- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In an increasingly interconnected world, sourcing reliable tyre air pumps has become a critical challenge for international B2B buyers. Whether you’re operating in the bustling markets of Africa, the diverse landscapes of South America, the resource-rich regions of the Middle East, or the established economies of Europe, the demand for efficient and durable tyre inflation solutions is universal. This guide serves as a comprehensive resource, addressing key aspects such as the various types of tyre air pumps available, their specific applications, and essential supplier vetting processes.

As businesses strive to meet customer expectations while managing costs, understanding the nuances of tyre air pump technologies is vital. From portable electric inflators designed for convenience to heavy-duty compressors suitable for commercial use, each product presents unique advantages and challenges. This guide empowers buyers with actionable insights, enabling informed purchasing decisions that align with regional needs and market dynamics.

By navigating the complexities of sourcing tyre air pumps, B2B buyers can ensure that their operations remain competitive and efficient. Our focus on detailed product comparisons, supplier evaluations, and cost assessments will equip you with the knowledge necessary to make strategic investments in tyre inflation solutions that not only enhance service delivery but also drive business growth across diverse markets.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Portable Electric Pump | Compact, rechargeable, often with digital pressure gauges | ورش تصليح السيارات، المساعدة على الطريق | Pros: Easy to use, portable; Cons: Battery life may vary. |

| Heavy-Duty Air Compressor | High PSI output, suitable for larger vehicles and equipment | Fleet maintenance, heavy machinery repair | Pros: Fast inflation, durable; Cons: Bulky, requires power source. |

| Manual Hand Pump | Simple design, no electricity needed, lightweight | Bicycle shops, outdoor equipment retailers | Pros: Cost-effective, reliable; Cons: Labor-intensive, slower inflation. |

| Multi-Function Inflator | Combines inflating with other features (e.g., vacuum, power bank) | Automotive and outdoor retail | Pros: Versatile, space-saving; Cons: More complex, potentially higher cost. |

| Smart Tire Inflator | Connects to apps, monitors tire health, automatic shutoff | Fleet management, automotive diagnostics | Pros: High-tech, enhances safety; Cons: Can be expensive, requires app compatibility. |

Portable electric pumps are designed for ease of use and convenience, making them ideal for B2B applications in automotive repair shops and roadside assistance services. They typically feature rechargeable batteries and digital pressure gauges, allowing users to set desired PSI levels and monitor inflation. When purchasing, B2B buyers should consider battery life, portability, and ease of operation, ensuring the pump can handle various vehicle types.

Heavy-duty air compressors are built for high-performance applications, delivering significant PSI output suitable for larger vehicles and heavy machinery. These pumps are essential in fleet maintenance and heavy equipment repair, where rapid inflation is crucial. Buyers should assess the compressor’s power requirements, portability, and maintenance needs, as these factors can impact operational efficiency and costs.

Manual hand pumps are a straightforward, cost-effective solution for inflating tires without the need for electricity. They are particularly useful in bicycle shops and outdoor equipment retailers where portability and reliability are paramount. While they lack the speed and convenience of electric pumps, their lightweight design and low cost make them an appealing choice for B2B buyers focused on budget constraints and simplicity.

Multi-function inflators combine tire inflation with additional features, such as vacuuming capabilities or power bank functions, making them attractive for automotive and outdoor retailers. Their versatility helps businesses save space and cater to diverse customer needs. Buyers should consider the range of features offered, as well as the potential for increased customer satisfaction through multifunctionality.

Smart tire inflators connect to mobile applications to monitor tire health, providing data-driven insights for fleet management and automotive diagnostics. Their automatic shutoff feature enhances safety by preventing over-inflation. While they may come at a higher price point, the investment can lead to improved operational efficiency and safety, making them a smart choice for B2B buyers looking to stay ahead in technology adoption.

| الصناعة/القطاع | Specific Application of tyre air pump | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Manufacturing | Quality Control in Tire Production | Ensures precise tire pressure for safety and performance standards. | Reliability, accuracy of pressure settings, and durability. |

| Transportation and Logistics | Fleet Maintenance | Reduces downtime by quickly addressing tire pressure issues. | Portability, ease of use, and speed of inflation. |

| Construction and Heavy Equipment | Tire Inflation for Construction Vehicles | Enhances operational efficiency and safety in rugged conditions. | Robustness, compatibility with various tire sizes, and quick inflation time. |

| الزراعة | Tire Maintenance for Farm Equipment | Maximizes productivity by ensuring optimal tire performance. | Versatility in inflation capabilities and ease of operation in remote areas. |

| Sports and Recreation | Inflation of Sports Equipment | Improves customer satisfaction through quick service. | Compact size, multi-functionality, and ease of transport. |

In automotive manufacturing, tyre air pumps are crucial for quality control during tire production. They ensure that tires are inflated to precise specifications, which is vital for safety and performance. This reduces the risk of defects and enhances product reliability, which can significantly impact brand reputation. Buyers in this sector should prioritize pumps that offer high reliability, precise pressure settings, and durability to withstand continuous use in a manufacturing environment.

Transportation and logistics companies rely on tyre air pumps for fleet maintenance. Regular tire pressure checks and adjustments help prevent breakdowns and accidents, thus minimizing operational downtime. Quick inflation capabilities are essential for these businesses, as they often operate under tight schedules. When sourcing, logistics companies should consider the portability and ease of use of the tyre air pump to facilitate quick roadside assistance.

In the construction industry, tyre air pumps are essential for maintaining the tire pressure of heavy equipment like bulldozers and excavators. Proper tire inflation enhances vehicle safety and operational efficiency, particularly in rugged terrain. Buyers in this sector should look for robust and durable pumps that can handle various tire sizes and provide quick inflation times to minimize equipment downtime.

For agricultural businesses, maintaining tire pressure in farm equipment is critical to maximizing productivity. Properly inflated tires improve traction and reduce fuel consumption, which directly impacts operational costs. Buyers should seek versatile tyre air pumps that can operate effectively in remote areas, ensuring that they can quickly address any tire pressure issues that arise during fieldwork.

In the sports and recreation sector, tyre air pumps are vital for quickly inflating sports equipment such as balls and inflatable toys. Providing quick service enhances customer satisfaction, especially in retail or rental environments. Compact and portable models are preferred, as they allow easy transport to various locations. Buyers should focus on pumps that offer multi-functionality and ease of use, ensuring they can meet diverse inflation needs on the go.

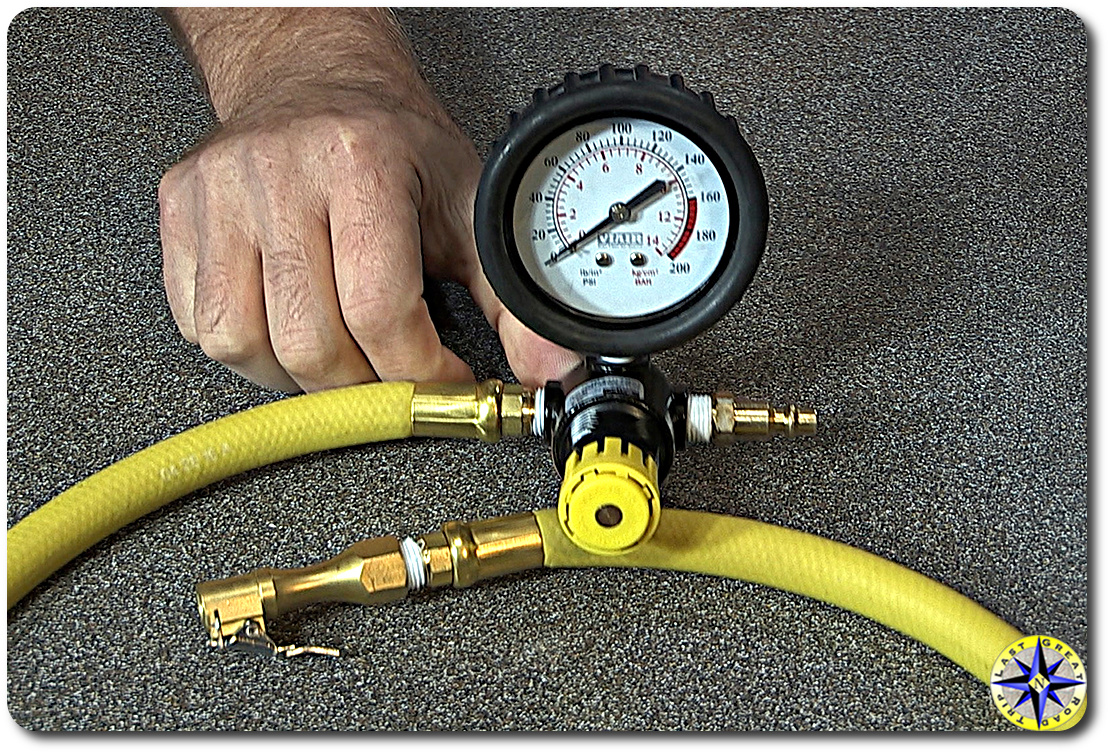

Illustrative image related to tyre air pump

المشكلة For B2B buyers managing a fleet, ensuring that all vehicles maintain optimal tire pressure can be a significant challenge. Different vehicles may require different pressure levels, and fluctuations in temperature and road conditions can exacerbate this issue. Neglecting tire pressure can lead to increased fuel consumption, reduced tire lifespan, and safety risks, ultimately affecting operational efficiency and costs.

الحل: To tackle this problem, B2B buyers should invest in a range of portable tire air pumps equipped with digital pressure gauges and preset pressure settings. These features allow for precise inflation tailored to each vehicle type. Establishing a routine check schedule, perhaps bi-weekly or monthly, will help ensure all tires are inflated to the correct pressure. Additionally, integrating the use of connected devices that monitor tire pressure in real-time can further streamline the process, allowing fleet managers to receive alerts and take action proactively.

المشكلة In many regions, particularly in developing markets or remote areas, access to reliable power sources can be limited. This poses a significant issue for businesses that rely on tire pumps to maintain equipment and vehicles. Manual pumps can be inefficient and labor-intensive, leading to downtime and delays in operations.

Illustrative image related to tyre air pump

الحل: B2B buyers should consider investing in battery-operated or rechargeable tire air pumps that can operate independently of power sources. Models with high PSI ratings and rapid inflation capabilities are ideal for this scenario. It’s also advisable to stock a variety of pumps to cater to different vehicle types, ensuring that all operational needs are met without being tethered to an outlet. Additionally, implementing staff training on the proper use and maintenance of these pumps can maximize their longevity and efficiency.

المشكلة B2B buyers often face difficulties in sourcing tire air pumps that meet quality and reliability standards. Poor-quality pumps can fail unexpectedly, leading to operational disruptions and potential safety hazards. Furthermore, warranty issues and lack of customer support can compound these problems, leaving buyers frustrated and seeking solutions after the fact.

الحل: To mitigate these risks, B2B buyers should prioritize suppliers with a proven track record in the market. Conduct thorough due diligence, including checking reviews and seeking recommendations from peers in the industry. Establish partnerships with manufacturers who offer comprehensive warranties and robust customer service support. Additionally, consider sourcing pumps that come with advanced features such as automatic shut-off and overheating protection, which enhance reliability and usability. Regularly review product performance and keep a feedback loop with users to identify any recurring issues and address them promptly.

By understanding these common pain points and implementing the suggested solutions, B2B buyers can enhance their operations, ensuring they have the right tire air pumps for their needs while minimizing downtime and maximizing efficiency.

When selecting materials for tyre air pumps, several factors must be considered, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of tyre air pumps: plastic, aluminum, steel, and rubber. Each material has distinct properties that influence its suitability for various applications.

Illustrative image related to tyre air pump

Plastic is commonly used in the housing and components of tyre air pumps due to its lightweight nature and resistance to corrosion. Key properties include a temperature rating of around -30°C to 60°C and moderate pressure resistance, making it suitable for low to medium-pressure applications.

الإيجابيات: Plastic is cost-effective and easy to mold into complex shapes, allowing for innovative designs. It is also resistant to rust and can be produced in various colors, appealing to aesthetic preferences.

السلبيات: However, plastic is generally less durable than metals and can degrade over time when exposed to UV light or extreme temperatures. This can lead to failure in high-stress environments.

For international buyers, especially in regions with varying climates like Africa and South America, ensuring compliance with standards such as ASTM for plastics is crucial.

Aluminum is another popular choice for tyre air pumps, particularly for components that require a balance between weight and strength. It has a temperature rating of approximately -50°C to 150°C and excellent corrosion resistance, making it ideal for outdoor and rugged applications.

الإيجابيات: Aluminum is lightweight yet strong, providing durability without adding significant weight. It is also recyclable, aligning with sustainability goals.

السلبيات: The primary drawback is its cost, which is higher than plastic. Additionally, aluminum can be prone to dents and scratches, which may affect its aesthetic and functional longevity.

International B2B buyers must consider the availability of aluminum and its compliance with standards like DIN or JIS, particularly in regions like Europe where regulations may be stricter.

Steel is often used in high-performance tyre air pumps, particularly for components that require high strength and durability. It can withstand higher temperatures and pressures, with ratings typically exceeding 200°C and 300 PSI.

الإيجابيات: Steel is incredibly durable and resistant to mechanical stress, making it suitable for heavy-duty applications. It also has a long lifespan, which can reduce replacement costs over time.

السلبيات: The main disadvantages of steel include its weight and susceptibility to rust if not properly coated or treated. This can be a significant consideration for portable air pumps.

Illustrative image related to tyre air pump

For B2B buyers, especially in humid regions like parts of Africa and the Middle East, ensuring that steel components meet corrosion resistance standards is essential. Compliance with ASTM standards for steel is also critical.

Rubber is primarily used in seals and hoses within tyre air pumps due to its excellent flexibility and sealing properties. It can operate effectively at temperatures ranging from -40°C to 100°C and withstand moderate pressure.

الإيجابيات: Rubber provides a reliable seal, preventing air leaks and enhancing the efficiency of the pump. It is also relatively inexpensive and easy to replace.

السلبيات: The main limitation of rubber is its susceptibility to degradation from UV exposure and ozone, which can lead to cracks and failures over time.

International buyers should ensure that the rubber used in tyre air pumps complies with relevant standards, particularly in terms of safety and performance, which may vary by region.

| المواد | Typical Use Case for tyre air pump | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| بلاستيك | السكن والمكونات | خفيف الوزن ومقاوم للتآكل | Less durable; UV degradation | منخفضة |

| ألومنيوم | Structural components | Strong and lightweight | Higher cost; prone to dents | ميد |

| الفولاذ | High-performance components | Extremely durable and long-lasting | Heavy and rust-prone | عالية |

| المطاط | Seals and hoses | Excellent sealing and flexibility | Degrades under UV and ozone | منخفضة |

This guide provides a comprehensive overview of the materials used in tyre air pumps, enabling international B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

The manufacturing process of tyre air pumps involves several key stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

إعداد المواد: The first step involves sourcing high-quality materials. Common materials include durable plastics for the casing and rubber for seals and hoses. Suppliers often provide certifications to ensure that materials meet specific standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). B2B buyers should inquire about these certifications to ensure compliance with international regulations.

التشكيل: Once materials are prepared, they undergo forming processes. This may involve injection molding for plastic components and rubber molding for seals. Advanced techniques such as CNC (Computer Numerical Control) machining may also be used for precision components. These processes require skilled labor and sophisticated machinery to ensure accuracy and durability.

التجميع: The next phase is assembly, where all components are brought together. This stage often employs automated assembly lines to increase efficiency and reduce human error. Each unit is carefully assembled, and components like pressure gauges, motors, and power supplies are integrated. It is crucial for manufacturers to maintain a clean and controlled environment during assembly to prevent contamination.

التشطيب: The final stage includes surface treatment, painting, and quality inspections. Finishing processes may involve applying protective coatings to enhance durability and aesthetics. Additionally, final assembly inspections are performed to verify that the product meets design specifications and safety standards.

Quality assurance (QA) is vital in the manufacturing of tyre air pumps to ensure reliability and safety. Adhering to international standards and implementing rigorous QA processes can help B2B buyers assess the quality of their suppliers.

المعايير الدولية: Many manufacturers comply with ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that a company has established processes to enhance customer satisfaction and ensure consistent product quality. Other certifications, such as CE marking for compliance with EU safety, health, and environmental protection standards, are also important for international trade.

نقاط التحقق من الجودة: Manufacturers implement several quality checkpoints throughout the production process:

– مراقبة الجودة الواردة (IQC): This initial inspection assesses raw materials and components before they enter the production line. It ensures that only materials meeting specified criteria are used.

– مراقبة الجودة أثناء المعالجة (IPQC): During manufacturing, regular inspections are conducted to monitor the production process. This includes checking the accuracy of machinery and adherence to assembly protocols.

– مراقبة الجودة النهائية (FQC): Once the product is assembled, final inspections are performed to test functionality, safety, and compliance with specifications. This may involve pressure testing the tyre air pumps to ensure they operate correctly under various conditions.

طرق الاختبار الشائعة: Manufacturers employ various testing methods, such as:

– Performance Testing: Evaluating the inflating speed, pressure accuracy, and noise levels.

– اختبار المتانة: Subjecting pumps to extreme conditions to assess their resilience and lifespan.

– Safety Testing: Ensuring that electrical components meet safety standards to prevent hazards.

For B2B buyers, verifying the quality control processes of suppliers is crucial in mitigating risks associated with product quality. Here are several strategies:

إجراء عمليات التدقيق: Buyers should perform regular audits of suppliers’ facilities. This involves reviewing their manufacturing processes, quality control measures, and compliance with international standards. Audits can be conducted by the buyer’s quality assurance team or by hiring third-party inspection agencies.

طلب تقارير الجودة: Suppliers should provide detailed quality reports that outline their QA processes, testing results, and compliance certifications. These reports should be transparent and easy to understand, allowing buyers to assess the supplier’s commitment to quality.

إشراك مفتشي الطرف الثالث: Utilizing independent third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality assurance practices. These inspectors can perform random checks and tests to confirm that products meet the required standards before shipment.

Understanding QC Certification Nuances: International buyers should familiarize themselves with the specific certifications relevant to their regions. For example, certifications accepted in Europe may differ from those in Africa or South America. Understanding these nuances can help buyers choose suppliers that comply with local regulations and market expectations.

Navigating quality control challenges in the global marketplace requires a strategic approach, especially for buyers in regions like Africa, South America, the Middle East, and Europe. Here are some considerations:

Illustrative image related to tyre air pump

Cultural and Regulatory Differences: Buyers should be aware of the cultural and regulatory differences that may affect quality standards. Engaging local experts or consultants can help bridge these gaps and ensure that suppliers meet the necessary requirements.

Establishing Clear Communication: Maintaining open lines of communication with suppliers is essential. Buyers should clearly outline their quality expectations, specifications, and compliance requirements upfront. Regular communication can help identify potential issues early in the manufacturing process.

بناء علاقات طويلة الأمد: Establishing long-term partnerships with reliable suppliers can lead to better quality control over time. As trust develops, suppliers may be more willing to invest in quality improvements and share insights into their processes.

Utilizing Technology: Leveraging technology, such as supply chain management software and quality management systems, can enhance visibility into the manufacturing process. These tools allow buyers to track quality metrics and production schedules, providing real-time insights into supplier performance.

By understanding the manufacturing processes and quality assurance measures for tyre air pumps, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality standards and regulatory requirements.

To successfully procure tyre air pumps for your business, it’s essential to follow a systematic approach that ensures you meet quality, cost, and operational requirements. This guide serves as a checklist to streamline your sourcing process, helping you make informed decisions that align with your company’s needs.

Establishing clear technical specifications is the first step in your procurement process. Consider the types of vehicles or equipment the tyre air pumps will service, as well as the required pressure levels, flow rates, and power sources (electric, manual, etc.). This clarity will help you narrow down your options and ensure compatibility with your existing fleet or equipment.

Illustrative image related to tyre air pump

Understanding the current market landscape is vital for effective procurement. Analyze trends in tyre air pump technology, such as advancements in battery life or inflation speed. Additionally, compare pricing across various suppliers to gauge market averages and identify competitive offers. This step will empower you to negotiate better terms and avoid overpaying.

Before committing to a supplier, thorough vetting is essential. Request company profiles, product catalogs, and references from businesses in similar sectors or regions. Look for suppliers with a proven track record and positive customer reviews, as this indicates reliability and quality.

Once you have a shortlist of potential suppliers, request samples of the tyre air pumps for testing. Testing samples will allow you to evaluate performance, durability, and ease of use. Pay attention to factors such as inflation time, noise levels, and any additional features that may enhance usability, like digital displays or auto shut-off functions.

After-sales support can significantly impact the longevity of your investment. Assess the warranty offered by suppliers; a longer warranty often reflects the manufacturer’s confidence in their product quality. Additionally, inquire about the availability of spare parts and customer service responsiveness, as these factors are critical for maintaining operational efficiency.

Illustrative image related to tyre air pump

Once you’ve selected a supplier, it’s time to negotiate terms and conditions. Discuss pricing, delivery timelines, and payment terms to ensure they align with your budget and operational needs. Be clear about your expectations for delivery schedules and the consequences of any delays to establish accountability.

After agreeing on terms, finalize your order and maintain an open line of communication with your supplier. Building a strong relationship can lead to better service, potential discounts on future orders, and priority access to new products. Regularly evaluate the supplier’s performance to ensure continued alignment with your business needs.

By following this checklist, you can navigate the complexities of sourcing tyre air pumps efficiently, ensuring that your procurement process is both effective and beneficial to your business operations.

Understanding the cost structure for tyre air pump sourcing involves several crucial components. The primary elements include materials, which generally account for the bulk of production costs. Common materials for tyre air pumps include plastics, metals, and rubber, which can vary significantly in price based on quality and sourcing location. Labor costs also play a critical role, particularly in regions with varying wage standards. For instance, manufacturing in countries with lower labor costs, such as Vietnam or Nigeria, can lead to significant savings.

Illustrative image related to tyre air pump

النفقات العامة للتصنيع encompasses utilities, rent, and administrative expenses, which can affect the overall pricing. Additionally, tooling costs for the initial setup of production lines can be substantial, particularly for custom designs. Quality control (QC) measures are essential to ensure product reliability and safety, adding to the overall costs. Finally, logistics must be factored in, including shipping, handling, and any tariffs or taxes that may apply when exporting to different regions.

Several factors influence the pricing of tyre air pumps in the B2B marketplace. الحجم والحد الأدنى لكمية الطلب (MOQ) are significant; suppliers often provide discounts for larger orders, making it crucial for buyers to assess their needs accurately. المواصفات والتخصيص can also impact pricing. Tailored designs or additional features, such as built-in pressure gauges or specific voltage requirements, will typically increase costs.

The choice of materials directly affects the price as high-quality or specialized materials will lead to higher manufacturing costs. Furthermore, the perceived الجودة والشهادات of a tyre air pump can influence buyer willingness to pay a premium. For example, pumps that comply with international safety standards may command higher prices.

Illustrative image related to tyre air pump

عوامل الموردين such as reputation, reliability, and geographic location can also impact costs. Suppliers in regions with robust manufacturing capabilities may offer competitive pricing due to economies of scale. Finally, understanding المصطلحات التجارية الدولية is critical, as they define the responsibilities of buyers and sellers concerning shipping and logistics costs, which can significantly influence total pricing.

When negotiating prices for tyre air pumps, B2B buyers should focus on creating a comprehensive التكلفة الإجمالية للملكية (TCO) analysis. This includes not only the purchase price but also shipping costs, potential tariffs, and the expected lifespan of the product. Understanding the lifecycle cost can lead to better negotiations and smarter purchasing decisions.

Buyers should also consider long-term partnerships with suppliers. Establishing a reliable relationship can lead to favorable terms, including better pricing and priority service. Additionally, being transparent about expected order volumes and timelines can help negotiate more favorable terms.

Understanding الفروق الدقيقة في التسعير specific to international markets is vital, especially for buyers from Africa, South America, the Middle East, and Europe. For instance, buyers in Nigeria may face different logistical challenges compared to those in South America, which can affect pricing dynamics. Awareness of local market conditions, including currency fluctuations and economic stability, can also provide leverage during negotiations.

While indicative prices can provide a useful benchmark, they should be approached with caution. Prices for tyre air pumps can vary widely based on market conditions, supplier negotiations, and specific requirements. Therefore, it is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Illustrative image related to tyre air pump

As businesses seek efficient solutions for tyre inflation, exploring alternatives to traditional tyre air pumps is essential. This analysis compares tyre air pumps with two viable alternatives: electric tyre inflators and air compressors. Each solution offers unique advantages and drawbacks, enabling buyers to make informed decisions based on their specific requirements.

| جانب المقارنة | Tyre Air Pump | Electric Tyre Inflator | Air Compressor |

|---|---|---|---|

| الأداء | Moderate inflation speed; ideal for occasional use | Fast inflation; often portable with automatic shut-off | High-performance; suitable for heavy-duty use |

| التكلفة | Generally low; prices range from $20 to $50 | Mid-range; typically $40 to $100 | Higher initial investment; usually $100+ |

| سهولة التنفيذ | Simple operation; manual or basic electric versions | User-friendly; often one-button operation | Requires setup; may need an electrical outlet |

| الصيانة | Low; minimal upkeep required | Low to moderate; occasional battery check | Moderate; regular oil checks and maintenance needed |

| أفضل حالة استخدام | Personal vehicles, bicycles | Roadside emergencies, light vehicles | Workshops, garages, heavy machinery |

Electric tyre inflators are designed for convenience and speed, making them a popular choice for both individual consumers and businesses. They typically feature automatic shut-off functions that prevent over-inflation, enhancing safety and efficiency. However, their reliance on battery power can be a limitation in remote areas where charging options are scarce. Additionally, while they are generally portable, their performance may not match the heavy-duty requirements of larger vehicles or commercial applications.

Air compressors offer robust performance suitable for a variety of inflation tasks beyond tyres, including powering pneumatic tools and inflating larger equipment. They excel in environments that require continuous use and can handle higher volumes of air quickly. However, the initial investment is significantly higher than that of tyre air pumps or electric inflators, and they may require more maintenance. For businesses that need versatility and high performance, air compressors can be a worthwhile investment, but they may not be the best choice for casual or infrequent use.

When selecting the right tyre inflation solution, B2B buyers should consider factors such as the specific needs of their operations, the volume of inflation required, and the environment in which the equipment will be used. For occasional use, a simple tyre air pump may suffice. However, for businesses that require rapid inflation and portability, electric tyre inflators are an excellent choice. For heavy-duty applications or workshops, investing in an air compressor may provide the best long-term value.

By weighing the performance, cost, ease of implementation, maintenance requirements, and best use cases, buyers can make informed decisions that align with their operational goals and budget constraints.

Illustrative image related to tyre air pump

When considering a tyre air pump for B2B procurement, understanding its technical properties is essential for making informed purchasing decisions. Here are several critical specifications to consider:

Maximum Pressure Rating (PSI)

The maximum pressure rating indicates the highest pressure the pump can achieve, typically measured in pounds per square inch (PSI). For example, many electric tyre inflators range from 30 PSI to 150 PSI. A higher PSI rating is crucial for commercial applications, as it ensures compatibility with various vehicle types, including trucks and SUVs, which may require higher inflation pressures.

Flow Rate (CFM)

The flow rate, measured in cubic feet per minute (CFM), denotes how quickly the pump can inflate a tyre. A higher flow rate translates to faster inflation times, which is vital for businesses that need to service multiple vehicles efficiently. For instance, a pump with a flow rate of 2 CFM can significantly reduce downtime during fleet operations.

درجة المادة

The material grade refers to the quality of materials used in the pump’s construction, such as plastic, aluminum, or steel. High-grade materials enhance durability and resistance to wear and tear, which is particularly important for pumps used in rugged environments. Understanding material specifications can help buyers assess longevity and performance under various conditions.

مصدر الطاقة

Tyre air pumps can be powered by various sources, including AC mains, DC (car battery), or rechargeable batteries. The choice of power source affects portability and convenience. For example, portable pumps powered by rechargeable batteries offer flexibility for use in remote locations, while AC-powered models may provide higher performance in fixed locations.

Noise Level (dB)

Noise level is an often-overlooked specification, measured in decibels (dB). For businesses operating in residential areas or confined spaces, selecting a quieter model can minimize disturbances. Pumps with noise levels below 70 dB are generally considered acceptable for commercial use.

Weight and Portability

The weight of the air pump influences its portability, especially for businesses that require frequent relocation. Lightweight models are easier to transport but should not compromise on power or durability. A balance between weight and performance is essential for businesses that need reliable equipment on the go.

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to tyre air pumps:

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking for branded or compatible tyre air pumps that meet specific standards and quality expectations.

موك (الحد الأدنى لكمية الطلب)

MOQ denotes the minimum number of units a supplier is willing to sell. This is particularly important for B2B buyers looking to manage inventory costs. Knowing the MOQ helps businesses assess whether a supplier’s offer aligns with their purchasing power and requirements.

طلب عرض الأسعار (RFQ)

An RFQ is a standard business process for soliciting price quotes from suppliers. B2B buyers should prepare an RFQ when seeking specific tyre air pump models to ensure they receive competitive pricing and terms from multiple suppliers.

إنكوترمز (الشروط التجارية الدولية)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps mitigate risks related to shipping and logistics, essential for international transactions involving tyre air pumps.

المهلة الزمنية

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is critical for businesses that rely on timely product availability, especially when scaling operations or responding to market demands.

فترة الضمان

The warranty period indicates the duration a product is covered for defects or issues. A longer warranty period can signify a manufacturer’s confidence in their product quality and provide peace of mind for buyers. Knowing the warranty details helps businesses make informed decisions about the reliability of their tyre air pump investments.

By understanding these technical properties and trade terms, B2B buyers can navigate the procurement process more effectively, ensuring they select the right tyre air pump for their operational needs.

The global tyre air pump market is currently experiencing significant growth, driven by rising vehicle ownership and increasing awareness of road safety. The demand for efficient and portable tyre inflators is being propelled by urbanization and the need for convenient roadside assistance. In regions such as Africa, South America, and parts of Europe, the adoption of electric and portable inflators is accelerating, as consumers seek quick and reliable solutions for maintaining optimal tyre pressure. This trend aligns with the growing interest in electric vehicles (EVs), which often require specialized inflators to meet their unique specifications.

Emerging technologies are reshaping the tyre air pump landscape, with features such as digital pressure gauges, automatic shut-off functions, and fast inflation capabilities becoming standard. B2B buyers are increasingly looking for products that not only meet performance standards but also offer smart technology integration, such as mobile app connectivity for monitoring tyre health. Additionally, the rise of e-commerce platforms has made it easier for international buyers to source a diverse range of tyre inflators, allowing for greater competition and innovation within the market.

Furthermore, the shift towards sustainable practices is influencing purchasing decisions. Buyers are now prioritizing suppliers that demonstrate a commitment to quality and sustainability, especially in regions where environmental regulations are becoming stricter. This shift is encouraging manufacturers to invest in eco-friendly materials and production processes, creating a more sustainable supply chain.

Sustainability has emerged as a critical consideration for B2B buyers in the tyre air pump sector. The environmental impact of manufacturing processes, including resource consumption and waste generation, has come under scrutiny. As such, buyers are increasingly demanding products that are not only high-performing but also produced through environmentally responsible methods. This has led to a rise in the adoption of “green” certifications and the use of recycled or sustainably sourced materials in the production of tyre inflators.

Ethical sourcing practices are also gaining prominence, particularly in regions where labor conditions and environmental standards vary significantly. B2B buyers are encouraged to engage with suppliers who uphold ethical labor practices and demonstrate transparency in their supply chains. This not only enhances brand reputation but also aligns with the growing consumer demand for corporate social responsibility (CSR).

Illustrative image related to tyre air pump

Moreover, the importance of energy-efficient products cannot be overstated. Inflators that consume less power or incorporate renewable energy sources are becoming increasingly attractive to buyers, especially in regions with fluctuating energy prices. Suppliers that can showcase their commitment to sustainability and ethical sourcing will not only meet regulatory requirements but also enhance their market competitiveness.

The tyre air pump sector has evolved significantly over the past few decades. Initially dominated by manual pumps, the market has transitioned to electric and portable inflators, driven by technological advancements and consumer demand for convenience. The introduction of battery-operated and compact designs has made it easier for consumers to carry these devices for emergency situations, while digital gauges and auto-shutoff features have improved user experience.

The proliferation of e-commerce has further transformed the way buyers access tyre inflators, allowing for a wider range of options and competitive pricing. As the market continues to innovate, the focus on sustainability and smart technology integration is expected to shape the future of the tyre air pump industry, catering to the evolving needs of international B2B buyers.

How do I choose the right tyre air pump for my business needs?

Selecting the appropriate tyre air pump involves assessing the specific requirements of your operations. Consider factors such as the types of vehicles you service, the frequency of use, and the desired inflation speed. For instance, if your business caters to a fleet of heavy-duty vehicles, investing in a high-capacity compressor with robust PSI ratings is essential. Additionally, evaluate portability and ease of use, especially if your operations are mobile. Always request product specifications and performance data from suppliers to ensure alignment with your needs.

What are the key features to look for in a tyre air pump?

When sourcing a tyre air pump, prioritize features such as PSI capacity, power source (electric vs. manual), portability, and additional functionalities like auto shut-off and pressure presets. Advanced models may also include digital displays for precise pressure readings and built-in lights for low-light conditions. Assessing durability and warranty terms is crucial, as reliable performance over time is a key concern for businesses that rely on these pumps daily.

What are the typical minimum order quantities (MOQs) for tyre air pumps in international trade?

Minimum order quantities (MOQs) for tyre air pumps can vary significantly depending on the manufacturer and your negotiation capabilities. Generally, MOQs can range from 50 to several hundred units. It’s advisable to communicate your anticipated volume and explore flexible options with suppliers, especially if you’re entering a new market. Consider starting with a smaller test order to evaluate product quality and supplier reliability before committing to larger purchases.

How can I ensure the quality of the tyre air pumps I source internationally?

To ensure quality, conduct thorough supplier vetting, including checking references, certifications, and production capabilities. Request samples before placing large orders, and consider third-party quality assurance inspections during production. Establish clear quality standards and performance metrics in your contract to hold suppliers accountable. Additionally, staying informed about international quality standards applicable in your target markets can help you maintain compliance and customer satisfaction.

What payment terms should I negotiate with tyre air pump suppliers?

Payment terms can significantly impact cash flow, so it’s essential to negotiate favorable conditions. Common practices include a deposit (20-30%) upfront, with the balance due upon shipment or receipt of goods. Explore options for letter of credit or escrow services to mitigate risk, especially with new suppliers. Ensure that payment terms are clearly outlined in the contract to avoid misunderstandings and protect your business interests.

What shipping options are available for importing tyre air pumps?

Importing tyre air pumps typically involves various shipping options, including air freight for quicker deliveries and sea freight for cost-effective bulk shipments. Your choice depends on urgency, budget, and order size. Coordinate with your supplier to understand their shipping capabilities and any associated costs. Additionally, consider customs regulations and logistics providers that can facilitate smooth clearance and delivery in your target markets.

Are there customization options available for tyre air pumps?

Many manufacturers offer customization options for tyre air pumps, allowing you to tailor products to your brand specifications. Customization can include branding, color variations, and technical modifications to suit specific market needs. Discuss your requirements with potential suppliers early in the negotiation process to determine feasibility and associated costs. Ensure that any agreed-upon modifications are documented in your contract to avoid disputes later.

What are the common challenges faced when sourcing tyre air pumps internationally?

Common challenges in sourcing tyre air pumps internationally include language barriers, cultural differences, and varying quality standards. Additionally, navigating customs regulations and potential delays in shipping can complicate the procurement process. To mitigate these issues, invest time in building strong relationships with suppliers, engage local experts for market insights, and stay informed about trade regulations in both your home country and the supplier’s country. Effective communication and thorough planning are essential to successful international sourcing.

المجال: fanttik.com

مسجل: 2020 (5 سنوات)

مقدمة: 2X Faster Electric Tire Inflators, various models including X9 Ace, X9 Pro, X8 APEX, X9 APEX, X9 Classic, X9 Ultra, X10 Cross. Sale prices range from $48.99 to $199.97 with discounts up to 50%. Regular prices range from $59.97 to $129.99. Ratings for products are around 4.8. Black Friday Sale from 11.20 to 12.1.

In the evolving landscape of tyre air pumps, strategic sourcing emerges as a crucial element for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for efficient, portable, and technologically advanced tyre inflators continues to rise, driven by the increasing number of vehicles and a growing emphasis on road safety. Buyers should prioritize suppliers that offer innovative products, such as high-performance electric inflators with quick inflation capabilities and automatic shut-off features, ensuring both efficiency and convenience.

Moreover, understanding regional market dynamics and consumer preferences is vital. Sourcing from manufacturers that provide customizable solutions can enhance your product offerings, catering to specific needs in diverse markets.

As we look forward, the tyre air pump industry is poised for further growth, with advancements in battery technology and smart features likely to shape the future landscape. We encourage international B2B buyers to leverage strategic sourcing to not only enhance their product portfolios but also to establish long-lasting partnerships that drive mutual success in this competitive market. Embrace the opportunity to innovate and respond to the evolving demands of your customers—your strategic sourcing decisions today will define your success tomorrow.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.