- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the dynamic landscape of global tire management, understanding when tire inflation should be checked is crucial for B2B buyers focused on optimizing vehicle safety and performance. With the potential for underinflated tires to lead to increased operational costs and safety hazards, sourcing reliable information on tire pressure management becomes a priority for businesses across Africa, South America, the Middle East, and Europe. This guide provides an in-depth exploration of tire inflation best practices, covering essential aspects such as types of tires, their applications, and supplier vetting processes.

As international buyers navigate the complexities of tire procurement, this resource empowers them to make informed purchasing decisions. It outlines the significance of regular tire pressure checks—ideally every month or before long journeys—to ensure that vehicles operate efficiently and safely. The guide delves into the implications of tire inflation on cost-effectiveness, longevity, and environmental impact, making it an invaluable tool for companies looking to enhance their fleet management strategies.

By addressing common challenges and providing actionable insights, this guide equips B2B buyers with the knowledge necessary to optimize their tire maintenance protocols. From understanding the nuances of tire pressure specifications to evaluating suppliers based on quality and service, this comprehensive resource serves as a roadmap for effective tire management in diverse global markets.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Standard Air Inflation | Utilizes ambient air, widely available and cost-effective. | General vehicle fleets, logistics firms. | الإيجابيات: Low cost, easy access. السلبيات: Less stable pressure over time, may require frequent checks. |

| Nitrogen Inflation | Uses nitrogen gas, reduces pressure loss and improves fuel efficiency. | Commercial trucking, high-performance vehicles. | الإيجابيات: Longer tire life, better fuel economy. السلبيات: Higher initial cost, limited availability. |

| Tire Pressure Monitoring Systems (TPMS) | Integrated technology that alerts drivers to low pressure. | Fleet management, safety compliance. | الإيجابيات: Real-time monitoring, enhances safety. السلبيات: Initial investment in technology, maintenance required. |

| Cold Inflation | Pressure measured when tires are cold, providing accurate readings. | All vehicle types, especially in extreme climates. | الإيجابيات: Accurate pressure readings, prevents overinflation. السلبيات: Requires awareness of timing for checks. |

| High-Pressure Inflation | Higher PSI for specific applications, improves load capacity. | Heavy-duty trucks, construction vehicles. | الإيجابيات: Enhanced load support, better handling. السلبيات: May lead to reduced ride comfort, requires careful monitoring. |

Standard air inflation is the most common method for maintaining tire pressure. It utilizes ambient air, which is readily available and cost-effective. This type of inflation is suitable for general vehicle fleets and logistics firms, where frequent tire checks are manageable. While it offers low initial costs, buyers must consider that ambient air can lead to pressure loss over time, necessitating regular monitoring to ensure optimal tire performance.

Nitrogen inflation employs nitrogen gas, which significantly reduces pressure loss and improves fuel efficiency. This method is particularly advantageous for commercial trucking and high-performance vehicles, where tire longevity is crucial. Although the initial costs may be higher and availability can be limited, the long-term benefits include extended tire life and reduced fuel consumption, making it a worthwhile investment for businesses focused on operational efficiency.

Tire Pressure Monitoring Systems (TPMS) integrate advanced technology to alert drivers when tire pressure falls below safe levels. This system is essential for fleet management and safety compliance, allowing companies to maintain optimal tire conditions without manual checks. While the initial investment in TPMS can be significant, the enhanced safety and potential reduction in tire-related incidents provide a compelling return on investment for B2B buyers.

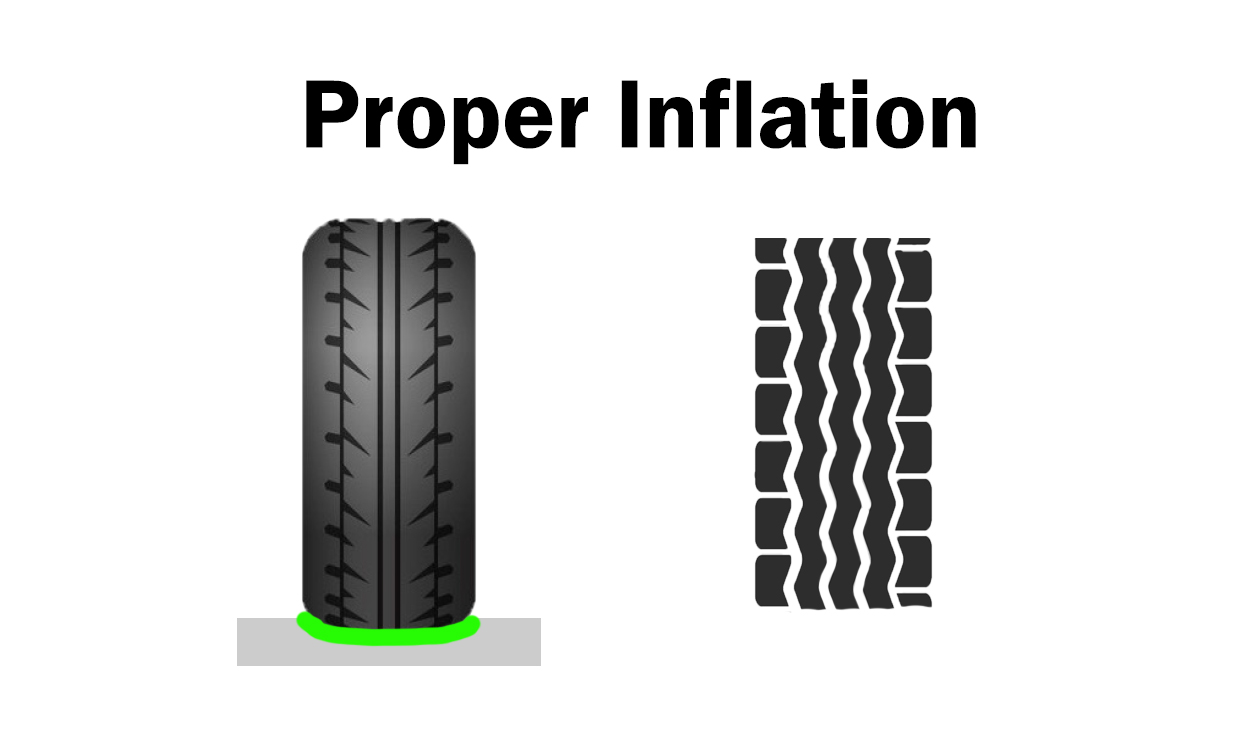

Cold inflation refers to checking tire pressure when the tires are cold, which provides the most accurate readings. This method is essential for all vehicle types, particularly in regions with extreme climates where temperature fluctuations can affect tire pressure. While it requires careful timing for checks, the accuracy gained helps prevent issues such as overinflation, ensuring that tires perform optimally and safely.

High-pressure inflation is characterized by a higher PSI tailored for specific applications, such as heavy-duty trucks or construction vehicles. This approach enhances load capacity and improves handling, making it suitable for demanding environments. However, buyers should be aware that high-pressure inflation may result in a stiffer ride and requires diligent monitoring to prevent potential tire damage, making it essential for businesses that prioritize performance and safety.

| الصناعة/القطاع | Specific Application of tire inflation should be checked when the tires are | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| النقل والخدمات اللوجستية | Fleet management for commercial vehicles | Enhanced safety, reduced downtime, and lower fuel costs | Reliable tire pressure monitoring systems and gauges |

| الزراعة | Agricultural machinery and equipment | Improved operational efficiency and reduced tire wear | Durable tires suited for various terrains and conditions |

| Construction | Heavy machinery and construction vehicles | Increased safety, productivity, and equipment longevity | Heavy-duty tires with proper inflation monitoring capabilities |

| Mining | Mining trucks and equipment | Prevention of tire blowouts and enhanced safety | Specialized tire inflation solutions for extreme conditions |

| Automotive Services | Maintenance services for passenger and commercial vehicles | Better customer satisfaction and reduced service costs | Quality tire pressure gauges and monitoring systems |

In the transportation and logistics sector, tire inflation is crucial for fleet management. Regular checks ensure that tires are maintained at optimal pressure, minimizing the risk of blowouts and enhancing vehicle safety. This translates to reduced downtime and lower fuel costs, as properly inflated tires improve fuel efficiency. Buyers in this sector should prioritize sourcing reliable tire pressure monitoring systems (TPMS) and gauges that can withstand rigorous use, particularly in diverse climates across Africa, South America, and the Middle East.

In agriculture, tire inflation is vital for ensuring the efficiency of machinery such as tractors and harvesters. Properly inflated tires facilitate better traction and reduce soil compaction, enhancing operational performance. This is particularly important for agricultural operations in regions like Nigeria and Vietnam, where varied terrain can affect machinery performance. Buyers should consider sourcing durable tires designed for agricultural use, along with reliable inflation monitoring tools to prevent wear and optimize productivity.

In the construction industry, maintaining tire pressure on heavy machinery is essential for safety and productivity. Under-inflated tires can lead to accidents, while over-inflated tires may cause premature wear. Ensuring proper tire inflation helps extend the life of construction equipment, thus reducing operational costs. Buyers should focus on sourcing heavy-duty tires equipped with monitoring capabilities that can handle the demands of construction sites, particularly in regions with challenging environments.

In mining operations, maintaining proper tire inflation is critical for the safety of personnel and equipment. Mining trucks and equipment face extreme conditions, and tire blowouts can lead to catastrophic accidents. Regular checks and monitoring of tire pressure can prevent such incidents and ensure operational continuity. Buyers in this sector must look for specialized tire inflation solutions that can endure harsh environments and provide real-time monitoring to enhance safety and productivity.

For automotive service providers, ensuring that tire inflation is regularly checked is essential for customer satisfaction and vehicle safety. Proper tire maintenance not only enhances vehicle performance but also reduces the likelihood of tire-related issues, leading to lower service costs. Providers should invest in high-quality tire pressure gauges and monitoring systems to offer reliable services. This is particularly important for automotive businesses operating in diverse climates across Europe and other regions, where temperature fluctuations can significantly affect tire pressure.

المشكلة In many businesses, particularly those operating in regions with varying climates, tire inflation is often neglected. Companies managing fleets may be under the impression that checking tire pressure once every few months is sufficient. This oversight can lead to underinflated tires, resulting in decreased fuel efficiency and increased wear and tear. Not only does this affect operational costs, but it also compromises safety, potentially resulting in accidents that can harm personnel and damage vehicles.

Illustrative image related to tire inflation should be checked when the tires are

الحل: To mitigate this issue, businesses should implement a systematic tire maintenance schedule. Designate a specific day each month for tire pressure checks across the fleet. Utilize a digital tire pressure monitoring system (TPMS) that alerts fleet managers when tire pressure drops below recommended levels. Additionally, training staff on the importance of proper tire inflation can create a culture of safety and proactive maintenance. By integrating these practices, companies can enhance safety, extend tire life, and ultimately save on costs associated with fuel and premature tire replacement.

المشكلة For international businesses operating in diverse regions like Africa and South America, varying environmental factors can lead to inconsistent tire pressure across vehicles. High temperatures in some areas may cause tires to overinflate, while colder climates can lead to underinflation. These discrepancies not only lead to uneven tire wear but also impact vehicle handling and safety, creating significant challenges for fleet management.

الحل: Businesses should establish standardized guidelines for checking tire pressure based on the specific environmental conditions of each location. This involves creating a localized tire pressure chart that considers temperature fluctuations and adjusts the recommended PSI accordingly. Additionally, investing in training for local teams on how to calibrate tire pressure based on climate can ensure that all vehicles maintain optimal performance. Regular audits of tire conditions and pressure can further reinforce adherence to these guidelines, ensuring a consistent approach to tire maintenance across various geographical areas.

المشكلة Many B2B buyers may not fully understand the specific tire pressure requirements for different vehicles within their fleet. Misinterpretation of manufacturer specifications can lead to incorrect tire inflation, resulting in suboptimal vehicle performance and increased risk of tire failure. This knowledge gap can significantly impact operational efficiency, particularly in industries reliant on timely deliveries and logistics.

الحل: To address this knowledge gap, companies should invest in comprehensive training programs that educate staff about tire specifications and the importance of adhering to manufacturer recommendations. Additionally, providing easy access to vehicle handbooks and digital resources can empower employees to check and adjust tire pressure accurately. Incorporating a checklist as part of the pre-trip inspection can also ensure that tire pressure is routinely verified before operations commence. Regular refresher courses can reinforce this knowledge, ultimately enhancing safety and operational effectiveness across the fleet.

When considering the materials for tire inflation systems, it is crucial to analyze their properties, advantages, disadvantages, and overall impact on performance. This analysis is particularly relevant for B2B buyers in diverse markets, including Africa, South America, the Middle East, and Europe.

Rubber is the most common material used in tire manufacturing due to its excellent elasticity and ability to withstand high pressures. It typically has a high temperature rating, making it suitable for various climates. Rubber also exhibits good corrosion resistance, which is vital for maintaining tire integrity over time.

الإيجابيات والسلبيات: The durability of rubber is a significant advantage, as it can last for thousands of kilometers when properly maintained. However, the cost of high-quality rubber can be relatively high, and its manufacturing complexity can increase production times. Additionally, rubber may degrade faster in extreme temperatures or under heavy loads.

التأثير على التطبيق: Rubber is compatible with air and nitrogen, commonly used for tire inflation. However, buyers must consider the specific rubber formulations used, as some may not perform well in extreme conditions.

اعتبارات للمشترين الدوليين: Compliance with international standards, such as ASTM or DIN, is essential when sourcing rubber materials. Buyers in regions like Africa and South America may also need to consider local climate conditions that could affect rubber performance.

Aluminum is often used in tire pressure monitoring systems (TPMS) and valve stems due to its lightweight and corrosion-resistant properties. It can withstand high pressures, making it an excellent choice for tire inflation applications.

الإيجابيات والسلبيات: The primary advantage of aluminum is its lightweight nature, which contributes to overall vehicle efficiency. However, aluminum can be more expensive than other materials like steel, and its manufacturing process is more complex, potentially leading to higher costs.

التأثير على التطبيق: Aluminum is compatible with various tire inflation media, including air and nitrogen. Its resistance to corrosion ensures that it maintains integrity over time, which is crucial for safety.

اعتبارات للمشترين الدوليين: Buyers should ensure that aluminum components meet relevant international standards, especially in regions with stringent regulations. Additionally, the availability of aluminum products can vary by region, impacting supply chains.

Steel is frequently used for tire rims and valve stems due to its strength and durability. It can handle high pressure and is resistant to deformation, making it a reliable choice for tire inflation systems.

الإيجابيات والسلبيات: Steel’s strength is a significant advantage, as it can withstand heavy loads and impacts. However, it is heavier than aluminum, which can affect vehicle efficiency. Steel is also susceptible to corrosion, which can compromise its longevity if not properly treated.

التأثير على التطبيق: Steel is compatible with standard tire inflation media but may require protective coatings to enhance corrosion resistance.

اعتبارات للمشترين الدوليين: Buyers must be aware of the various grades of steel and their respective compliance with international standards. In regions with humid climates, corrosion-resistant treatments are essential.

Plastic is increasingly used in tire inflation systems, particularly in valve components and TPMS housings. It is lightweight and can be manufactured in various shapes and sizes.

الإيجابيات والسلبيات: The lightweight nature of plastic contributes to overall vehicle efficiency, and its manufacturing process is generally less complex than metal. However, plastic may not withstand high temperatures or pressures as effectively as rubber or metal, which can limit its applications.

التأثير على التطبيق: Plastic is compatible with air and nitrogen, but its performance may vary based on the specific type of plastic used.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastics used comply with international standards and are suitable for the specific environmental conditions of their region.

Illustrative image related to tire inflation should be checked when the tires are

| المواد | Typical Use Case for tire inflation should be checked when the tires are | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Tire manufacturing and inflation systems | Excellent elasticity and durability | Degradation in extreme temperatures | عالية |

| ألومنيوم | Valve stems and TPMS components | خفيف الوزن ومقاوم للتآكل | ارتفاع التكلفة والتصنيع المعقد | متوسط |

| الفولاذ | Rims and valve stems | قوة ومتانة عالية | Heavier and susceptible to corrosion | متوسط |

| بلاستيك | Valve components and TPMS housings | Lightweight and versatile | Limited performance under high pressure | منخفضة |

This analysis provides a comprehensive overview of the materials commonly used in tire inflation systems, highlighting their properties, advantages, and considerations for international B2B buyers. Understanding these factors can aid in making informed sourcing decisions that align with specific application requirements and regional standards.

The manufacturing of tires involves a complex series of processes aimed at creating durable and reliable products that maintain optimal inflation. Understanding these processes is essential for B2B buyers seeking quality tires that meet international standards.

Material preparation is the first crucial step in tire manufacturing. High-quality rubber compounds are formulated, incorporating various materials such as natural rubber, synthetic rubber, carbon black, and other additives to enhance performance characteristics like durability, heat resistance, and traction. The formulation is meticulously designed to ensure that the tires can withstand the rigors of diverse environments, particularly in regions like Africa and South America where road conditions can be challenging.

Once the rubber compounds are prepared, they undergo mixing, where they are blended to achieve uniformity. This stage is critical, as inconsistencies in the mixture can lead to uneven wear and potential failure during use. Buyers should inquire about the specific materials used and their sourcing, as this can affect the overall performance and reliability of the tires.

The forming stage involves shaping the tire components, including the tread, sidewalls, and inner linings. This is typically achieved through processes such as extrusion, molding, and calendering.

Extrusion: This technique is used to create the tire’s inner liner and tread. Heated rubber is forced through a die to produce long strips, which are then cut to size.

القوالب: Tire components are placed in molds and subjected to heat and pressure. This process bonds the layers together, allowing for the creation of complex tread patterns essential for performance.

Calendering: This method is employed to produce tire fabric and steel belts, which provide strength and stability. Layers of rubber are rolled out and combined with textile or steel materials to form belts that enhance tire integrity.

After forming, the assembly process combines all tire components into a complete unit. This stage involves several key steps:

Building: Individual components, such as the inner liner, belts, and tread, are assembled onto a tire-building machine. Precision is critical here; any misalignment can lead to imbalance and performance issues.

Curing: The assembled tire is then cured in a mold, where it undergoes a chemical reaction that solidifies the rubber and bonds all layers together. This step is vital for ensuring the tire’s structural integrity and performance.

The finishing stage includes various processes to ensure the tires meet quality and aesthetic standards. This involves trimming excess rubber, applying markings, and conducting visual inspections.

Additionally, tires may undergo surface treatments to enhance resistance to wear and environmental factors. Proper finishing ensures that the tires not only perform well but also meet the appearance standards expected by B2B buyers.

Illustrative image related to tire inflation should be checked when the tires are

Quality assurance (QA) is integral to the manufacturing process, ensuring that each tire meets international standards and performs reliably under various conditions.

Manufacturers typically adhere to international standards such as ISO 9001, which emphasizes quality management systems, and various industry-specific standards like CE (Conformité Européenne) and API (American Petroleum Institute) certifications. These standards help ensure that tires are produced consistently and meet safety requirements.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

مراقبة الجودة الواردة (IQC): This involves the inspection of raw materials upon receipt to ensure they meet specified standards before production begins.

مراقبة الجودة أثناء المعالجة (IPQC): Continuous monitoring occurs during manufacturing to identify and correct any issues as they arise, minimizing waste and ensuring product consistency.

مراقبة الجودة النهائية (FQC): After tires are cured and finished, they undergo rigorous testing, including pressure tests, visual inspections, and performance evaluations to verify that they meet safety and performance standards.

Several testing methods are employed to ensure tire quality:

Inflation Pressure Testing: This assesses the tire’s ability to maintain the recommended inflation pressure under various conditions.

اختبار المتانة: Tires are subjected to simulated road conditions to evaluate their performance over time.

Uniformity Testing: This checks for balance and consistency in the tire’s structure, crucial for vehicle handling and safety.

B2B buyers should take proactive steps to ensure that their suppliers maintain robust quality assurance practices. Here are some strategies:

Conduct Audits: Regular audits of suppliers can help verify their adherence to quality standards and manufacturing processes.

Request Quality Reports: Suppliers should provide documentation demonstrating compliance with international standards and internal QA procedures.

Engage Third-Party Inspectors: Hiring independent inspectors can provide an unbiased assessment of the supplier’s manufacturing processes and product quality.

Evaluate Certification Status: Buyers should verify that suppliers hold relevant certifications and are compliant with regional regulations, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

International buyers should be aware of regional variations in quality standards and regulations. Factors such as climate, road conditions, and local regulations can impact tire performance. Additionally, understanding the nuances of shipping and handling practices in different regions is crucial to maintaining tire integrity during transit.

By focusing on the manufacturing processes and quality assurance measures outlined above, B2B buyers can make informed decisions when sourcing tires, ensuring they receive products that not only meet their performance expectations but also adhere to the highest safety standards.

Ensuring optimal tire inflation is critical for vehicle safety, performance, and cost efficiency. This practical sourcing guide provides a step-by-step checklist to help B2B buyers—particularly in regions such as Africa, South America, the Middle East, and Europe—understand when and how to check tire inflation effectively. By following these steps, buyers can enhance their procurement strategies and improve fleet maintenance practices.

Before checking tire inflation, familiarize yourself with the manufacturer’s recommended tire pressure for each vehicle model. This specification is crucial as it varies based on vehicle type and load capacity. Refer to the vehicle handbook or the label found on the driver’s door post for precise figures.

Check tire pressure when the tires are cold—ideally before the vehicle has been driven. Tire pressure readings can fluctuate significantly with temperature changes; a cold tire will provide a more accurate PSI measurement. Plan regular inspections early in the day or after the vehicle has been stationary for a few hours.

Invest in a quality tire pressure gauge, whether digital or analog, to ensure accurate readings. A good gauge will help prevent discrepancies that can arise from using faulty or subpar equipment. Look for gauges that have clear markings and are easy to use, as this will enhance operational efficiency during checks.

Incorporate tire pressure checks into your monthly maintenance routine. Regular inspections can prevent tire blowouts and extend tire life by ensuring proper inflation levels. Create a calendar reminder for your team to perform these checks consistently, especially before long-distance trips or when carrying heavy loads.

Maintain a record of tire pressure readings and any adjustments made. This documentation can help identify patterns, such as persistent underinflation, which might indicate leaks or other issues. Keeping detailed logs not only aids in maintenance tracking but also supports compliance with safety regulations.

Educate your team about the importance of proper tire inflation and the steps to check it effectively. Knowledgeable staff can recognize potential issues early and respond accordingly. Consider providing training sessions or resources that cover tire safety, inflation procedures, and maintenance protocols.

Analyze how tire inflation affects your operational costs, including fuel efficiency and tire longevity. Underinflated tires can lead to increased fuel consumption and more frequent tire replacements, impacting your bottom line. Use this analysis to advocate for regular tire maintenance practices within your organization.

Illustrative image related to tire inflation should be checked when the tires are

By following this checklist, B2B buyers can ensure that tire inflation is consistently checked and maintained, leading to safer operations and improved vehicle performance.

When sourcing tire inflation services and products, several cost components come into play. Understanding these can help B2B buyers make informed purchasing decisions.

المواد: The primary materials involved include the rubber used for tires and inflation mediums (air or nitrogen). The cost of these materials can fluctuate based on global supply chains, especially for regions heavily reliant on imports.

العمالة: Labor costs encompass the wages of technicians who check and maintain tire pressure. These costs can vary significantly depending on the local labor market conditions in the buyer’s region. For instance, labor in Europe may be more expensive than in parts of Africa or South America.

نفقات التصنيع الزائدة: Overhead costs include utilities, facilities maintenance, and administrative expenses. For manufacturers, these costs can be proportionally higher in regions with stringent regulations, impacting the overall pricing of tire inflation products and services.

الأدوات: Specialized equipment, such as tire pressure gauges and inflation systems, contribute to the tooling costs. This can be a one-time investment for B2B buyers, but maintenance and calibration can incur ongoing expenses.

مراقبة الجودة (QC): Ensuring that tire inflation products meet safety and performance standards involves quality control processes. This adds to the cost but is crucial, especially in regions where tire failure can lead to significant safety hazards.

الخدمات اللوجستية: Transportation and shipping costs are particularly relevant for international buyers. Costs can vary based on the distance from suppliers, the mode of transport chosen, and any tariffs or duties applicable in the buyer’s country.

الهامش: Finally, suppliers will include a margin that reflects their business model, market positioning, and competitive landscape. This margin can be negotiated, especially in bulk purchases.

Illustrative image related to tire inflation should be checked when the tires are

Several factors influence pricing for tire inflation services and products, which B2B buyers should consider when sourcing.

الحجم/معدل العرض/الطلب: The minimum order quantity (MOQ) can significantly affect pricing. Larger volumes typically lead to lower per-unit costs due to economies of scale. B2B buyers should assess their needs to leverage bulk purchasing.

المواصفات/التخصيص: Customized solutions, such as specific tire pressure monitoring systems (TPMS) or nitrogen inflation setups, can increase costs. Buyers should balance their needs for customization against budget constraints.

Illustrative image related to tire inflation should be checked when the tires are

المواد: The choice between standard air inflation and nitrogen inflation can impact pricing. Nitrogen systems may have higher initial costs but can offer long-term benefits in tire life and fuel efficiency.

Quality/Certifications: Products with higher certifications or those that meet specific quality standards often come at a premium. Buyers must evaluate whether these certifications are necessary for their operational needs.

عوامل الموردين: The reputation and reliability of suppliers can also influence pricing. Established brands may charge higher rates due to perceived value, while newer entrants might offer competitive pricing to gain market share.

Illustrative image related to tire inflation should be checked when the tires are

المصطلحات التجارية الدولية: Understanding international commercial terms (Incoterms) is essential for pricing clarity. These terms dictate responsibilities for shipping, insurance, and tariffs, impacting the total landed cost for B2B buyers.

To optimize costs when sourcing tire inflation services, B2B buyers should consider the following strategies:

التفاوض: Always negotiate terms, especially if purchasing in bulk. Suppliers may be willing to offer discounts or better payment terms to secure large orders.

كفاءة التكلفة: Evaluate the total cost of ownership rather than just upfront prices. Consider long-term benefits of investments in quality products that can extend tire life and reduce fuel consumption.

Pricing Nuances for International Buyers: Understand the local market dynamics, including currency fluctuations and regional supply chain issues, which can affect pricing. Building relationships with suppliers in target regions like Africa, South America, and the Middle East can provide better insights into local pricing strategies.

Disclaimer for Indicative Prices: It’s essential to remember that prices can vary widely based on the factors discussed above. Buyers should seek quotes from multiple suppliers to ensure they receive competitive pricing tailored to their specific needs.

By understanding these components, influencers, and tips, B2B buyers can make informed decisions when sourcing tire inflation products and services, leading to enhanced operational efficiency and cost savings.

In the realm of tire maintenance, ensuring proper inflation is crucial for vehicle safety, performance, and efficiency. However, there are alternative solutions that can complement or even replace the traditional method of manual tire inflation checks. This section explores these alternatives, providing B2B buyers with insights into their respective benefits and drawbacks.

| جانب المقارنة | Tire Inflation Should Be Checked When The Tires Are | Tire Pressure Monitoring System (TPMS) | Nitrogen Inflation |

|---|---|---|---|

| الأداء | Ensures optimal handling and safety | Provides real-time monitoring | Reduces pressure loss |

| التكلفة | Low (manual checking tools) | Moderate (installation costs) | Higher (initial setup) |

| سهولة التنفيذ | Simple, requires minimal training | Requires installation and setup | Requires specific equipment |

| الصيانة | Monthly checks needed | Minimal (alerts when pressure is low) | Less frequent adjustments |

| أفضل حالة استخدام | General vehicle maintenance | Fleet vehicles, high-use scenarios | Performance vehicles, racing |

TPMS is an advanced technology that continuously monitors tire pressure and alerts the driver if levels drop below a safe threshold. Its primary advantage lies in its ability to provide real-time data, allowing for immediate action. However, the installation costs can be significant, and it may require professional setup, making it less accessible for smaller businesses or individual vehicle owners. Maintenance is minimal once installed, though regular checks are still recommended to ensure the system is functioning correctly.

Using nitrogen instead of regular air for tire inflation is another alternative that has gained traction, particularly in high-performance settings. Nitrogen-filled tires maintain pressure longer due to the larger molecular size of nitrogen compared to oxygen, which reduces leakage. This can lead to improved fuel efficiency and tire longevity. However, the initial setup can be more expensive, and access to nitrogen filling stations may be limited, especially in regions with less developed automotive services. Regular monitoring is still necessary, as nitrogen does not eliminate the need for periodic checks entirely.

When selecting a tire maintenance strategy, B2B buyers should evaluate their specific operational needs, budget, and vehicle usage patterns. Traditional tire inflation checks are cost-effective and simple but require consistent manual effort. In contrast, TPMS offers convenience and real-time monitoring at a higher initial investment, while nitrogen inflation presents long-term benefits for performance and efficiency but may involve logistical challenges. By carefully considering these alternatives, businesses can enhance their tire management practices and ensure optimal vehicle performance.

Understanding tire inflation involves several technical properties that are vital for ensuring safety, performance, and longevity of tires. Here are some essential specifications to consider:

Pressure Specifications (PSI)

Tire pressure is typically measured in pounds per square inch (PSI). Each vehicle has manufacturer-recommended pressure levels for both front and rear tires, which are crucial for optimal performance. Maintaining the correct PSI ensures even tire wear, maximizes fuel efficiency, and enhances vehicle handling. For B2B buyers, adhering to these specifications can lead to reduced operational costs and improved safety.

Temperature Sensitivity

Tire pressure can fluctuate with temperature changes. For instance, a rise of 10°C can increase tire pressure by approximately 1.6 PSI. This property is particularly important in regions with extreme temperatures, as it directly affects tire performance and safety. Businesses operating in diverse climates should consider temperature-sensitive monitoring systems to ensure consistent tire performance.

سعة الحمولة

Each tire has a specified load index that indicates the maximum load it can safely support. This property is crucial for businesses involved in logistics or transportation, as exceeding this load can lead to tire failure. Understanding load capacity helps in selecting appropriate tires for different vehicles, ensuring safety and compliance with regulatory standards.

Tread Depth and Design

The tread depth affects traction and handling. Tires must meet minimum tread depth regulations, which vary by region. For B2B buyers, ensuring adequate tread depth not only improves safety but also reduces the risk of accidents and associated liabilities, making it an essential consideration in fleet management.

Inflation Material

Many tires are inflated with air, while others may use nitrogen. Nitrogen inflation can reduce tire wear and improve fuel efficiency due to lower permeability compared to air. Businesses should evaluate the benefits of nitrogen inflation, especially for high-performance or commercial vehicles, to enhance their operational efficiency.

Navigating the tire industry involves understanding several key terms that can impact procurement and supply chain decisions. Here are some commonly used terms:

OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the tire industry, understanding OEM specifications ensures that buyers procure tires that meet the original design standards of vehicles, which is crucial for maintaining warranty coverage and performance.

موك (الحد الأدنى لكمية الطلب)

This is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management. Purchasing below the MOQ can lead to higher costs per unit or difficulty in sourcing specific tire types.

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers to invite them to submit price quotes for specific products. In the tire industry, using RFQs helps businesses compare prices, negotiate terms, and ensure they are getting the best value for their tire procurement.

إنكوترمز (الشروط التجارية الدولية)

These are a set of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B transactions, especially when importing or exporting tires across borders.

TPMS (Tire Pressure Monitoring System)

This technology continuously monitors tire pressure and alerts drivers when it falls below a safe threshold. For companies operating fleets, implementing TPMS can prevent accidents, reduce tire wear, and enhance overall safety, making it a valuable investment.

Tire Warranty

A tire warranty covers defects in material or workmanship and can vary by manufacturer. Understanding warranty terms is essential for B2B buyers to ensure they are protected against premature tire failure, which can significantly impact operational costs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions regarding tire inflation and maintenance, ultimately leading to safer and more efficient operations.

The tire inflation sector is increasingly influenced by global trends emphasizing safety, efficiency, and sustainability. With the automotive industry evolving rapidly, international B2B buyers must navigate these changes to ensure they source products that meet both current and future demands. The rising awareness of road safety has made regular tire pressure checks essential. In many regions, including Africa and South America, government regulations are beginning to mandate tire maintenance standards, which drives demand for reliable tire monitoring systems and services.

Illustrative image related to tire inflation should be checked when the tires are

Emerging technologies such as Tire Pressure Monitoring Systems (TPMS) are reshaping how businesses approach tire maintenance. These systems not only provide real-time data on tire pressure but also help in preventing accidents caused by underinflated tires. Additionally, the integration of IoT and predictive analytics is enabling businesses to forecast tire performance and maintenance needs, thus optimizing their operational efficiency.

B2B buyers are also witnessing a surge in demand for high-quality, durable tires that can withstand varying climatic conditions, particularly in regions like the Middle East and Europe, where temperature fluctuations can significantly impact tire performance. This trend is pushing manufacturers to innovate, leading to the development of tires that are not only more resilient but also offer enhanced fuel efficiency. As a result, sourcing strategies must adapt to prioritize suppliers who can provide advanced tire solutions that align with these emerging market dynamics.

Sustainability is becoming a critical factor in the tire industry, particularly regarding tire inflation practices. Improperly inflated tires contribute to increased fuel consumption, leading to higher CO2 emissions and a larger carbon footprint. By ensuring optimal tire pressure, businesses can significantly reduce their environmental impact while also enhancing operational efficiency. This dual benefit positions tire inflation practices as a key component of broader sustainability strategies.

Illustrative image related to tire inflation should be checked when the tires are

Moreover, ethical sourcing is gaining traction among B2B buyers who are increasingly concerned about the environmental and social implications of their supply chains. Suppliers that focus on sustainable practices—such as using eco-friendly materials and adhering to fair labor standards—are becoming more attractive to buyers. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are essential for businesses looking to establish a responsible supply chain.

Investing in sustainable tire inflation solutions can also enhance a company’s brand reputation. As consumers and businesses alike prioritize eco-conscious practices, aligning sourcing strategies with sustainability goals is no longer optional but a competitive necessity. For B2B buyers, collaborating with manufacturers who prioritize green technologies and ethical sourcing will not only fulfill compliance requirements but also contribute positively to their corporate social responsibility (CSR) initiatives.

Historically, tire inflation practices were largely manual, relying on drivers to check pressure levels sporadically. The introduction of pressure gauges in the early 20th century marked a significant advancement, allowing for more accurate measurements. However, it wasn’t until the late 20th century that Tire Pressure Monitoring Systems (TPMS) emerged, revolutionizing the industry by providing real-time data on tire conditions. This evolution has been driven by advancements in automotive technology, the growing emphasis on safety, and increasing regulatory requirements across various regions.

Today, the focus has shifted towards integrating digital technologies into tire maintenance, allowing businesses to leverage data analytics for proactive decision-making. As the industry continues to evolve, B2B buyers must stay informed about these advancements to ensure they are making strategic sourcing decisions that align with both current trends and future innovations.

How often should tire inflation be checked for optimal performance?

Tire inflation should be checked at least once a month, as tires typically lose about 1 pound per square inch (PSI) of pressure monthly due to natural permeation. Additionally, it’s crucial to check tire pressure before long journeys or when carrying heavier loads. Regular checks not only enhance safety and performance but also prolong tire life and improve fuel efficiency, making it a critical aspect of vehicle maintenance for businesses operating fleets.

What are the consequences of improper tire inflation?

Improper tire inflation can lead to rapid or uneven tire wear, which may result in costly replacements and potential safety hazards, including blowouts. Underinflated tires can increase rolling resistance, leading to higher fuel consumption, while overinflated tires can reduce traction and handling. For businesses, maintaining proper tire pressure is essential to minimize operational costs and ensure the safety of drivers and cargo.

How do I choose a reliable supplier for tire inflation products?

When selecting a supplier for tire inflation products, consider their reputation, certifications, and experience in the industry. Look for suppliers who offer comprehensive quality assurance processes and have positive customer reviews. Additionally, inquire about their supply chain reliability, lead times, and whether they can meet your specific requirements, such as customization options or bulk orders, to ensure you receive high-quality products consistently.

What payment terms should I expect when sourcing tire inflation solutions internationally?

Payment terms can vary significantly by supplier and region. Common terms include advance payment, net 30, or letters of credit. It’s important to clarify these terms upfront to avoid misunderstandings. For international transactions, consider factors such as currency fluctuations and transaction fees. Establishing clear payment terms can enhance trust and facilitate smoother transactions, particularly in regions with diverse economic conditions.

How can I ensure the quality of tire inflation products I purchase?

To ensure quality, request product specifications, certifications, and testing standards from suppliers. Conducting on-site audits or requesting samples can also help assess product quality before committing to larger orders. Additionally, consider suppliers who offer warranties or guarantees, as this indicates confidence in their products. Regular quality checks upon receipt of goods can further safeguard against defects and ensure compliance with your standards.

What logistical considerations should I keep in mind when sourcing tires?

Logistical considerations include shipping methods, customs regulations, and lead times. Ensure that your supplier has experience with international shipping and can navigate customs efficiently to minimize delays. Factor in the total cost of logistics, including shipping, taxes, and duties, when calculating the overall expense of your purchase. Establishing clear communication with your supplier can help address any potential logistical challenges proactively.

Are there customization options available for tire inflation products?

Many suppliers offer customization options for tire inflation products, such as specific pressure settings, branding, or tailored features to meet your business needs. When sourcing, clearly communicate your requirements and ask about the supplier’s ability to accommodate these requests. Customization can enhance the effectiveness of tire inflation solutions and align them more closely with your operational goals.

What should I consider regarding minimum order quantities (MOQ) for tire inflation products?

Minimum order quantities (MOQ) can vary by supplier and product type. When sourcing, inquire about the MOQ to ensure it aligns with your purchasing capacity. Consider the implications of bulk purchasing, such as potential cost savings versus the risk of overstocking. Establishing a good relationship with your supplier may also provide flexibility in MOQs, allowing you to negotiate terms that suit your business needs better.

المجال: reddit.com

مسجل: 2005 (20 سنة)

مقدمة: This company, Reddit – Tire Pressure Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

المجال: continental-tires.com

مسجل: 2000 (25 سنة)

مقدمة: Tire pressure is crucial for vehicle safety and performance. It is recommended to check tire pressure once a month, ideally when the tires are cold. Refer to the vehicle handbook for the recommended PSI (pounds per square inch) for front and rear tires. Use a reliable tire pressure gauge to measure the pressure and adjust accordingly based on the vehicle’s load. Underinflated tires can lead to acc…

المجال: bridgestoneamericas.com

مسجل: 2002 (23 سنة)

مقدمة: Proper tire inflation is crucial for maximizing tire performance and longevity. Tires should be checked at least once a month, as they lose approximately 1 PSI of pressure monthly. Tire pressure can change with temperature, losing about 1 PSI for every 10 degrees Fahrenheit change. The correct tire pressure is not found on the tire’s sidewall, which indicates maximum pressure, but rather on the dr…

المجال: jaguarmelbourne.net

Registered: 2021 (4 years)

مقدمة: Optimal tire pressure checks should be done at least once a month and before long trips. Proper tire inflation is crucial for vehicle handling, tire life, and fuel efficiency. The ideal PSI varies by vehicle model and can be found inside the driver’s door or in the vehicle’s manual. Jaguar Melbourne offers tire pressure checks and adjustments. Regular checks improve handling, reduce blowout risks,…

المجال: pirelli.com

مسجل: 1995 (30 سنة)

مقدمة: Recommended tire pressure is established by the vehicle manufacturer and typically falls between 28 and 36 PSI. The correct pressure can be found in the car’s operator manual or on a sticker inside the driver’s door. Tire pressure should be checked when the tire is cold for accuracy. Maximum tire pressure is indicated on the tire’s sidewall and should not be used for everyday driving as it can imp…

المجال: tiresplus.com

مسجل: 1995 (30 سنة)

مقدمة: Bridgestone DriveGuard tire: Can be driven up to 50 miles at speeds of up to 50 MPH after complete air loss.

Maintaining optimal tire pressure is crucial for vehicle safety, efficiency, and longevity. Regular checks—ideally once a month—can prevent costly repairs, enhance fuel economy, and significantly reduce the risk of accidents caused by tire failures. For businesses operating in diverse climates across Africa, South America, the Middle East, and Europe, understanding local conditions and their impact on tire performance is essential. By investing in reliable tire pressure monitoring systems and ensuring that your fleet adheres to manufacturer recommendations, you can create a safer and more cost-effective operation.

Strategic sourcing allows businesses to partner with reputable suppliers who provide high-quality tires and maintenance equipment tailored to regional needs. This approach not only enhances operational efficiency but also fosters long-term relationships that can lead to better pricing and support.

Illustrative image related to tire inflation should be checked when the tires are

As tire technology evolves, including advancements in tire pressure monitoring systems and eco-friendly materials, staying informed will be key to maintaining a competitive edge. Engage with suppliers who prioritize innovation and sustainability to ensure your fleet is not only safe but also aligned with global environmental standards.

In conclusion, prioritize tire inflation checks as a core component of your vehicle maintenance strategy. By doing so, you enhance safety, optimize costs, and position your business for future growth. Take action today and explore strategic sourcing options that will empower your fleet’s performance.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.