- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

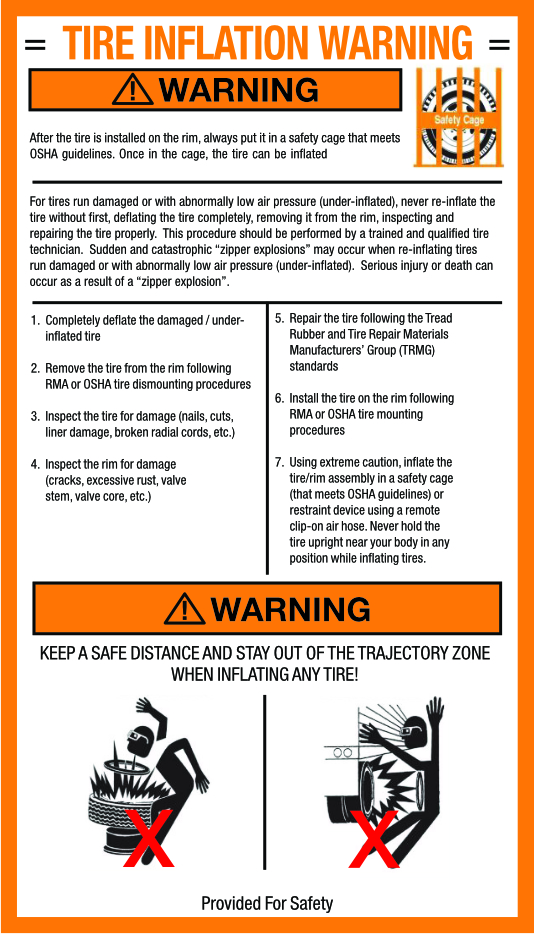

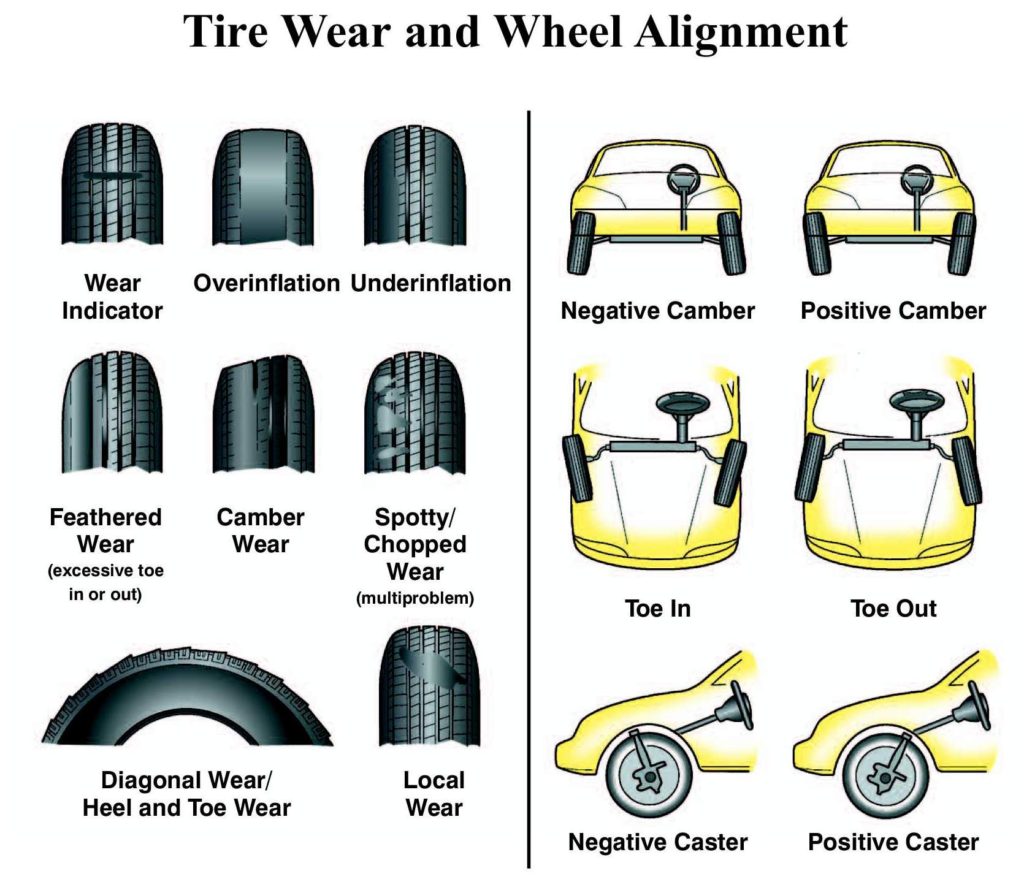

In today’s competitive landscape, one of the critical challenges facing international B2B buyers is the impact of incorrect tire inflation on operational efficiency. Mismanaged tire pressure can lead to increased tire wear, diminished vehicle handling, and suboptimal fuel efficiency, ultimately affecting your bottom line. This guide delves into the various dimensions of tire inflation, from understanding the types of tire inflation systems available to identifying the right suppliers who can provide reliable products and services.

We will explore the applications of proper tire inflation in various sectors, including transportation, logistics, and manufacturing, and discuss best practices for supplier vetting to ensure you partner with the most trustworthy vendors. Additionally, we’ll provide insights into cost implications associated with tire maintenance and inflation, enabling you to make informed purchasing decisions that enhance operational efficiency.

By equipping B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Vietnam—with actionable knowledge and strategic insights, this guide aims to empower you to navigate the complexities of tire management. Understanding how to mitigate the risks of incorrect tire inflation not only supports sustainable business practices but also maximizes your fleet’s performance and reliability.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Under-inflation | Tires have less air pressure than recommended, leading to increased rolling resistance and uneven wear. | Freight and logistics companies | الإيجابيات: Reduces tire wear; السلبيات: Increases fuel consumption. |

| Over-inflation | Tires are inflated beyond recommended levels, causing a harsh ride and decreased traction. | Construction and heavy machinery | الإيجابيات: Improved fuel efficiency; السلبيات: Higher risk of tire blowouts. |

| Uneven inflation | Different tires on the same vehicle are inflated to varying pressures, affecting handling and stability. | Fleet management services | الإيجابيات: Potentially lower maintenance costs; السلبيات: Compromised safety and handling. |

| Seasonal inflation | Tire pressure adjustments based on seasonal temperature changes, impacting performance. | Automotive service providers | الإيجابيات: Enhances tire longevity; السلبيات: Requires regular monitoring and adjustments. |

| Tire pressure monitoring system (TPMS) inaccuracies | Reliance on technology that may not provide accurate readings, leading to inflation issues. | Automotive manufacturing and repair | الإيجابيات: Can alert to pressure changes; السلبيات: May lead to complacency in manual checks. |

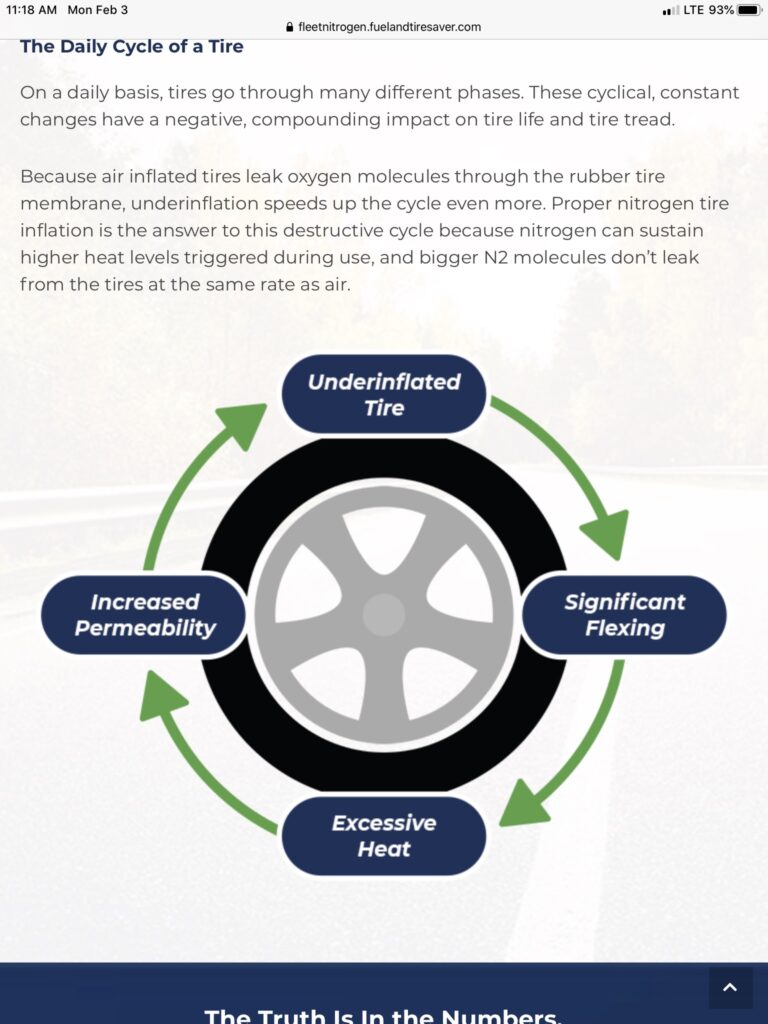

Under-inflation occurs when tires are not filled to the manufacturer’s recommended pressure. This situation leads to increased rolling resistance, which can significantly reduce fuel efficiency and increase operational costs for businesses, particularly in freight and logistics. B2B buyers in this sector should consider the long-term savings associated with regular tire pressure checks and adjustments, as under-inflation can lead to premature tire wear and necessitate costly replacements.

Over-inflation refers to tires that are inflated beyond the manufacturer’s specifications. This condition can enhance fuel efficiency due to reduced rolling resistance but poses a risk of tire blowouts and a harsher ride. Construction and heavy machinery operators should weigh the benefits of increased efficiency against the potential safety hazards and higher maintenance costs associated with over-inflated tires, making it crucial to maintain the correct pressure.

Uneven inflation occurs when tires on the same vehicle are inflated to different pressures. This inconsistency can lead to compromised vehicle handling and stability, posing safety risks, particularly in fleet operations where reliability is paramount. Fleet managers should prioritize regular tire inspections and ensure uniform inflation across all tires to enhance safety and vehicle performance while potentially reducing maintenance expenses.

Seasonal inflation involves adjusting tire pressures based on changes in temperature. As temperatures drop, tire pressure decreases, leading to under-inflation if not monitored. Automotive service providers can benefit from promoting seasonal tire maintenance to their clients, emphasizing the importance of regular pressure checks to enhance tire longevity and overall vehicle performance. This proactive approach can reduce the likelihood of tire-related issues during extreme weather conditions.

Inaccuracies in Tire Pressure Monitoring Systems (TPMS) can lead to incorrect assumptions about tire health, resulting in improper inflation. While TPMS can provide alerts about pressure changes, B2B buyers in automotive manufacturing and repair should not rely solely on this technology. Regular manual checks are essential to avoid the pitfalls of complacency, ensuring that tire safety and performance are maintained, ultimately safeguarding the bottom line against unexpected repair costs.

| الصناعة/القطاع | Specific Application of incorrect tire inflation will adversely affect | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| النقل والخدمات اللوجستية | Fleet management of commercial vehicles | Reduces operational costs and enhances safety | Reliable tire pressure monitoring systems and maintenance services |

| الزراعة | Agricultural machinery and equipment | Improves fuel efficiency and reduces equipment downtime | Durable tires suitable for rough terrains and inflation monitoring tools |

| Construction | Heavy machinery operations | Ensures safety and optimal performance of construction vehicles | High-quality, heavy-duty tires and regular maintenance schedules |

| Automotive Manufacturing | Production line efficiency in vehicle assembly | Minimizes defects and enhances product quality | Consistent quality control measures and tire pressure calibration tools |

| Mining | Haulage trucks and equipment in mining operations | Increases productivity and reduces maintenance costs | Specialized tires for extreme conditions and inflation monitoring systems |

In the transportation and logistics sector, incorrect tire inflation can severely disrupt fleet management. Poorly inflated tires lead to increased fuel consumption, higher maintenance costs, and compromised safety, which can result in accidents and liability claims. For businesses operating in Africa and South America, where road conditions can be challenging, investing in reliable tire pressure monitoring systems and regular tire maintenance is essential. These measures ensure that fleets operate efficiently, reducing operational costs and enhancing safety.

In agriculture, the impact of incorrect tire inflation on machinery can be significant. Under-inflated tires can cause uneven wear, increasing the risk of tire failure and leading to costly downtime during critical planting or harvesting seasons. For international buyers in regions like Brazil and Vietnam, sourcing durable tires designed for rough terrains, along with inflation monitoring tools, is crucial. Ensuring proper tire inflation not only improves fuel efficiency but also enhances the overall productivity of agricultural operations.

In the construction industry, heavy machinery relies heavily on proper tire inflation for optimal performance and safety. Incorrect inflation can lead to equipment failures, resulting in project delays and increased costs. For construction firms operating in the Middle East, where extreme temperatures can affect tire pressure, sourcing high-quality, heavy-duty tires and establishing regular maintenance schedules is vital. This proactive approach minimizes risks and ensures that construction vehicles operate smoothly and safely on-site.

In automotive manufacturing, incorrect tire inflation can negatively affect production line efficiency. Defective tires can lead to increased defects in finished products, impacting quality control. For businesses in Europe, where regulations on vehicle safety are stringent, consistent quality control measures and tire pressure calibration tools are necessary. By ensuring proper tire inflation throughout the manufacturing process, companies can enhance product quality and reduce waste, ultimately improving profitability.

Mining operations face unique challenges where incorrect tire inflation can lead to significant productivity losses. Haulage trucks and equipment require specialized tires that can withstand extreme conditions, and improper inflation can increase the risk of tire blowouts and maintenance costs. For mining companies sourcing equipment in regions with harsh environments, investing in specialized tires and inflation monitoring systems is essential. This investment not only boosts productivity but also enhances the safety of operations, reducing the likelihood of accidents.

المشكلة Fleet managers often face the challenge of maintaining optimal tire pressure across a diverse range of vehicles. Incorrect tire inflation can lead to uneven tire wear, which not only shortens the lifespan of the tires but also affects vehicle handling and safety. This scenario becomes even more pronounced in regions with extreme climates, where temperature fluctuations can cause tire pressure to change unexpectedly. As a result, fleet operators may experience increased maintenance costs and reduced operational efficiency, leading to significant financial strain.

الحل: To mitigate the impact of incorrect tire inflation, fleet managers should implement a robust tire maintenance program that includes regular pressure checks and staff training. Investing in advanced tire pressure monitoring systems (TPMS) can provide real-time data on tire conditions, allowing for proactive maintenance. Additionally, establishing a routine schedule for tire inspections—at least once a month or before long trips—can help ensure that tire pressures are within the recommended range. Providing training to drivers on how to check tire pressures and recognize signs of improper inflation can also empower them to take immediate action, further enhancing safety and efficiency.

المشكلة In industries where transportation is critical, such as logistics and delivery services, fuel costs represent a significant portion of operating expenses. Incorrect tire inflation can lead to increased rolling resistance, which forces vehicles to consume more fuel. This not only escalates costs but also contributes to a larger carbon footprint, an issue that many companies are striving to mitigate in today’s eco-conscious market.

الحل: To address this pain point, companies should adopt a comprehensive tire management strategy that includes the use of fuel-efficient tires specifically designed for low rolling resistance. Regularly scheduled tire pressure checks should be integrated into the maintenance routine, ideally using automated systems that alert management when pressures fall outside acceptable limits. Additionally, companies can invest in training programs for drivers that emphasize the importance of proper tire inflation and its direct correlation to fuel efficiency. By consistently monitoring tire pressures and using advanced tire technologies, businesses can significantly reduce fuel consumption and overall transportation costs.

المشكلة Safety is a paramount concern for businesses that rely on vehicles for operations. Incorrect tire inflation can severely compromise vehicle handling and stability, leading to an increased risk of accidents. This is especially critical in industries such as construction and transportation, where the stakes are high, and the potential for liability is significant. Companies may find themselves facing lawsuits and reputational damage if accidents occur due to negligence in tire maintenance.

الحل: To enhance safety and mitigate risks, organizations should prioritize the implementation of a comprehensive safety program focused on tire maintenance. This includes conducting regular training sessions for employees on the importance of tire pressure and the potential dangers of neglecting this aspect of vehicle maintenance. Establishing a clear policy for routine tire inspections—preferably before every shift—can ensure that all vehicles are roadworthy. Furthermore, integrating technology such as TPMS can provide continuous monitoring, allowing for immediate corrective actions. By fostering a culture of safety and accountability, companies can significantly reduce the risk of accidents related to incorrect tire inflation, thereby protecting both their employees and their bottom line.

When considering the implications of incorrect tire inflation, the choice of materials used in tire construction and related components is crucial. This analysis focuses on four common materials: rubber, steel belts, nylon, and foam. Each material has distinct properties that can significantly influence tire performance, durability, and overall vehicle safety.

Rubber is the primary material used in tire manufacturing. It is designed to withstand varying temperatures and pressures, making it essential for performance under different driving conditions.

Illustrative image related to incorrect tire inflation will adversely affect

Steel belts are often incorporated into tires to enhance strength and stability.

Nylon is often used in tire construction for its strength and flexibility.

Foam inserts are increasingly used in tires to provide additional support and cushioning.

| المواد | Typical Use Case for incorrect tire inflation will adversely affect | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Primary tire material affecting wear and grip | مرونة ومرونة ممتازة | يتحلل بمرور الوقت بسبب التعرض للأشعة فوق البنفسجية | متوسط |

| Steel Belts | Provides strength and puncture resistance | قوة شد عالية | Susceptible to corrosion in humid environments | عالية |

| نايلون | Enhances durability and flexibility | قوة شد عالية | أكثر تكلفة وتعقيدًا في التصنيع | متوسط |

| Foam Inserts | Provides cushioning and support | Improves ride comfort | Increases weight and complicates recycling | متوسط |

This strategic material selection guide underscores the importance of understanding how various materials interact with tire inflation. By considering these factors, international B2B buyers can make informed decisions that enhance tire performance and safety across diverse markets.

In the tire manufacturing industry, understanding the intricacies of production processes is essential for ensuring that products meet safety and performance standards. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

Material preparation is the foundational step where raw materials, including natural and synthetic rubber, fabric, and steel cords, are sourced and processed. Each material is selected based on its specific properties and how they contribute to the tire’s performance. For instance, the rubber compounds are mixed with various chemicals to enhance durability, flexibility, and heat resistance. This stage is critical as the quality of materials directly influences the tire’s ability to maintain proper inflation and withstand wear and tear.

The forming stage involves shaping the prepared materials into the tire’s structure. This is typically achieved through processes such as extrusion, where rubber is molded into specific shapes, and calendaring, which creates layers of rubber for the tire. The use of advanced techniques like computer numerical control (CNC) allows for precise cutting and shaping, ensuring uniformity in tire dimensions. This precision is vital, as any inconsistencies can lead to improper tire inflation, affecting performance and safety.

Assembly combines all the components, including the tread, sidewalls, and inner linings, into a cohesive unit. This stage often involves techniques such as tire building, where the tire is constructed on a rotating drum, allowing for the careful layering of materials. The assembly process is meticulously monitored to ensure that each component is correctly positioned and bonded, minimizing the risk of defects that could lead to incorrect tire inflation.

Finishing processes include curing and inspection. During curing, the assembled tire is heated in a mold, which solidifies the rubber and gives the tire its final shape. This process is crucial for achieving the necessary strength and elasticity. After curing, tires undergo rigorous inspection, including visual checks and pressure tests, to identify any defects. These processes ensure that the tires are capable of maintaining the correct inflation and performance standards required for safe operation.

Quality assurance (QA) is vital in the tire manufacturing process to ensure product safety and reliability. B2B buyers should be familiar with international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement.

In addition to general standards, specific industry certifications, such as the European CE marking and the American Petroleum Institute (API) standards, are essential for tires used in specialized applications. These certifications ensure that the tires meet specific safety and performance criteria, which is especially important for B2B buyers operating in diverse markets, including Africa, South America, the Middle East, and Europe.

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process to ensure compliance with quality standards. These checkpoints typically include:

B2B buyers should be aware of common testing methods used in tire quality assurance, including:

These testing methods are crucial for verifying that the tires will maintain proper inflation and perform reliably throughout their lifespan.

When sourcing tires, B2B buyers should take proactive steps to verify supplier QC processes. This can include:

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must navigate varying regulations and standards. Understanding these nuances is crucial for ensuring compliance and quality assurance. For instance, buyers should consider local regulations regarding tire safety and performance, as these can differ significantly from one region to another.

Moreover, establishing strong communication channels with suppliers can facilitate better understanding and adherence to quality standards, ensuring that all parties are aligned on expectations.

Illustrative image related to incorrect tire inflation will adversely affect

For B2B buyers, understanding the manufacturing processes and quality assurance measures in tire production is essential for making informed purchasing decisions. By prioritizing suppliers who adhere to international standards and robust QC practices, businesses can mitigate the risks associated with incorrect tire inflation, ensuring safety, efficiency, and longevity in their operations.

To ensure the safety, efficiency, and longevity of your fleet or transportation operations, addressing the issue of incorrect tire inflation is paramount. This guide offers a step-by-step checklist for B2B buyers to effectively source products and services that help mitigate the adverse effects of improper tire inflation.

Understanding your specific tire requirements is the first step. Assess the types of vehicles in your fleet, their typical load capacities, and the driving conditions they face. This information will guide you in selecting the right tires that are compatible with your operational demands.

Illustrative image related to incorrect tire inflation will adversely affect

Tire pressure monitoring systems (TPMS) are essential in maintaining proper tire inflation. Investigate various TPMS technologies available in the market, focusing on their accuracy and reliability. Look for systems that provide real-time data and alerts, which can significantly reduce the risk of driving on under-inflated or over-inflated tires.

When sourcing tires and monitoring systems, verify that suppliers hold relevant certifications. Certifications such as ISO 9001 for quality management systems can indicate that a supplier maintains high standards in their manufacturing processes.

Assess the total cost of ownership when evaluating tire options and inflation systems. This includes not only the initial purchase price but also the expected lifespan, fuel savings from improved gas mileage, and potential costs incurred from premature tire replacements due to improper inflation.

Before making a bulk purchase, request samples of the tires or monitoring systems. Testing these products in real-world conditions can help you evaluate their performance and suitability for your specific needs.

Look for testimonials from other businesses that have used the products you are considering. Case studies can provide insights into how well the products have performed in similar operational contexts.

Once you have selected potential suppliers, enter negotiations to establish favorable terms. Discuss pricing, delivery schedules, warranties, and after-sales support. Clear agreements can protect your business from unexpected costs or service disruptions.

By following this checklist, B2B buyers can make informed decisions regarding tire procurement, ultimately enhancing safety, efficiency, and cost savings in their operations.

When evaluating the impact of incorrect tire inflation on sourcing, several cost components must be considered.

Illustrative image related to incorrect tire inflation will adversely affect

المواد: The quality of tires and their inflation systems can significantly influence costs. Poor-quality materials can lead to rapid wear and tear, resulting in higher replacement frequencies. Investing in higher-quality tires may incur higher upfront costs but can lead to long-term savings by reducing the need for frequent replacements.

العمالة: Labor costs related to maintenance and replacement of tires are critical. Incorrect tire inflation can lead to increased labor hours for tire replacements, repairs, and inspections. Training staff on proper tire maintenance and inflation can mitigate these costs over time.

نفقات التصنيع الزائدة: Companies often overlook the overhead costs associated with producing tires. Inefficient production methods due to a lack of quality control can lead to higher costs. Ensuring adherence to strict quality standards during manufacturing can prevent defects and reduce overhead.

Tooling and Equipment: Proper equipment for tire inflation and maintenance is essential. Investing in high-quality inflation systems and monitoring equipment can ensure proper tire pressure, reducing the risk of accidents and subsequent costs associated with tire failures.

مراقبة الجودة (QC): Implementing stringent QC measures can prevent defects associated with incorrect tire inflation. Although this may increase initial costs, it can significantly lower long-term costs by minimizing recalls and warranty claims.

الخدمات اللوجستية: The logistics of transporting tires must also be factored in. Incorrect tire inflation can lead to increased fuel consumption during transportation, ultimately raising logistics costs. Efficient logistics planning can help mitigate these expenses.

الهامش: Companies must consider their profit margins when evaluating tire sourcing. Higher-quality, properly inflated tires may have a lower turnover rate, thus improving overall profit margins in the long run.

Several price influencers play a crucial role in determining the cost structure associated with tire sourcing:

الحجم/الكمية (الحد الأدنى لكمية الطلب): Suppliers often offer better pricing for larger orders. B2B buyers should negotiate volume discounts, as purchasing in bulk can lead to significant savings.

المواصفات والتخصيص: Custom tires designed for specific vehicle requirements can incur higher costs. Buyers should weigh the benefits of customization against the potential for increased expenses.

جودة المواد والشهادات: Tires that meet international safety and quality certifications may have higher price tags. However, investing in certified products can enhance safety and reduce the risk of costly failures.

عوامل الموردين: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge premium prices but can offer better quality assurance and after-sales support.

المصطلحات التجارية الدولية: Understanding Incoterms is crucial for international B2B buyers. These terms dictate responsibility for costs and risks associated with shipping, which can affect the overall price structure.

التفاوض: Effective negotiation can significantly influence tire pricing. Buyers should be prepared to discuss terms and seek favorable pricing while ensuring quality is not compromised.

التكلفة الإجمالية للملكية (TCO): It’s essential to consider the TCO, which includes initial purchase price, maintenance, and operational costs. Buyers should evaluate how proper tire inflation can enhance fuel efficiency and reduce maintenance costs.

Pricing Nuances for International Markets: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local market conditions, tariffs, and regulations that may affect pricing. Understanding these nuances can lead to more informed purchasing decisions.

Disclaimer for Indicative Prices: It’s important for buyers to understand that prices can fluctuate based on market conditions, currency exchange rates, and supplier pricing strategies. Regularly reviewing supplier quotes and market trends will help buyers stay competitive.

By taking into account these cost components, pricing influencers, and actionable tips, B2B buyers can make informed sourcing decisions that minimize costs associated with incorrect tire inflation while maximizing safety and efficiency.

Incorrect tire inflation can lead to significant operational inefficiencies, affecting tire wear, vehicle handling, and fuel economy. For B2B buyers, understanding alternative solutions is essential to mitigate these adverse effects. This analysis compares the implications of incorrect tire inflation against two viable alternatives: advanced tire pressure monitoring systems (TPMS) and automatic tire inflation systems (ATIS). Each solution presents unique benefits and challenges that can impact fleet performance and cost efficiency.

| جانب المقارنة | Incorrect Tire Inflation Will Adversely Affect | Advanced Tire Pressure Monitoring System (TPMS) | Automatic Tire Inflation System (ATIS) |

|---|---|---|---|

| الأداء | Decreases tire lifespan, handling, and mileage | Improves tire condition and fuel efficiency | Maintains optimal tire pressure |

| التكلفة | Potentially high due to premature tire replacement | Moderate initial investment, low maintenance | Higher upfront costs, but long-term savings |

| سهولة التنفيذ | No implementation, but requires manual checks | Easy to install on most vehicles | Complex installation, may require retrofitting |

| الصيانة | Regular checks needed to avoid issues | Minimal, requires periodic checks | Low, mostly automated maintenance |

| أفضل حالة استخدام | General vehicle operation | Fleets needing performance monitoring | Fleets requiring constant tire pressure management |

Advanced TPMS offers a significant upgrade over manual tire checks. These systems provide real-time tire pressure data, alerting drivers to any deviations from optimal inflation levels. The primary advantage is enhanced safety and performance, as well as improved fuel efficiency. However, the effectiveness of TPMS is contingent on the proper functioning of the sensors, which can malfunction. Additionally, while TPMS installation is relatively straightforward, it may still require initial investment and training for fleet operators.

ATIS is an advanced solution that actively adjusts tire pressure while vehicles are in operation. This system continuously monitors tire pressure and automatically inflates or deflates tires as needed, ensuring optimal performance at all times. The primary benefit of ATIS is its capacity to eliminate the risks associated with incorrect tire inflation altogether. However, the installation process can be complex and costly, especially for existing fleets that may require retrofitting. Despite the higher upfront costs, ATIS can lead to substantial long-term savings by extending tire life and improving fuel efficiency.

When selecting a solution to combat the issues arising from incorrect tire inflation, B2B buyers must consider their specific operational needs and budget constraints. Advanced TPMS provides a cost-effective means to monitor tire pressure actively, while ATIS offers a comprehensive approach to maintaining optimal tire conditions without manual intervention. Ultimately, the decision should align with the fleet’s operational goals, whether prioritizing safety, cost-efficiency, or overall performance. By carefully evaluating these alternatives, buyers can make informed decisions that enhance their fleet’s reliability and efficiency.

Tire Pressure Specification (PSI)

Tire pressure is measured in pounds per square inch (PSI) and is crucial for optimal tire performance. Each vehicle has a recommended PSI that ensures safety, fuel efficiency, and tire longevity. For B2B buyers, understanding the correct tire pressure specifications for different vehicle types is vital for fleet management and operational safety.

Tread Depth

Tread depth refers to the distance between the top of the tire’s tread and the bottom of the tire’s grooves. Adequate tread depth is essential for traction and handling, especially in adverse weather conditions. Businesses must monitor tread depth closely to prevent accidents and reduce liability, ensuring that all vehicles in their fleet maintain safe operational standards.

Load Index

The load index indicates the maximum weight a tire can support at a specific pressure. Each tire has a designated load index rating, which is critical for determining compatibility with various vehicles and loads. For companies involved in logistics or transportation, understanding load indices helps in selecting the right tires for their fleet, minimizing the risk of tire blowouts due to overloading.

Rolling Resistance

Rolling resistance is the energy lost as a tire rolls under load, affecting fuel efficiency. Tires with lower rolling resistance can significantly improve a vehicle’s gas mileage, an essential consideration for companies looking to reduce operational costs. B2B buyers should prioritize tires that balance performance and efficiency to enhance overall fleet economics.

Temperature Resistance

Tire performance is also influenced by temperature, which can affect tire pressure and wear. Tires that can withstand higher temperatures are particularly important for commercial vehicles that travel long distances or operate in hot climates. Understanding the temperature resistance properties of tires can help businesses make informed decisions about tire selection for specific operational environments.

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that manufacture parts or equipment that may be marketed by another manufacturer. In the context of tires, OEM tires are those produced specifically for a vehicle manufacturer. B2B buyers should consider OEM tires for reliability and compatibility, ensuring that their vehicles perform optimally.

موك (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses looking to procure tires in bulk, as it can affect inventory management and cost efficiency. Buyers should negotiate MOQs that align with their operational needs while maintaining a healthy supply chain.

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For tire procurement, an RFQ allows businesses to compare offers from different suppliers, enabling informed purchasing decisions. This process helps to ensure that companies receive competitive pricing and favorable terms.

إنكوترمز (الشروط التجارية الدولية)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is crucial for B2B buyers involved in international tire procurement, as they dictate who is responsible for shipping, insurance, and tariffs. Proper knowledge of Incoterms can streamline the import/export process and minimize unexpected costs.

TPMS (Tire Pressure Monitoring System)

TPMS is an electronic system that monitors tire pressure and alerts drivers when it falls below the recommended level. While beneficial, reliance on TPMS can lead to complacency regarding manual tire checks. B2B buyers should incorporate regular tire inspections alongside TPMS to ensure safety and performance across their fleets.

By understanding these critical properties and trade terms, B2B buyers can make informed decisions regarding tire procurement, ensuring that their fleets operate safely and efficiently while minimizing costs associated with incorrect tire inflation.

Illustrative image related to incorrect tire inflation will adversely affect

The global tire industry is experiencing significant shifts due to the increasing awareness of the adverse effects of incorrect tire inflation. With rising fuel prices and heightened environmental concerns, businesses are prioritizing tire maintenance to improve vehicle performance and reduce operational costs. One major driver in this market is the growing adoption of advanced tire pressure monitoring systems (TPMS). However, studies indicate that these systems can be inaccurate, leading to a substantial percentage of vehicles operating with improperly inflated tires. As such, B2B buyers are increasingly seeking reliable monitoring solutions and tire management services to ensure optimal tire performance.

Emerging technologies, such as IoT and machine learning, are transforming tire management practices. These innovations allow for real-time monitoring and predictive maintenance, significantly reducing the risks associated with incorrect tire inflation. International buyers, particularly in regions like Africa and South America, are focusing on sourcing high-quality, technology-enabled tire solutions that enhance safety and efficiency. Moreover, partnerships with local distributors who understand regional market dynamics are becoming essential for navigating these sourcing challenges.

In addition, regulatory changes and sustainability initiatives are influencing market dynamics. Governments worldwide are implementing stricter regulations on vehicle emissions, which indirectly affect tire performance. B2B buyers must stay informed about these regulations to ensure compliance and leverage them for competitive advantage.

The environmental impact of tire production and usage is a growing concern for businesses, particularly in sectors that rely heavily on transportation. Improperly inflated tires not only compromise safety but also contribute to increased fuel consumption and greenhouse gas emissions. For B2B buyers, this emphasizes the importance of sourcing tires that are designed for efficiency and durability.

Ethical supply chains are becoming a focal point in the tire industry. Companies are increasingly looking for suppliers that adhere to sustainable practices, such as using eco-friendly materials and minimizing waste during production. Certifications like the Global Recycling Standard (GRS) and ISO 14001 Environmental Management System are gaining traction as indicators of responsible sourcing. Buyers should prioritize partnerships with manufacturers that demonstrate a commitment to sustainability, as this not only enhances brand reputation but also aligns with consumer expectations for corporate social responsibility.

Illustrative image related to incorrect tire inflation will adversely affect

Moreover, adopting ‘green’ tire technologies, such as low rolling resistance tires, can lead to significant cost savings and reduced environmental impact. By investing in sustainable tire solutions, businesses can improve their operational efficiency while contributing to global sustainability efforts.

The tire industry has undergone significant changes since the introduction of the pneumatic tire in the late 19th century. Initially, tire inflation was a manual task, often neglected by vehicle owners, leading to widespread issues with tire performance. As vehicles became more complex, the importance of proper tire maintenance gained recognition, culminating in the development of tire pressure monitoring systems in the early 2000s.

Over the years, technological advancements have enabled better monitoring and management of tire pressure, but challenges remain. The introduction of smart technologies and IoT solutions is reshaping the landscape, making it essential for B2B buyers to stay updated on these innovations. Understanding the evolution of tire technology helps businesses recognize the importance of proper tire inflation and the critical role it plays in vehicle safety and operational efficiency.

How do I solve the issue of incorrect tire inflation affecting my fleet’s performance?

To address incorrect tire inflation, implement a regular tire maintenance program that includes checking tire pressure at least once a month and before long trips. Consider investing in tire pressure monitoring systems (TPMS) that provide real-time data on tire conditions. Ensure all drivers are trained to recognize signs of improper inflation, such as uneven tire wear or changes in vehicle handling. Establish a partnership with a reliable tire supplier who can provide timely replacements and expert advice on maintenance practices.

What is the best way to manage tire procurement for optimal performance and cost?

For effective tire procurement, evaluate suppliers based on their product quality, pricing, and after-sales support. Look for manufacturers that offer a comprehensive warranty and have a proven track record in the industry. Consider bulk purchasing agreements to reduce costs, and negotiate favorable payment terms that align with your cash flow needs. Additionally, assess the supplier’s ability to provide customized tire solutions tailored to your specific vehicle types and operating conditions.

How can I ensure tire quality when sourcing from international suppliers?

To guarantee tire quality, conduct thorough due diligence on potential suppliers. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Evaluate samples of tires to assess performance metrics such as tread wear, handling, and fuel efficiency. Establish clear quality assurance protocols, including regular inspections and compliance checks, to ensure that the tires meet your specifications consistently.

What are the minimum order quantities (MOQ) for tires, and how can they impact my supply chain?

Minimum order quantities (MOQ) for tires can vary significantly by supplier and region. Understanding these quantities is crucial, as they can impact your inventory levels and cash flow. If MOQs are too high, consider consolidating orders with other businesses to meet the requirement or negotiate with suppliers for lower MOQs. Ensure that your purchasing strategy aligns with your operational needs to avoid overstocking or stockouts.

What payment terms should I negotiate with tire suppliers for B2B transactions?

When negotiating payment terms, aim for conditions that support your cash flow while ensuring timely payments to suppliers. Common options include net 30 or net 60 payment terms, which provide a grace period for payment. Consider discussing discounts for early payment or bulk purchases, which can enhance your profitability. Always review the supplier’s financial stability and reputation to mitigate risks associated with payment delays.

How does incorrect tire inflation affect gas mileage, and what can I do to improve it?

Incorrect tire inflation can lead to increased rolling resistance, which decreases fuel efficiency. Regularly check and adjust tire pressures according to manufacturer specifications to optimize gas mileage. Educate your drivers about the importance of maintaining proper tire pressure and its direct impact on fuel costs. Additionally, consider investing in fuel-efficient tires designed to minimize rolling resistance, further enhancing your fleet’s fuel economy.

What logistics considerations should I keep in mind when sourcing tires internationally?

When sourcing tires internationally, consider logistics factors such as shipping costs, customs duties, and lead times. Choose suppliers with efficient shipping practices and the ability to provide timely delivery. Ensure that your logistics provider is experienced in handling tire shipments to avoid damage during transit. Additionally, factor in local regulations and compliance requirements to streamline the import process and prevent delays.

How can I customize tire solutions to meet specific operational needs?

To customize tire solutions, engage with suppliers to discuss your specific requirements, such as load capacity, terrain, and vehicle types. Many manufacturers offer tailored options, including specialized tread patterns and rubber compounds. Conduct a thorough analysis of your operational environment to determine the best tire specifications. Collaborate with your supplier on prototype testing to ensure the customized tires meet performance expectations before full-scale orders.

المجال: brainly.com

مسجل: 2004 (21 سنة)

مقدمة: Incorrect tire inflation can adversely affect: A. Tire wear: Improper inflation can cause uneven wear on the tires. B. Vehicle handling: Tires that are not properly inflated can reduce the vehicle’s ability to grip the road, leading to poor handling and control. C. Gas mileage: Tires that are under-inflated create more rolling resistance, making the engine work harder and thus using more fuel. The…

المجال: eastcoasttoyota.com

مسجل: 2000 (25 سنة)

مقدمة: The article discusses the hidden risks associated with overinflated and underinflated tires, emphasizing the importance of maintaining proper tire pressure for vehicle performance and safety. Key points include: 1. Uneven Tread Wear: Overinflated tires wear the center tread faster, while underinflated tires wear the outer edges, leading to reduced tire lifespan and potential alignment issues. 2. R…

المجال: jacosuperiorproducts.com

مسجل: 2014 (11 سنة)

مقدمة: JACO Superior Products offers a top-rated collection of certified accurate tire pressure gauges and inflators designed to ensure proper tire inflation for safety and performance. Their products are engineered with precision and are trusted by over 1 million customers. JACO provides fast and free standard shipping for all orders in the USA. They emphasize the importance of using high-quality, relia…

المجال: facebook.com

مسجل: 1997 (28 سنة)

مقدمة: Tires are the only part of the vehicle that touches the road; tire care and proper maintenance should be a top priority. Helpful tire inspection tips are provided, and consulting an automotive technician is recommended to ensure tires are in good shape.

المجال: guerrallp.com

Registered: 2024 (1 years)

مقدمة: Driving on underinflated tires poses significant safety risks, including a threefold increase in the likelihood of tire-related accidents, longer stopping distances, overheating, and accelerated tire wear. Underinflated tires can cause an estimated 11,000 crashes annually and lead to increased stress on tire components. Proper tire inflation is crucial for efficiency, gas mileage, and overall vehi…

In conclusion, the implications of incorrect tire inflation extend far beyond mere inconvenience; they represent significant operational risks for businesses engaged in transportation and logistics. Key takeaways for international B2B buyers include the understanding that improperly inflated tires can lead to uneven wear, compromised vehicle handling, and increased fuel consumption. These factors not only drive up maintenance costs but can also jeopardize safety and operational efficiency.

Strategic sourcing of high-quality tires and tire monitoring systems can mitigate these risks effectively. By investing in reliable products and services, businesses can enhance their fleet performance, reduce downtime, and ultimately lower operational costs. It’s crucial for companies in regions such as Africa, South America, the Middle East, and Europe to prioritize tire maintenance as part of their broader supply chain strategy.

Illustrative image related to incorrect tire inflation will adversely affect

Looking ahead, the focus should shift towards adopting advanced tire management technologies and sourcing strategies that emphasize safety and efficiency. B2B buyers are encouraged to evaluate their current tire procurement practices and consider partnerships with suppliers that offer comprehensive solutions. By taking these steps, businesses can not only safeguard their assets but also contribute to sustainable operational practices in the transportation sector.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

Illustrative image related to incorrect tire inflation will adversely affect

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.