide peace of mind by ensuring that tires are properly inflated, which is vital for safety and reliability on off-road excursions. Lightweight models are particularly beneficial for RV owners, allowing for easy transport and storage. Buyers from Europe and South America should consider the compressor’s features, such as portability and ease of use, to enhance their travel experiences.

Illustrative image related to slime compressor

المشكلة For B2B buyers operating in sectors like transportation or delivery services, the need for a portable tire inflator is critical. However, many users find that traditional slime compressors can be cumbersome and heavy, making them impractical for frequent use in various locations. This challenge is exacerbated in regions where mobility is key, such as in African countries where road conditions can be unpredictable. The inconvenience of managing a bulky compressor can result in delays and inefficiencies in operations.

الحل: To address this issue, buyers should look for lightweight, cordless slime compressors that offer high functionality without the bulk. Models such as the Cordless Tire Inflator can be particularly beneficial, as they are designed for ease of transport and quick deployment. When sourcing these compressors, prioritize those with robust battery life and fast inflation capabilities. Ensure that your team is trained on how to utilize these compressors effectively, including understanding the optimal pressure settings for various tire types. By investing in a compact and efficient compressor, businesses can enhance their operational efficiency and reduce downtime caused by tire-related issues.

المشكلة B2B buyers often experience frustration with compressors that do not deliver consistent performance, particularly in high-demand environments. For instance, a fleet of delivery vehicles may encounter repeated flat tires, leading to increased maintenance costs and operational delays if the compressors fail to inflate tires effectively. Inconsistent performance can stem from factors like inadequate power, lack of features for different tire sizes, or even poor design that leads to overheating during extended use.

الحل: To mitigate this issue, buyers should conduct thorough research on the performance specifications of various slime compressors. It’s essential to select models that provide adjustable pressure settings and have a cooling mechanism to prevent overheating. Additionally, consider investing in compressors that feature automatic shut-off functions to prevent over-inflation and ensure safety. Regular maintenance of these compressors, including checking for wear and tear on hoses and connectors, will also enhance performance longevity. By implementing these strategies, businesses can minimize the risk of downtime and ensure that their vehicles remain roadworthy.

Illustrative image related to slime compressor

المشكلة Many modern slime compressors come equipped with advanced technology features, such as digital pressure gauges and preset inflation settings. However, B2B buyers may find these features overwhelming, particularly if their teams are not technically inclined. In regions where staff training is limited, the inability to utilize these features can lead to improper use, resulting in under-inflated tires or wasted time troubleshooting the devices.

الحل: To overcome this challenge, it’s crucial for buyers to prioritize user-friendly models that feature clear instructions and intuitive interfaces. When selecting a slime compressor, look for those that offer comprehensive user manuals and online tutorial resources. Additionally, consider organizing training sessions for your staff to familiarize them with the equipment. Creating a step-by-step guide on how to set desired pressure levels and utilize automatic shut-off features can empower your team and enhance their confidence in using the equipment. By investing in training and choosing user-friendly technology, businesses can optimize their tire maintenance processes and ensure their teams are equipped to handle any situation effectively.

When selecting materials for slime compressors, it is essential to consider their properties, advantages, and limitations. The choice of material impacts not only the performance and durability of the compressor but also its compliance with international standards, which is particularly relevant for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Aluminum is a popular choice for compressor housing due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels. The primary advantage of aluminum is its durability combined with low weight, making it easier to transport and install. However, it can be more expensive than other metals and may require specialized manufacturing techniques, which can increase production costs. For international buyers, aluminum components must comply with standards such as ASTM B221, ensuring quality and reliability.

Steel, particularly stainless steel, is another common material used in slime compressors. It offers high tensile strength and excellent resistance to wear and tear, making it suitable for high-pressure applications. Steel can handle temperatures exceeding 300°C, which is beneficial for compressors operating in extreme conditions. The downside is that steel is heavier and can be prone to corrosion if not properly treated. For buyers in regions with high humidity or saline environments, such as coastal areas in South America or the Middle East, selecting galvanized or coated steel can mitigate corrosion risks. Compliance with standards like DIN 17440 is crucial for ensuring the material’s integrity.

Plastic materials, such as high-density polyethylene (HDPE) and polypropylene, are often used for non-structural components in slime compressors, such as housing for electrical parts or connectors. These materials are lightweight, resistant to chemicals, and can handle moderate temperatures up to 80°C. The advantages of using plastic include lower manufacturing costs and ease of molding into complex shapes. However, their lower strength compared to metals can be a limitation in high-stress applications. B2B buyers should ensure that any plastic components meet relevant standards like ISO 9001 to guarantee quality and performance.

Rubber is critical for seals and hoses in slime compressors, providing flexibility and excellent sealing capabilities. Common rubber types used include nitrile and silicone, which can withstand temperatures ranging from -40°C to 120°C. The primary advantage of rubber is its ability to create airtight seals, which is essential for maintaining pressure. However, rubber can degrade over time, especially when exposed to extreme temperatures or chemicals. Buyers should consider the specific operating environment of their compressors, ensuring that rubber components are compliant with standards such as ASTM D2000 to ensure longevity and performance.

| المواد | Typical Use Case for slime compressor | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | Compressor housing | خفيف الوزن ومقاوم للتآكل | ارتفاع التكلفة وتعقيد التصنيع | متوسط |

| الفولاذ | Structural components | High strength and wear resistance | Heavier and potential for corrosion | متوسط |

| بلاستيك | Non-structural components | Low cost and easy to mold | Lower strength than metals | منخفضة |

| المطاط | Seals and hoses | Excellent sealing capabilities | Degradation over time | متوسط |

In conclusion, selecting the right materials for slime compressors is crucial for performance, durability, and compliance with international standards. Buyers should carefully assess their specific application needs, environmental conditions, and regulatory requirements to make informed decisions.

The manufacturing process of slime compressors involves several critical stages, ensuring that the final product meets both performance and quality standards. Here’s a breakdown of these stages:

The first step in manufacturing slime compressors is sourcing and preparing high-quality materials. Key components such as the motor, casing, hoses, and electrical wiring are sourced from reputable suppliers. Materials undergo rigorous inspection to ensure they meet the necessary specifications and standards. This initial phase is crucial, as the durability and efficiency of the compressor heavily depend on the quality of these raw materials.

Once materials are prepared, they move to the forming stage. This involves various techniques such as injection molding for plastic parts, metal stamping for casing, and die-casting for components that require precise shapes. Advanced machinery is used to ensure consistency and precision in forming, which is essential for the operational efficiency of the compressor.

Illustrative image related to slime compressor

The assembly phase is where all components come together. Skilled technicians or automated assembly lines integrate the motor, casing, and other parts. Each assembly line may have specialized stations for different components, ensuring that each part is installed correctly. During this stage, manufacturers often employ tools like torque wrenches to ensure that all fittings are secure, which is vital for the compressor’s performance and safety.

The finishing stage includes quality checks and surface treatments. This may involve painting, coating, or adding labels to the compressors. Finishing not only enhances the aesthetic appeal but also provides protection against environmental factors. Additionally, final inspections are conducted to ensure that each unit meets the specified design and functional criteria before moving on to quality assurance.

Quality assurance is a fundamental aspect of the manufacturing process, ensuring that slime compressors meet international and industry-specific standards. Here’s how quality assurance is typically structured:

Illustrative image related to slime compressor

Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with such standards ensures that manufacturers have established processes for consistent quality. In addition, certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for certain components are also significant.

Quality control (QC) is integrated into various stages of the manufacturing process, typically encompassing three main checkpoints:

مراقبة الجودة الواردة (IQC): This is the initial stage where raw materials are inspected upon arrival at the manufacturing facility. The objective is to verify that the materials meet predefined specifications before they are used in production.

مراقبة الجودة أثناء المعالجة (IPQC): During the manufacturing process, QC personnel conduct ongoing inspections at various stages of production. This real-time monitoring helps identify and rectify any defects immediately, reducing the risk of faulty products reaching the final inspection stage.

مراقبة الجودة النهائية (FQC): The final inspection occurs after assembly and finishing. Each compressor undergoes thorough testing to ensure it operates within the required parameters. This may include pressure tests, performance tests, and safety checks.

Testing is a crucial part of the quality assurance process, ensuring that slime compressors perform reliably under various conditions. Common testing methods include:

Performance Testing: Compressors are tested to ensure they meet specified performance criteria, such as inflation speed and maximum pressure output. This testing simulates real-world usage to ensure reliability.

اختبار المتانة: This involves subjecting compressors to extended operational cycles to evaluate their longevity and identify potential failure points.

Safety Testing: Manufacturers conduct tests to ensure the compressor adheres to safety standards, including electrical safety and pressure containment.

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are some effective strategies:

Illustrative image related to slime compressor

Buyers can arrange for on-site audits to assess the manufacturing processes and quality control systems of suppliers. This provides insights into the operational standards and practices in place.

Requesting detailed QC reports from suppliers can give buyers an understanding of the testing and inspection processes. These reports should include data on failure rates, inspection results, and corrective actions taken.

For added assurance, buyers may consider hiring third-party inspection services. These independent entities can provide unbiased evaluations of the manufacturing processes and product quality, ensuring compliance with international standards.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control and certification:

Regional Standards Compliance: Different regions may have varying compliance requirements. For instance, products entering the European market must meet CE marking requirements, while products in the Middle East may need to adhere to GCC standards.

التوثيق: Buyers should ensure that suppliers provide all necessary documentation, including certificates of compliance, test reports, and warranty information. This documentation is essential for customs clearance and regulatory compliance.

الاعتبارات الثقافية: Understanding cultural differences in business practices can aid in effectively communicating quality expectations and requirements. Establishing clear lines of communication regarding quality standards can help mitigate misunderstandings.

In conclusion, thorough knowledge of manufacturing processes and quality assurance practices is vital for B2B buyers in making informed purchasing decisions regarding slime compressors. By understanding these elements, buyers can ensure they source reliable and high-quality products that meet their operational needs.

Illustrative image related to slime compressor

This guide provides a systematic approach for B2B buyers seeking to procure slime compressors. By following this step-by-step checklist, you can ensure that you make informed decisions that align with your operational needs and budget, while also fostering strong supplier relationships.

Before initiating your search, clearly outline the technical specifications required for the slime compressor. This includes determining the necessary power source (e.g., 12V, AC), desired pressure output, and any additional features such as digital controls or portability. Understanding these specifics is crucial to matching your operational needs with the right product.

Conduct thorough research to identify suppliers who specialize in slime compressors. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors. Pay attention to their market reputation and presence in your target regions, such as Africa, South America, the Middle East, and Europe.

Illustrative image related to slime compressor

Verify the certifications and compliance of potential suppliers. Certifications such as ISO 9001 or specific safety standards relevant to compressors can indicate a commitment to quality and reliability. This step is essential to mitigate risks associated with subpar products that can lead to operational downtime.

Examine the range of slime compressors offered by suppliers. A diverse product line can provide flexibility in selecting the right model for your needs. Additionally, inquire about customization options, as some suppliers may offer tailored solutions that can enhance functionality in specific applications.

Before finalizing your purchase, request samples of the slime compressors. Testing these units allows you to assess their performance and suitability for your specific requirements. This step is vital for ensuring that the product meets your expectations in real-world conditions.

Carefully analyze the pricing structures offered by different suppliers. Be sure to consider not just the upfront cost but also potential long-term savings related to efficiency and durability. Additionally, negotiate payment terms that align with your cash flow needs, such as extended payment options or discounts for bulk purchases.

Illustrative image related to slime compressor

Effective communication is crucial for a successful procurement process. Ensure that the supplier is responsive and willing to provide ongoing support post-purchase. Clear communication can prevent misunderstandings and enhance your overall experience with the supplier.

By following this checklist, you can confidently navigate the sourcing process for slime compressors, ensuring that you select a supplier and product that meet your specific business needs.

When sourcing slime compressors, understanding the cost structure is crucial for effective budgeting and decision-making. The primary components of cost include:

المواد: The materials used in manufacturing slime compressors significantly influence the overall cost. High-quality components, such as durable plastics and metals, can increase the price but will likely enhance the product’s longevity and reliability.

العمالة: Labor costs vary depending on the region of production. Countries with lower labor costs can offer competitive pricing, but this may come at the expense of quality or consistency. It’s vital to assess the skill level of the workforce involved in manufacturing.

نفقات التصنيع الزائدة: This includes costs related to utilities, rent, and administrative expenses associated with the production facility. Efficient factories may have lower overhead, which can translate into better pricing for buyers.

الأدوات: The initial investment in tooling for manufacturing slime compressors can be substantial. Custom designs or specialized features may require additional tooling costs, impacting the final price.

مراقبة الجودة (QC): Quality assurance processes ensure that products meet specified standards. Rigorous QC practices may increase costs, but they can prevent defects and reduce returns, ultimately offering better value.

الخدمات اللوجستية: Shipping costs play a crucial role, especially for international buyers. Factors such as distance, shipping method, and freight costs can significantly impact the total cost of acquisition.

الهامش: Suppliers typically include a profit margin in their pricing, which can vary widely. Understanding market standards can help buyers negotiate better deals.

Several factors can influence the pricing of slime compressors, particularly for international B2B buyers:

Illustrative image related to slime compressor

الحجم والحد الأدنى لكمية الطلب (MOQ): Purchasing in larger quantities often leads to discounts. Buyers should consider their inventory needs and negotiate MOQs to maximize cost efficiency.

المواصفات والتخصيص: Custom features or specifications can lead to higher costs. Buyers must balance the need for tailored solutions with budget constraints.

المواد وشهادات الجودة: Higher-grade materials and internationally recognized quality certifications (e.g., ISO) can drive up costs but may also enhance product reliability and marketability.

عوامل الموردين: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer better quality but at a premium. Buyers should research suppliers thoroughly to ensure they are getting fair pricing for the quality offered.

المصطلحات التجارية الدولية: Understanding the Incoterms (International Commercial Terms) can help buyers manage costs related to shipping, insurance, and delivery. Selecting the right Incoterm can minimize unexpected expenses.

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should keep the following tips in mind when negotiating prices for slime compressors:

Establish Clear Requirements: Clearly define your specifications and requirements upfront. This helps suppliers provide accurate quotes and reduces the risk of misunderstandings.

تقييم التكلفة الإجمالية للملكية (TCO): Consider not just the purchase price but the total cost over the product’s lifecycle, including maintenance and operational costs. This holistic view can lead to more informed purchasing decisions.

Leverage Multiple Quotes: Obtain quotes from multiple suppliers to compare prices and terms. This competitive approach can provide leverage during negotiations.

Understand Local Market Conditions: Familiarize yourself with the local market dynamics in the supplier’s region. Economic factors, currency fluctuations, and trade agreements can influence pricing.

Build Relationships: Developing a strong relationship with suppliers can lead to better pricing and more favorable terms. Trust and communication are key elements in any successful negotiation.

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, exchange rates, and supplier negotiations. Always conduct thorough market research and engage directly with suppliers for the most accurate pricing information.

In the realm of tire inflation and emergency roadside assistance, the Slime compressor stands out as a popular choice among B2B buyers. However, various alternative solutions are available, each offering unique advantages and drawbacks. This section will provide a comparative analysis of the Slime compressor against two viable alternatives: traditional air compressors and CO2 inflators.

| جانب المقارنة | Slime Compressor | Traditional Air Compressor | CO2 Inflator |

|---|---|---|---|

| الأداء | Quick inflation with preset pressure | High volume, suitable for larger tires | Instant inflation, limited volume |

| التكلفة | Moderate ($70-$100) | Varies ($50-$300) | Generally low ($30-$70) |

| سهولة التنفيذ | User-friendly, plug-and-play | Requires setup and may need an outlet | Simple, but limited to specific uses |

| الصيانة | Low, minimal upkeep | Moderate, regular checks needed | Low, but cartridges must be replaced |

| أفضل حالة استخدام | Personal vehicles, emergencies | Commercial fleets, workshops | Bicycles, sports equipment |

Traditional air compressors have long been a staple for tire inflation, especially in commercial settings. Their primary advantage lies in their high performance and volume capacity, making them suitable for larger vehicles and fleets. However, they often require a more complex setup, including a power source and hoses, which can make them less convenient for on-the-go use. Additionally, while they may have a higher upfront cost, their versatility allows for broader applications beyond just tire inflation, such as powering pneumatic tools. The trade-off is the need for maintenance, which includes regular checks for leaks and oil levels.

Illustrative image related to slime compressor

CO2 inflators present a compact and efficient solution for quick tire inflation, particularly for bicycles and sports equipment. They offer the benefit of instant inflation, which can be crucial in emergency situations. Their relatively low cost makes them an attractive option for individuals and small businesses. However, CO2 inflators have limitations in volume and pressure, making them less suitable for larger tires or more extensive applications. Additionally, users must purchase replacement cartridges, which can add to the long-term cost. The ease of use is a significant plus, as they require minimal setup and are highly portable.

When selecting the right tire inflation solution, B2B buyers should consider their specific needs and operational context. The Slime compressor is ideal for personal vehicles and emergency roadside assistance due to its user-friendly features and moderate cost. In contrast, traditional air compressors are better suited for commercial applications where high volume and versatility are paramount. CO2 inflators, while limited in scope, serve as an excellent choice for lightweight and portable needs, particularly for bicycles or sports gear. By evaluating performance, cost, ease of implementation, and maintenance, buyers can make informed decisions that align with their operational requirements and budget constraints.

When evaluating a slime compressor, several technical specifications are crucial for B2B buyers to consider. These properties can significantly impact performance, reliability, and overall value.

Airflow Rate (CFM)

– The airflow rate, measured in cubic feet per minute (CFM), indicates how quickly the compressor can inflate tires. A higher CFM allows for faster inflation, which is essential for emergency situations. For instance, the Slime Digital Pro Power boasts an airflow rate of 1.23 CFM, making it competitive in the market. Understanding this metric helps buyers assess the efficiency of the compressor and match it to their operational needs.

مصدر الطاقة

– Most slime compressors operate on either a 12V DC power source or an AC power source. While 12V models are portable and suitable for vehicles, AC models are more appropriate for stationary use in garages. Buyers must consider their primary application to select the right power source, ensuring that the compressor meets their specific requirements.

Maximum Pressure (PSI)

– The maximum pressure, expressed in pounds per square inch (PSI), determines the compressor’s capability to inflate tires to the required specifications. A typical slime compressor can achieve pressures of up to 100 PSI, which is sufficient for most passenger vehicles. Understanding the maximum pressure is vital for ensuring the compressor can handle the demands of various tire types.

التركيب المادي

– The materials used in the construction of the compressor affect its durability and performance. High-grade plastics and metals are preferred for their lightweight and corrosion-resistant properties. B2B buyers should inquire about material grades to ensure they are investing in a product that can withstand the rigors of frequent use.

Size and Portability

– The dimensions and weight of the compressor impact its portability. Compact and lightweight designs are advantageous for on-the-go applications. For instance, the Slime Digital Pro Power measures 8.5 x 6.0 x 4.5 inches, making it easy to store in a vehicle. Buyers should evaluate the size based on their storage capacity and mobility needs.

الضمان والدعم

– A solid warranty period indicates the manufacturer’s confidence in their product. Typically, slime compressors come with a one-year warranty, covering defects and performance issues. Understanding warranty terms is essential for B2B buyers as it can affect long-term operational costs and service expectations.

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B space. Here are some common terms related to slime compressors:

Illustrative image related to slime compressor

OEM (الشركة المصنعة للمعدات الأصلية)

– OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of slime compressors, knowing whether a product is OEM can indicate quality and compatibility with existing systems.

موك (الحد الأدنى لكمية الطلب)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers as it can affect inventory management and cash flow, particularly for smaller businesses.

طلب عرض الأسعار (RFQ)

– An RFQ is a document sent to suppliers requesting pricing and other details for specific products. B2B buyers often use RFQs to compare prices and terms before making purchasing decisions.

إنكوترمز (الشروط التجارية الدولية)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their liabilities and costs in international transactions.

المهلة الزمنية

– Lead time refers to the amount of time it takes for a supplier to fulfill an order. Knowing the lead time is essential for planning and inventory management, as it can impact project timelines and operational efficiency.

After-Sales Support

– This term encompasses services provided to customers after a product purchase, including maintenance, repairs, and customer service. Reliable after-sales support can significantly enhance customer satisfaction and loyalty, making it a vital consideration for B2B buyers.

Understanding these technical properties and trade terms equips B2B buyers with the necessary insights to make informed decisions when purchasing slime compressors, ensuring they select products that meet their operational needs and align with their business goals.

The global slime compressor market is experiencing significant growth driven by several factors. Firstly, the increasing prevalence of flat tires due to urbanization and poor road conditions is propelling demand for portable tire inflators. B2B buyers, especially in regions such as Africa and South America, are keenly aware of the necessity for reliable tire maintenance solutions. Additionally, advancements in technology, such as digital pressure settings and faster inflation times, are enhancing product offerings and attracting business buyers focused on efficiency and quality.

Emerging trends in sourcing highlight the importance of versatility in product features. Modern slime compressors are not only used for vehicle tires but are also adaptable for various applications, including bicycles and lawn equipment. This multifunctionality is appealing to international buyers who are looking to maximize their investment. Furthermore, the rise of e-commerce platforms has streamlined the purchasing process, allowing B2B buyers in diverse geographical locations, including the Middle East and Europe, to access a broader range of products and competitive pricing.

Illustrative image related to slime compressor

Sustainability is also becoming a critical consideration in market dynamics. B2B buyers are increasingly seeking suppliers who prioritize eco-friendly manufacturing processes and materials. This trend is particularly relevant in Europe, where regulations around environmental impact are more stringent. As such, companies that can demonstrate a commitment to sustainability will likely have a competitive edge in the slime compressor market.

Environmental impact and ethical sourcing are becoming central themes in the slime compressor sector. Manufacturers are under pressure to adopt sustainable practices, from using recyclable materials in their products to minimizing waste in their production processes. B2B buyers are increasingly prioritizing suppliers that can provide transparency regarding their sourcing and manufacturing practices.

The importance of ethical supply chains cannot be overstated. Companies that source materials responsibly not only contribute to environmental conservation but also enhance their brand reputation. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can serve as indicators of a company’s commitment to sustainable practices. These certifications are particularly appealing to international buyers who are keen on aligning their purchasing decisions with corporate social responsibility goals.

Moreover, the growing emphasis on sustainability is pushing manufacturers to innovate. This includes developing slime compressors that consume less energy and are designed for durability, thereby reducing the frequency of replacements. Buyers from regions like Saudi Arabia and Germany are especially inclined toward these innovations, as they seek to balance performance with environmental considerations.

The evolution of the slime compressor sector has been marked by significant technological advancements and changing consumer needs. Initially, these compressors were bulky and primarily mechanical, focusing solely on tire inflation. However, as automotive technology evolved, so did the demand for more compact, efficient, and user-friendly solutions.

Over the past two decades, the introduction of digital technology has transformed the industry. Modern slime compressors now feature digital displays, preset pressure settings, and faster inflation capabilities, catering to a more tech-savvy consumer base. This evolution has not only improved user experience but has also expanded the market to include a wider variety of applications, from recreational vehicles to everyday commuter cars.

As the market continues to evolve, B2B buyers are advised to stay abreast of these trends and innovations, ensuring that their sourcing strategies align with both current demands and future advancements in the slime compressor sector.

How do I solve supply chain issues when sourcing slime compressors?

To address supply chain issues, begin by building strong relationships with multiple suppliers across different regions. Diversifying your supplier base mitigates risks associated with political instability or natural disasters in a specific area. Consider utilizing local distributors who understand the regional market and logistics, especially in areas like Africa and South America. Implementing inventory management software can also help track stock levels and forecast demand, ensuring you have adequate supplies during peak seasons.

What is the best slime compressor for commercial use?

For commercial applications, the Slime Digital Pro Power Tire Inflator is highly recommended. It features robust performance with a maximum pressure of 150 PSI, allowing for quick and efficient tire inflation. Its digital preset function enables users to set desired pressure levels, reducing the risk of over-inflation. Additionally, its compact design and multiple power options (12V and AC) make it versatile for various environments, from roadside assistance to fleet maintenance.

What are the minimum order quantities (MOQ) for slime compressors?

Minimum order quantities (MOQ) can vary significantly by supplier and region. Generally, for slime compressors, MOQs may range from 50 to 500 units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing the market or entering a new region. Some manufacturers might offer lower MOQs for first-time buyers or during promotional periods. Establishing a solid partnership can also lead to more favorable terms over time.

How can I vet suppliers for slime compressors?

To effectively vet suppliers, start by assessing their credentials, including certifications and industry experience. Request references and case studies from other clients to gauge their reliability and quality standards. Conduct factory audits, either in-person or virtually, to inspect production processes and quality control measures. Additionally, consider suppliers with established reputations in international markets, especially in regions like Europe and the Middle East, where quality assurance is critical.

What payment terms are typical when sourcing slime compressors internationally?

Typical payment terms in international trade can include options like letter of credit (LC), advance payment, or net 30/60/90 days. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. For first-time transactions, advance payments or partial payments upon order confirmation may be common. As relationships strengthen, you might secure more favorable terms like extended net payment options. Always ensure clarity in payment terms to avoid misunderstandings.

What quality assurance measures should I consider for slime compressors?

When sourcing slime compressors, prioritize suppliers who implement rigorous quality assurance (QA) processes. Look for ISO certifications or adherence to international quality standards. Request detailed quality control documentation, including inspection reports and testing protocols. It’s also beneficial to include QA clauses in your purchase agreement, specifying acceptable defect rates and remedies for non-compliance, ensuring that products meet your expectations upon delivery.

What logistics considerations should I keep in mind for shipping slime compressors?

Logistics is a critical aspect of sourcing slime compressors. Assess the shipping methods available—air freight is faster but more expensive, while sea freight is cost-effective for larger quantities but takes longer. Ensure your supplier has experience with international shipping and can handle customs clearance efficiently. Additionally, consider the packaging of compressors to prevent damage during transit. Collaborating with a reliable freight forwarder can simplify the logistics process and provide valuable insights into cost-effective shipping routes.

Can I customize slime compressors for my specific market needs?

Yes, many manufacturers offer customization options for slime compressors to meet specific market demands. Customizations can include branding, color variations, and even modifications in functionality, such as adding digital pressure gauges or different power sources. When approaching suppliers, clearly outline your requirements and inquire about the feasibility and costs associated with customization. Early discussions can lead to tailored products that resonate better with your target audience and enhance your competitive edge in the market.

المجال: thedrive.com

مسجل: 2000 (25 سنة)

مقدمة: Product Name: Slime Digital Pro Power Tire Inflator

Retail Price: $99.99 (often available for $10 off)

Dimensions: 8.5 x 6.0 x 4.5 inches

Power Source: 12V socket

Output: 1.23 CFM without load

Hose Length: 15 feet (coiled)

Adaptors Included: Yes (for sports balls and pool floaties)

Inflation Time: 1 minute, 54 seconds to fill a tire from 9 to 35 psi

Automatic Shut-off: Yes, when target pressure is…

المجال: target.com

مسجل: 1997 (28 سنة)

مقدمة: This company, Target – Slime Tire Inflators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In conclusion, the strategic sourcing of slime compressors offers significant benefits to international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These compressors not only provide quick and efficient tire inflation solutions but also enhance vehicle maintenance and safety, which are crucial in diverse markets with varying infrastructure challenges. The versatility of products like the Slime Digital Pro Power Tire Inflator, which combines compact design with advanced features such as preset pressure settings, underscores the importance of selecting high-quality, reliable equipment that meets the specific needs of your business.

Illustrative image related to slime compressor

As the demand for efficient automotive solutions continues to rise, investing in strategic sourcing can lead to substantial cost savings and improved operational efficiency. Buyers are encouraged to evaluate suppliers based on product quality, customer service, and availability of support services.

Looking ahead, the global market for tire inflators and compressors is poised for growth. Now is the time to leverage strategic sourcing opportunities to enhance your product offerings and ensure you remain competitive in the evolving landscape. Engage with trusted suppliers, assess the latest innovations, and position your business to meet the rising expectations of your customers.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

Illustrative image related to slime compressor

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.