In the competitive landscape of the automotive industry, sourcing reliable auto air compressors poses a significant challenge for international B2B buyers. With an array of options available, from portable inflators to heavy-duty compressors, understanding the nuances of each type is crucial for making informed decisions. This guide offers a comprehensive overview of auto air compressors, covering various types, their applications across different markets, and insights on supplier vetting processes.

Buyers from regions such as Africa, South America, the Middle East, and Europe will find tailored insights that address their specific needs and challenges. The guide delves into cost considerations, performance metrics, and key features that distinguish quality compressors, enabling businesses to optimize their procurement strategies. By empowering decision-makers with actionable information, this resource aims to streamline the purchasing process, ensuring that buyers can confidently invest in equipment that enhances operational efficiency and meets regulatory standards.

Navigating the global market for auto air compressors can be daunting, but with the right knowledge and tools at hand, B2B buyers can make choices that not only meet their immediate needs but also contribute to long-term success in their respective industries. Whether you are expanding your fleet or upgrading your workshop equipment, this guide is designed to illuminate the path toward optimal air compressor solutions.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Air Compressors | Compact, lightweight, often battery-operated | Automotive repair, roadside assistance | Pros: Easy to transport, versatile. Cons: Limited power and capacity compared to larger models. |

| Stationary Air Compressors | Fixed installations, higher capacity and power | Workshops, manufacturing, heavy-duty applications | Pros: High efficiency and durability. Cons: Requires dedicated space and power supply. |

| Electric Tire Inflators | Designed specifically for inflating tires, usually compact | Automotive service stations, personal vehicles | Pros: Fast inflation, easy to use. Cons: Limited to tire inflation, not suitable for other applications. |

| Gas-Powered Air Compressors | Operates on gasoline, high mobility and power | Construction sites, remote locations | Pros: No need for electrical outlets, high power. Cons: Noise and emissions; requires more maintenance. |

| Oil-Free Air Compressors | Uses a special design to eliminate oil in the air | Food processing, medical applications | Pros: Cleaner air output, less maintenance. Cons: May not be as durable as oil-lubricated models. |

Portable air compressors are designed for mobility, making them ideal for on-the-go applications such as automotive repair and roadside assistance. These units are typically lightweight and can be powered by batteries or vehicle outlets, allowing for convenient use in various locations. When considering a purchase, B2B buyers should assess the compressor’s PSI ratings, battery life, and versatility to ensure it meets their specific operational needs.

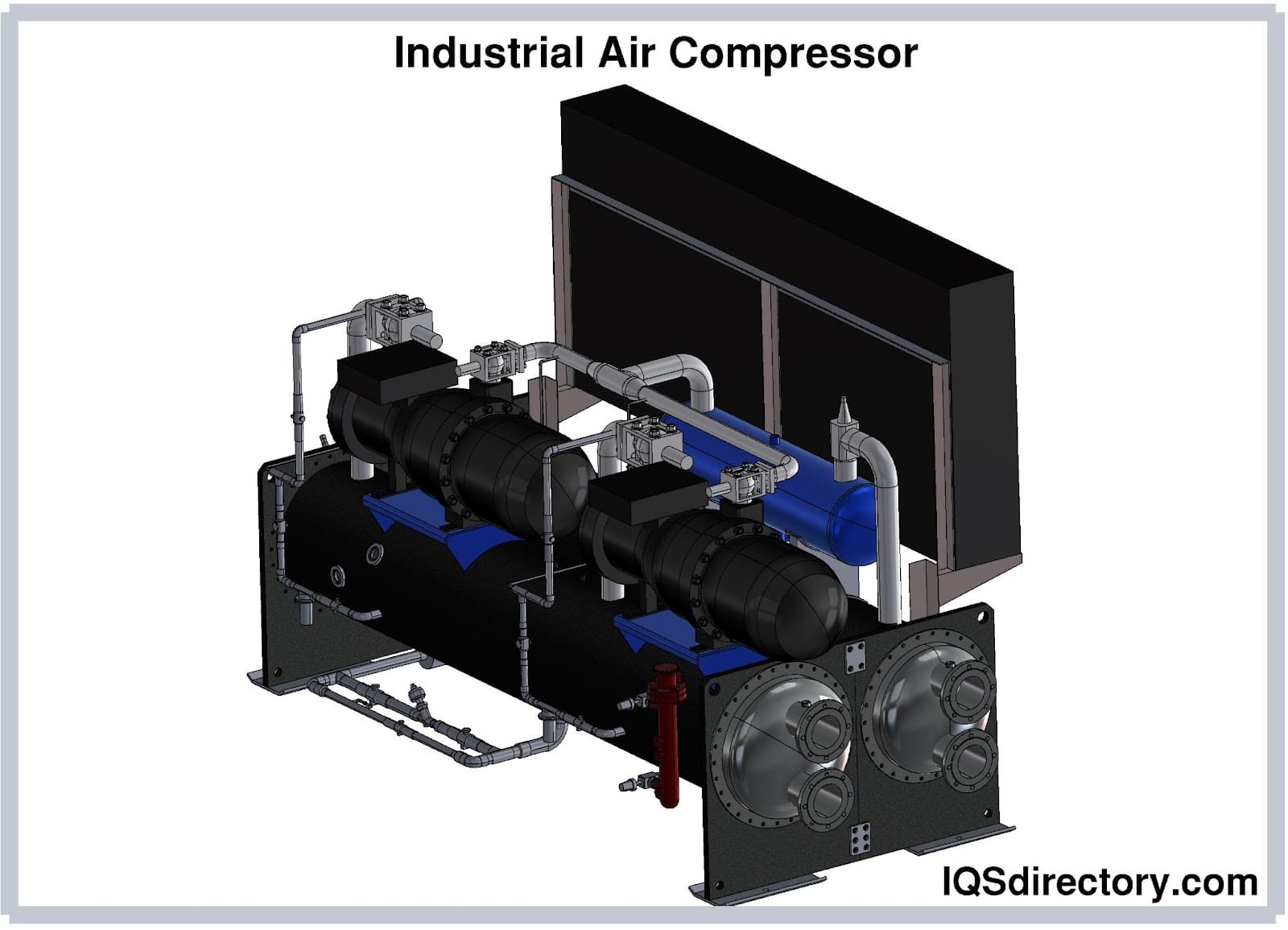

Stationary air compressors are robust machines designed for fixed installations in workshops or manufacturing settings. They provide high capacity and power, making them suitable for heavy-duty applications such as assembly lines and pneumatic tools. Buyers should evaluate the compressor’s CFM (cubic feet per minute) output and duty cycle to ensure it can handle the demands of their specific operations without downtime.

Electric tire inflators are specialized tools primarily used for inflating tires quickly and efficiently. These compact devices are essential for automotive service stations and personal vehicles, providing rapid inflation capabilities. When purchasing, B2B buyers should consider the inflator’s maximum PSI, ease of use, and additional features like built-in pressure gauges and portability to enhance their service offerings.

Gas-powered air compressors are ideal for construction sites or remote locations where electrical access is limited. These compressors deliver high power and mobility, making them suitable for demanding tasks. However, buyers should be aware of the trade-offs, including increased noise levels, emissions, and maintenance requirements. Understanding the operational environment and power needs is crucial when selecting this type of compressor.

Oil-free air compressors are designed to produce clean air, making them suitable for industries like food processing and healthcare. These compressors eliminate the risk of oil contamination, which is critical in sensitive applications. B2B buyers should consider the compressor’s performance specifications and maintenance needs, as oil-free models may have different durability characteristics compared to traditional oil-lubricated compressors.

| Industry/Sector | Specific Application of auto air compressors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance | Ensures vehicle safety and optimal performance | Reliability, PSI capacity, portability, and durability |

| Manufacturing | Pneumatic tools operation | Increases efficiency and productivity in production | Energy consumption, compatibility with existing equipment |

| Construction | Powering air tools for construction projects | Enhances work speed and reduces manual labor | Noise levels, mobility, tank size, and maintenance requirements |

| Agriculture | Inflating agricultural equipment | Supports operational efficiency in farming operations | Pressure requirements, ruggedness for outdoor use, and service support |

| Transportation & Logistics | Maintenance of commercial vehicle tires | Reduces downtime and extends tire life | Size, power source options, and ease of use |

In the automotive repair industry, auto air compressors are essential for tire inflation and maintenance. They ensure that vehicles operate safely and efficiently by maintaining optimal tire pressure, which can improve fuel efficiency and handling. For international buyers, especially in regions like Africa and South America, it’s crucial to select compressors with high PSI capacities and portability, as these features can facilitate quick service in remote locations. Reliability is also vital to minimize downtime in workshops.

In manufacturing, auto air compressors are integral to operating pneumatic tools, which are widely used for assembly lines, painting, and other production processes. By providing consistent and powerful airflow, these compressors boost efficiency and productivity. Buyers should consider energy consumption and compatibility with existing machinery when sourcing compressors, particularly in Europe, where energy efficiency regulations may be stringent. Additionally, understanding the maintenance requirements can help businesses avoid unexpected operational disruptions.

In the construction sector, auto air compressors power pneumatic tools, such as nail guns and drills, which significantly enhance work speed and reduce manual labor. This efficiency is crucial in meeting tight deadlines and maintaining project budgets. When sourcing compressors for construction, businesses should evaluate noise levels, mobility, and tank size to ensure they meet site-specific requirements. Furthermore, durability is essential, as construction sites often present challenging conditions.

For agricultural operations, auto air compressors are used to inflate various equipment, such as tractor tires and irrigation systems. Maintaining proper tire pressure is vital for ensuring equipment efficiency and reducing wear and tear. Buyers in this sector should prioritize ruggedness and pressure requirements when sourcing compressors, as agricultural environments can be demanding. Additionally, having accessible service support can be beneficial in regions where agricultural machinery is frequently used.

In the transportation and logistics industry, auto air compressors are crucial for maintaining the tires of commercial vehicles. Proper tire maintenance reduces downtime and extends the life of tires, which can lead to significant cost savings. When sourcing compressors, businesses should focus on size and power source options to ensure they can efficiently service their fleet. Ease of use is also a consideration, as quick and effective tire maintenance can enhance overall operational efficiency.

The Problem: B2B buyers managing fleets often face the challenge of maintaining consistent tire pressure across multiple vehicles. Tire pressure can fluctuate due to environmental conditions and usage, leading to increased fuel consumption and wear on tires. Inconsistent tire pressure not only affects the safety and performance of vehicles but can also result in significant operational costs for businesses that rely on their fleet for timely deliveries and service.

Illustrative image related to auto air compressors

The Solution: To tackle this issue, fleet managers should invest in high-quality auto air compressors equipped with digital pressure gauges and automatic shut-off features. These compressors can ensure accurate inflation to the manufacturer-recommended pressure levels, preventing over-inflation or under-inflation. When sourcing compressors, consider models with built-in monitoring systems that provide real-time pressure readings and alerts. Implement a regular maintenance schedule where each vehicle is checked and inflated as needed, ideally before long trips or at the start of each workday. This proactive approach not only enhances safety but also contributes to fuel efficiency and prolongs tire life, ultimately leading to cost savings for the business.

The Problem: In the automotive and transportation sectors, downtime caused by equipment failure can be detrimental. B2B buyers may experience issues when their auto air compressors malfunction, leading to delays in tire inflation and maintenance services. This can be particularly costly for businesses that rely on quick turnaround times for vehicle readiness, especially in regions where road conditions are less predictable, such as parts of Africa or South America.

The Solution: To minimize downtime, buyers should select auto air compressors known for their durability and reliability. It’s crucial to invest in models with robust warranties and comprehensive after-sales support. Additionally, implementing a scheduled maintenance program can help identify potential issues before they lead to equipment failure. Buyers should also train their staff on the proper use and care of compressors, ensuring they are familiar with routine checks and maintenance tasks. By fostering a culture of equipment care and investing in reliable technology, businesses can reduce the risk of unexpected failures and enhance overall operational efficiency.

The Problem: Many B2B buyers in the automotive repair industry face challenges related to the portability of auto air compressors. When performing on-site repairs, having a heavy or cumbersome compressor can limit mobility, making it difficult to service vehicles in various locations. This can be especially problematic for businesses that operate in remote areas or regions with limited access to repair facilities.

Illustrative image related to auto air compressors

The Solution: Buyers should prioritize lightweight, compact auto air compressors designed for portability without sacrificing performance. Look for models that include features like cordless operation or rechargeable batteries, enabling technicians to easily transport them to different job sites. Additionally, consider compressors with multiple power options, such as those that can be plugged into a vehicle’s 12V outlet or run on batteries, providing flexibility in various environments. Investing in a robust carrying case can also enhance mobility and protect the unit during transport. By choosing the right compressor, businesses can ensure that their technicians are equipped to perform efficient, high-quality repairs, regardless of location.

When selecting materials for auto air compressors, it is crucial to consider their properties, advantages, and limitations to ensure optimal performance and longevity. Below, we analyze four common materials used in the construction of auto air compressors: aluminum, steel, plastic, and cast iron.

Aluminum is often favored for its lightweight properties and excellent corrosion resistance. With a temperature rating up to 200°C and a pressure rating that can exceed 300 psi, aluminum is suitable for various compressor applications.

Pros: Aluminum is durable yet lightweight, making it easier to transport and install. Its resistance to rust and oxidation enhances the longevity of the compressor, particularly in humid environments.

Cons: While aluminum is generally cost-effective, its manufacturing complexity can increase costs when precision machining is required. Additionally, it may not withstand extreme pressure as effectively as steel or cast iron.

Impact on Application: Aluminum is compatible with air and non-corrosive gases, making it ideal for standard automotive applications.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM for material specifications, to avoid issues with quality and performance.

Steel is a popular choice for auto air compressors due to its high strength and durability. It typically has a temperature rating of around 300°C and a pressure rating that can reach 500 psi.

Pros: Steel’s robustness makes it suitable for high-pressure applications, and it offers excellent wear resistance. Its cost is relatively low compared to other materials, making it a cost-effective option for manufacturers.

Cons: Steel is heavier than aluminum, which can complicate installation and transportation. It is also prone to rust if not properly coated or maintained.

Impact on Application: Steel is highly compatible with air and various gases, making it versatile for different compressor types.

Considerations for International Buyers: Buyers must be aware of corrosion resistance requirements, especially in humid climates, and ensure compliance with relevant standards like DIN for material specifications.

Plastics are increasingly being utilized in auto air compressors, especially for non-structural components. They can withstand temperatures up to 100°C and pressures around 150 psi, depending on the type of plastic used.

Pros: Plastics are lightweight and resistant to corrosion, which can reduce overall manufacturing costs. They can also be molded into complex shapes, allowing for innovative designs.

Cons: Plastics generally have lower strength compared to metals, which may limit their use in high-pressure applications. Additionally, they may degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Suitable for housing and non-critical components, plastics can be used effectively in compressors designed for light-duty applications.

Considerations for International Buyers: Ensure that the plastics used meet safety and environmental standards, particularly in regions with strict regulations regarding material safety.

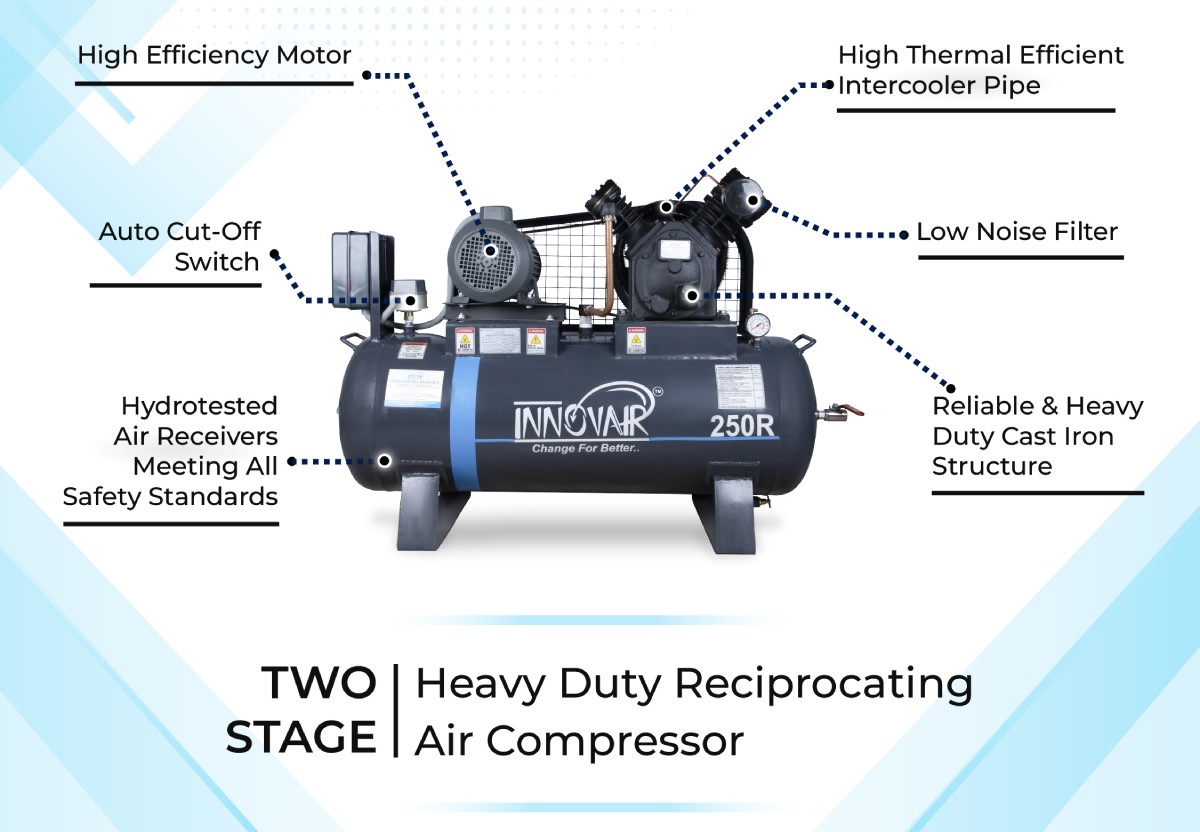

Cast iron is known for its durability and ability to absorb vibration, making it a common choice for heavy-duty compressors. It typically has a temperature rating of 200°C and can handle pressures up to 300 psi.

Pros: Cast iron is highly durable and can withstand high pressure and temperature, making it ideal for industrial applications. Its vibration-dampening properties also contribute to quieter operation.

Cons: The weight of cast iron can be a disadvantage in applications where portability is essential. It is also more expensive to manufacture and transport due to its bulk.

Impact on Application: Cast iron is suitable for heavy-duty applications, especially in industrial settings where durability is paramount.

Illustrative image related to auto air compressors

Considerations for International Buyers: Buyers should check for compliance with international standards, such as JIS, to ensure quality and safety in their applications.

| Material | Typical Use Case for auto air compressors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight portable compressors | Excellent corrosion resistance | Higher manufacturing complexity | Medium |

| Steel | High-pressure industrial compressors | High strength and durability | Prone to rust without coating | Low |

| Plastic | Non-structural components | Lightweight and moldable | Lower strength and UV degradation | Medium |

| Cast Iron | Heavy-duty industrial applications | Vibration absorption and durability | Heavy and costly to transport | High |

This strategic material selection guide aims to assist B2B buyers in making informed decisions when sourcing auto air compressors, ensuring compliance with international standards and suitability for specific applications.

The manufacturing process for auto air compressors typically comprises several critical stages, each essential for producing a high-quality product that meets industry standards.

The first step in manufacturing auto air compressors involves the careful selection and preparation of materials. Common materials include high-strength alloys for the compressor housing, rubber or synthetic materials for seals, and copper or aluminum for electrical components. Suppliers often source these materials from certified vendors to ensure compliance with international standards. Prior to production, materials undergo rigorous inspections to confirm their quality, including checks for strength, corrosion resistance, and compatibility with other components.

Once materials are prepared, the forming stage begins. This process can involve various techniques such as casting, machining, and stamping. For instance, the compressor housing may be cast using high-pressure die casting, which offers precision and efficiency. Machining is employed to achieve specific tolerances and surface finishes required for components like pistons and valves. Additionally, advanced techniques such as CNC (Computer Numerical Control) machining are increasingly utilized for their accuracy and repeatability, which are crucial in maintaining quality standards.

Illustrative image related to auto air compressors

After forming, the assembly stage involves bringing together all manufactured components. This process is often done in a clean and controlled environment to minimize contamination. Automated assembly lines are common, as they enhance efficiency and consistency. Key components such as the motor, compressor unit, and control systems are integrated during this phase. Each assembly line is typically designed to allow for flexibility, enabling manufacturers to adapt to different models and specifications based on customer demands.

The final stage, finishing, includes processes that enhance the durability and aesthetic appeal of the air compressors. This may involve surface treatments such as painting, anodizing, or powder coating to protect against corrosion and wear. Additionally, quality checks are performed to ensure that all cosmetic and functional aspects of the product meet established standards. This is critical for B2B buyers, who often require a product that not only functions well but also presents a professional appearance.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for auto air compressors, ensuring that products meet both customer expectations and regulatory standards.

For B2B buyers, understanding the quality assurance standards applicable to auto air compressors is crucial. ISO 9001 is a widely recognized international standard that outlines criteria for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) mark compliance and API (American Petroleum Institute) certifications may be relevant, depending on the market and application of the compressors. These certifications signify that products have been tested for safety, performance, and environmental impact.

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process to ensure adherence to quality standards. These checkpoints can be categorized into three main types:

Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers are often required to provide certificates of compliance, and materials may be subjected to random testing to confirm their quality.

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the production stages. This includes checking dimensions, tolerances, and functionality of components. The use of statistical process control (SPC) can help identify any deviations from quality standards early in the process.

Final Quality Control (FQC): Before products are shipped, a final inspection is performed to ensure that all units meet specified standards. This includes functional testing of compressors to verify performance under load and ensuring all safety features are operational.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality. Here are some effective strategies:

One of the most effective ways to verify quality control is through supplier audits. A comprehensive audit allows buyers to assess the manufacturer’s quality management system, production capabilities, and compliance with international standards. Audits can be conducted in person or through third-party services that specialize in supplier assessments.

Buyers should request quality control reports that detail the inspection and testing processes the manufacturer employs. These reports should provide insights into the frequency of inspections, types of tests conducted, and any issues identified during production. Transparent reporting can indicate a commitment to quality and continuous improvement.

Utilizing third-party inspection services can provide an unbiased assessment of a manufacturer’s quality control processes. These services often include pre-shipment inspections, where random samples of the product are tested for compliance with specifications. Engaging with reputable inspection agencies can add an extra layer of confidence for buyers.

International buyers must be aware of specific nuances related to quality control and certifications. Regional standards can vary significantly, and compliance with local regulations may be necessary for market entry. For instance, while ISO 9001 is globally recognized, certain markets may require additional certifications that reflect local safety and environmental standards.

Furthermore, understanding the certification processes in different countries can help buyers navigate potential pitfalls. For example, in Europe, the CE mark signifies compliance with EU safety and health requirements, while in the Middle East, local standards may vary based on country-specific regulations.

By being aware of these nuances, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality auto air compressors that meet their operational needs.

To assist B2B buyers in sourcing auto air compressors effectively, this guide provides a structured checklist that outlines essential steps to consider during the procurement process. By following these steps, you can ensure that your purchase meets both operational needs and quality standards.

Establishing clear technical specifications is critical for ensuring that the auto air compressor you select aligns with your operational requirements. Consider factors such as air pressure capacity (measured in PSI), tank size, and power source (electric vs. gas). Additionally, assess the intended applications—whether for light vehicles or heavy-duty trucks—as this will influence the specifications needed.

Illustrative image related to auto air compressors

Before engaging with suppliers, it’s essential to outline your budget constraints. Having a clear budget helps narrow down options and allows for more focused negotiations. Keep in mind that while lower prices may be attractive, they can sometimes correlate with lower quality; therefore, consider the total cost of ownership, including maintenance and operational expenses.

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request detailed company profiles, product catalogs, and references from existing customers, especially those in similar industries or regions. Pay attention to their reputation in the market and check for certifications that demonstrate compliance with international quality standards.

After-sales support is a crucial factor that can significantly affect your long-term satisfaction with the product. Inquire about warranty terms and the availability of replacement parts and technical support. A robust warranty and accessible support can minimize downtime and ensure that any issues can be resolved quickly.

Where possible, request samples or demonstrations of the auto air compressors you are considering. This allows you to evaluate performance, usability, and overall build quality firsthand. Testing the compressor in real-world scenarios can provide invaluable insights into its reliability and effectiveness in your specific applications.

Ensure that the compressors you are considering comply with local environmental regulations and standards. This includes noise level restrictions, emissions, and energy efficiency ratings. Compliance not only helps avoid potential legal issues but also aligns with sustainability goals that may be important to your business.

Once you have selected a supplier, carefully review and negotiate the purchase terms and conditions. This should include delivery schedules, payment terms, and any additional services such as installation or training. Clear agreements on these aspects can prevent misunderstandings and ensure a smooth procurement process.

By following this comprehensive checklist, B2B buyers can make informed decisions when sourcing auto air compressors, ultimately leading to successful procurement outcomes.

When considering the sourcing of auto air compressors, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers. This section delves into the key components that influence costs and pricing, providing actionable insights for buyers in regions such as Africa, South America, the Middle East, and Europe.

The cost structure of auto air compressors typically includes several critical components:

Materials: The type and quality of materials used in manufacturing air compressors significantly affect pricing. High-grade metals and durable plastics increase initial costs but may enhance longevity and performance.

Labor: Labor costs vary by region and are influenced by local wage standards and the level of skill required for assembly. In countries with lower labor costs, like some in South America and Africa, overall production expenses may be reduced.

Manufacturing Overhead: This includes costs related to the facilities, utilities, and indirect labor involved in production. Efficient manufacturing processes can help minimize these overheads, impacting the final pricing.

Tooling: The cost of specialized tools and molds required for production can be substantial, especially for custom designs. This upfront investment is often amortized over larger production runs.

Quality Control (QC): Implementing stringent QC processes is crucial for ensuring product reliability. However, enhanced QC measures can lead to increased costs, which suppliers may pass on to buyers.

Logistics: Shipping and handling costs, including freight, customs duties, and local transportation, can significantly influence total pricing, especially for international buyers.

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin varies based on market conditions and competitive pressures.

Several factors can influence the pricing of auto air compressors:

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can help suppliers manage production efficiently.

Specifications and Customization: Custom features or specifications can lead to increased costs. Buyers should weigh the benefits of customization against the potential for higher pricing.

Materials: The choice of materials impacts durability and performance. Buyers should consider the long-term value of investing in higher-quality materials, which can reduce maintenance costs.

Quality and Certifications: Products that meet international quality standards or certifications often command higher prices due to the assurance of reliability and safety.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge a premium.

Incoterms: Understanding international commercial terms is essential for managing shipping costs and responsibilities. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly alter the total cost.

For international B2B buyers, particularly in diverse markets like Africa and South America, negotiation is key:

Leverage Volume: Utilize larger order quantities to negotiate better pricing and terms. Suppliers are often more flexible when dealing with significant orders.

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the overall costs associated with operation, maintenance, and potential downtime. A lower initial price may not always equate to the best long-term value.

Explore Multiple Suppliers: Don’t settle for the first quote. Engage multiple suppliers to gain insights into market pricing and leverage competition to secure better deals.

Understand Pricing Nuances: Be aware of regional pricing variations and adjust expectations accordingly. Factors like local tariffs, currency fluctuations, and market demand can impact pricing.

Navigating the complexities of sourcing auto air compressors requires a comprehensive understanding of cost structures and pricing dynamics. By considering key cost components, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions that enhance their sourcing efficiency and overall profitability. It’s important to approach pricing discussions with an awareness of the broader market context and a clear focus on long-term value.

In the realm of tire inflation and maintenance, auto air compressors have long been a reliable choice for many businesses and consumers alike. However, various alternative solutions exist that can fulfill similar needs, each with its own set of advantages and drawbacks. This section provides a comprehensive comparison of auto air compressors against viable alternatives, helping B2B buyers make informed decisions based on their specific requirements.

| Comparison Aspect | Auto Air Compressors | Portable Tire Inflators | Manual Foot Pumps |

|---|---|---|---|

| Performance | High PSI, suitable for multiple tires | Moderate PSI, suitable for quick fixes | Low PSI, best for occasional use |

| Cost | Moderate to high (varies by model) | Low to moderate (typically $20-$100) | Very low (usually under $30) |

| Ease of Implementation | Requires power source, often complex | Easy to use, often battery-operated | Simple mechanics, no power needed |

| Maintenance | Regular checks needed, oil changes for some | Minimal maintenance, just battery checks | Very low, just clean occasionally |

| Best Use Case | Fleet maintenance, heavy-duty applications | Emergency roadside assistance, small vehicles | Occasional use for bicycles or small cars |

Portable tire inflators, such as those from brands like AstroAI and Craftsman, offer a compact and user-friendly solution for tire inflation. They are often battery-operated or can be plugged into a vehicle’s power outlet, making them highly portable. While they generally do not reach the same high PSI levels as traditional air compressors, they are ideal for topping off tires or addressing minor emergencies. Their affordability and ease of use make them a popular choice for small businesses or individual consumers needing quick fixes. However, they may not be suitable for heavy-duty applications or frequent use due to their limited power and capacity.

Manual foot pumps present a low-cost alternative for tire inflation, particularly in areas where electricity is scarce or unavailable. These pumps rely on human power, making them lightweight and easy to transport. They are especially well-suited for bicycles and smaller vehicles. While they require more effort and time to inflate tires compared to powered options, their simplicity and low maintenance needs can appeal to businesses seeking budget-friendly solutions. The main drawback is their low PSI output, which may not be sufficient for larger vehicles or high-pressure requirements.

When considering whether to invest in auto air compressors or explore alternatives like portable tire inflators or manual foot pumps, B2B buyers should assess their specific needs. For businesses managing a fleet or requiring heavy-duty tire maintenance, auto air compressors provide the performance and efficiency needed. Conversely, for those seeking budget-friendly, portable solutions for occasional use, portable tire inflators or manual foot pumps may be more appropriate. Evaluating factors such as cost, ease of use, and maintenance will help ensure that the chosen solution aligns with operational requirements and budget constraints.

When selecting auto air compressors for B2B applications, understanding specific technical properties is essential. Here are critical specifications that impact performance and usability:

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. This is crucial for applications requiring specific pressure levels, such as inflating tires or powering pneumatic tools. A higher PSI rating is typically better for heavy-duty applications, making it essential for buyers to assess their needs.

The duty cycle represents the ratio of operational time to rest time. For instance, a 50% duty cycle means the compressor can operate for 30 minutes and then requires a 30-minute cooldown. Understanding the duty cycle helps buyers determine how long the compressor can run without overheating, ensuring optimal performance in demanding environments.

The tank size, measured in gallons, affects the volume of air stored and the compressor’s ability to deliver sustained pressure. Larger tanks provide a more significant air supply, reducing the frequency of compressor cycling. This is particularly beneficial in commercial settings where high-volume air is necessary, such as in automotive workshops.

Illustrative image related to auto air compressors

The airflow rate, measured in cubic feet per minute (CFM), indicates how much air the compressor can deliver. A higher CFM rating is essential for tasks that require rapid inflation or operation of multiple air tools simultaneously. Buyers should match the CFM rating with their operational needs to ensure efficiency and productivity.

Auto air compressors can be powered by electricity, gas, or batteries. The choice of power source affects portability and application suitability. Electric compressors are typically quieter and more suitable for indoor use, while gas-powered units offer greater mobility for outdoor applications. Understanding the operational context will guide buyers in selecting the appropriate power source.

The materials used in the construction of an air compressor influence its durability and performance. Common materials include aluminum for lightweight portability and steel for rugged durability. Buyers should evaluate the material grade to ensure that the compressor can withstand the specific operational demands of their industry.

Illustrative image related to auto air compressors

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B sector. Here are some essential trade terms:

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of auto air compressors, understanding OEM relationships can help buyers source parts or entire units that meet specific quality and compatibility standards.

MOQ indicates the smallest quantity of product a supplier is willing to sell. This term is critical for B2B buyers, as it affects purchasing decisions and inventory management. Understanding MOQ helps companies plan their procurement strategies and budget accordingly.

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document outlines the specifications and quantities desired. Utilizing RFQs can lead to better pricing and terms, making it a vital tool for B2B procurement.

Illustrative image related to auto air compressors

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They clarify aspects such as shipping costs, risk transfer, and delivery timelines. Familiarity with Incoterms is crucial for international buyers to avoid misunderstandings and ensure smooth transactions.

The warranty period specifies the duration for which a manufacturer guarantees the product against defects. Understanding warranty terms is essential for B2B buyers, as it reflects the manufacturer’s confidence in their product and can influence long-term maintenance costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting auto air compressors, ensuring they choose the right products for their operational needs.

The global auto air compressors market is experiencing significant growth, driven by the increasing demand for automotive maintenance and repair services. Key trends influencing this market include advancements in technology, such as the integration of IoT and smart features in air compressors, which enhance usability and efficiency. Additionally, the rise of electric vehicles (EVs) is reshaping the industry, necessitating air compressors that are compatible with new vehicle technologies. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging sourcing trends highlight a shift towards portable and compact air compressor models, which are particularly appealing for both personal and commercial use. This trend is bolstered by the growing popularity of DIY maintenance among consumers and small businesses. Furthermore, the demand for energy-efficient compressors is on the rise, as businesses seek to reduce operational costs and environmental impact. Buyers should also consider regional market variations; for instance, Brazil and Vietnam are witnessing a surge in automotive service centers, creating opportunities for suppliers to cater to a burgeoning customer base.

Sustainability is becoming an integral part of the auto air compressors sector, driven by increasing regulatory pressures and consumer expectations. The environmental impact of manufacturing processes and product lifecycle is a growing concern, prompting manufacturers to adopt greener practices. International B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainability, such as utilizing eco-friendly materials and processes.

Ethical sourcing is paramount, especially for buyers in emerging markets, where the implications of supply chain practices are often scrutinized. Certifications such as ISO 14001 for environmental management and various green certifications for products can significantly enhance a supplier’s appeal. Buyers should evaluate suppliers based on their adherence to these standards, ensuring that the products they source contribute to reducing the carbon footprint. Additionally, the integration of recyclable materials in air compressors is a trend that not only meets regulatory requirements but also aligns with the values of environmentally conscious consumers.

The evolution of auto air compressors can be traced back to the early 20th century, when the first pneumatic tools emerged, significantly changing the landscape of automotive repair and maintenance. Initially, air compressors were bulky and primarily used in industrial settings. However, as automotive technology advanced and consumer demand for efficient maintenance solutions grew, manufacturers began to innovate, leading to the development of portable and more efficient models.

In recent decades, the shift towards automation and smart technology has revolutionized the sector, with features such as digital pressure gauges and automatic shut-off mechanisms becoming standard. This historical context underscores the importance of adaptability in the auto air compressors market, as suppliers must continuously evolve to meet the changing needs of B2B buyers globally. Understanding this evolution can provide valuable insights for buyers looking to source the latest technologies and innovations in air compressor solutions.

How do I choose the right air compressor for my business needs?

Selecting the right air compressor involves assessing your specific requirements, such as the types of tasks you’ll be performing, the volume of air needed, and the required pressure levels. Evaluate the horsepower and tank size appropriate for your applications, whether for tire inflation, powering pneumatic tools, or other uses. Consider the mobility of the compressor if you’ll be using it in various locations. Consulting with suppliers about your needs and requesting product demonstrations can also aid in making an informed decision.

What is the best air compressor for heavy-duty applications?

For heavy-duty applications, look for compressors with a higher CFM (cubic feet per minute) rating and PSI (pounds per square inch) capacity. Models like rotary screw compressors are ideal as they provide continuous air supply and are efficient for larger operations. Brands such as Ingersoll Rand and Atlas Copco are well-regarded for their durability and performance in demanding environments. Additionally, ensure that the compressor has adequate tank size and horsepower to handle your specific tasks without lag.

What factors should I consider when vetting international suppliers of air compressors?

When vetting international suppliers, prioritize their experience and reputation in the industry. Review their certifications and compliance with international standards, such as ISO or CE. Request references from previous clients and check for customer feedback online. Additionally, consider their ability to provide after-sales support, warranty services, and spare parts availability. Engaging in direct communication can also help assess their responsiveness and professionalism.

What are the common payment terms for purchasing air compressors internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common arrangements include letters of credit, advance payments, or payment upon delivery. It is advisable to negotiate terms that provide some level of security, such as partial upfront payments combined with milestone payments based on delivery stages. Ensure that all terms are clearly outlined in the purchase agreement to avoid misunderstandings.

What is the minimum order quantity (MOQ) for air compressors?

The MOQ for air compressors typically depends on the supplier and the specific models being ordered. Some suppliers may have a low MOQ for standard models, while custom specifications could require larger orders. It’s important to discuss your needs upfront with potential suppliers to find a suitable arrangement. Additionally, consider the implications of MOQ on your inventory management and cash flow.

How can I ensure quality assurance (QA) for the air compressors I purchase?

To ensure quality assurance, request detailed specifications and quality certifications from suppliers. Conduct factory audits if possible, or rely on third-party inspection services to verify product quality before shipment. Establish clear QA protocols in your purchase agreement, including testing procedures and acceptable defect rates. Regular communication with your supplier during the manufacturing process can also help identify any potential issues early on.

What logistics considerations should I keep in mind when importing air compressors?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder who understands international shipping nuances, including documentation and tariffs. Factor in potential delays at customs and ensure compliance with local import regulations. It’s also advisable to have a contingency plan for unforeseen logistics challenges, such as shipping disruptions or damage during transit.

Can I customize the specifications of the air compressors I order?

Yes, many suppliers offer customization options for air compressors to meet specific business needs. Customizations can include adjustments in power output, tank size, and additional features such as noise reduction or portability enhancements. Discuss your requirements with suppliers to explore available options. Keep in mind that custom orders may have longer lead times and could impact pricing, so plan accordingly.

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: Portable & Vehicle Mounted Air Compressor Systems from ARB 4×4 USA. Key features include: 1. Reliable, high-performance compressors for tires, tools, and Air Lockers. 2. Available types: Onboard (12V and 24V), Portable (12V), and Brushless models. 3. Price range: $224.95 to $1,379.95. 4. Promotions: 10% off Air Compressors & Accessories, Free Ground Shipping over $75. 5. Products include: Twin Mot…

Domain: ezflate.com

Registered: 2019 (6 years)

Introduction: This company, EzFlate – Portable Air Compressors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In today’s competitive market, the strategic sourcing of auto air compressors is pivotal for businesses aiming to optimize efficiency and performance. By understanding the unique requirements of different regions—such as the varying demands in Africa, South America, the Middle East, and Europe—buyers can tailor their sourcing strategies to align with local preferences and regulatory standards. The evaluation of compressor performance, durability, and adaptability to diverse conditions not only ensures reliability but also enhances customer satisfaction.

Illustrative image related to auto air compressors

Moreover, leveraging partnerships with manufacturers who prioritize innovation can lead to significant cost savings and improved product offerings. As international markets continue to evolve, the importance of sourcing high-quality, efficient air compressors will only grow.

Looking ahead, B2B buyers are encouraged to proactively engage with suppliers, explore emerging technologies, and invest in advanced solutions to stay ahead of the curve. By prioritizing strategic sourcing now, companies can position themselves as leaders in their markets, ensuring sustained growth and a competitive edge in the years to come.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to auto air compressors

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.