- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In an increasingly interconnected world, sourcing effective solutions for Tesla tire inflation presents a unique challenge for international B2B buyers. With the growing popularity of electric vehicles, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of tire maintenance, including inflation methods and equipment, is crucial for optimizing performance and safety. This comprehensive guide addresses the multifaceted aspects of Tesla tire inflation, covering essential topics such as types of inflation systems, applications of air compressors, supplier vetting processes, and cost considerations.

Navigating the global market requires a strategic approach, especially when considering the diverse climates and road conditions that affect tire performance. By delving into the specifications and functionalities of products like the Air Compressor + Tire Repair Kit 3.0, this guide empowers B2B buyers to make informed decisions that enhance their fleet’s operational efficiency. Additionally, it highlights best practices for tire maintenance, ensuring that businesses can mitigate risks associated with tire failure and improve overall vehicle longevity.

With actionable insights and authoritative recommendations, this guide serves as a vital resource for businesses looking to enhance their understanding of Tesla tire inflation solutions. It not only equips buyers with the knowledge to select the right products but also fosters confidence in their purchasing decisions, ultimately driving success in the competitive automotive landscape.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Standard Air Inflation | Utilizes regular air compressors; widely available. | General vehicle maintenance services. | الإيجابيات: Readily accessible; low cost. السلبيات: May require frequent checks and adjustments. |

| Nitrogen Inflation | Uses nitrogen gas, offering better pressure retention. | Fleet management and high-performance vehicles. | الإيجابيات: Reduces tire wear; improves fuel efficiency. السلبيات: Higher initial cost; limited availability. |

| Tesla Air Compressor Kit | Specifically designed for Tesla vehicles; includes sealant. | Emergency roadside assistance services. | الإيجابيات: Tailored for Tesla; compact and portable. السلبيات: Temporary solution; not a permanent fix. |

| Smart Tire Pressure Monitoring | Integrates with vehicle systems for real-time monitoring. | Advanced fleet operations and logistics. | الإيجابيات: Enhanced safety; proactive maintenance alerts. السلبيات: Requires initial investment; potential for technical issues. |

| Mobile Tire Inflation Services | On-site tire inflation services using portable equipment. | Automotive service providers and roadside assistance. | الإيجابيات: Convenience; saves time for businesses. السلبيات: May be more expensive than DIY options. |

Standard air inflation is the most common method used for tire maintenance, where regular air compressors are utilized to inflate tires. This method is widely accessible and cost-effective, making it suitable for general maintenance services. However, businesses should be aware that standard air may require more frequent checks, particularly in varying climate conditions. For B2B buyers, investing in high-quality air compressors can ensure reliability and efficiency in service delivery.

Nitrogen inflation is gaining traction, especially among fleet management and high-performance vehicle sectors. This method uses nitrogen gas, which provides better pressure retention and reduces tire wear. While the initial investment may be higher, the long-term benefits, such as improved fuel efficiency and longer tire life, can offset the costs. B2B buyers should evaluate the availability of nitrogen inflation services in their region to maximize this technology’s benefits.

The Tesla Air Compressor Kit is specifically designed for Tesla vehicles and comes with a tire sealant for emergency situations. This kit is particularly useful for roadside assistance services that cater to Tesla owners. While it offers convenience and portability, it is important to note that this kit serves as a temporary solution and should not replace professional tire repairs. B2B buyers should consider stocking these kits for enhanced customer service offerings.

Smart tire pressure monitoring systems integrate with vehicle systems to provide real-time tire pressure data, improving safety and proactive maintenance. This technology is particularly beneficial for advanced fleet operations and logistics companies that require detailed vehicle performance data. Although the initial investment may be substantial, the long-term safety and efficiency benefits can justify the costs. B2B buyers should assess their operational needs to determine if this technology aligns with their business objectives.

Mobile tire inflation services offer convenience by bringing tire maintenance directly to the location of the vehicle. This service is ideal for automotive service providers and roadside assistance companies that aim to save time for their clients. While mobile services may come at a premium compared to traditional methods, the time saved and increased customer satisfaction can be worth the investment. B2B buyers should evaluate their operational capabilities to determine if incorporating mobile services is feasible and beneficial.

| الصناعة/القطاع | Specific Application of Tesla Tire Inflation | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Mobile tire inflation service | Enhances service offerings and customer satisfaction | Compatibility with various Tesla models, ease of use, reliable performance |

| الخدمات اللوجستية والنقل | Fleet maintenance | Reduces downtime and increases operational efficiency | Bulk purchasing options, warranty and support services, maintenance training |

| Car Rentals | On-site tire maintenance | Improves vehicle safety and reliability for customers | Lightweight and portable solutions, ease of storage, quick inflation time |

| Construction | Maintenance for heavy machinery tires | Ensures safety and operational continuity on job sites | Adaptability to different tire sizes, rugged design, high PSI capability |

| خدمات الطوارئ | Rapid response tire repair | Minimizes response time and enhances service reliability | Durability under various environmental conditions, compact design for easy transport |

In automotive repair, Tesla tire inflation kits are employed in mobile tire services. Technicians utilize the air compressor and sealant to quickly address tire issues on-site, enhancing customer satisfaction through immediate service. B2B buyers in this sector must consider compatibility with various Tesla models and the ease of operation, ensuring that technicians can efficiently perform repairs without extensive training.

Illustrative image related to tesla tire inflation

In logistics and transportation, maintaining fleet vehicle tire pressure is critical for operational efficiency. Tesla tire inflation tools allow fleet managers to conduct regular tire maintenance, reducing the risk of tire-related breakdowns that can lead to costly downtimes. Businesses should prioritize bulk purchasing options and reliable after-sales support to ensure consistent availability and effective maintenance training for their staff.

Car rental agencies can benefit significantly from Tesla tire inflation solutions by offering on-site tire maintenance. This capability improves vehicle safety, ensuring that customers receive well-maintained vehicles. When sourcing these products, rental companies should look for lightweight, portable solutions that can be easily stored within vehicles, along with quick inflation capabilities to minimize service time.

In the construction industry, tire inflation kits are essential for maintaining heavy machinery and vehicles used on-site. Regular tire maintenance helps prevent accidents and equipment failures, ensuring continuous operation. Buyers in this sector should focus on the adaptability of the inflation tools to various tire sizes, as well as their rugged design to withstand harsh job site conditions and high PSI capabilities for heavy-duty applications.

Emergency services rely on quick response times, making Tesla tire inflation tools invaluable for rapid tire repairs. These kits enable first responders to address tire issues promptly, ensuring that vehicles remain operational during critical missions. When sourcing these tools, organizations should prioritize durability under diverse environmental conditions and a compact design for easy transport, allowing for efficient use in emergency situations.

المشكلة For B2B buyers operating fleets of Tesla vehicles in remote regions—such as rural areas in Africa or South America—access to specialized tire inflation equipment can be a significant challenge. Many gas stations or service centers may not have the appropriate tools, like a Tesla-compatible air compressor, leading to potential downtime for vehicles. In addition, these buyers may lack the knowledge to effectively use standard air pumps without risking over-inflation or damaging the tires.

الحل: To address this issue, B2B buyers should invest in the Tesla Air Compressor + Tire Repair Kit 3.0, which is specifically designed for Tesla vehicles. This kit not only allows for easy inflation but also includes a sealant for minor repairs. Buyers can establish a routine maintenance protocol that includes training staff on how to operate this compressor safely and effectively. Furthermore, creating a network with local tire specialists who understand Tesla requirements will ensure that any complex issues can be addressed swiftly, minimizing vehicle downtime and enhancing operational efficiency.

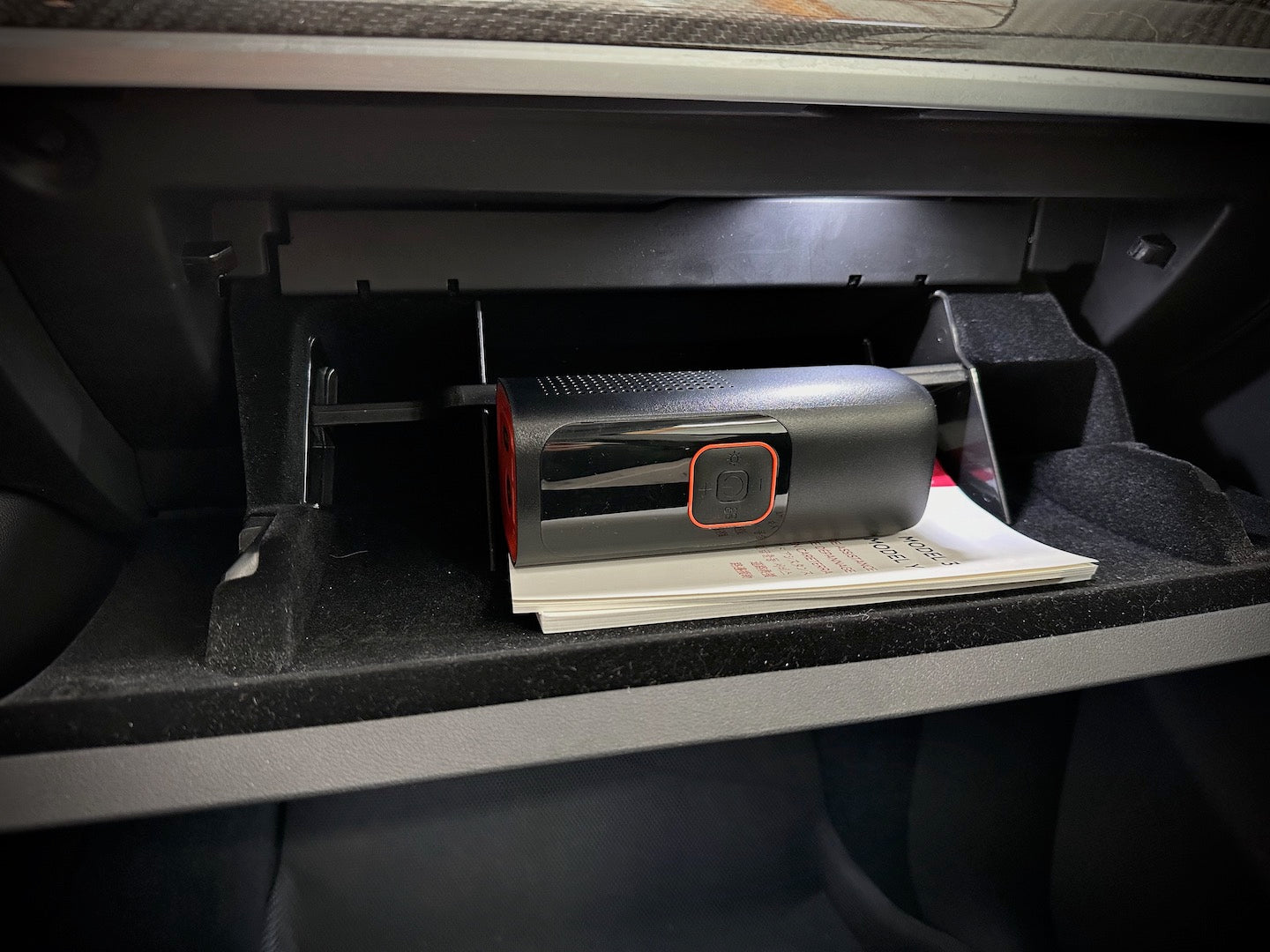

Illustrative image related to tesla tire inflation

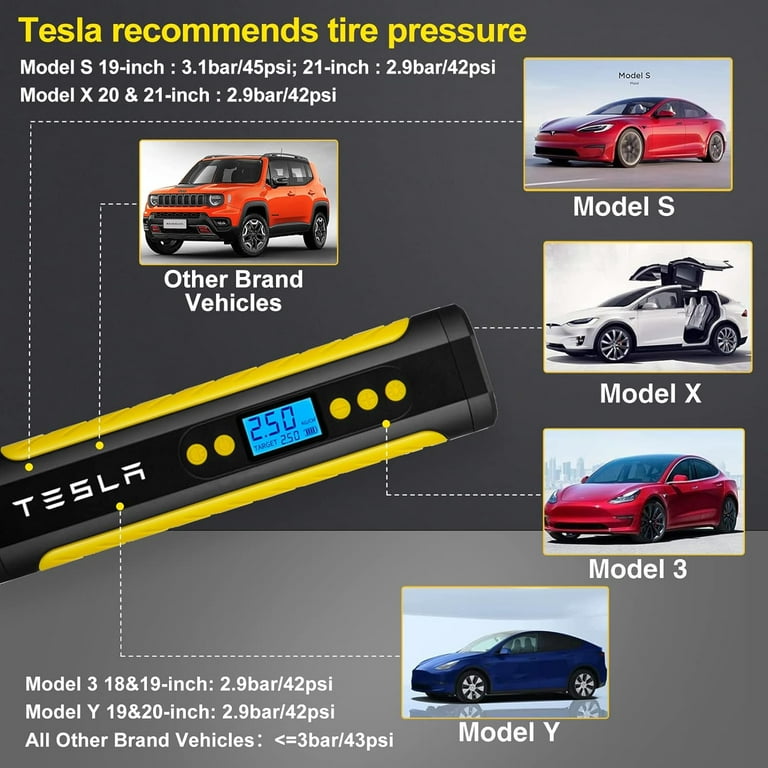

المشكلة B2B buyers may struggle with understanding the correct tire pressure specifications for different Tesla models. Miscommunication or lack of clear information can lead to incorrect tire inflation, which affects vehicle performance and safety. This is particularly important in international markets where buyers may be unfamiliar with Tesla’s requirements, resulting in inconsistent maintenance practices across the fleet.

الحل: To eliminate confusion, businesses should compile a comprehensive guide detailing the correct tire pressure for each Tesla model in their fleet. This guide should include visual aids, such as diagrams showing where to find the tire pressure information on the vehicle. Moreover, implementing a digital solution, such as a mobile app or an internal platform, can help fleet managers track tire pressure maintenance schedules and reminders. Regular training sessions can also keep all staff updated on the importance of adhering to tire pressure standards, ensuring that all vehicles are maintained correctly.

المشكلة When a Tesla experiences a flat tire or puncture during a business trip, B2B buyers may face significant delays if they are unprepared for such emergencies. Many businesses operate in regions where roadside assistance may not be readily available, leading to increased risk of stranded vehicles and disrupted operations.

Illustrative image related to tesla tire inflation

الحل: To mitigate this risk, businesses should equip each Tesla vehicle in their fleet with the Tesla Air Compressor + Tire Repair Kit 3.0. This kit provides essential tools for emergency tire repair, allowing drivers to address minor issues quickly without needing immediate roadside assistance. Additionally, companies should create an emergency response protocol that includes guidance on how to use the tire repair kit effectively. Training drivers on this protocol will not only empower them to handle minor tire issues independently but also foster confidence in managing unexpected road challenges, thereby enhancing operational continuity.

By addressing these common pain points with tailored solutions, B2B buyers can improve their operational efficiency, reduce vehicle downtime, and ensure the longevity of their Tesla fleet.

When selecting materials for Tesla tire inflation solutions, it is crucial to consider various factors that impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Rubber is a primary material used in tire manufacturing, including components for tire inflation systems. It exhibits excellent elasticity and resilience, allowing it to withstand varying pressures and temperatures. Rubber can typically handle temperature ranges from -40°C to 100°C and pressures up to 80 psi, making it suitable for tire applications.

الإيجابيات والسلبيات: Rubber is durable and cost-effective, but it may degrade over time due to exposure to UV light and ozone. Additionally, manufacturing complexity can vary, particularly when incorporating specialized compounds for enhanced performance.

التأثير على التطبيق: Rubber is compatible with air and nitrogen, which are commonly used for tire inflation. However, it may not be suitable for environments with extreme temperatures or chemicals.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM for rubber products. In Europe, adherence to DIN standards is essential.

Aluminum is often used in tire inflation equipment, such as air compressors and fittings. It has a high strength-to-weight ratio, excellent corrosion resistance, and can withstand high pressures, making it ideal for tire inflation systems.

الإيجابيات والسلبيات: Aluminum is lightweight and durable, which enhances the portability of inflation devices. However, it can be more expensive than other materials, and its manufacturing process may require specialized techniques.

Illustrative image related to tesla tire inflation

التأثير على التطبيق: Aluminum components are compatible with various gases and can handle pressures well above typical tire inflation requirements.

International Considerations: B2B buyers in the Middle East and Europe should ensure that aluminum components meet relevant standards, such as JIS for Japan and EN standards in Europe, to guarantee quality and safety.

Steel is commonly used in the construction of tire inflation systems, particularly in high-pressure hoses and fittings. It offers excellent strength and durability, withstanding high pressures and providing resistance to wear and tear.

الإيجابيات والسلبيات: Steel is robust and relatively inexpensive compared to other materials. However, it is prone to corrosion if not properly coated or maintained, which can lead to failures in high-humidity environments.

Illustrative image related to tesla tire inflation

التأثير على التطبيق: Steel is suitable for high-pressure applications but may not be ideal for environments with exposure to corrosive elements.

International Considerations: Buyers from regions such as Europe should consider compliance with ASTM and DIN standards for steel products, ensuring that they meet safety and performance criteria.

Plastic is increasingly used in tire inflation systems for components like valves and housings. It is lightweight, resistant to corrosion, and can be molded into complex shapes.

Illustrative image related to tesla tire inflation

الإيجابيات والسلبيات: Plastic is cost-effective and versatile, but it may not withstand high temperatures or pressures as effectively as metals. Additionally, certain plastics can degrade under UV exposure.

التأثير على التطبيق: Plastic components are generally compatible with air and nitrogen but may not be suitable for high-pressure applications.

International Considerations: B2B buyers should ensure that plastic components meet relevant standards, such as ASTM and ISO, particularly in regions like Africa and South America where material quality may vary.

Illustrative image related to tesla tire inflation

| المواد | Typical Use Case for tesla tire inflation | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Tire manufacturing and sealing components | Excellent elasticity and durability | Degrades with UV exposure | منخفضة |

| ألومنيوم | Air compressors and fittings | Lightweight with high corrosion resistance | ارتفاع التكلفة والتصنيع المعقد | عالية |

| الفولاذ | High-pressure hoses and fittings | Robust and cost-effective | Prone to corrosion without protection | متوسط |

| بلاستيك | Valves and housings | Lightweight and versatile | Limited high-pressure and temperature resistance | منخفضة |

This analysis provides a comprehensive overview for international B2B buyers, helping them make informed decisions regarding material selection for Tesla tire inflation systems. Each material presents unique advantages and challenges, necessitating careful consideration based on specific application requirements and regional standards.

The manufacturing process of Tesla’s tire inflation products, such as the Air Compressor + Tire Repair Kit 3.0, involves several critical stages, each designed to ensure quality, reliability, and efficiency. Here’s a breakdown of the main stages:

The first step in the manufacturing process involves sourcing high-quality materials that meet stringent performance standards. This includes durable plastics for the compressor housing, metals for internal components, and specialized sealants that can effectively patch punctures. Suppliers must adhere to specifications that guarantee compatibility with Tesla vehicles and provide adequate performance under various conditions.

Illustrative image related to tesla tire inflation

Once materials are prepared, the forming stage begins. This involves techniques such as injection molding for plastic components and precision machining for metal parts. Tesla employs advanced technologies to ensure that each component is manufactured to exact specifications, which is critical for the overall performance of the tire inflation system.

The assembly stage is where individual components come together to form the final product. Automated assembly lines are often utilized to enhance precision and efficiency. Each unit, such as the air compressor, is assembled with attention to detail, ensuring that all parts fit perfectly and function correctly. This stage may also involve the integration of electronic components for features like pressure monitoring.

Finishing processes may include surface treatments, painting, or coating to enhance durability and aesthetic appeal. This stage ensures that the products not only perform well but also meet the visual standards expected by consumers. Quality control checks are integrated throughout this phase to catch any defects before products are packaged.

Quality control (QC) is a fundamental aspect of Tesla’s manufacturing process, ensuring that each tire inflation product meets international and industry-specific standards. Here are the key elements of their QC approach:

Tesla adheres to various international standards, including ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that the manufacturing process is continually evaluated and improved. Additionally, CE marking is utilized for products sold within the European Economic Area, ensuring that they meet safety and environmental requirements.

Illustrative image related to tesla tire inflation

In addition to general quality standards, Tesla products may require industry-specific certifications such as API (American Petroleum Institute) for components that interact with fluids or gases. These certifications validate that products meet specific performance and safety criteria, which is particularly important for B2B buyers in regulated markets.

Quality control checkpoints are integrated at multiple stages throughout the manufacturing process:

مراقبة الجودة الواردة (IQC): At this initial stage, raw materials and components are inspected for compliance with specifications before they enter the production line.

مراقبة الجودة أثناء العملية (IPQC): During assembly, periodic inspections and tests are conducted to ensure that each component functions as intended. This may include pressure tests for compressors to verify their performance and safety.

مراقبة الجودة النهائية (FQC): Once assembly is complete, the finished products undergo comprehensive testing, including functionality tests and visual inspections to ensure they meet Tesla’s quality standards before packaging and distribution.

Testing methods are crucial for verifying the performance and safety of tire inflation products. Common methods used by Tesla include:

Pressure Testing: Ensures that the air compressor can achieve and maintain specified pressures without failure.

Flow Rate Testing: Measures the compressor’s ability to deliver air at the required flow rate, ensuring efficiency during use.

اختبار المتانة: Products undergo stress tests to simulate real-world conditions, verifying their resilience and longevity.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps to ensure that suppliers meet quality standards:

Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. These audits should assess compliance with international standards, manufacturing practices, and overall product quality.

Illustrative image related to tesla tire inflation

B2B buyers should request documentation related to quality assurance processes, including test reports, certifications, and compliance with international standards. This information can help verify that the supplier maintains high-quality production standards.

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality. These services can conduct inspections at various manufacturing stages, ensuring that products meet specified standards before shipment.

Navigating quality control nuances is particularly important for international B2B buyers. Different regions may have varying standards and regulations, impacting product compliance and acceptance. Buyers should be aware of:

Regional Certifications: Understanding local certification requirements can prevent compliance issues and ensure that products are market-ready.

الاعتبارات الثقافية: Quality expectations may vary across regions. Engaging with local partners or experts can provide valuable insights into specific market demands.

Logistics and Supply Chain Factors: Consideration of logistics and supply chain dynamics is crucial. Quality control measures should extend beyond manufacturing to include transportation and handling processes to ensure product integrity upon arrival.

By understanding these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing Tesla tire inflation products, ensuring they receive high-quality, reliable solutions that meet their operational needs.

In today’s competitive automotive market, ensuring optimal tire performance is essential for both safety and efficiency. This practical sourcing guide is designed to assist B2B buyers in procuring effective solutions for Tesla tire inflation, helping to streamline operations and maintain vehicle integrity.

Illustrative image related to tesla tire inflation

Understanding the precise requirements for tire inflation is fundamental. Consider factors such as the type of Tesla models being serviced, the typical tire sizes, and the average distance driven. This will help you determine the necessary specifications for air compressors or tire repair kits that cater to your fleet or service center.

Selecting reputable suppliers is crucial for ensuring quality and reliability. Focus on companies that specialize in automotive tools and equipment, particularly those with a proven track record in providing tire inflation products for electric vehicles.

When assessing tire inflation products, pay close attention to their features. Look for air compressors that offer maximum pressure capabilities and fast inflation rates. Additionally, consider whether the product includes essential accessories such as sealant and storage options.

Ensure that the products you intend to purchase comply with local and international safety standards. This is particularly important in regions with stringent regulations regarding automotive equipment.

Illustrative image related to tesla tire inflation

Before making a bulk purchase, it’s wise to request product samples or demonstrations. This allows you to evaluate the performance and usability of the tire inflation tools firsthand.

Pricing can vary significantly among suppliers. Conduct a thorough analysis of costs, ensuring that you balance quality with affordability. Additionally, inquire about warranty options to safeguard your investment.

Once you’ve selected a supplier, focus on building a long-term partnership. Regular communication can lead to better pricing, access to new products, and insights into market trends.

Illustrative image related to tesla tire inflation

By following this checklist, B2B buyers can make informed decisions regarding Tesla tire inflation solutions, ensuring they invest in high-quality products that meet their operational requirements.

In sourcing tire inflation solutions for Tesla vehicles, understanding the cost structure is crucial for B2B buyers. Key components include:

المواد: The primary materials in tire inflation solutions include air compressors, sealants, and storage bags. The quality of these materials directly affects performance and durability, which can vary significantly between suppliers.

العمل: Labor costs encompass the workforce involved in the manufacturing and assembly of tire inflation kits. Skilled labor may command higher wages but can ensure better quality control and product reliability.

نفقات التصنيع الزائدة: This includes costs associated with utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, ultimately impacting pricing.

الأدوات: Initial tooling costs for custom or specialized equipment can be substantial. Buyers should consider whether they require standard or customized solutions, as this will influence the overall pricing.

مراقبة الجودة (QC): Rigorous QC processes ensure that the products meet safety and performance standards. Investing in QC can increase costs but is essential for maintaining product integrity, especially for international markets.

الخدمات اللوجستية: Transportation costs vary widely based on distance, shipping methods, and import/export tariffs. Buyers must account for logistics in their total cost calculations, particularly when sourcing from overseas.

الهامش: Supplier margins will vary based on market competition, brand reputation, and perceived value. Understanding these margins can help buyers gauge fair pricing.

Several factors influence the pricing of tire inflation solutions, particularly for international B2B buyers:

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing while ensuring they do not overstock.

المواصفات والتخصيص: Customized products often come at a premium. Buyers should assess whether standard products meet their needs before opting for custom solutions.

المواد: The choice of materials significantly affects pricing. High-quality, durable materials may incur higher upfront costs but can offer better longevity and performance, resulting in lower total cost of ownership.

Quality and Certifications: Products with certifications (e.g., ISO, CE) may carry a higher price tag. However, these certifications can assure buyers of compliance with safety and quality standards, especially in regulated markets.

عوامل الموردين: Supplier reliability, reputation, and service levels can influence pricing. Establishing long-term relationships with reputable suppliers may lead to better pricing and terms.

المصطلحات التجارية الدولية: Understanding Incoterms is crucial for international transactions. They define shipping responsibilities and costs, which can significantly impact the overall purchase price.

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

التفاوض: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate better terms, including discounts or extended payment periods.

Cost-Efficiency Analysis: Conduct a total cost of ownership analysis, considering not just the initial purchase price but also the long-term costs associated with maintenance, repairs, and potential replacements.

Consider Local Sourcing: Evaluate the feasibility of sourcing from local suppliers to reduce logistics costs and tariffs. This can also minimize delivery times and support local economies.

Stay Informed About Market Trends: Keep abreast of market trends and fluctuations in material costs. Timing your purchases strategically can yield cost savings.

Utilize Technology for Procurement: Employ procurement software to streamline purchasing processes and gain insights into pricing trends and supplier performance.

Understanding the cost structure and pricing influencers in Tesla tire inflation sourcing is vital for B2B buyers looking to optimize their procurement strategies. By leveraging negotiation tactics, conducting thorough cost analyses, and staying informed about market dynamics, buyers can achieve significant cost efficiencies while ensuring they secure reliable and high-quality tire inflation solutions.

Illustrative image related to tesla tire inflation

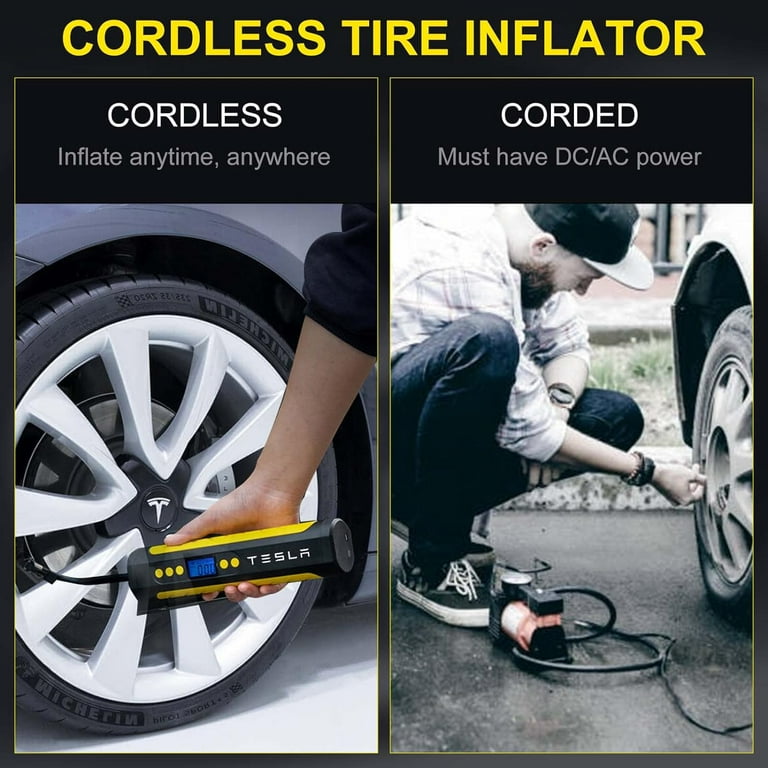

When it comes to maintaining optimal tire pressure for Tesla vehicles, the options extend beyond the proprietary Tesla tire inflation solutions. B2B buyers in various regions, including Africa, South America, the Middle East, and Europe, should consider alternative methods that can complement or serve as substitutes. The choice of tire inflation solution can significantly impact vehicle performance, safety, and overall cost-effectiveness. Below is a comparative analysis of Tesla’s tire inflation system against other viable solutions.

| جانب المقارنة | Tesla Tire Inflation | Portable Air Compressor | Gas Station Air Pump |

|---|---|---|---|

| الأداء | Up to 80 psi; good for quick fixes | Versatile; suitable for various vehicles | Generally adequate for basic inflation |

| التكلفة | $110 | $30 – $100 (varies by brand) | Typically free or minimal cost |

| سهولة التنفيذ | Simple to use within the vehicle | Requires carrying; can be used anywhere | Requires travel to a station |

| الصيانة | Minimal (periodic checks) | Requires upkeep; check for leaks | No maintenance needed |

| أفضل حالة استخدام | Emergency tire repair | Regular maintenance; versatile use | Quick inflation needs |

Portable air compressors are an attractive alternative for tire inflation, particularly for B2B buyers managing fleets or needing on-the-go solutions. They are versatile and can inflate tires of various sizes and types, making them ideal for businesses with diverse vehicle fleets. However, the need to carry them can be a drawback, especially in regions with limited space in vehicles. Additionally, while they provide good inflation performance, the quality can vary significantly by brand, potentially affecting reliability.

Gas station air pumps are a convenient solution for quick tire inflation and are often free or low-cost. They are widely accessible, making them a feasible option for businesses with a local presence. However, their performance may not be as consistent as dedicated tire inflation systems like Tesla’s. Furthermore, traveling to a gas station can be impractical during emergencies, and the quality of the air can be variable, raising concerns about moisture and contaminants.

Illustrative image related to tesla tire inflation

Choosing the right tire inflation solution depends on the specific needs and operational context of your business. For those who prioritize convenience and cost-effectiveness, gas station air pumps may be sufficient for occasional tire maintenance. However, for businesses requiring more reliability and the ability to handle emergencies, investing in Tesla’s tire inflation system or a portable air compressor might be the better option. Evaluating factors such as performance, cost, and ease of use will help international B2B buyers select the most suitable solution for their operational demands.

When dealing with Tesla tire inflation, several technical properties are vital for ensuring optimal performance and safety. Understanding these specifications can aid B2B buyers in making informed decisions regarding tire maintenance and purchasing related equipment.

The maximum pressure rating for Tesla tires typically ranges from 40 to 50 PSI, depending on the model. This specification is critical as it ensures the tire maintains its structural integrity and performance under load. For B2B buyers, adhering to the recommended PSI helps reduce the risk of tire blowouts and enhances fuel efficiency, ultimately translating to cost savings in fleet operations.

Illustrative image related to tesla tire inflation

The flow rate of an air compressor, such as the 25 L/min at 0 PSI for the Tesla Air Compressor, indicates how quickly the tire can be inflated. A higher flow rate can significantly reduce downtime for vehicles, especially in commercial settings. For companies that rely on timely vehicle operation, choosing compressors with optimal flow rates is essential for maintaining productivity.

The sealant included in Tesla’s tire repair kit is designed to temporarily fix punctures. It can seal holes up to 6mm in diameter but is not effective on sidewall punctures. Understanding the limitations of sealants is crucial for B2B buyers to ensure that they provide adequate emergency solutions while also planning for permanent repairs, thereby minimizing potential liabilities.

The air compressor has a maximum operating time of 30 minutes, followed by a required rest period of 60 minutes to prevent overheating. This specification is important for operational planning, especially in commercial fleets where multiple vehicles may require inflation services. Buyers should ensure that their maintenance schedules account for these operational limits to avoid equipment damage.

Temperature tolerance for tire inflation is a key factor, as tires can expand and contract based on environmental conditions. B2B buyers should consider how temperature variations in different regions (e.g., Africa versus Europe) can affect tire performance and inflation needs. Understanding these dynamics can help in selecting appropriate tires and inflation strategies for diverse markets.

Illustrative image related to tesla tire inflation

Familiarity with industry jargon is essential for B2B buyers to navigate the tire inflation landscape effectively. Here are some critical terms to understand:

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For Tesla, OEM tires and components ensure compatibility and performance standards, making it crucial for buyers to source original parts to maintain vehicle integrity.

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs to ensure they do not overstock or understock critical components.

Illustrative image related to tesla tire inflation

An RFQ is a document sent to suppliers to request pricing and availability of products. For B2B buyers, issuing RFQs is a strategic way to compare suppliers and negotiate better terms, ultimately leading to cost-effective procurement.

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B transactions, especially when dealing with international suppliers of tire inflation equipment.

TPMS is a technology designed to monitor tire pressure and alert the driver when it falls below a certain level. For B2B buyers, investing in vehicles with TPMS can enhance safety and reduce maintenance costs by ensuring tires are always inflated to the correct levels.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and maintain safety standards in their fleets.

The Tesla tire inflation market is currently experiencing transformative changes driven by several global factors. The increasing adoption of electric vehicles (EVs) and a growing focus on sustainability are reshaping sourcing dynamics. B2B buyers from regions like Africa, South America, the Middle East, and Europe (including markets like Vietnam and Germany) are particularly influenced by the demand for innovative tire maintenance solutions. Notably, products like the Air Compressor + Tire Repair Kit 3.0 are gaining traction due to their convenience and effectiveness, aligning with the increasing preference for emergency preparedness among EV owners.

Illustrative image related to tesla tire inflation

Emerging technologies such as smart tire monitoring systems are also making waves. These systems can remotely monitor tire pressure and provide alerts, allowing for proactive maintenance. B2B buyers are encouraged to consider these technologies not just for immediate cost savings but also for long-term operational efficiency. Additionally, the trend towards digital procurement platforms is enhancing accessibility, enabling international buyers to source products more efficiently and transparently.

As the market matures, the emphasis on aftermarket products, including tire inflation solutions, is expected to rise. This trend suggests a shift in purchasing behavior, where businesses look for high-quality, reliable products that can withstand diverse environmental conditions, particularly in emerging markets.

The environmental impact of tire manufacturing and maintenance is an increasingly critical consideration for B2B buyers in the Tesla tire inflation sector. Companies are now under pressure to adopt ethical sourcing practices, focusing on reducing their carbon footprint while ensuring product integrity. This shift is leading to a demand for ‘green’ certifications and sustainable materials in tire inflation products.

Illustrative image related to tesla tire inflation

For instance, sourcing air compressors and tire repair kits that utilize eco-friendly materials and processes can significantly reduce environmental harm. Additionally, companies are exploring partnerships with suppliers that prioritize sustainable practices, such as using recyclable components and minimizing waste in their production lines.

Buyers are also becoming more discerning, seeking vendors who transparently communicate their sustainability initiatives. This not only aligns with corporate social responsibility goals but also resonates with consumers who prefer brands that demonstrate a commitment to environmental stewardship. Therefore, B2B buyers should prioritize suppliers who can offer comprehensive sustainability credentials, as this will enhance their market positioning and appeal to a broader customer base.

The evolution of tire inflation solutions for Tesla vehicles reflects the broader advancements in automotive technology and consumer needs. Initially, tire inflation was a straightforward process, predominantly relying on manual pumps or gas station air compressors. However, as Tesla vehicles gained popularity, the need for specialized tire maintenance solutions emerged.

Illustrative image related to tesla tire inflation

Tesla’s introduction of the Air Compressor + Tire Repair Kit marked a significant milestone in this evolution, providing vehicle owners with a compact, efficient solution for tire emergencies. This product not only simplified the process but also catered to the unique needs of Tesla’s electric vehicle owners, who often prioritize convenience and reliability.

As the market continues to develop, the focus on enhancing user experience and addressing the specific challenges faced by EV drivers will likely drive further innovations in tire inflation technologies. For B2B buyers, understanding this historical context can provide valuable insights into future trends and product offerings in the Tesla tire inflation sector.

How do I solve tire pressure issues in Tesla vehicles?

To address tire pressure issues in Tesla vehicles, it’s crucial to regularly check and maintain the recommended PSI levels as indicated on the driver’s door sticker. For minor pressure drops, using a portable air compressor, such as the Tesla Air Compressor + Tire Repair Kit 3.0, can be effective for topping off tire pressure. In case of significant leaks or damage, contacting a tire specialist or using the tire repair kit for temporary fixes is advisable. Always ensure the vehicle is parked on a level surface when checking tire pressure for accuracy.

What is the best tire inflation solution for Tesla vehicles?

The best tire inflation solution for Tesla vehicles is the Tesla Air Compressor + Tire Repair Kit 3.0. This kit includes an air compressor capable of inflating tires up to 80 psi and a sealant to temporarily fix punctures up to 6mm in diameter. It’s designed for ease of use, connecting directly to the vehicle’s 12V port. For B2B buyers, sourcing this kit ensures that fleet vehicles can handle minor tire issues effectively, minimizing downtime and ensuring safety.

What are the import regulations for tire inflation products in my region?

Import regulations for tire inflation products vary by country and region. It is essential to check with local customs authorities to understand specific import duties, required certifications, and safety standards. For B2B buyers in Africa, South America, the Middle East, and Europe, ensuring compliance with local regulations can prevent delays and additional costs. Consulting with a logistics partner familiar with your region’s import laws can streamline the process.

How can I vet suppliers for Tesla tire inflation products?

Vetting suppliers for Tesla tire inflation products involves researching their business credentials, reputation, and product quality. Look for suppliers with a proven track record in the automotive sector, preferably with experience in Tesla products. Request references, check online reviews, and consider visiting their facilities if possible. Additionally, ensure they comply with international quality standards and have robust customer support to address any post-purchase issues.

What customization options are available for tire inflation kits?

Many suppliers offer customization options for tire inflation kits, including branding, packaging, and specific components tailored to your fleet’s needs. B2B buyers should discuss their requirements with suppliers to determine available options, such as different sizes of compressors or additional tools in the kit. Customization can enhance brand visibility and ensure that the product meets specific operational requirements.

What is the minimum order quantity (MOQ) for tire inflation products?

Minimum order quantities (MOQs) for tire inflation products can vary significantly between suppliers. Many manufacturers set MOQs based on production costs and logistics efficiency. B2B buyers should directly inquire with suppliers to understand their specific MOQs and explore negotiation options for smaller orders, particularly if they are testing products for a new market or fleet.

What payment terms should I expect when purchasing tire inflation products?

Payment terms for tire inflation products typically include options such as advance payment, partial payment upfront with the balance due on delivery, or net payment terms (e.g., Net 30 or Net 60). B2B buyers should negotiate favorable terms that align with their cash flow needs while ensuring the supplier is comfortable with the arrangement. Always confirm payment methods accepted by the supplier, including bank transfers, credit cards, or letters of credit.

How can I ensure quality assurance for tire inflation products?

To ensure quality assurance for tire inflation products, B2B buyers should request certifications and quality control documentation from suppliers. This may include ISO certifications, test reports, and warranty information. Additionally, establishing a clear return policy and discussing post-purchase support can safeguard your investment. Conducting regular audits and quality checks upon receipt can further ensure that the products meet the specified standards and perform reliably.

المجال: teslamotorsclub.com

مسجل: 2006 (19 سنة)

مقدمة: Tesla Model S 70D with 19″ slipstream wheels; recommended tire pressure: 45 PSI (310 kPa) for 19″ wheels; current tire pressure: 41 PSI cold, 42 PSI when driving; gas station air pumps can be used; nitrogen-filled tires indicated by green valve caps; air pressure should not exceed the door sticker recommendation.

المجال: service.tesla.com

Registered: 1992 (33 years)

مقدمة: Tire pressures display on the touchscreen in the cards area or by touching Controls > Service. The pressure of each tire displays in the visualization of Model 3, along with the last measured time. Recommended cold tire pressures are shown on the touchscreen. Users can choose to display tire pressures in Bar or PSI. Tire pressures can also be viewed in the Tesla mobile app. To check and adjust tir…

In conclusion, strategic sourcing plays a pivotal role in optimizing tire inflation solutions for Tesla vehicles. By leveraging high-quality equipment like the Air Compressor + Tire Repair Kit 3.0, businesses can ensure that their fleet remains operational while minimizing downtime. This kit not only facilitates easy tire pressure adjustments but also provides a temporary fix for punctures, thereby enhancing overall vehicle safety and efficiency.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, the focus should be on establishing reliable supply chains that can deliver these essential products. Understanding regional regulations and market demands will enable businesses to source effectively and capitalize on the growing electric vehicle market.

As we move forward, the importance of maintaining optimal tire pressure cannot be overstated. It not only contributes to vehicle performance but also supports sustainability efforts by improving energy efficiency. We encourage businesses to actively seek partnerships that enhance their tire maintenance capabilities and invest in the latest technology to meet the needs of their customers. Embrace strategic sourcing today to drive your business into a successful future.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.