- اللغة الإنجليزية

- الروسية

- الإسبانية

- إيطالي

- اللغة العربية

- البرتغالية

- الألمانية

Navigating the complexities of trailer tire inflation pressure is a critical concern for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The challenge lies not only in ensuring optimal performance and safety but also in sourcing the right solutions that meet diverse regulatory and environmental standards. Understanding the nuances of tire pressure—ranging from specifications for various trailer types to the implications of load capacities—can significantly impact operational efficiency and safety.

This comprehensive guide delves into the essential aspects of trailer tire inflation pressure, covering various trailer types, their specific applications, and the best practices for maintenance. It provides actionable insights on supplier vetting processes, cost considerations, and the impact of tire pressure on overall fuel efficiency and tire longevity. By equipping buyers with the knowledge to make informed decisions, this resource empowers businesses to enhance their fleet management strategies and mitigate risks associated with improper tire inflation.

As you navigate the global market for trailer tire inflation pressure, this guide serves as an indispensable tool, ensuring you are well-prepared to select the best products that align with your operational needs and regional requirements.

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| Standard Trailer Tires | PSI range typically 50-80, suitable for general loads | Utility and travel trailers | الإيجابيات: Cost-effective; السلبيات: Limited load capacity for heavy-duty applications. |

| High-Pressure Tires | PSI ratings of 80+ for heavy loads | Commercial and industrial trailers | الإيجابيات: Enhanced load capacity; السلبيات: Increased risk of overinflation. |

| Boat Trailer Tires | Lower PSI (30-50), designed for water traction | Marine and recreational boating | الإيجابيات: Better traction on ramps; السلبيات: Not suitable for heavy loads. |

| Specialty Tires | Custom PSI specifications for unique applications | Custom-built and specialized trailers | الإيجابيات: Tailored performance; السلبيات: Higher cost and limited availability. |

| Dual-Axle Trailer Tires | PSI range similar to standard, but designed for stability | Heavy-duty and dual-axle trailers | الإيجابيات: Improved stability; السلبيات: Heavier and may require more maintenance. |

Standard trailer tires typically operate within a PSI range of 50-80, making them suitable for a variety of general loads. These tires are commonly used in utility and travel trailers, which are prevalent in many businesses for transporting goods or equipment. When purchasing standard trailer tires, B2B buyers should consider load capacity, tread design, and durability, as these factors will impact performance and lifespan. While they are cost-effective, their load capacity may not meet the needs of heavier applications.

High-pressure tires, with PSI ratings often exceeding 80, are specifically designed for commercial and industrial trailers that carry heavy loads. These tires provide enhanced load capacity and stability, which is crucial for businesses that transport heavy machinery or materials. However, buyers should be aware of the increased risk of overinflation, which can lead to tire failure if not monitored. It’s essential to assess the specific load requirements and operating conditions before investing in high-pressure tires.

Boat trailer tires are designed with lower PSI ratings, typically between 30-50, to enhance traction on slippery surfaces like ramps and during loading. This type of tire is particularly relevant for businesses involved in marine and recreational boating. While they provide excellent performance in wet conditions, boat trailer tires are not suitable for heavy loads. Buyers should ensure that these tires meet the specific requirements of their boating activities and consider the trade-off between traction and load capacity.

Specialty tires come with custom PSI specifications tailored to meet the demands of unique or specialized trailers. These tires are often used in custom-built applications, where standard options may not suffice. While they offer tailored performance benefits, such as improved handling or load capacity, they can be more expensive and may have limited availability. B2B buyers should carefully evaluate their specific needs and budget when considering specialty tires, as they may provide significant advantages in niche markets.

Dual-axle trailer tires share a PSI range similar to standard tires but are engineered to provide enhanced stability for heavy-duty and dual-axle trailers. This design is particularly beneficial for businesses transporting larger loads, as it helps distribute weight more evenly and reduces the risk of swaying. However, dual-axle tires are generally heavier and may require more maintenance. Buyers should assess their towing requirements and ensure compatibility with their trailer setup to maximize performance and safety.

| الصناعة/القطاع | Specific Application of trailer tire inflation pressure | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| الخدمات اللوجستية والنقل | Ensuring optimal tire pressure for freight trailers | Improved safety, reduced fuel costs, extended tire life | Compatibility with diverse trailer types and load requirements |

| الزراعة | Maintaining tire pressure for agricultural equipment trailers | Enhanced stability during transport, lower maintenance costs | Availability of pressure monitoring systems for remote locations |

| Construction | Tire pressure management for construction material transport | Increased load capacity, reduced risk of accidents | Robust tires suited for rough terrains and heavy loads |

| Marine and Recreational | Managing tire pressure for boat and recreational vehicle trailers | Enhanced towing safety, improved fuel efficiency | Specific PSI requirements based on trailer type and load |

| Waste Management | Monitoring tire pressure in waste collection trailers | Lower operational costs, reduced downtime due to tire failures | Durable tires designed for heavy waste loads and varied road conditions |

In the logistics and transport sector, maintaining optimal tire inflation pressure is crucial for freight trailers. Properly inflated tires enhance vehicle handling and stability, thereby reducing the likelihood of accidents during transit. This is particularly important for international shipping routes that may face varying road conditions. Businesses must consider the compatibility of tire types with diverse trailer configurations and load capacities to ensure safety and efficiency.

In agriculture, tire inflation pressure is vital for the safe transport of equipment and harvested goods. Proper tire pressure ensures stability, minimizing the risk of tipping or losing cargo on uneven terrain. This is especially critical in regions with limited infrastructure, such as parts of Africa and South America. Buyers should prioritize sourcing tires that include pressure monitoring systems to facilitate maintenance in remote areas, ensuring that equipment remains operational with minimal downtime.

For the construction industry, managing tire pressure in trailers transporting materials is essential. Correct inflation allows for increased load capacity and enhances the safety of transporting heavy equipment. In regions with rugged landscapes, such as the Middle East and parts of Europe, selecting tires designed for durability and stability under heavy loads is crucial. Additionally, businesses should consider the availability of local tire service providers to ensure timely maintenance and support.

In the marine and recreational sectors, maintaining the correct tire pressure for boat trailers and RVs is fundamental for safe towing. Proper inflation improves fuel efficiency and reduces the risk of blowouts, which can be particularly dangerous on highways. Buyers must be aware of the specific PSI requirements based on their trailer type and load to ensure compliance with safety standards. Additionally, sourcing tires that can withstand varying weather conditions is essential for long-distance travel.

In waste management, monitoring tire pressure in collection trailers is critical for operational efficiency. Properly inflated tires minimize rolling resistance, leading to reduced fuel consumption and lower operational costs. Businesses should consider sourcing tires that are robust enough to handle heavy waste loads and diverse road conditions. Furthermore, integrating real-time tire pressure monitoring systems can significantly reduce downtime, ensuring that waste collection services remain uninterrupted.

Illustrative image related to trailer tire inflation pressure

المشكلة Many B2B buyers managing fleets of trailers face the challenge of inconsistent tire pressure monitoring. Variability in tire pressure across multiple trailers can lead to serious safety issues, reduced fuel efficiency, and increased maintenance costs. For companies operating in diverse climates—like those in Africa or South America—temperature fluctuations can exacerbate the problem, making it even harder to maintain consistent pressure across the fleet. This inconsistency can also lead to overinflation in some cases, causing uneven wear and premature tire failure.

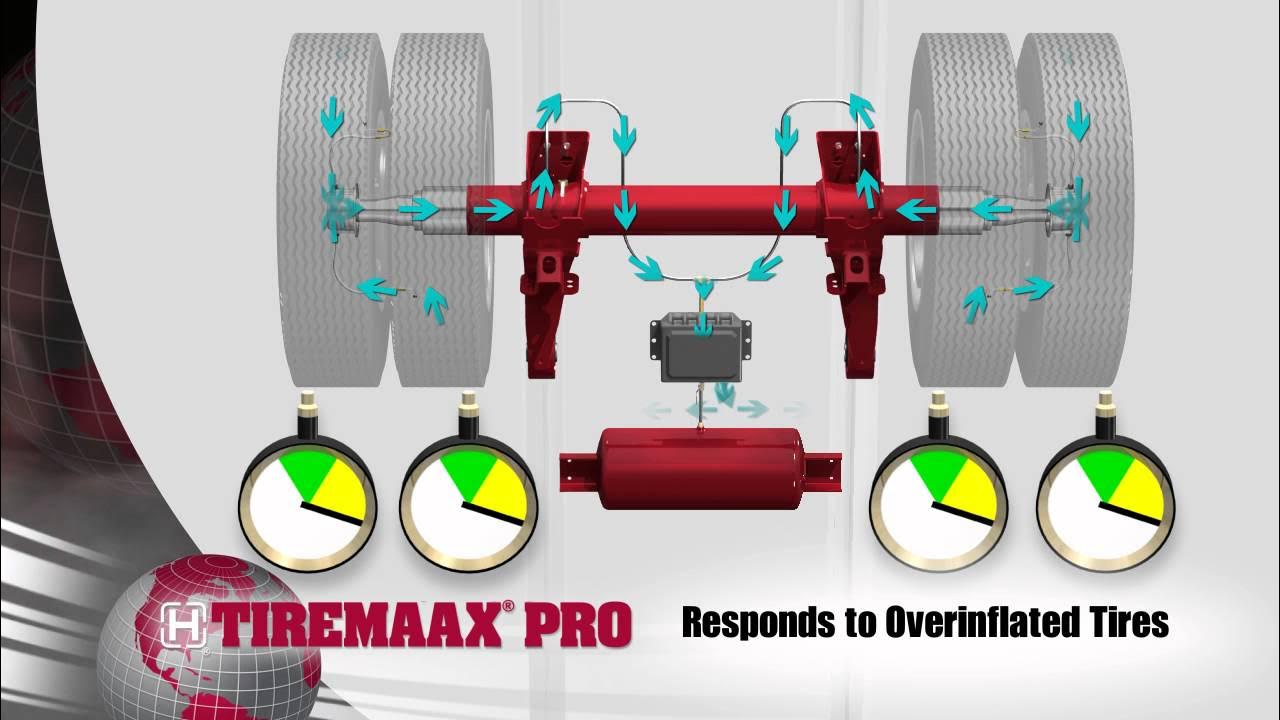

الحل: To address this issue, B2B buyers should invest in centralized tire pressure monitoring systems (TPMS) that provide real-time data on tire pressure and temperature across all trailers. These systems can alert fleet managers to any deviations from the recommended PSI, allowing for immediate corrective actions. Additionally, establishing a routine maintenance schedule that includes regular checks and calibrations of the TPMS can help ensure accuracy. Training personnel on the importance of tire pressure management and the potential risks associated with neglecting this aspect will further enhance safety and operational efficiency.

المشكلة B2B buyers often struggle with knowing the correct tire pressure specifications for different types of trailers. This lack of knowledge can lead to inflated or deflated tires, resulting in dangerous blowouts, increased wear, and reduced fuel efficiency. For companies that transport high-value goods or operate in regions with varying road conditions, this ignorance can translate into costly disruptions and safety hazards.

Illustrative image related to trailer tire inflation pressure

الحل: To combat this knowledge gap, companies should create a comprehensive tire pressure guideline document for all their trailer types. This document should include the manufacturer-recommended PSI for each trailer, taking into account the load capacity and environmental conditions. Buyers can also benefit from engaging with tire suppliers to ensure they have access to the latest information and best practices. Furthermore, implementing training sessions for drivers and maintenance teams about the importance of adhering to these specifications can significantly reduce the risk of tire-related incidents.

المشكلة A prevalent issue among B2B buyers is the misconception that tire pressure should always be adjusted to the maximum PSI indicated on the tire sidewall. This misunderstanding can lead to overinflation, which is particularly dangerous when towing heavy loads. Overinflated tires can wear unevenly, decrease traction, and increase the likelihood of blowouts—especially in changing road conditions or temperatures.

الحل: To rectify this misconception, companies should educate their teams on the importance of adhering to the recommended PSI for different load conditions rather than simply inflating to the maximum. A practical approach would involve developing a tire pressure adjustment protocol based on real-time load assessments and environmental conditions. This can include using load gauges and temperature monitoring tools that help drivers make informed decisions about tire pressure before and during transportation. By fostering a culture of informed tire management, businesses can enhance safety, improve fuel efficiency, and prolong the lifespan of their tires.

Illustrative image related to trailer tire inflation pressure

When selecting materials for trailer tire inflation pressure systems, it’s essential to consider several factors, including performance characteristics, cost, and regional compliance standards. Here, we analyze four common materials used in this application: rubber, steel, aluminum, and composite materials.

Rubber is the most widely used material for tire construction due to its excellent elasticity and ability to withstand varying pressures. It offers a high temperature and pressure rating, making it suitable for maintaining tire inflation under different load conditions. Rubber is also resistant to corrosion and degradation from environmental factors, contributing to its durability.

الإيجابيات: Rubber tires provide superior grip and shock absorption, enhancing vehicle handling and comfort. They are relatively low-cost and easy to manufacture, making them a popular choice for trailer manufacturers.

السلبيات: While rubber is durable, it can be susceptible to wear and tear over time, especially in extreme temperatures. Additionally, rubber tires may require more frequent maintenance checks to ensure proper inflation levels.

For international buyers, particularly in regions like Africa and South America, it’s crucial to consider local climate conditions, as extreme heat can accelerate rubber degradation. Compliance with ASTM standards is often necessary for quality assurance.

Illustrative image related to trailer tire inflation pressure

Steel is commonly used in the construction of tire rims and valves, providing strength and structural integrity. It has a high pressure rating, making it suitable for heavy-duty applications. Steel is also resistant to deformation under load, ensuring that the tire maintains its shape.

الإيجابيات: Steel components are highly durable and can withstand significant impacts, making them ideal for rugged use. They are also relatively inexpensive compared to other materials.

السلبيات: Steel is prone to rust and corrosion, particularly in humid or coastal environments, which can compromise the integrity of the tire inflation system. Additionally, the manufacturing process can be complex, requiring additional treatments for corrosion resistance.

Illustrative image related to trailer tire inflation pressure

For buyers in the Middle East and Europe, adherence to DIN standards is essential for ensuring the quality and safety of steel components. Buyers should also consider the local availability of corrosion-resistant coatings to enhance longevity.

Aluminum is increasingly popular for tire rims and inflation valves due to its lightweight nature and corrosion resistance. It has a good pressure rating and can withstand temperature fluctuations, making it suitable for various climates.

الإيجابيات: Aluminum components reduce overall trailer weight, improving fuel efficiency during towing. They also have a longer lifespan than steel due to their resistance to corrosion.

السلبيات: Aluminum can be more expensive than steel, and its manufacturing process may involve more complexity, particularly in achieving the desired strength-to-weight ratio.

International buyers should be aware of JIS standards for aluminum components, especially in regions like Japan and Southeast Asia, to ensure compatibility and performance.

Illustrative image related to trailer tire inflation pressure

Composite materials, which combine various substances to achieve desirable properties, are becoming more common in tire inflation systems. They offer high strength-to-weight ratios and excellent resistance to environmental factors.

الإيجابيات: Composites are lightweight and can be engineered for specific performance characteristics, such as enhanced flexibility or rigidity. They are also resistant to corrosion and UV degradation.

السلبيات: The primary drawback is the higher cost associated with composite materials, as well as the complexity in manufacturing processes. Additionally, they may not be as widely available as traditional materials.

For international buyers, understanding the specific composite material standards in their region is crucial. Compliance with international quality standards can ensure that the materials used will perform optimally in diverse environments.

| المواد | Typical Use Case for trailer tire inflation pressure | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| المطاط | Tire construction | Excellent grip and shock absorption | Susceptible to wear in extreme heat | منخفضة |

| الفولاذ | Tire rims and valves | Highly durable | Prone to rust and corrosion | ميد |

| ألومنيوم | Lightweight rims and valves | Reduces trailer weight | Higher cost than steel | عالية |

| مركب | Specialized tire components | Customizable performance | تعقيد التصنيع العالي | عالية |

This strategic material selection guide provides essential insights for B2B buyers, enabling informed decisions that align with regional standards and specific application needs.

The manufacturing process of trailer tires involves several critical stages that ensure the end product meets the required performance and safety standards. Understanding these stages is vital for B2B buyers, particularly those looking to source tires that will reliably perform under various conditions.

The first stage in tire manufacturing begins with the careful selection of raw materials. The primary components include rubber compounds, steel belts, fabric plies, and various chemical additives.

Quality in this stage is paramount, as the materials dictate the tire’s performance characteristics, such as load capacity, durability, and resistance to wear.

Once the materials are prepared, the forming stage involves shaping the rubber compounds into the tire’s desired profile.

The assembly process is closely monitored to ensure that all components are correctly positioned and adhered, as any misalignment can compromise tire performance.

In the finishing stage, the tires undergo several processes to ensure they are ready for the market.

This stage is critical for ensuring that the tires meet both aesthetic and functional standards before they are packaged and shipped.

Quality assurance (QA) in tire manufacturing is vital for ensuring that the products meet international safety and performance standards. B2B buyers must be familiar with the relevant standards and checkpoints to verify the quality of the tires they are sourcing.

Several international standards govern the manufacturing of trailer tires, including:

Familiarity with these standards helps buyers ensure they are sourcing products that comply with necessary regulations.

Illustrative image related to trailer tire inflation pressure

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to catch any defects early. Key checkpoints include:

These checkpoints are essential for minimizing defects and ensuring the tires’ reliability and safety.

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is crucial to ensure product quality.

By employing these methods, B2B buyers can mitigate risks associated with sourcing inferior products and ensure they are investing in high-quality trailer tires.

International buyers should also be aware of specific nuances in QC that may affect their sourcing decisions:

By considering these factors, B2B buyers can make informed decisions when sourcing trailer tires, ensuring they receive products that meet their performance and safety needs.

In conclusion, understanding the manufacturing processes and quality assurance measures in trailer tire production is critical for B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control, buyers can ensure they are investing in high-quality, reliable tires that will perform safely under various conditions.

The following guide provides a practical checklist for B2B buyers focused on procuring the right trailer tire inflation pressure solutions. Ensuring optimal tire pressure is critical for safety, performance, and cost-efficiency in transportation.

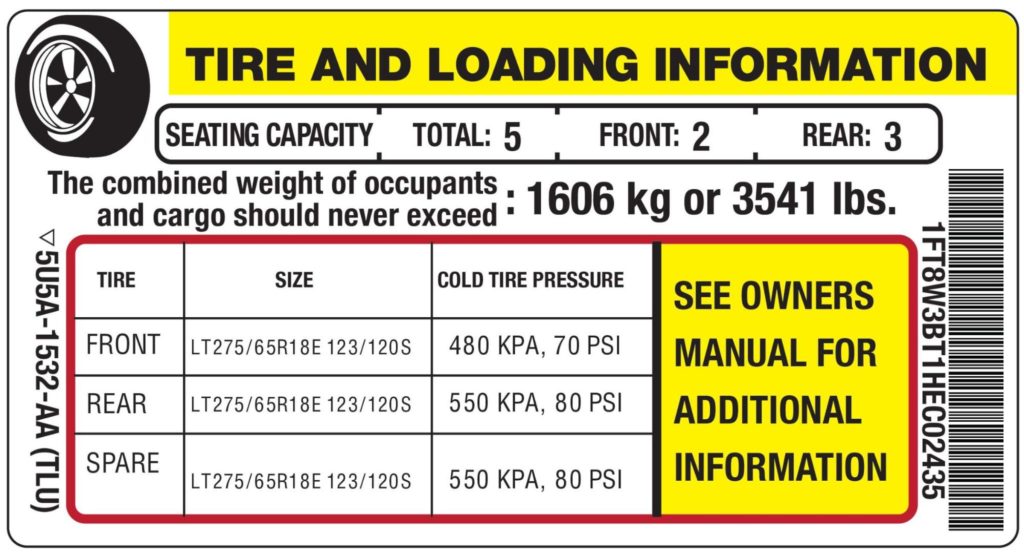

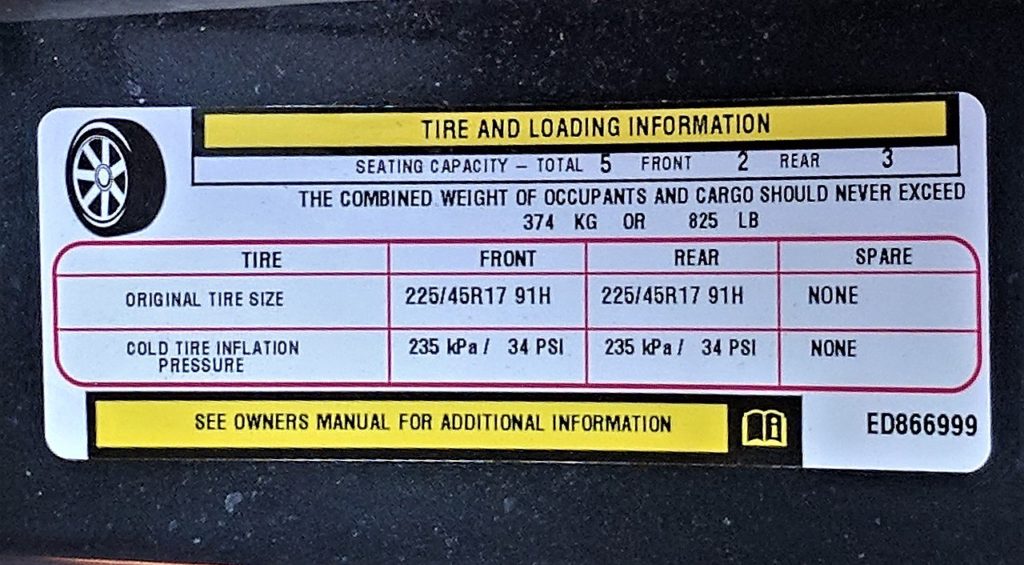

Understanding the specific requirements for your trailer tires is essential. Determine the type of trailer you are using (e.g., utility, travel, boat) as each has different inflation pressure needs. Knowing the load capacity and the maximum pressure indicated on the tire sidewall will help you set clear expectations for suppliers.

Before sourcing, familiarize yourself with relevant safety and performance standards for tire inflation. Various regions may have specific regulations regarding tire pressure and safety standards. This knowledge will ensure compliance and enhance safety during operations, especially in international markets.

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from other clients, particularly those in similar industries or geographic areas. Assess their experience with the type of tire and inflation systems you need, as well as their ability to provide ongoing support.

Ensure that the suppliers you are considering hold necessary certifications relevant to tire safety and performance. Look for certifications from recognized bodies that indicate adherence to quality and safety standards. This verification can prevent issues related to substandard products and ensure reliability.

Technical support is crucial for maintaining optimal tire pressure over time. Confirm that your supplier offers responsive customer service, including troubleshooting and maintenance advice. Having access to a knowledgeable support team can significantly reduce downtime and enhance safety.

Before finalizing your order, ask for samples or the opportunity to test the tire inflation systems. Testing allows you to evaluate performance under real conditions, ensuring that the products meet your specifications. This step is vital to avoid costly mistakes and ensure that the products perform as expected.

Once you have selected a supplier, ensure that all terms and conditions are clearly outlined in a contract. This includes pricing, delivery schedules, warranty conditions, and return policies. Clear agreements will protect your interests and ensure smooth transactions throughout the procurement process.

Illustrative image related to trailer tire inflation pressure

By following this step-by-step checklist, B2B buyers can confidently procure the right trailer tire inflation pressure solutions, ensuring safety, performance, and efficiency in their operations.

When sourcing trailer tire inflation pressure solutions, several cost components play a crucial role in the overall pricing structure. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

المواد: The primary material involved is the rubber used in tire manufacturing, which can fluctuate based on global oil prices. Other materials include steel belts and fabrics that enhance durability. Opting for high-quality materials can increase initial costs but often results in longer tire life and reduced total cost of ownership (TCO).

العمالة: Labor costs vary significantly by region. In countries with higher labor costs, such as those in Europe, the manufacturing expenses can be more substantial compared to regions in Africa or South America where labor may be less expensive.

نفقات التصنيع الزائدة: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs.

الأدوات: The initial investment in molds and machinery specific to tire production can be significant. Custom tooling for specialized tire types may further increase costs but can lead to better product differentiation.

مراقبة الجودة (QC): Ensuring that products meet safety and performance standards incurs additional costs. Investments in QC processes can prevent costly recalls and enhance brand reputation.

الخدمات اللوجستية: Transportation costs can vary widely depending on the distance from the manufacturer to the buyer, as well as the chosen shipping method. Efficient logistics can help mitigate these costs.

الهامش: Suppliers typically apply a margin to cover their costs and profit. Understanding the balance between quality and price is critical for buyers.

Several factors influence the pricing of trailer tire inflation pressure solutions, which are essential for international B2B buyers to consider:

الحجم/معدل العرض/الطلب: Bulk purchasing can significantly reduce unit costs. Suppliers often provide discounts for larger orders, making it crucial for buyers to assess their needs and negotiate minimum order quantities (MOQs).

المواصفات والتخصيص: Tires can be tailored to specific requirements, which may increase costs. Buyers should carefully evaluate whether customization is necessary for their operations.

جودة المواد والشهادات: Higher-quality materials and certifications (such as ISO or local standards) may lead to increased costs but enhance safety and performance, which can justify the higher price.

عوامل الموردين: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may charge a premium but offer better service and quality assurance.

المصطلحات التجارية الدولية: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers, affecting shipping costs and risk. Buyers should negotiate terms that minimize their exposure to unexpected costs.

For international buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings and improved terms:

Illustrative image related to trailer tire inflation pressure

أسعار سوق الأبحاث: Having a clear understanding of market rates and competitor offerings can provide leverage during negotiations.

بناء علاقات طويلة الأمد: Establishing a strong rapport with suppliers can lead to better pricing, more favorable terms, and reliability.

التركيز على التكلفة الإجمالية للملكية (TCO): While negotiating, emphasize the importance of TCO, which considers not just the purchase price but also maintenance, longevity, and performance. Highlighting these factors can justify a higher upfront cost.

Be Flexible on Specifications: If possible, be open to alternative specifications that may lower costs without compromising essential safety and performance requirements.

Leverage Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce financial risk.

Understanding the intricacies of cost components and price influencers in sourcing trailer tire inflation pressure solutions is vital for international B2B buyers. By leveraging negotiation strategies and being aware of total cost considerations, buyers can make informed decisions that align with their operational needs while optimizing their budgets.

إخلاء المسؤولية: The prices discussed are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek personalized quotes from suppliers to obtain accurate pricing.

When it comes to ensuring the safety and performance of trailers, maintaining the correct tire inflation pressure is crucial. However, there are alternative solutions that can complement or even replace the traditional focus on tire inflation. In this analysis, we will compare the conventional method of managing trailer tire pressure against two viable alternatives: tire monitoring systems and automatic tire inflation systems.

| جانب المقارنة | Trailer Tire Inflation Pressure | Tire Monitoring Systems | Automatic Tire Inflation Systems |

|---|---|---|---|

| الأداء | Essential for safety and handling; directly affects fuel efficiency and tire longevity. | Provides real-time data on tire pressure, enhancing safety and efficiency. | Automatically adjusts tire pressure, ensuring optimal inflation at all times. |

| التكلفة | Low initial costs for gauges and manual checks, but ongoing maintenance required. | Moderate cost for systems; savings on tire replacements and fuel efficiency may offset initial investment. | Higher initial investment, but can lead to significant long-term savings through reduced tire wear and improved fuel economy. |

| سهولة التنفيذ | Simple to implement with basic tools; requires regular manual checks. | Requires installation and some training for effective use; data can be accessed via apps. | More complex installation; may require professional assistance, but operates automatically after setup. |

| الصيانة | Requires regular manual checks and monitoring; dependent on user diligence. | Minimal maintenance after installation; requires periodic battery changes and software updates. | Low maintenance once installed; system self-regulates pressure levels. |

| أفضل حالة استخدام | Ideal for budget-conscious operations with low maintenance capabilities. | Best for fleets that prioritize safety and real-time data analytics. | Suitable for high-volume operations where tire performance is critical and downtime must be minimized. |

Tire Monitoring Systems

Tire monitoring systems provide real-time data on tire pressure and temperature, alerting users to any deviations from optimal levels. The primary advantage is enhanced safety, as these systems can prevent blowouts and improve fuel efficiency by ensuring tires are always within the recommended pressure range. However, the initial cost of these systems can be a barrier, especially for smaller businesses. Additionally, they require some level of user training to interpret the data effectively.

Automatic Tire Inflation Systems

Automatic tire inflation systems offer a more advanced solution by maintaining optimal tire pressure without manual intervention. These systems continuously monitor and adjust tire pressure, which minimizes the risk of under- or over-inflation. The main advantage is the significant reduction in tire wear and fuel consumption, leading to cost savings over time. However, the installation can be complex and expensive, making it less accessible for smaller operations. Furthermore, if the system fails, it can lead to serious safety issues if not promptly addressed.

For B2B buyers, the choice between maintaining trailer tire inflation pressure manually or investing in alternative technologies depends largely on operational needs and budget constraints. For companies with limited resources or those operating on a tight budget, regular monitoring of tire pressure may suffice. However, for larger fleets or businesses that prioritize safety and efficiency, investing in tire monitoring or automatic inflation systems could provide significant long-term benefits. Evaluating the specific demands of your operations will help determine the most suitable solution for ensuring trailer safety and performance.

Understanding the technical properties of trailer tire inflation pressure is essential for B2B buyers in the transportation and logistics sectors. Proper tire inflation not only enhances safety but also optimizes performance and longevity. Here are critical specifications to consider:

Pounds per Square Inch (PSI)

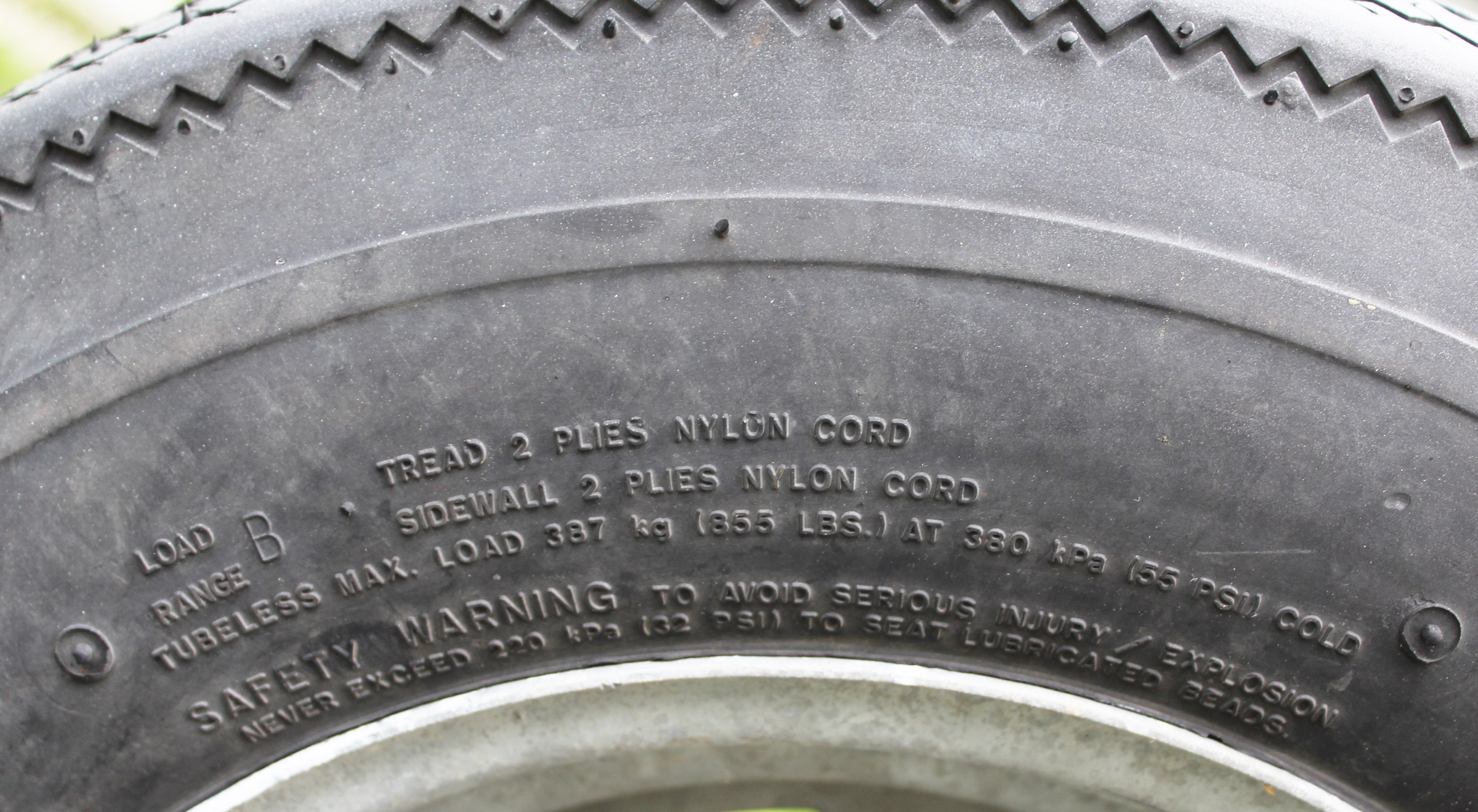

PSI measures the air pressure within the tire, indicating how much weight the tire can safely carry. Most trailer tires recommend a PSI range between 30 and 80, depending on the type and load of the trailer. Maintaining the correct PSI is vital, as underinflated tires can lead to blowouts, while overinflated tires can cause uneven wear and reduced traction.

Load Range

The load range signifies the maximum weight a tire can support at its recommended PSI. This is often categorized by letters (e.g., C, D, E) that correspond to specific weight capacities. For example, a Load Range C tire can handle up to 1,820 pounds. Understanding load range helps businesses select the right tires for their trailers, ensuring safety and compliance with transport regulations.

Tread Depth

Tread depth is a critical factor in tire performance, affecting traction and safety. A minimum tread depth of 2/32 of an inch is typically recommended for safe operation. Businesses should monitor tread wear closely, as insufficient tread depth can lead to reduced grip, especially in wet conditions, increasing the risk of accidents.

التركيب المادي

Trailer tires are usually made from a combination of rubber compounds and fabric layers. The material grade affects durability, heat resistance, and overall performance. Higher-grade materials may offer better resistance to punctures and longer life, making them a worthwhile investment for companies that rely on trailers for transportation.

Temperature Resistance

Tire performance can be affected by temperature fluctuations, which impact air pressure. Proper temperature resistance ensures that tires maintain their integrity under various conditions, helping to prevent blowouts and other failures. B2B buyers should consider tires rated for their operating environments, especially in regions with extreme temperatures.

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are several key terms related to trailer tire inflation pressure:

Illustrative image related to trailer tire inflation pressure

OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of trailer tires, OEM specifications are critical for ensuring compatibility and performance standards.

موك (الحد الأدنى لكمية الطلب)

MOQ defines the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and ensure they meet supplier requirements without overcommitting.

طلب عرض الأسعار (RFQ)

An RFQ is a document sent to suppliers asking for a quote for specific products or services. In the context of trailer tires, an RFQ can help buyers obtain competitive pricing and terms from multiple suppliers, allowing for informed decision-making.

المصطلحات التجارية الدولية

International Commercial Terms (Incoterms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowledge of Incoterms is essential for B2B buyers to understand shipping costs, risk management, and delivery obligations related to trailer tires.

Tread Wear Indicators

These are built-in markers on the tire that indicate when the tread has worn down to an unsafe level. Understanding tread wear indicators helps businesses assess tire health and make timely replacements, reducing the risk of accidents and ensuring compliance with safety regulations.

Cold Inflation Pressure

This term refers to the tire pressure measured when the tires are cold, typically before driving. Maintaining the correct cold inflation pressure is vital for accurate readings and optimal tire performance, as heat generated during driving can increase pressure and skew results.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions about trailer tire inflation pressure, enhancing safety, efficiency, and overall operational effectiveness.

The trailer tire inflation pressure sector is witnessing significant transformation driven by several global trends. A primary driver is the increasing emphasis on safety standards, which mandates that B2B buyers prioritize proper tire maintenance to mitigate risks associated with blowouts and accidents. Additionally, the rise of e-commerce and logistics in regions such as Africa, South America, and the Middle East has propelled demand for reliable trailer systems, including tires that can withstand varying loads and conditions.

Emerging technologies are also reshaping sourcing strategies. Smart tire monitoring systems, which provide real-time data on tire pressure and temperature, are gaining traction among B2B buyers. This technology not only enhances safety but also optimizes fuel efficiency, offering a dual benefit that is particularly appealing in cost-sensitive markets like Brazil and Vietnam. Furthermore, the adoption of predictive maintenance tools is becoming prevalent, allowing businesses to preemptively address tire issues before they escalate.

As buyers navigate these dynamics, understanding local regulations and market conditions is crucial. For instance, in Europe, stricter environmental regulations are influencing tire design and performance criteria, pushing manufacturers to innovate continuously. The interplay of these factors is creating a dynamic marketplace that international buyers must navigate with strategic foresight.

Sustainability is becoming a non-negotiable aspect of sourcing in the trailer tire inflation pressure sector. The environmental impact of tire production and disposal is under scrutiny, prompting buyers to seek out suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials and the implementation of energy-efficient manufacturing processes.

Ethical sourcing has emerged as a critical consideration, with buyers increasingly favoring suppliers that can demonstrate responsible supply chain practices. Certifications such as ISO 14001 for environmental management systems and the use of recycled materials are becoming vital for suppliers seeking to attract international buyers. Moreover, sustainable practices not only mitigate environmental impact but can also reduce costs over time, as they often lead to improved operational efficiencies.

As the global market shifts towards sustainability, B2B buyers should actively engage with suppliers who are committed to green initiatives. This not only enhances their corporate social responsibility profile but also aligns with the growing consumer demand for environmentally conscious products.

The evolution of trailer tire technology has been marked by significant advancements that have shaped the current market landscape. Historically, trailer tires were primarily designed for durability and load-bearing capacity, focusing on basic materials and construction techniques. However, as transportation needs evolved, so did the technology behind tire inflation and maintenance.

Illustrative image related to trailer tire inflation pressure

In the late 20th century, innovations such as radial tires introduced improved performance and fuel efficiency, while advancements in material science led to the development of more resilient rubber compounds. The introduction of smart tire technology in the 21st century marked a pivotal shift, allowing for real-time monitoring and data analytics that have revolutionized how businesses manage tire maintenance and safety.

This historical perspective underscores the importance of continuous innovation in the trailer tire inflation pressure sector, as manufacturers strive to meet the demands of modern logistics and transportation while ensuring safety and sustainability. As B2B buyers consider their sourcing options, understanding this evolution can provide valuable insights into selecting the right products that align with their operational needs.

1. How do I solve tire pressure issues with my trailer?

To address tire pressure issues, regularly check the PSI using a reliable gauge, especially before long hauls. Ensure the tires are cold when measuring for accurate readings. If your tires are underinflated, inflate them to the maximum PSI indicated on the sidewall. Conversely, if they are overinflated, release air until the recommended PSI is reached. Regular inspections will help you catch potential problems early, such as leaks or wear, ensuring safe and efficient towing.

Illustrative image related to trailer tire inflation pressure

2. What is the best tire pressure for different types of trailers?

The best tire pressure varies by trailer type. For utility trailers, a PSI between 50-60 is ideal, while travel trailers typically require 65-80 PSI. Boat trailers generally need 30-50 PSI for better traction, and fifth-wheel trailers should maintain 80-110 PSI due to their weight distribution. Always refer to the tire’s sidewall or the trailer’s manual for specific recommendations to ensure optimal performance and safety.

3. How do I verify the quality of trailer tires from suppliers?

To verify tire quality, request certification documents from suppliers, such as ISO or DOT certifications. Conduct thorough research on the supplier’s reputation, checking for reviews and testimonials from previous clients. Additionally, ask for sample tires to assess their quality firsthand. It’s also prudent to inquire about warranties and return policies, which can indicate the supplier’s confidence in their product quality.

4. What are the minimum order quantities (MOQs) for trailer tires?

Minimum order quantities (MOQs) for trailer tires vary by supplier and the specific tire type. Typically, MOQs can range from 50 to several hundred units. When negotiating, consider your storage capacity and demand forecasts to ensure you can manage the order efficiently. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s worth discussing your needs directly with them.

5. What payment terms should I expect when sourcing trailer tires?

Payment terms for trailer tires can vary widely. Common practices include upfront payment, a deposit followed by the balance upon delivery, or net terms (e.g., net 30 or net 60). Establishing clear payment terms in your contract is crucial to avoid misunderstandings. Additionally, consider using secure payment methods and escrow services to protect your investment, especially when dealing with international suppliers.

6. How can I ensure timely logistics and delivery of trailer tires?

To ensure timely logistics and delivery, coordinate closely with your supplier on shipping methods and schedules. Discuss lead times upfront and establish clear timelines for production and shipping. Utilize freight forwarders familiar with international shipping regulations to streamline the process. Additionally, consider tracking systems to monitor your shipment’s progress and address any potential delays proactively.

7. What are the implications of incorrect tire pressure on my trailer’s performance?

Incorrect tire pressure can severely impact your trailer’s performance and safety. Underinflated tires increase rolling resistance, leading to higher fuel consumption and a greater risk of blowouts. They also cause uneven tire wear, shortening tire lifespan. Conversely, overinflated tires can result in a harsh ride and reduced traction, especially in adverse conditions. Maintaining the correct tire pressure is essential for optimal towing performance and safety.

8. How do temperature changes affect trailer tire pressure?

Temperature changes can significantly affect tire pressure. Typically, for every 10-degree Fahrenheit change in temperature, tire pressure can fluctuate by about 1 PSI. It’s essential to check your tire pressure regularly, especially when temperatures vary, such as during seasonal changes. Be proactive in adjusting the pressure according to the current temperature to maintain optimal performance and safety while towing.

المجال: reddit.com

مسجل: 2005 (20 سنة)

مقدمة: Trailer tires rated to 110 PSI; recommended to fill to the cold PSI rating stamped on the tire; underinflation (e.g., 80 PSI in a 110 PSI rated tire) can cause excessive heat buildup and lead to blowouts; sidewalls on trailer tires are designed for load bearing; normal for tire pressure to increase to 120-130 PSI during towing.

المجال: etrailer.com

مسجل: 1999 (26 سنة)

مقدمة: The text discusses a question about the installation of a trailer hitch on a 2015 Honda CR-V. It mentions the need for a specific wiring harness and provides details about the weight capacity and compatibility of the hitch with various accessories.

المجال: facebook.com

مسجل: 1997 (28 سنة)

مقدمة: This company, Facebook – Tire Pressure Guidelines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

المجال: trailerplus.eu

مقدمة: The correct air pressure for trailer tires is crucial for safety and performance. The recommended air pressures for various tire sizes are as follows:

– 3.50×8: 2.5 bar

– 4.00×8: 5.0 bar

– 16.5×8: 4.8 bar

– 5.00×8: 4.0 bar

– 18.5×8.50-8: 3.4 bar

– 4.00 x 10 4pr: 3.0 bar

– 4.00 x 10 6pr: 3.5 bar

– 4.50×10: 4.25 bar

– 5.00×10: 3.5-4.0 bar

– 145×10: 3.5 bar

– 18×8-10: 6 bar

– 20.5×8-10: 6…

المجال: teamtalk.mastercraft.com

مسجل: 1997 (28 سنة)

مقدمة: Goodyear Endurance 225/75/15, Load Range E, Max PSI rating of 80.

In conclusion, maintaining optimal trailer tire inflation pressure is crucial for ensuring safety, enhancing performance, and extending tire lifespan. For international B2B buyers, understanding the specific PSI requirements for various trailer types is essential for efficient operations, particularly in diverse markets like Africa, South America, the Middle East, and Europe. Strategic sourcing of high-quality tires and reliable monitoring systems can significantly mitigate risks associated with underinflation or overinflation, ultimately leading to cost savings and improved operational efficiency.

As the demand for safe and efficient transportation solutions continues to rise, investing in the right tire management practices will position your business favorably in the competitive landscape. By prioritizing tire maintenance and sourcing strategies, you can enhance your fleet’s reliability and safety, fostering trust with your clients and partners.

Illustrative image related to trailer tire inflation pressure

We encourage you to take proactive steps in evaluating your trailer tire needs and explore partnerships with reputable suppliers that can offer the necessary expertise and products. Together, let’s pave the way for safer roads and more efficient logistics in your region.

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.