In the fast-evolving world of cycling, sourcing reliable bike tire inflators presents a unique challenge for international B2B buyers. The demand for efficient, portable, and user-friendly inflators has surged, particularly in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia. This guide delves into the complexities of the global market for bike tire inflators, examining various types, applications, and the essential criteria for supplier vetting.

As you navigate this comprehensive landscape, you will discover insights on the latest innovations in electric bike pumps, CO2 inflators, and traditional hand pumps. We will explore the cost implications associated with each type, enabling you to make informed purchasing decisions that align with your business needs. Additionally, this guide highlights critical considerations such as product durability, inflation speed, and user experience, ensuring that you choose inflators that not only meet your specifications but also enhance customer satisfaction.

By equipping yourself with the knowledge presented in this guide, you will be empowered to select the most suitable bike tire inflators for your market, optimizing your supply chain and ultimately driving sales. Join us as we explore the essential factors that will lead to successful sourcing and procurement in this dynamic sector.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Floor Pumps | Requires physical effort, large capacity, often with analog gauges | Bike shops, rental services, cycling events | Pros: Cost-effective, durable; Cons: Labor-intensive, less portable. |

| CO2 Inflators | Compact, uses pressurized CO2 cartridges for quick inflation | Emergency repair kits, racing teams | Pros: Lightweight, fast inflation; Cons: Single-use cartridges, ongoing costs. |

| Electric Pumps | Battery-operated, portable, often with digital gauges | Retailers, workshops, cycling enthusiasts | Pros: Convenient, precise pressure control; Cons: Requires charging, higher initial cost. |

| Hand Pumps | Manual operation, lightweight, compact | Individual cyclists, touring groups | Pros: Portable, no power needed; Cons: Slow inflation, often less efficient. |

| Mini Pumps | Ultra-compact, designed for emergency situations | Cyclists on long rides, bike commuters | Pros: Extremely portable, fits in pockets; Cons: Limited inflation power, slower than larger models. |

Manual floor pumps are the traditional choice for tire inflation, characterized by their large air capacity and robust build. They typically feature analog gauges for pressure readings and are well-suited for use in bike shops or rental services. B2B buyers should consider the durability and long-term cost-effectiveness of these pumps, despite their labor-intensive operation and lack of portability.

Illustrative image related to bike tire inflator

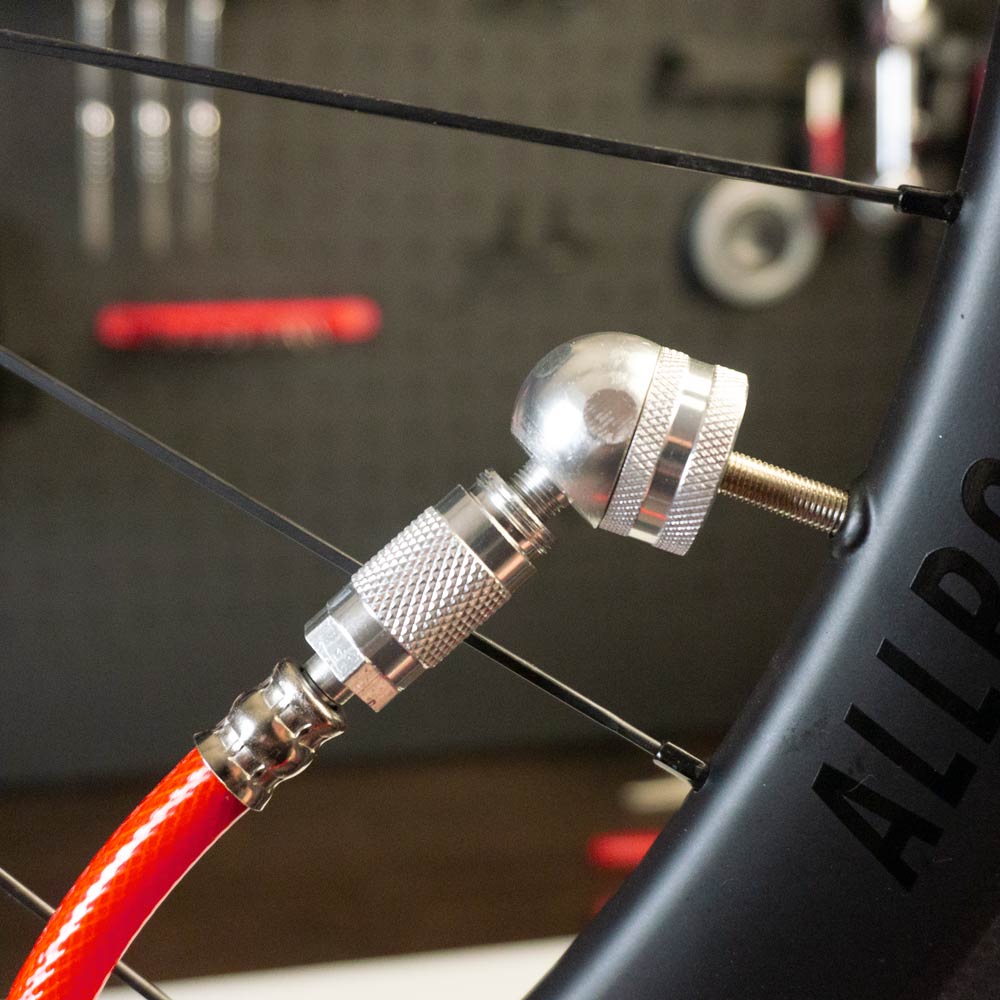

CO2 inflators are compact devices that utilize pressurized cartridges for rapid tire inflation, making them ideal for emergency repair kits and racing teams. Their lightweight design allows cyclists to carry them without added burden. However, B2B buyers should be aware of the ongoing costs associated with purchasing CO2 cartridges and the environmental implications of single-use products.

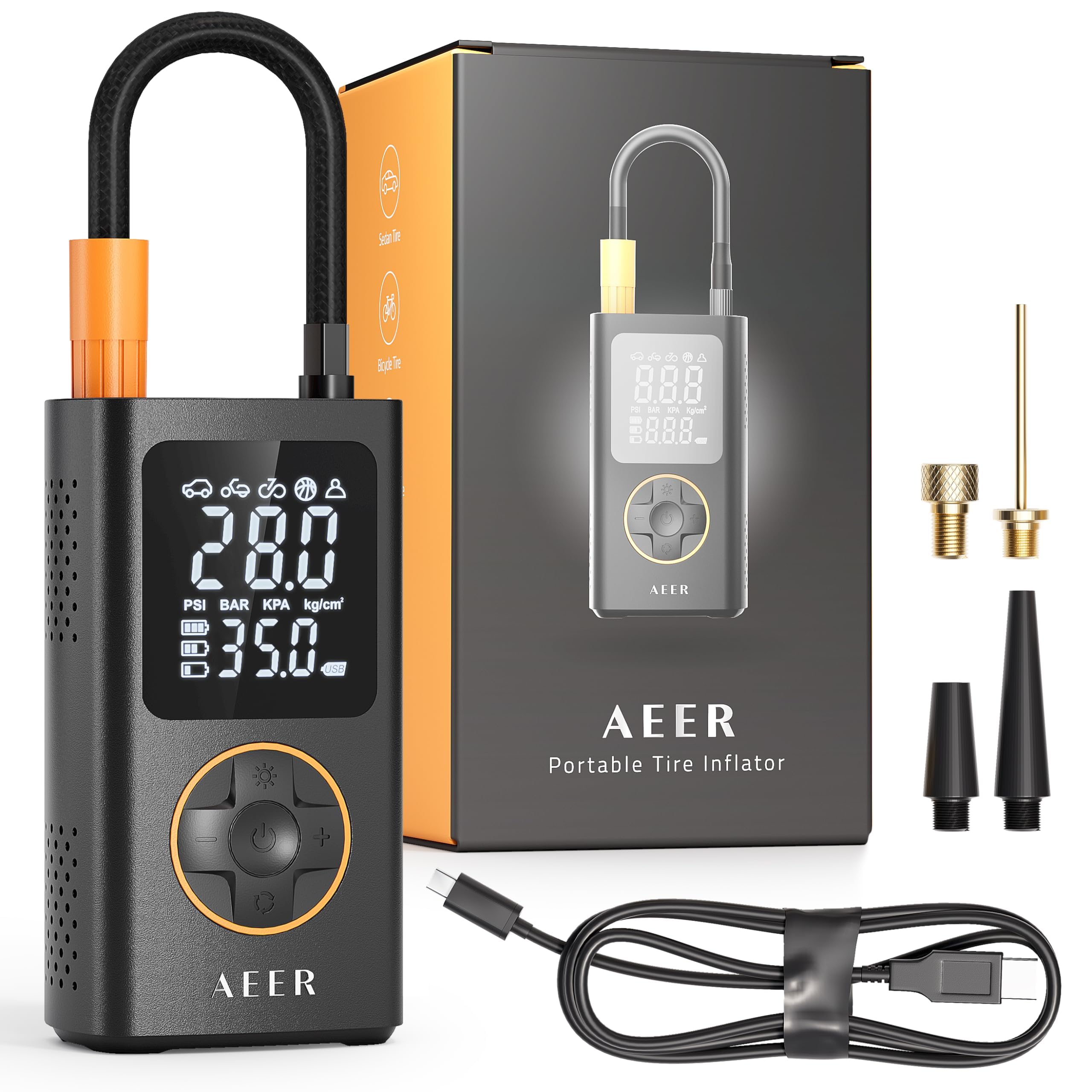

Electric pumps represent a modern solution for tire inflation, offering battery-operated convenience and often featuring digital gauges for precise pressure settings. They are increasingly popular among retailers and workshops due to their efficiency and ease of use. While the initial investment may be higher, B2B buyers benefit from their ability to streamline operations and improve customer satisfaction.

Hand pumps are lightweight and compact, making them a favorite among individual cyclists and touring groups. They require no power source, which adds to their appeal for long-distance rides. However, B2B buyers should consider their slower inflation rates and the potential for fatigue during use, especially for larger tires.

Illustrative image related to bike tire inflator

Mini pumps are ultra-compact inflators designed for emergency situations, fitting easily into pockets or small bags. They are particularly useful for cyclists who need a lightweight solution while commuting or on long rides. Despite their portability, B2B buyers must weigh their limited inflation power and slower performance against the convenience they offer.

| Industry/Sector | Specific Application of bike tire inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bicycle Manufacturing | Assembly line integration for tire inflation | Increased efficiency in production and reduced labor costs | Reliability and speed of inflation, compatibility with various tire types |

| Rental Services | Quick tire inflation for rental bicycles | Enhanced customer satisfaction through prompt service | Portability, ease of use, and battery life for outdoor operations |

| Logistics & Delivery | Maintenance of delivery bicycles in urban environments | Reduced downtime and improved delivery efficiency | Compact design, charging capabilities, and durability in diverse climates |

| Sports & Recreation | Support for cycling events and competitions | Streamlined operations for event organizers | Speed of inflation, accuracy, and multi-functional capabilities |

| Emergency Services | Rapid inflation for emergency response bicycles | Improved response times in critical situations | Reliability, battery life, and ease of storage in emergency kits |

In bicycle manufacturing, tire inflators are integrated into the assembly line to ensure tires are inflated efficiently before shipping. This automation reduces labor costs and enhances production speed. Manufacturers must consider the reliability and speed of inflation, as well as compatibility with various tire types. For international buyers, sourcing inflators that meet different regional standards and are adaptable to various tire specifications is crucial.

In rental services, bike tire inflators are essential for quickly inflating tires between rentals. This ensures that customers receive well-maintained bicycles, leading to higher satisfaction and repeat business. The inflators need to be portable, easy to operate, and have a long battery life to accommodate outdoor operations. B2B buyers from regions like Africa and South America should prioritize inflators that can withstand varying environmental conditions.

Logistics and delivery companies utilize bike tire inflators to maintain their fleet of delivery bicycles, especially in urban settings where quick service is paramount. By ensuring that tires are always properly inflated, companies can minimize downtime and improve overall delivery efficiency. Buyers in this sector should seek inflators with a compact design and robust charging capabilities to ensure reliability in diverse climates.

Illustrative image related to bike tire inflator

The sports and recreation industries leverage bike tire inflators to support cycling events and competitions, where quick and efficient tire inflation is critical. This streamlines operations for event organizers, allowing for faster setup and maintenance. Key considerations for B2B buyers include the speed of inflation, accuracy, and the ability to handle various tire types, ensuring readiness for all participants.

Bike tire inflators play a vital role in emergency services by providing rapid inflation for bicycles used in critical response situations. This capability can significantly improve response times, making it essential for emergency personnel. Buyers in this field should focus on the reliability and battery life of inflators, as well as their ease of storage in emergency kits, to ensure they are always prepared for urgent scenarios.

The Problem: B2B buyers in the cycling industry often face the challenge of inconsistent inflation performance from bike tire inflators. Retailers and distributors may receive complaints from customers about pumps that either underinflate or overinflate tires, leading to diminished riding experiences and potential safety issues. This inconsistency can stem from various factors, including low-quality materials, inadequate design, or poorly calibrated pressure gauges. Such issues not only affect customer satisfaction but also reflect poorly on the retailer’s brand reputation.

The Solution: To ensure consistent inflation performance, B2B buyers should prioritize sourcing inflators with reliable pressure calibration and robust construction. When evaluating suppliers, request product samples to test their accuracy and performance under real-world conditions. Look for inflators equipped with digital gauges, as these tend to offer more precise readings compared to analog ones. Additionally, consider suppliers that provide detailed specifications about the inflators’ pressure range and any quality certifications they might have. Implementing a return policy that allows customers to exchange malfunctioning inflators can also enhance trust in your brand.

The Problem: Many B2B buyers encounter challenges in establishing reliable supply chains for electric bike tire inflators. This is particularly true for businesses in regions with limited access to high-quality manufacturing, such as parts of Africa and South America. Fluctuations in availability, shipping delays, and quality inconsistencies can lead to stockouts, affecting the ability to meet customer demand. This situation can severely hinder a business’s growth potential and profitability.

The Solution: To mitigate supply chain issues, B2B buyers should diversify their sourcing strategies. Establish partnerships with multiple suppliers across different regions, ensuring that if one supplier faces delays, another can fulfill orders. Conduct thorough due diligence by visiting factories or utilizing third-party inspections to verify quality standards. Implement just-in-time inventory practices to reduce holding costs while maintaining enough stock to meet demand. Finally, consider leveraging logistics partners who specialize in international shipping to streamline the process and minimize delays.

The Problem: B2B buyers often find that their customers lack proper knowledge regarding the usage and maintenance of bike tire inflators. Many users fail to understand how to effectively operate the devices, leading to misuse, damage, or reduced lifespan of the inflators. This knowledge gap can result in increased customer complaints and returns, which ultimately impacts sales and customer loyalty.

The Solution: To address this issue, B2B buyers should invest in comprehensive educational resources for their customers. Develop user manuals that include clear instructions, diagrams, and troubleshooting tips. Consider creating video tutorials that visually demonstrate the proper usage and maintenance of the inflators, which can be shared on your website and social media platforms. Organizing workshops or webinars can also be beneficial, allowing customers to engage directly with experts who can answer their questions. Additionally, providing excellent customer support, such as a dedicated hotline for inflator-related inquiries, can enhance customer satisfaction and loyalty.

When selecting materials for bike tire inflators, several options are commonly considered. Each material presents unique properties, advantages, and limitations that can significantly influence product performance and marketability, especially in diverse international markets.

Aluminum is a popular choice for bike tire inflators due to its lightweight and strength. With a temperature rating that can withstand a wide range of conditions and a pressure rating suitable for high-pressure applications, aluminum is highly functional. It also exhibits good corrosion resistance, making it suitable for various environments.

Pros: Aluminum’s durability and lightweight nature enhance portability, which is crucial for consumers who prioritize convenience. It is relatively easy to manufacture, allowing for intricate designs that can improve user experience.

Cons: The primary downside is that aluminum can be more expensive than some alternatives, which may affect pricing strategies in cost-sensitive markets. Additionally, while it is resistant to corrosion, it can still be susceptible to scratches and dents.

Impact on Application: Aluminum inflators are compatible with various media, including air and CO2, making them versatile. However, they should be designed to avoid issues with heat dissipation, especially in high-use scenarios.

Illustrative image related to bike tire inflator

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, particularly concerning safety and performance. The higher initial cost may be justified by the long-term durability and reduced maintenance needs.

Plastic is often utilized in the housing and components of bike tire inflators. It offers a lightweight alternative to metals and can be engineered to provide adequate pressure ratings for low to moderate applications.

Pros: The primary advantage of plastic is its cost-effectiveness, making it attractive for budget-conscious consumers. It is also resistant to corrosion and can be molded into complex shapes, enhancing design flexibility.

Cons: However, plastic may not provide the same level of durability as metals, particularly under high-stress conditions. It can also be less heat-resistant, which may limit its performance in extreme conditions.

Impact on Application: Plastic inflators are generally suitable for air applications but may not withstand the pressures required for CO2 cartridges as effectively as metal counterparts.

Illustrative image related to bike tire inflator

Considerations for International Buyers: Buyers should be aware of the varying quality standards for plastics in different regions. Compliance with local regulations regarding materials safety is essential, especially in markets with stringent consumer protection laws.

Steel is another material option, particularly for components requiring high strength and durability. It can handle high pressure and temperature variations, making it suitable for heavy-duty applications.

Pros: Steel’s strength ensures longevity and reliability, which is appealing for users who require robust performance. It also has a lower cost compared to aluminum, making it an attractive option for manufacturers.

Cons: The downside is that steel is heavier than aluminum and plastic, which may deter consumers looking for lightweight solutions. Additionally, steel is prone to corrosion if not properly treated, which can affect its lifespan.

Impact on Application: Steel inflators are ideal for high-pressure applications but may require protective coatings to enhance corrosion resistance.

Considerations for International Buyers: In regions like South America and Europe, buyers should consider the environmental impact of steel production and disposal. Compliance with recycling regulations and sustainability practices is increasingly important.

Composite materials, often a blend of plastic and metal, are becoming more common in bike tire inflators. These materials aim to combine the benefits of both plastics and metals.

Pros: Composites can provide a lightweight solution with enhanced durability and resistance to environmental factors. They can be engineered for specific performance characteristics, making them versatile.

Cons: The manufacturing complexity can lead to higher costs, and not all composites are equally reliable under extreme conditions.

Impact on Application: Composite inflators can effectively handle various media, but their performance may vary based on the specific material formulation.

Considerations for International Buyers: Buyers should ensure that composite materials meet international safety and performance standards, especially in regions with strict regulations.

| Material | Typical Use Case for bike tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight inflators | Durable and corrosion-resistant | Higher cost compared to alternatives | Medium |

| Plastic | Budget-friendly models | Cost-effective and flexible design | Lower durability under stress | Low |

| Steel | Heavy-duty inflators | High strength and reliability | Heavier and prone to corrosion | Medium |

| Composite | Versatile applications | Lightweight with enhanced durability | Higher manufacturing complexity | High |

This analysis provides B2B buyers with a comprehensive overview of the materials used in bike tire inflators, enabling informed decision-making based on performance, cost, and regional considerations.

The manufacturing process for bike tire inflators involves several critical stages, each designed to ensure that the final product meets the performance and quality standards expected by consumers and businesses alike.

The process begins with material preparation, where high-quality plastics, metals, and electronic components are sourced. Common materials include durable thermoplastics for the casing, lightweight aluminum for components, and rubber for seals to ensure airtight performance. Suppliers must be vetted to ensure compliance with international standards, particularly regarding the sustainability and safety of raw materials.

Following material preparation, forming techniques come into play. Injection molding is typically used for the plastic components, allowing for intricate designs and ensuring consistency across units. Metal parts may be produced using processes such as stamping or CNC machining, which provide the precision needed for moving parts like pumps and gauges. This stage is critical, as any defect in component shaping can lead to performance issues later on.

Illustrative image related to bike tire inflator

The assembly stage combines all individual components into a cohesive unit. This process often employs automated assembly lines for efficiency, alongside manual labor for delicate tasks, such as attaching the digital displays or calibrating the gauges. Quality assurance checks are integrated into this stage to identify defects or misalignments early in the process, reducing waste and ensuring that products meet specifications.

Finally, the finishing stage involves surface treatments, such as painting or coating, to enhance durability and aesthetic appeal. Products may undergo additional testing to ensure they meet waterproof and shock-resistant standards. This stage also includes packaging, which must be designed to protect the inflator during shipping while also being visually appealing to attract B2B buyers.

Quality assurance (QA) is paramount in the manufacturing of bike tire inflators, ensuring that each product not only meets but exceeds customer expectations.

B2B buyers should be aware of international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that the manufacturer has effective processes in place to ensure consistent quality. In addition, certifications such as CE mark indicate compliance with European safety standards, while API certification may be relevant for manufacturers producing inflators that also cater to automotive markets.

Effective quality control (QC) is typically structured around several key checkpoints:

Incoming Quality Control (IQC): This initial stage checks the quality of raw materials and components before they enter the production line. Suppliers must provide certificates of compliance for materials to ensure they meet specified standards.

In-Process Quality Control (IPQC): During the assembly process, routine inspections are conducted to monitor the quality of components and assemblies. This includes functionality tests for mechanical parts and calibration checks for electronic components.

Final Quality Control (FQC): Once assembly is complete, the finished product undergoes a series of tests to assess performance, including pressure testing, battery life evaluations, and accuracy of digital gauges. Products that do not pass these tests are either reworked or discarded.

A variety of testing methods are employed to ensure the reliability of bike tire inflators:

Functional Testing: Each unit is tested for its ability to inflate tires to specified pressures, ensuring that both Presta and Schrader valves are accommodated.

Durability Testing: Products are subjected to stress tests that simulate real-world usage conditions, including temperature fluctuations and physical impacts.

Electrical Testing: For electric inflators, battery performance and electrical safety tests are crucial. This ensures that the inflator operates efficiently and safely under various conditions.

B2B buyers must take proactive steps to verify the QC processes of potential suppliers:

Supplier Audits: Conducting on-site audits allows buyers to observe manufacturing processes and quality control measures firsthand. This also builds relationships and trust with suppliers.

Quality Reports: Requesting documentation of quality control processes, including test results and compliance certifications, helps buyers assess supplier reliability.

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality management practices, ensuring that products meet international standards.

For international B2B buyers, understanding the nuances of quality control and certifications is vital:

Illustrative image related to bike tire inflator

Regional Standards: Different regions may have specific standards that must be met. For example, products sold in Europe must have CE marking, while those entering the U.S. market may require compliance with UL standards.

Import Regulations: Buyers must be aware of import regulations that may affect product acceptance in their country. This includes tariffs, safety standards, and documentation requirements.

Cultural Considerations: Building relationships with suppliers from different regions may require understanding cultural nuances in business practices, communication styles, and negotiation tactics.

By understanding the manufacturing processes and quality assurance measures for bike tire inflators, B2B buyers can make informed decisions that ensure product reliability, safety, and compliance with international standards. This knowledge not only helps in selecting quality suppliers but also in establishing long-term partnerships that contribute to business success in the competitive bike accessory market.

This sourcing guide is designed to assist B2B buyers in the procurement of bike tire inflators, ensuring that you make informed decisions that align with your operational needs and market demands. By following this checklist, you can streamline your purchasing process and secure high-quality products that meet the expectations of your clientele.

Establishing clear technical specifications is the foundation of your procurement process. Consider the types of bikes your customers use, the valve types (Presta or Schrader), and the desired inflation pressure range. Additionally, evaluate the inflator’s size and weight, particularly if portability is a key factor for your target market.

Illustrative image related to bike tire inflator

Understanding current market trends is essential to ensure your product offering remains relevant. Investigate consumer preferences in your target regions, such as Africa, South America, the Middle East, and Europe. Pay attention to features like electric versus manual inflators, digital gauges, and eco-friendly options, as these can influence purchasing decisions.

Before committing to a supplier, conducting thorough evaluations is crucial. Request company profiles, product catalogs, and references from other buyers within similar industries. Look for suppliers with a proven track record in delivering reliable inflators, and consider their experience in your target markets to ensure they understand local needs.

Ensure that the products meet industry standards and regulatory requirements. This may include certifications related to safety, environmental impact, and quality control. Verify if the inflators comply with international norms, especially if you plan to distribute in multiple regions, to avoid legal issues and enhance customer trust.

Pricing is a critical factor in your sourcing decision. Compare prices from different suppliers while considering the quality of the products offered. Additionally, negotiate payment terms that align with your cash flow needs, such as discounts for bulk purchases or favorable credit terms, which can enhance your profitability.

Illustrative image related to bike tire inflator

Before finalizing any purchase, request samples to evaluate the inflators’ performance. Testing their ease of use, inflation speed, and accuracy will provide insights into their reliability and customer satisfaction potential. Ensure that the samples meet the specifications you’ve defined in earlier steps.

Finally, develop a robust supply chain strategy to ensure timely delivery and inventory management. Identify logistics partners that can efficiently handle your shipments, especially considering the geographical challenges in regions like Africa and South America. Establishing a clear communication channel with your suppliers will also help mitigate potential delays and issues.

By following this step-by-step checklist, you can effectively navigate the procurement process for bike tire inflators, ensuring that you meet the demands of your business and your customers.

When sourcing bike tire inflators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly impacts the cost. High-quality plastics and metals used in the construction of inflators can elevate the price, while cheaper alternatives may compromise durability.

Labor: Labor costs can vary based on the manufacturing location. Countries with lower wage rates may offer more competitive pricing, but this can also affect the quality of craftsmanship.

Manufacturing Overhead: This includes costs related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead, but these efficiencies often depend on the scale of production.

Tooling: The initial investment in tooling is substantial, particularly for custom designs. Buyers should inquire about tooling costs, especially if they’re considering a unique model.

Quality Control (QC): Ensuring that each unit meets quality standards incurs costs. Companies that prioritize QC may charge more but can offer better reliability and performance.

Logistics: Shipping and handling costs are integral to the total price. International shipping can add significant expenses, especially if there are delays or customs issues.

Margin: Suppliers typically add a profit margin to their costs, which can vary widely. Understanding the market and potential supplier margins can assist in negotiating better deals.

Several factors influence pricing, particularly for international B2B buyers:

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts. Buyers should evaluate their needs to determine the optimal order size that balances cost savings with inventory management.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether these enhancements provide sufficient value to justify the additional expense.

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO standards) often come at a premium. Buyers should weigh the benefits of quality against their budget constraints.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more but can reduce the risk of defects and returns.

Incoterms: The terms of delivery can significantly affect the total cost. Understanding responsibilities for shipping, insurance, and customs clearance is essential in negotiating prices.

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost efficiencies:

Research and Benchmarking: Conduct thorough market research to understand standard pricing for similar products. This knowledge can bolster your negotiation position.

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price, but also logistics, maintenance, and potential replacements. A higher upfront cost may be justified if the product offers long-term savings.

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Discuss options like extended payment periods or installment payments to lessen the immediate financial burden.

Build Relationships: Establishing a rapport with suppliers can lead to better terms and preferential pricing over time. Regular communication and feedback can foster mutual benefits.

Understand Pricing Nuances: Be aware of regional pricing variations and adjust your strategies accordingly. For instance, tariffs, taxes, and currency fluctuations can all impact final costs.

It is essential to note that prices for bike tire inflators can fluctuate based on market conditions, supplier negotiations, and currency exchange rates. The figures mentioned in this analysis are indicative and should be verified with suppliers for accurate pricing.

Illustrative image related to bike tire inflator

In today’s market, businesses have a variety of options when it comes to inflating bike tires. While bike tire inflators are becoming increasingly popular due to their convenience and efficiency, it’s essential to consider other viable solutions that may better suit specific needs. This analysis will compare bike tire inflators with traditional floor pumps and CO2 inflators, providing B2B buyers with a comprehensive overview of each option.

| Comparison Aspect | Bike Tire Inflator | Traditional Floor Pump | CO2 Inflator |

|---|---|---|---|

| Performance | Quick inflation with digital accuracy; suitable for various tire sizes. | Slower inflation; requires manual effort; less accurate without a gauge. | Fast inflation for emergencies; limited to one-time use per cartridge. |

| Cost | Ranges from $50 to $130, depending on features and brand. | Typically $60 to $150, depending on quality and features. | Costs around $30 for the inflator; cartridges about $10 for a 3-pack. |

| Ease of Implementation | Simple to use; often portable with rechargeable batteries. | Requires more physical effort; less portable. | Very easy to use; requires no physical effort, but limited in capacity. |

| Maintenance | Minimal; occasional battery charging required. | Regular maintenance needed to ensure functionality. | Low; disposable cartridges mean no ongoing maintenance but recurring costs. |

| Best Use Case | Ideal for both home use and on-the-go; perfect for frequent cyclists. | Best for stationary use; suitable for those who prefer manual inflation. | Excellent for emergencies and short rides; not ideal for regular use. |

Traditional floor pumps are a staple in many cyclists’ garages. They provide a reliable way to inflate tires, especially when combined with a digital gauge for accuracy. However, they require physical effort and time, making them less suitable for quick fixes on the road. Their bulkiness also limits portability, which can be a disadvantage for mobile cyclists. Additionally, the performance can vary based on the model, and lower-quality pumps may not provide accurate readings.

CO2 inflators are an excellent option for quick inflation during emergencies, especially for competitive cyclists who need to minimize downtime. These inflators are lightweight and easy to carry, making them ideal for races or long rides. However, they come with limitations, such as the need to purchase and carry additional cartridges. Once a cartridge is used, it cannot be reused, leading to ongoing costs. Furthermore, CO2 inflation can be less precise than other methods, potentially leading to over or under-inflation.

Illustrative image related to bike tire inflator

When selecting a bike tire inflation solution, B2B buyers should consider their specific operational needs, frequency of use, and the environments in which they operate. If quick, accurate inflation is a priority, a bike tire inflator may be the best option due to its efficiency and ease of use. For businesses that require a reliable, stationary solution, traditional floor pumps might suffice. Alternatively, CO2 inflators are perfect for emergency kits but may not be suitable for regular use due to cost and limitations. Ultimately, understanding the unique requirements of your business will guide the right choice in tire inflation solutions.

When sourcing bike tire inflators for B2B purposes, understanding the essential technical specifications is critical. Here are some of the most important properties to consider:

The maximum inflation pressure capacity, measured in PSI (pounds per square inch), indicates how much pressure the inflator can deliver. For example, a quality bike tire inflator may have a capacity of up to 120 PSI, making it suitable for various bike types, including road and mountain bikes. This specification is crucial for B2B buyers as it determines the compatibility of the inflator with different tire sizes and types.

Battery life refers to how many inflations can be completed on a single charge, while recharge time indicates how long it takes to restore the battery. For example, a bike tire inflator that can fully inflate a tire three times on a single charge and recharges within an hour offers significant operational efficiency. This is particularly important for businesses that require quick turnaround times in service environments.

Illustrative image related to bike tire inflator

The weight of the inflator affects its portability, which is especially relevant for cyclists who carry their inflators during rides. A lightweight model, ideally around 150 grams, can easily fit in a saddlebag, making it more attractive to consumers. B2B buyers should consider this property when targeting markets where portability is a key selling point.

The materials used in the construction of the inflator impact its durability and performance. High-grade plastics or aluminum alloys are often preferred for their resilience and lightweight characteristics. Understanding material specifications is vital for B2B buyers looking to ensure product longevity and reliability in various environmental conditions.

A built-in digital gauge provides real-time pressure readings, allowing for precise inflation. Accuracy within ±1 PSI is ideal for performance-oriented cyclists. This feature not only enhances user experience but also reduces the risk of over-inflation, which can lead to tire damage. For B2B buyers, promoting this feature can help differentiate products in a competitive market.

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms:

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, knowing the OEM can provide insight into the quality and reliability of the inflators, as well as possible customization options.

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding the MOQ is critical for B2B buyers to plan inventory levels and negotiate better pricing based on larger orders.

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. For B2B transactions, submitting an RFQ helps buyers gather competitive offers and streamline the procurement process.

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risk management, and delivery responsibilities.

An SKU is a unique identifier for each distinct product and service that can be purchased. In the context of bike tire inflators, using SKUs helps businesses efficiently manage inventory and streamline sales processes.

Illustrative image related to bike tire inflator

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for B2B buyers to manage supply chain expectations and ensure timely availability of products.

By grasping these technical properties and industry terminology, B2B buyers can make informed decisions, ensuring they select the right bike tire inflators that meet their business needs and customer expectations.

The bike tire inflator market is witnessing significant growth driven by several global trends. The increasing popularity of cycling as a sustainable mode of transportation and recreational activity has amplified the demand for efficient and portable tire inflators. Emerging markets in Africa and South America, particularly countries like Nigeria and Brazil, are seeing a surge in cycling culture, spurred by urbanization and a growing middle class seeking affordable transportation solutions. In the Middle East, countries like Saudi Arabia are investing in cycling infrastructure as part of broader health and fitness initiatives, further driving the demand for high-quality tire inflators.

Illustrative image related to bike tire inflator

Technological advancements are also reshaping the market, with electric and digital inflators gaining popularity due to their convenience and efficiency. Innovations in battery technology have led to more compact and lightweight models that are easy to transport, appealing to both casual cyclists and enthusiasts. Furthermore, B2B buyers are increasingly seeking products that offer enhanced features such as built-in digital gauges and multi-functionality (e.g., compatibility with various valve types), which are crucial for meeting diverse customer needs.

Additionally, the rise of e-commerce platforms is transforming sourcing strategies, enabling international buyers to access a wider range of suppliers and products. This trend is particularly relevant for buyers in regions with developing markets, where traditional distribution channels may be less established.

As environmental concerns become increasingly prominent, sustainability and ethical sourcing have emerged as critical considerations in the bike tire inflator sector. B2B buyers are increasingly prioritizing products that minimize environmental impact, which includes the use of sustainable materials and environmentally friendly manufacturing processes. Companies that adopt green certifications, such as ISO 14001 for environmental management, are likely to gain a competitive edge in the market.

The production of bike tire inflators often involves the use of plastics and metals, which can have significant environmental repercussions if not sourced responsibly. Suppliers that utilize recycled materials or implement energy-efficient manufacturing practices are becoming more attractive to buyers focused on corporate social responsibility. Additionally, the demand for products that are durable and repairable is rising, as they contribute to reduced waste and longer product lifecycles.

Ethical supply chains are also gaining importance. Buyers are looking for transparency in sourcing practices to ensure that materials are obtained without exploiting labor or harming communities. This shift toward ethical sourcing not only aligns with consumer values but also mitigates risks associated with supply chain disruptions and reputational damage.

Illustrative image related to bike tire inflator

The evolution of bike tire inflators dates back to the early days of cycling, where manual pumps were the only option available. Traditional floor pumps and hand pumps dominated the market for decades, relying on manual labor to inflate tires. However, as cycling gained popularity and technology advanced, the demand for more efficient solutions led to the development of CO2 inflators in the late 20th century. These provided a quick fix for flat tires, albeit with limitations related to sustainability and ongoing costs associated with cartridges.

The 21st century has ushered in a new era of electric tire inflators, which combine the ease of use with improved efficiency and environmental considerations. These innovations have not only transformed the way cyclists approach tire maintenance but have also opened up new opportunities for B2B suppliers to cater to a diverse and expanding market. Today’s electric inflators are compact, lightweight, and equipped with features that enhance user experience, reflecting the evolving needs and preferences of cyclists globally.

How do I choose the right bike tire inflator for my business needs?

When selecting a bike tire inflator, consider factors such as inflation speed, size, weight, and compatibility with various valve types (Presta and Schrader). Assess the capacity to inflate multiple tires on a single charge, as this can impact efficiency for your customers. Additionally, look for features like digital gauges for precision and ease of use. It’s also wise to evaluate the brand’s reputation and warranty options, ensuring that you are sourcing a reliable product that meets your quality standards.

What is the best type of bike tire inflator for retail purposes?

Electric bike tire inflators are increasingly popular for retail due to their convenience and efficiency. Models that are compact, lightweight, and equipped with digital gauges tend to attract customers, as they simplify the inflation process. Brands like Cycplus, RockBros, and Airbank have gained positive reviews for their performance and portability. Offering a range of models at different price points can cater to various customer segments, enhancing your retail strategy.

What should I consider when vetting suppliers for bike tire inflators?

When vetting suppliers, prioritize their manufacturing capabilities, quality control processes, and compliance with international standards. Request samples to evaluate product quality firsthand. Additionally, inquire about their experience in exporting to your target regions, such as Africa or South America, and check their references or customer testimonials. Assess their communication responsiveness and willingness to accommodate customization requests, which can indicate their reliability as a business partner.

What are the typical minimum order quantities (MOQ) for bike tire inflators?

MOQs for bike tire inflators can vary significantly based on the supplier and the product specifications. Generally, MOQs range from 100 to 1,000 units. For customized products, the MOQ may be higher due to the additional setup and manufacturing costs. It’s advisable to discuss your business needs with potential suppliers to negotiate favorable terms that align with your market entry strategy.

How can I ensure the quality of bike tire inflators I source?

To ensure quality, request certifications that demonstrate compliance with safety and performance standards, such as ISO or CE markings. Conduct factory audits or use third-party inspection services to verify manufacturing processes. Implement a quality assurance plan that includes pre-shipment inspections and clearly defined return policies. Building a strong relationship with your supplier can also facilitate better quality control and communication.

What are the common payment terms when sourcing bike tire inflators internationally?

Payment terms can vary, but common practices include a deposit (typically 30%) upfront, with the balance due before shipment. Some suppliers may offer letters of credit or payment through platforms like PayPal or escrow services for added security. Always clarify payment terms before finalizing contracts to avoid misunderstandings and ensure a smooth transaction process.

What logistics considerations should I keep in mind when importing bike tire inflators?

When importing, consider shipping methods (air vs. sea), lead times, and customs regulations specific to your target markets. Engage with logistics partners who have experience in handling bike accessories to facilitate smooth transportation. Ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared to avoid customs delays. Additionally, factor in costs related to duties and taxes when budgeting your overall expenses.

How can I customize bike tire inflators for my brand?

Customization options typically include branding (logos and colors), packaging design, and specific features tailored to your target market. Discuss your customization needs with potential suppliers early in the negotiation process. Some manufacturers may require higher MOQs for customized products due to additional production setups. Ensure clear communication regarding timelines and costs associated with customization to align with your business goals.

Domain: planetbike.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘ALX 2.0 bike floor pump’, ‘price’: ‘$60.00’}, {‘name’: ’20g CO2 replacement cartridges – threaded’, ‘price’: ‘$15.00 – $55.00’}, {‘name’: ‘Red Zeppelin CO2 bike tire inflator’, ‘price’: ‘$20.00’}, {‘name’: ‘Comp 2.0 bike floor pump’, ‘price’: ‘$30.00’}, {‘name’: ‘STX bike floor pump’, ‘price’: ‘$55.00’}, {‘name’: ‘Fresh Air mini pump’, ‘price’: ‘$20.00’}, {‘name’: ‘Shockmate 3.0 bike su…

Domain: cycplus.com

Registered: 2017 (8 years)

Introduction: {“products”:[{“name”:”AS2 Ultra Tiny E-pump for Bike”,”regular_price”:”$119.00″},{“name”:”AS2 Pro Tiny E-Pump For Bike”,”regular_price”:”$109.00″,”discount”:”12% OFF”,”sale_price”:”$114.00″},{“name”:”AS2 Pro Max Tiny E-Pump For Bike”,”regular_price”:”$129.00″,”sale_price”:”$114.00″},{“name”:”AS2 Tiny E-Pump For Bike”,”regular_price”:”$89.00″},{“name”:”Electric Air Pump A2 Pro”,”regular_price”:”$49…

Domain: intheknowcycling.com

Registered: 2013 (12 years)

Introduction: The best electric bike pumps are compact, easy to use, and accurate, replacing traditional inflation tools like floor pumps, CO2 inflators, and hand pumps. They weigh around 150 grams (5½ ounces) and cost between $50 and $75. These pumps can fully inflate a flat 28mm road tire to 70 psi or a 40mm gravel tire to 45 psi in about a minute, with the ability to do this 3 to 4 times on a full charge. Th…

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall Floor Pump: Silca Terra

Best Cheap Pump: Vibrelli Bike Floor Pump

Best Value Floor Pump: Specialized Air Tool Comp

Best Value Electric Mini Inflator: Cycplus Electric Mini Pump with Gauge

Best Mini Pump: Topeak Mountain DA Mini

Vibrelli Bike Floor Pump:

– Height: 2 feet

– Weight: 2.75 pounds

– Accurate gauge up to 100 psi (max 160 psi)

– Best for road and thin gravel tires

– Not ide…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Topeak Mini Morph: small, lightweight, functions as a floor pump, suitable for 700C×45 gravel tires; Lezyne Pocket Drive: compact and portable; Nano electric pumps (NanoFumpa, Cyclists Nano, RockBros): under 100g, very small, can fill 2 gravel tires.

Domain: rei.com

Registered: 1996 (29 years)

Introduction: Bike Pumps: Portable, Hand, Mini Bicycle Pumps

Domain: ridepdw.com

Registered: 2008 (17 years)

Introduction: Timber to Town: Cloud Cap CO2 Inflator – $39.00; Shiny Object – from $19.00; Tiny Object – $22.00; Fatty Object – from $19.00; Timber to Town: Cloud Cap Gravel Pump + CO2 Inflator – $89.00; Ninja Pump – $35.00; 38g CO2 Cartridge – $15.00; 16g CO2 Cartridge – Packs from $10.00; Leather CO2 Cartridge Sleeve – $5.00; Pump Mount – $5.00; Shiny Object Rebuild Kit – $4.00; Tiny Object Rebuild Kit – $4.0…

In conclusion, the evolving landscape of bike tire inflators presents significant opportunities for international B2B buyers, particularly those in emerging markets across Africa, South America, the Middle East, and Europe. The shift towards electric inflators, which offer superior efficiency, portability, and user-friendliness, underscores the importance of strategic sourcing in this sector. By prioritizing quality, innovation, and supplier reliability, businesses can enhance their product offerings and cater to the growing demand for high-performance cycling accessories.

As the global cycling market continues to expand, particularly in regions with increasing urbanization and a rising interest in sustainable transportation, the potential for growth in the bike tire inflator segment is substantial. Buyers should leverage data-driven insights to identify trends and make informed purchasing decisions that align with their customers’ needs.

Now is the time to engage with reliable manufacturers and suppliers who can provide cutting-edge solutions. By investing in strategic sourcing practices, businesses can position themselves advantageously in the competitive landscape, ensuring they meet the demands of an evolving market. Embrace the future of bike tire inflators and capitalize on the opportunities that lie ahead.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to bike tire inflator