- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

Navigating the global market for car tire inflators presents a unique set of challenges for international B2B buyers. With an overwhelming array of options available, sourcing the right tire inflator that meets specific regional demands and application needs can be daunting. This guide is designed to simplify your procurement process by providing a comprehensive overview of the various types of tire inflators, their applications, and essential factors to consider when evaluating suppliers.

From portable models tailored for personal use to robust industrial inflators designed for commercial fleets, understanding the diverse landscape of tire inflators is crucial for making informed purchasing decisions. This guide also covers critical aspects such as supplier vetting, pricing strategies, and market trends, ensuring you are well-equipped to navigate the complexities of the tire inflator market.

For B2B buyers in Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—this resource is invaluable. It empowers you to identify the right products that align with your operational needs while optimizing cost efficiency. By leveraging the insights provided in this guide, you can confidently select tire inflators that enhance your business operations and meet your customers’ expectations.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Portable Tire Inflators | Compact, battery-operated, suitable for emergency use | Automotive service providers, fleets | الإيجابيات: Easy to store, quick inflation. السلبيات: Limited battery life, may require frequent recharging. |

| Heavy-Duty Tire Inflators | High-capacity, designed for larger tires and commercial vehicles | Trucking companies, construction firms | الإيجابيات: Fast inflation, robust construction. السلبيات: Bulky, less portable. |

| Multi-Function Inflators | Combines inflator with additional features (e.g., jump starter, power bank) | Emergency response units, rental services | الإيجابيات: Versatile, space-saving. السلبيات: May lack specialized performance for tire inflation. |

| أجهزة نفخ الإطارات الرقمية | Features digital displays for precise pressure readings and preset settings | Automotive repair shops, tire retailers | الإيجابيات: Accurate, user-friendly. السلبيات: More expensive, potential for electronic malfunctions. |

| مضخات الإطارات اليدوية | Hand-operated, lightweight, and portable | Emergency kits, remote locations | الإيجابيات: No power source needed, very portable. السلبيات: تضخم كثيف العمالة وبطيء التضخم. |

Portable tire inflators are compact, battery-operated devices designed for emergency use. They are lightweight and easy to store in vehicles, making them ideal for roadside assistance and personal emergency kits. B2B buyers in automotive service or fleet management find these inflators beneficial for quick tire top-offs in various situations. However, the limited battery life can be a drawback, necessitating frequent recharges or reliance on a vehicle’s power outlet.

Heavy-duty tire inflators are engineered for larger tires found on commercial vehicles, such as trucks and construction equipment. They often feature powerful motors that deliver rapid inflation, catering to businesses that require efficiency and reliability. Trucking companies and construction firms benefit from these inflators due to their robust construction and ability to handle high-volume demands. However, their bulkiness can hinder portability, making them less suitable for smaller vehicles.

Multi-function inflators combine tire inflation capabilities with additional features like jump-starting batteries and serving as power banks. This versatility is particularly appealing to emergency response units and rental service companies, as it allows them to carry fewer tools while maximizing utility. While these inflators save space, they may not perform as well in specialized tire inflation tasks compared to dedicated models, which is a consideration for B2B buyers focused on performance.

Digital tire inflators come equipped with advanced features, including digital displays that provide precise pressure readings and preset inflation settings. This accuracy is crucial for automotive repair shops and tire retailers where maintaining proper tire pressure is essential for safety and performance. Although they tend to be more expensive than analog models, the user-friendly interface and reliability can justify the investment for businesses prioritizing quality and efficiency.

Manual tire pumps are lightweight and portable, requiring no power source, making them suitable for remote locations or emergency kits. They are particularly useful for businesses that operate in areas with limited access to electricity. However, they are labor-intensive and slower in comparison to powered inflators, which can be a disadvantage for companies needing quick and efficient tire inflation solutions.

| الصناعة/القطاع | Specific Application of car tire inflators | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | Routine tire maintenance for vehicles | Enhanced customer satisfaction and safety | Durability, inflation speed, and ease of use |

| Transportation and Logistics | Emergency tire inflation for fleets | Reduced downtime and operational efficiency | Power source versatility, portability, and inflation capacity |

| Car Rental Companies | Quick tire inflation for rental vehicles | Improved vehicle readiness and customer service | Compact design, reliability, and maintenance support |

| Off-Road and Adventure Sports | Tire pressure adjustments for off-road vehicles | Enhanced performance and safety in rugged terrains | Robustness, battery life, and compatibility with various tire types |

| Construction and Heavy Equipment | Tire inflation for construction vehicles | Maximized equipment uptime and productivity | High pressure capability, rugged design, and ease of transport |

In automotive repair shops, car tire inflators are essential tools for routine tire maintenance. Technicians use these devices to ensure that vehicles are operating at optimal tire pressure, which enhances safety and fuel efficiency. For international buyers, especially in regions with varying climate conditions, sourcing inflators that can withstand different temperatures and humidity levels is crucial. Additionally, the durability and ease of use of these inflators can significantly impact customer satisfaction and retention.

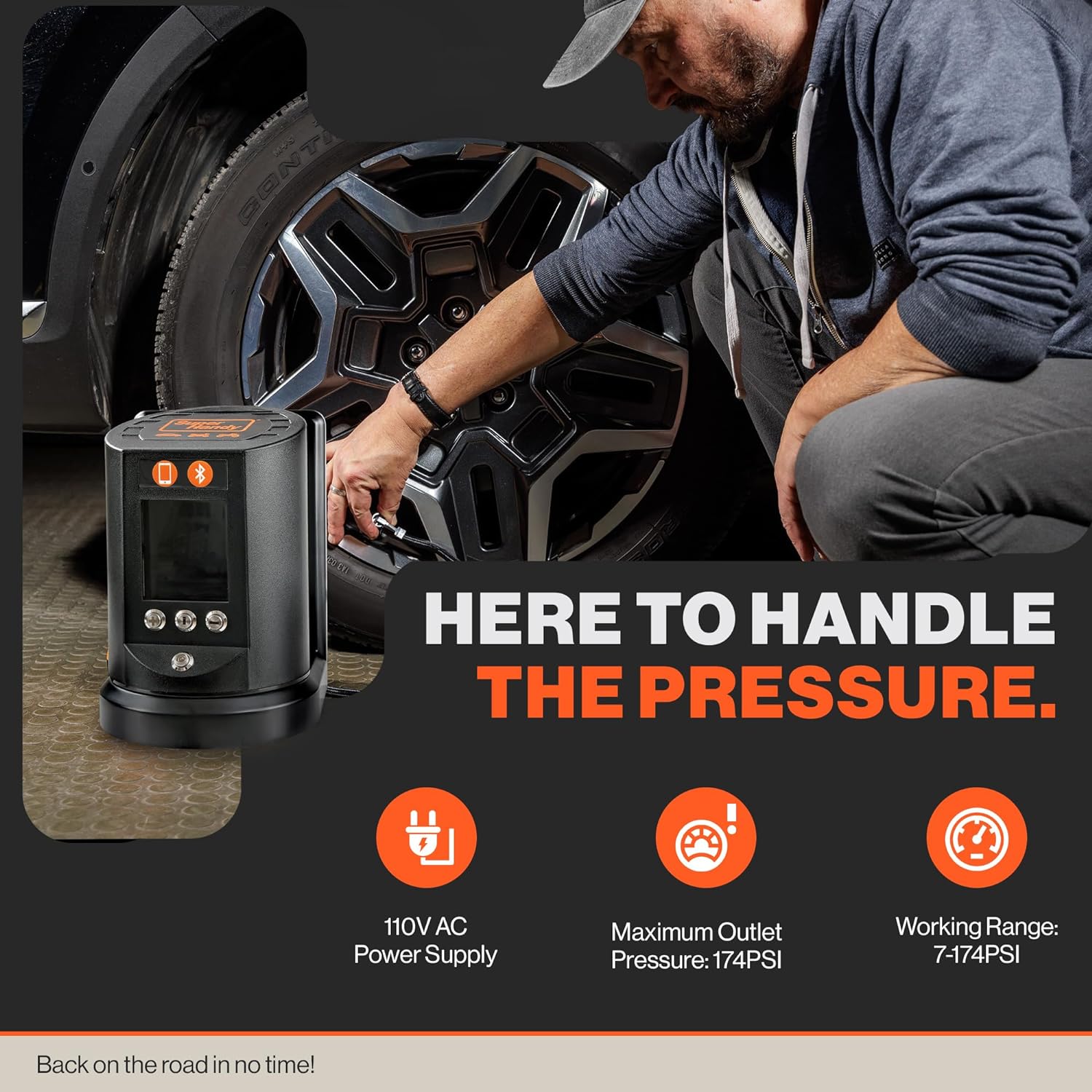

Illustrative image related to car tire inflators

For transportation and logistics companies, car tire inflators serve as critical tools for maintaining the tire health of fleet vehicles. In emergency situations, these inflators can quickly restore tire pressure, minimizing downtime and ensuring timely deliveries. Buyers in this sector should consider inflators that offer versatility in power sources—such as battery, 12-volt, or 120-volt options—to accommodate various vehicle types. Efficiency in inflation speed is also a key factor, as it directly affects operational productivity.

Car rental companies utilize car tire inflators to ensure that their fleet is always ready for customer use. Quick tire inflation capabilities allow for rapid turnaround times during vehicle servicing, enhancing overall customer service. International buyers, particularly in regions with diverse terrain and driving conditions, should prioritize compact and reliable inflators that can handle various tire sizes and types. Maintenance support and warranty options are also important considerations to reduce long-term operational costs.

In the off-road and adventure sports industry, maintaining proper tire pressure is vital for performance and safety. Car tire inflators are used to make quick adjustments to tire pressure based on changing terrain conditions. Buyers in this sector should look for robust inflators with a long battery life, as they may be used in remote locations without immediate access to power sources. Additionally, compatibility with different tire types, including larger off-road tires, is essential for ensuring versatility.

In construction and heavy equipment sectors, car tire inflators are crucial for maintaining the tire pressure of large machinery. Properly inflated tires maximize equipment uptime and productivity, which is essential for meeting project deadlines. Buyers in this industry should focus on inflators that can handle high pressure and are designed to withstand rugged environments. Portability and ease of transport are also vital, as these inflators may need to be moved frequently across job sites.

المشكلة B2B buyers often face the challenge of selecting the appropriate tire inflator that meets the varying requirements of their fleet or service offerings. With numerous options available, including different inflation speeds, power sources, and portability features, the decision can be overwhelming. For example, a fleet manager might need a compact inflator for light vehicles but also require a heavy-duty model for larger trucks. This inconsistency can lead to wasted time and resources if the wrong products are chosen.

Illustrative image related to car tire inflators

الحل: To address this challenge, B2B buyers should develop a clear understanding of their specific requirements before making a purchase. Conduct a thorough assessment of the types of vehicles in the fleet and their average tire sizes. Look for tire inflators that offer versatility—models that can handle a range of PSI levels and have multiple power options (12-volt, battery, or AC). Additionally, consider investing in a few different models to cater to specific needs, ensuring that there is always an inflator available that matches the task at hand. Engaging with suppliers who can provide detailed product specifications and comparisons can also streamline this decision-making process.

المشكلة Many B2B buyers report issues with user experience, particularly in terms of ease of use and operational efficiency. For instance, tire inflators with complex interfaces or poor design can lead to inefficiencies during emergency situations. If a service technician struggles to operate a complicated inflator, it could delay roadside assistance, impacting customer satisfaction and potentially leading to loss of business.

الحل: To enhance user experience, B2B buyers should prioritize tire inflators that feature intuitive controls and clear digital displays. It’s beneficial to conduct hands-on trials with potential products before purchasing. Additionally, investing in models that come with comprehensive user manuals or training videos can ensure that staff are well-equipped to use the inflators effectively. Consider sourcing inflators with ergonomic designs, which can minimize fatigue during prolonged use. Furthermore, regular training sessions can be implemented for staff to familiarize them with the equipment, ultimately improving response times and service quality.

Illustrative image related to car tire inflators

المشكلة Reliability and durability are paramount for B2B buyers, especially those in regions with harsh climates or rough terrains. Buyers often express concerns over the longevity of tire inflators, fearing that frequent breakdowns or malfunctions will lead to increased maintenance costs and downtime. For example, inflators that fail in extreme heat or cold may leave drivers stranded, which not only affects service efficiency but also poses safety risks.

الحل: To mitigate these concerns, B2B buyers should focus on sourcing tire inflators from reputable manufacturers known for their durability and performance under various conditions. Look for models with high-quality materials and positive reviews regarding their resilience. Implementing a regular maintenance schedule, including routine checks and servicing of the inflators, can also extend their lifespan. Additionally, consider purchasing extended warranties or service agreements from suppliers, which can provide peace of mind and protect against unexpected failures. Utilizing inflators designed specifically for rugged environments can further reduce the risk of operational disruptions in challenging conditions.

When selecting materials for car tire inflators, several factors must be considered, including performance, durability, cost, and compliance with international standards. Here we analyze four common materials used in tire inflators: plastics, metals, rubber, and composites.

Illustrative image related to car tire inflators

Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are often used for the housing of tire inflators. These materials offer excellent resistance to corrosion and are lightweight, which enhances portability. They can withstand moderate temperature variations, making them suitable for various climates.

الإيجابيات: Plastics are cost-effective and easy to mold into complex shapes, which simplifies manufacturing. They are also resistant to rust and corrosion, making them ideal for outdoor use.

السلبيات: The main limitation of plastics is their lower durability compared to metals. They may not withstand high-pressure applications as effectively, which is critical for tire inflators that need to perform under pressure.

التأثير على التطبيق: Plastics are generally compatible with air and non-corrosive gases, but caution is needed when using them with certain chemicals.

اعتبارات للمشترين الدوليين: Buyers in regions like Africa and South America should ensure that the plastics used comply with local regulations and standards, such as ASTM or ISO certifications, to guarantee safety and performance.

Metals, such as aluminum and stainless steel, are commonly used for components that require high strength and durability, such as the pump and connectors. These materials can handle high pressures and temperatures, making them ideal for tire inflation.

الإيجابيات: Metals offer superior strength and longevity, making them suitable for heavy-duty applications. They are also resistant to wear and tear, ensuring a longer lifespan for the inflator.

السلبيات: The primary drawback of metals is their weight, which can affect the portability of the inflator. Additionally, they are generally more expensive than plastics.

التأثير على التطبيق: Metals are highly compatible with air and can withstand the high pressures associated with tire inflation. However, they may corrode if not properly treated or if exposed to moisture.

اعتبارات للمشترين الدوليين: Buyers from Europe, particularly Germany, should prioritize compliance with European standards for metal components, such as DIN standards, to ensure quality and safety.

Rubber is often used for seals, hoses, and nozzles in tire inflators due to its excellent flexibility and air-tight properties. It can withstand significant pressure and is resistant to wear.

الإيجابيات: Rubber provides a reliable seal, preventing air leaks during inflation. It is also relatively inexpensive and easy to replace.

السلبيات: The main limitation of rubber is its susceptibility to degradation from UV exposure and extreme temperatures, which can shorten its lifespan.

التأثير على التطبيق: Rubber is highly compatible with air and is essential for maintaining pressure in the inflator. However, it may not be suitable for applications involving chemicals or oils.

Illustrative image related to car tire inflators

اعتبارات للمشترين الدوليين: Buyers in the Middle East should consider the impact of high temperatures on rubber components and look for products that use heat-resistant formulations.

Composite materials, which combine various materials to enhance performance, are increasingly used in tire inflators. They can offer the benefits of both plastics and metals, providing strength while remaining lightweight.

الإيجابيات: Composites are highly durable and resistant to corrosion, making them suitable for various environmental conditions. They can also be engineered for specific performance characteristics.

السلبيات: The manufacturing process for composites can be complex and costly, which may increase the overall price of the inflator.

التأثير على التطبيق: Composites can be tailored for specific applications, making them versatile for different types of tire inflators. However, compatibility with certain chemicals should be assessed.

Illustrative image related to car tire inflators

اعتبارات للمشترين الدوليين: Buyers from regions like Vietnam should ensure that composite materials meet local and international safety standards, as well as environmental regulations.

| المواد | Typical Use Case for car tire inflators | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| بلاستيك | السكن والغلاف | خفيف الوزن ومقاوم للتآكل | Lower durability under high pressure | منخفضة |

| المعادن | Pump and connectors | قوة ومتانة عالية | أثقل وزناً وأغلى ثمناً | عالية |

| المطاط | Seals and hoses | Excellent sealing properties | Susceptible to UV and temperature degradation | منخفضة |

| المركبات | Specialized components | أداء مصمم خصيصاً وخفيف الوزن | Complex and potentially costly manufacturing | متوسط |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in car tire inflators, helping them make informed decisions based on performance, cost, and regional compliance standards.

The manufacturing of car tire inflators involves several key stages that ensure both functionality and quality. The process typically includes material preparation, forming, assembly, and finishing.

إعداد المواد

The initial stage involves sourcing high-quality materials such as plastics, metals, and electronic components. Manufacturers often opt for durable materials that can withstand high pressure and extreme temperatures. For instance, the casing is usually made from robust plastics or aluminum, while the internal mechanisms may include rubber gaskets and seals to prevent air leakage.

Illustrative image related to car tire inflators

تقنيات التشكيل

Once the materials are prepared, the next step is forming. This can involve injection molding for plastic components or die-casting for metal parts. Advanced techniques like 3D printing are also emerging, allowing for rapid prototyping and customization. Each component is designed to fit precisely with others, which is crucial for the inflator’s performance and reliability.

عملية التجميع

Following the forming stage, the components are assembled. This often takes place on automated assembly lines, where robotic arms may be employed for precision tasks. Manual assembly is also common, especially for complex parts that require human oversight. During this stage, it’s vital to ensure that all parts are correctly aligned and securely fastened, as any misalignment can lead to performance issues.

اللمسات الأخيرة

The final stage is finishing, which may include painting, surface treatment, and quality checks. Products are often tested for aesthetics and durability. A well-finished product not only looks appealing but also enhances longevity, which is a crucial selling point for B2B buyers.

Quality assurance (QA) is integral to the manufacturing of tire inflators, ensuring that each unit meets international standards and buyer expectations.

Relevant International Standards

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which provides a framework for quality management systems. Compliance with CE marking is also crucial, especially for products sold in Europe, as it indicates conformity with health, safety, and environmental protection standards. In regions like the Middle East and Africa, adherence to local regulations and standards is equally important.

Illustrative image related to car tire inflators

الشهادات الخاصة بالصناعة

In addition to general standards, there are industry-specific certifications such as API (American Petroleum Institute) for products related to the automotive sector. These certifications assure buyers that the inflators have been tested for safety and performance.

Quality control (QC) is implemented through various checkpoints throughout the manufacturing process, commonly categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

مراقبة الجودة الواردة (IQC)

IQC is the first line of defense in quality management. Here, raw materials and components are inspected upon arrival to ensure they meet the required specifications. This might include visual inspections, measurements, and material composition tests.

مراقبة الجودة أثناء المعالجة (IPQC)

During the manufacturing process, IPQC monitors production at various stages. This includes checking the tolerances of formed parts, ensuring that assembly is performed correctly, and verifying that machinery operates within set parameters. Automated systems often track these metrics, alerting operators to any deviations in real-time.

Illustrative image related to car tire inflators

مراقبة الجودة النهائية (FQC)

FQC involves a comprehensive assessment of the finished product before it is packaged and shipped. This includes functional testing, performance evaluations, and safety checks. For tire inflators, this may involve testing the inflation speed, pressure accuracy, and overall durability under simulated conditions.

Manufacturers employ a variety of testing methods to ensure the quality and reliability of tire inflators. These tests may include:

Pressure Testing

This involves inflating the unit to its maximum pressure to ensure it can withstand operational loads without failure. This test is crucial for identifying weak points that could lead to leaks or ruptures.

Illustrative image related to car tire inflators

Performance Testing

Inflators are evaluated on their inflation speed and accuracy. This may involve timed tests to see how quickly the inflator can reach a specified pressure level. Manufacturers often benchmark their products against competitors to ensure they meet market expectations.

اختبار المتانة

To assess the longevity of the inflators, manufacturers may subject them to repeated cycles of inflation and deflation. This helps identify potential points of failure that could arise from regular use.

For B2B buyers, verifying the quality control processes of suppliers is essential to ensure that products meet the required standards and specifications. Here are some actionable steps:

Illustrative image related to car tire inflators

عمليات تدقيق الموردين

Conducting supplier audits allows buyers to evaluate a manufacturer’s facilities, processes, and quality control measures. This should include assessing documentation, quality management systems, and compliance with international standards.

مراجعة تقارير الجودة

Suppliers should provide detailed quality reports that outline their testing methodologies, results, and any corrective actions taken. These reports can give buyers insight into the supplier’s commitment to quality.

عمليات التفتيش من طرف ثالث

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and tests on behalf of buyers, ensuring that the inflators meet all necessary standards before shipment.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certifications.

Illustrative image related to car tire inflators

الامتثال الإقليمي

Different regions have varying regulations and standards. For instance, the EU has stringent CE marking requirements, while other regions may have less formalized standards. Buyers should ensure that their suppliers are compliant with both local and international regulations.

Language Barriers and Documentation

Documentation may be in different languages or formats, which can complicate the verification process. Buyers should establish clear communication with suppliers to ensure that they understand the quality control measures and certifications being utilized.

شفافية سلسلة التوريد

Given the complexities of international logistics, transparency in the supply chain is vital. Buyers should inquire about the traceability of materials and components used in tire inflators to ensure that they meet quality standards from the outset.

By understanding the manufacturing processes and quality assurance protocols involved in car tire inflators, B2B buyers can make informed decisions that enhance their purchasing strategies and build strong supplier relationships.

When sourcing car tire inflators for your business, it’s essential to follow a structured approach to ensure you select the best products that meet your operational needs. This guide provides a step-by-step checklist to help you navigate the procurement process effectively.

Understanding your specific needs is the first step in sourcing car tire inflators. Consider the types of vehicles you will serve, the typical tire sizes, and whether you need portable or stationary units. Additionally, evaluate the required inflation speed, power options (battery, 12V outlet), and any additional features like built-in pressure gauges or multiple nozzles.

Illustrative image related to car tire inflators

Stay informed about the latest trends in the tire inflator market. Analyzing consumer preferences can provide insights into popular features and designs. Look for reports or surveys specific to your target regions, such as Africa, South America, or Europe, to understand what buyers prioritize, whether it’s portability, ease of use, or multi-functionality.

Before making a purchase, vet potential suppliers thoroughly. Look for companies with a solid reputation in the automotive accessories market. Request company profiles, product catalogs, and references from other businesses in your industry to assess reliability. Consider suppliers who have experience exporting to your region, as they will better understand local regulations and customs.

Quality assurance is paramount when sourcing tire inflators. Check if the products comply with international standards and local regulations. Look for certifications such as ISO or CE, which indicate adherence to quality and safety benchmarks. Additionally, request samples or conduct performance tests to evaluate the inflators’ durability and functionality.

Once you have shortlisted potential suppliers, compare their pricing structures. Ensure that the costs align with your budget while also considering the quality of the products. Review payment terms and conditions, including any discounts for bulk purchases or extended payment options, which can be beneficial for cash flow management.

Illustrative image related to car tire inflators

Reliable after-sales support is crucial for maintaining customer satisfaction. Inquire about warranty terms and the availability of spare parts or repair services. A robust support system can enhance your relationship with customers and ensure you can address any issues that arise post-purchase.

After thorough evaluation and negotiation, finalize contracts with your chosen supplier. Ensure all terms are clearly stated, including delivery timelines, payment schedules, and return policies. Once contracts are signed, place your orders and establish a follow-up plan to monitor delivery and product performance.

By following this checklist, you can confidently navigate the sourcing process for car tire inflators, ensuring that you select the right products to meet your business needs while maintaining quality and reliability.

When sourcing car tire inflators, understanding the cost structure is essential for B2B buyers. The primary cost components include:

المواد: The quality and type of materials used in the construction of tire inflators significantly impact pricing. Common materials include plastics, metals, and electronic components. High-quality materials may increase initial costs but can enhance durability and performance.

العمالة: Labor costs vary by region and production scale. For instance, countries with lower labor costs may offer more competitive pricing, but this can also reflect on product quality and consistency.

نفقات التصنيع الزائدة: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower these costs, impacting the final price of the inflators.

الأدوات: The cost of molds and specialized equipment for manufacturing tire inflators is a significant factor, especially for custom designs. High initial tooling costs can be offset by larger production runs.

مراقبة الجودة (QC): Ensuring product quality is vital, particularly for safety-related items like tire inflators. Comprehensive QC processes add to the overall cost but are essential for maintaining standards and certifications.

الخدمات اللوجستية: Transportation and warehousing costs must be considered, especially for international shipping. These costs can vary based on shipping methods, distances, and local regulations.

الهامش: Suppliers typically add a profit margin to cover their expenses and ensure profitability. This margin can vary significantly based on market competition and demand.

Several factors influence the pricing of car tire inflators, making it crucial for buyers to be aware of them:

الحجم/معدل العرض/الطلب: Bulk purchases usually lead to lower per-unit costs. Understanding minimum order quantities (MOQ) can help buyers negotiate better deals.

المواصفات والتخصيص: Customized inflators with specific features or branding will generally incur higher costs. Buyers should weigh the benefits of customization against budget constraints.

جودة المواد والشهادات: Higher quality materials and certifications (like ISO or CE marks) can enhance reliability but increase costs. Buyers should consider the importance of these certifications in their markets.

عوامل الموردين: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their quality assurance and service levels.

المصطلحات التجارية الدولية: The terms of sale can significantly affect total costs. Understanding whether costs include shipping, insurance, and tariffs is vital for accurate budgeting.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing effectiveness:

Negotiation Skills: Be prepared to negotiate terms, especially on pricing and MOQ. Establishing a good rapport with suppliers can lead to better deals.

كفاءة التكلفة: Analyze the total cost of ownership rather than just the purchase price. Consider factors like longevity, warranty, and maintenance costs, which can impact overall value.

فهم الفروق الدقيقة في التسعير: Be aware of regional pricing variations. For instance, European suppliers may offer higher-quality products but at a premium price, while suppliers from Asia may provide cost-effective alternatives with varying quality.

Research Supplier Backgrounds: Investigate potential suppliers’ histories, production capabilities, and customer feedback. This diligence can help mitigate risks associated with quality and reliability.

Stay Informed About Market Trends: Keep an eye on market trends, including technological advancements in tire inflators, which may influence pricing and feature offerings.

Prices for car tire inflators can vary widely based on the factors discussed above. This analysis provides a general framework, but actual costs may differ based on specific supplier negotiations, market conditions, and unique buyer requirements. Always conduct thorough market research and supplier assessments to obtain accurate pricing for your sourcing needs.

When it comes to maintaining optimal tire pressure, car tire inflators are a popular choice among vehicle owners. However, several alternative solutions can effectively address the same need. Understanding the comparative strengths and weaknesses of these options is essential for B2B buyers looking to make informed purchasing decisions. This analysis will provide a detailed comparison of car tire inflators against two viable alternatives: manual foot pumps and air compressor stations.

| جانب المقارنة | Car Tire Inflators | Manual Foot Pumps | Air Compressor Stations |

|---|---|---|---|

| الأداء | Fast inflation, varying PSI levels | Slower inflation, limited PSI | High-speed inflation, consistent PSI |

| التكلفة | $50 – $250 | $20 – $100 | $0.50 – $5 per use |

| سهولة التنفيذ | User-friendly, portable | Requires physical effort | Accessible but may require travel |

| الصيانة | Low maintenance, occasional checks | Minimal maintenance | Regular maintenance needed |

| أفضل حالة استخدام | Emergency roadside assistance | Occasional home use | Frequent use in workshops or commercial settings |

Manual foot pumps are a classic solution for tire inflation, particularly in regions where electricity may be less accessible. They are typically lightweight, portable, and inexpensive, making them an attractive option for budget-conscious consumers. However, their performance is limited; inflating tires can be labor-intensive and time-consuming, especially for larger tires. Additionally, foot pumps often have lower PSI capabilities, which may not meet the requirements for high-performance or larger vehicles. For occasional home use, they can be a practical choice, but they may not be suitable for emergency situations where speed is critical.

Air compressor stations are commonly found at gas stations and service centers, providing a reliable source for tire inflation. They offer high-speed inflation and can typically achieve consistent PSI levels, making them suitable for heavy-duty applications. However, the cost per use can add up, especially for businesses that require frequent tire maintenance. Accessibility can also be an issue, as drivers may need to travel to find a station, which is not ideal during emergencies. Furthermore, users may encounter long wait times if the station is busy. While air compressor stations are an effective solution, they may not provide the convenience and immediacy that portable tire inflators offer.

Selecting the right tire inflation solution hinges on specific operational needs and circumstances. For businesses operating in regions with frequent roadside emergencies or requiring quick inflation, portable tire inflators are generally the most efficient choice. On the other hand, companies that prioritize cost and have lower frequency needs might consider manual foot pumps. For businesses with a high volume of vehicles or those operating in a garage environment, investing in air compressor stations could prove beneficial despite the higher maintenance and operational costs. Ultimately, B2B buyers must evaluate their unique requirements—considering factors such as performance, cost, and convenience—to make the best decision for their tire maintenance strategy.

When selecting car tire inflators for B2B procurement, understanding technical specifications is crucial for ensuring product quality and performance. Here are key properties to consider:

The inflation rate, measured in PSI (pounds per square inch), indicates how quickly a tire inflator can fill a tire to a specified pressure. For instance, a unit that can inflate a tire to 30 PSI in under three minutes is generally preferred. This property is essential for minimizing downtime and ensuring efficient service, especially in commercial settings where vehicles need to be operational quickly.

Illustrative image related to car tire inflators

Tire inflators may operate on various power sources, including AC (120V), DC (12V), or battery-operated systems. Understanding the power source is vital for compatibility with existing tools and equipment. Battery-operated inflators offer portability, while AC inflators provide consistent power for higher performance. B2B buyers should evaluate their operational environment to select the most suitable option.

The length and type of hose significantly affect usability. A longer hose allows for easier access to tires in various positions, while the type (e.g., clamp-on or screw-on) influences how securely it attaches to the tire valve. This property impacts the efficiency of tire inflation and the overall user experience, making it an important consideration for procurement.

Measured in decibels (dBA), the noise level of a tire inflator can affect workplace environments, particularly in service stations or repair shops. A quieter inflator contributes to a more comfortable working atmosphere. B2B buyers should consider noise levels, especially if the inflators will be used in close proximity to customers or employees.

The durability of a tire inflator is often determined by its material grade, which can include plastics, metals, and rubber components. Higher-grade materials typically offer better resistance to wear and tear, ensuring a longer lifespan. For B2B buyers, investing in durable inflators reduces long-term costs associated with replacements and repairs.

The weight of a tire inflator affects its portability. Lightweight models are easier to handle and store, making them ideal for emergency kits or mobile service units. Understanding the balance between weight and performance is crucial for B2B buyers, especially when considering transportation logistics.

Familiarizing oneself with industry terminology can enhance communication and negotiation with suppliers. Here are some essential trade terms relevant to tire inflators:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, understanding whether a product is OEM can affect warranty and service options. B2B buyers often prefer OEM products for their reliability and compatibility with existing systems.

MOQ is the smallest quantity of a product that a supplier is willing to sell. For tire inflators, MOQs can vary significantly between manufacturers. Knowing the MOQ helps buyers assess budget constraints and plan inventory levels effectively.

Illustrative image related to car tire inflators

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods. This process is crucial for B2B buyers to gather competitive pricing and evaluate potential suppliers for tire inflators.

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and customs duties. Understanding these terms is essential for B2B buyers engaged in cross-border procurement of tire inflators, as they dictate the cost implications and risk levels involved in shipping.

The warranty period indicates the duration for which the manufacturer guarantees the product against defects. A longer warranty period is often preferred by B2B buyers as it signifies confidence in product quality and provides assurance against unexpected failures.

Lead time refers to the time taken from placing an order until it is delivered. For businesses relying on tire inflators, understanding lead times is critical for inventory management and operational planning.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right tire inflators that meet their operational needs while optimizing costs.

The global car tire inflators market is experiencing significant growth, driven by increased vehicle ownership and rising awareness of road safety. In regions such as Africa, South America, the Middle East, and Europe, demand for portable tire inflators is escalating as consumers prioritize convenience and safety. The emergence of compact, multifunctional inflators that combine features like jump-starting capabilities and USB charging ports is particularly noteworthy. This trend reflects a shift towards products that offer added value, catering to consumers looking for efficiency and multifunctionality in their automotive tools.

B2B buyers should also be aware of the rising adoption of smart technology in tire inflators, including digital displays and automatic shut-off features that enhance usability. The integration of IoT technologies allows for real-time monitoring of tire pressure, a feature increasingly sought after by fleet operators and automotive service providers. Furthermore, the trend towards online purchasing platforms is reshaping sourcing dynamics, making it easier for international buyers to access a broader range of products. As a result, understanding these market dynamics is crucial for B2B buyers looking to stay competitive and meet evolving consumer needs.

Sustainability is becoming a central pillar in the sourcing of car tire inflators, driven by growing environmental concerns and consumer demand for eco-friendly products. The automotive industry is under increasing pressure to reduce its carbon footprint, prompting manufacturers to explore sustainable materials and production processes. B2B buyers should prioritize suppliers who are committed to ethical sourcing and sustainable practices, as this not only aligns with global sustainability goals but also enhances brand reputation.

Products that feature ‘green’ certifications, such as Energy Star or eco-labels, signal a commitment to environmental responsibility. Buyers should consider sourcing tire inflators that utilize recyclable materials and energy-efficient manufacturing processes. Additionally, the focus on durability and repairability is gaining traction, as longer-lasting products contribute to waste reduction. By aligning procurement strategies with sustainability principles, businesses can strengthen their market position and appeal to a growing demographic of environmentally conscious consumers.

The evolution of car tire inflators dates back to the early 20th century when manual pumps were the standard for tire inflation. As automotive technology advanced, the introduction of electric inflators revolutionized the market, offering greater convenience and efficiency. By the late 20th century, portable tire inflators gained popularity, driven by a growing emphasis on safety and the need for emergency preparedness.

In recent years, the market has seen a significant shift towards compact, multifunctional devices that cater to the modern consumer’s needs. The integration of digital technology, such as automatic pressure regulation and smart features, marks the latest phase in this evolution. Understanding this historical context allows B2B buyers to appreciate the technological advancements that shape current offerings and anticipate future trends in the tire inflator market.

كيف أختار نافخ الإطارات المناسب لاحتياجات عملي؟

Choosing the right tire inflator involves assessing your specific needs. Consider factors such as the inflator’s power source (battery or electric), inflation speed, portability, and versatility. If you require an inflator for commercial use, prioritize models with high inflation rates and durability. Additionally, evaluate the attachments available for various valve types and whether the inflator can handle different tire sizes. Reading reviews and comparing features from multiple suppliers can help you make an informed decision.

What is the best portable tire inflator for heavy-duty vehicles?

For heavy-duty vehicles, the Milwaukee M18 Tire Inflator is often recommended due to its super-fast inflation times and robust design. It can inflate tires to 30 psi in just over a minute, making it ideal for commercial fleets or off-road vehicles. However, ensure that you have access to the proprietary M18 battery, as it does not come included. Always check the specifications against the tire sizes of your vehicles to ensure compatibility.

What customization options are available for tire inflators?

Many manufacturers offer customization options for tire inflators, including branding, color choices, and specific attachments for different valve types. Inquire with suppliers about the possibility of customizing features to meet your operational requirements. Customization can enhance your brand visibility and ensure that the inflators meet the diverse needs of your clientele.

What are the typical minimum order quantities (MOQ) for tire inflators?

Minimum order quantities for tire inflators can vary significantly depending on the supplier and the specific model. Generally, MOQs can range from 50 to 500 units for bulk orders. It’s essential to negotiate with suppliers to find a quantity that suits your budget while still meeting your operational needs. Some manufacturers may offer lower MOQs for first-time buyers or allow sample orders.

How do I vet potential suppliers for tire inflators?

To vet potential suppliers, start by researching their reputation in the industry. Look for customer reviews, certifications, and their history in manufacturing tire inflators. Request references and verify their production capabilities and quality control processes. Additionally, consider visiting their facilities if possible, or using third-party inspection services to ensure compliance with international standards.

What payment terms should I expect when sourcing tire inflators internationally?

Payment terms can vary, but common practices include options such as 30% upfront and 70% upon delivery, or full payment before shipping. Some suppliers may offer letters of credit or escrow services for added security. Always clarify payment methods accepted (e.g., bank transfer, credit card) and ensure that terms are documented in the purchase agreement to avoid misunderstandings.

What quality assurance measures should I look for when buying tire inflators?

When purchasing tire inflators, ensure that the supplier has robust quality assurance measures in place. Look for manufacturers that adhere to international quality standards such as ISO 9001. Ask about their testing procedures, warranty policies, and return/exchange options. Request certifications or test reports to verify that the inflators meet safety and performance requirements.

What logistics considerations should I keep in mind when importing tire inflators?

Logistics considerations include understanding shipping costs, lead times, and customs regulations in your country. Work closely with your supplier to determine the best shipping method, whether by air or sea, based on your urgency and budget. Familiarize yourself with import duties and taxes applicable to tire inflators in your region to avoid unexpected costs. Establish a clear communication channel with your logistics provider to ensure timely delivery and compliance with all regulations.

المجال: martinsindustries.com

مسجل: 2005 (20 سنة)

مقدمة: Automatic Tire Inflators for Professionals, Wall-mounted and handheld options, compatible with nitrogen inflation, digital gauge for accurate pressure, various models available including: Handheld digital tire inflator – Flate Mate Handheld MH-30 ($107.72), Analog Handheld Tire Inflator – Flate Mate Analog Handheld MH-31-PSI (Pre-order $107.72), Automatic Tire Inflator – Flatematic Handheld MHA-10…

In today’s competitive automotive market, strategic sourcing of car tire inflators is crucial for B2B buyers aiming to enhance their product offerings. The diverse range of portable tire inflators, from compact models to multifunctional devices, showcases the evolving needs of consumers. Key takeaways include the importance of selecting inflators that balance speed, portability, and additional features such as battery life and ease of use. Brands like Slime and Milwaukee stand out for their innovation and reliability, making them valuable partners for distributors and retailers.

Investing in quality tire inflators not only meets customer demands but also strengthens brand reputation in emerging markets across Africa, South America, the Middle East, and Europe. The growing awareness of vehicle maintenance and safety presents a significant opportunity for B2B buyers to capitalize on high-demand products.

As the automotive landscape continues to evolve, staying ahead of market trends and consumer preferences is essential. We encourage international B2B buyers to engage with suppliers who prioritize quality and innovation in their tire inflator offerings. By making informed sourcing decisions today, you position your business for success in tomorrow’s marketplace.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.