- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

As global trade expands, sourcing high-quality air tires poses a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Navigating the complexities of tire specifications, supplier reliability, and regional regulations can be daunting for businesses aiming to optimize their logistics and fleet performance. This guide comprehensively addresses these challenges, offering insights into various types of air tires, their applications across industries, and critical supplier vetting processes.

Moreover, we delve into cost analysis, ensuring that international buyers can make informed purchasing decisions that align with their operational budgets and quality expectations. With an emphasis on actionable strategies, this resource equips B2B buyers with the knowledge to identify reliable suppliers, evaluate product performance, and understand market trends. By focusing on regional nuances, such as the specific needs of markets in Saudi Arabia or Brazil, this guide empowers businesses to enhance their procurement strategies and ultimately improve their bottom line.

Understanding the dynamics of the air tire market is essential for achieving operational efficiency and competitive advantage. Whether you are looking to enhance your fleet’s performance or expand your product offerings, this guide serves as a vital tool for navigating the global market for air tires with confidence.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Radial Tires | Feature a radial ply construction for better flexibility | Passenger vehicles, light trucks | الإيجابيات: Improved fuel efficiency; better traction. السلبيات: Higher initial cost compared to bias tires. |

| Bias-Ply Tires | Constructed with overlapping plies for durability | Heavy-duty vehicles, agricultural use | الإيجابيات: Stronger sidewalls; cost-effective. السلبيات: Less fuel-efficient; poorer traction on wet surfaces. |

| Tubeless Tires | Eliminate the need for an inner tube | Commercial fleets, motorcycles | الإيجابيات: Reduced risk of blowouts; easier maintenance. السلبيات: Requires specific rims; initial installation can be complex. |

| Nitrogen-Filled Tires | Use nitrogen gas instead of regular air | Racing cars, aircraft, heavy machinery | الإيجابيات: Better pressure retention; reduces oxidation. السلبيات: Higher cost; limited availability in some regions. |

| All-Season Tires | Designed for various weather conditions | Family vehicles, delivery trucks | الإيجابيات: Versatile performance; suitable for multiple climates. السلبيات: May not perform as well in extreme conditions compared to specialized tires. |

Radial tires are characterized by their construction, where the plies are arranged radially from the center of the tire. This design enhances flexibility and improves fuel efficiency, making them suitable for passenger vehicles and light trucks. B2B buyers should consider radial tires for their fleet vehicles due to their superior traction and longevity, despite a higher initial investment. The long-term savings on fuel and maintenance often justify the upfront costs.

Bias-ply tires are constructed with plies that overlap in a crisscross pattern, offering robust sidewall strength. These tires are commonly used in heavy-duty vehicles and agricultural applications due to their durability and ability to carry heavy loads. While they are more cost-effective than radial tires, B2B buyers should weigh their performance limitations in fuel efficiency and wet traction, which may affect operational costs in the long run.

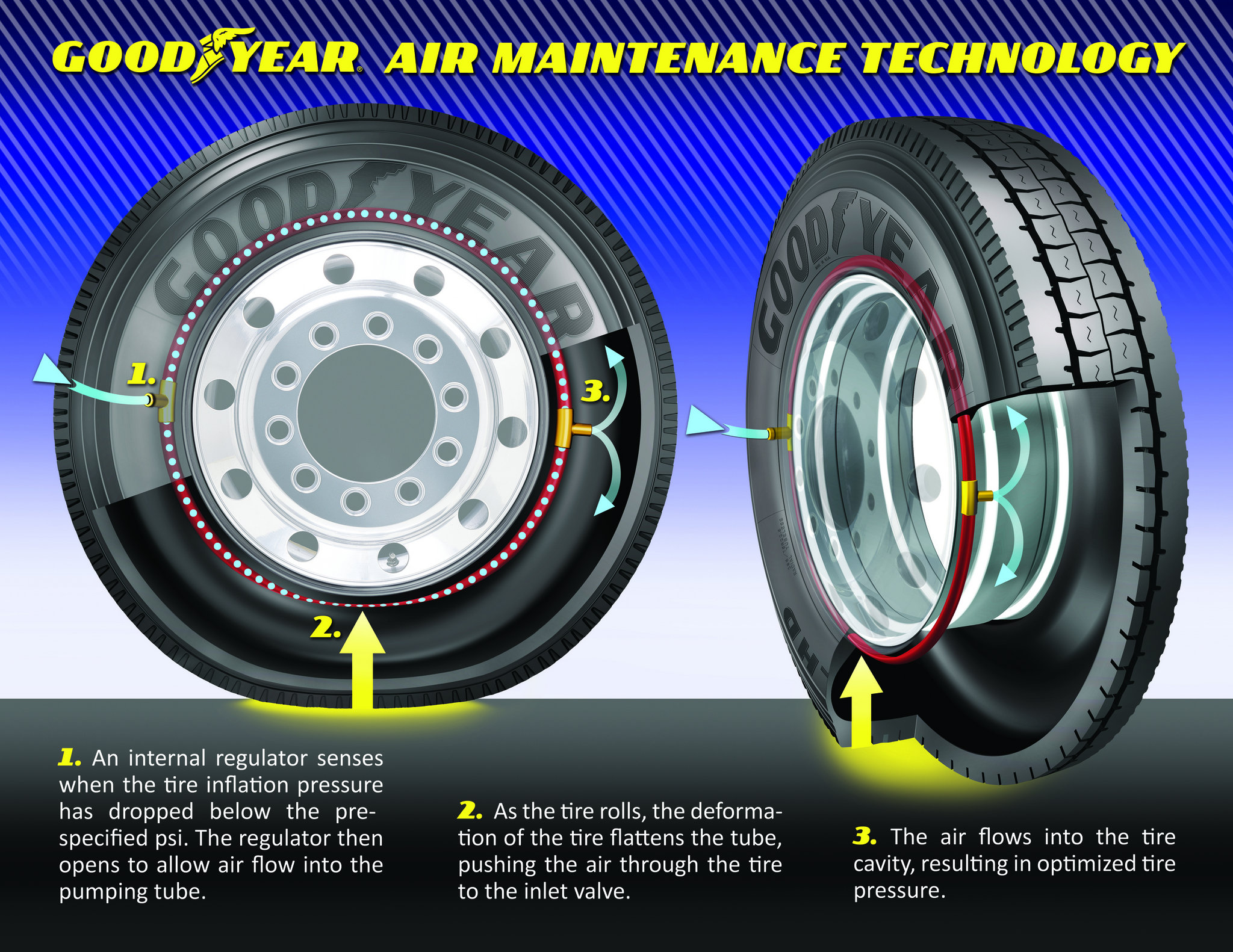

Illustrative image related to air tires

Tubeless tires eliminate the need for an inner tube, which can significantly reduce the risk of blowouts and facilitate easier maintenance. They are particularly beneficial for commercial fleets and motorcycles. B2B buyers should consider the initial complexity of installation and the requirement for specific rims, but the overall safety and convenience can lead to lower operational risks and costs over time.

Nitrogen-filled tires utilize nitrogen gas instead of regular air, providing better pressure retention and reducing oxidation within the tire. This feature is particularly advantageous in racing, aviation, and heavy machinery applications, where performance and safety are paramount. While the higher costs and limited availability may deter some buyers, the benefits of enhanced performance and reduced tire wear can make them a worthwhile investment for specialized fleets.

All-season tires are designed to perform across various weather conditions, making them suitable for family vehicles and delivery trucks. Their versatility is a key selling point for B2B buyers looking for a balance between performance and cost-effectiveness. However, while they offer convenience, they may not excel in extreme weather, prompting buyers to consider specific seasonal tires for optimal performance in harsher conditions.

| الصناعة/القطاع | Specific Application of air tires | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive | Passenger vehicles and light trucks | Enhanced fuel efficiency and improved ride quality | Ensure compliance with local regulations and quality standards. |

| Construction | Heavy machinery and construction vehicles | Increased load capacity and durability under harsh conditions | Look for tires with reinforced sidewalls and tread patterns suited for rough terrain. |

| الزراعة | Tractors and agricultural equipment | Better traction and reduced soil compaction | Consider tires designed for specific agricultural tasks and soil types. |

| الخدمات اللوجستية والنقل | Delivery trucks and freight carriers | Improved fuel efficiency and reduced downtime due to tire failures | Evaluate tire performance in varying climates and road conditions. |

| Mining and Industrial | Mining trucks and equipment | Enhanced safety and reliability in extreme environments | Source tires that are resistant to punctures and have high abrasion resistance. |

In the automotive sector, air tires are critical for passenger vehicles and light trucks. They contribute significantly to fuel efficiency, safety, and comfort. Properly inflated tires improve vehicle handling and reduce rolling resistance, which is vital for long-distance travel. International buyers, especially in regions like Africa and South America, must consider local climate conditions and road quality when sourcing tires to ensure optimal performance and durability. Compliance with local regulations regarding tire specifications is also essential.

In the construction industry, air tires are utilized on heavy machinery and construction vehicles, including bulldozers and excavators. These tires are designed to handle substantial loads and provide stability on uneven surfaces. The benefits include improved durability and a reduction in the risk of tire-related downtimes, which can be costly. For buyers in the Middle East or Europe, sourcing tires with reinforced sidewalls and specialized tread patterns can enhance performance in rugged environments, ensuring safety and operational efficiency.

Air tires are integral to agricultural machinery, such as tractors and harvesters, where they provide essential traction and stability on various terrains. The right tire selection can minimize soil compaction, promoting healthier crop growth. Buyers in agricultural sectors should focus on tires tailored to specific tasks, such as planting or harvesting, and consider factors like soil type and climate. This ensures that the tires not only meet operational needs but also contribute to sustainable farming practices.

In logistics and transport, air tires are crucial for delivery trucks and freight carriers. They enhance fuel efficiency and lower the risk of tire-related failures, directly impacting operational costs. For B2B buyers in regions with diverse climates, it is important to evaluate tire performance against varying road conditions to ensure reliability and safety. Sourcing tires that provide optimal performance under local conditions can significantly reduce maintenance costs and improve service delivery.

In the mining industry, air tires are used on heavy-duty mining trucks and equipment, where they must withstand extreme conditions and heavy loads. The benefits include enhanced safety and reliability, crucial for operations in hazardous environments. Buyers should focus on sourcing tires with high puncture resistance and abrasion durability to minimize downtime and ensure worker safety. Understanding the specific demands of the mining environment is essential for selecting the right tire solution.

Illustrative image related to air tires

المشكلة B2B buyers often face challenges in locating reliable sources for tire inflation, especially in regions where access to air stations is limited. In many areas, particularly in less urbanized regions of Africa or South America, tire service stations may not be readily available. This can lead to operational delays, increased downtime, and ultimately a negative impact on logistics and supply chain efficiency. The frustration of managing fleets with under-inflated tires due to lack of air supply can also lead to increased tire wear and reduced fuel efficiency, compounding the issue.

الحل: To combat this issue, B2B buyers should consider investing in portable air compressors for their fleet operations. These devices can be easily stored in vehicles or at central depots, ensuring that tire inflation is always accessible regardless of location. When sourcing portable air compressors, look for models that offer both efficiency and durability, suitable for commercial usage. Additionally, establishing partnerships with local tire shops or service stations that guarantee air supply can create a network of reliable resources. Buyers should also implement regular maintenance schedules for tire checks to ensure that inflation levels are consistently monitored, thereby preventing any operational interruptions.

المشكلة B2B buyers managing fleets across diverse climates may struggle with maintaining optimal tire pressure due to temperature fluctuations. In regions like the Middle East, where extreme heat can cause tires to expand and lead to over-inflation, or in colder climates in Europe, where tires may contract, the inability to manage these variations effectively can result in safety hazards and increased tire degradation. This is especially concerning for businesses relying on transportation, where tire performance directly impacts safety and operational costs.

الحل: To address this problem, B2B buyers should implement a proactive tire pressure monitoring system (TPMS). These systems provide real-time data on tire pressure and temperature, allowing fleet managers to make immediate adjustments as needed. Additionally, investing in nitrogen inflation can offer more stability in tire pressure over a range of temperatures, as nitrogen has lower permeability than regular air, reducing the frequency of pressure loss. Regular training for drivers on the importance of tire maintenance and how to check pressures before each journey will also enhance safety and efficiency.

Illustrative image related to air tires

المشكلة Many B2B buyers are unsure whether to use nitrogen or regular air for tire inflation, leading to confusion and inconsistent practices across their fleets. This indecision can stem from misconceptions about the benefits of nitrogen, particularly in commercial applications. Buyers may fear that opting for the wrong inflation method could lead to higher operational costs or safety risks, ultimately affecting their bottom line and the efficiency of their transport services.

الحل: B2B buyers should conduct a thorough assessment of their operational needs and the environments in which their vehicles operate. For general fleet use, regular air is typically sufficient, as it is more readily available and cost-effective. However, for specialized applications, such as high-performance vehicles or equipment in extreme conditions, nitrogen may provide benefits, such as reduced moisture levels and slower pressure loss. To make informed decisions, it is advisable to consult with tire experts or manufacturers who can provide insights into the advantages and limitations of both options. Training staff on tire maintenance best practices and the specific needs of their fleet will also ensure that tire inflation methods align with operational requirements.

When selecting materials for air tires, it is crucial for B2B buyers to understand the properties, advantages, and limitations of each material. This knowledge aids in making informed purchasing decisions that align with specific application needs and regional standards.

Natural rubber is a primary material used in tire manufacturing due to its excellent elasticity and resilience. It has a high temperature and pressure rating, making it suitable for various climates and driving conditions. Natural rubber exhibits good abrasion resistance and can withstand significant wear, which is essential for tires that experience high levels of friction.

الإيجابيات: Natural rubber is durable and provides a comfortable ride due to its shock-absorbing properties. It is also relatively inexpensive compared to synthetic alternatives.

السلبيات: However, natural rubber can degrade when exposed to ozone and UV light, leading to cracking over time. Additionally, its performance can be affected by extreme temperatures, which may limit its applicability in hotter regions.

التأثير على التطبيق: Natural rubber is compatible with a wide range of media, including air and moisture. However, buyers should consider the local climate, particularly in regions like Africa and the Middle East, where high temperatures and UV exposure are prevalent.

Synthetic rubber, often derived from petroleum, is engineered to enhance specific properties such as chemical resistance and durability. It offers superior ozone and UV resistance compared to natural rubber, making it a popular choice for tires used in harsh environments.

الإيجابيات: The ability to customize synthetic rubber formulations allows manufacturers to optimize performance characteristics, leading to longer tire life and better fuel efficiency.

السلبيات: The primary downside is the higher cost of synthetic rubber compared to natural rubber. Additionally, its production process is more complex, which can lead to increased manufacturing lead times.

التأثير على التطبيق: Synthetic rubber is suitable for various applications, including high-performance and heavy-duty tires. Buyers in Europe and South America may prefer synthetic options due to stricter environmental regulations and performance standards.

Steel belts are commonly used in tire construction to provide structural integrity and enhance performance. These belts improve the tire’s resistance to punctures and help maintain shape under high pressure.

الإيجابيات: The use of steel belts significantly increases durability and load-bearing capacity, making them ideal for commercial vehicles and heavy machinery.

Illustrative image related to air tires

السلبيات: However, steel belts can add weight to the tire, which may affect fuel efficiency. Additionally, the manufacturing process for steel-belted tires can be more complex and costly.

التأثير على التطبيق: Steel belts are particularly beneficial in regions with rough terrain or where heavy loads are common, such as in parts of Africa and South America. Compliance with local standards for load capacity is essential.

Composite materials, which may include blends of rubber, plastics, and fibers, are increasingly being used in tire manufacturing to enhance performance characteristics. These materials can provide improved flexibility and weight reduction.

Illustrative image related to air tires

الإيجابيات: Composites can be tailored to achieve specific performance metrics, such as better fuel efficiency and enhanced grip on various surfaces.

السلبيات: The primary limitation is the higher cost associated with composite materials and the complexity of their manufacturing processes.

التأثير على التطبيق: Composite materials are gaining traction in markets that demand high-performance tires, such as in Europe and the Middle East, where advanced technology and sustainability are prioritized.

| المواد | Typical Use Case for air tires | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| Natural Rubber | Standard passenger and light truck tires | Excellent elasticity and durability | Degrades under UV exposure | منخفضة |

| Synthetic Rubber | High-performance and specialty tires | Superior ozone and UV resistance | Higher cost and complex production | عالية |

| Steel Belts | Commercial and heavy-duty tires | Increased durability and load capacity | Adds weight, affecting fuel efficiency | متوسط |

| Composite Materials | High-performance and advanced tires | Tailored performance metrics | ارتفاع التكلفة وتعقيد التصنيع | عالية |

Understanding these materials and their implications will help international B2B buyers make informed decisions that align with their operational needs and regional standards.

Illustrative image related to air tires

The manufacturing process for air tires consists of several critical stages, each designed to ensure the final product meets high-performance standards. These stages include material preparation, forming, assembly, and finishing.

The foundation of any tire begins with its materials. The primary components include natural and synthetic rubber, fabric (such as polyester or nylon), and steel. Each of these materials is sourced based on specific performance requirements, such as durability and heat resistance.

During material preparation, raw materials undergo rigorous testing to ensure they meet industry standards. This may involve checking for consistency in rubber compounds and verifying the strength of the fabric and steel. Suppliers play a crucial role in this phase, and B2B buyers should ensure that their suppliers adhere to international standards for sourcing materials.

The forming stage involves shaping the prepared materials into the tire’s basic structure. This is typically achieved through a combination of extrusion and molding processes.

Extrusion: Rubber compounds are extruded into long strips that will become different tire components, such as the tread and sidewalls. These strips are then cut to the required lengths.

القوالب: The cut pieces are assembled into a green tire, which is a tire that has not yet been cured. This is done using specialized molds that shape the tire while also incorporating design features like tread patterns.

In the assembly stage, the green tire components are brought together. This involves layering the rubber components and integrating the fabric and steel belts that provide structural integrity and strength.

Illustrative image related to air tires

Once assembled, the green tire is placed in a curing mold where heat and pressure are applied. This curing process chemically bonds the materials, solidifying the tire into its final form.

After curing, tires undergo various finishing processes to ensure they meet quality and aesthetic standards. This may include trimming excess rubber, inspecting for defects, and applying surface treatments for improved performance.

Finishing also involves marking the tires with relevant information, such as size, load index, and production codes, which are crucial for traceability and compliance with international standards.

Quality assurance is critical in tire manufacturing, as it directly impacts safety and performance. Various international standards govern the manufacturing process, including ISO 9001, which focuses on quality management systems.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are also relevant. These certifications ensure that the tires meet specific safety and environmental criteria.

Illustrative image related to air tires

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that every tire meets the required standards. Common checkpoints include:

مراقبة الجودة الواردة (IQC): This stage involves inspecting raw materials before they enter the production line. Materials are tested for quality and compliance with specifications.

مراقبة الجودة أثناء المعالجة (IPQC): During production, continuous monitoring is performed to identify any deviations from quality standards. This includes checking dimensions, weight, and material properties at various stages.

مراقبة الجودة النهائية (FQC): Once the tires are completed, a final inspection is conducted. This includes visual inspections and performance testing to verify that each tire meets established quality criteria.

For B2B buyers, ensuring that suppliers maintain high-quality standards is essential. Here are some effective methods to verify supplier QC practices:

Audits: Conduct regular audits of the supplier’s manufacturing facility. This allows buyers to assess compliance with quality standards and manufacturing processes firsthand.

تقارير الجودة: Request detailed quality reports from suppliers. These should include information on testing methods, results, and any corrective actions taken for non-conformance.

عمليات التفتيش من طرف ثالث: Engaging independent third-party inspectors can provide an unbiased evaluation of a supplier’s QC practices. This is especially important for buyers in regions where local regulations may vary.

Several testing methods are standard in the tire manufacturing industry to ensure quality:

Tensile Testing: This assesses the strength and elasticity of the rubber materials used in tire production.

Uniformity Testing: This checks for balance and uniformity of the tire, which is crucial for performance and safety.

اختبار المتانة: Tires are subjected to rigorous tests that simulate various driving conditions to ensure they can withstand wear and tear over time.

Performance Testing: This includes evaluating traction, braking, and handling characteristics under different environmental conditions.

International buyers must be aware of regional nuances in quality standards and regulations. For example, tires sold in Europe must comply with EU regulations, while those in the Middle East and Africa may have different requirements.

Illustrative image related to air tires

Additionally, buyers should consider local testing labs and certification bodies that can provide verification services tailored to their specific market needs. Understanding these nuances can help mitigate risks and ensure compliance with local laws.

In conclusion, the manufacturing processes and quality assurance measures in air tire production are complex and critical for ensuring performance and safety. B2B buyers must be diligent in verifying the practices of their suppliers, understanding international standards, and employing robust QC measures to ensure they receive high-quality products that meet their operational needs. By focusing on these areas, buyers can make informed decisions that enhance their supply chain and contribute to overall business success.

When sourcing air tires for your business, a systematic approach can ensure that you make informed decisions that align with your operational needs and budget. This guide outlines essential steps to help you navigate the procurement process effectively.

Start by clearly outlining the technical requirements of the air tires you need. Consider factors such as size, load capacity, tread pattern, and intended use (e.g., passenger vehicles, commercial trucks, or specialized machinery). Defining these specifications upfront will streamline your search for suppliers and help you avoid costly mistakes down the line.

Conduct thorough research to identify potential suppliers that specialize in air tires. Utilize industry directories, trade shows, and online marketplaces to gather a list of candidates. Focus on suppliers with a strong presence in your target markets, particularly in regions like Africa, South America, the Middle East, and Europe, as they may better understand local demands and regulations.

Illustrative image related to air tires

Before finalizing your list, verify the certifications and standards that suppliers adhere to. Look for industry-specific certifications, such as ISO or local regulatory compliance, to ensure that the tires meet safety and quality benchmarks. This step is crucial in mitigating risks associated with subpar products that could impact your operations.

Once you’ve narrowed down your options, request samples from shortlisted suppliers. Conduct quality checks on these samples to assess performance, durability, and compatibility with your equipment. Pay attention to feedback from your technical team and consider conducting field tests if possible, as real-world performance can differ significantly from specifications.

Obtain detailed quotations from each supplier, ensuring that you understand the pricing structure, including bulk discounts, shipping costs, and any additional fees. Compare payment terms to find the most favorable options that align with your cash flow. Negotiating terms may lead to better pricing or extended payment periods, which can enhance your financial flexibility.

Before making a final decision, reach out to references provided by the suppliers. Ask previous clients about their experiences regarding product quality, delivery times, and customer service. Additionally, check online reviews and ratings to gather unbiased feedback. This step will help you assess the reliability and reputation of potential suppliers.

After selecting a supplier, draft a comprehensive contract that outlines all agreed-upon terms, including delivery schedules, warranty conditions, and after-sales support. Ensure that both parties understand their responsibilities and that there are clear channels for communication. A well-defined contract protects your interests and fosters a solid business relationship.

By following these steps, you can enhance your sourcing strategy for air tires, ensuring that you partner with reliable suppliers who meet your technical and operational needs.

When sourcing air tires, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the total cost include:

المواد: The type of rubber, additives, and reinforcements used in tire manufacturing significantly impact costs. High-performance tires may require specialized compounds, increasing the material cost.

العمالة: Labor costs vary based on geographic location and the skill level of the workforce. In regions with higher wages, such as parts of Europe, labor will represent a larger share of the total cost.

نفقات التصنيع الزائدة: This includes utilities, rent, and general operational expenses. Efficient manufacturing processes can help mitigate these costs, but they are essential to consider when evaluating supplier pricing.

الأدوات: The initial investment in molds and machinery can be substantial, especially for custom tire designs. Buyers should inquire about tooling costs when considering customization options.

مراقبة الجودة (QC): Ensuring that tires meet safety and performance standards incurs costs related to testing and inspection. Certifications for quality assurance can also add to the overall expense.

الخدمات اللوجستية: Shipping costs depend on the origin of the tires and the destination market. Factors such as distance, transportation mode, and tariffs can significantly influence logistics costs.

الهامش: Suppliers will include a profit margin in their pricing. Understanding the market dynamics can help buyers negotiate better deals.

Several factors influence the pricing of air tires that B2B buyers should consider:

الحجم والحد الأدنى لكمية الطلب (MOQ): Bulk orders typically lower per-unit costs. Understanding the supplier’s MOQ can help buyers leverage better pricing.

المواصفات والتخصيص: Custom specifications can lead to higher costs due to unique materials or manufacturing processes. Buyers should weigh the necessity of customization against potential price increases.

المواد وشهادات الجودة: Tires made from premium materials or those that comply with specific quality certifications will usually carry higher prices. Buyers should assess the value of these certifications in relation to their needs.

عوامل الموردين: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

المصطلحات التجارية الدولية: The terms of shipping and delivery can significantly impact final costs. Understanding Incoterms helps buyers calculate total expenses, including duties and tariffs.

When negotiating air tire prices, B2B buyers should keep the following strategies in mind:

Conduct Market Research: Understanding the market price range for different tire types helps in making informed negotiations. Comparing quotes from multiple suppliers can provide leverage.

تقييم التكلفة الإجمالية للملكية (TCO): Consider not just the purchase price but also the long-term costs associated with tire performance, maintenance, and fuel efficiency. TCO can reveal more economical choices over time.

Negotiate Payment Terms: Favorable payment terms can improve cash flow. Discussing options such as deferred payments or discounts for early payment can yield savings.

بناء علاقات مع الموردين: Establishing long-term relationships can lead to better pricing and service. Suppliers may be more willing to negotiate with buyers they trust.

Stay Informed About Pricing Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of regional pricing variations influenced by local market conditions, exchange rates, and shipping complexities.

In the competitive landscape of air tire sourcing, understanding the cost structure and pricing dynamics is essential for B2B buyers. By focusing on the key cost components, price influencers, and effective negotiation strategies, businesses can optimize their procurement processes and achieve better value from their investments. It is important to note that prices can vary widely based on the specific requirements and market conditions; therefore, ongoing market analysis is recommended for accurate budgeting and planning.

In the realm of tire technology, air tires have long been the standard for various vehicles, providing a balance of performance, comfort, and cost. However, with advancements in technology and growing concerns about sustainability, several alternatives have emerged. This analysis will compare air tires with two viable alternatives: nitrogen-filled tires and solid tires, assessing their performance, costs, implementation ease, maintenance requirements, and ideal use cases.

| جانب المقارنة | ‘Air Tires’ | Nitrogen-Filled Tires | Solid Tires |

|---|---|---|---|

| الأداء | Good comfort and handling | Improved pressure retention | Excellent durability |

| التكلفة | Generally lower initial cost | Moderate to high initial cost | Higher initial cost |

| سهولة التنفيذ | Widely available | Requires specialized service | التثبيت البسيط |

| الصيانة | Frequent pressure checks needed | Monthly checks recommended | Minimal maintenance required |

| أفضل حالة استخدام | Everyday vehicles | Performance and heavy-duty vehicles | Urban settings, low maintenance needs |

Nitrogen-filled tires offer a unique alternative to standard air tires, primarily due to their enhanced pressure retention capabilities. Nitrogen, being an inert gas, reduces the rate of pressure loss due to permeation through the tire material. This can lead to more consistent tire pressure, which is crucial for performance in high-speed or heavy-duty applications. However, the initial cost of nitrogen inflation can be higher, and the need for specialized equipment for inflation limits accessibility in some regions. Additionally, while nitrogen provides benefits, it does not eliminate the need for regular pressure checks, as punctures and other leaks can still occur.

Illustrative image related to air tires

Solid tires, often made from rubber or other composite materials, are designed to eliminate the risk of punctures entirely, making them a highly durable option. They are particularly advantageous in urban settings where road hazards are common, and maintenance is a significant concern. The absence of air pressure means that solid tires require little to no regular maintenance, thus reducing operational costs in the long run. However, their higher initial cost and relatively stiffer ride can be drawbacks, as they may not provide the same level of comfort and performance as air-filled tires, especially in terms of handling and ride quality.

When selecting the appropriate tire solution for their specific needs, B2B buyers should consider factors such as the intended use of the vehicle, environmental conditions, and maintenance capabilities. For everyday vehicles operating under normal conditions, air tires remain a cost-effective and reliable choice. Conversely, for performance-oriented or heavy-duty applications, nitrogen-filled tires could provide the needed pressure stability and performance. Meanwhile, solid tires might be the ideal solution for urban fleets seeking to minimize maintenance and downtime. Ultimately, understanding the unique demands of your operation will guide you in making the best tire choice that balances performance, cost, and maintenance requirements.

Understanding the technical properties of air tires is essential for B2B buyers, particularly when sourcing products that meet specific performance and safety requirements. Here are some critical specifications to consider:

Air tires are typically made from a combination of natural and synthetic rubbers, along with reinforcing materials like steel belts and fabric. The choice of materials affects durability, traction, and resistance to wear and tear. Buyers should evaluate the material grades to ensure the tires can withstand the demands of their intended applications, whether for passenger vehicles, commercial trucks, or specialized machinery.

The tread pattern of a tire significantly influences its performance characteristics, such as grip, handling, and noise reduction. Different tread designs are suited for various environments—e.g., all-season, off-road, or performance tires. B2B buyers must align the tread pattern with the operational conditions of their vehicles to optimize safety and efficiency.

The load index indicates the maximum load a tire can support, while the speed rating denotes the maximum speed the tire can safely maintain. These specifications are critical for ensuring that the tires meet the operational demands of specific vehicles and applications. Buyers should carefully match these ratings with the intended use to avoid premature tire failure.

Modern vehicles often come equipped with TPMS that alerts drivers to under-inflated tires. B2B buyers should ensure that the tires they procure are compatible with these systems, which not only enhance safety but also contribute to fuel efficiency and tire longevity.

Illustrative image related to air tires

Tolerance refers to the allowable variations in the tire’s dimensions and performance characteristics. This is crucial for ensuring uniformity and compatibility with vehicle specifications. Understanding tolerance levels can help buyers avoid issues related to fitment and performance, which can lead to costly downtime.

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B tire market. Here are some essential terms:

OEM tires are those made by the original manufacturer of the vehicle. These tires are designed to meet the specific performance and safety standards required by the vehicle’s design. Buyers often prefer OEM tires for replacement due to their guaranteed compatibility and performance.

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for buyers as it can affect pricing and inventory management. Buyers should negotiate MOQs that align with their purchasing needs and storage capabilities.

An RFQ is a document used by buyers to solicit price quotes from suppliers. This process helps buyers compare costs, terms, and conditions from multiple vendors. A well-structured RFQ can streamline purchasing decisions and foster competitive pricing.

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They clarify aspects such as shipping costs, insurance, and delivery points. Familiarity with Incoterms can help buyers avoid misunderstandings and ensure smoother transactions.

Retreading is the process of applying a new tread to a worn tire, extending its life and reducing waste. This is particularly relevant for B2B buyers seeking cost-effective and sustainable tire solutions. Understanding retreading can help businesses lower their overall tire costs while promoting environmental responsibility.

By grasping these technical specifications and trade terminologies, B2B buyers can make informed purchasing decisions that align with their operational needs and market demands.

The air tires market is experiencing significant growth driven by several global factors. Firstly, the increasing demand for vehicles in emerging markets such as Africa and South America is a primary driver, as urbanization and rising disposable incomes lead to higher vehicle ownership rates. Additionally, the growing emphasis on road safety and fuel efficiency is prompting manufacturers to innovate in tire technology, focusing on performance and longevity.

Emerging technologies, including smart tire solutions that monitor tire pressure and temperature in real-time, are gaining traction. This technology not only enhances safety but also improves fuel efficiency, appealing to cost-conscious B2B buyers. Another trend is the rise of e-commerce platforms, which facilitate direct sourcing from manufacturers, allowing international buyers to find competitive pricing and diverse product offerings.

Illustrative image related to air tires

In terms of market dynamics, fluctuating raw material prices, particularly for natural rubber and synthetic compounds, are influencing procurement strategies. Buyers must navigate these complexities by developing relationships with reliable suppliers and employing strategic sourcing practices that mitigate risk. Moreover, geopolitical factors and trade regulations can impact supply chains, necessitating adaptability in sourcing strategies.

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the air tires sector. The environmental impact of tire production is significant, with concerns over carbon emissions, resource depletion, and waste management. As regulations tighten and consumer preferences shift towards eco-friendly products, companies are increasingly held accountable for their supply chain practices.

Ethical supply chains not only enhance brand reputation but also attract a growing segment of environmentally conscious customers. This has led to a rise in ‘green’ certifications and materials, such as sustainable rubber and recycled materials, which are now available for tire production. B2B buyers should prioritize suppliers who adhere to these standards, as they often lead to better long-term partnerships and reduced operational risks.

Additionally, adopting sustainable practices can result in cost savings through improved efficiency and waste reduction. Buyers are encouraged to engage with manufacturers that demonstrate a commitment to sustainability, as this can also enhance marketability and compliance with international standards.

The evolution of air tires has been pivotal in shaping the modern automotive landscape. Introduced in the late 19th century, air-filled tires revolutionized the vehicle industry by offering a smoother ride and improved traction compared to solid rubber tires. This innovation facilitated the rise of the automobile, making personal and commercial transportation more accessible.

Illustrative image related to air tires

In the decades that followed, advancements in materials and manufacturing processes led to the development of tubeless tires, enhancing safety and performance. The introduction of synthetic rubber during World War II marked a significant turning point, providing manufacturers with greater flexibility and cost efficiency in production.

Today, the air tires sector continues to evolve with the incorporation of smart technologies and sustainable practices, reflecting the growing demand for enhanced performance and environmental responsibility. For B2B buyers, understanding this evolution is crucial, as it informs sourcing decisions and aligns with market trends.

How do I choose the right air tires for my fleet?

Choosing the right air tires for your fleet involves considering several factors including vehicle type, load capacity, and operating environment. Evaluate the tire’s tread design for traction and durability, and ensure it meets the manufacturer’s specifications for your vehicles. Additionally, consider local climate conditions, as they can influence tire performance. It’s also wise to consult with suppliers about their recommendations based on your specific use case and to review feedback from other businesses in your industry.

What is the best air tire for heavy-duty vehicles?

For heavy-duty vehicles, the best air tires typically feature reinforced sidewalls and a robust tread pattern designed for high load capacities and tough terrains. Look for tires specifically designed for commercial use, such as those used in trucks or construction vehicles. Brands with a solid reputation in the commercial tire market, like Michelin or Bridgestone, often offer options tailored for durability and performance under heavy loads. Always verify the specifications against your fleet’s requirements to ensure optimal performance.

What should I consider when vetting air tire suppliers internationally?

When vetting international air tire suppliers, consider factors such as their reputation, quality certifications (e.g., ISO), and compliance with international standards. Review customer testimonials and case studies to gauge reliability and service quality. Additionally, assess their production capabilities, lead times, and responsiveness to inquiries. It’s beneficial to request samples or trial orders to evaluate the product quality firsthand before committing to larger purchases.

What are the typical minimum order quantities (MOQs) for air tires?

Minimum order quantities (MOQs) for air tires can vary significantly based on the supplier and the specific tire model. Generally, MOQs for bulk purchases can range from 50 to several hundred tires. Some suppliers may offer lower MOQs for first-time buyers or specific tire types. When negotiating with suppliers, clarify MOQs and inquire about the possibility of mixed orders to ensure you can meet your fleet’s diverse needs without overcommitting on specific models.

What payment terms should I expect when sourcing air tires internationally?

Payment terms for international tire purchases can vary widely depending on the supplier’s policies and the buyer’s negotiation power. Common arrangements include advance payment, letters of credit, or payment upon delivery. It’s crucial to clarify these terms upfront to avoid cash flow issues. Additionally, consider discussing payment methods that offer buyer protection, such as escrow services, especially for first-time transactions to mitigate risks associated with international trade.

How can I ensure quality assurance (QA) for air tires from suppliers?

To ensure quality assurance (QA) for air tires, establish clear quality standards and specifications before placing an order. Request that suppliers provide quality certifications and compliance documents. It’s also advisable to conduct factory audits or inspections if feasible, or partner with a third-party inspection service. Regular communication throughout the production process can help address potential issues early and ensure that the final products meet your quality expectations.

What logistics considerations should I keep in mind when importing air tires?

When importing air tires, consider logistics aspects such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling tire shipments, as they can navigate the complexities of international shipping. Additionally, ensure proper documentation is in place to expedite customs clearance. Factor in lead times for production and shipping to avoid delays, and consider warehousing options to manage inventory effectively upon arrival.

What are the advantages of using nitrogen instead of air for tire inflation?

Using nitrogen instead of air for tire inflation can offer several advantages, particularly in commercial applications. Nitrogen is less prone to permeation, meaning tires retain pressure longer, which can lead to improved fuel efficiency and reduced tire wear. Additionally, nitrogen does not support moisture, reducing the risk of corrosion within the tire. However, for most everyday consumer applications, standard air inflation is adequate. Businesses should evaluate the cost versus benefits based on their specific operational needs.

المجال: freeairpump.com

مسجل: 2012 (13 سنة)

مقدمة: Map of places that provide free air for tires, with over 12k locations in the U.S. User-generated content, updated weekly. Users can submit new locations. Offers search functionality by device location or address. Suggests portable air compressors as an alternative. Lists common places offering free air: tire shops, car repair stations, bike shops, and specific gas station chains (e.g., Co-op, Fam…

المجال: reddit.com

مسجل: 2005 (20 سنة)

مقدمة: 1. Electric Tire Pump: Cost around $35, available at auto parts stores. 2. Tire Pressure Gauge: Recommended to purchase separately, as gas station gauges may be broken. 3. Tire Pressure Information: Usually found on a sticker in the driver’s door jamb, typically around 30 pounds for most cars. 4. Digital Tire Pumps: Available that allow setting desired pressure automatically. 5. Tire Warning Light…

المجال: continentaltire.com

مسجل: 1996 (29 سنة)

مقدمة: Nitrogen is offered as an alternative to air for tire inflation. It is an inert gas that does not support moisture or combustion, primarily used in specialized applications like aircraft, mining, and professional auto racing. While nitrogen may reduce tire inflation loss by permeation, it does not prevent loss from punctures or leaks. Regular tire pressure checks are critical regardless of the inf…

المجال: goodyearautoservice.com

مسجل: 2006 (19 سنة)

مقدمة: Proper tire inflation is crucial for tire care, extending tire life, improving vehicle performance, and enhancing safety. Goodyear Auto Service offers free tire pressure checks. Recommended air pressure can be found on the vehicle’s door edge, door jamb, glove box door, fuel door, or in the owner’s manual. It’s important to check tire pressure when tires are cool, and to visually inspect tires for…

المجال: courtesychryslerdodgeramsuperstitionsprings.com

مسجل: 2019 (6 سنوات)

مقدمة: The text provides a guide on how to properly inflate tires and reset the tire pressure light for vehicles. Key details include: 1. Importance of maintaining proper tire pressure for safety, fuel economy, and tire lifespan. 2. Recommended tire pressure for passenger cars is generally 32 to 35 psi when cold, with a caution against inflating to the maximum pressure indicated on the tire itself. 3. St…

In conclusion, strategic sourcing in the air tire market is essential for optimizing procurement processes and ensuring the acquisition of high-quality products. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers who can provide reliable products and services. Understanding the differences between air and nitrogen inflation, as well as the importance of regular tire maintenance, can significantly impact operational efficiency and safety.

Investing time in supplier research and leveraging local market insights can yield substantial benefits. By aligning with suppliers who understand the regional demands and can offer customized solutions, businesses can enhance their supply chain resilience. This approach not only reduces costs but also improves service delivery and customer satisfaction.

As you navigate the complexities of the air tire market, consider developing a strategic sourcing plan that includes diverse suppliers across different regions. Engage with industry experts, attend trade shows, and utilize digital platforms to expand your network. By taking proactive steps now, you can position your business for future success and stay ahead in an ever-evolving marketplace.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.