- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the rapidly evolving industrial landscape, sourcing the right air motor pump can be a pivotal challenge for businesses aiming to enhance their operational efficiency. With increasing demands for versatile and reliable pumping solutions, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—must navigate a complex array of options. This guide serves as a comprehensive resource, detailing various types of air motor pumps, their applications across different industries, and essential factors for supplier vetting.

Understanding the nuances of air motor pumps is crucial for making informed purchasing decisions. This guide explores critical aspects such as performance specifications, cost considerations, and maintenance requirements, empowering buyers to assess their needs effectively. Additionally, it provides insights into market trends and technological advancements that are shaping the future of air motor pumps.

By leveraging this guide, B2B buyers will gain the knowledge necessary to select high-quality products that align with their operational goals, ensuring reliability and efficiency in their processes. With a focus on actionable insights and strategic sourcing, this resource is designed to equip businesses with the confidence to invest in air motor pumps that can drive productivity and enhance performance in their respective markets.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Rotary Vane Pumps | Compact design, continuous flow, low maintenance | Automotive, manufacturing | الإيجابيات: Efficient, reliable; السلبيات: Limited pressure range. |

| Diaphragm Pumps | Self-priming, can handle viscous fluids | Chemical processing, food industry | الإيجابيات: Versatile, safe for sensitive materials; السلبيات: More complex maintenance. |

| Piston Pumps | High pressure output, robust construction | Oil & gas, heavy machinery | الإيجابيات: Powerful, suitable for high-demand applications; السلبيات: Bulkier, higher energy consumption. |

| Scroll Pumps | Quiet operation, high efficiency, minimal vibration | HVAC systems, laboratory use | الإيجابيات: Low noise, energy-efficient; السلبيات: تكلفة أولية أعلى. |

| Screw Pumps | Continuous flow, suitable for high viscosity fluids | Wastewater treatment, industrial | الإيجابيات: Consistent performance, handles large volumes; السلبيات: Requires precise installation. |

Rotary vane pumps are characterized by their compact design and ability to provide a continuous flow of air. They require minimal maintenance, making them ideal for applications in automotive and manufacturing industries. When considering a rotary vane pump, B2B buyers should evaluate the efficiency and reliability it offers, but be aware of its limited pressure range, which may not meet the demands of all applications.

Diaphragm pumps are notable for their self-priming capability and versatility in handling various fluids, including viscous substances. This makes them particularly suitable for chemical processing and the food industry, where safety and material integrity are paramount. Buyers should consider the complexity of maintenance and potential higher costs, but the benefits of using diaphragm pumps often outweigh these concerns.

Piston pumps are known for their robust construction and high-pressure output, making them indispensable in the oil and gas industry and for heavy machinery applications. Their power makes them suitable for high-demand scenarios, but potential buyers should note their bulkier design and higher energy consumption, which may influence operational costs and space considerations.

Scroll pumps are distinguished by their quiet operation and high efficiency, making them ideal for HVAC systems and laboratory applications. They produce minimal vibration, enhancing their suitability for sensitive environments. While the initial investment may be higher, the long-term energy savings and reduced noise levels can lead to significant benefits for B2B buyers.

Screw pumps provide a continuous flow and can handle high-viscosity fluids, making them ideal for wastewater treatment and various industrial processes. Their ability to maintain consistent performance while managing large volumes is a key advantage. However, buyers should be mindful of the precise installation requirements, which may necessitate additional investment in setup and maintenance.

| الصناعة/القطاع | Specific Application of air motor pump | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Manufacturing | Tire inflation and maintenance | Ensures optimal vehicle performance and safety | Consider compatibility with various tire types and PSI requirements. |

| Construction | Pneumatic tool operation | Enhances efficiency and productivity on job sites | Evaluate air pressure requirements and durability for rugged environments. |

| الزراعة | Equipment cleaning and maintenance | Reduces downtime and maintenance costs | Look for portability and ease of use in remote locations. |

| Oil & Gas | Fuel transfer and pneumatic control systems | Improves operational efficiency and safety | Ensure compliance with industry regulations and safety standards. |

| النقل والخدمات اللوجستية | Loading and unloading of goods | Streamlines operations and reduces labor costs | Assess the air motor pump’s capacity and reliability for heavy-duty tasks. |

In the automotive manufacturing sector, air motor pumps are essential for tire inflation and routine maintenance. They ensure that vehicles are equipped with properly inflated tires, which is critical for performance and safety. These pumps help reduce the time spent on tire checks and adjustments, enhancing overall production efficiency. For international buyers, especially in regions with varying tire specifications, it’s important to choose pumps that can accommodate diverse tire types and pressure requirements, ensuring compliance with local safety standards.

In construction, air motor pumps are vital for powering pneumatic tools, which are commonly used for tasks such as drilling, nailing, and sanding. These pumps facilitate the efficient operation of tools, leading to increased productivity on job sites. They also contribute to reduced manual labor, allowing workers to focus on more complex tasks. Buyers should consider the durability and pressure output of the pumps to match the demanding conditions of construction environments, especially in regions with harsh weather or rugged terrains.

In agriculture, air motor pumps are used for cleaning equipment and maintaining machinery, which is crucial for preventing breakdowns and prolonging equipment life. By providing a reliable source of compressed air, these pumps help farmers keep their tools and machinery in optimal condition, thereby minimizing downtime during critical planting and harvesting seasons. Buyers in this sector should prioritize portability and ease of use, as agricultural operations often occur in remote locations where access to power sources may be limited.

Air motor pumps are integral to the oil and gas industry, particularly for fuel transfer and operating pneumatic control systems. They enhance operational efficiency by providing a reliable source of compressed air for various applications, including equipment maintenance and emergency response. Safety is paramount in this sector, so buyers must ensure that the pumps comply with industry regulations and safety standards, particularly in hazardous environments where flammable materials are present.

In the transportation and logistics sector, air motor pumps streamline the loading and unloading of goods by powering pneumatic lifting and handling equipment. This capability reduces the physical strain on workers and enhances operational efficiency, leading to significant labor cost savings. For international buyers, it’s crucial to assess the pump’s capacity and reliability, especially when dealing with heavy-duty tasks, to ensure that the equipment can handle varying load requirements across different regions.

Illustrative image related to air motor pump

المشكلة B2B buyers often encounter air motor pumps that perform inconsistently in varying environmental conditions, such as extreme temperatures or high humidity. For instance, a construction company may find that their air motor pumps work well in moderate climates but struggle in hotter or colder regions, leading to delays in projects and increased downtime. This inconsistency can result in frustration and financial loss, as companies rely on these tools for timely operations.

الحل: To mitigate this issue, buyers should prioritize sourcing air motor pumps that are specifically designed for versatility in extreme conditions. Look for products that feature robust construction, such as those made from durable materials that can withstand temperature fluctuations. Additionally, ensure that the pump has a reliable motor that can function effectively in a range of environmental conditions. It is also beneficial to consult with manufacturers about the operational limits of their products and request performance data in various climates before making a purchase. Regular maintenance and testing of the pumps can further enhance their reliability, ensuring they meet operational demands regardless of the environment.

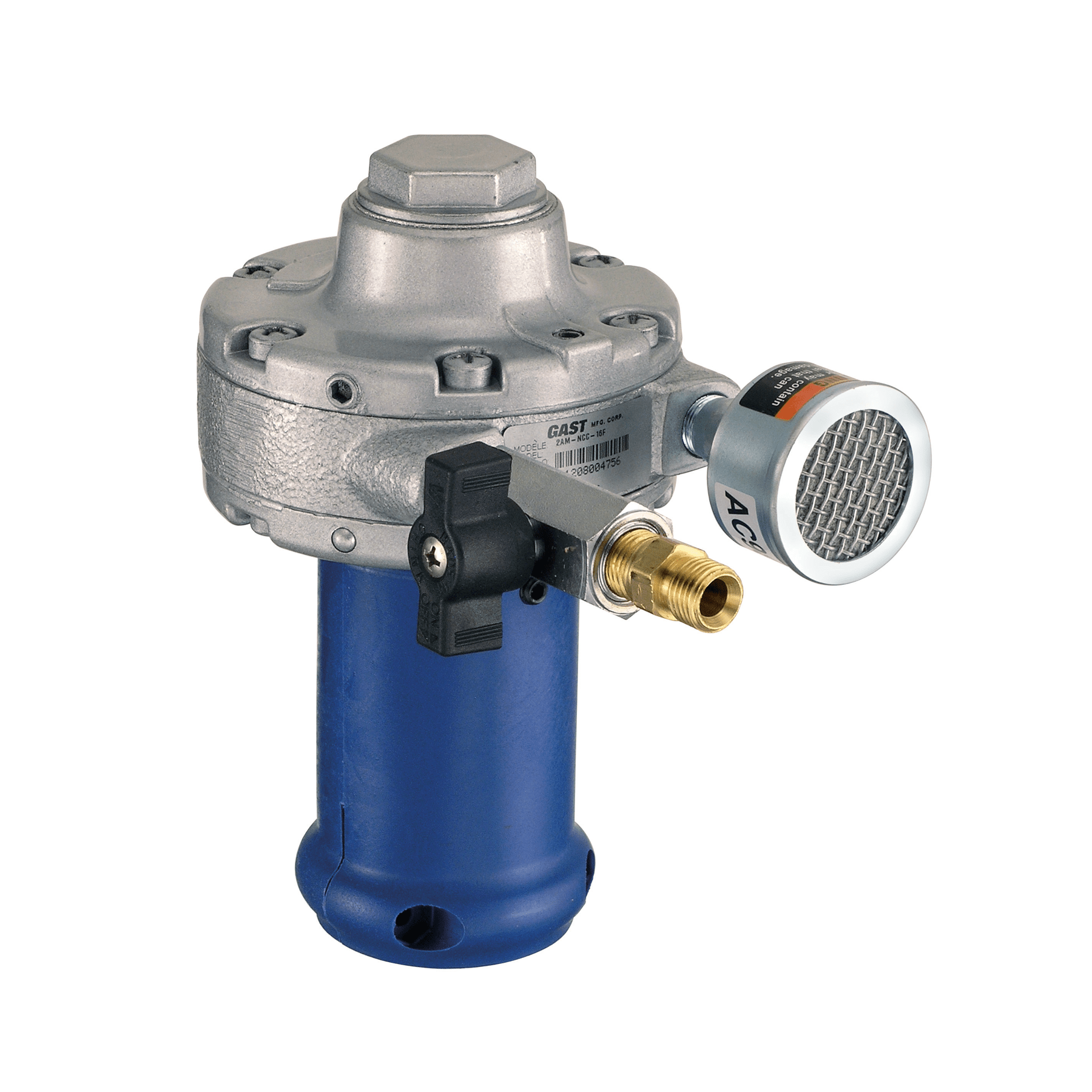

المشكلة Many B2B buyers face challenges in sourcing compatible accessories for their air motor pumps, such as hoses, fittings, and pressure gauges. This can be particularly frustrating for companies that need to ensure seamless integration of equipment for their operations. For example, a manufacturing facility may find that their air motor pump does not work well with available hoses, leading to air leaks and inefficiencies that compromise productivity.

Illustrative image related to air motor pump

الحل: To address this compatibility issue, buyers should consider purchasing air motor pumps from suppliers that offer a comprehensive range of compatible accessories. Before finalizing a purchase, conduct thorough research on the specifications of the pump and the accessories needed. It is advisable to choose a supplier that provides a complete solution package, including hoses and fittings tailored for their pumps. Additionally, establishing relationships with suppliers who can provide guidance on the best accessory options can streamline operations and reduce downtime caused by equipment mismatches. Finally, maintaining an inventory of critical accessories can help ensure that operations run smoothly without delays.

المشكلة B2B buyers often struggle with unclear maintenance requirements for air motor pumps, leading to decreased longevity and performance. A logistics company might invest in a high-quality pump only to discover that it requires specific maintenance practices that were not clearly communicated. This lack of clarity can result in premature wear and tear, unexpected breakdowns, and costly repairs, which can affect service delivery and customer satisfaction.

الحل: To avoid these pitfalls, it is crucial for buyers to seek out air motor pumps that come with detailed maintenance guides and customer support. Before purchasing, inquire about the recommended maintenance schedule, including any necessary lubrication, filter changes, and inspections. Additionally, consider training programs offered by manufacturers that help staff understand proper care and troubleshooting methods for the pumps. Regular training sessions can empower employees to perform basic maintenance, thus extending the lifespan of the equipment and enhancing overall performance. Buyers should also document maintenance activities to create a historical record, which can help identify trends and areas for improvement in pump usage.

When selecting materials for air motor pumps, several factors such as performance, durability, and cost must be considered. The choice of material directly impacts the pump’s efficiency, longevity, and suitability for various applications. Below, we analyze four common materials used in the manufacturing of air motor pumps, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Aluminum is a lightweight and corrosion-resistant material, making it a popular choice for air motor pumps. It typically has a temperature rating of up to 150°C and can withstand moderate pressure levels.

الإيجابيات: The primary advantage of aluminum is its excellent strength-to-weight ratio, which enhances the portability of the pump. Additionally, it is relatively inexpensive compared to other metals, making it a cost-effective option for manufacturers.

السلبيات: However, aluminum can be less durable than steel under high-stress conditions, and it may require additional coatings to enhance its corrosion resistance in harsh environments.

التأثير على التطبيق: Aluminum is suitable for applications involving air and non-corrosive gases but may not be ideal for aggressive media.

اعتبارات للمشترين الدوليين: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should also consider the availability of aluminum alloys that meet local regulations.

Steel is another common material used in air motor pumps, known for its strength and durability. It can handle high pressures and temperatures, often rated up to 300°C.

الإيجابيات: Steel’s robustness makes it ideal for heavy-duty applications, ensuring longevity and reliability. It is also widely available and can be manufactured with various surface treatments to enhance corrosion resistance.

السلبيات: The main drawback of steel is its weight, which can affect the portability of the pump. Additionally, the cost of high-quality steel can be significantly higher than aluminum.

التأثير على التطبيق: Steel is suitable for applications involving high-pressure air and aggressive media, making it versatile for various industrial uses.

اعتبارات للمشترين الدوليين: Buyers should ensure that the steel used complies with relevant standards such as JIS and ASTM. In regions like Europe, adherence to environmental regulations regarding steel production is also essential.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in air motor pumps due to their lightweight and corrosion-resistant properties.

الإيجابيات: Plastics are generally less expensive and easier to mold into complex shapes, allowing for innovative designs. They are also resistant to a wide range of chemicals, making them suitable for various applications.

السلبيات: However, plastics can have lower temperature and pressure ratings compared to metals, limiting their use in high-performance applications. They may also degrade over time when exposed to UV light or extreme temperatures.

التأثير على التطبيق: Plastic is ideal for applications requiring lightweight and corrosion-resistant components, particularly in consumer-grade pumps.

اعتبارات للمشترين الدوليين: Buyers should verify that the plastics used meet safety and quality standards, especially in regions with stringent regulations like Europe.

Rubber is often used for seals and gaskets in air motor pumps due to its excellent elasticity and ability to create airtight seals.

الإيجابيات: Rubber provides superior sealing capabilities, preventing air leaks and enhancing pump efficiency. It is also resistant to wear and can handle a range of temperatures.

Illustrative image related to air motor pump

السلبيات: The downside is that rubber can degrade over time, especially when exposed to oils or extreme temperatures, necessitating regular maintenance and replacement.

التأثير على التطبيق: Rubber is essential for applications where airtight seals are critical, such as in pneumatic systems.

اعتبارات للمشترين الدوليين: Buyers should ensure that rubber components comply with international standards for safety and performance, particularly in industries like automotive and aerospace.

| المواد | Typical Use Case for air motor pump | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| ألومنيوم | Lightweight, portable pumps | Excellent strength-to-weight ratio | Less durable under high stress | منخفضة |

| الفولاذ | Heavy-duty, high-pressure applications | Robust and long-lasting | أثقل وزناً وأغلى ثمناً | عالية |

| بلاستيك | Consumer-grade, lightweight pumps | Cost-effective and easy to mold | Lower temperature/pressure ratings | منخفضة |

| المطاط | Seals and gaskets in pumps | Superior sealing capabilities | يتحلل بمرور الوقت | منخفضة |

This guide provides valuable insights for B2B buyers in Africa, South America, the Middle East, and Europe, helping them make informed decisions about material selection for air motor pumps.

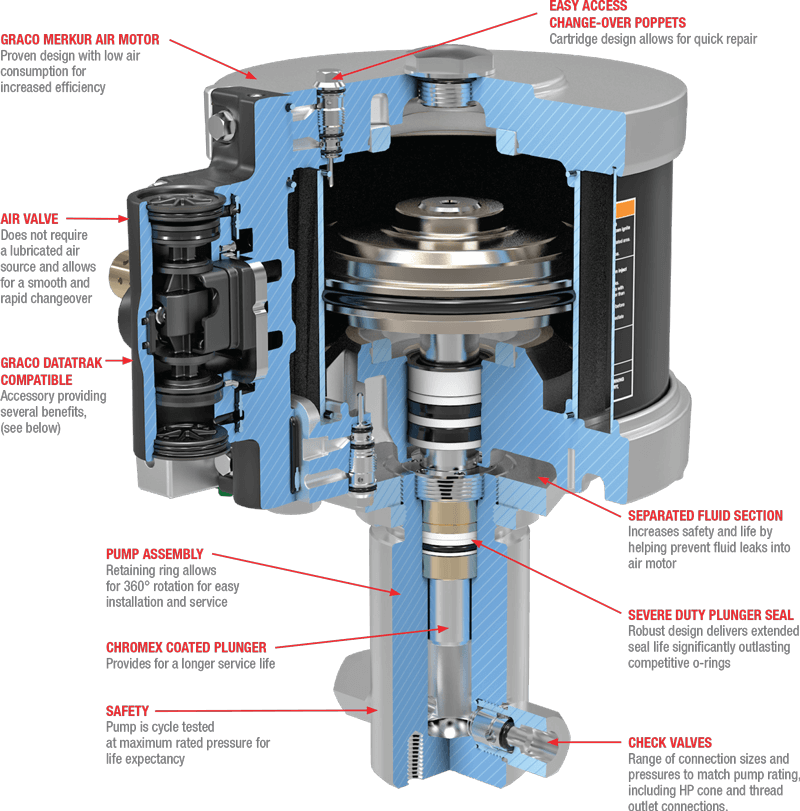

The manufacturing process of air motor pumps involves several critical stages that ensure the final product meets the high standards required by B2B buyers. These stages typically include material preparation, forming, assembly, and finishing.

The first step in manufacturing air motor pumps is the preparation of raw materials, which usually consist of high-quality metals, plastics, and rubber. Suppliers often source materials that comply with international standards to ensure durability and reliability. For instance, aluminum and stainless steel are commonly used for their strength and resistance to corrosion. During this stage, materials are inspected for quality, and any non-conforming materials are discarded. This initial quality check is crucial as it sets the foundation for the entire manufacturing process.

Following material preparation, the forming stage transforms raw materials into specific shapes required for pump components. Common techniques include machining, injection molding, and die casting. Machining allows for precise tolerances, which are vital for the pump’s performance. Injection molding is often used for plastic components, allowing for complex shapes and reduced waste. Die casting may be employed for metal parts, providing strength and dimensional accuracy. Each technique is selected based on the component’s requirements and the desired performance characteristics.

Once individual components are formed, they are assembled into the final product. This stage involves both manual and automated processes, depending on the complexity of the pump. Skilled technicians typically perform quality checks during assembly, ensuring that each component fits correctly and functions as intended. The use of jigs and fixtures can aid in maintaining consistency and accuracy. An effective assembly process not only enhances the reliability of the air motor pump but also minimizes the risk of defects.

The final stage in the manufacturing process is finishing, which may include surface treatments, painting, or coating. These processes serve multiple purposes, such as enhancing corrosion resistance, improving aesthetic appeal, and providing a smoother operation. For instance, anodizing aluminum components can increase their durability and resistance to wear. Quality assurance during this stage is critical, as any imperfections can affect the pump’s overall performance and lifespan.

Illustrative image related to air motor pump

Quality assurance (QA) is paramount in the manufacturing of air motor pumps, particularly for B2B buyers who require reliability and compliance with international standards. Key QA standards include ISO 9001, which outlines a framework for consistent quality management systems, and industry-specific certifications like CE and API.

ISO 9001 certification ensures that manufacturers adhere to a structured quality management system, which includes processes for continuous improvement and customer satisfaction. CE marking indicates that a product meets European health, safety, and environmental protection standards, while API certification is relevant for products used in the petroleum and natural gas industries. Manufacturers seeking these certifications must undergo rigorous audits and assessments to ensure compliance.

Quality control in the manufacturing of air motor pumps typically involves several checkpoints, including:

مراقبة الجودة الواردة (IQC): This step inspects raw materials before they enter the production line, ensuring they meet the required specifications.

مراقبة الجودة أثناء العملية (IPQC): During manufacturing, continuous checks are conducted to monitor processes and identify defects early.

مراقبة الجودة النهائية (FQC): Once the pumps are assembled, final inspections are performed to verify functionality, safety, and compliance with specifications.

These checkpoints help ensure that each pump meets quality standards before reaching the market.

Testing methods play a crucial role in the quality assurance process for air motor pumps. Common methods include:

اختبار الأداء: Evaluates the pump’s ability to operate under specified conditions, such as pressure and flow rate.

اختبار المتانة: Assesses the product’s longevity by simulating real-world operating conditions over extended periods.

Leak Testing: Ensures that the pump does not leak under pressure, which is critical for its reliability and safety.

B2B buyers should inquire about the specific testing methods employed by manufacturers to ensure that their products meet rigorous performance standards.

B2B buyers must conduct due diligence when selecting suppliers for air motor pumps. Here are several strategies to verify supplier quality control practices:

عمليات تدقيق الموردين: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall compliance with international standards.

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QA processes, including results from IQC, IPQC, and FQC.

عمليات التفتيش من طرف ثالث: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s quality control practices and product reliability.

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider in quality assurance:

الامتثال التنظيمي: Each region may have different regulatory requirements. Understanding these regulations is crucial for ensuring that the products comply with local laws.

Cultural Differences in Quality Expectations: Different markets may have varying expectations regarding quality and performance. It’s essential to communicate these expectations clearly to suppliers.

Logistics and Supply Chain: Quality assurance doesn’t end at manufacturing. Ensuring that products remain undamaged during shipping and handling is equally important. Buyers should establish agreements with suppliers regarding packaging and transportation standards.

By understanding these aspects of manufacturing and quality assurance, B2B buyers can make informed decisions when sourcing air motor pumps, ensuring they receive reliable, high-quality products that meet their operational needs.

In the dynamic landscape of B2B procurement, sourcing an air motor pump requires a strategic approach to ensure you select the right product for your operational needs. This guide provides a step-by-step checklist to help buyers navigate the sourcing process effectively, ensuring that all critical factors are considered.

Before initiating the sourcing process, clearly outline the technical requirements for the air motor pump. Consider factors such as pressure capacity, flow rate, and compatibility with existing equipment.

– Key Specifications: Determine the PSI range you need, as well as any specific features like portability or power source (e.g., rechargeable vs. plug-in).

Conduct thorough market research to identify potential suppliers and understand the competitive landscape. This step is crucial for benchmarking prices and features.

– Market Analysis: Look into established brands and new entrants in the air motor pump market, focusing on their market reputation and product range.

– Regional Considerations: Pay attention to suppliers that have a strong presence in your target regions, such as Africa or South America.

Before committing, vet suppliers thoroughly to ensure they meet your standards. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Due Diligence: Look for suppliers with certifications that validate their quality and reliability, such as ISO or industry-specific accreditations.

– Customer Feedback: Check for reviews and testimonials from other customers to gauge supplier performance.

Illustrative image related to air motor pump

Once you have shortlisted suppliers, request product samples for evaluation. Testing samples allows you to verify the performance claims made by suppliers.

– Performance Assessment: Evaluate the samples based on your defined specifications, focusing on ease of use, durability, and reliability under operating conditions.

– Compatibility Check: Ensure the air motor pump is compatible with your existing systems and meets your operational requirements.

Carefully review pricing structures and payment terms offered by each supplier. Cost is a significant factor in procurement, but it should not compromise quality.

– التكلفة الإجمالية للملكية: Consider not just the initial purchase price but also potential maintenance costs and warranty offerings.

– Flexible Payment Options: Look for suppliers who offer favorable payment terms, such as net payment options or discounts for bulk purchases.

Once you have selected a supplier, enter into negotiations to finalize pricing, delivery schedules, and other contractual terms.

– Contract Clarity: Ensure that all terms are clearly defined in the contract to avoid misunderstandings later, including delivery timelines and after-sales support.

– Performance Metrics: Include performance metrics and warranties to safeguard against product failures or discrepancies in quality.

After finalizing the procurement, establish a plan for ongoing support and maintenance.

– Support Structure: Verify that the supplier offers adequate customer support, including technical assistance and spare parts availability.

– Training and Resources: Consider if training is necessary for your team to effectively use and maintain the air motor pumps.

By following this checklist, B2B buyers can ensure a comprehensive and informed sourcing process for air motor pumps, leading to successful procurement that meets their operational needs.

Understanding the cost structure and pricing strategies for air motor pumps is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis outlines the key components of cost, influential pricing factors, and strategic buyer tips to optimize sourcing decisions.

The cost structure of air motor pumps encompasses several critical components:

المواد: The selection of materials significantly impacts the overall cost. High-quality components, such as durable plastics and metals, enhance product performance but can increase expenses. Buyers should consider the trade-off between cost and longevity.

العمالة: Labor costs vary by region. Countries with lower wage standards may offer more competitive pricing, but this can affect product quality. Understanding the labor landscape in supplier countries is crucial for assessing overall costs.

نفقات التصنيع الزائدة: This includes utilities, rent, and administrative costs associated with production. Efficient manufacturing processes can reduce overhead, leading to lower prices for buyers.

الأدوات: Initial tooling costs for custom designs can be substantial. Buyers seeking bespoke air motor pumps should factor in these costs, which can be amortized over larger production volumes.

مراقبة الجودة (QC): Robust QC processes ensure product reliability and compliance with industry standards. However, stringent QC measures may increase costs, which should be weighed against the potential for returns and warranty claims.

الخدمات اللوجستية: Shipping costs can vary widely based on distance, shipping method, and the chosen Incoterms. Buyers must consider these factors when evaluating total costs.

الهامش: Suppliers typically add a profit margin on top of their costs. Understanding the market dynamics can help buyers negotiate better terms.

Several pricing influencers play a significant role in determining the final cost of air motor pumps:

الحجم والحد الأدنى لكمية الطلب (MOQ): Higher order volumes usually lead to lower per-unit costs. Buyers should assess their needs carefully to negotiate favorable MOQ terms with suppliers.

المواصفات والتخصيص: Customized pumps that meet specific requirements can incur higher costs due to additional design and manufacturing efforts. Clear communication of specifications can help avoid unexpected charges.

المواد وشهادات الجودة: The choice of materials and the presence of quality certifications (e.g., ISO, CE) can influence pricing. Buyers should prioritize suppliers who demonstrate compliance with relevant standards to ensure product reliability.

عوامل الموردين: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their products due to perceived quality and service.

المصطلحات التجارية الدولية: The chosen Incoterms dictate the responsibilities for shipping and logistics costs. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating total landed costs.

International B2B buyers can employ several strategies to enhance cost efficiency:

التفاوض على الأسعار والشروط: Engage in open discussions with suppliers about pricing structures and potential discounts for bulk orders. Building a strong relationship can lead to better terms over time.

النظر في التكلفة الإجمالية للملكية (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. A higher upfront investment in a quality product can lead to savings in the long run.

كن على دراية بالفروق الدقيقة في التسعير: Different markets may exhibit varying pricing strategies. For example, European suppliers may prioritize quality and compliance, while suppliers in other regions may compete primarily on price.

Conduct Market Research: Understanding the competitive landscape can empower buyers to make informed decisions. Analyzing multiple suppliers and their offerings will facilitate better negotiation outcomes.

Navigating the cost and pricing landscape of air motor pumps requires a thorough understanding of various components and influencers. By leveraging strategic insights and negotiating effectively, international B2B buyers can optimize their sourcing decisions, ensuring they obtain high-quality products at competitive prices. Always remember to consider indicative prices as starting points for negotiations rather than fixed amounts.

When evaluating the best solutions for tire inflation and various pneumatic needs, the air motor pump stands out as a popular choice. However, it’s essential to consider alternatives that may offer unique advantages depending on specific use cases. This analysis will compare the air motor pump against two viable alternatives: electric tire inflators and manual hand pumps. By understanding the strengths and weaknesses of each, B2B buyers can make more informed decisions.

| جانب المقارنة | Air Motor Pump | Electric Tire Inflator | Manual Hand Pump |

|---|---|---|---|

| الأداء | High pressure (up to 120 PSI), quick inflation times | Varies, generally effective for cars and bikes | Low pressure, time-consuming for larger tires |

| التكلفة | Moderate initial investment (~$70-$130) | Varies widely ($30-$150), depending on features | Low-cost option, typically $10-$30 |

| سهولة التنفيذ | Simple setup, portable, rechargeable | Plug-and-play with car outlets, some battery-operated options | Requires physical effort, limited portability |

| الصيانة | Low maintenance, occasional battery replacement | Minimal maintenance, check battery and connections | Requires manual effort, prone to wear and tear |

| أفضل حالة استخدام | Ideal for emergency situations and diverse vehicles | Best for regular use, especially in personal vehicles | Suitable for light use, budget-conscious buyers |

Electric tire inflators offer a convenient solution for many users, especially those who require consistent performance. They are typically easy to operate—many models plug directly into the vehicle’s cigarette lighter or run on batteries. Their inflation speed can be decent, but it varies based on the model. The downside is that electric inflators can be more expensive than air motor pumps and may not provide the same high pressure for larger tires. Additionally, they may require a reliable power source, making them less suitable for remote locations.

Manual hand pumps present a budget-friendly alternative for those who need a basic inflation tool. They are lightweight and portable, making them easy to carry. However, they require physical effort to operate, which can be a significant drawback, especially for larger tires. Manual pumps also generally provide lower pressure, making them less efficient for quick inflation needs. Their simplicity, however, means they are less prone to mechanical failure, appealing to those seeking minimal maintenance.

In conclusion, selecting the right inflation solution depends on various factors, including your specific requirements, budget, and intended use. The air motor pump is a versatile and powerful option, ideal for emergency situations and diverse vehicle types. Electric tire inflators offer convenience and ease of use for regular applications, while manual hand pumps serve as a cost-effective choice for light-duty tasks. By carefully assessing these alternatives, B2B buyers can make strategic investments that align with their operational demands and enhance efficiency in tire maintenance.

Illustrative image related to air motor pump

When sourcing air motor pumps, understanding the technical specifications is crucial for making informed purchasing decisions. Here are several key properties to consider:

The material used in an air motor pump typically includes high-grade aluminum or reinforced plastics. These materials ensure durability and resistance to corrosion, which is particularly important in varying climates. For B2B buyers, selecting pumps made from superior materials can lead to longer product lifespans and reduced maintenance costs.

Pressure rating, often measured in PSI (pounds per square inch), indicates the maximum pressure the pump can generate. Common ratings for air motor pumps range from 60 PSI to 120 PSI. Understanding this specification is vital for applications requiring specific pressure levels, ensuring compatibility with the intended use and preventing operational failures.

The flow rate, expressed in cubic feet per minute (CFM), measures the volume of air the pump can deliver. Higher flow rates allow for quicker inflation and reduced downtime, which is critical for businesses that rely on efficiency. Buyers should assess their operational needs to choose a pump with an appropriate flow rate.

Tolerance refers to the acceptable range of deviation in pump dimensions and performance. This specification ensures that components fit together correctly and function as intended. In a B2B context, precise tolerances are essential for maintaining quality control and reliability in industrial applications.

Air motor pumps can be powered by various sources, including pneumatic, electric, or battery-operated systems. The choice of power source affects portability and convenience. B2B buyers must consider the operational environment and frequency of use when selecting the appropriate power option to enhance productivity.

The weight of the pump is a significant factor for businesses that need to transport equipment frequently. Lighter models are typically easier to handle and store, while heavier pumps may offer more robust features. Assessing weight against the needs of your operation can lead to better decision-making in terms of logistics and usability.

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

Illustrative image related to air motor pump

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For air motor pumps, sourcing from OEMs can ensure quality and compatibility with existing machinery, which is vital for maintaining operational efficiency.

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cash flow. Understanding MOQs can help businesses negotiate better terms and avoid overstocking.

An RFQ is a document issued by buyers to solicit price quotes from suppliers. This term is important in the procurement process, as it helps businesses compare options and make cost-effective decisions regarding air motor pumps.

Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify aspects such as shipping costs, risk transfer, and delivery points. For businesses sourcing air motor pumps globally, understanding these terms is essential to avoid disputes and ensure smooth transactions.

Lead time refers to the time taken from placing an order to receiving the product. In the context of air motor pumps, shorter lead times can enhance project timelines and operational efficiency. Buyers should consider lead times when planning procurement cycles.

Illustrative image related to air motor pump

A warranty is a promise from the manufacturer regarding the repair or replacement of the product within a specified period. For air motor pumps, a solid warranty can indicate quality and reliability, providing peace of mind for B2B buyers concerning their investment.

By familiarizing yourself with these technical properties and trade terminologies, you can make more informed decisions when purchasing air motor pumps, ensuring that your business needs are effectively met.

The air motor pump sector is witnessing significant transformation driven by several global factors. Increasing demand for portable and efficient pumping solutions across various industries, such as automotive, construction, and agriculture, is reshaping the market landscape. In regions like Africa and South America, rapid urbanization and infrastructure development are creating opportunities for air motor pumps, particularly in construction applications where reliability and mobility are paramount.

Illustrative image related to air motor pump

Emerging technologies are also influencing sourcing trends. The integration of smart technologies, such as IoT-enabled pumps that allow real-time monitoring and automated performance adjustments, is gaining traction. This trend is particularly appealing to B2B buyers seeking increased operational efficiency and reduced downtime. Additionally, the rise of e-commerce platforms is streamlining procurement processes, enabling buyers from the Middle East and Europe to access a wider array of products at competitive prices.

Moreover, sustainability is becoming a crucial factor in purchasing decisions. As companies strive to meet regulatory requirements and consumer expectations for greener products, air motor pump manufacturers are increasingly focusing on energy-efficient designs and sustainable materials. This shift is particularly relevant for B2B buyers who prioritize long-term investments in eco-friendly technologies.

Sustainability is a core consideration for businesses today, influencing how air motor pumps are sourced. The environmental impact of manufacturing processes, including resource consumption and waste generation, has prompted many buyers to seek suppliers who adhere to sustainable practices. This includes using recycled materials and minimizing carbon footprints during production.

Ethical sourcing is equally important, particularly for international buyers who are increasingly scrutinizing supply chains for compliance with labor and environmental standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can enhance a supplier’s credibility and attract B2B buyers focused on corporate social responsibility.

Furthermore, the trend towards using ‘green’ materials in the production of air motor pumps—such as biodegradable plastics and low-VOC (volatile organic compound) components—can significantly reduce the environmental impact of these products. As buyers in markets like Germany and Nigeria become more environmentally conscious, they are more likely to partner with manufacturers committed to sustainable practices, creating a competitive edge for those who prioritize ethical sourcing.

The evolution of air motor pumps has been marked by technological advancements and shifts in market demand. Initially designed for industrial applications, these pumps have expanded into various sectors, including automotive and consumer goods. The introduction of portable air motor pumps has revolutionized their use, allowing for increased mobility and convenience, appealing especially to sectors requiring quick and efficient solutions.

Over the years, the integration of advanced materials and technologies has improved the performance and efficiency of air motor pumps. This evolution has enabled manufacturers to cater to diverse needs, from high-pressure applications to more intricate designs suited for specific industries. As B2B buyers continue to seek innovative and reliable solutions, understanding the historical context of air motor pumps provides valuable insights into current market dynamics and future trends.

In conclusion, the air motor pump sector is poised for growth, driven by technological innovation, sustainability, and evolving buyer expectations. International B2B buyers must stay informed about these dynamics to make strategic sourcing decisions that align with their operational goals and ethical standards.

How do I select the right air motor pump for my business needs?

Choosing the right air motor pump involves assessing your specific application requirements, including the type of fluids you will be pumping, desired flow rates, and pressure ranges. Consider the environment where the pump will operate, such as temperature extremes or exposure to corrosive substances. Additionally, evaluate the pump’s compatibility with existing systems and its power source. Consulting with suppliers about their offerings can provide insights into which models are best suited for your operational needs.

What are the key specifications to consider when purchasing air motor pumps?

When sourcing air motor pumps, focus on specifications like flow rate, pressure capacity, material construction, and size. Flow rate indicates how much fluid the pump can handle within a given timeframe, while pressure capacity ensures the pump meets your operational demands. Material construction is crucial for durability, especially in harsh environments. Finally, size impacts installation and integration into existing systems, so ensure the pump fits your spatial constraints.

What are the typical lead times for air motor pump orders?

Lead times can vary significantly based on the supplier’s location, production capacity, and the complexity of the order. Generally, standard orders may take anywhere from 4 to 8 weeks for delivery. However, if you require customization or have larger quantities, expect longer lead times. It’s advisable to discuss timelines upfront with your supplier to align expectations and plan your operations accordingly.

How can I ensure quality assurance when sourcing air motor pumps?

To ensure quality assurance, request certifications and compliance documentation from suppliers, such as ISO standards or safety certifications. It’s beneficial to inquire about their manufacturing processes, quality control measures, and any third-party testing they perform. Additionally, consider visiting the manufacturing facility if possible or requesting samples to evaluate performance and quality firsthand before making a larger purchase.

What is the minimum order quantity (MOQ) for air motor pumps?

Minimum order quantities can vary widely among suppliers, often ranging from 10 to 100 units depending on the pump model and the supplier’s production capabilities. Some manufacturers may offer flexibility for first-time buyers or smaller businesses. Always clarify MOQs during negotiations to ensure they align with your purchasing capabilities and inventory management strategies.

What payment terms are typically available for B2B purchases of air motor pumps?

Payment terms can vary by supplier but often include options such as upfront payment, net 30/60/90 days, or letters of credit for larger transactions. Some suppliers may also offer financing options or installment plans for significant orders. It’s essential to discuss payment terms in detail before finalizing your order to avoid any misunderstandings and to ensure they fit within your budgetary constraints.

How do international shipping and logistics work for air motor pumps?

International shipping for air motor pumps typically involves coordination with freight forwarders and understanding customs regulations specific to your country. Suppliers often provide shipping options, including air freight for quicker delivery or sea freight for cost-effective solutions. Be sure to clarify shipping costs, estimated delivery times, and any potential duties or tariffs applicable in your region, as these factors can significantly impact your total costs.

What are the benefits of customizing air motor pumps for my specific application?

Customizing air motor pumps allows you to tailor specifications to meet unique operational needs, enhancing efficiency and performance. Custom features might include specific materials, size adjustments, or modifications for particular fluid types. While customization may involve higher upfront costs and longer lead times, the long-term benefits often include improved reliability, reduced downtime, and better overall compatibility with your existing systems, leading to increased productivity.

المجال: getairmoto.com

Registered: 2021 (4 years)

مقدمة: Airmoto – Portable Air Pump and Smart Tire Inflator

– Free Shipping for Orders $100+

– Compact and portable design, fits easily in glove box

– Effortlessly inflates vehicle tires, motorcycles, bicycles, and more

– Inflates from flat to full in minutes

– Powerful 120 PSI for optimal performance on any terrain

– Rechargeable battery with fast USB charging capability

– Built-in LED light for low-ligh…

المجال: pumpworld.com

مسجل: 1997 (28 سنة)

مقدمة: Air Operated Double Diaphragm (AODD) pumps are reciprocating, positive-displacement pumps used for transferring diverse feeds such as sludges, slurries, abrasive fluids, and shear-sensitive fluids. They are known for durability, reliability, and ease of maintenance. Key products include: 1. All-Flo A100 Metal AODD Pump – Max 120psi, 1/4-inch FNPT air inlet, starting at $1,524.00. 2. Iwaki Air TC-X…

المجال: motopumps.com

مسجل: 2006 (19 سنة)

مقدمة: Product Name: MotoPumps® Air Shot 2.1

Made in: USA

Price Range: $79.99 – $89.99 MSRP

Availability: In Stock with Free US Shipping

Dimensions (Pump Body): 4.5″ x 4.75″ x 1.8″

Weight (Pump): Just over 1 pound

Power: 12v system, draws about 7.5 amps

Inflation Rate: Inflates a typical motorcycle tire at about 15 psi per minute, rated to 50 psi

Inflation Time: Inflates a completely flat motorcycle tire…

In the competitive landscape of air motor pumps, strategic sourcing emerges as a critical factor for international B2B buyers seeking high-quality, reliable solutions. Understanding the diverse applications of air motor pumps—from automotive maintenance to industrial uses—enables businesses to make informed purchasing decisions. Prioritizing features such as portability, durability, and ease of use can significantly enhance operational efficiency and customer satisfaction.

Illustrative image related to air motor pump

By leveraging strategic sourcing, businesses can secure favorable terms and build long-lasting relationships with suppliers. This approach not only fosters cost savings but also ensures access to innovative products that meet evolving market demands. For buyers in regions like Africa, South America, the Middle East, and Europe, aligning with reputable manufacturers can lead to enhanced product reliability and better service support.

As technology advances, the air motor pump market is poised for growth, with opportunities for integration of smart features and improved energy efficiency. International buyers are encouraged to stay abreast of these trends and consider the long-term value of their investments. Embrace the future of air motor pumps—partner with trusted suppliers today to ensure your business is equipped with the best tools for success.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

Illustrative image related to air motor pump

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.