- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

In the fast-paced world of automotive maintenance and repair, sourcing the right tools, such as the Ryobi cordless tire inflator, is crucial for efficiency and customer satisfaction. International B2B buyers face the challenge of navigating diverse markets, where product availability, quality, and pricing can vary significantly. This comprehensive guide aims to equip you with essential insights into the Ryobi cordless tire inflator, covering various models, applications, and the specific needs of your target market—be it in Africa, South America, the Middle East, or Europe, including regions like Vietnam and Brazil.

Throughout this guide, we will delve into the key features and specifications of the Ryobi cordless tire inflator, examining its versatility in inflating not just vehicle tires but also sports equipment and more. We will provide actionable advice on supplier vetting, helping you identify reliable partners that meet your business needs. Additionally, we will discuss cost considerations and potential pricing strategies that align with market expectations.

By empowering you with the knowledge to make informed purchasing decisions, this guide will enhance your ability to select the right inflator for your operations, ensuring that you can meet customer demands effectively while optimizing your supply chain. Join us as we explore the global market for the Ryobi cordless tire inflator and position your business for success in this competitive landscape.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| RYOBI ONE+ High Pressure Inflator | Auto shut-off, digital pressure gauge, inflates up to 160 PSI | Automotive service, tire repair shops | الإيجابيات: High accuracy, versatile; السلبيات: Tool only option requires battery purchase separately. |

| RYOBI ONE+ Dual Function Inflator/Deflator | Dual function for inflation and deflation, compact design | Sports equipment, camping gear | الإيجابيات: Multi-functional, portable; السلبيات: Lower PSI limit compared to high-pressure models. |

| RYOBI Whisper Series High Volume Inflator | Quiet operation, high volume airflow | Construction sites, event setups | الإيجابيات: Noise reduction, efficient; السلبيات: May not reach high PSI for all applications. |

| RYOBI ONE+ Digital Inflator Kit | Comes with battery and charger, LCD screen | Fleet management, emergency services | الإيجابيات: Complete kit, easy to use; السلبيات: Higher initial investment. |

| RYOBI ONE+ High Volume Inflator | Designed for rapid inflation, suitable for larger items | Recreational vehicle maintenance, large tires | الإيجابيات: Fast inflation rates; السلبيات: Less portable due to size. |

The RYOBI ONE+ High Pressure Inflator is designed for precision with an auto shut-off feature that stops inflation once the desired PSI is reached. This model is particularly suitable for automotive service and tire repair shops, ensuring tires are inflated accurately to manufacturer specifications. B2B buyers should consider its compatibility with the RYOBI ONE+ battery system, providing versatility across over 300 tools, although purchasing the battery separately may be a drawback for some.

The RYOBI ONE+ Dual Function Inflator/Deflator offers both inflation and deflation capabilities in a compact design, making it ideal for businesses dealing with sports equipment or camping gear. Its versatility allows for quick transitions between inflating air mattresses and deflating beach balls. However, its lower PSI limit may restrict use for heavy-duty applications, so buyers should evaluate their specific needs.

The RYOBI Whisper Series High Volume Inflator is engineered for quiet operation while delivering high volume airflow, making it suitable for construction sites and event setups where noise control is essential. This model excels in environments that require efficiency without disturbing surroundings. However, its inability to reach high PSI levels may limit its utility in some applications, which is a consideration for B2B buyers focused on high-pressure tasks.

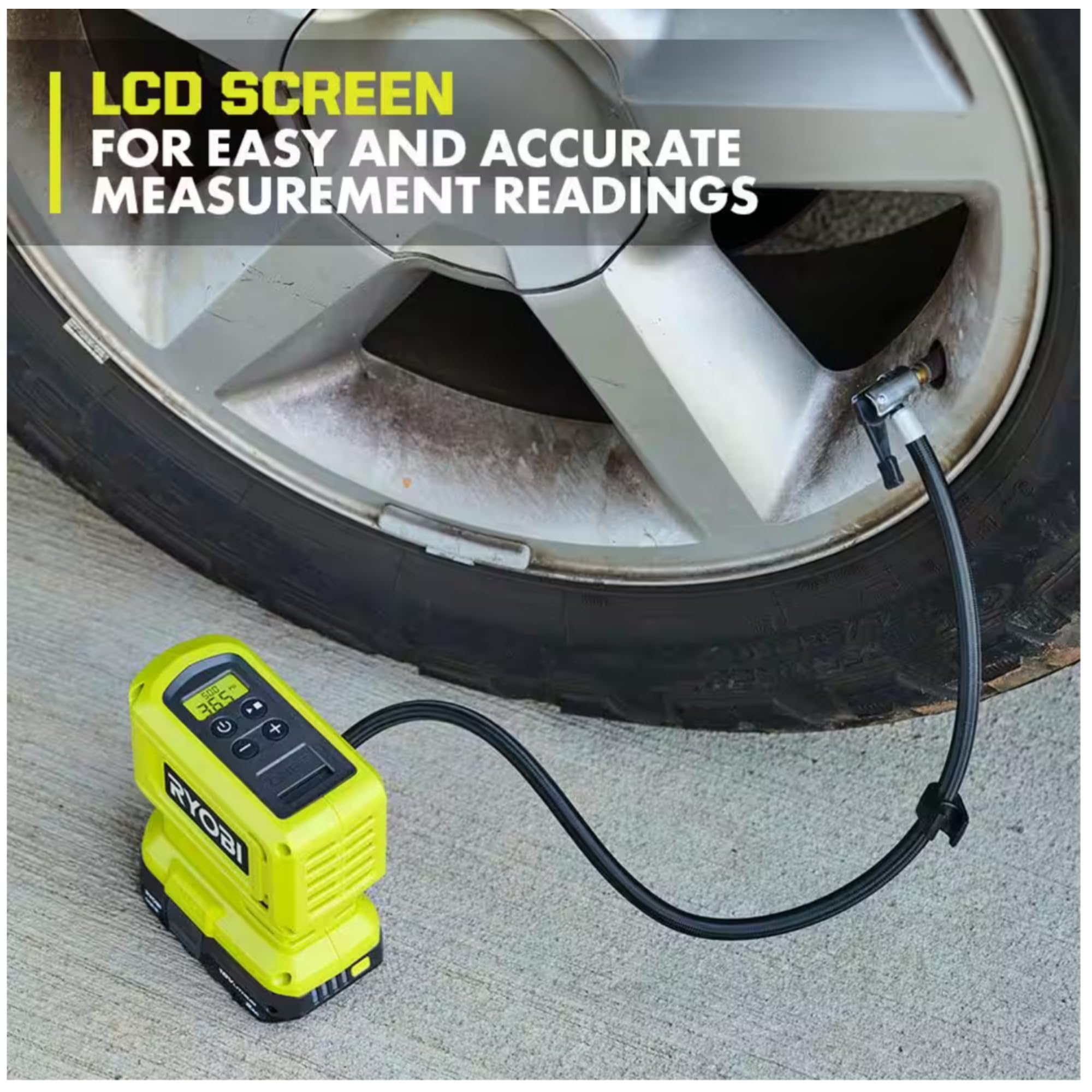

The RYOBI ONE+ Digital Inflator Kit includes a battery and charger, making it a comprehensive solution for fleet management and emergency services. The LCD screen enhances usability by providing clear pressure readings, which is critical for ensuring safety and compliance. The initial investment may be higher than purchasing a tool alone, but the convenience of a complete kit can justify the cost for many businesses.

The RYOBI ONE+ High Volume Inflator is designed for rapid inflation, making it perfect for businesses that deal with recreational vehicles and larger tires. Its ability to quickly inflate larger items saves time, which is a crucial factor in high-demand environments. However, its size may affect portability, so companies should assess their operational needs when considering this model.

Illustrative image related to ryobi cordless tire inflator

| الصناعة/القطاع | Specific Application of ryobi cordless tire inflator | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| Automotive Repair | Quick tire inflation for vehicles during servicing | Reduces downtime, increases efficiency in tire service operations | Battery compatibility, ease of use, and durability in a workshop setting |

| النقل والخدمات اللوجستية | On-site tire inflation for delivery and logistics vehicles | Enhances fleet readiness and minimizes delays in deliveries | Portability, battery life, and charging options |

| Sports & Recreation | Inflating sports equipment (balls, bicycles) for events and training | Ensures readiness for training sessions and events | Versatile attachments, accuracy of pressure gauge, and portability |

| Construction | Inflation of pneumatic tools and equipment on job sites | Increases operational efficiency and reduces manual labor | Power output, battery compatibility, and ruggedness for outdoor use |

| الزراعة | Tire inflation for farming vehicles and equipment | Maintains optimal performance of machinery, reducing downtime | Compatibility with various tire types, ease of maintenance, and battery life |

In the automotive repair industry, the Ryobi cordless tire inflator is essential for quickly inflating tires during routine maintenance and repairs. By providing precise inflation up to 160 PSI with an auto shut-off feature, it minimizes the risk of over-inflation and ensures safety. This tool’s portability and ease of use enable mechanics to efficiently service multiple vehicles without the need for bulky air compressors, ultimately reducing downtime and increasing overall efficiency in tire service operations.

For businesses in transportation and logistics, the Ryobi cordless tire inflator serves as a vital tool for maintaining the readiness of delivery and logistics vehicles. On-site tire inflation capabilities help to prevent delays caused by flat tires and ensure that vehicles are always in optimal condition. The inflator’s lightweight design and battery operation make it easy for drivers to use on the go, facilitating quick adjustments to tire pressure and enhancing overall fleet efficiency.

In the sports and recreation sector, the Ryobi cordless tire inflator is utilized to inflate various sports equipment, including balls and bicycles, before events and training sessions. Its digital pressure gauge ensures accuracy, allowing coaches and athletes to prepare equipment to the required specifications. This readiness is crucial for performance, as properly inflated equipment can significantly impact training outcomes and event success. The inflator’s compact size and battery operation make it an ideal companion for sports teams and recreational facilities.

In construction, the Ryobi cordless tire inflator is used for inflating pneumatic tools and equipment, which are vital for various tasks on job sites. By ensuring that tools are properly inflated, construction teams can increase operational efficiency and reduce manual labor associated with tire maintenance. The tool’s rugged design and compatibility with multiple tire types make it suitable for harsh job site conditions, while its cordless nature provides flexibility and ease of movement across different areas of the site.

In agriculture, the Ryobi cordless tire inflator plays a crucial role in maintaining the performance of farming vehicles and equipment. Regular tire inflation is essential for optimizing machinery efficiency and minimizing downtime due to tire issues. The inflator’s ability to handle a variety of tire types, along with its long battery life, ensures that farmers can quickly address tire pressure needs without disrupting their workflow. This reliability is essential for agricultural operations that depend on timely and efficient equipment performance.

المشكلة B2B buyers often face challenges with the accuracy of tire inflation, particularly when dealing with a diverse range of vehicles and equipment. In industries such as logistics, construction, and automotive services, maintaining precise tire pressure is critical for safety and efficiency. Buyers may find that inflating tires to the correct PSI can be cumbersome, especially when manual gauges are unreliable or when there is a lack of experience in adjusting pressures for different applications.

الحل: The RYOBI ONE+ 18V Cordless High Pressure Inflator comes equipped with a digital pressure gauge that allows for precise filling up to 160 PSI, with an auto shut-off feature that stops inflation once the desired pressure is reached. To optimize usage, B2B buyers should ensure that operators are trained on how to set and read the digital display properly. Additionally, it’s beneficial to have a standard operating procedure that includes checking the manufacturer’s recommended PSI for each vehicle type. By leveraging the inflator’s automatic features, businesses can minimize the risk of overinflation or underinflation, ensuring that all tires are properly maintained without the need for constant supervision.

المشكلة For businesses that operate in remote locations or require extensive tire inflation capabilities, the battery life of portable inflators can become a significant limitation. B2B buyers might find themselves in a situation where multiple vehicles need servicing, but the inflator’s battery drains quickly, leading to delays in operations and increased downtime.

الحل: To address battery life concerns, B2B buyers should consider investing in additional RYOBI 18V ONE+ batteries. The ONE+ system is designed to be compatible with over 300 tools, meaning that spare batteries can be used across various tools, maximizing efficiency. Furthermore, purchasing the inflator kit that includes a higher-capacity battery can enhance performance during high-demand periods. Encouraging teams to rotate batteries between tools can also ensure that there is always a charged battery ready for use, thereby reducing interruptions and maintaining workflow continuity.

المشكلة In a commercial setting, B2B buyers often deal with a variety of inflation needs, from vehicle tires to sports equipment. A common pain point is the lack of proper storage for accessories, leading to disorganization and inefficiency. When inflators do not come with adequate storage solutions, operators may waste time searching for necessary attachments, negatively impacting productivity.

الحل: The RYOBI ONE+ Cordless Tire Inflator includes on-board accessory storage, which allows users to keep all attachments organized and easily accessible. To maximize this feature, businesses should implement an inventory checklist that specifies which accessories are needed for different inflation tasks. This ensures that all operators are familiar with the available attachments and can quickly access them when needed. Additionally, creating a dedicated storage space for the inflator and its accessories can further enhance organization and streamline operations, ultimately improving overall productivity. By capitalizing on the inflator’s versatile design, businesses can cater to a wider range of inflation tasks without the hassle of disorganization.

When selecting materials for the RYOBI cordless tire inflator, several options are commonly utilized, each offering unique properties and performance characteristics. Understanding these materials is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, where specific compliance and performance standards may apply.

Plastic is often used in the housing and various components of the RYOBI cordless tire inflator. Key properties include lightweight construction and resistance to corrosion, making it suitable for portable applications. Plastics like ABS (Acrylonitrile Butadiene Styrene) can withstand temperature variations, typically rated for use between -20°C to 80°C (-4°F to 176°F).

Pros and Cons: The main advantage of plastic is its cost-effectiveness and ease of manufacturing, which can lower production costs. However, its durability may be a concern, particularly in high-stress environments. Plastic components may not be suitable for high-pressure applications beyond their rated limits.

التأثير على التطبيق: The use of plastic allows for a lightweight design, enhancing portability. However, care must be taken to ensure that any media compatibility issues, such as exposure to certain chemicals, are addressed.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastic used complies with local regulations regarding safety and environmental impact, such as REACH in Europe or similar standards in other regions.

Illustrative image related to ryobi cordless tire inflator

Metal components, particularly aluminum and steel, are often used in the internal mechanisms of the inflator, such as the pump and fittings. These materials provide high strength and durability, with aluminum typically offering a good balance of weight and resistance to corrosion.

Pros and Cons: The primary advantage of metal is its structural integrity and resistance to wear and tear, making it suitable for high-pressure applications. However, metals can increase the overall weight of the product and may be more expensive than plastic alternatives.

التأثير على التطبيق: Metal components can handle higher pressures and temperatures, ensuring reliable performance in various conditions. This makes them ideal for inflating tires in diverse environments, from cold climates to hot regions.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM for metals is crucial. Buyers should also consider the sourcing of metals, ensuring they meet local regulations regarding manufacturing and environmental impact.

Rubber is typically used in seals and O-rings within the inflator to prevent air leaks. Key properties include flexibility and excellent resistance to compression, which helps maintain airtight seals under varying pressure conditions.

Pros and Cons: Rubber seals are relatively inexpensive and provide excellent sealing capabilities. However, they can degrade over time, especially when exposed to UV light or extreme temperatures.

التأثير على التطبيق: The effectiveness of rubber seals directly affects the inflator’s performance, as leaks can lead to inefficiencies and reduced pressure. Proper maintenance and replacement of seals are essential for optimal functionality.

اعتبارات للمشترين الدوليين: Buyers should ensure that rubber components comply with local standards for durability and safety, such as those set by JIS in Japan or similar organizations in other regions.

Composite materials, such as fiberglass-reinforced plastics, are increasingly being used in high-performance applications. These materials offer an excellent strength-to-weight ratio and can be engineered to meet specific performance criteria.

Pros and Cons: The main advantage is their durability and resistance to environmental factors. However, they can be more expensive and complex to manufacture compared to traditional materials.

التأثير على التطبيق: Composites can enhance the inflator’s performance by providing lightweight yet strong components, suitable for high-pressure applications.

اعتبارات للمشترين الدوليين: Buyers should verify that composite materials meet international standards for safety and performance, as well as local environmental regulations.

| المواد | Typical Use Case for ryobi cordless tire inflator | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| بلاستيك | Housing and non-structural components | خفيفة الوزن وفعالة من حيث التكلفة | Less durable under high stress | منخفضة |

| معدن | Internal mechanisms (pump, fittings) | قوة ومتانة عالية | Increased weight and cost | متوسط |

| المطاط | Seals and O-rings | Excellent sealing capabilities | يتحلل بمرور الوقت | منخفضة |

| مركب | High-performance components | Strong and lightweight | تعقيد التصنيع العالي | عالية |

This strategic material selection guide provides valuable insights for B2B buyers considering the RYOBI cordless tire inflator, ensuring informed decisions that align with performance needs and regional compliance standards.

Illustrative image related to ryobi cordless tire inflator

The manufacturing process for the Ryobi cordless tire inflator encompasses several critical stages, ensuring both efficiency and quality.

The first stage involves sourcing high-quality materials, including plastics for the housing, metal for internal components, and electronic parts for the digital pressure gauge. Suppliers are selected based on their ability to meet international quality standards, ensuring consistency in the raw materials used. Rigorous supplier audits are often conducted to verify compliance with standards such as ISO 9001, which focuses on effective quality management systems.

Once materials are sourced, they undergo forming processes. This typically includes injection molding for plastic components and stamping or machining for metal parts. Advanced techniques such as Computer Numerical Control (CNC) machining may be employed to achieve precise tolerances, which are essential for the inflator’s performance. This precision is crucial, as any discrepancies can lead to inefficiencies in inflation or potential safety hazards.

The assembly stage involves integrating the various components into a final product. This process is often automated to enhance speed and accuracy, but skilled technicians are also engaged for quality-sensitive operations. Assembly lines are designed to minimize handling time and maximize efficiency, utilizing techniques such as lean manufacturing to reduce waste. Each unit undergoes initial quality checks to ensure proper assembly before moving to the next stage.

After assembly, the inflators receive finishing touches, including surface treatment and labeling. Finishing processes may involve painting or coating to enhance durability and aesthetics. The quality assurance team performs visual inspections at this stage to catch any defects that may have slipped through earlier stages. This attention to detail is vital, especially for B2B buyers who expect products that meet stringent quality standards.

Illustrative image related to ryobi cordless tire inflator

Quality assurance is a cornerstone of the manufacturing process for Ryobi cordless tire inflators. A robust QC system is in place to ensure that each product meets both international and industry-specific standards.

Ryobi adheres to various international standards, including ISO 9001 for quality management and CE marking for compliance with European safety regulations. For electrical components, compliance with RoHS (Restriction of Hazardous Substances) is also critical, ensuring that materials used are safe for both consumers and the environment.

Quality control checkpoints are strategically placed throughout the manufacturing process:

مراقبة الجودة الواردة (IQC): This initial stage involves inspecting raw materials as they arrive at the factory. Any materials that do not meet specifications are rejected or returned to the supplier.

مراقبة الجودة أثناء المعالجة (IPQC): During the production phase, ongoing inspections are conducted to ensure that each step of the manufacturing process adheres to quality standards. This includes monitoring machinery and assembly processes to prevent defects.

مراقبة الجودة النهائية (FQC): Before the inflators are packaged and shipped, they undergo a final inspection to ensure functionality and compliance with specifications. This includes testing the inflator’s pressure gauge and auto shut-off features.

Testing methods for Ryobi inflators include:

الاختبار الوظيفي: Each unit is tested for operational efficiency, including the ability to reach the specified PSI and the accuracy of the digital pressure gauge.

اختبار المتانة: Inflators may undergo stress tests to assess their performance under extreme conditions, simulating real-world usage scenarios.

Safety Testing: Electrical safety tests ensure that the inflator complies with safety standards, preventing hazards such as overheating or electrical failures.

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are several strategies to ensure that suppliers maintain high standards:

Buyers should request detailed quality assurance reports, including results from past audits and inspections. These reports should outline compliance with relevant standards and any corrective actions taken for non-compliance.

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes. These inspections can occur at various stages of production, offering buyers peace of mind that the products meet their specifications.

International buyers must navigate several nuances in quality control. Understanding regional compliance requirements is essential, as standards may differ significantly across markets. For example, while CE marking is crucial for the European market, UL certification might be more relevant for North American buyers.

Additionally, cultural considerations may influence quality expectations and communication. Establishing clear quality criteria and maintaining open lines of communication with suppliers can mitigate misunderstandings and ensure that product quality meets or exceeds expectations.

The manufacturing and quality assurance processes for the Ryobi cordless tire inflator are designed to meet high standards of performance and reliability. By understanding the intricacies of these processes, B2B buyers can make informed decisions when sourcing products, ensuring that they partner with suppliers who are committed to quality and compliance.

Illustrative image related to ryobi cordless tire inflator

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring the Ryobi Cordless Tire Inflator. With a focus on quality, performance, and supplier reliability, this checklist will help you navigate the complexities of sourcing this essential tool for automotive and recreational applications.

Before initiating the procurement process, clearly outline the technical specifications required for the Ryobi Cordless Tire Inflator. Consider factors such as maximum pressure (up to 160 PSI), battery compatibility (18V ONE+ system), and functionalities like auto shut-off and digital pressure gauge. Defining these specifications ensures that the inflator meets your operational needs and enhances efficiency.

Engage in comprehensive market research to identify potential suppliers and products available in your region. Utilize online platforms, trade shows, and industry publications to gather data on various models and their features. This research will help you compare options and make informed decisions based on the latest market trends and innovations.

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, product certifications, and references from existing clients, especially those in similar industries or regions. This evaluation will help you gauge the supplier’s credibility, reliability, and customer service capabilities.

Confirm that the selected supplier has adequate stock levels of the Ryobi Cordless Tire Inflator and can meet your delivery timelines. Delays in receiving essential tools can disrupt operations, so understanding lead times and potential shipping issues is critical.

Illustrative image related to ryobi cordless tire inflator

Before finalizing your order, consider requesting a sample unit for testing. This step allows you to evaluate the product’s performance, durability, and ease of use in real-world scenarios. Testing helps mitigate risks associated with bulk purchases, ensuring that the inflator meets your expectations.

Engage in negotiations to secure favorable pricing and payment terms with your chosen supplier. Discuss bulk purchase discounts, warranty conditions, and after-sales support. A clear understanding of financial terms can lead to better budgeting and long-term partnerships.

Once all criteria are met and terms are agreed upon, finalize the purchase. Ensure all agreements, specifications, and warranties are documented. This documentation serves as a reference for future transactions and helps protect your investment.

By following these steps, B2B buyers can streamline the procurement process for the Ryobi Cordless Tire Inflator, ensuring they select a high-quality product from a reliable supplier while minimizing risks associated with purchasing decisions.

When analyzing the cost structure for sourcing Ryobi cordless tire inflators, several key components contribute to the overall pricing. المواد include high-quality plastics, metals, and electrical components necessary for the inflator’s functionality. The labor cost is influenced by the region of manufacturing; for instance, labor in Southeast Asia may be lower than in Europe, impacting the final price. النفقات العامة للتصنيع covers utilities, facility costs, and indirect labor, which can vary significantly based on the supplier’s operational efficiency.

Illustrative image related to ryobi cordless tire inflator

Tooling costs are associated with the initial setup of production lines, which may require investment in specific molds and fixtures. مراقبة الجودة (QC) is essential to ensure product reliability and safety, especially given the varying regulations across regions. Logistics costs involve shipping, handling, and customs duties, which can fluctuate based on destination and shipping method. Lastly, the margin added by suppliers or distributors reflects their profit expectations and market positioning.

Several factors influence the pricing of Ryobi cordless tire inflators. الحجم والحد الأدنى لكمية الطلب (MOQ) play a crucial role; larger orders often lead to discounts, making it economically viable for bulk buyers. المواصفات والتخصيص also affect the price; unique features or tailored designs typically incur higher costs. The choice of materials can significantly impact pricing as well, particularly if premium materials are specified for enhanced durability.

Quality and certifications are vital, especially for international buyers who may require compliance with specific standards. Suppliers that offer certifications can command higher prices due to perceived quality assurance. Additionally, supplier factors such as reputation, production capacity, and reliability can influence pricing. Understanding the المصطلحات التجارية الدولية (International Commercial Terms) is crucial, as they define the responsibilities of buyers and sellers, impacting total costs.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Buyers should research market prices and be prepared to negotiate terms that align with their budget while considering the value of quality and service.

Illustrative image related to ryobi cordless tire inflator

Evaluating the التكلفة الإجمالية للملكية (TCO) is essential. This includes not just the initial purchase price but also long-term factors such as maintenance, warranty, and potential repairs. Buyers should inquire about الفروق الدقيقة في التسعير, such as discounts for early payments or long-term contracts, which can lower overall costs.

Additionally, understanding the local market and establishing relationships with suppliers can yield better pricing and service. Buyers should also consider logistics and the impact of shipping costs, which can vary based on the chosen Incoterms. By engaging with multiple suppliers, buyers can compare offers and find the most competitive pricing without compromising quality.

In conclusion, sourcing Ryobi cordless tire inflators requires a thorough understanding of the cost structure and pricing influencers. By considering material costs, labor, overhead, and logistics, alongside price influencers such as volume and customization, buyers can make informed decisions. Employing strategic negotiation tactics and evaluating TCO will further enhance cost-efficiency, ensuring that international buyers secure favorable terms while acquiring high-quality products.

Disclaimer: Prices and costs mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements.

Illustrative image related to ryobi cordless tire inflator

In today’s fast-paced world, businesses often seek efficient and effective solutions for their operational needs. When it comes to tire inflation, the RYOBI Cordless Tire Inflator stands out for its convenience and performance. However, it’s essential to explore alternative options that may suit varying business requirements, especially for international buyers in regions like Africa, South America, the Middle East, and Europe. This analysis compares the RYOBI inflator with two viable alternatives: a traditional air compressor and a manual tire pump.

| جانب المقارنة | Ryobi Cordless Tire Inflator | Traditional Air Compressor | Manual Tire Pump |

|---|---|---|---|

| الأداء | Inflates up to 160 PSI, auto shut-off | High PSI, suitable for heavy-duty use | Limited PSI, labor-intensive |

| التكلفة | Approx. $64.97 (tool only) | $100 – $300 (varies widely) | $20 – $50 |

| سهولة التنفيذ | User-friendly, portable, battery-operated | Requires power source, less portable | Simple design, no power needed |

| الصيانة | Minimal, battery care required | Moderate, oil and filter changes needed | Very low, occasional cleaning |

| أفضل حالة استخدام | Ideal for cars, bikes, sports balls | Best for garages and workshops | Suitable for emergencies or low-use scenarios |

Traditional air compressors are powerful tools that deliver high PSI, making them suitable for heavy-duty applications such as tire inflation for trucks or for powering pneumatic tools. They generally have a higher upfront cost and require a continuous power source, which may limit portability. Maintenance can be more involved due to the need for oil changes and filter replacements. However, for businesses that require consistent and powerful inflation capabilities, a traditional air compressor is a robust choice.

Manual tire pumps offer a budget-friendly alternative for businesses with minimal inflation needs. They are simple to use, require no power, and have very low maintenance costs. However, their performance is limited to lower PSI levels and can be labor-intensive, requiring significant physical effort to inflate tires. This option is best suited for emergency situations or for businesses that do not require frequent tire inflation.

When selecting a tire inflation solution, B2B buyers must assess their specific operational requirements. The RYOBI Cordless Tire Inflator is ideal for those who prioritize portability and ease of use, making it a great choice for mobile applications. In contrast, a traditional air compressor is better suited for businesses that need high performance and versatility in a workshop setting. Manual tire pumps may be appropriate for those seeking a cost-effective and straightforward solution for occasional use. Ultimately, the decision should align with the business’s specific needs, budget constraints, and operational environment.

Understanding the technical specifications of the Ryobi cordless tire inflator is crucial for B2B buyers aiming to meet their operational needs efficiently. Below are the essential properties that define the product’s performance and reliability:

Pressure Capacity (PSI): The Ryobi cordless tire inflator can achieve a maximum pressure of up to 160 PSI. This high-pressure capability is vital for inflating various types of tires, including those on cars, bikes, and sports equipment. For businesses, this ensures versatility across different applications, allowing for quick and efficient service.

Power Source (Battery Voltage): Operating on an 18V battery from the Ryobi ONE+ system, this inflator is compatible with over 300 Ryobi tools. The benefit of a standardized battery system is significant for businesses, as it reduces the need for multiple battery types, simplifies inventory management, and lowers replacement costs.

مقياس الضغط الرقمي: Equipped with a digital pressure gauge, the inflator offers precise pressure readings. This feature is critical for maintaining optimal tire pressure, enhancing safety, and improving fuel efficiency. For B2B buyers, accurate inflation can minimize the risk of over-inflation or under-inflation, thereby extending tire life and performance.

Auto Shut-off Feature: The inflator includes an auto shut-off feature that stops inflation once the preset PSI is reached. This not only prevents damage to tires but also enhances user convenience, allowing operators to multitask while the inflator works. For businesses, this can significantly improve workflow efficiency.

Accessory Storage: The on-board accessory storage allows users to keep various inflation nozzles organized and readily accessible. This is particularly useful for businesses that require quick transitions between different inflation tasks, reducing downtime and improving service speed.

Weight and Portability: Weighing approximately 3.5 lbs, the inflator’s lightweight design contributes to its portability. For businesses involved in mobile services or those that operate in multiple locations, ease of transport is a crucial factor that can influence productivity.

Navigating the B2B landscape requires familiarity with specific jargon and trade terms. Here are some common terms that are relevant to the purchase of the Ryobi cordless tire inflator:

Illustrative image related to ryobi cordless tire inflator

OEM (الشركة المصنعة للمعدات الأصلية): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for B2B buyers as it can affect the quality and compatibility of products purchased.

موك (الحد الأدنى لكمية الطلب): MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory planning, as it can dictate the volume of inflators or parts they need to purchase at once.

طلب عرض الأسعار (RFQ): An RFQ is a document that solicits price quotes from suppliers for specific products or services. For businesses looking to procure the Ryobi inflator, issuing an RFQ can ensure competitive pricing and better terms.

إنكوترمز (الشروط التجارية الدولية): These are a series of predefined commercial terms used in international trade. Familiarity with Incoterms helps buyers understand their responsibilities regarding shipping, insurance, and tariffs, which is critical when importing tools like the Ryobi inflator.

المهلة الزمنية: This term refers to the amount of time it takes for a supplier to fulfill an order. For B2B buyers, understanding lead times is essential for effective project planning and ensuring that tools are available when needed.

الضمان: A warranty is a promise made by the manufacturer regarding the condition of the product. For B2B buyers, a solid warranty can mitigate risks associated with defects or performance issues, making it an important consideration during the purchasing process.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their procurement of the Ryobi cordless tire inflator aligns with their operational goals and market demands.

The global market for cordless tire inflators, particularly the Ryobi brand, is witnessing significant growth driven by several factors. The increasing emphasis on convenience and portability in consumer products has made cordless inflators highly desirable. As urbanization accelerates in regions such as Africa, South America, and the Middle East, the demand for quick and efficient tire maintenance solutions is on the rise. Additionally, advancements in battery technology, such as lithium-ion batteries, enhance performance, allowing inflators to achieve higher PSI levels while maintaining lightweight designs.

Emerging trends in B2B sourcing include a shift towards digital platforms for procurement, where buyers can compare specifications, prices, and features of inflators like the Ryobi ONE+ series. B2B buyers are increasingly favoring suppliers who can provide comprehensive product data, warranty information, and customer support. Furthermore, the integration of IoT technology into inflators is becoming prevalent, offering features like pressure monitoring and smartphone connectivity, thereby increasing user engagement and satisfaction.

International buyers from diverse markets, including Europe, Vietnam, and Brazil, are also prioritizing suppliers who can demonstrate reliability and responsiveness. This demand is often met through strategic partnerships with local distributors who understand regional preferences and logistical challenges.

Sustainability is becoming a crucial consideration in the procurement of cordless tire inflators. The environmental impact of manufacturing processes and product lifecycle management is increasingly scrutinized. For Ryobi’s cordless tire inflators, there is a growing expectation for manufacturers to adopt eco-friendly practices, such as using recyclable materials and reducing carbon footprints during production.

B2B buyers are keen on sourcing products that come with sustainability certifications, such as Energy Star or certifications indicating the use of recycled materials. This not only aligns with corporate social responsibility goals but also appeals to environmentally-conscious consumers. Additionally, ethical sourcing of raw materials is essential to ensure that the supply chain is free from exploitation and environmental degradation. Buyers should inquire about the sourcing practices of their suppliers, ensuring that they support fair labor practices and environmentally sustainable methods.

Moreover, as part of the Ryobi ONE+ ecosystem, inflators can be marketed as part of a broader commitment to sustainability, emphasizing battery compatibility with over 300 Ryobi tools, thereby reducing waste and encouraging product longevity.

The Ryobi brand has evolved significantly since its inception in 1943, transitioning from a manufacturer of die-cast products to a leading name in power tools and outdoor equipment. The introduction of the Ryobi ONE+ system in the early 2000s marked a pivotal moment, allowing for interchangeable battery use across a wide range of tools, including cordless tire inflators. This innovation not only enhanced convenience for users but also positioned Ryobi as a versatile choice for both DIY enthusiasts and professional users.

Illustrative image related to ryobi cordless tire inflator

Over the years, the cordless tire inflator segment has expanded, reflecting changes in consumer preferences towards more portable and efficient solutions. The incorporation of digital technology and enhanced safety features has further solidified Ryobi’s market presence, making it a preferred choice for international B2B buyers looking for reliability and performance in tire maintenance solutions. As the brand continues to innovate, it remains attuned to market dynamics, ensuring that its products meet the evolving needs of consumers globally.

How do I choose the right Ryobi cordless tire inflator for my business needs?

When selecting a Ryobi cordless tire inflator, consider factors such as the inflator’s PSI capabilities, battery compatibility within the Ryobi ONE+ system, and specific use cases. For businesses focusing on automotive services, a model that reaches 160 PSI will be essential for diverse vehicle types. Additionally, evaluate features like auto shut-off for precision and portability, as well as on-board accessory storage for convenience. Understanding your operational requirements will guide you in selecting the most suitable model.

What are the benefits of using a cordless tire inflator over a traditional one?

Cordless tire inflators, like those from Ryobi, offer significant advantages including portability, ease of use, and flexibility in various environments. Without the constraint of a power cord, these inflators can be used in remote locations, making them ideal for businesses in outdoor or on-site settings. Furthermore, Ryobi’s cordless models are designed for quick inflation with features like digital pressure gauges, ensuring accuracy and efficiency that can enhance service delivery and customer satisfaction.

What is the minimum order quantity (MOQ) for Ryobi cordless tire inflators?

The minimum order quantity (MOQ) for Ryobi cordless tire inflators varies by supplier and region. Typically, wholesalers may require MOQs ranging from 10 to 50 units to qualify for bulk pricing. It’s advisable to engage directly with authorized Ryobi distributors or manufacturers to negotiate terms that suit your business needs. Establishing a strong relationship with your supplier can also provide opportunities for customized orders and better pricing structures.

What payment terms should I expect when purchasing Ryobi inflators internationally?

Payment terms for international purchases of Ryobi inflators generally include options such as advance payment, letter of credit, or payment on delivery, depending on your supplier’s policies. Common practices involve a deposit of 30% at order placement, with the remaining balance due before shipment. Always confirm payment methods that offer security and flexibility for your business, and consider negotiating terms that align with your cash flow requirements.

How can I ensure the quality of Ryobi cordless tire inflators during procurement?

To ensure quality when sourcing Ryobi cordless tire inflators, request product certifications and quality assurance documentation from your supplier. Conducting a factory audit or utilizing third-party inspection services can provide additional assurance of product standards. Establishing clear communication regarding your quality expectations and performance benchmarks will help mitigate risks and ensure that you receive reliable and durable inflators suitable for your business operations.

What logistics considerations should I be aware of when importing Ryobi products?

When importing Ryobi products, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Opt for a reliable freight forwarder familiar with importing tools and equipment to navigate customs efficiently. It’s crucial to understand the import duties and taxes applicable in your region, as these can significantly affect total costs. Planning ahead and maintaining clear communication with your logistics provider will streamline the import process and minimize delays.

Can I customize Ryobi cordless tire inflators for my brand?

Customization options for Ryobi cordless tire inflators may be limited, as they are primarily branded products. However, some suppliers may offer co-branding opportunities or customization in terms of packaging and accessories. Discussing your branding needs with authorized distributors can provide insights into available options. Consider the potential benefits of offering unique accessories or bundled kits that align with your brand while maintaining the quality and reliability of Ryobi tools.

What after-sales support is available for Ryobi cordless tire inflators?

After-sales support for Ryobi cordless tire inflators typically includes warranty services, repair options, and customer service assistance. Ryobi offers a standard warranty that covers manufacturing defects, which can vary by region. It is advisable to register your product to access support easily. Additionally, inquire with your supplier about local service centers or authorized repair facilities to ensure your inflators remain in optimal working condition, thus enhancing your operational efficiency.

المجال: ryobitools.com

مسجل: 1999 (26 سنة)

مقدمة: {“Product Name”: “18V ONE+ HIGH PRESSURE DIGITAL INFLATOR KIT”, “Model”: “PCL001K1”, “Price”: “$64.97 (originally $89.97)”, “Max Pressure”: “160 PSI”, “Features”: [“Digital pressure gauge for accurate filling”, “Auto shut-off when desired PSI is reached”, “On-board accessory storage”, “Ideal for filling car, bike, and other small tires and sports balls”], “Battery Compatibility”: “18V ONE+ System”…

In evaluating the strategic sourcing of the Ryobi Cordless Tire Inflator, it’s essential to recognize its robust features that cater specifically to the needs of B2B buyers in diverse markets. The inflator’s precision, capable of reaching up to 160 PSI with an auto shut-off feature, offers efficiency and reliability, making it ideal for various applications—from automotive to sports equipment. Furthermore, the integration with the Ryobi ONE+ battery system enhances versatility, allowing users to power over 300 tools with a single battery type, thereby streamlining operational costs and inventory management.

Strategic sourcing remains pivotal in ensuring that businesses not only procure high-quality products but also foster long-term supplier relationships that can adapt to market demands. For international buyers, particularly in Africa, South America, the Middle East, and Europe, aligning with trusted suppliers of Ryobi products can yield significant competitive advantages.

Illustrative image related to ryobi cordless tire inflator

Looking ahead, as markets continue to evolve, investing in reliable tools like the Ryobi Cordless Tire Inflator can enhance operational efficiency and reduce downtime. We encourage B2B buyers to explore partnerships that prioritize quality and innovation, positioning themselves for success in an increasingly competitive landscape.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.

Illustrative image related to ryobi cordless tire inflator