- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

Navigating the complexities of sourcing air pressure machines can pose significant challenges for international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe. The demand for reliable and efficient air pressure solutions is on the rise, driven by industries ranging from automotive to manufacturing. However, buyers often grapple with identifying the right types of machines, understanding their applications, and evaluating potential suppliers to ensure quality and compliance with regional standards.

This comprehensive guide aims to demystify the global market for air pressure machines by covering various types, including portable inflators, industrial compressors, and specialized equipment tailored for unique applications. We will delve into critical aspects such as supplier vetting processes, cost considerations, and maintenance requirements, providing actionable insights that empower B2B buyers to make informed purchasing decisions.

With a focus on key markets like Brazil and Germany, this guide is designed to equip you with the knowledge necessary to navigate the intricacies of international procurement. By understanding the landscape and leveraging best practices, you can enhance operational efficiency and ensure that your investment in air pressure machines yields maximum return. Whether you’re sourcing for a startup or an established enterprise, this resource will serve as your roadmap to success in the global marketplace.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Reciprocating Compressors | Positive displacement, varying horsepower options | Manufacturing, automotive repair | الإيجابيات: High efficiency; السلبيات: Noisy operation |

| Rotary Screw Compressors | Continuous air flow, quieter operation | Food processing, pharmaceuticals | الإيجابيات: Low maintenance; السلبيات: Higher initial cost |

| Scroll Compressors | Compact design, oil-free operation | Electronics, healthcare | الإيجابيات: Energy-efficient; السلبيات: Limited pressure range |

| Portable Compressors | Lightweight, typically electric or gas-powered | Construction, outdoor applications | الإيجابيات: Versatile; السلبيات: Limited capacity |

| Inflators | Simple design, often 12V or cordless options | Automotive, recreational activities | الإيجابيات: Easy to use; السلبيات: Limited power for heavy-duty tasks |

Reciprocating compressors utilize a piston mechanism to compress air, making them ideal for applications requiring high pressure. They are commonly used in manufacturing and automotive repair settings. When considering a purchase, B2B buyers should evaluate the compressor’s horsepower, as this affects output and efficiency. While they offer high efficiency, they can be noisy, which may necessitate soundproofing in work environments.

Rotary screw compressors provide a continuous flow of compressed air, making them suitable for high-demand industrial applications such as food processing and pharmaceuticals. Their quieter operation and low maintenance requirements appeal to businesses looking for reliable solutions. However, buyers must be prepared for a higher initial investment, which can be justified by their long-term operational savings.

Scroll compressors are known for their compact design and oil-free operation, making them ideal for sensitive industries like electronics and healthcare. Their energy efficiency can lead to significant cost savings over time. However, their limited pressure range might not meet the needs of all applications. B2B buyers should assess their specific requirements to ensure compatibility.

Portable compressors are lightweight and often powered by electricity or gas, making them perfect for construction sites and outdoor activities. Their versatility allows for a range of applications, from powering tools to inflating equipment. Buyers should consider the compressor’s capacity and pressure ratings to ensure it meets their operational needs. While convenient, their limited capacity may restrict use in larger projects.

Inflators are simple machines designed for quick air pressure adjustments, often available in 12V or cordless options. They are primarily used in automotive settings and recreational activities. Their ease of use and portability make them attractive to buyers; however, their limited power may restrict their effectiveness for heavy-duty tasks. Businesses should evaluate their specific needs to determine if an inflator is sufficient for their applications.

| الصناعة/القطاع | Specific Application of air pressure machine | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Manufacturing | Pneumatic Tools Operation | Enhanced productivity and reduced labor costs | Durability, energy efficiency, and compatibility with existing systems |

| Automotive Repair | Tire Inflation and Maintenance | Improved safety and operational efficiency | Speed of inflation, portability, and pressure accuracy |

| Construction | Concrete Compaction | Increased structural integrity and work speed | Power output, tank capacity, and ease of transport |

| الزراعة | Crop Spraying and Irrigation | Optimized resource use and reduced waste | Pressure range, nozzle compatibility, and maintenance requirements |

| Food and Beverage | Packaging and Sealing | Extended shelf life and enhanced product quality | Compliance with health standards, reliability, and efficiency |

In the manufacturing sector, air pressure machines are integral to operating pneumatic tools, which are essential for tasks like assembly and material handling. These machines provide consistent air pressure, which enhances productivity and reduces labor costs by automating repetitive tasks. For international buyers, especially in regions like Africa and South America, sourcing machines that offer durability and energy efficiency is crucial, as these factors directly impact operational costs and long-term reliability.

Air pressure machines are vital for tire inflation and maintenance within the automotive repair industry. They ensure tires are inflated to the correct pressure, improving safety and fuel efficiency. For businesses in Europe and the Middle East, the speed of inflation and the accuracy of pressure gauges are key considerations when sourcing these machines. Portable models are preferred for their convenience, allowing mechanics to service vehicles on-site efficiently.

Illustrative image related to air pressure machine

In construction, air pressure machines are used for concrete compaction, a critical process that enhances the structural integrity of buildings and pavements. These machines help in achieving optimal compaction levels, thereby speeding up the construction process. Buyers in regions like Africa and South America should consider the power output and tank capacity of these machines to ensure they meet the demands of large-scale projects while remaining easy to transport to various job sites.

Air pressure machines are increasingly utilized in agriculture for applications such as crop spraying and irrigation. By providing a controlled pressure output, these machines optimize resource usage and minimize waste, which is essential for sustainable farming practices. Buyers from the Middle East and Europe should focus on the pressure range and nozzle compatibility to ensure efficient application, as well as the maintenance requirements to keep the machines operational throughout the farming season.

In the food and beverage sector, air pressure machines play a crucial role in packaging and sealing processes. They ensure that products are sealed correctly, extending shelf life and maintaining quality. When sourcing these machines, businesses must consider compliance with health standards, as well as the reliability and efficiency of the machines to keep production lines running smoothly. For international buyers, understanding local regulations and standards is essential for successful procurement.

المشكلة Many B2B buyers, particularly in manufacturing or automotive sectors, encounter issues with air pressure machines that deliver inconsistent air pressure. This inconsistency can lead to inefficiencies in production lines, cause equipment malfunctions, and ultimately result in increased downtime. For instance, a tire manufacturing plant may find that its inflators cannot maintain a steady pressure, leading to defective products and costly reworks.

الحل: To address this challenge, B2B buyers should prioritize sourcing air pressure machines with advanced pressure regulation features. When evaluating equipment, look for models that offer digital pressure gauges and automatic shut-off mechanisms. Additionally, investing in periodic maintenance and calibration of machines ensures they perform optimally. Establish a routine check-up schedule to monitor performance metrics, and consider partnering with suppliers who provide reliable after-sales support, ensuring that any issues can be addressed swiftly to minimize downtime.

المشكلة For companies operating air pressure machines, high energy consumption can significantly inflate operational costs. Businesses in regions like Africa or South America, where electricity prices may vary greatly, often face pressure to reduce energy expenditures. A manufacturing facility may find itself spending a disproportionate amount of its budget on energy bills due to inefficient air compressors that consume excessive power.

الحل: To mitigate this issue, buyers should consider energy-efficient models that are designed to consume less power while providing the same output. Look for machines with variable speed drives (VSD) or those that meet international energy standards such as ISO 50001. Implementing an energy audit can help identify inefficiencies in current systems, and investing in a comprehensive air system management solution can further optimize energy use. Additionally, educating staff on best practices for machine usage can lead to more conscientious energy consumption, ultimately reducing costs.

المشكلة B2B buyers often struggle with sourcing replacement parts and obtaining technical support for their air pressure machines, especially in remote regions. This challenge can lead to extended downtimes and operational disruptions. For example, a construction company relying on pneumatic tools may find that when their air compressor breaks down, the lack of readily available parts can halt projects and impact client relationships.

الحل: To alleviate this concern, it is crucial for buyers to establish relationships with reputable suppliers who can guarantee availability of spare parts and provide timely technical support. When selecting an air pressure machine, inquire about the supplier’s distribution network and after-sales service capabilities. Consider investing in machines from manufacturers known for their global presence and robust service networks. Additionally, implementing a parts inventory system can help track the lifespan of components and facilitate proactive replacements before breakdowns occur. Regular training for staff on machine operation and troubleshooting can also empower teams to address minor issues swiftly, reducing dependency on external support.

When selecting materials for air pressure machines, it is crucial to consider properties that directly impact performance, longevity, and compatibility with various applications. Here, we analyze four common materials used in air pressure machines: aluminum, steel, plastic, and composite materials. Each material has unique characteristics that can influence the operational efficiency and cost-effectiveness of the machines.

Aluminum is renowned for its lightweight and excellent corrosion resistance, making it a favored choice for various components in air pressure machines. Its temperature rating typically ranges from -200°C to 600°C, and it can withstand pressures up to 250 psi, depending on the alloy used.

الإيجابيات والسلبيات: The primary advantage of aluminum is its low weight, which enhances portability and ease of handling. It also offers good thermal conductivity, which can be beneficial in heat dissipation. However, aluminum can be more expensive than some alternatives and may require additional protective coatings to enhance its durability in harsh environments.

التأثير على التطبيق: Aluminum is compatible with a wide range of media, including air and various gases, making it suitable for general-purpose applications. However, it might not be the best choice for applications involving aggressive chemicals.

اعتبارات للمشترين الدوليين: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM and ISO. Additionally, local sourcing of aluminum can mitigate costs and reduce lead times.

Steel, particularly carbon steel, is widely used in air pressure machines due to its strength and durability. It has a high temperature rating (up to 500°C) and can handle pressures exceeding 300 psi, making it suitable for high-performance applications.

الإيجابيات والسلبيات: The key advantage of steel is its robustness, which translates to longer service life and reduced maintenance costs. However, steel is heavier than aluminum, which can affect portability. It is also prone to corrosion if not properly treated, necessitating protective coatings or galvanization.

Illustrative image related to air pressure machine

التأثير على التطبيق: Steel is compatible with various media, including air and water, but its susceptibility to rust can limit its use in humid or corrosive environments.

اعتبارات للمشترين الدوليين: Steel compliance with standards such as DIN and JIS is critical, especially in Europe and the Middle East. Buyers should also consider the availability of corrosion-resistant coatings to enhance performance in challenging environments.

Plastics, especially engineering plastics like polycarbonate and nylon, are increasingly used in air pressure machines due to their lightweight and corrosion-resistant properties. They can typically withstand temperatures up to 100°C and pressures around 150 psi.

Illustrative image related to air pressure machine

الإيجابيات والسلبيات: The main advantage of plastics is their resistance to corrosion and chemical attack, making them ideal for specific applications. They are also cost-effective and easy to mold into complex shapes. However, plastics may not provide the same structural integrity as metals, limiting their use in high-pressure applications.

التأثير على التطبيق: Plastics are suitable for applications involving non-corrosive gases and fluids. However, they should be avoided in high-temperature or high-pressure scenarios.

اعتبارات للمشترين الدوليين: Buyers should verify compliance with local regulations regarding plastic materials, especially in regions with stringent environmental standards.

Illustrative image related to air pressure machine

Composite materials, such as fiberglass and carbon fiber, are becoming popular in the manufacturing of air pressure machines due to their high strength-to-weight ratio and excellent corrosion resistance. They can handle temperatures up to 200°C and pressures similar to steel.

الإيجابيات والسلبيات: The key advantage of composites is their lightweight and high strength, which can significantly enhance the performance of air pressure machines. However, they are often more expensive and can require specialized manufacturing processes, which may complicate production.

التأثير على التطبيق: Composites are ideal for applications requiring high strength while minimizing weight, such as portable air compressors.

Illustrative image related to air pressure machine

اعتبارات للمشترين الدوليين: Buyers should consider the availability of composite materials in their region and ensure compliance with relevant standards, as these can vary significantly across different markets.

| المواد | Typical Use Case for air pressure machine | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | General-purpose components | خفيف الوزن ومقاوم للتآكل | Higher cost, requires coatings | متوسط |

| الفولاذ | Structural components | قوة ومتانة عالية | Heavier, prone to corrosion | متوسط |

| بلاستيك | Non-corrosive applications | Corrosion-resistant, cost-effective | Limited structural integrity | منخفضة |

| مركب | High-performance portable machines | High strength-to-weight ratio | Expensive, complex manufacturing | عالية |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering the optimal materials for air pressure machines, ensuring informed decisions that align with their operational needs and regional compliance requirements.

The manufacturing of air pressure machines, including air compressors and inflators, involves several critical stages that ensure the final product meets industry standards and customer expectations.

إعداد المواد: The process begins with sourcing high-quality materials, typically metals like aluminum or steel for the casing, and specialized polymers for internal components. Suppliers often provide certifications to guarantee material quality, which is crucial for durability and performance.

التشكيل: This stage involves shaping the materials into the desired components. Techniques such as stamping, casting, and machining are commonly used to create parts like the compressor housing, pistons, and valves. Advanced manufacturers may utilize CNC (Computer Numerical Control) machines for precision, ensuring that each part meets strict tolerances.

التجميع: After the components are formed, they are assembled into the final product. This step may involve manual labor and automated processes. Skilled technicians carefully fit together the various parts, including the motor, pump, and control systems, ensuring that everything is aligned and functioning correctly.

التشطيب: The final stage of manufacturing includes surface treatments and painting to enhance appearance and corrosion resistance. Processes such as powder coating or anodizing can be employed to ensure longevity and compliance with aesthetic standards.

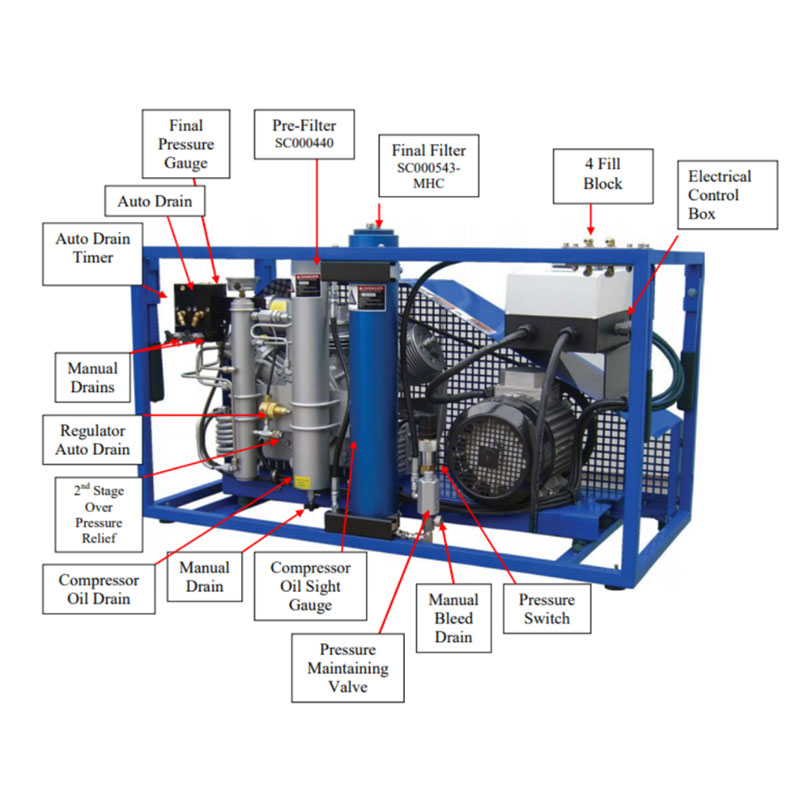

Quality control (QC) is integral to the manufacturing process, ensuring that every air pressure machine produced meets both international and industry-specific standards.

المعايير والشهادات الدولية: Compliance with standards such as ISO 9001 is crucial for manufacturers targeting international markets. This certification demonstrates a commitment to quality management systems and continuous improvement. Additionally, region-specific certifications like CE (Conformité Européenne) for the European market or API (American Petroleum Institute) standards for specific applications can enhance credibility.

نقاط التحقق من الجودة: Various checkpoints are established during the manufacturing process:

– مراقبة الجودة الواردة (IQC): Inspects raw materials and components upon arrival to ensure they meet specifications.

– مراقبة الجودة أثناء المعالجة (IPQC): Monitors production processes in real-time, identifying defects early. Techniques include visual inspections and measurements using calibrated tools.

– مراقبة الجودة النهائية (FQC): Conducts comprehensive testing of the completed air pressure machines, including functionality tests, pressure tests, and safety inspections.

طرق الاختبار الشائعة: Manufacturers often use several testing methodologies to assess product performance:

– Performance Testing: Measures the machine’s output pressure and airflow.

– اختبار المتانة: Simulates prolonged use to ensure longevity and reliability under stress.

– Safety Testing: Evaluates compliance with safety regulations, especially regarding electrical components and pressure containment.

For B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks associated with product failures.

عمليات تدقيق الموردين: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and QC practices. This direct observation helps buyers assess compliance with international standards and the overall capability of the supplier.

طلب تقارير الجودة: Suppliers should provide documentation of their QC processes, including reports from IQC, IPQC, and FQC. These documents should detail testing results, non-conformance reports, and corrective actions taken.

عمليات التفتيش من طرف ثالث: Engaging third-party inspection services can offer an independent assessment of the supplier’s QC practices. These inspections can be scheduled at various stages of the manufacturing process and can help verify that products meet required specifications before shipment.

International buyers must navigate various quality control and certification nuances when sourcing air pressure machines.

Understanding Regional Standards: Different regions may have unique standards that affect the certification process. For instance, European buyers must ensure compliance with CE marking, which indicates conformity with health, safety, and environmental protection standards. In contrast, buyers in the Middle East may prioritize certification from local regulatory bodies.

Customs and Import Regulations: Familiarity with the customs regulations of the importing country is essential. Some regions may require additional testing or documentation for imported air pressure machines, impacting delivery timelines and costs.

Cultural and Business Practices: Building relationships with suppliers in different regions can enhance trust and communication regarding quality expectations. Understanding cultural nuances can facilitate smoother negotiations and ensure that both parties are aligned on quality standards.

The manufacturing processes and quality assurance measures for air pressure machines are multifaceted, involving rigorous steps from material preparation to final testing. For B2B buyers, particularly those operating across diverse global markets, understanding these processes is crucial for ensuring product reliability and compliance with international standards. By leveraging audits, quality reports, and third-party inspections, buyers can effectively verify supplier capabilities, ultimately leading to successful procurement strategies.

To assist B2B buyers in procuring an air pressure machine, this guide provides a structured checklist to streamline your sourcing process. Understanding the specific requirements and nuances of air pressure machines is essential for making an informed purchasing decision that aligns with your business needs.

Illustrative image related to air pressure machine

Before initiating the procurement process, it’s critical to outline your technical specifications. Determine the required pressure levels, airflow capacity, and intended applications (e.g., tire inflation, powering tools). This clarity helps narrow down options that suit your operational needs and ensures compatibility with existing equipment.

Establishing a budget is a key step in the sourcing process. Consider not only the initial purchase price but also ongoing costs such as maintenance, energy consumption, and potential accessories. A well-defined budget will guide your search and help prevent overspending on features that may not be necessary for your operations.

Research and compile a list of potential suppliers known for their reliability and quality. Look for manufacturers with established reputations in your industry and regions, especially in Africa, South America, the Middle East, and Europe. Supplier websites, industry forums, and trade shows can be valuable resources to gather insights and reviews.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence helps verify the supplier’s credibility and can reveal important information about their customer service and post-sale support.

Illustrative image related to air pressure machine

Once you have narrowed down potential suppliers, request detailed quotations that include pricing, delivery timelines, and warranty information. Ensure that the quote outlines all costs, including shipping and installation, to avoid unexpected expenses later.

Engage in negotiations to secure favorable terms, including payment options, delivery schedules, and warranty conditions. Strong negotiation can lead to better pricing or additional services such as extended warranties or maintenance agreements. Be clear about your expectations to avoid misunderstandings later.

Consider the support and service offerings from your chosen supplier after the purchase. Ensure that they provide adequate training for your staff, as well as accessible customer service for any technical issues that may arise. Reliable post-purchase support can significantly enhance the value of your investment in an air pressure machine.

By following these steps, B2B buyers can effectively navigate the sourcing process for air pressure machines, ensuring that they select the best options tailored to their specific needs and operational requirements.

In the procurement of air pressure machines, understanding the cost structure is essential for international B2B buyers. The primary components contributing to the overall cost include:

المواد: The quality and type of materials used—such as metals for the casing, motors, and electrical components—can significantly influence costs. Premium materials often lead to higher durability and performance, which can justify a higher price point.

العمالة: Labor costs vary by region. For instance, countries with higher wage standards may reflect increased labor costs in the final pricing. Conversely, sourcing from regions with lower labor costs may offer savings but could raise concerns about quality and compliance.

نفقات التصنيع الزائدة: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can help reduce these overheads, allowing suppliers to offer more competitive pricing.

الأدوات: Investment in specialized tooling for manufacturing can be a significant upfront cost. Buyers should assess whether suppliers have the necessary tooling to meet their specifications or if additional costs will be incurred.

مراقبة الجودة (QC): QC processes are critical in ensuring that the machines meet specified performance and safety standards. Suppliers with rigorous QC protocols may charge more but offer greater assurance of product reliability.

الخدمات اللوجستية: Transportation costs, including shipping and customs duties, are crucial in international sourcing. These costs can vary widely based on the shipping method, destination, and supplier location.

الهامش: Suppliers typically include a profit margin that can vary based on market demand, competition, and the perceived value of their products.

Several factors can influence the pricing of air pressure machines, particularly in international markets:

الحجم والحد الأدنى لكمية الطلب (MOQ): Higher order volumes can lead to discounts. Buyers should negotiate MOQs to achieve better pricing, especially when sourcing for large-scale operations.

المواصفات والتخصيص: Custom specifications can add to the cost. Buyers should clearly define their requirements to avoid unexpected price increases.

المواد وشهادات الجودة: Products made with high-grade materials or that meet specific industry certifications (like ISO or CE) may command higher prices. Understanding the necessity of these certifications for your market can help guide purchasing decisions.

عوامل الموردين: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their products due to their track record of quality and service.

المصطلحات التجارية الدولية: The agreed-upon Incoterms can influence the total landed cost of goods. Buyers should ensure they understand the implications of terms like FOB (Free on Board) and CIF (Cost, Insurance, Freight) when negotiating contracts.

To optimize sourcing strategies, international buyers should consider the following tips:

التفاوض: Leverage volume and long-term relationships to negotiate better pricing. Open discussions about potential future orders can incentivize suppliers to provide favorable terms.

التكلفة الإجمالية للملكية (TCO): Look beyond the initial purchase price. Consider maintenance costs, energy efficiency, and potential downtimes. A slightly higher upfront cost may result in lower TCO over the machine’s lifespan.

Pricing Nuances for International Buyers: Be aware of regional pricing differences. For example, suppliers in Europe may have different pricing structures compared to those in South America or Africa due to local market conditions and import tariffs.

Market Research: Conduct thorough market research to understand prevailing prices and trends. This information can empower buyers during negotiations and help in selecting the right supplier.

Understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers of air pressure machines. By analyzing cost components, recognizing price influencers, and employing strategic negotiation tactics, buyers can make informed decisions that optimize their procurement processes. Keep in mind that prices may vary significantly based on region, supplier, and order specifications, making it essential to conduct thorough due diligence.

When evaluating solutions for air pressure needs, it is essential to explore various alternatives to an air pressure machine. Each option can cater to different operational requirements, budgets, and industry contexts. This analysis will compare the air pressure machine against two notable alternatives: electric tire inflators and gas-powered compressors, providing B2B buyers with actionable insights to make informed decisions.

Illustrative image related to air pressure machine

| جانب المقارنة | Air Pressure Machine | Electric Tire Inflator | Gas-Powered Compressor |

|---|---|---|---|

| الأداء | High, versatile for various tasks | Moderate, best for tires and small inflatables | Very high, suitable for heavy-duty applications |

| التكلفة | Moderate to high | Low to moderate | High upfront costs with operational fuel expenses |

| سهولة التنفيذ | Requires setup and power source | Plug-and-play, easy to use | Requires more setup and maintenance |

| الصيانة | Regular maintenance needed | Minimal maintenance | High maintenance due to engine care |

| أفضل حالة استخدام | Industrial applications, multi-purpose | Personal use, light-duty tasks | Construction, heavy machinery applications |

Electric tire inflators are compact and user-friendly, making them ideal for personal use and light-duty tasks. Their affordability is a significant advantage, appealing to budget-conscious buyers. However, their performance is limited compared to air pressure machines, often struggling with larger inflatables or industrial applications. Additionally, they typically require a power source, which could restrict their usability in remote areas.

Gas-powered compressors excel in performance, providing high-pressure output suitable for demanding tasks such as construction and heavy machinery operation. They are not tethered to an electrical outlet, allowing for greater mobility in outdoor environments. However, they come with a higher initial investment and ongoing fuel costs. Maintenance can be burdensome due to the need for engine upkeep, which may deter some buyers seeking a more straightforward solution.

When selecting the right air pressure solution, B2B buyers should consider their specific operational requirements, budget constraints, and the nature of the tasks at hand. For industrial applications requiring versatility and high performance, an air pressure machine may be the best fit. Alternatively, for lighter, more occasional use, electric tire inflators offer a cost-effective solution. In scenarios demanding mobility and heavy-duty performance, gas-powered compressors shine despite their higher costs and maintenance needs. By carefully evaluating these factors, buyers can align their choice with their business objectives and operational efficiency.

Understanding the essential technical specifications of air pressure machines is vital for B2B buyers. These properties directly impact the performance, reliability, and suitability of the equipment for specific applications. Here are several critical specifications to consider:

Pressure Rating (PSI)

– The pressure rating, typically measured in pounds per square inch (PSI), indicates the maximum pressure the air compressor can achieve. This specification is crucial for determining the applications the machine can handle, such as inflating tires, powering pneumatic tools, or other industrial uses. A higher PSI often correlates with a more versatile and powerful machine, making it essential for businesses with diverse needs.

Horsepower (HP)

– Horsepower measures the power output of the air compressor’s motor. It directly influences the compressor’s efficiency and ability to sustain high pressure over time. For B2B buyers, selecting the right horsepower ensures the machine can meet operational demands without overheating or wearing out prematurely. Typical options range from 0.5 HP for smaller tasks to over 5 HP for industrial applications.

Tank Capacity (Gallons)

– The tank capacity, measured in gallons, indicates the volume of compressed air the machine can store. A larger tank allows for longer run times without needing to refill, making it suitable for high-demand tasks. Businesses should evaluate their operational requirements to select an appropriate tank size, balancing the need for portability and storage.

درجة المادة

– The material grade of the compressor, often made from steel or aluminum, affects its durability and resistance to corrosion. Higher-grade materials typically enhance the lifespan of the machine and reduce maintenance costs. Buyers should consider the operating environment, especially in regions with high humidity or exposure to chemicals, to ensure the longevity of their investment.

Noise Level (Decibels)

– Noise level, measured in decibels (dB), is an important consideration for workplaces where sound levels are regulated or where employee comfort is a priority. Compressors with lower noise ratings are particularly valuable in urban settings or enclosed spaces. Businesses should assess their work environment to choose a model that minimizes disruption.

Familiarity with industry jargon can facilitate smoother negotiations and transactions. Here are several common terms that B2B buyers should understand:

Illustrative image related to air pressure machine

OEM (الشركة المصنعة للمعدات الأصلية)

– OEM refers to companies that manufacture products that may be marketed by another company under its brand. In the context of air pressure machines, OEM parts are often considered more reliable and compatible with existing systems. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components for maintenance or upgrades.

موك (الحد الأدنى لكمية الطلب)

– MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B transactions as it can impact inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing needs without overcommitting resources.

طلب عرض الأسعار (RFQ)

– An RFQ is a formal document requesting pricing and terms from suppliers for specific products. In the air pressure machine market, submitting an RFQ can streamline the procurement process, allowing buyers to compare offers and negotiate better terms.

إنكوترمز (الشروط التجارية الدولية)

– Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Understanding Incoterms is crucial for international transactions, as they clarify who bears the risk and costs associated with transportation. This knowledge helps buyers mitigate potential disputes and plan logistics effectively.

CFM (Cubic Feet per Minute)

– CFM measures the flow rate of air produced by the compressor. This specification is vital for determining how quickly the machine can fill a tank or power pneumatic tools. Buyers should assess their air consumption needs to select a compressor with adequate CFM ratings for their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right air pressure machines for their operational needs.

The air pressure machine sector is experiencing significant growth driven by several global factors. Firstly, the increasing demand for energy-efficient and compact machinery in various industries, such as automotive, construction, and manufacturing, is reshaping sourcing decisions. With a growing emphasis on automation and smart technologies, B2B buyers are increasingly looking for air compressors equipped with IoT capabilities that enable real-time monitoring and predictive maintenance. This trend is particularly relevant for international buyers from regions like Africa and South America, where infrastructure development is accelerating.

Emerging markets are also witnessing a surge in demand for portable air compressors, driven by the rise of DIY projects and the need for mobile solutions. In Europe, particularly in Germany, sustainability is becoming a key purchasing criterion, prompting manufacturers to innovate with energy-efficient models that comply with stringent environmental regulations. Furthermore, the shift toward e-commerce platforms for sourcing air pressure machines is altering traditional procurement methods, making it easier for B2B buyers to compare products and prices across borders.

Sustainability is no longer just an option; it is a necessity for businesses in the air pressure machine sector. With increasing awareness of environmental impact, B2B buyers are prioritizing ethical sourcing practices. This includes selecting suppliers who demonstrate commitment to reducing carbon footprints through energy-efficient manufacturing processes and recyclable materials. The adoption of ‘green’ certifications, such as Energy Star or ISO 14001, is becoming a crucial factor in supplier selection, particularly for companies operating in regions with stringent environmental regulations.

Illustrative image related to air pressure machine

Moreover, sustainable sourcing extends beyond the machines themselves to encompass the entire supply chain. Buyers are encouraged to assess their suppliers’ practices in terms of labor rights and community impact, ensuring that their procurement strategies align with ethical standards. By prioritizing suppliers who invest in sustainable technologies and practices, companies can not only reduce their environmental impact but also enhance their brand reputation and customer loyalty.

The air pressure machine industry has evolved significantly since its inception. Originally designed for simple pneumatic tasks, these machines have transformed into sophisticated devices incorporating advanced technologies. The late 20th century saw the introduction of electric air compressors, which revolutionized the market by offering cleaner and more efficient alternatives to gas-powered models. As industries began to recognize the advantages of automation, air pressure machines evolved to meet these demands, integrating features such as variable speed drives and smart controls.

The 21st century has brought about a focus on sustainability and efficiency, with manufacturers continually innovating to reduce energy consumption and enhance functionality. This evolution has not only expanded the applications of air pressure machines across various sectors but has also opened new avenues for international trade, especially in emerging markets where industrialization is rapidly advancing. Understanding this historical context helps B2B buyers appreciate the current trends and make informed sourcing decisions that align with their operational needs.

1. How do I solve issues with air pressure machines losing pressure?

To address pressure loss in air pressure machines, first, inspect all connections, hoses, and fittings for leaks. Use a soap solution to identify leaks visually, as bubbles will form at the leak sites. Additionally, check the machine’s seals and valves for wear or damage. If the problem persists, consult the manufacturer’s technical support or service manual for troubleshooting specific to your model. Regular maintenance, including replacing worn parts, can also mitigate future issues.

2. What is the best air pressure machine for industrial applications?

The best air pressure machine for industrial applications typically depends on the specific needs of your operation. For heavy-duty tasks, look for machines with higher horsepower ratings and larger tank capacities, as these provide sustained pressure for longer periods. Brands known for reliability in industrial settings include Ingersoll Rand and Atlas Copco. It’s crucial to consider factors such as airflow requirements, noise levels, and energy efficiency when making your selection.

3. How can I verify the reliability of an air pressure machine supplier?

To verify a supplier’s reliability, conduct thorough due diligence. Check for industry certifications such as ISO 9001, which indicates quality management standards. Request references from previous clients, and explore online reviews or testimonials. Visiting their manufacturing facility, if possible, can also provide insights into their operations and quality control processes. Engaging in direct communication can reveal their responsiveness and willingness to address concerns.

4. What are common customization options available for air pressure machines?

Customization options for air pressure machines can include tank size, motor type, and additional features such as automatic shut-off or integrated moisture separators. Some manufacturers may also offer bespoke solutions tailored to specific industry requirements, such as explosion-proof designs for hazardous environments. Discuss your unique needs with potential suppliers to explore available customization options that enhance performance and efficiency.

5. What is the minimum order quantity (MOQ) for air pressure machines?

Minimum order quantities for air pressure machines can vary significantly between suppliers and are often influenced by the machine type and customization requirements. Generally, MOQs range from one unit for standard models to higher quantities for customized solutions. It’s advisable to negotiate MOQs, especially if you are a first-time buyer, as some suppliers may offer flexibility to build a long-term relationship.

6. What payment terms should I expect when purchasing air pressure machines internationally?

Payment terms for international purchases of air pressure machines can differ widely among suppliers. Common arrangements include a deposit (often 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may accept letters of credit or offer financing options. Always clarify payment methods, currency, and any additional fees upfront to avoid misunderstandings later.

7. How can I ensure quality assurance for air pressure machines?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Inquire about their quality control processes, including testing standards and inspection protocols. It may also be beneficial to establish a quality assurance agreement outlining your expectations. If feasible, consider arranging for third-party inspections before shipment to verify that the machines meet your requirements.

8. What logistics considerations should I keep in mind when importing air pressure machines?

When importing air pressure machines, consider the logistics of shipping, including freight costs, lead times, and customs regulations in your country. Ensure that your supplier is experienced in international shipping and can provide the necessary documentation for customs clearance. Additionally, assess the machine’s packaging and handling requirements to prevent damage during transit. Partnering with a reliable freight forwarder can simplify the logistics process and help you navigate potential challenges.

Could not verify enough suppliers for air pressure machine to create a list at this time.

In conclusion, the strategic sourcing of air pressure machines is vital for international B2B buyers looking to enhance operational efficiency and reduce costs. Key takeaways include the importance of evaluating supplier reliability, understanding local market conditions, and ensuring compliance with international standards. Buyers should prioritize suppliers that offer a range of options, from compact inflators to robust industrial compressors, to meet diverse operational needs.

Illustrative image related to air pressure machine

Strategic sourcing not only helps in securing favorable pricing but also fosters long-term partnerships that can lead to innovation and improved product offerings. As the demand for air pressure machines continues to rise, especially in emerging markets across Africa, South America, the Middle East, and Europe, it’s crucial for businesses to stay ahead of market trends and technological advancements.

Looking forward, international buyers should actively engage with suppliers to explore advancements in energy efficiency and smart technology integration. By adopting a proactive approach to sourcing, companies can position themselves competitively in a rapidly evolving landscape. Now is the time to invest in strategic sourcing practices that will not only meet current demands but also prepare your business for future growth in the air pressure machine market.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.