Navigating the global market for the best portable tire inflator compressor can be a daunting task for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for reliable tire inflation solutions is on the rise, driven by the growing automotive industry and the increasing prevalence of electric and hybrid vehicles. However, sourcing the right products that meet both performance and budgetary requirements is crucial for maintaining operational efficiency.

This comprehensive guide delves into various types of portable tire inflators, highlighting their applications across different vehicle categories, from passenger cars to heavy-duty trucks. We explore essential considerations such as power sources, inflation speed, pressure capacities, and additional features that enhance usability. Furthermore, we provide insights into effective supplier vetting processes to ensure quality and reliability, as well as a thorough analysis of pricing structures to help buyers maximize their investment.

By equipping international B2B buyers with the knowledge needed to make informed purchasing decisions, this guide aims to streamline the procurement process. Whether you are a fleet manager in Brazil or an automotive service provider in Vietnam, understanding the nuances of portable tire inflators will empower you to select the best solutions for your operational needs, ensuring safety and efficiency on the road.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

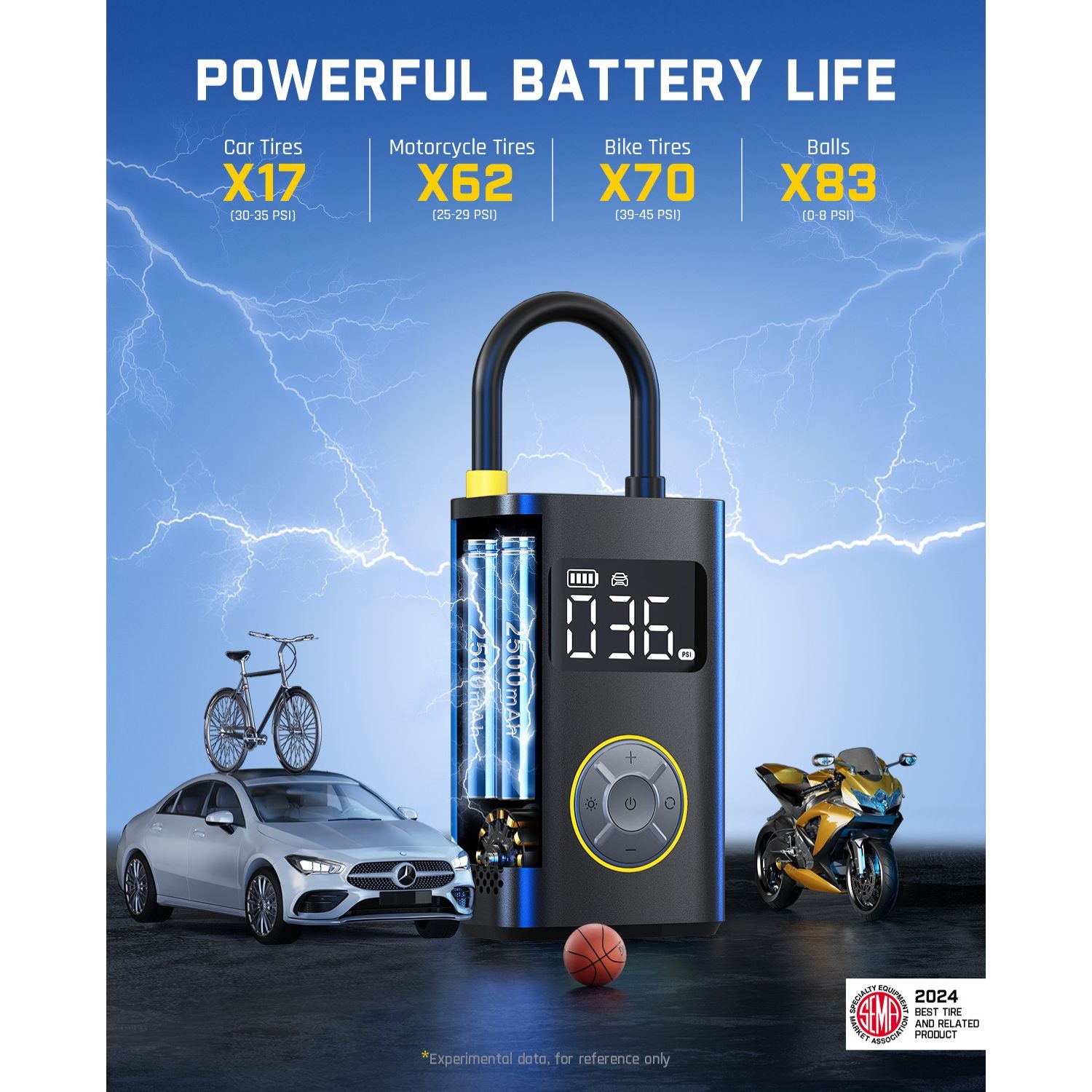

| Cordless Tire Inflators | Battery-operated, portable, often compact design | Automotive service, roadside assistance | Pros: High portability, no need for power outlet. Cons: Limited battery life, may require recharging. |

| 12V Powered Tire Inflators | Connects to vehicle’s 12V outlet, often faster inflation | Fleet maintenance, automotive workshops | Pros: Continuous power while vehicle is running. Cons: Limited reach without extension cables. |

| Heavy-Duty Tire Inflators | Designed for high PSI, suitable for trucks and SUVs | Off-road vehicle service, commercial use | Pros: Can handle larger tires, robust construction. Cons: Bulkier, requires more storage space. |

| Digital Tire Inflators | Equipped with digital pressure gauges for accuracy | Car rental services, tire shops | Pros: Accurate readings, easy to use. Cons: May be more expensive than analog models. |

| Multi-Function Tire Inflators | Includes additional features (USB ports, adapters) | Recreational vehicle maintenance, events | Pros: Versatile for various inflatables, added utility. Cons: Complexity may lead to higher failure rates. |

Cordless tire inflators are battery-operated devices that offer exceptional portability, making them ideal for on-the-go applications. They are compact and can easily fit in a vehicle’s trunk or even a glove compartment. For B2B buyers, particularly those involved in roadside assistance or mobile automotive services, these inflators provide the convenience of being able to inflate tires without needing an external power source. However, their battery life may limit their use, necessitating careful management of charging cycles.

Illustrative image related to best portable tire inflator compressor

12V powered tire inflators connect directly to a vehicle’s power outlet, allowing for continuous operation as long as the vehicle is running. They are often faster than their cordless counterparts, making them suitable for fleet maintenance and automotive workshops where time efficiency is crucial. B2B buyers should consider the reach of the inflator’s cord and whether extension cables are needed, as this can impact usability in larger vehicles or when servicing multiple tires.

Heavy-duty tire inflators are specifically designed to handle high PSI requirements, making them essential for trucks and SUVs. Their robust construction allows them to fill larger tires quickly, which is particularly beneficial for off-road vehicle service or commercial applications. While they excel in performance, B2B buyers should be mindful of their bulkiness, which may necessitate additional storage considerations in service vehicles.

Digital tire inflators come equipped with accurate digital pressure gauges, allowing for precise inflation and easy monitoring of tire pressure. This feature is particularly advantageous for car rental services and tire shops where accuracy is paramount. Although they may come at a higher price point compared to analog models, the reliability and ease of use they offer make them a worthwhile investment for B2B buyers focused on quality service delivery.

Multi-function tire inflators provide added features such as USB ports for charging devices and various adapters for inflating different items. This versatility makes them suitable for recreational vehicle maintenance and event setups where multiple inflatables may be required. While they offer increased utility, B2B buyers should consider the potential for increased complexity, which may lead to higher rates of malfunction if not properly maintained.

| Industry/Sector | Specific Application of best portable tire inflator compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Routine tire pressure checks and inflation for customer vehicles | Enhances customer satisfaction and safety | Reliability, speed of inflation, and compact design |

| Logistics and Transportation | On-the-road tire maintenance for delivery vehicles | Minimizes downtime and improves operational efficiency | Durability, power source options, and ease of use |

| Construction and Heavy Machinery | Inflating tires of heavy equipment and vehicles | Reduces delays in project timelines | High PSI capacity, rugged construction, and portability |

| Recreational Vehicle (RV) Rentals | Tire maintenance for rental RVs and trailers | Ensures safety and reliability for customers | Battery operation, size, and versatility for different tire types |

| Emergency Services | Quick tire inflation for emergency response vehicles | Critical for timely response in emergencies | Fast inflation time, compactness for storage, and reliability |

Automotive repair shops can utilize portable tire inflators for routine tire pressure checks and inflation services. By providing quick and efficient tire inflation, these businesses enhance customer satisfaction and safety. Repair shops should consider inflators that offer reliability, rapid inflation times, and a compact design for easy storage and use.

In the logistics and transportation sector, portable tire inflators are essential for on-the-road tire maintenance of delivery vehicles. They help minimize downtime caused by flat or under-inflated tires, thereby improving operational efficiency. Buyers in this sector should prioritize inflators that are durable, have multiple power source options, and are easy to operate, ensuring they can handle various tire sizes and pressures.

Illustrative image related to best portable tire inflator compressor

In construction and heavy machinery applications, portable tire inflators are vital for inflating tires of heavy equipment and vehicles. Proper tire inflation ensures that equipment operates efficiently and reduces delays in project timelines caused by tire issues. Businesses should look for inflators with high PSI capacity, rugged construction to withstand harsh environments, and portability for easy transport to job sites.

For recreational vehicle (RV) rental companies, maintaining tire pressure is crucial for ensuring the safety and reliability of rental units. Portable tire inflators allow for quick tire maintenance, which is essential for customer satisfaction. When sourcing inflators, companies should focus on models that operate on battery power, are compact, and versatile enough to accommodate various tire types commonly found in RVs and trailers.

Emergency services rely on portable tire inflators for quick inflation of tires on emergency response vehicles. In critical situations, timely response is paramount, and having a reliable inflator can mean the difference between life and death. Buyers in this sector should prioritize inflators that offer fast inflation times, compactness for easy storage in emergency vehicles, and overall reliability to ensure they perform under pressure.

The Problem: In many regions, particularly in Africa and parts of South America, B2B buyers often struggle to find high-quality portable tire inflators that can withstand local conditions. Factors such as varying power supply reliability, extreme temperatures, and rugged terrains can lead to frequent malfunctions or subpar performance. Buyers may invest in inflators that promise high performance but end up with products that are unreliable, resulting in wasted time and resources, especially for businesses that rely on transportation logistics.

The Solution: To mitigate this issue, B2B buyers should prioritize sourcing from reputable manufacturers known for durability and reliability. It’s essential to look for tire inflators with robust construction, capable of functioning in extreme conditions. When specifying products, consider inflators that feature multiple power sources, such as rechargeable batteries and 12-volt adapters, ensuring they can operate even when traditional power sources are down. Additionally, conducting thorough research on user reviews and performance tests specific to the local environment can provide insights into which models hold up best. Engaging with suppliers who offer warranties or service agreements can also provide an extra layer of security against potential malfunctions.

Illustrative image related to best portable tire inflator compressor

The Problem: Many portable tire inflators come equipped with built-in pressure gauges, but the accuracy of these gauges can vary significantly. For B2B buyers managing fleets or rental services, maintaining precise tire pressure is critical for safety, fuel efficiency, and tire longevity. Inflators that provide inaccurate readings can lead to under-inflated or over-inflated tires, resulting in performance issues, increased operational costs, and potential safety hazards.

The Solution: Buyers should prioritize tire inflators with digital pressure gauges known for their precision. When sourcing, it is beneficial to request detailed specifications regarding the accuracy and calibration of pressure gauges. Furthermore, buyers can consider investing in separate, calibrated pressure gauges to verify the inflator’s readings. Implementing a routine maintenance schedule that includes checking tire pressures with a reliable gauge can help ensure that all inflators are functioning correctly. Training personnel on the importance of monitoring tire pressure and how to properly use these tools can also enhance safety and operational efficiency.

The Problem: For businesses that require frequent travel or have limited storage space, the size and weight of portable tire inflators can be a significant concern. Many inflators are bulky and cumbersome, making them difficult to transport and store in vehicles, especially for companies with a fleet of vehicles. This can lead to a lack of preparedness in the event of a flat tire, resulting in downtime and loss of productivity.

Illustrative image related to best portable tire inflator compressor

The Solution: B2B buyers should look for ultra-compact tire inflators specifically designed for portability without sacrificing performance. When evaluating options, consider models that feature lightweight materials and compact designs, making them easy to stow away in glove compartments or toolboxes. Additionally, buyers should assess the ease of use; inflators that come with carrying cases or integrated storage solutions can further enhance portability. It’s also beneficial to conduct a cost-benefit analysis comparing the size and weight of various models against their performance capabilities, ensuring that the chosen inflator meets both portability and functionality needs. Finally, creating a standardized procedure for checking and maintaining inflators can help ensure that they are always ready for use, regardless of the travel demands.

When selecting a portable tire inflator compressor, the choice of materials plays a critical role in determining the product’s performance, durability, and overall suitability for various applications. Below, we analyze four common materials used in the construction of these devices, focusing on their properties, pros and cons, and specific considerations for international B2B buyers.

Key Properties: Plastic is lightweight, corrosion-resistant, and can be molded into complex shapes. It typically withstands moderate temperatures and pressures, making it suitable for housing components like motors and gauges.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for mass production of components. However, it may not withstand extreme temperatures or high pressures as effectively as metals, which could limit its use in heavy-duty applications.

Impact on Application: Plastic is often used for non-structural components, such as casings and knobs. Its compatibility with various media is generally good, but it may degrade over time when exposed to certain chemicals.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with international standards such as ASTM or ISO. In regions with high UV exposure, such as Africa and South America, UV-stabilized plastics are preferred to prevent degradation.

Illustrative image related to best portable tire inflator compressor

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and good thermal conductivity. It can handle higher pressures than plastic, making it suitable for critical components like pressure vessels.

Pros & Cons: Aluminum’s strength-to-weight ratio is a significant advantage, allowing manufacturers to create compact designs without compromising durability. However, it is generally more expensive than plastic, and the manufacturing process can be more complex, requiring specialized equipment.

Impact on Application: Aluminum is ideal for components that require strength and pressure resistance, such as the housing for the compressor mechanism. Its compatibility with various media is high, and it can withstand a wide range of temperatures.

Considerations for International Buyers: Buyers should verify that aluminum components meet relevant standards, such as DIN or JIS, especially in regions like Europe and the Middle East where compliance is critical.

Key Properties: Steel is known for its high strength and durability, with excellent resistance to wear and high temperatures. It can handle extreme pressures, making it suitable for heavy-duty applications.

Pros & Cons: The main advantage of steel is its robustness, which allows it to withstand harsh operating conditions. However, it is heavier and can be prone to rust if not properly coated, which may affect long-term performance.

Impact on Application: Steel is commonly used in the compressor housing and structural components where high strength is required. It is compatible with a wide range of media and can handle high-pressure applications effectively.

Considerations for International Buyers: Buyers should ensure that steel components are treated for corrosion resistance, especially in humid climates found in parts of Africa and South America. Compliance with international standards for steel quality is also essential.

Key Properties: Rubber is flexible, resilient, and can withstand a range of temperatures. It is often used for seals and hoses due to its excellent sealing properties.

Illustrative image related to best portable tire inflator compressor

Pros & Cons: The flexibility of rubber allows for effective sealing, preventing air leaks and ensuring efficient operation. However, it can degrade over time, especially when exposed to UV light or extreme temperatures, which may necessitate replacement.

Impact on Application: Rubber components are critical for maintaining airtight seals in inflators, particularly in hoses and connectors. Their compatibility with air is excellent, but they may not perform well with certain chemicals.

Considerations for International Buyers: Buyers should look for rubber materials that are UV-resistant and suitable for the specific environmental conditions in their regions. Compliance with standards for material safety and performance is also a key consideration.

| Material | Typical Use Case for best portable tire inflator compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Casings and non-structural components | Lightweight and cost-effective | Limited temperature and pressure resistance | Low |

| Aluminum | Compressor housing and critical components | High strength-to-weight ratio | Higher cost and complex manufacturing | Medium |

| Steel | Structural components and heavy-duty applications | Exceptional durability and strength | Heavier and prone to rust | High |

| Rubber | Seals and hoses | Excellent sealing properties | Degrades over time with exposure | Medium |

This analysis provides a comprehensive overview of the materials commonly used in portable tire inflator compressors, emphasizing their properties and considerations for international B2B buyers. Understanding these factors can help in making informed purchasing decisions that align with operational needs and regional conditions.

Illustrative image related to best portable tire inflator compressor

The manufacturing of portable tire inflators involves several critical stages, each essential for ensuring that the final product meets quality and performance standards. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

The initial stage begins with the selection and preparation of materials. Portable tire inflators typically consist of components made from plastic, rubber, and metal. High-quality plastics are chosen for housings due to their durability and lightweight properties. Rubber is often used for seals and hoses to ensure airtight connections, while metals, such as aluminum, are utilized for internal mechanisms and pumps due to their strength and resistance to wear.

Manufacturers must also ensure that all materials comply with international standards, including those related to environmental impact and safety. For instance, sourcing materials that meet REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations is critical, particularly for buyers in Europe.

The forming stage involves shaping the prepared materials into specific components. This is typically achieved through injection molding for plastics, where molten plastic is injected into molds to create the desired shapes, such as the housing of the inflator. For metal parts, processes like die-casting or machining may be employed.

Illustrative image related to best portable tire inflator compressor

Once the individual components are formed, the assembly process begins. This stage is often automated but may include manual assembly for more complex components. Key assembly operations include:

Finishing processes are crucial for both aesthetics and functionality. Common techniques include:

Quality assurance is integral to manufacturing portable tire inflators, ensuring that each unit meets both safety and performance standards. Various international and industry-specific standards guide these practices.

ISO 9001 is one of the most recognized quality management standards globally. It outlines requirements for a quality management system (QMS) that can help organizations ensure consistent quality in their products and services. Compliance with ISO 9001 indicates that the manufacturer has established processes to monitor and improve quality continually.

Illustrative image related to best portable tire inflator compressor

In addition, specific certifications such as CE (Conformité Européenne) mark products for compliance with European health, safety, and environmental standards. For inflators intended for markets like the Middle East, manufacturers may need to comply with Gulf Conformity Mark (G-Mark) requirements.

Quality control typically involves several checkpoints throughout the manufacturing process:

Buyers should take an active role in verifying the quality control practices of their suppliers. Here are some actionable steps:

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, observe processes firsthand, and evaluate the application of quality control measures.

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including records of inspections and testing outcomes. This can include compliance certificates for relevant international standards.

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control systems. This is particularly important for buyers in regions with strict regulatory requirements.

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control can be crucial. These regions often have varying standards and expectations.

Cultural Differences: Recognizing cultural differences in business practices and expectations can influence negotiations and quality perceptions. For instance, buyers in Europe may expect more stringent adherence to environmental standards than those in other regions.

Regulatory Compliance: Buyers must be aware of local regulations that may affect product compliance. This includes understanding import/export regulations and certification requirements specific to their region.

Logistical Considerations: Quality control does not stop at manufacturing. Buyers should also consider the logistics of shipping and storage, as these can impact the final product’s quality. Ensuring that suppliers have robust logistics protocols in place is essential.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they source high-quality portable tire inflators that meet their operational needs and compliance standards.

This guide serves as a practical checklist for B2B buyers aiming to procure the best portable tire inflator compressors. By following these steps, you can ensure that you select a product that meets both your operational needs and budget constraints while maximizing reliability and efficiency.

Illustrative image related to best portable tire inflator compressor

Understanding the primary applications for the tire inflator is crucial. Will it be used for passenger vehicles, trucks, or specialized equipment? Different inflators cater to varying pressure requirements and speed, so knowing your specific use cases will help narrow down your options effectively.

Establishing clear technical specifications is key to ensuring compatibility with your needs. Consider factors such as:

– Maximum Pressure Rating: Ensure the inflator can handle the highest PSI required for your vehicles.

– Power Source: Decide between cordless models for portability or plug-in options for continuous use.

– Inflation Speed: Look for models that can inflate tires quickly, especially in emergency situations.

Before finalizing a supplier, verify their industry certifications and compliance with international standards. Check for certifications like ISO 9001, which indicate a commitment to quality management. This step helps mitigate risks associated with product reliability and supplier integrity.

Investigate the additional features offered by various models, as these can significantly enhance usability. Look for:

– Built-in Pressure Gauges: Digital gauges provide more accurate readings.

– Portability Features: Lightweight designs and carrying cases facilitate easy transport.

– Extras: Features like USB charging ports or built-in lights can add value, depending on your operational needs.

If possible, request samples or demo units to evaluate performance directly. Testing should include:

– Inflation Tests: Measure how quickly and efficiently the inflator can raise tire pressure from low levels.

– Durability Tests: Assess how the unit holds up under regular use, especially in varying environmental conditions.

Illustrative image related to best portable tire inflator compressor

Gather pricing information from multiple suppliers to ensure competitive rates. Don’t just consider the initial cost; evaluate warranty options and after-sales support as well. A robust warranty can provide peace of mind and protect your investment in the long term.

Finally, review feedback from other B2B buyers who have used the inflators you are considering. Look for testimonials that speak to performance, reliability, and customer service experiences. This step can provide insights that technical specifications may not reveal.

By following this checklist, B2B buyers can make informed decisions when sourcing portable tire inflator compressors, ensuring they select products that align with their operational needs and standards.

When sourcing portable tire inflators, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The choice of materials significantly influences the overall cost. High-quality plastic and metal components that enhance durability will typically raise the price. Additionally, features like digital displays and integrated battery systems add to material costs.

Labor: Labor costs can vary depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can sometimes impact product quality. It’s vital to balance cost with the expertise of the workforce in producing reliable inflators.

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help lower these overhead costs, impacting the final price.

Tooling: The initial investment in tooling for production can be substantial, especially for customized designs. This cost is often spread over the volume of units produced, making higher volume orders more cost-effective.

Quality Control (QC): Ensuring that each inflator meets safety and performance standards incurs additional costs. However, robust QC processes can reduce returns and warranty claims, providing long-term savings.

Logistics: Shipping and handling costs depend on the size and weight of the inflators. International shipments may also incur tariffs and customs duties, which should be factored into the total cost.

Margin: Suppliers typically mark up the base cost to achieve their profit margins. Understanding the market can help buyers negotiate better prices.

Several factors influence the pricing of portable tire inflators, including order volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often result in lower per-unit costs, as suppliers can distribute fixed costs over more units.

Specs/Customization: Customized inflators with specific features or branding will generally be more expensive. Buyers should assess whether the added costs align with their market needs.

Materials: As previously mentioned, the quality of materials directly impacts pricing. Buyers should evaluate the trade-offs between cost and durability.

Quality/Certifications: Products that meet international safety and quality standards may carry higher price tags but can reduce liability and enhance brand reputation.

Supplier Factors: Established suppliers with a track record of reliability may charge more, but their products often come with better support and warranty services.

Incoterms: Understanding shipping terms is vital. The choice of Incoterms can affect the total landed cost, impacting budgeting for international buyers.

B2B buyers should consider several strategies to enhance cost-efficiency when sourcing portable tire inflators.

Negotiation: Engage suppliers in discussions about pricing, especially when placing bulk orders. Many suppliers may be willing to provide discounts for long-term contracts or repeat business.

Cost-Efficiency: Look beyond the initial purchase price. Evaluating the Total Cost of Ownership (TCO), which includes operational costs, maintenance, and potential savings from lower failure rates, can lead to smarter purchasing decisions.

Pricing Nuances for International Buyers: Understand the economic conditions and currency exchange rates in your region. This knowledge can aid in negotiations and help anticipate price fluctuations.

Quality vs. Cost: While lower prices may be appealing, ensure that quality is not compromised. Opting for reputable suppliers who offer warranties and support can prevent costly issues in the future.

Market Research: Stay informed about market trends and competitor pricing. This awareness can help you make more informed decisions and recognize when a supplier’s price is competitive.

Understanding the cost structure and pricing dynamics of portable tire inflators is essential for B2B buyers aiming to make informed sourcing decisions. By analyzing key cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their purchasing process, ensuring they receive the best value for their investment. Always remember that indicative prices can fluctuate based on market conditions, so staying adaptable is key.

In the realm of tire maintenance, portable tire inflator compressors are a popular choice among B2B buyers looking for efficiency and convenience. However, there are alternative solutions that can also effectively address tire inflation needs. This section explores how these alternatives stack up against the best portable tire inflator compressor, providing insights into their viability for businesses operating in diverse markets, including Africa, South America, the Middle East, and Europe.

Illustrative image related to best portable tire inflator compressor

| Comparison Aspect | Best Portable Tire Inflator Compressor | CO2 Tire Inflation System | Manual Foot Pump |

|---|---|---|---|

| Performance | Fast inflation, handles multiple tires efficiently | Quick inflation, limited by CO2 cartridge size | Slower, labor-intensive process |

| Cost | Moderate ($40 – $90) | Higher initial cost ($100+) | Low ($20 – $50) |

| Ease of Implementation | User-friendly, often cordless | Requires cartridge purchase and storage | Simple design, no setup needed |

| Maintenance | Low maintenance; battery replacement may be needed | Moderate; cartridges must be replaced | Very low; minimal parts involved |

| Best Use Case | Regular vehicle maintenance, emergencies | Off-road or racing environments | Occasional use, low-pressure applications |

CO2 Tire Inflation System:

This system utilizes CO2 cartridges to quickly inflate tires, making it an attractive option for users needing rapid inflation, especially in off-road or racing scenarios. The primary advantage of CO2 systems is their speed; they can inflate a tire much faster than manual pumps. However, the ongoing cost of purchasing cartridges can add up, and the system is limited by the number of cartridges available. Additionally, CO2 inflators may not be suitable for larger vehicles or high-pressure applications, as the cartridges can only provide a limited amount of air.

Manual Foot Pump:

Manual foot pumps are a low-cost alternative that requires no electricity or batteries. They are straightforward to use and can be an effective solution for occasional tire inflation needs, particularly in remote areas where power sources are unavailable. However, the performance of manual foot pumps is significantly slower compared to powered inflators, requiring more physical effort and time to achieve desired pressure levels. They are best suited for low-pressure applications, such as bicycles or small vehicles, and may not be practical for businesses that require rapid and consistent tire inflation.

Selecting the right tire inflation solution depends on several factors, including the specific needs of the business, budget constraints, and operational environment. For companies that prioritize speed and efficiency, a portable tire inflator compressor is the best choice, especially for regular maintenance and emergencies. Conversely, businesses engaged in off-road activities might find CO2 systems beneficial due to their quick inflation capabilities, despite the higher ongoing costs. For those with infrequent needs or operating in remote areas, a manual foot pump provides a cost-effective solution, albeit with limitations in performance and efficiency. Ultimately, understanding the unique requirements of the business will guide B2B buyers toward the most suitable tire inflation method.

When evaluating portable tire inflators for B2B purchasing, understanding critical technical specifications is essential for ensuring product quality, performance, and suitability for various applications. Here are key specifications to consider:

Maximum pressure, measured in pounds per square inch (PSI), indicates the highest air pressure the inflator can achieve. For instance, inflators designed for heavy-duty vehicles may need to reach up to 160 PSI, while standard car inflators typically max out around 80 PSI. B2B buyers should assess the intended use—whether for passenger vehicles, trucks, or recreational vehicles—to select an inflator that meets specific pressure requirements.

The duty cycle refers to the amount of time an inflator can operate continuously before requiring a cooldown period. Measured as a percentage, a higher duty cycle (e.g., 25 minutes on, 15 minutes off) indicates a more robust unit suitable for frequent use. This specification is crucial for businesses that may need to inflate multiple tires in succession, ensuring efficiency and reducing downtime.

Portable tire inflators can be powered by various sources, including rechargeable batteries, 12-volt vehicle outlets, or AC power. Understanding the power source is vital for B2B buyers, as it affects portability and usability in different environments. For example, battery-operated inflators offer convenience for roadside assistance, while AC-powered units may be better suited for workshop settings.

The weight and dimensions of an inflator impact its portability and storage. Compact and lightweight models are ideal for emergency kits or vehicle storage, while larger units may offer enhanced performance but at the cost of convenience. B2B buyers should evaluate their specific needs for transportability versus power and performance.

Illustrative image related to best portable tire inflator compressor

Hose length determines the reach of the inflator and can influence usability, particularly for larger vehicles or when accessing hard-to-reach tires. A longer hose reduces the need to reposition the inflator frequently, enhancing efficiency in commercial applications such as fleet maintenance.

The type of pressure gauge (digital vs. analog) affects the ease of reading tire pressure. Digital gauges typically offer more precise readings and are easier to read, which can minimize user error. For businesses, selecting inflators with reliable gauge systems can improve operational efficiency and ensure accurate inflation.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

An OEM is a company that manufactures products or components that are sold by another company under its brand name. Understanding OEM relationships can help B2B buyers identify reputable suppliers and negotiate better pricing based on volume.

MOQ refers to the smallest quantity of product a supplier is willing to sell. This is critical for B2B buyers as it affects inventory management and cost-efficiency. Knowing the MOQ can help businesses plan their purchasing strategies and negotiate terms that align with their operational needs.

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes detailed specifications and quantities. For B2B buyers, a well-prepared RFQ can lead to competitive pricing and better supplier relationships.

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms is crucial for B2B transactions, particularly in international trade, as they dictate aspects such as risk transfer, delivery points, and cost responsibilities.

Warranty terms outline the conditions under which a product is covered for defects or issues. Understanding warranty terms is essential for B2B buyers to assess long-term value and support options, ensuring that they are protected against potential product failures.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing portable tire inflators, ultimately enhancing their operational efficiency and product reliability.

Illustrative image related to best portable tire inflator compressor

The global market for portable tire inflators is witnessing significant growth, driven by rising consumer awareness about vehicle maintenance, increasing vehicle ownership, and the growing trend of outdoor recreational activities. In regions like Africa, South America, the Middle East, and Europe, urbanization and improved infrastructure have led to a surge in vehicle usage, further amplifying the demand for effective tire maintenance solutions. B2B buyers are particularly focused on sourcing products that combine efficiency, portability, and advanced features, such as digital pressure gauges and multiple power options.

Technological advancements are reshaping the industry, with innovations in battery technology leading to more powerful and compact inflators. Cordless models are gaining traction, as they offer enhanced convenience and flexibility. Additionally, manufacturers are increasingly incorporating smart features, such as automatic shut-off and smartphone connectivity, which appeal to tech-savvy consumers and businesses alike. The growing emphasis on e-commerce and online marketplaces is also influencing sourcing strategies, enabling international buyers to access a wider range of products and competitive pricing.

International B2B buyers should remain vigilant about evolving market dynamics, including fluctuating raw material costs and the impact of global trade regulations. Understanding local market preferences and adapting to regional requirements will be crucial for successful sourcing in this sector.

Sustainability is becoming a key factor in the purchasing decisions of international B2B buyers. As environmental concerns rise, companies are increasingly prioritizing products that minimize ecological impact. For the portable tire inflator sector, this means sourcing from manufacturers that utilize eco-friendly materials and production processes. Buyers should look for inflators made with recyclable components and those that meet stringent environmental standards.

Illustrative image related to best portable tire inflator compressor

Ethical sourcing is equally important, as consumers and businesses alike demand transparency in supply chains. Companies that can demonstrate responsible sourcing practices and fair labor conditions are likely to gain a competitive edge. Certifications such as ISO 14001 for environmental management and Fair Trade practices can serve as indicators of a supplier’s commitment to sustainability.

Moreover, incorporating “green” certifications can enhance brand reputation and appeal to environmentally conscious consumers. For B2B buyers, aligning with suppliers who prioritize sustainability not only supports global environmental goals but also fosters long-term business relationships built on shared values.

The evolution of portable tire inflators has been marked by significant technological advancements and changing consumer needs. Initially, tire inflators were primarily mechanical devices that required manual operation, limiting their efficiency and usability. Over the years, the introduction of electric inflators revolutionized the market, offering faster inflation times and greater convenience.

Illustrative image related to best portable tire inflator compressor

In recent years, the focus has shifted towards portability and multifunctionality. Modern inflators are now designed to be lightweight and compact, making them ideal for both personal and professional use. Features such as built-in pressure gauges, multiple power sources, and even smart technology have become standard in high-quality models. This evolution reflects a broader trend in the automotive industry towards enhanced user experience and efficiency.

For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions. As the market continues to innovate, staying updated on the latest trends and technologies will ensure access to the most effective and reliable tire inflator solutions.

How do I choose the right portable tire inflator compressor for my business needs?

Selecting the right portable tire inflator involves assessing your specific requirements, such as tire sizes, expected usage frequency, and whether you need additional features like built-in pressure gauges or multiple power sources. For heavy-duty applications, consider inflators with higher psi capabilities, such as the Viair 88P, which is designed for larger tires. If portability is crucial, the AstroAI Cordless Tire Inflator is a great choice due to its compact size and battery operation. Always review product specifications and conduct real-world tests to ensure the inflator meets your operational needs.

What is the best portable tire inflator compressor for high-pressure tires?

For high-pressure tires, particularly in trucks and SUVs, the Viair 88P is highly recommended due to its robust design and ability to reach up to 120 psi. This inflator is efficient for off-road vehicles, making it ideal for businesses that require frequent tire inflation in rugged conditions. It’s essential to ensure that the inflator can handle the specific psi requirements of your vehicles, which may vary between models and manufacturers.

What factors should I consider when vetting suppliers for tire inflators?

When vetting suppliers, focus on their reputation, product quality, and compliance with international standards. Request samples to assess the inflators’ performance and durability. Additionally, check for certifications that validate the supplier’s commitment to quality and safety. Evaluate their manufacturing processes, customer service responsiveness, and ability to provide after-sales support. Engaging with previous customers can also provide insights into the supplier’s reliability and service levels.

What are the common payment terms for purchasing portable tire inflators in bulk?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the goods. It’s crucial to clarify these terms before finalizing any agreements and to consider options for securing your payment, such as letters of credit or escrow services, especially when dealing with international transactions.

What is the minimum order quantity (MOQ) for tire inflators?

Minimum order quantities (MOQs) for tire inflators typically range from 50 to 500 units, depending on the supplier and the specific model. It’s essential to negotiate MOQs that align with your business needs and inventory capabilities. Some suppliers may offer flexibility on MOQs for first-time buyers or larger orders, so be prepared to discuss your requirements and explore potential compromises.

Can I customize tire inflators with my brand logo?

Yes, many manufacturers offer customization options for branding, including adding your logo or specific color schemes to the inflators. Customization typically requires a minimum order quantity and may incur additional costs. It’s advisable to discuss your branding requirements during the initial conversations with suppliers to understand the available options and any related fees, ensuring that the final product aligns with your brand identity.

How can I ensure the quality of tire inflators before purchasing?

To ensure quality, request product samples for testing prior to bulk orders. Conduct thorough evaluations on performance metrics like inflation speed, accuracy, and durability under various conditions. Additionally, inquire about the supplier’s quality assurance processes, including any certifications or standards they adhere to during manufacturing. Establishing a quality inspection plan can also help maintain standards during production and shipping.

What logistics considerations should I keep in mind when importing tire inflators?

When importing tire inflators, consider shipping methods, lead times, and customs regulations in your destination country. Assess the total landed cost, including shipping, duties, and taxes, to avoid unexpected expenses. It’s advisable to work with logistics partners experienced in international trade to navigate potential challenges. Ensure that your supplier provides the necessary documentation for customs clearance to streamline the import process and avoid delays.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Dewalt Compressor – Uses the same battery as impact tools, long-lasting performance. 2. HF Maddox 12 Volt 125 PSI Compressor – Clips onto the battery, positive reviews. 3. Milwaukee M12 and M18 Compressors – Highly rated, can inflate an average tire from resting on the rim to 30 PSI in 1-2 minutes.

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: good but inexpensive portable compressor (tire inflator)

Domain: jacosuperiorproducts.com

Registered: 2014 (11 years)

Introduction: SmartPro™ Digital Tire Inflator – 100 PSI (12V DC) – $49.95 (was $79.99) – Ultra compact, powerful, and efficient portable air compressor pump designed for performance and reliability.

SmartPro 2.0™ AC/DC Digital Tire Inflator – 100 PSI (12V DC, 120V AC) – $69.95 (was $99.99) – Fast, powerful, quiet, and efficient tire inflator with automatic shut-off and inflation progress bar.

TrailPro™ Heav…

In the competitive landscape of portable tire inflators, strategic sourcing is critical for B2B buyers aiming to optimize their fleet maintenance operations. Key insights highlight the importance of selecting inflators that balance performance, portability, and user-friendly features. For instance, models like the AstroAI Cordless Tire Inflator and Craftsman 12V Max offer impressive inflation speeds and versatility, making them ideal choices for diverse markets across Africa, South America, the Middle East, and Europe.

Effective sourcing not only ensures that businesses secure high-quality products at competitive prices, but it also fosters long-term partnerships with reliable suppliers. By prioritizing inflators with robust performance metrics, such as maximum pressure capabilities and battery longevity, buyers can enhance operational efficiency and reduce downtime.

Looking ahead, the demand for portable tire inflators is expected to rise, driven by the increasing focus on vehicle maintenance and safety. International B2B buyers should leverage this trend by identifying suppliers who offer innovative solutions tailored to specific regional needs. By investing in the best portable tire inflators now, businesses can position themselves for sustained success in an evolving market.

Illustrative image related to best portable tire inflator compressor

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.