In today’s fast-paced global market, sourcing the right air compressor for tire inflation can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the increasing demand for efficient tire maintenance solutions, businesses must navigate a landscape filled with diverse products and suppliers. This guide serves as a comprehensive resource, addressing various types of air compressors, their applications across different sectors, and essential criteria for supplier vetting.

From portable inflators suitable for personal vehicles to heavy-duty compressors designed for commercial fleets, understanding the range of available options is crucial for making informed purchasing decisions. Additionally, we will delve into cost considerations, helping you balance quality and budget effectively. By providing insights into market trends and best practices, this guide empowers international B2B buyers to confidently select the right air compressor for their specific needs.

Whether you are based in Nigeria, Vietnam, or any part of the world, this resource is tailored to enhance your procurement strategies and optimize your operations. With the right air compressor, you can ensure vehicle safety, improve operational efficiency, and ultimately contribute to your bottom line. Let’s explore the intricacies of the global air compressor market and equip you with the knowledge needed to succeed.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Tire Inflators | Lightweight, battery-powered, compact design | Automotive repair shops, roadside assistance | Pros: Easy to transport, quick inflation Cons: Limited power for larger tires |

| Heavy-Duty Compressors | High PSI capacity, often connected to power sources | Trucking companies, construction sites | Pros: Fast inflation for large tires Cons: Bulky, requires electrical outlet |

| Dual-Power Compressors | Operates on both AC and DC power | Garages, mobile workshops | Pros: Versatile power options Cons: May be heavier, higher initial cost |

| Corded Electric Compressors | Continuous power supply, typically higher CFM ratings | Tire service centers, automotive workshops | Pros: Consistent performance, no battery limitations Cons: Limited mobility due to cords |

| Mini Tire Compressors | Ultra-compact, often USB-powered | Personal use, motorcycles, bicycles | Pros: Extremely portable, affordable Cons: Low inflation capacity, slower performance |

Portable tire inflators are designed for convenience and ease of use, making them ideal for automotive repair shops and roadside assistance services. They are typically lightweight and battery-powered, allowing for quick inflation without the need for a power source. While they are excellent for topping off tires, their performance may be limited when inflating larger tires or multiple tires in one session. Buyers should consider battery life and inflation speed when selecting a model.

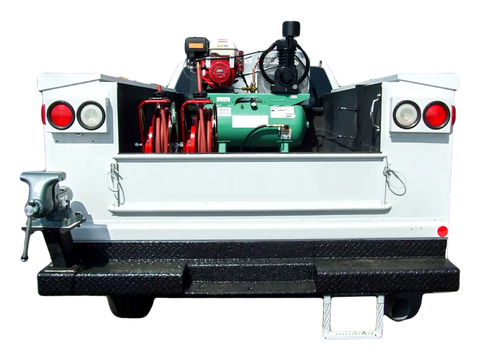

Illustrative image related to air compressor for tire

Heavy-duty compressors are engineered for high-pressure applications, often exceeding 100 PSI, making them suitable for trucking companies and construction sites where large tires are common. These compressors usually require a direct connection to a power source, providing rapid inflation for larger tires. However, their bulkiness can be a drawback for mobile applications, and buyers should assess their space and power availability before purchasing.

Dual-power compressors offer versatility by functioning on both AC and DC power, making them ideal for garages and mobile workshops. This flexibility allows users to operate the compressor from home outlets or vehicle batteries, accommodating various work environments. While they may be heavier and carry a higher upfront cost, their adaptability can justify the investment for businesses that require reliable inflation solutions in different settings.

Corded electric compressors provide consistent performance without the limitations of battery life, making them a staple in tire service centers and automotive workshops. They typically offer higher CFM ratings, enabling faster inflation of multiple tires. However, their mobility is restricted due to the need for an electrical outlet, which may not suit all operational needs. Buyers should weigh the benefits of power and speed against the necessity for portability.

Mini tire compressors are ultra-compact and often USB-powered, making them ideal for personal use or for inflating smaller tires, such as those on motorcycles and bicycles. Their portability and affordability appeal to individual consumers and small businesses. However, their low inflation capacity and slower performance may limit their effectiveness for larger vehicles. B2B buyers should consider whether their applications require more robust options or if a mini compressor suffices for their needs.

| Industry/Sector | Specific Application of air compressor for tire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Tire inflation and maintenance services | Enhances customer satisfaction and safety | Reliable performance, portability, and ease of use |

| Logistics and Transportation | Fleet tire management and inflation | Reduces downtime and fuel costs | Capacity for high PSI, durability, and power source options |

| Construction and Mining | Inflation of heavy-duty vehicle tires | Increases operational efficiency and safety | Robust construction, mobility, and pressure control features |

| Agriculture | Inflation for agricultural vehicles and equipment | Optimizes productivity and reduces tire wear | Compatibility with various tire sizes and reliability in remote areas |

| Retail Automotive Services | Retail tire sales and inflation services | Attracts customers and increases sales | Compact design, affordability, and multifunctionality |

In automotive repair shops, air compressors are essential for providing tire inflation and maintenance services. These compressors enable technicians to quickly and efficiently inflate tires to the correct pressure, ensuring vehicle safety and performance. By maintaining optimal tire pressure, businesses can enhance customer satisfaction and reduce the risk of accidents due to under-inflated tires. When sourcing compressors, repair shops should prioritize reliability, portability, and ease of use to accommodate various tire sizes and types.

In the logistics and transportation sector, air compressors are crucial for fleet tire management and inflation. Keeping tires properly inflated reduces fuel consumption and minimizes the risk of tire blowouts, which can lead to costly downtime. An efficient tire inflation system can significantly enhance operational efficiency, making it a valuable investment for logistics companies. Buyers should consider compressors with high PSI capacity, durability for frequent use, and versatile power source options to ensure functionality across diverse fleet vehicles.

In construction and mining, air compressors are vital for inflating heavy-duty vehicle tires used in transporting materials and equipment. Proper tire inflation enhances traction and safety, reducing the likelihood of accidents on challenging terrains. Additionally, well-inflated tires improve fuel efficiency, which is critical in these cost-sensitive industries. When sourcing compressors, businesses should focus on robust construction, portability for use in remote locations, and advanced pressure control features to manage the specific requirements of heavy machinery.

Agricultural operations rely on air compressors for inflating tires on various vehicles and equipment, such as tractors and harvesters. Proper tire inflation optimizes productivity by ensuring that vehicles operate efficiently and experience reduced tire wear. This is particularly important in remote areas where access to repair facilities may be limited. Buyers in this sector should look for compressors that are compatible with different tire sizes and offer reliability in diverse environmental conditions to ensure uninterrupted operations.

In retail automotive services, air compressors are used for tire inflation and maintenance, attracting customers who require quick and reliable service. Offering tire inflation services can lead to increased sales of tires and related accessories, enhancing overall profitability. Retailers should focus on sourcing compact, affordable compressors that are multifunctional, allowing them to serve various customer needs, such as inflating bicycle tires or sports equipment, thereby maximizing utility and customer engagement.

Illustrative image related to air compressor for tire

The Problem: B2B buyers often face challenges in sourcing air compressors that meet a range of specific needs across different vehicles and applications. For instance, a fleet manager might require high-performance compressors capable of servicing both light-duty cars and heavy-duty trucks. The inconsistency in product quality, reliability, and performance can lead to increased downtime and maintenance costs, negatively impacting overall operational efficiency.

The Solution: To effectively address this challenge, buyers should prioritize suppliers that offer a diverse range of air compressors specifically designed for various applications. When sourcing, look for manufacturers that provide detailed specifications, including maximum psi ratings, duty cycles, and adaptability features. Additionally, consider partnering with suppliers who offer comprehensive after-sales support, including maintenance services and warranties. Establishing relationships with reputable brands known for quality, such as AstroAI or Viair, can also enhance procurement decisions. Conducting thorough evaluations, such as pilot testing a small batch of compressors, can help in assessing their performance under real-world conditions before making larger commitments.

The Problem: Maintaining consistent tire pressure across a fleet can be a significant challenge, especially in regions with fluctuating temperatures and varying road conditions. Inconsistent tire pressure not only affects vehicle performance but also contributes to increased fuel consumption and safety hazards. For B2B buyers, this inconsistency can lead to higher operational costs and a negative impact on vehicle longevity.

The Solution: Implementing a proactive tire maintenance program is essential for managing tire pressure effectively. This includes investing in high-quality air compressors with built-in pressure gauges that provide accurate readings and automatic shut-off features. Additionally, equipping vehicles with portable tire inflators can enable on-the-spot adjustments, ensuring that all tires are adequately inflated before each journey. Buyers should also consider integrating tire pressure monitoring systems (TPMS) for real-time tracking and alerts on pressure variations. Regular training for drivers on the importance of checking tire pressure can further enhance awareness and adherence to maintenance protocols.

Illustrative image related to air compressor for tire

The Problem: For many B2B buyers, particularly those operating in remote or rugged environments, the portability and power source of air compressors are critical factors. Traditional compressors may require stationary power outlets, limiting their usability in field operations or during emergencies. Buyers may find themselves unable to service tires promptly, resulting in delays and potential safety risks.

The Solution: To overcome these portability challenges, buyers should look for battery-operated or dual-power air compressors that can be charged via multiple sources, such as vehicle batteries or standard electrical outlets. Models like the Craftsman 12V Max Portable Air Inflator offer compact designs and rechargeable options, making them ideal for on-the-go use. Additionally, it is beneficial to evaluate the weight and size of the compressors, ensuring they can be easily stored and transported within vehicles. Creating a standardized kit that includes a reliable portable air compressor, along with accessories such as extension cords and adapters for various applications, can streamline operations and enhance readiness for tire emergencies. Training staff on the effective use of these portable units will further ensure that tire maintenance is handled efficiently, regardless of location.

When selecting materials for air compressors designed for tire inflation, several factors come into play, including performance characteristics, durability, cost, and regional compliance standards. The following analysis covers four common materials used in the construction of air compressors, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum alloys are widely used in air compressor manufacturing due to their lightweight nature and excellent corrosion resistance. They typically have a temperature rating of up to 200°C and can withstand pressures of around 300 psi, making them suitable for various tire inflation tasks.

Pros: Aluminum is durable and resistant to rust, which is crucial for compressors exposed to outdoor environments. It is also relatively easy to machine, which simplifies manufacturing processes.

Illustrative image related to air compressor for tire

Cons: While aluminum is cost-effective compared to some other metals, it can be more expensive than plastics. Additionally, its lower tensile strength compared to steel can lead to deformation under excessive pressure.

Impact on Application: Aluminum is compatible with a range of media, including air and nitrogen, making it versatile for tire inflation. However, it may not be suitable for applications involving corrosive gases.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions. In regions like Africa and South America, where environmental conditions can be harsh, selecting high-quality aluminum alloys is essential to avoid premature failure.

Steel, particularly carbon steel, is another common material used in air compressors. It boasts a high tensile strength, with pressure ratings often exceeding 500 psi, making it ideal for high-performance applications.

Pros: Steel’s durability and strength make it suitable for heavy-duty compressors. It is also relatively inexpensive compared to other metals, which can lower overall manufacturing costs.

Illustrative image related to air compressor for tire

Cons: Steel is susceptible to rust and corrosion if not properly treated, which can lead to maintenance challenges. Additionally, it is heavier than aluminum, which may affect portability.

Impact on Application: Steel is compatible with a variety of gases and is often used in industrial applications where high pressure is required. However, its susceptibility to corrosion means that protective coatings or treatments are necessary for outdoor use.

Considerations for International Buyers: Compliance with standards such as ASTM A36 is crucial. In regions with high humidity or saline environments, such as coastal areas in the Middle East, corrosion-resistant coatings become a priority.

Plastics, particularly reinforced composites, are increasingly utilized in air compressor components. They offer excellent chemical resistance and can withstand temperatures up to 70°C.

Illustrative image related to air compressor for tire

Pros: Plastics are lightweight and resistant to corrosion, making them ideal for portable tire inflators. They can also be molded into complex shapes, allowing for innovative designs.

Cons: While they are cost-effective, plastics generally have lower pressure ratings, typically around 150 psi, which may limit their use in high-performance applications. They can also be less durable than metals.

Impact on Application: Plastics are suitable for non-pressurized components and are often used in housings and covers. However, they may not be compatible with certain chemicals, necessitating careful selection.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM D638 for tensile properties. In regions like Europe, where environmental regulations are stringent, selecting recyclable plastics can enhance marketability.

Illustrative image related to air compressor for tire

Copper alloys are often used in air compressor fittings and connectors due to their excellent thermal and electrical conductivity. They can handle temperatures up to 400°C and pressures around 300 psi.

Pros: The high conductivity of copper alloys enhances energy efficiency, making them ideal for applications requiring quick heat dissipation. They also exhibit good corrosion resistance.

Cons: Copper alloys can be more expensive than aluminum or steel, which may impact overall manufacturing costs. Their weight can also be a disadvantage in portable applications.

Impact on Application: Copper is particularly suitable for high-temperature applications and is often used in pneumatic systems. However, it may not be ideal for environments with corrosive substances.

Considerations for International Buyers: Compliance with standards such as ASTM B280 is essential. In regions like South America, where copper theft can be an issue, securing components may require additional measures.

Illustrative image related to air compressor for tire

| Material | Typical Use Case for air compressor for tire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Portable tire inflators | Lightweight and corrosion-resistant | Lower tensile strength than steel | Medium |

| Steel | Heavy-duty industrial compressors | High strength and durability | Susceptible to rust | Low |

| Plastics | Non-pressurized components | Lightweight and moldable | Lower pressure ratings | Low |

| Copper Alloys | Fittings and connectors | Excellent thermal and electrical conductivity | Higher cost and weight | High |

This analysis provides B2B buyers with essential insights into material selection for air compressors used in tire inflation, enabling informed decisions that consider performance, cost, and regional compliance.

The manufacturing of air compressors for tires involves several critical stages, each requiring precision and adherence to quality standards to ensure the final product is reliable and efficient.

The first stage in manufacturing involves sourcing high-quality raw materials. Common materials include metals such as aluminum and steel, which are preferred for their strength and durability. Plastics may also be used for components such as housing and knobs. Suppliers must ensure that these materials meet specific industry standards to withstand the demands of tire inflation.

Once materials are prepared, the forming stage begins. Key techniques include:

These techniques are critical for producing components that fit together seamlessly and function reliably.

Illustrative image related to air compressor for tire

The assembly stage is where individual components come together to form the complete air compressor. This process typically includes:

The finishing stage enhances both the aesthetic and functional aspects of the air compressor. Common techniques include:

Quality assurance (QA) is critical in the manufacturing of air compressors, particularly for B2B buyers who require reliable products.

Manufacturers of air compressors should comply with various international standards, including:

These certifications not only ensure quality but also help in gaining market acceptance.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

These checkpoints help in identifying and rectifying defects early in the production process, reducing waste and ensuring quality.

B2B buyers must ensure that their suppliers adhere to stringent quality control practices. Here are some effective ways to verify:

Illustrative image related to air compressor for tire

When sourcing air compressors from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

In summary, the manufacturing processes and quality assurance practices for air compressors are critical factors that B2B buyers must consider. By understanding these processes and verifying supplier quality, buyers can ensure that they procure reliable and efficient air compressors suitable for their needs. Investing time in supplier evaluation and ensuring adherence to international standards can lead to better product performance and customer satisfaction in the long run.

To effectively procure an air compressor for tire inflation, B2B buyers must follow a structured approach that ensures they select the right product to meet their operational needs. This guide outlines essential steps to streamline the sourcing process.

Before engaging with suppliers, it’s vital to outline the technical specifications required for your air compressor. Consider factors such as the compressor’s power source (e.g., battery-operated, 12-volt outlet), maximum pressure (psi) capabilities, and intended use (personal vehicles, trucks, or heavy machinery). This clarity helps in narrowing down options and ensures that the compressor meets the demands of your specific applications.

Illustrative image related to air compressor for tire

Conduct thorough research on available air compressor models and brands. Look for products that have been tested and reviewed for reliability and performance. Consider utilizing platforms like MotorTrend or industry-specific reviews to identify top-rated models that align with your specifications. This step is crucial for understanding market trends and ensuring you are aware of the latest innovations and competitive pricing.

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, product certifications, and references from buyers in similar industries or regions. Evaluate their customer service responsiveness and support options, as ongoing assistance can significantly impact your operational efficiency.

Ensure that the air compressors you are considering comply with regional and international safety and quality standards. Look for certifications such as ISO or CE, which indicate that the product has undergone rigorous testing and meets industry benchmarks. Compliance not only ensures safety but also enhances the credibility of your procurement process.

When comparing suppliers, do not focus solely on the initial purchase price. Analyze the total cost of ownership, which includes maintenance, warranties, and potential operational costs over the compressor’s lifespan. Seek quotes from multiple suppliers to gain a comprehensive understanding of pricing structures, and consider negotiating terms that might include bulk purchase discounts.

Evaluate the after-sales support that suppliers offer, including warranty duration and terms. A robust warranty and responsive customer service can significantly reduce downtime in case of product issues. Confirm whether the supplier provides training or resources for maintenance and troubleshooting, which can be invaluable for your team.

Once you have selected a supplier, carefully review the purchase agreement. Ensure that all specifications, delivery timelines, payment terms, and return policies are clearly stated. This protects both parties and sets clear expectations, ultimately leading to a smoother procurement experience.

By following these steps, B2B buyers can make informed decisions when sourcing air compressors for tire inflation, ensuring they select products that meet their operational needs while also providing value for money.

When analyzing the cost structure of air compressors for tires, several components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Several factors influence the pricing of air compressors, especially in the international B2B market. Key price influencers include volume and minimum order quantities (MOQs), specifications and customization, material choices, quality certifications, supplier factors, and Incoterms.

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, a strategic approach to sourcing can lead to significant cost savings and better procurement outcomes.

Pricing for air compressors can fluctuate based on market conditions, supplier negotiations, and other factors. The prices mentioned in this guide are indicative and should be verified with suppliers for accuracy. Always conduct thorough due diligence before finalizing purchases to ensure alignment with your budget and operational needs.

When it comes to maintaining optimal tire pressure, air compressors are a popular choice for both personal and commercial use. However, there are alternative solutions available that may better suit specific needs or circumstances. This analysis will compare air compressors for tires with two viable alternatives: portable tire inflators and manual pumps. Understanding these options can help international B2B buyers make informed decisions tailored to their operational requirements.

Illustrative image related to air compressor for tire

| Comparison Aspect | Air Compressor For Tire | Portable Tire Inflator | Manual Pump |

|---|---|---|---|

| Performance | High PSI capability, suitable for various tire sizes | Moderate PSI, ideal for passenger vehicles | Low PSI, suitable for bicycles and small tires |

| Cost | $50 – $200 | $30 – $100 | $10 – $30 |

| Ease of Implementation | Requires power source (electric/gas) | Battery-operated or 12V outlet | Manual operation, no power required |

| Maintenance | Regular checks needed for oil and parts | Low maintenance, battery replacement required | Minimal maintenance, usually durable |

| Best Use Case | Heavy-duty vehicles, commercial applications | Light vehicles, emergency situations | Recreational use, bicycles, small vehicles |

Portable tire inflators offer a balance between convenience and performance. They are typically battery-operated or can be plugged into a vehicle’s 12V outlet, making them easy to use on the go. These inflators can inflate tires quickly but may lack the high PSI capacity required for larger vehicles. Their affordability makes them attractive for B2B buyers focusing on cost-effective solutions, particularly in regions where heavy-duty compressors may be less accessible. However, the reliance on battery power can be a limitation, especially for high-volume or continuous use scenarios.

Manual pumps are the most basic alternative, requiring physical effort to inflate tires. They are lightweight, portable, and do not require any power source, making them ideal for remote locations or emergency situations. Their low cost is appealing to businesses with tight budgets or those that only occasionally need to inflate tires. However, manual pumps are not suitable for larger tires or high-pressure needs and can be labor-intensive, which may not align with the efficiency goals of many businesses. Additionally, the time taken to inflate a tire can be a significant drawback in a fast-paced environment.

Selecting the right tire inflation solution depends on specific business needs, including vehicle types, operational scale, and budget constraints. Air compressors are ideal for high-demand environments with heavy-duty vehicles, while portable tire inflators offer convenience for light vehicles and emergency situations. Manual pumps, though labor-intensive, can serve well in low-budget scenarios or for occasional use. B2B buyers should consider these factors and evaluate the trade-offs of each option to determine which solution aligns best with their operational requirements and long-term objectives.

Understanding the essential technical specifications of air compressors for tires is crucial for B2B buyers in selecting the right equipment for their needs. Here are some critical properties to consider:

The maximum pressure, measured in pounds per square inch (PSI), indicates how much air pressure the compressor can deliver. For tire inflators, common ranges are between 80 to 160 PSI. This specification is vital for accommodating various tire sizes, especially for larger vehicles like trucks and SUVs. Buyers should ensure the compressor can meet or exceed the pressure requirements of their fleet.

The duty cycle refers to the amount of time a compressor can operate before it needs to cool down. It’s typically expressed as a percentage over a specific time frame (e.g., 50% duty cycle means it can run for 5 minutes and must rest for 5 minutes). This property is essential for commercial applications where time efficiency is critical, allowing for continuous use without overheating or damaging the unit.

Air compressors can be powered by various sources, including battery, 12-volt outlets, or AC power. The choice of power source affects portability and convenience. For instance, battery-operated models offer flexibility for roadside assistance, while AC-powered models may be better suited for stationary garage use. Understanding the power requirements is crucial for ensuring compatibility with existing systems.

Measured in cubic feet per minute (CFM), the air flow rate indicates the volume of air the compressor can deliver. A higher CFM rating means faster inflation times, which is particularly important for commercial operations requiring quick tire servicing. Buyers should evaluate their needs based on the types of vehicles they service and select a compressor with adequate airflow.

The weight of an air compressor impacts its portability. Lighter models are easier to transport, making them ideal for mobile tire service providers. Conversely, heavier units may offer greater durability and performance but can be cumbersome for frequent relocation. Buyers must balance performance with ease of transport based on their operational requirements.

Familiarity with industry jargon can enhance communication and negotiation in B2B transactions. Here are several key terms:

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of air compressors, understanding whether a product is OEM or aftermarket can influence quality and compatibility. Buyers often prefer OEM products for reliability and warranty support.

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can affect purchasing decisions and inventory management. Buyers should assess their needs against the MOQ to avoid overcommitting to stock that may not sell.

An RFQ is a formal process where buyers request price quotes from suppliers for specified products. This process is essential for comparing costs and terms before making a purchasing decision. Crafting a detailed RFQ can lead to better pricing and terms.

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and reduce risks in international trade.

Warranty terms define the duration and conditions under which a manufacturer will repair or replace a defective product. Understanding warranty policies is crucial for buyers to ensure long-term support and mitigate risks associated with equipment failure.

Illustrative image related to air compressor for tire

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions that align with their operational requirements and business objectives.

The air compressor for tire sector is witnessing significant transformation driven by globalization, technological advancements, and changing consumer preferences. Internationally, the demand for portable and efficient tire inflators is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe. This is largely due to the growing automotive market, where maintaining tire pressure is crucial for vehicle safety and fuel efficiency. Key trends include the increasing popularity of cordless and compact inflators that offer convenience without compromising performance. Advanced features such as built-in pressure gauges, automatic shutoff, and multiple power options are becoming essential, as they enhance user experience and operational efficiency.

Moreover, B2B buyers are increasingly looking for suppliers that can provide innovative solutions, such as smart tire inflators that connect to mobile apps for real-time monitoring. This trend is particularly relevant for businesses in regions with challenging road conditions, where tire maintenance is critical. The market is also adapting to regional preferences, with manufacturers customizing products for different climates and terrains, thereby enhancing market penetration. As competition intensifies, buyers should prioritize suppliers who demonstrate agility in sourcing and can swiftly adapt to these evolving trends.

Illustrative image related to air compressor for tire

Sustainability is becoming a focal point in the air compressor for tire sector, driven by increasing environmental awareness among consumers and regulatory pressures on manufacturers. The production of air compressors can have significant environmental impacts, including energy consumption and material waste. Consequently, B2B buyers are increasingly seeking suppliers who prioritize sustainable practices throughout their supply chains. This includes the use of recycled materials, energy-efficient manufacturing processes, and eco-friendly packaging.

Ethical sourcing is equally important, with businesses recognizing the value of transparent supply chains. Buyers are encouraged to partner with manufacturers who have obtained ‘green’ certifications, such as ISO 14001, which demonstrates commitment to environmental management systems. Additionally, the adoption of materials that are less harmful to the environment, such as biodegradable plastics or sustainably sourced metals, is gaining traction. By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their corporate responsibility profiles but also cater to a growing segment of environmentally conscious consumers.

The air compressor for tire sector has evolved significantly since its inception. Initially, tire inflation was a manual process, relying heavily on hand pumps and basic mechanical devices. The introduction of electric air compressors in the late 20th century revolutionized the industry, making tire inflation more efficient and accessible. As automotive technology advanced, so did the designs and functionalities of air compressors, incorporating innovations such as digital pressure gauges and portable designs tailored for consumer convenience.

In the early 21st century, the focus shifted towards enhancing user experience through portability and multifunctionality. Modern inflators are designed not just for tires but for a variety of inflatables, reflecting the diverse needs of consumers. This evolution has been driven by both consumer demand and technological advancements, leading to a more competitive and diverse market landscape. As the industry continues to innovate, B2B buyers must remain vigilant in sourcing from suppliers who are at the forefront of these developments, ensuring they meet the demands of a dynamic marketplace.

1. How do I choose the right air compressor for tire inflation?

Selecting the right air compressor involves considering factors such as the type of vehicles you will service, the required psi levels, and portability. For commercial use, opt for models that can handle heavy-duty requirements, such as inflating truck tires, which may need up to 120 psi. Look for features like built-in pressure gauges for accuracy, quick inflation capabilities, and the ability to inflate multiple tires on a single charge. It’s also beneficial to evaluate the compressor’s durability and warranty options to ensure it meets your long-term business needs.

2. What is the best air compressor for tire inflation in a commercial setting?

The best air compressor for commercial tire inflation often depends on your specific needs, but models like the Viair 88P are highly regarded for their speed and ability to handle larger tires typical in trucks and SUVs. For smaller vehicles, the AstroAI Cordless Tire Inflator is recommended due to its portability and quick inflation. Evaluate factors such as power source (battery vs. corded), maximum psi, and features like automatic shut-off to prevent over-inflation, ensuring that the compressor aligns with your operational requirements.

3. What factors should I consider when sourcing air compressors internationally?

When sourcing air compressors internationally, consider the supplier’s reputation, product certifications, and compliance with local regulations in your target market. It’s crucial to assess the supplier’s ability to provide reliable after-sales support, warranty services, and spare parts availability. Additionally, evaluate shipping logistics, import duties, and currency exchange rates, as these can significantly impact your total cost. Establish clear communication regarding product specifications and delivery timelines to avoid misunderstandings.

4. How can I vet potential suppliers for air compressors?

To vet potential suppliers, start by researching their background, including years in business, customer reviews, and case studies. Request references from previous clients and inquire about their production capabilities, quality control processes, and adherence to international standards. Conduct on-site visits if feasible, or utilize third-party inspection services to verify product quality. Additionally, assess their response time and customer service approach to ensure they align with your business values.

5. What are typical minimum order quantities (MOQ) for air compressors?

Minimum order quantities (MOQ) for air compressors can vary significantly depending on the supplier and the type of compressor. Generally, MOQs range from 50 to 200 units for commercial-grade compressors. It’s essential to discuss MOQs upfront with potential suppliers, as some may offer flexibility for first-time buyers or smaller businesses. Be aware that lower MOQs might come with higher per-unit costs, so weigh the benefits of bulk purchasing against your immediate needs and storage capabilities.

6. What payment terms should I expect when purchasing air compressors?

Payment terms can vary by supplier and region but typically include options like a deposit upon order confirmation followed by the balance before shipment. Some suppliers may offer net 30 or net 60 payment terms, especially for established clients. It’s advisable to negotiate terms that provide both parties with a sense of security, such as escrow services or letters of credit for larger transactions. Always confirm the payment methods accepted, as international transfers can incur additional fees.

7. How can I ensure quality assurance (QA) for air compressors sourced internationally?

To ensure quality assurance for internationally sourced air compressors, request detailed product specifications and compliance certificates from your suppliers. Implement a rigorous quality control process, including pre-shipment inspections and testing samples before large orders. Collaborating with third-party inspection agencies can provide additional verification of product quality. Establishing clear quality expectations and having a return or defect policy in place will also help manage any potential issues effectively.

8. What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider shipping methods, customs clearance processes, and potential delays. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your timeline and budget. Be prepared for customs duties and taxes, which can vary by country and affect your total landed cost. Ensure that your supplier provides all necessary documentation, such as invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance and avoid unexpected charges.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is considering an air compressor for topping off tires and other tasks. Initially looking at the Makita MAC100Q for its quiet operation, but is open to other options. User contemplates a larger compressor than 1 gallon for potential future uses like blowing areas clear, but doubts the need for air tools. Also considers a portable inflator like the Dewalt 20V. Comments suggest pancake compress…

In the evolving landscape of tire maintenance, strategic sourcing of air compressors is essential for international B2B buyers looking to optimize their operations. Key considerations include the performance and reliability of various tire inflators, which can significantly impact vehicle safety and operational efficiency. Selecting high-quality, versatile models, such as cordless or heavy-duty inflators, ensures that businesses can meet diverse customer needs while minimizing downtime.

Illustrative image related to air compressor for tire

Moreover, understanding the specific requirements of different markets—such as the rugged demands in Africa or the compact solutions preferred in Europe—can guide buyers in making informed decisions. Establishing strong relationships with reliable suppliers will not only enhance procurement processes but also lead to better pricing and service agreements.

As the demand for efficient tire maintenance solutions continues to rise, now is the time for B2B buyers to leverage strategic sourcing to stay ahead of the competition. By prioritizing quality and performance in your sourcing strategy, you can ensure that your business is well-equipped to meet the challenges of tomorrow. Embrace these insights to refine your purchasing strategy and drive your business forward in the global marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to air compressor for tire

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.