In today’s competitive landscape, sourcing a reliable 12V air compressor can pose significant challenges for international B2B buyers. With diverse applications ranging from vehicle tire inflation to powering air suspension systems, understanding the variety of options available is crucial. This guide aims to equip businesses from Africa, South America, the Middle East, and Europe—countries such as Vietnam and Germany—with the knowledge needed to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore various types of 12V air compressors, their specific applications, and the essential factors to consider during the selection process. We will also delve into effective supplier vetting strategies to ensure quality and reliability, as well as provide insights into pricing structures to help you gauge the best value for your investment.

By addressing common pain points and offering actionable insights, this guide empowers B2B buyers to navigate the complexities of the global market confidently. With a deeper understanding of performance specifications, duty cycles, and additional features, businesses can optimize their operations and enhance their service offerings. The knowledge contained within this guide positions you to make strategic decisions that can lead to long-term success in a fast-paced and evolving marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Onboard Compressors | High PSI (up to 200), designed for continuous duty | Air suspension systems, tire inflation | Pros: Reliable performance, durable; Cons: Higher cost, requires installation. |

| Portable Dual Compressors | Lightweight, fast inflation rates (up to 10.6 CFM) | Recreational vehicles, emergency tire inflation | Pros: Easy to transport, versatile; Cons: Lower maximum pressure compared to heavy-duty. |

| Industrial 12V Compressors | Built for heavy-duty applications, high CFM output | Manufacturing, automotive service centers | Pros: High efficiency, suitable for air tools; Cons: Bulkier, higher power consumption. |

| Compact 12V Compressors | Small size, basic functionality, lower PSI | Light-duty tasks, small equipment inflation | Pros: Cost-effective, portable; Cons: Limited power and performance. |

| Military-Grade Compressors | Rugged design, high durability, often weather-resistant | Military operations, off-road vehicles | Pros: Extremely durable, reliable under tough conditions; Cons: Premium pricing, specialized use. |

Heavy-duty onboard air compressors are characterized by their ability to deliver high pressure (up to 200 PSI) and are specifically engineered for continuous operation. They are predominantly used in air suspension systems, tire inflation, and powering air horns in vehicles. B2B buyers should consider their durability and performance, making them ideal for industries that require consistent air supply. However, the installation requirement and higher upfront costs may deter some buyers.

Portable dual compressors are designed for versatility, offering fast inflation rates and the ability to inflate multiple tires simultaneously. With a flow rate of up to 10.6 CFM, these compressors are ideal for recreational vehicles and emergency situations. Their lightweight design and ease of transport make them attractive to B2B buyers in sectors like automotive services and outdoor recreation. However, potential buyers must balance the convenience with the lower maximum pressure output compared to heavy-duty models.

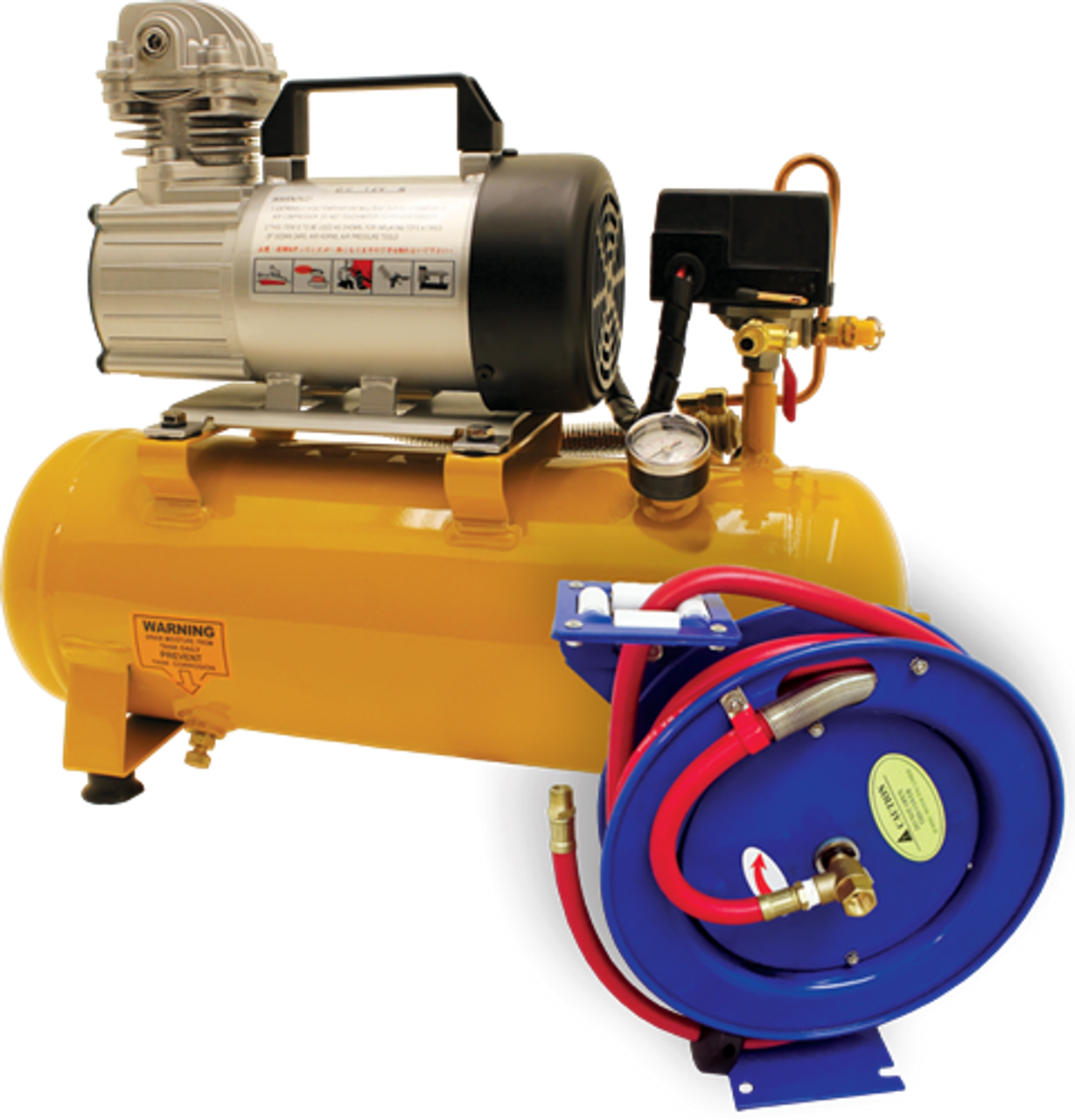

Illustrative image related to air compressor 12v

Industrial 12V compressors are robust machines built for heavy-duty applications, featuring high CFM outputs suitable for powering air tools and equipment in manufacturing settings. Their efficiency and reliability make them essential in automotive service centers and manufacturing plants. When considering a purchase, B2B buyers should evaluate the compressor’s capacity to handle continuous use, although the bulkier design and higher power consumption may pose logistical challenges.

Compact 12V compressors are smaller in size and generally provide basic functionality, ideal for light-duty tasks such as inflating small equipment or recreational gear. They are cost-effective and portable, making them suitable for small businesses or individual contractors. However, their limited power and performance capabilities may restrict their use in more demanding applications, which is a critical consideration for B2B buyers looking for efficiency and reliability.

Military-grade compressors are designed for rugged environments, offering high durability and weather resistance. They are commonly used in military operations and off-road vehicles, where reliability under extreme conditions is paramount. B2B buyers in sectors requiring specialized equipment should weigh the benefits of these compressors against their premium pricing and niche applications, ensuring they meet specific operational needs without compromising performance.

| Industry/Sector | Specific Application of air compressor 12v | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Tire Inflation for Fleet Vehicles | Enhances vehicle uptime and safety through quick inflation. | Look for high CFM ratings and portability for easy deployment. |

| Construction | Powering Air Tools for On-Site Work | Increases productivity by enabling the use of pneumatic tools. | Ensure compatibility with various air tools and a robust duty cycle. |

| Agriculture | Operating Air-Powered Equipment for Irrigation Systems | Improves efficiency and reduces manual labor in farming tasks. | Consider durability and resistance to environmental conditions. |

| Recreational Vehicles (RV) | Inflating Air Mattresses and Equipment | Provides convenience for outdoor activities and travel. | Lightweight, portable models with quick-connect features are ideal. |

| Emergency Services | Running Air Compressors for Rescue Tools | Ensures readiness in critical situations, enhancing response time. | Reliability and ease of maintenance are crucial for operational efficiency. |

In the automotive sector, 12V air compressors are essential for tire inflation in fleet vehicles. Quick and efficient tire inflation minimizes downtime, ensuring vehicles remain operational and safe on the road. Fleet managers must consider the compressor’s CFM rating to ensure rapid inflation capabilities, as well as its portability for easy access in various locations. For international buyers, sourcing compressors that are compatible with local vehicle power systems is also critical to avoid operational challenges.

In construction, 12V air compressors are used to power pneumatic tools such as nail guns and impact wrenches. This application significantly boosts productivity on job sites by providing a reliable air source without the need for bulky, stationary compressors. Buyers should focus on compressors with a robust duty cycle to support continuous use throughout the workday. Additionally, compatibility with a variety of air tools is vital for versatility, especially in regions where tool standards may differ.

Agriculture utilizes 12V air compressors to operate air-powered equipment for irrigation systems and other farming tasks. These compressors help improve operational efficiency by automating processes that would otherwise require manual labor. For agricultural buyers, durability against harsh environmental conditions is a key consideration, as well as the compressor’s ability to deliver consistent pressure for extended periods. Sourcing compressors that can withstand varying climates is essential for maximizing their utility.

Recreational vehicle (RV) owners rely on 12V air compressors to inflate air mattresses, sports equipment, and other inflatable items while on the go. The convenience of having a portable compressor enhances the overall travel experience, making it easier to set up and enjoy outdoor activities. Buyers should prioritize lightweight models that feature quick-connect attachments for various inflatables. Additionally, the ability to operate directly from the vehicle’s battery is crucial for ease of use during trips.

Illustrative image related to air compressor 12v

In emergency services, 12V air compressors are vital for powering rescue tools, ensuring that first responders can operate effectively in critical situations. The reliability of these compressors can significantly impact response times, making them a crucial investment for emergency service providers. When sourcing compressors for this application, it’s important to consider features such as ease of maintenance and operational reliability, as these factors directly affect performance in high-pressure scenarios.

The Problem: Many B2B buyers in industries such as automotive repair and construction face the challenge of inconsistent air pressure delivery from their 12V air compressors. This inconsistency can lead to inefficiencies, especially when inflating tires or using pneumatic tools. For instance, a compressor that fails to maintain the required PSI can result in inadequate tire inflation, compromising safety and performance, or can cause pneumatic tools to underperform, leading to project delays and increased labor costs.

The Solution: To mitigate this issue, buyers should prioritize the selection of air compressors with a proven track record for consistent pressure output. When sourcing 12V air compressors, look for models with specifications that explicitly mention a constant duty cycle and stable PSI ratings. Additionally, consider investing in compressors that come with built-in pressure regulators. These devices ensure that air pressure remains stable during operation, regardless of the load. It is also advisable to conduct a thorough comparison of various brands, checking for reviews and testimonials from users in similar industries to ensure reliability and performance.

The Problem: For businesses that require mobility—such as roadside assistance services or outdoor event setups—limited portability of 12V air compressors can be a significant pain point. Heavy or bulky compressors can hinder quick response times and complicate logistics, ultimately impacting customer satisfaction and operational efficiency.

The Solution: To address portability issues, B2B buyers should look for lightweight, compact models designed specifically for on-the-go applications. When evaluating options, prioritize features such as a carrying case, battery clamps for easy connection, and a lightweight design. Additionally, consider compressors that include quick-disconnect wiring harnesses, allowing for easy installation and removal. Brands that offer robust warranties and customer support can provide further assurance of product reliability, which is critical for businesses that rely on their equipment in the field.

Illustrative image related to air compressor 12v

The Problem: Many users of 12V air compressors encounter problems with overheating, particularly during extended use, which can lead to equipment failure and downtime. This is especially problematic for businesses that depend on air compressors for long periods, such as in manufacturing or automotive workshops. Overheating not only affects the longevity of the compressor but also leads to increased maintenance costs and operational inefficiencies.

The Solution: To combat overheating issues, B2B buyers should focus on compressors with a high duty cycle rating and built-in thermal protection features. A compressor with a duty cycle of at least 50% is preferable, as it allows for longer operational periods before requiring a cooldown. Additionally, selecting compressors with advanced cooling systems or those specifically designed for continuous operation can significantly reduce the risk of overheating. Buyers should also implement a regular maintenance schedule, which includes checking for blockages in air filters and ensuring that the compressor is used in well-ventilated areas. This proactive approach not only enhances performance but also prolongs the equipment’s lifespan, resulting in lower long-term costs.

When selecting materials for 12V air compressors, it’s essential to consider properties that directly impact performance, durability, and cost. Here we analyze four common materials used in the construction of these compressors: aluminum, steel, plastic, and rubber.

Aluminum is widely used in the housing and components of air compressors due to its lightweight and corrosion-resistant properties. With a temperature rating of up to 200°C and a high strength-to-weight ratio, aluminum is suitable for portable applications.

Pros: Aluminum is durable and resistant to corrosion, making it ideal for outdoor and rugged use. Its lightweight nature enhances portability, which is a significant advantage for users in remote areas.

Cons: However, aluminum can be more expensive than other materials and may require more complex manufacturing processes, such as extrusion or casting, which can increase production costs.

Impact on Application: Aluminum’s corrosion resistance makes it compatible with various media, including air and water vapor, which is vital for compressors used in humid environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM and DIN for aluminum grades, especially in regions like Europe and the Middle East, where material specifications are stringent.

Steel is another prevalent material, primarily used for structural components and pressure vessels in air compressors. It can withstand high pressures (up to 300 PSI) and has excellent durability.

Pros: Steel offers high tensile strength and durability, making it suitable for heavy-duty applications. It is also relatively cost-effective compared to aluminum.

Illustrative image related to air compressor 12v

Cons: On the downside, steel is heavier and more susceptible to corrosion unless treated or coated. This can limit portability, which is a consideration for users in regions with challenging terrains.

Impact on Application: Steel is ideal for applications requiring high pressure and durability, such as powering air tools or inflating large tires.

Considerations for International Buyers: Compliance with standards such as JIS and ASTM is crucial, particularly in regions like South America and Africa, where the quality of steel can vary significantly.

Plastic is often used in non-structural components, such as housing for electrical parts and gauges. Its lightweight and moldability make it an attractive option for manufacturers.

Illustrative image related to air compressor 12v

Pros: Plastic is cost-effective and can be produced in various colors and shapes, allowing for aesthetic customization. It is also resistant to corrosion and can be made to withstand moderate temperatures.

Cons: However, plastic lacks the durability and temperature resistance of metals, making it less suitable for high-pressure applications.

Impact on Application: Plastic components are typically used for low-pressure applications and are compatible with air and non-corrosive gases.

Considerations for International Buyers: Buyers should look for plastics that meet relevant safety and environmental standards, especially in Europe, where regulations around materials are stringent.

Rubber is primarily used for seals, hoses, and gaskets in air compressors. It provides flexibility and excellent sealing properties, essential for maintaining pressure.

Illustrative image related to air compressor 12v

Pros: Rubber is highly elastic and can withstand a range of temperatures, making it suitable for various applications. It also offers good resistance to wear and tear.

Cons: The main drawback of rubber is its susceptibility to degradation from UV light and ozone, which can limit its lifespan in outdoor applications.

Impact on Application: Rubber seals and hoses are critical for ensuring airtight connections, especially in compressors used in mobile applications.

Considerations for International Buyers: Buyers should consider the type of rubber used, as different grades may be required based on climate and application, particularly in regions like Africa and the Middle East, where temperature variations are significant.

| Material | Typical Use Case for air compressor 12v | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and components | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Structural components and pressure vessels | High strength and durability | Heavier and prone to corrosion | Low |

| Plastic | Non-structural components | Cost-effective and moldable | Less durable and temperature resistant | Low |

| Rubber | Seals, hoses, and gaskets | Excellent sealing properties | Degrades under UV light and ozone | Medium |

This guide provides a comprehensive overview of material selection for 12V air compressors, helping international B2B buyers make informed decisions based on performance, durability, and compliance with regional standards.

Illustrative image related to air compressor 12v

The manufacturing process of 12V air compressors involves several critical stages that ensure quality, efficiency, and reliability. Understanding these stages can help B2B buyers make informed purchasing decisions.

The manufacturing process begins with the selection of high-quality raw materials. Common materials for 12V air compressors include aluminum, steel, and various polymers. Aluminum is often used for the compressor body due to its lightweight and corrosion-resistant properties. Steel may be utilized for internal components that require strength and durability.

Material preparation involves cutting, machining, and treating these materials to achieve the desired specifications. For instance, aluminum may undergo anodizing to enhance corrosion resistance, while steel components may be galvanized to prevent rust. Ensuring the right material properties is crucial for the compressor’s performance and longevity.

Illustrative image related to air compressor 12v

The forming stage involves several techniques to create the individual components of the air compressor. Common methods include casting, forging, and machining.

These techniques ensure that each component meets specific performance standards, which is essential for the overall effectiveness of the air compressor.

Once the components are formed, the assembly process begins. This stage typically involves the following steps:

Effective assembly is critical, as improper assembly can lead to air leaks, inefficiencies, and decreased performance.

The finishing stage of manufacturing includes processes that enhance the compressor’s performance and aesthetic appeal. Common finishing techniques include:

These finishing touches play a significant role in the longevity and reliability of the compressor.

Quality assurance is a vital aspect of the manufacturing process, ensuring that the final products meet both international standards and customer expectations. Various methodologies and checkpoints are employed throughout the production cycle.

Several international standards govern the quality assurance processes in manufacturing, including:

Understanding these standards can help B2B buyers assess the credibility of potential suppliers.

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that defects are identified and addressed promptly. Common checkpoints include:

Implementing these checkpoints minimizes the risk of defects reaching the customer.

Various testing methods are employed to evaluate the performance and safety of 12V air compressors. These may include:

These tests provide valuable data that can be used to improve product design and manufacturing processes.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is critical. Here are some actionable steps:

Conducting supplier audits can provide insights into the manufacturing processes and quality control measures in place. Buyers should:

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can conduct thorough inspections at various stages of production and provide detailed reports on compliance with international standards.

B2B buyers must navigate the nuances of certification and quality control when sourcing internationally. This includes understanding:

Illustrative image related to air compressor 12v

By comprehensively understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing 12V air compressors, ensuring they receive high-quality, reliable products that meet their specific needs.

This practical sourcing guide is designed to assist B2B buyers in effectively procuring 12V air compressors. Given the diverse applications of these compressors—from tire inflation to powering air tools—it’s essential to approach the sourcing process with a clear strategy. This checklist outlines the critical steps to ensure you select a reliable compressor that meets your operational needs and aligns with your business objectives.

Before starting your search, clearly outline the technical requirements for your air compressor. Consider factors such as maximum pressure (PSI), airflow (CFM), and duty cycle. Understanding these specifications is vital to ensure the compressor will perform effectively for your intended applications, whether for tire inflation or powering tools.

Evaluate the compatibility of the air compressor with your existing power systems. Most 12V compressors connect directly to a vehicle’s battery, but it’s crucial to confirm that the voltage and amperage align with your equipment specifications. This step will prevent operational disruptions and potential equipment damage.

Thoroughly vet suppliers to ensure they are reputable and capable of delivering high-quality products. Request detailed company profiles, product catalogs, and references from clients in similar industries or regions. This step will help you identify reliable partners and avoid potential issues down the line.

Ensure that the compressors you are considering meet international quality and safety standards. Check for certifications such as ISO 9001 or CE marking, which indicate compliance with industry regulations. This step is crucial for safeguarding your investment and ensuring operational safety.

Determine whether you need a portable compressor or one that can be mounted. If portability is essential, assess the weight and dimensions of the compressor, as well as the ease of setup. If mounting, ensure that the installation space is adequate and does not interfere with other vehicle functions.

Illustrative image related to air compressor 12v

Before finalizing your order, request samples or arrange for a demonstration of the compressors. Testing their performance under real conditions can provide valuable insights into their reliability and efficiency. This step helps ensure that the compressor meets your expectations before committing to a larger purchase.

Once you have selected a supplier and confirmed product specifications, negotiate pricing, delivery terms, and payment options. Ensure that all agreements are documented to avoid misunderstandings later. This step is crucial for establishing a clear and mutually beneficial relationship with your supplier.

When analyzing the cost structure of 12V air compressors, several components come into play. Materials account for a significant portion of the total cost, with high-quality components such as motors, valves, and tanks being critical for performance and durability. Labor costs also contribute, particularly for skilled assembly and quality control processes. Manufacturing overhead covers expenses related to the production facility, utilities, and equipment maintenance, while tooling costs pertain to the molds and machinery used in production. Quality control (QC) processes are essential to ensure that each unit meets performance and safety standards, which can add to overall expenses. Finally, logistics costs encompass shipping, customs duties, and warehousing, especially relevant for international buyers. Each of these components must be carefully considered when evaluating the pricing of 12V air compressors.

Several factors influence the pricing of 12V air compressors, making it essential for buyers to understand these dynamics. Volume and minimum order quantities (MOQ) can significantly impact pricing; larger orders typically result in bulk discounts. Specifications and customization can also lead to variations in price, as unique features or tailored designs often require additional materials and labor. The quality of materials used and certifications (such as ISO or CE) also play a crucial role in determining price, as higher quality and certified products usually command a premium. Additionally, supplier factors such as reputation, reliability, and geographical location can affect pricing. Understanding the Incoterms (International Commercial Terms) is vital for international transactions, as they dictate responsibilities for shipping, insurance, and tariffs, further influencing overall costs.

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency. First, negotiation is key; buyers should engage suppliers in discussions about pricing, especially for larger orders or long-term contracts. Understanding the Total Cost of Ownership (TCO) is crucial as well, which includes not just the purchase price but also maintenance, energy consumption, and potential downtime costs. Additionally, buyers should be aware of pricing nuances such as currency fluctuations and import tariffs that can affect final costs. When sourcing from different regions, it is beneficial to consider local suppliers who may offer lower shipping costs and faster delivery times. Lastly, ensuring that the selected compressor meets the specific needs without unnecessary features can prevent overspending.

It’s essential to note that prices for 12V air compressors can vary widely based on the factors discussed. Prices listed by manufacturers or suppliers may be indicative and subject to change based on market conditions, material costs, and production capacities. Additionally, international buyers should be cognizant of potential added costs related to import duties and taxes that could impact the final price. Therefore, obtaining detailed quotes and understanding all associated costs is critical for making informed purchasing decisions.

In the realm of air management solutions, the 12V air compressor stands out for its versatility and ease of use, particularly for vehicle owners and outdoor enthusiasts. However, several alternative technologies and methods can also achieve similar objectives, offering distinct advantages and limitations. This analysis will compare the 12V air compressor with other viable solutions, helping B2B buyers make informed decisions.

Illustrative image related to air compressor 12v

| Comparison Aspect | Air Compressor 12V | Portable Gas-Powered Air Compressor | Electric Air Compressor |

|---|---|---|---|

| Performance | Up to 200 PSI, 1.75-15 CFM | Up to 150 PSI, 5-10 CFM | Up to 120 PSI, 2-6 CFM |

| Cost | $250 – $2,600 | $400 – $1,200 | $200 – $800 |

| Ease of Implementation | Simple installation, battery connections | Requires fuel, more complex setup | Plug-and-play, requires power outlet |

| Maintenance | Low, regular checks needed | Moderate, requires fuel maintenance | Low, periodic checks |

| Best Use Case | Tire inflation, air tools | Heavy-duty tasks, construction sites | Home use, light tasks |

Portable gas-powered air compressors offer significant power and portability, making them ideal for heavy-duty applications in construction or remote job sites. They can deliver higher air pressure and flow rates compared to 12V models, making them suitable for more demanding tools. However, they require fuel, which adds to operational costs and complexity. Additionally, noise levels can be high, and emissions are a concern for environmentally conscious buyers. Overall, these compressors are best for users needing robust performance and flexibility but may not be as practical for light-duty tasks.

Electric air compressors provide a quieter and cleaner alternative to gas-powered models. They are easy to use and typically require just a power outlet for operation. While they are more suited for indoor or stationary applications due to their reliance on electricity, they can effectively power smaller air tools and handle light-duty tasks. The downside is that they often have lower PSI and CFM ratings compared to both 12V and gas-powered compressors, limiting their use in high-demand scenarios. Their lower cost and ease of maintenance make them attractive for home users or businesses with less intensive air compression needs.

When selecting an air compression solution, B2B buyers should assess their specific needs, including the intended application, required performance, budget, and maintenance capacity. The 12V air compressor excels in versatility and portability, making it ideal for tire inflation and light air tool applications, particularly in mobile settings. In contrast, gas-powered compressors are better suited for heavy-duty tasks in remote locations, while electric compressors cater well to indoor environments with lighter demands. By evaluating these factors, buyers can make a well-informed choice that aligns with their operational requirements and financial considerations.

Understanding the essential specifications of a 12V air compressor is crucial for B2B buyers looking for reliable and efficient solutions. Here are the key technical properties to consider:

The maximum pressure, measured in pounds per square inch (PSI), indicates the highest air pressure the compressor can deliver. For instance, a compressor with a maximum PSI of 200 is suitable for heavy-duty applications like air suspension systems or powering air horns. Buyers must align the PSI with their specific operational requirements to ensure optimal performance.

Illustrative image related to air compressor 12v

Cubic Feet per Minute (CFM) measures the volume of air delivered by the compressor. A higher CFM rating is essential for applications that require rapid inflation or powering multiple air tools simultaneously. For example, a compressor with a 10 CFM rating can fill tires quickly and efficiently, making it ideal for automotive uses.

The duty cycle refers to the amount of time the compressor can operate continuously before it needs to cool down. Expressed as a percentage, a 50% duty cycle means the compressor can run for 30 minutes before requiring a 30-minute rest. This specification is critical for applications that demand prolonged use, such as in workshops or during outdoor activities.

Power consumption, measured in watts, indicates the energy required to operate the compressor. Knowing the wattage helps buyers evaluate compatibility with their vehicle’s electrical system and ensures that the compressor will function without overloading the circuit. A well-rated compressor balances performance with energy efficiency, which is vital for cost-effectiveness.

Portability is a significant factor for many users, especially in off-road or mobile applications. Features like lightweight design, integrated carrying handles, and battery clamps enhance usability. Buyers should assess these features to ensure the compressor meets their mobility needs without compromising performance.

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some common terms related to 12V air compressors:

OEM refers to companies that manufacture products that may be marketed by another company. In the context of air compressors, buyers should consider OEM products for quality assurance and reliability, as these are often built to meet specific industry standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budget management and inventory planning. Buyers should negotiate MOQs to align with their purchasing capabilities while ensuring a steady supply of compressors.

An RFQ is a formal document that buyers send to suppliers to request pricing and terms for specific products. Including detailed specifications for the 12V air compressor in an RFQ ensures that suppliers provide accurate quotes, facilitating better decision-making.

Illustrative image related to air compressor 12v

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps buyers understand shipping costs, risks, and insurance obligations associated with purchasing air compressors from international suppliers.

Warranty terms outline the conditions under which a manufacturer will repair or replace defective products. Buyers should carefully review warranty details to ensure they receive adequate protection, especially for high-value items like air compressors.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and financial goals.

The global market for 12V air compressors is experiencing significant growth, driven by increasing demand across various industries, including automotive, construction, and recreational activities. In regions like Africa, South America, the Middle East, and Europe, the need for portable and efficient air solutions is particularly pronounced, as businesses look to enhance operational efficiency and reduce downtime. B2B buyers are increasingly prioritizing performance specifications, including PSI and CFM ratings, to ensure that the compressors meet diverse applications—from tire inflation to powering air tools.

Emerging technologies are reshaping the sourcing landscape, with manufacturers adopting smart technologies for enhanced performance and user experience. Features such as automatic shut-off, thermal protection, and integrated digital gauges are becoming standard, offering users improved safety and efficiency. Additionally, the rise of e-commerce platforms is facilitating easier access to a broader range of products, allowing international buyers to compare options, read reviews, and make informed purchasing decisions.

Moreover, sustainability is gaining traction as a key consideration among B2B buyers. Companies are increasingly looking for products that not only meet performance standards but also align with their corporate social responsibility goals. This trend is prompting manufacturers to innovate and develop compressors that utilize eco-friendly materials and processes, thus creating a competitive advantage in the marketplace.

Sustainability and ethical sourcing are becoming critical factors in the decision-making process for B2B buyers of 12V air compressors. The environmental impact of manufacturing processes, including carbon emissions and waste generation, is under scrutiny as companies strive to minimize their ecological footprint. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and implementing energy-efficient production methods.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly aware of the labor practices involved in the production of air compressors. Companies that provide transparency in their sourcing and manufacturing processes—showcasing fair labor practices and compliance with international labor standards—are more likely to attract partnerships. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are valuable indicators of a supplier’s commitment to sustainability and ethical practices.

As the market evolves, the demand for “green” certifications and materials will likely continue to rise. Suppliers that can showcase their eco-friendly credentials will not only appeal to environmentally conscious buyers but also position themselves favorably in a competitive market.

The evolution of the 12V air compressor industry can be traced back to the increasing need for portable air solutions in automotive and recreational sectors. Initially, these compressors were primarily used for tire inflation and powering air horns in vehicles. However, with advancements in technology and materials, the functionality of 12V compressors has expanded significantly.

In the early 2000s, the market saw the introduction of more compact and efficient models, allowing for greater versatility and convenience. As outdoor and recreational activities gained popularity, the demand for portable compressors surged, leading manufacturers to innovate further. Today, 12V air compressors are equipped with advanced features such as digital pressure gauges, quick-connect fittings, and heavy-duty construction, catering to a wider range of applications including air suspension adjustments and powering pneumatic tools.

This evolution reflects a broader trend in the manufacturing sector towards enhancing user experience, efficiency, and environmental sustainability—key factors that continue to drive the market forward.

How do I choose the right 12V air compressor for my business needs?

When selecting a 12V air compressor, evaluate your specific requirements, including pressure (PSI) and airflow (CFM) ratings. Consider the applications you intend to use the compressor for, such as tire inflation or powering air tools. It’s essential to assess the duty cycle, which indicates how long the compressor can operate before needing a cooldown. Additionally, check for portability and compatibility with your power source, ensuring it meets the demands of your operations.

What are the primary applications of a 12V air compressor in various industries?

12V air compressors are versatile tools used in numerous industries. They are commonly employed for tire inflation in automotive and transportation sectors, powering air suspension systems in heavy-duty vehicles, and inflating equipment in construction and outdoor activities. Additionally, they can be used in agricultural settings for pneumatic tools or powering air horns in transportation vehicles. Understanding these applications can help you determine the right compressor for your business.

Can I customize my order for 12V air compressors when sourcing from suppliers?

Many suppliers offer customization options for 12V air compressors, allowing you to tailor specifications such as pressure output, design, and additional features. When negotiating, clearly communicate your requirements and ensure the supplier can accommodate them. Discuss minimum order quantities (MOQ) as well, as some manufacturers may have specific limits for customized products. Always request samples or prototypes to evaluate quality before finalizing your order.

What should I consider regarding minimum order quantities (MOQ) when sourcing 12V air compressors?

MOQs vary by supplier and can significantly impact your purchasing strategy. When negotiating, consider your budget, storage capacity, and anticipated demand for the compressors. If you are entering a new market or testing a product, look for suppliers with flexible MOQs. This flexibility allows you to minimize risk and gauge market response before committing to larger orders.

How can I ensure the quality of 12V air compressors from international suppliers?

To ensure quality, conduct thorough supplier vetting, including checking certifications, customer reviews, and production capabilities. Request quality assurance (QA) documentation, including test reports and compliance with international standards. If feasible, arrange for a factory visit or third-party inspection before shipment. Establish clear quality expectations in your contract to safeguard against defects and ensure your requirements are met.

What payment terms are typical when sourcing 12V air compressors internationally?

Payment terms can vary significantly among suppliers, often influenced by your relationship with them and order size. Common terms include a deposit upon order confirmation (typically 30%-50%) and the balance before shipping. Some suppliers may offer letters of credit or payment upon delivery. Always negotiate favorable terms and ensure they are documented in your purchase agreement to protect your investment.

What logistics considerations should I keep in mind when importing 12V air compressors?

When importing, consider shipping methods, costs, and delivery timelines. Determine whether to use air freight for speed or sea freight for cost-effectiveness, based on your urgency and budget. Ensure compliance with import regulations, tariffs, and duties in your country. Collaborate with a reliable logistics partner who can manage customs clearance and provide tracking information for your shipments.

What warranty and after-sales support should I expect for 12V air compressors?

Reputable suppliers typically offer warranties ranging from one to five years, covering defects in materials and workmanship. Review the warranty terms carefully, including what is covered and the process for claims. After-sales support is crucial for addressing any operational issues or maintenance needs. Assess the supplier’s responsiveness and support channels to ensure you can get assistance when required, which is vital for maintaining your operational efficiency.

Domain: hornblasters.com

Registered: 2003 (22 years)

Introduction: This company, HornBlasters – 12V Compressors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domain: thorslightningairsystems.com

Registered: 2022 (3 years)

Introduction: 12v Portable Air Compressors from Thor’s Lightning include: 1. Thor’s Lightning Strike Compressor – Starting at €396,95 2. Jeep® Thor’s Lightning Strike Compressor – Starting at €396,95 3. Customize Your Compressor – Starting at €0,00 4. Thor’s Lightning Bolt TrueDual Air Compressor TotalControl – Starting at €225,95 5. Thor’s Lightning Bolt Portable 12v True Dual Air Compressor – 10.6 CFM – Start…

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: Portable & Vehicle Mounted Air Compressor Systems from ARB 4×4 USA. Key features include: durable, high-performance compressors for tires, tools, and Air Lockers. Product categories include Mounted Compressors, Portable Compressors, and Brushless Compressors. Promotions: 10% off Air Compressors & Accessories, free ground shipping over $75 (excludes Brushless Compressors). Notable products: Twin Mo…

In conclusion, the strategic sourcing of 12V air compressors offers significant advantages for international B2B buyers. By focusing on performance specifications, compatibility, and durability, companies can ensure they select compressors that meet their operational needs, whether for tire inflation, air suspension, or powering air tools. The versatility of 12V compressors makes them essential for various applications across different industries, enhancing productivity and efficiency.

As global markets continue to evolve, the demand for reliable and high-performance air compressors is expected to grow, particularly in regions such as Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers who demonstrate a commitment to quality, innovation, and customer support.

Looking ahead, we encourage B2B buyers to explore the latest advancements in 12V air compressor technology and consider partnerships with reputable manufacturers. Engaging with suppliers who understand the unique challenges of your market can lead to better sourcing decisions and enhanced operational capabilities. Embrace the opportunities that lie ahead, and make informed choices that will propel your business forward.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air compressor 12v

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.