- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the fast-evolving landscape of the global market, sourcing Hendrickson tire inflation system parts presents a unique challenge for international B2B buyers. With the increasing demand for efficient tire management solutions, navigating the complexities of procurement can be daunting. This guide serves as an essential resource, detailing the various types of Hendrickson tire inflation systems, their applications, and critical considerations for supplier vetting.

Buyers will gain insights into the cost structures associated with these components and the best practices for ensuring optimal performance in diverse environments, from the rugged terrains of Africa to the bustling logistics hubs in Europe and South America. The comprehensive nature of this guide empowers businesses to make informed purchasing decisions, minimizing downtime and maximizing operational efficiency.

By understanding the nuances of Hendrickson tire inflation systems, including installation requirements and maintenance protocols, buyers can confidently engage with suppliers, ensuring they procure the right parts tailored to their specific needs. This guide not only highlights the technical specifications of each component but also addresses the strategic implications of sourcing decisions in a competitive marketplace. With a focus on actionable insights, it equips B2B buyers with the knowledge needed to navigate the global market effectively, fostering long-term partnerships and sustainable growth.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| TIREMAAX® PRO Inflation Kit | Inflate and deflate capabilities, pre-set pressure of 110 PSI | Two-axle trailers, long-haul trucking | الإيجابيات: Enhances tire life, improves fuel efficiency. السلبيات: Higher initial investment. |

| TIREMAAX® Standard Inflation Kit | Basic inflation system, manual operation, no deflation feature | Light-duty trailers, cost-sensitive fleets | الإيجابيات: Lower cost, straightforward installation. السلبيات: Less control over tire pressure. |

| TIREMAAX® Gease Hub Caps | Integrated grease management with inflation system | Fleet maintenance, heavy-duty applications | الإيجابيات: Reduces maintenance frequency, improves performance. السلبيات: Requires specific axle compatibility. |

| TIREMAAX® Wheel End Hoses | Flexible hoses for air transfer, various lengths available | Custom installations, retrofitting | الإيجابيات: Customizable lengths, easy to replace. السلبيات: Potential for wear and tear over time. |

| TIREMAAX® Control Box | Centralized control for tire pressure management | Fleet management systems, monitoring | الإيجابيات: Centralized monitoring, alerts for pressure changes. السلبيات: Requires electrical knowledge for installation. |

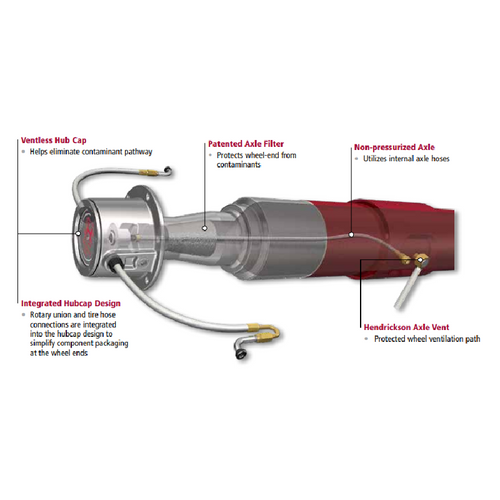

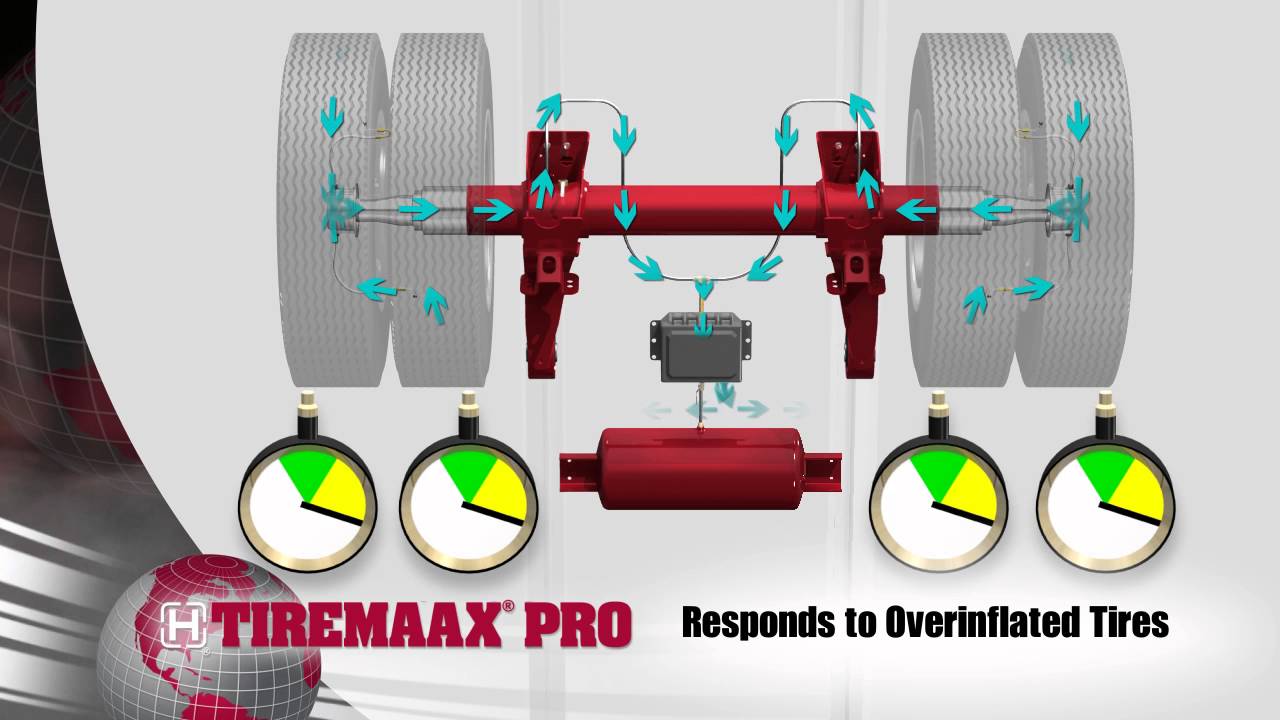

The TIREMAAX® PRO Inflation Kit is designed for two-axle trailers, featuring an inflate and deflate mechanism with a pre-set pressure of 110 PSI. This capability is particularly beneficial for long-haul trucking, where tire pressure can fluctuate significantly due to varying terrains and temperatures. The system not only extends tire life but also enhances fuel efficiency, making it a valuable investment for fleets operating in diverse conditions. Buyers should consider the upfront costs against potential savings in maintenance and fuel.

The TIREMAAX® Standard Inflation Kit offers a simpler, more cost-effective solution for light-duty trailers, operating manually without deflation features. While it is easier to install and has a lower price point, this kit lacks the advanced pressure management capabilities of the PRO version. This makes it suitable for cost-sensitive fleets that require basic inflation without the need for sophisticated monitoring. Buyers should assess their operational needs and budget when considering this option.

TIREMAAX® Gease Hub Caps integrate tire inflation with grease management, reducing the frequency of maintenance for heavy-duty applications. This system is particularly advantageous for fleets that prioritize uptime and performance. However, compatibility with specific axle types is essential, so buyers must ensure their existing equipment can accommodate these caps. The investment pays off in reduced maintenance costs and improved tire and wheel performance.

TIREMAAX® Wheel End Hoses are vital components for custom air transfer installations, available in various lengths to meet specific needs. Their flexibility allows for easy replacements and adjustments during installation, making them suitable for retrofitting existing systems. While they offer customization benefits, buyers should be aware of the potential for wear and tear, necessitating regular inspections and replacements to ensure optimal performance.

The TIREMAAX® Control Box centralizes tire pressure management, allowing fleet managers to monitor and adjust pressure levels efficiently. This system provides alerts for pressure changes, enabling proactive maintenance and reducing the risk of tire blowouts. However, installation requires some electrical knowledge, which could be a consideration for buyers lacking technical expertise. The benefits of centralized monitoring often outweigh the initial learning curve, making it a worthwhile addition for comprehensive fleet management.

Illustrative image related to hendrickson tire inflation system parts

| الصناعة/القطاع | Specific Application of hendrickson tire inflation system parts | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| النقل والخدمات اللوجستية | Fleet Management for Long-Haul Trucks | Enhanced fuel efficiency and reduced tire wear | Compatibility with existing fleet systems and regulatory standards |

| Construction | Heavy-Duty Equipment for Site Operations | Improved safety and operational efficiency | Durability in harsh environments and ease of maintenance |

| الزراعة | Agricultural Vehicles and Equipment | Optimized tire performance for varying terrains | Adaptability to different vehicle types and local environmental conditions |

| Mining & Resource Extraction | Off-Road Vehicles and Heavy Machinery | Increased uptime and reduced operational costs | Reliability under extreme conditions and availability of parts |

| Waste Management | Refuse Collection Vehicles | Reduced downtime and maintenance costs | Compliance with local regulations and service support availability |

In the transportation and logistics sector, Hendrickson tire inflation system parts are crucial for fleet management, particularly for long-haul trucks. These systems help maintain optimal tire pressure, which is vital for fuel efficiency and minimizing tire wear. By ensuring that tires are consistently inflated to the correct pressure, businesses can significantly reduce operational costs and enhance safety. International buyers should consider compatibility with their existing fleet systems and any regional regulatory standards that may apply.

In the construction industry, Hendrickson tire inflation system parts are used in heavy-duty equipment, ensuring that vehicles operate at optimal tire pressure for various site conditions. This application enhances safety by reducing the risk of tire blowouts and improves operational efficiency by minimizing downtime. Buyers in this sector should prioritize durability and ease of maintenance, as equipment often operates in harsh environments that demand high reliability.

Agricultural vehicles and equipment benefit significantly from Hendrickson tire inflation system parts, which optimize tire performance on varying terrains. Proper tire pressure is essential for effective fieldwork, impacting traction and fuel consumption. For international agricultural buyers, adaptability to different vehicle types and local environmental conditions is a key consideration when sourcing these systems.

In the mining and resource extraction sector, off-road vehicles and heavy machinery utilize Hendrickson tire inflation system parts to maintain tire pressure in challenging environments. This application leads to increased uptime and reduced operational costs, as properly inflated tires can navigate rough terrain more effectively. Buyers should focus on the reliability of these systems under extreme conditions and ensure that spare parts are readily available for maintenance.

Refuse collection vehicles leverage Hendrickson tire inflation system parts to ensure optimal tire performance, which is crucial for minimizing downtime and maintenance costs. By maintaining the correct tire pressure, these systems enhance the efficiency of waste management operations. Buyers in this sector need to consider compliance with local regulations and the availability of service support to ensure continuous operation.

المشكلة B2B buyers in the logistics and transportation sectors often face the challenge of maintaining optimal tire pressure in varying geographical and climatic conditions. For instance, a fleet operating in both mountainous regions and arid deserts may experience fluctuating tire pressure due to changes in altitude and temperature. This inconsistency can lead to uneven tire wear, increased fuel consumption, and compromised vehicle safety. Fleet managers may struggle to find a reliable solution that adapts to these environmental challenges, making it crucial to utilize a tire inflation system that can handle diverse scenarios.

الحل: The Hendrickson Tiremaax PRO Inflation Kit is specifically designed to address this issue with its innovative inflate-and-deflate feature. By maintaining a constant pressure of 110 PSI, this system automatically adjusts tire pressure based on real-time conditions, ensuring optimal performance regardless of the environment. To effectively implement this solution, fleet managers should ensure that their trailers are equipped with the right components, such as the control box harness and wheel end hoses included in the kit. Regular training for maintenance personnel on the system’s operation will also enhance the effectiveness of this solution, allowing for quicker troubleshooting and adjustments as needed.

المشكلة Many buyers encounter difficulties during the installation and maintenance of tire inflation systems. This complexity can stem from a lack of technical knowledge or inadequate instructions, leading to potential installation errors that compromise system performance. For instance, misidentifying connections or improperly installing hoses can result in leaks or malfunctions. This not only incurs additional costs for repairs but also impacts the operational efficiency of the fleet, which relies on consistent tire pressure for safe and economical operation.

الحل: To mitigate these installation challenges, it is essential to utilize the detailed installation instructions provided with the Hendrickson Tiremaax PRO Kit. Buyers should consider investing time in understanding the components and their functions, as well as following the step-by-step guide that accompanies the kit. Additionally, reaching out to Hendrickson’s customer service for technical support can provide real-time assistance during installation. For those less confident in their installation skills, partnering with a certified technician or service provider who is familiar with Hendrickson products can ensure that the system is installed correctly and efficiently, minimizing the risk of future maintenance issues.

Illustrative image related to hendrickson tire inflation system parts

المشكلة B2B buyers often struggle with sourcing the correct tire inflation system parts tailored to specific axle configurations. With various types of Hendrickson axles available, such as the HN tapered spindles, identifying the right parts can be time-consuming and confusing. This misalignment can lead to purchasing errors that not only delay operations but also increase costs as buyers may need to return or exchange incorrectly sourced parts.

الحل: To effectively source the appropriate parts, buyers should first familiarize themselves with the specific axle configurations used in their fleet. The Hendrickson Tiremaax Parts List provides a comprehensive overview of compatible parts for various axle types. Buyers can streamline the sourcing process by utilizing the resources available on the Hendrickson website, such as the online parts catalog, or by consulting with a knowledgeable distributor. Furthermore, proactive communication with suppliers about their specific needs and configurations will enable them to receive tailored recommendations, ensuring that they acquire the correct components without unnecessary delays. Regularly reviewing parts compatibility as fleet configurations evolve will help maintain operational efficiency and cost-effectiveness in the long run.

When selecting materials for Hendrickson tire inflation system parts, it’s essential to consider their properties, advantages, and disadvantages. The most commonly used materials include aluminum, stainless steel, rubber, and composite materials. Each material has unique characteristics that affect performance, durability, and suitability for specific applications.

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 150°C (302°F) and can withstand moderate pressure, making it suitable for various tire inflation components.

الإيجابيات: Aluminum is durable, lightweight, and cost-effective compared to other metals. Its resistance to corrosion is particularly beneficial in environments with high humidity or exposure to road salts.

السلبيات: While aluminum is strong, it may not withstand very high pressures compared to steel. It can also be more susceptible to wear and tear under heavy loads.

التأثير على التطبيق: Aluminum is compatible with air and nitrogen, making it suitable for tire inflation systems. However, it may not be ideal for applications involving aggressive chemicals.

اعتبارات للمشترين الدوليين: Buyers in regions like Africa and South America should ensure compliance with local standards for aluminum alloys, such as ASTM or EN specifications.

Stainless steel is renowned for its strength and resistance to corrosion, especially in harsh environments. It can handle high temperatures (up to 870°C or 1600°F) and high pressures, making it an excellent choice for critical components in tire inflation systems.

الإيجابيات: Stainless steel’s durability and longevity make it suitable for heavy-duty applications. Its resistance to rust and corrosion ensures reliability over time.

السلبيات: The primary drawback is its higher cost compared to aluminum and rubber. Additionally, stainless steel can be heavier, which may affect overall vehicle weight.

التأثير على التطبيق: Stainless steel is compatible with various gases and fluids, making it versatile for tire inflation systems. Its robustness ensures it can handle extreme conditions without compromising performance.

اعتبارات للمشترين الدوليين: Buyers from Europe and the Middle East should verify compliance with standards such as DIN and ISO for stainless steel grades used in tire inflation systems.

Rubber is commonly used for seals, hoses, and grommets in tire inflation systems due to its flexibility and resilience. It typically operates effectively within a temperature range of -40°C to 100°C (-40°F to 212°F) and can withstand moderate pressure.

الإيجابيات: Rubber’s flexibility allows it to absorb vibrations and impacts, making it ideal for parts that require movement. It is also relatively inexpensive and widely available.

السلبيات: Rubber can degrade over time when exposed to UV light, ozone, and certain chemicals. Its lifespan may be shorter compared to metals.

التأثير على التطبيق: Rubber is suitable for air and nitrogen but may not be compatible with all chemicals. Its performance can be affected by environmental factors.

اعتبارات للمشترين الدوليين: Buyers should consider the specific rubber grades and their compliance with local standards, particularly in regions with extreme weather conditions.

Composite materials, often made from a combination of fibers and resins, are increasingly used in tire inflation systems. They offer a unique blend of lightweight properties and high strength, with temperature ratings varying depending on the resin used.

Illustrative image related to hendrickson tire inflation system parts

الإيجابيات: Composites are lightweight and resistant to corrosion, making them ideal for applications where weight reduction is critical. They can also be molded into complex shapes.

السلبيات: The manufacturing process for composites can be more complex and costly than traditional materials. They may also have limitations in pressure resistance compared to metals.

التأثير على التطبيق: Composites can be suitable for various environments but may not be ideal for high-pressure applications unless specifically designed for such use.

اعتبارات للمشترين الدوليين: Buyers should check for compliance with international standards and certifications relevant to composite materials, especially in Europe and the Middle East.

Illustrative image related to hendrickson tire inflation system parts

| المواد | Typical Use Case for Hendrickson Tire Inflation System Parts | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | Hoses and brackets | خفيف الوزن ومقاوم للتآكل | Susceptible to wear under heavy loads | متوسط |

| الفولاذ المقاوم للصدأ | High-pressure fittings and valves | قوة ومتانة عالية | Higher cost and weight | عالية |

| المطاط | Seals and flexible hoses | Flexibility and vibration absorption | Degrades under UV and ozone exposure | منخفضة |

| مركب | Lightweight structural components | Lightweight and customizable shapes | Complex manufacturing and potential pressure limits | متوسط |

The manufacturing of Hendrickson tire inflation system parts involves several critical stages, each designed to ensure the highest quality and performance standards. Understanding these stages is essential for B2B buyers, particularly those in international markets, to assess the reliability and functionality of the components they procure.

The first stage in the manufacturing process involves the careful selection and preparation of raw materials. Typically, materials such as high-strength steel and durable polymers are chosen for their resistance to wear and environmental factors. Suppliers often source these materials from certified vendors to ensure compliance with international standards.

Once the materials are selected, they undergo various preparatory processes, including cutting, milling, and surface treatment. These processes enhance the material properties and prepare them for the forming stage. Quality checks at this stage include verifying material specifications against industry standards, ensuring that only materials meeting stringent requirements proceed to the next stage.

The forming stage utilizes advanced techniques such as stamping, forging, and injection molding to shape the parts. For instance, steel components may be forged to achieve the necessary strength and durability, while plastic parts are often produced through injection molding to ensure precision and consistency.

Modern manufacturing facilities employ Computer Numerical Control (CNC) machines to automate these processes, enhancing accuracy and reducing human error. This stage is crucial as it directly affects the fit and functionality of the tire inflation system components. Rigorous inspections are performed during and after forming to ensure dimensional accuracy and surface quality.

Following the forming stage, components are assembled into the final product. This step often requires skilled labor and specialized tools, particularly for complex systems like the Tiremaax® Pro Inflation Kit. The assembly process must adhere to specific protocols to ensure that all parts fit together seamlessly and function as intended.

Quality assurance during assembly involves checking for proper alignment, secure fittings, and operational functionality. Automated systems may also be used to monitor assembly parameters, minimizing the risk of defects. Each assembly line typically has its checkpoints, where quality control personnel verify compliance with assembly specifications.

The finishing stage encompasses processes such as painting, coating, and final inspections. These processes not only enhance the aesthetic appeal of the products but also provide protective layers against environmental factors. For instance, corrosion-resistant coatings are often applied to metal parts to extend their lifespan.

Before final packaging, products undergo a series of inspections and tests to ensure they meet predefined quality standards. This includes functional testing to verify that the inflation systems operate correctly under various conditions. Detailed documentation of these tests is crucial for traceability and quality assurance.

Quality assurance is paramount in the manufacturing of tire inflation system parts. Buyers must understand the international standards that govern these processes to ensure they are sourcing high-quality products.

One of the most recognized quality management standards is ISO 9001. Compliance with this standard indicates that a manufacturer has established effective quality management systems, ensuring consistent product quality and customer satisfaction. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the specific application and market requirements.

Quality control (QC) is integrated into various stages of manufacturing, typically categorized into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

مراقبة الجودة الواردة (IQC): This stage involves inspecting raw materials and components upon receipt to ensure they meet specifications before entering the manufacturing process.

مراقبة الجودة أثناء العملية (IPQC): During manufacturing, ongoing checks are performed at different stages to monitor processes and identify defects early. This proactive approach helps minimize waste and rework.

مراقبة الجودة النهائية (FQC): The final inspection involves comprehensive testing and verification of the finished products against quality standards and specifications. This is crucial for ensuring the reliability and performance of tire inflation systems.

B2B buyers must take proactive steps to verify the quality control measures employed by their suppliers. Here are several strategies to consider:

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers can schedule regular audits to evaluate compliance with international standards and internal quality policies. During these audits, buyers should review documentation, inspect facilities, and engage with quality assurance personnel to gain insights into the manufacturing processes.

Requesting quality assurance reports from suppliers can provide valuable insights into their QC practices. These reports should detail inspection results, compliance with standards, and corrective actions taken for any identified issues. Additionally, engaging third-party inspection services can offer an unbiased assessment of supplier quality, providing further assurance to buyers.

When sourcing from international suppliers, buyers must navigate various quality assurance nuances influenced by regional standards and practices.

Illustrative image related to hendrickson tire inflation system parts

Different regions may have specific regulations that impact the quality assurance process. For example, European buyers often require CE certification for compliance with EU safety standards, while buyers in other regions may have different requirements. Understanding these regional standards is crucial for ensuring that purchased components are compliant with local regulations.

Buyers should inquire about the quality certifications held by their suppliers and verify their authenticity. Certifications should be current and relevant to the products being sourced. Furthermore, understanding the processes behind these certifications can provide deeper insights into a supplier’s commitment to quality.

By comprehensively understanding the manufacturing processes and quality assurance standards associated with Hendrickson tire inflation system parts, international B2B buyers can make informed decisions that align with their operational needs and quality expectations.

The procurement of Hendrickson tire inflation system parts is a critical process for businesses aiming to maintain efficiency and safety in their operations. This guide provides a structured approach to help international B2B buyers navigate the sourcing of these essential components.

Establishing clear technical specifications is vital to ensure that you procure the right parts for your needs. Consider factors such as the type of vehicles or trailers you operate, the specific models of Hendrickson axles, and the required pressure settings for the tire inflation system. Documenting these details helps streamline the procurement process and minimizes the risk of purchasing incompatible parts.

Identifying reliable suppliers is crucial for obtaining quality parts. Conduct thorough research to find vendors that specialize in Hendrickson tire inflation systems. Look for suppliers with a solid reputation, positive customer reviews, and a proven track record of delivering high-quality products.

Before committing to a supplier, it’s essential to conduct a comprehensive evaluation. Request detailed company profiles, product catalogs, and case studies that demonstrate their capabilities and past performance.

Understanding pricing structures and payment terms is critical for budgeting and financial planning. Request quotes from multiple suppliers to compare costs effectively.

Before finalizing your order, confirm the availability of the specific parts you need and the expected lead times for delivery.

Once you have selected a supplier, it’s time to finalize contracts. Ensure that all agreed-upon terms are documented, including pricing, delivery schedules, and warranty information.

By following this structured checklist, B2B buyers can efficiently navigate the sourcing of Hendrickson tire inflation system parts, ensuring they make informed decisions that enhance operational reliability and safety.

When considering the sourcing of Hendrickson tire inflation system parts, understanding the comprehensive cost structure is crucial for international buyers. The total cost can be broken down into several key components, each influencing the overall pricing and procurement strategy.

المواد: The primary materials involved in the production of tire inflation system components include high-quality plastics, metals, and rubber. The choice of materials significantly impacts both the durability and performance of the parts, leading to variations in pricing based on quality and source.

العمالة: Labor costs encompass the wages of skilled workers involved in manufacturing and assembly. In regions where labor is more affordable, such as parts of South America and Africa, this can lower overall costs. However, specialized skills may command higher wages, particularly in Europe.

نفقات التصنيع الزائدة: This includes the costs associated with running the production facility, such as utilities, maintenance, and administrative expenses. Higher overhead costs can lead to increased prices, particularly in regions with stringent regulations or higher operational costs.

الأدوات: Tooling costs refer to the investment in molds and equipment necessary for production. Custom tooling can be a significant upfront cost but may reduce per-unit costs over time for large orders.

مراقبة الجودة (QC): Ensuring that components meet industry standards involves quality assurance processes, which can add to the overall cost. Certifications and compliance with international standards are critical factors that influence pricing.

الخدمات اللوجستية: Shipping costs can vary significantly based on the distance from the supplier, the mode of transportation, and the Incoterms agreed upon. Buyers should factor in both inbound logistics (from suppliers to manufacturers) and outbound logistics (from manufacturers to end-users).

الهامش: Suppliers typically include a profit margin in their pricing. This margin can vary based on market demand, competition, and the exclusivity of the parts being sourced.

Several factors influence pricing beyond the basic cost structure:

الحجم/الكمية (الحد الأدنى لكمية الطلب): Higher order volumes often lead to lower per-unit costs. Buyers should assess their needs carefully to determine the most cost-effective order size.

المواصفات والتخصيص: Custom parts tailored to specific applications may incur additional costs. Buyers should consider whether standard parts can meet their needs to avoid unnecessary expenses.

عوامل الموردين: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer competitive pricing to gain market share.

المصطلحات التجارية الدولية: The choice of Incoterms affects shipping responsibilities and costs. Buyers should negotiate terms that minimize their exposure to unexpected fees and delays.

التفاوض: Engage suppliers in discussions about pricing and explore options for discounts based on volume or long-term contracts. Building a good relationship can lead to better terms.

كفاءة التكلفة: Assess the total cost of ownership rather than just the purchase price. Consider factors such as maintenance, durability, and performance to make informed decisions.

Pricing Nuances for International Buyers: Be aware of regional pricing variations and economic factors that may influence costs. For instance, tariffs and import duties can significantly impact final costs for buyers in Africa and South America.

Market Research: Conduct thorough market research to understand pricing trends and identify the best suppliers. This knowledge can empower buyers during negotiations and sourcing decisions.

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always verify the latest pricing directly with suppliers to ensure accuracy and relevance to your sourcing needs.

In the realm of tire inflation systems, various solutions exist to maintain optimal tire pressure, which is crucial for vehicle performance, fuel efficiency, and safety. This section explores how Hendrickson tire inflation system parts compare with alternative solutions available in the market. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific operational needs.

| جانب المقارنة | Hendrickson Tire Inflation System Parts | Tire Pressure Monitoring Systems (TPMS) | Manual Tire Inflation Systems |

|---|---|---|---|

| الأداء | Automatic inflation and deflation; maintains constant pressure; proven reliability in various conditions. | Monitors pressure but does not inflate; alerts when pressure is low. | Requires manual checks and adjustments; less reliable for consistent pressure. |

| التكلفة | Higher initial investment (approx. $1,349.99 for a complete kit). | Moderate cost, generally lower than automated systems. | Low initial cost but may incur higher long-term costs due to tire wear. |

| سهولة التنفيذ | Straightforward installation; may require basic knowledge of trailer air systems. | Simple installation; often plug-and-play systems available. | Labor-intensive; requires regular manual intervention. |

| الصيانة | Low maintenance; designed for long-term use with minimal upkeep. | Moderate maintenance; sensors may require periodic battery replacements. | High maintenance; frequent manual checks and potential for human error. |

| أفضل حالة استخدام | Ideal for long-haul trucking and operations in varied terrains. | Best for fleets needing monitoring without automation; suitable for short-haul operations. | Suitable for smaller vehicles or operations with limited budgets. |

Tire Pressure Monitoring Systems (TPMS) provide a digital solution for tire pressure monitoring. They are designed to alert drivers when tire pressure falls below a preset threshold. The primary advantage of TPMS is its cost-effectiveness compared to automated systems like the Hendrickson Tire Inflation System. However, it lacks the capability to actively inflate or deflate tires, which can lead to increased tire wear if not monitored diligently. TPMS is best suited for fleets that prioritize monitoring over automation and may not operate in challenging terrains.

Manual tire inflation systems are the most basic form of tire maintenance, requiring drivers to check and adjust tire pressure manually. The major advantage of this system is its low cost and simplicity. However, it demands significant time and labor, leading to potential inefficiencies and increased risk of human error. As a result, while manual systems can be appropriate for smaller fleets or those with budget constraints, they fall short in terms of performance and long-term reliability compared to automated solutions like the Hendrickson system.

When selecting a tire inflation system, B2B buyers should carefully consider their specific operational requirements, including the type of vehicles in use, the terrain they operate in, and their budget constraints. For fleets that prioritize efficiency and safety, investing in Hendrickson tire inflation system parts may yield significant long-term benefits despite the higher upfront cost. Conversely, for businesses with tighter budgets or those operating in less demanding environments, TPMS or manual systems may provide adequate solutions. Ultimately, the choice should align with the operational goals and maintenance capabilities of the fleet.

Illustrative image related to hendrickson tire inflation system parts

When considering Hendrickson tire inflation system parts, several technical properties are vital for ensuring optimal performance and compatibility with various vehicle models. Below are essential specifications that international B2B buyers should understand:

درجة المادة

– The materials used in tire inflation systems, such as high-grade steel or aluminum, dictate durability and resistance to environmental factors. Materials must withstand high pressure and varying temperatures, especially in regions with extreme weather conditions. A robust material grade ensures long-term reliability, reducing maintenance costs and downtime.

Pressure Tolerance

– Each tire inflation component is designed to operate within specific pressure limits, typically ranging from 70 to 110 PSI for the TIREMAAX systems. Understanding pressure tolerance is crucial for safe operation and prevents premature failure or accidents due to over-inflation or under-inflation. Proper pressure management contributes to improved fuel efficiency and tire longevity.

Compatibility Standards

– Components must meet industry standards for compatibility with different axle types, particularly Hendrickson’s HN spindles. Ensuring that parts align with OEM specifications is critical for seamless integration into existing systems. Compatibility reduces the risk of installation errors and enhances overall system performance.

Installation Requirements

– Many tire inflation systems come with specific installation instructions and may require additional tools or components, such as power harnesses and control boxes. Understanding these requirements can streamline the procurement process and ensure that buyers are prepared for installation without incurring unexpected costs.

سعة الوزن

– The weight capacity of tire inflation system components is essential for maintaining the vehicle’s overall load-bearing capacity. Buyers should be aware of the weight limitations to ensure compliance with regional transportation regulations and to optimize vehicle performance.

الضمان والدعم

– A robust warranty and reliable customer support are critical in the B2B space. Understanding warranty terms can help buyers assess the long-term value and reliability of their investment in Hendrickson tire inflation system parts.

Navigating the purchasing process for tire inflation system parts involves familiarity with industry jargon. Here are some key terms that B2B buyers should know:

OEM (الشركة المصنعة للمعدات الأصلية)

– OEM parts are components made by the original manufacturer of the vehicle or system. Using OEM parts ensures compatibility and performance, which is particularly important for maintaining warranty coverage and optimal system functionality.

موك (الحد الأدنى لكمية الطلب)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for companies that require parts in bulk or across multiple locations.

طلب عرض الأسعار (RFQ)

– An RFQ is a standard business process where buyers request pricing information from suppliers for specific parts. This term is critical for negotiating costs and ensuring that procurement teams can compare offers effectively.

إنكوترمز (الشروط التجارية الدولية)

– Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers mitigate risks and understand their obligations during the import/export process.

المهلة الزمنية

– Lead time is the period from when an order is placed until it is delivered. Understanding lead times is crucial for supply chain planning and inventory management, especially in industries where timely delivery is essential for operational continuity.

Aftermarket Parts

– Aftermarket parts are components produced by third-party manufacturers that are not made by the original manufacturer. While often cheaper, they may vary in quality and compatibility, so buyers should evaluate their options carefully based on performance requirements and warranty considerations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Hendrickson tire inflation system parts, ultimately leading to better operational efficiency and cost management.

The global market for Hendrickson tire inflation system parts is influenced by several key drivers, including increasing demand for efficiency in fleet operations and enhanced safety measures. As transportation costs rise, businesses seek solutions that improve fuel efficiency and extend tire life, driving the adoption of advanced tire inflation systems. In regions like Africa and South America, where logistics and transportation infrastructure are rapidly evolving, the demand for reliable tire management solutions is expected to surge. Similarly, in Europe, particularly Germany, regulatory pressures for sustainability and safety in transportation are prompting fleet operators to invest in sophisticated tire pressure management systems.

Emerging technologies, such as IoT-enabled tire monitoring systems, are revolutionizing the sourcing landscape. These technologies allow real-time data collection and analytics, enabling businesses to make informed decisions regarding tire maintenance and replacement. Moreover, the integration of artificial intelligence in supply chain management is streamlining sourcing processes, making it easier for international buyers to identify and procure the right parts efficiently. Additionally, the trend towards digital marketplaces is reshaping how companies interact with suppliers, facilitating faster transactions and improved transparency.

Sustainability has become a critical focus in the sourcing of Hendrickson tire inflation system parts, reflecting a broader shift in global supply chains towards environmentally responsible practices. The environmental impact of tire waste and the energy-intensive nature of tire production are prompting companies to seek out suppliers who prioritize sustainability. This includes sourcing parts made from recycled materials or those that minimize waste during production.

The importance of ethical supply chains cannot be overstated. International buyers are increasingly demanding transparency regarding the sourcing of materials, with a keen eye on labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and other “green” labels are becoming essential for suppliers aiming to establish credibility in the market. As businesses in Africa, South America, the Middle East, and Europe pursue sustainable practices, those who prioritize ethical sourcing will not only enhance their brand reputation but also meet the growing consumer demand for environmentally friendly products.

The evolution of Hendrickson tire inflation systems can be traced back to the growing recognition of the importance of tire management in enhancing fleet efficiency and safety. Initially, tire inflation systems were manual, requiring regular checks and adjustments by drivers. However, as the trucking industry faced increasing pressures related to fuel costs and safety regulations, the need for automated solutions became evident.

Hendrickson responded to this demand by developing advanced tire inflation systems like TIREMAAX, which automates the inflation and deflation process to maintain optimal tire pressure. This innovation not only extends tire life but also contributes to fuel savings and improved vehicle safety. Over the years, the integration of technology into these systems has further transformed the market, enabling real-time monitoring and data analytics, which have become essential tools for fleet operators in making informed maintenance decisions. As the industry continues to evolve, the focus on sustainability and efficiency will likely drive further innovations in tire inflation system parts.

1. How do I ensure the quality of Hendrickson tire inflation system parts?

To ensure the quality of Hendrickson tire inflation system parts, it’s essential to source from reputable suppliers with a proven track record. Request certifications, such as ISO 9001, which indicates adherence to quality management principles. Additionally, consider conducting audits or requesting product samples for testing. Establishing a relationship with manufacturers who provide detailed product specifications and warranties can also help maintain quality assurance. Lastly, customer reviews and feedback can provide insights into the reliability of the parts and the supplier’s service.

2. What are the typical lead times for ordering Hendrickson tire inflation system parts?

Lead times for ordering Hendrickson tire inflation system parts can vary based on several factors, including the supplier’s location, the parts’ availability, and the order size. Generally, expect lead times ranging from two weeks to several months for customized orders. It is advisable to discuss timelines with your supplier upfront and consider potential delays due to customs or logistics, especially for international shipments. For urgent needs, inquire about expedited shipping options and whether the supplier can accommodate rush orders.

3. What payment terms should I expect when sourcing Hendrickson parts internationally?

Payment terms for international sourcing of Hendrickson parts typically range from advance payment to net 30 or net 60 days, depending on the supplier’s policies and the buyer’s creditworthiness. Many suppliers may require a deposit upon order confirmation, with the balance due before shipment or upon delivery. It is prudent to negotiate terms that align with your cash flow and ensure that payment methods are secure, such as using letters of credit or escrow services, to mitigate risks associated with international transactions.

4. Are there minimum order quantities (MOQs) for Hendrickson tire inflation system parts?

Minimum order quantities (MOQs) for Hendrickson tire inflation system parts can vary significantly depending on the supplier and the specific parts being ordered. Some suppliers may have MOQs as low as a single unit, while others may require larger quantities to justify production or shipping costs. When negotiating with suppliers, clarify their MOQ policies and explore options for consolidating orders to meet these requirements. Additionally, consider collaborating with other businesses to combine orders, which can help reduce costs and meet MOQ thresholds.

5. How can I customize Hendrickson tire inflation system parts to fit my needs?

Customization of Hendrickson tire inflation system parts often involves discussing specific requirements with your supplier. Many manufacturers offer tailored solutions, such as different pressure settings or configurations based on your operational needs. Provide detailed specifications and performance requirements to the supplier, and inquire about their capabilities for customization. Be aware that custom parts may involve longer lead times and higher costs, so plan accordingly and ensure that the supplier can meet your quality standards.

6. What should I consider when vetting suppliers for Hendrickson parts?

When vetting suppliers for Hendrickson tire inflation system parts, consider their experience, reputation, and capacity to meet your specific needs. Check for industry certifications, such as ISO standards, and ask for references from other clients. Evaluate their customer service responsiveness, as effective communication is vital for resolving issues. Additionally, assess their logistics capabilities, including shipping options and delivery times, to ensure they can meet your timelines. A thorough due diligence process will help mitigate risks in your supply chain.

7. What logistics challenges should I be aware of when importing Hendrickson parts?

Importing Hendrickson tire inflation system parts may present logistics challenges such as customs clearance, shipping delays, and tariff implications. Familiarize yourself with the import regulations specific to your country, including documentation requirements and potential duties. Work closely with your logistics provider to streamline the shipping process and consider options for air versus sea freight based on urgency and cost. Additionally, keep an eye on global shipping trends that may impact delivery times and costs, especially in the context of international trade disruptions.

8. How do I handle warranty claims for Hendrickson tire inflation system parts?

Handling warranty claims for Hendrickson tire inflation system parts requires a clear understanding of the warranty terms provided by the supplier. Review the warranty policy carefully to know what is covered, the duration, and the process for filing a claim. Maintain detailed records of purchases, installation, and maintenance to support your claim. If issues arise, communicate promptly with the supplier, providing necessary documentation and evidence of the defect. Establishing a strong relationship with the supplier can facilitate smoother claims processing and resolution.

المجال: parts.ectts.com

مسجل: 1999 (26 سنة)

مقدمة: TIREMAXX Tire Inflation Kit 19.5 | Hendrickson

– Price: $799.00

– SKU: 15392

– Weight: 0.00 LBS

– Shipping: Free Shipping

– Features:

– Designed for 19.5 in. wheels

– Enhances tire life

– Reduces maintenance

– Conserves fuel

– Trims labor costs

– Automatic tire inflation system

– Draws from trailer air supply

– Simple mechanical design (no pressure switches, electronics, or transd…

Strategic sourcing for Hendrickson tire inflation system parts is not just about procurement; it’s about enhancing operational efficiency and maximizing return on investment. By leveraging the right suppliers and understanding the unique specifications of products like the TIREMAAX PRO Inflation Kit, businesses can ensure optimal tire performance, reduce maintenance costs, and enhance fleet safety.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should prioritize sourcing strategies that align with their logistical and operational needs. This may include evaluating local distributors for faster delivery times or considering bulk purchasing to benefit from economies of scale.

As the global market continues to evolve, embracing technological advancements in tire management will be critical. Investing in high-quality tire inflation systems not only supports sustainability goals but also positions companies to adapt to future challenges.

For buyers looking to stay ahead, now is the time to engage with trusted suppliers and explore innovative tire inflation solutions. By doing so, you can ensure that your fleet remains competitive and efficient in an ever-changing marketplace.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.