In today’s fast-paced global market, sourcing the best tire inflator portable air compressor can be a daunting challenge for B2B buyers. With varying needs across regions like Africa, South America, the Middle East, and Europe, it’s essential to identify equipment that not only meets specific performance standards but also aligns with regional demands and expectations. This guide serves as a comprehensive resource, covering the diverse types of tire inflators, their applications, and the critical factors to consider when evaluating suppliers.

From evaluating the performance capabilities of different models to understanding pricing structures and potential shipping logistics, this guide empowers international buyers to make informed decisions. We delve into essential features such as portability, inflation speed, and maximum pressure capabilities—vital attributes that can significantly impact the effectiveness of these devices in various environments, whether in urban settings or remote locations.

Additionally, we provide insights on how to vet suppliers effectively, ensuring that your investment in tire inflators translates into long-term reliability and customer satisfaction. By arming yourself with the knowledge contained in this guide, you can confidently navigate the complexities of the tire inflator market, ensuring you select the best solutions tailored to your business’s unique needs.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-powered, portable, often lightweight | Automotive repair shops, roadside assistance | Pros: High portability, ease of use. Cons: Limited battery life may require recharging. |

| 12V Plug-In Tire Inflators | Powered by vehicle’s 12V outlet, often compact | Fleet maintenance, automotive service centers | Pros: Continuous power supply, generally faster. Cons: Limited mobility without vehicle access. |

| Heavy-Duty Air Compressors | High PSI capacity, rugged build, often larger | Construction sites, off-road vehicle maintenance | Pros: Suitable for larger tires, robust performance. Cons: Bulky and less portable. |

| Ultra-Compact Inflators | Extremely lightweight, designed for small spaces | Motorcycles, bicycles, emergency kits | Pros: Easy to store, affordable. Cons: Limited inflation capacity, slower performance. |

| Multi-Function Inflators | Additional features like USB charging, lights | Automotive retail, emergency services | Pros: Versatile use for various inflatables. Cons: May be pricier due to extra features. |

Cordless tire inflators are battery-operated units designed for maximum portability. They are ideal for businesses that require quick and convenient solutions for tire inflation, such as automotive repair shops and roadside assistance services. When considering a cordless model, buyers should look for battery life, ease of use, and the ability to inflate multiple tires on a single charge. However, the limitation of battery capacity can be a concern, especially for larger vehicles or multiple inflations.

12V plug-in tire inflators connect directly to a vehicle’s power outlet, making them a reliable choice for continuous operation. These inflators are commonly used in fleet maintenance and automotive service centers, where quick access to power is essential. Buyers should prioritize features like hose length, inflation speed, and ease of use. While they offer a consistent power source, their dependence on vehicle access can be a drawback in some scenarios.

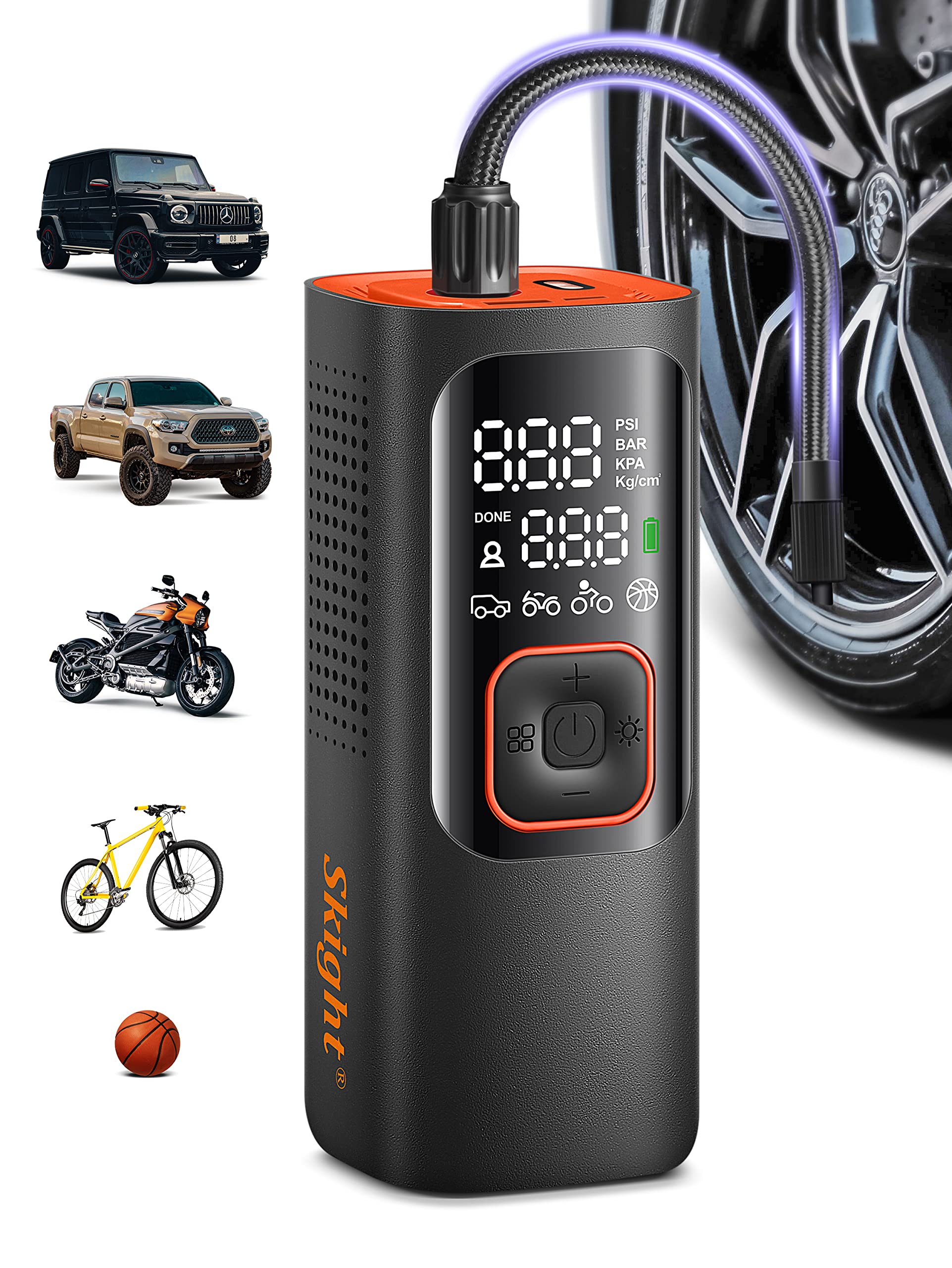

Illustrative image related to best tire inflator portable air compressor

Heavy-duty air compressors are designed to handle high PSI requirements and larger tires, making them suitable for construction sites and off-road vehicle maintenance. Their robust construction and powerful performance are essential for businesses that regularly deal with heavy machinery or larger vehicles. Buyers should consider factors such as portability, storage space, and the compressor’s overall weight. While they provide exceptional inflation capabilities, their bulkiness can limit mobility and ease of transport.

Ultra-compact inflators are designed for portability and ease of storage, fitting easily into glove compartments or backpacks. They are particularly useful for motorcycles, bicycles, and emergency kits, catering to businesses that require a lightweight solution for tire inflation. When selecting an ultra-compact model, buyers should evaluate the inflation speed and maximum pressure capacity. However, their limited performance and slower inflation rates can be a trade-off for their small size.

Multi-function inflators come equipped with additional features such as USB charging ports and built-in lights, making them versatile tools for various applications. These inflators are often used in automotive retail and emergency services, where adaptability is crucial. Buyers should assess the range of features offered and their relevance to specific business needs. While the added functionalities may come at a higher price, the versatility can justify the investment for many businesses.

| Industry/Sector | Specific Application of best tire inflator portable air compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Quick tire inflation for customer vehicles | Reduces wait times, enhances customer satisfaction | Reliability, speed of inflation, and ease of use |

| Transportation and Logistics | Maintaining tire pressure on delivery trucks | Improves fuel efficiency and safety, reduces breakdowns | Portability, power source options, and maximum pressure |

| Construction and Heavy Equipment | Inflating tires on construction machinery | Ensures operational efficiency and safety on-site | Durability, high-pressure capabilities, and ruggedness |

| Sports and Recreation | Inflating tires for bicycles, ATVs, and recreational vehicles | Supports diverse recreational activities, enhancing user experience | Compact size, multiple adapters, and battery life |

| Agriculture | Tire maintenance for farm vehicles and equipment | Increases productivity and reduces downtime | Versatility, ease of transport, and compatibility with various vehicles |

Automotive repair shops rely on efficient service to keep customers satisfied. The best tire inflators allow mechanics to quickly inflate tires, reducing customer wait times. This efficiency can directly enhance customer satisfaction and retention, as clients appreciate prompt and effective service. For international buyers, sourcing inflators with reliable performance under varying climatic conditions is crucial, especially in regions like Africa and South America where extreme temperatures can affect equipment functionality.

In the transportation sector, maintaining optimal tire pressure is vital for delivery trucks. A portable tire inflator helps logistics companies avoid costly breakdowns and enhances fuel efficiency by ensuring that tires are properly inflated. This can lead to significant cost savings over time. Buyers in regions with extensive road networks, such as the Middle East and Europe, should prioritize inflators that offer quick inflation times and can operate on multiple power sources, ensuring they remain functional in diverse environments.

Construction sites often use heavy machinery that requires regular tire maintenance. Portable tire inflators enable quick inflation of equipment tires, which is essential for maintaining operational efficiency. This reduces downtime and enhances safety on-site. Buyers from Europe, where regulatory compliance is strict, should consider inflators that meet safety standards and can handle high-pressure requirements, ensuring they are suited for heavy-duty applications.

In the sports and recreation sector, portable tire inflators are essential for inflating tires on bicycles, ATVs, and other recreational vehicles. They facilitate easy maintenance, allowing users to enjoy their activities without the hassle of flat tires. Buyers in this sector should look for compact models with multiple adapters to accommodate various tire types, as well as robust battery life to ensure they can be used in remote locations.

Agricultural vehicles and equipment require consistent tire maintenance to ensure productivity on farms. Portable tire inflators enable farmers to quickly inflate tires, minimizing downtime during critical operations. For agricultural buyers, especially in South America and Africa, it is important to source durable inflators that can withstand rugged conditions and offer versatility for different types of vehicles and machinery, ensuring that they can handle the demands of the agricultural sector.

The Problem: B2B buyers often require tire inflators that can handle multiple vehicles or high-frequency usage, especially in sectors like transportation and logistics. A common pain point is that many portable air compressors have limited battery life, making them inadequate for inflating multiple tires in one go. This can lead to downtime, as users must wait for the device to recharge or switch to a less efficient model, ultimately impacting productivity and service delivery.

Illustrative image related to best tire inflator portable air compressor

The Solution: When sourcing a portable tire inflator, prioritize models with robust battery capacities or dual power options. For example, the AstroAI Cordless Tire Inflator is designed to inflate multiple tires on a single charge, allowing users to top off all four tires without interruption. To ensure maximum efficiency, consider investing in inflators with replaceable battery packs or those that can plug into a vehicle’s 12-volt outlet, thus providing a backup power source. Additionally, evaluate the inflator’s performance metrics, such as the time taken to inflate from a low psi to the desired level, ensuring it meets your operational needs.

The Problem: Inaccurate pressure readings can be a significant issue for B2B buyers, particularly in industries where tire performance is critical, such as freight and transportation. Over-inflated tires can lead to blowouts, while under-inflated tires can reduce fuel efficiency and increase tire wear. Many portable inflators come with analog gauges that may not provide reliable readings, leading to costly mistakes.

The Solution: When evaluating tire inflators, opt for models with digital pressure gauges, which tend to offer more accurate readings than their analog counterparts. For instance, products like the Craftsman 12V Max Portable Air Inflator feature a clear LED screen displaying precise pressure settings. Furthermore, implement a standard operating procedure that includes periodic calibration of the inflator’s pressure gauge against a professional-grade gauge to ensure ongoing accuracy. Educating users on the importance of verifying tire pressure before and after inflation can also mitigate risks associated with improper inflation.

The Problem: B2B buyers in sectors that utilize heavy-duty vehicles, such as construction and agriculture, often encounter challenges when inflating larger tires. Many portable tire inflators are not designed to handle high-pressure requirements or the physical size of these tires, which can lead to inefficiencies and increased operational costs.

The Solution: For buyers dealing with larger tires, it is crucial to choose inflators specifically designed for high-capacity needs, such as the Viair 88P, which is renowned for its ability to inflate larger tires quickly. Ensure that the inflator you select is compatible with the specific psi requirements of your fleet’s tires. Additionally, consider purchasing inflators with longer hose lengths and robust construction to accommodate the demands of heavy-duty applications. Training personnel on the proper use of these inflators can also enhance safety and efficiency, as they can learn to monitor the inflation process closely and make adjustments as needed.

When selecting materials for portable tire inflators, manufacturers often consider several common materials that can enhance performance, durability, and user experience. Here, we analyze four prevalent materials: plastic, aluminum, steel, and rubber, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Plastic is widely used in the housing and components of tire inflators due to its lightweight nature and resistance to corrosion. Key properties include low thermal conductivity and good impact resistance, making it suitable for various environmental conditions.

Pros: Plastic is cost-effective, lightweight, and can be molded into complex shapes, allowing for innovative designs. It also resists rust and corrosion, which is beneficial for outdoor use.

Cons: However, plastic may not withstand high temperatures or pressures as well as metals, limiting its use in high-performance applications. Over time, exposure to UV light can degrade plastic, making it less durable.

Impact on Application: Plastic components are generally suitable for inflators designed for light to moderate use, such as those intended for passenger vehicles.

Illustrative image related to best tire inflator portable air compressor

Considerations for International Buyers: Compliance with international standards (e.g., ASTM D638 for tensile properties) is crucial. Buyers in regions like Europe may prefer materials that meet specific environmental regulations regarding plastics.

Aluminum is another popular choice for tire inflators, particularly for components requiring strength and lightweight characteristics. Its properties include excellent thermal conductivity and resistance to corrosion.

Pros: Aluminum is durable, lightweight, and can handle higher pressures, making it ideal for inflators designed for trucks and SUVs. It also has a good strength-to-weight ratio, which enhances portability.

Cons: The main disadvantage is its higher cost compared to plastic. Additionally, aluminum can be more complex to manufacture, requiring specialized processes.

Impact on Application: Aluminum is suitable for high-performance inflators that need to operate under varying temperature and pressure conditions, ensuring reliability during intense usage.

Illustrative image related to best tire inflator portable air compressor

Considerations for International Buyers: Buyers should ensure that aluminum components comply with relevant standards (e.g., DIN 1725 for aluminum alloys). European buyers may have preferences for specific alloys that enhance performance and corrosion resistance.

Steel is often used in the construction of heavy-duty tire inflators, particularly in components that require high durability and strength. Key properties include high tensile strength and excellent resistance to wear and impact.

Pros: Steel is incredibly strong and can withstand high pressures, making it ideal for industrial-grade inflators. It is also relatively affordable compared to other metals.

Cons: The downside is that steel is heavier than aluminum and plastic, which can affect portability. Additionally, it is prone to rust if not properly coated or treated.

Impact on Application: Steel is suitable for inflators designed for commercial use or heavy-duty applications, such as those used in construction or agricultural settings.

Illustrative image related to best tire inflator portable air compressor

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM A36 for structural steel. In regions with high humidity, additional corrosion-resistant coatings may be necessary.

Rubber is primarily used for seals and hoses in tire inflators due to its flexibility and excellent sealing properties. Key properties include good elasticity and resistance to wear.

Pros: Rubber provides a reliable seal, preventing air leaks and ensuring efficient inflation. It is also resistant to various chemicals, making it versatile for different applications.

Cons: However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures. This can lead to cracks and reduced performance.

Illustrative image related to best tire inflator portable air compressor

Impact on Application: Rubber components are essential for inflators that require airtight seals, particularly in portable models that need to maintain pressure over time.

Considerations for International Buyers: Compliance with standards such as ASTM D2000 for rubber materials is essential. Buyers should also consider the climate of their region, as extreme temperatures may affect rubber performance.

| Material | Typical Use Case for best tire inflator portable air compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and lightweight components | Lightweight and corrosion-resistant | Limited high-temperature/pressure performance | Low |

| Aluminum | High-performance inflators for trucks/SUVs | Durable and high strength-to-weight ratio | Higher cost and complex manufacturing | Medium |

| Steel | Heavy-duty commercial inflators | Very strong and affordable | Heavier and prone to rust | Medium |

| Rubber | Seals and hoses | Excellent sealing properties | Degrades over time with exposure | Low |

This analysis provides B2B buyers with insights into material selection for tire inflators, helping them make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing of portable tire inflators involves several critical stages, each designed to ensure that the final product meets performance and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to best tire inflator portable air compressor

Material Preparation

The manufacturing process begins with sourcing high-quality materials. Common materials used in tire inflators include durable plastics for the casing, rubber for hoses, and metal for internal components. Suppliers should provide Material Safety Data Sheets (MSDS) to verify material quality and compliance with international standards. The materials undergo rigorous inspections to eliminate defects before they proceed to the next stage.

Forming

In this stage, materials are shaped into their respective components using various techniques. For plastic parts, injection molding is a prevalent method, allowing for precise shapes and dimensions. Metal components may be produced through stamping or machining processes. Quality control checks at this stage ensure that parts are produced within specified tolerances, which is critical for the inflator’s performance.

Assembly

Once components are formed, they are assembled into the final product. This step can be manual or automated, depending on the manufacturer’s capabilities. Assembly lines are designed to streamline the process, with checkpoints to verify that components fit correctly and function as intended. Automated assembly can enhance consistency, while manual assembly allows for detailed inspection by skilled workers.

Finishing

The finishing stage includes final touches such as painting, labeling, and packaging. This stage also involves final quality checks to ensure that the inflators meet aesthetic and functional standards. Finishing is crucial for branding and user experience, as well as for compliance with international regulations.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for portable tire inflators, aimed at ensuring that products are safe, reliable, and effective. Various international standards and industry-specific regulations guide this process.

International Standards for Quality Assurance

Compliance with ISO 9001, the international standard for quality management systems, is essential for manufacturers aiming to compete in global markets. This standard emphasizes continuous improvement, customer satisfaction, and process consistency. Additionally, certifications like CE mark (for products sold in the European Economic Area) and API (American Petroleum Institute) standards ensure compliance with safety and performance regulations specific to tire inflators.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated into the manufacturing process to monitor product quality at various stages:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. It ensures that all materials comply with specifications and are free from defects.

– In-Process Quality Control (IPQC): During manufacturing, IPQC checks are conducted to monitor production processes and ensure that components meet design specifications. This helps identify issues early in the process, reducing waste and rework.

– Final Quality Control (FQC): The last checkpoint occurs before the products are packaged and shipped. FQC involves comprehensive testing of the final product, including performance tests, safety checks, and visual inspections.

Common Testing Methods for Tire Inflators

Manufacturers employ various testing methods to assess the functionality and durability of tire inflators. Common tests include:

– Pressure Testing: Inflators are tested to ensure they can reach and maintain specified pressure levels, simulating real-world conditions.

– Durability Testing: This involves subjecting the inflators to extreme conditions, such as high temperatures and continuous operation, to evaluate their longevity and reliability.

– Electrical Safety Testing: For electric inflators, tests are conducted to ensure that electrical components meet safety standards and do not pose hazards to users.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability and compliance with regional standards.

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should consider on-site audits to evaluate the production environment, equipment, and adherence to quality management systems. A thorough audit can uncover potential risks and help establish a more robust partnership.

Requesting Quality Assurance Reports

Suppliers should provide documentation detailing their quality control processes, including IQC, IPQC, and FQC results. These reports should highlight any certifications, compliance with international standards, and results from common testing methods. Buyers can analyze these reports to assess the supplier’s commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased perspective on a supplier’s quality control practices. These services can conduct random inspections during production or before shipment, ensuring that products meet quality standards. Buyers can request inspection reports to verify that the inflators have undergone rigorous testing and meet specified criteria.

International buyers must navigate various quality control nuances when sourcing portable tire inflators. Understanding these nuances can help mitigate risks and ensure compliance with local regulations.

Cultural and Regulatory Differences

Different regions may have varying standards and regulations for tire inflators. For example, European buyers may prioritize CE certification, while buyers in the Middle East may look for compliance with local safety standards. Understanding these differences is crucial for selecting the right supplier.

Language and Communication Barriers

Effective communication is essential for ensuring quality. Buyers should ensure that all specifications, expectations, and quality requirements are clearly communicated to suppliers. Language barriers can lead to misunderstandings, so it may be beneficial to work with suppliers who have experience in international markets.

Establishing Clear Terms and Conditions

Buyers should clearly define quality expectations, testing requirements, and acceptable tolerance levels in contracts. This ensures that both parties have a mutual understanding of quality standards and can help prevent disputes over product quality.

In conclusion, the manufacturing processes and quality assurance practices for portable tire inflators are critical for ensuring product reliability and safety. B2B buyers must engage in thorough due diligence when selecting suppliers, focusing on quality control measures, compliance with international standards, and effective communication to foster successful partnerships.

Illustrative image related to best tire inflator portable air compressor

In the competitive landscape of automotive maintenance, selecting the right portable tire inflator is crucial for ensuring efficiency and reliability. This guide provides a practical checklist for B2B buyers looking to procure the best tire inflator portable air compressor, helping you make informed decisions that align with your operational needs.

Establishing clear technical specifications is the foundation of your procurement process. Consider the intended use of the inflator—whether for passenger vehicles, trucks, or SUVs—as this will dictate the required PSI range and power source. Additionally, assess portability needs, such as weight and storage dimensions, to ensure ease of use in various settings.

Stay updated on market trends and technological innovations in tire inflators. This includes advancements in battery technology, inflation speed, and integrated features like digital pressure gauges and USB ports. Understanding these trends can help you identify products that not only meet current demands but also offer future-proof solutions.

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, including years of operation, customer testimonials, and case studies from businesses in similar industries. Look for suppliers who have a proven track record of reliability and customer service, as these factors can significantly impact your experience.

Product performance is paramount when evaluating tire inflators. Look for models that have been tested for speed, efficiency, and accuracy under real-world conditions. Consider conducting your own tests or relying on third-party reviews to gauge how well a product performs in various scenarios, such as inflating multiple tires or handling flat tires.

A robust warranty and dependable after-sales support are critical factors in your purchasing decision. Ensure that the inflator comes with a warranty that covers defects and performance issues. Additionally, assess the supplier’s customer service capabilities, including their responsiveness to inquiries and availability of replacement parts.

While initial pricing is important, consider the total cost of ownership, which includes maintenance, operational costs, and potential repairs. Compare prices across different suppliers and models, but also evaluate the long-term value offered by features such as durability and energy efficiency. This comprehensive approach will help you make a financially sound decision.

Once you’ve selected a supplier, clarify logistics and delivery terms. Ensure that the shipping timelines align with your operational needs and that the supplier can accommodate your order volume. Discuss any potential customs or import regulations if sourcing internationally, particularly in regions like Africa or South America.

By following this checklist, B2B buyers can streamline their sourcing process for portable tire inflators, ensuring they choose a product that meets their needs while fostering strong supplier relationships.

When sourcing tire inflators, it is essential to understand the various cost components involved in their production. The primary factors include:

Illustrative image related to best tire inflator portable air compressor

Materials: The choice of materials significantly influences the cost. High-quality plastics, metals, and electronic components contribute to durability and performance but come at a higher price. For instance, inflators with lithium-ion batteries or advanced pressure sensors will generally be more expensive due to the cost of these components.

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs, such as those in Southeast Asia, may offer competitive pricing, but this can also affect the quality of workmanship.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and indirect labor. Efficient production processes can help reduce these costs, impacting the final pricing.

Tooling: Initial tooling costs for production molds and machinery can be substantial, particularly for custom designs. These costs are typically amortized over large production runs, making them less significant per unit for higher volumes.

Quality Control (QC): Implementing strict quality control measures is vital to ensure product reliability, especially in B2B markets. However, this adds to the overall cost. Suppliers with ISO certifications or similar credentials may charge a premium for their assurance of quality.

Logistics: Transportation and warehousing are critical components of the cost structure. Costs can vary widely based on the shipping method (air vs. sea), distance, and any tariffs or customs duties applicable in the destination country.

Margin: Finally, manufacturers will include a profit margin in their pricing. This can vary based on market conditions and competition.

Several factors can significantly influence the pricing of tire inflators in the B2B market:

Volume/MOQ: Bulk purchases often lead to better pricing. Suppliers are more willing to offer discounts for larger orders, which can reduce the per-unit cost substantially.

Specifications and Customization: Custom-designed inflators tailored to specific needs (e.g., higher pressure capabilities or unique features) may incur additional costs. Buyers should evaluate whether these customizations are essential for their market.

Materials: As mentioned, the choice of materials impacts cost. Buyers should balance quality and price, ensuring that the materials used will meet their performance expectations without unnecessary expenditure.

Quality and Certifications: Products with recognized certifications (like CE, UL) may come at a premium but can provide assurance regarding safety and performance, which is critical for B2B buyers.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding the terms of trade (Incoterms) can influence overall costs. Buyers should be clear about who is responsible for shipping costs, insurance, and customs duties, as this can significantly impact the total cost of ownership.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

Negotiate Terms: Engage suppliers in discussions about pricing, especially for large orders. Being clear about your purchasing intentions can yield better deals.

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, handling, and potential warranty costs. A lower initial price may lead to higher overall expenses if quality is compromised.

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local demand, competition, and market saturation. Research local market conditions to make informed purchasing decisions.

Leverage Relationships: Building a strong relationship with suppliers can lead to better pricing and service. Long-term partnerships often yield mutual benefits in terms of flexibility and pricing.

Prices for tire inflators can vary widely based on market conditions, supplier negotiations, and specific customization requests. Always obtain multiple quotes and conduct thorough market research to ensure competitive pricing.

When it comes to maintaining vehicle tire pressure, the best tire inflator portable air compressor is a popular choice among businesses and individuals alike. However, there are several alternative solutions available that can also effectively address tire inflation needs. This analysis will compare the best portable tire inflators against two viable alternatives: traditional air compressors and manual tire pumps. Each solution has its own strengths and weaknesses, making it essential for B2B buyers to understand the differences.

| Comparison Aspect | Best Tire Inflator Portable Air Compressor | Traditional Air Compressor | Manual Tire Pump |

|---|---|---|---|

| Performance | Quick inflation, precise pressure control | High volume, continuous use | Limited pressure output |

| Cost | Moderate ($40 – $90) | Higher ($150 – $500) | Low ($10 – $30) |

| Ease of Implementation | User-friendly, portable | Requires installation and power source | Simple, no power needed |

| Maintenance | Minimal, occasional battery checks | Regular maintenance needed | Very low maintenance |

| Best Use Case | Personal vehicles, emergencies | Workshops, garages, fleet maintenance | Emergency backup, bicycles |

Traditional air compressors are often used in commercial settings, where high-volume tire inflation is required. They can inflate tires quickly and continuously, making them ideal for garages and workshops. However, they are typically more expensive and require a power source, which can limit their portability. Maintenance is also more involved, as components like filters and oil levels must be regularly checked. For businesses with a high demand for tire inflation, the investment in a traditional air compressor can be justified, but for occasional use, it may be overkill.

Manual tire pumps are the most basic form of tire inflation technology. They are compact, inexpensive, and require no power, making them highly portable and suitable for emergency situations. While they are effective for inflating bicycle tires or topping off low-pressure tires, their performance is limited compared to powered inflators. Manual pumps require physical effort and time, making them less practical for larger vehicles or multiple tires. They are best utilized as a backup solution when other options are unavailable.

Illustrative image related to best tire inflator portable air compressor

When selecting the right tire inflation solution, B2B buyers should consider their specific needs, including the volume of tires to be inflated, budget constraints, and the importance of portability. The best tire inflator portable air compressor offers a balance of performance, ease of use, and reasonable cost, making it suitable for personal vehicles and emergencies. Traditional air compressors are ideal for high-demand environments but may not be necessary for every business. Meanwhile, manual tire pumps serve as an economical backup option but lack the efficiency of powered solutions. By evaluating these factors, buyers can make an informed decision that aligns with their operational requirements.

Understanding the technical specifications of a tire inflator is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential properties to consider:

Maximum pressure, measured in pounds per square inch (PSI), indicates the highest air pressure the inflator can achieve. This specification is vital for users with vehicles that require higher tire pressures, such as SUVs and trucks. A unit with a higher PSI rating can accommodate a wider range of vehicles and applications, ensuring versatility in the field.

The duty cycle reflects the duration for which a tire inflator can operate continuously before needing a cooldown period. For example, a duty cycle of 20 minutes means the inflator can run for that duration before requiring a break. This is particularly important for commercial buyers who may need to inflate multiple tires in quick succession, as it affects productivity and operational efficiency.

Portable tire inflators can be powered by batteries, 12-volt outlets, or AC power. Understanding the power source is essential for determining usability in various environments. Battery-operated models provide convenience for remote areas, while those that plug into a vehicle’s power outlet can offer continuous operation without the risk of battery depletion.

Illustrative image related to best tire inflator portable air compressor

The inflation speed indicates how quickly the inflator can fill a tire to the desired pressure. This is measured in minutes, and a faster inflation rate can significantly improve efficiency, especially in high-demand situations like roadside assistance. B2B buyers should prioritize models that balance speed with accuracy to ensure customer satisfaction.

Inflators come with different types of pressure gauges, such as digital or analog. Digital gauges offer precise readings and are easier to read, reducing the chances of over-inflation. For B2B buyers, investing in inflators with reliable pressure gauges can enhance safety and operational efficiency, especially in professional settings.

The dimensions and weight of a tire inflator influence its portability. Models designed to be compact are easier to store and transport, which is a significant advantage for businesses that require mobile solutions. The ability to easily stow the inflator in a vehicle can enhance its appeal to buyers focused on convenience.

Familiarity with industry jargon can streamline communication and negotiations between buyers and suppliers. Here are some key terms:

Illustrative image related to best tire inflator portable air compressor

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflators, understanding OEM relationships can help buyers identify quality products and reliable suppliers.

MOQ specifies the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory effectively and to ensure they meet supplier requirements without overcommitting.

An RFQ is a document used to solicit price quotes from suppliers. B2B buyers should prepare RFQs to obtain competitive pricing and terms for tire inflators, ensuring they can make informed purchasing decisions based on market conditions.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risks associated with the purchase of tire inflators from overseas suppliers.

Warranty terms define the conditions under which a product will be repaired or replaced. Buyers should pay close attention to warranty details for tire inflators, as they can indicate the manufacturer’s confidence in product quality and reliability.

Illustrative image related to best tire inflator portable air compressor

By grasping these essential properties and trade terms, B2B buyers can better navigate the market for portable tire inflators, ensuring they select products that meet their operational needs while optimizing their purchasing strategies.

The global market for portable tire inflators is witnessing significant growth, driven by increasing vehicle ownership, rising awareness of vehicle maintenance, and a surge in outdoor recreational activities. In regions like Africa, South America, the Middle East, and Europe, the demand for efficient and reliable tire inflators is further propelled by the need for safety and performance in both personal and commercial vehicles. Key trends include the rising popularity of cordless and compact models, which cater to a diverse range of consumer needs, from everyday drivers to off-road enthusiasts. The integration of smart technology, such as digital pressure gauges and automated shut-off features, is also reshaping the landscape, appealing to tech-savvy buyers.

Emerging sourcing trends highlight a shift towards online purchasing channels, where B2B buyers can access a wide array of products and compare features, specifications, and prices effectively. The demand for high-performance inflators capable of handling larger tires for SUVs and trucks is on the rise, especially in regions with rugged terrains. Moreover, as supply chains adapt to global disruptions, international buyers are increasingly seeking suppliers who can demonstrate agility and reliability in product availability and delivery timelines.

In the contemporary B2B landscape, sustainability and ethical sourcing have become paramount considerations for buyers in the tire inflator sector. The environmental impact of manufacturing processes and the materials used in products like tire inflators is under increasing scrutiny. Companies are now expected to adopt eco-friendly practices, including the use of recyclable materials and sustainable manufacturing techniques. This shift is particularly relevant for international buyers who prioritize brands that align with global sustainability goals.

Additionally, certifications such as ISO 14001 (Environmental Management) and the use of green materials can serve as indicators of a manufacturer’s commitment to sustainability. B2B buyers are also interested in the lifecycle of the products they source, emphasizing durability and repairability to minimize waste. By sourcing from manufacturers who prioritize ethical supply chains and environmental impact, companies can enhance their brand reputation while contributing to a more sustainable future.

The evolution of portable tire inflators reflects significant advancements in technology and consumer preferences over the years. Initially, tire inflators were bulky, heavy, and limited in functionality, primarily serving the needs of roadside assistance. However, with the advent of cordless battery-operated models, the market has transformed, offering greater convenience and portability. This shift has made it easier for consumers to maintain tire pressure proactively, reducing the risk of blowouts and improving vehicle efficiency.

The introduction of smart features, such as programmable settings and digital displays, has further enhanced user experience. As buyers become more discerning, the focus has shifted towards products that offer not only performance but also ease of use and compact design. Today’s inflators are equipped with additional functionalities, such as USB charging ports and built-in lights, catering to a wide range of applications, from personal vehicles to recreational equipment. This evolution continues to shape the market, presenting opportunities for B2B buyers to source innovative products that meet the demands of modern consumers.

How do I choose the right tire inflator for my business needs?

Selecting the right tire inflator involves evaluating several key factors. Assess your typical use cases, such as whether you need an inflator for light vehicles or heavy-duty trucks. Consider the inflator’s maximum PSI, speed of inflation, and whether it’s cordless or requires a power source. Additionally, think about portability and storage, especially if you plan to transport it frequently. Lastly, ensure the product has a reliable warranty and customer support to address any potential issues.

What are the essential features to look for in a portable tire inflator?

When sourcing a portable tire inflator, prioritize features that enhance usability and efficiency. Look for built-in pressure gauges for accuracy, multiple power options (like battery and vehicle adapter), and the ability to inflate tires to high pressures (at least 80 PSI). Additional features such as LED lights, auto shut-off functions, and compatibility with various valve types can also be beneficial. A compact design that fits easily in storage compartments is vital for convenience, especially in mobile operations.

What is the average lead time for ordering tire inflators from suppliers?

Lead times for tire inflators can vary significantly based on the supplier’s location and manufacturing capabilities. Typically, you can expect a lead time of 4 to 12 weeks for bulk orders, especially if customization is required. Always clarify lead times during negotiations, as delays can affect your inventory management and sales strategy. It’s wise to factor in shipping times, customs clearance, and potential delays due to international logistics, particularly when importing from overseas.

How can I vet suppliers of tire inflators for reliability?

To ensure you partner with reliable suppliers, conduct thorough due diligence. Check their business credentials, including registration, certifications, and industry experience. Request references from previous clients and evaluate online reviews or ratings. Consider visiting their manufacturing facilities if feasible, and ask for samples of their products to assess quality firsthand. Establishing communication about your needs and expectations can also provide insight into their responsiveness and customer service.

What are the minimum order quantities (MOQs) for tire inflators?

Minimum order quantities for tire inflators often depend on the supplier’s production capabilities and your negotiation skills. Typically, MOQs can range from 50 to 500 units. However, larger orders may qualify for better pricing or terms. Discuss MOQs directly with suppliers and explore the possibility of combining orders for different models or accessories to meet MOQ requirements while maximizing your investment.

What payment terms should I expect when sourcing tire inflators internationally?

Payment terms for international orders can vary, but common practices include a deposit (often 30% to 50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger transactions to protect both parties. Always clarify payment methods accepted, such as wire transfers or credit cards, and be aware of any additional fees associated with currency conversion or international transactions.

How do I ensure quality assurance (QA) for tire inflators before purchase?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. It’s advisable to conduct a quality inspection, either by hiring a third-party inspection service or by visiting the manufacturing site. Ask for samples to evaluate performance and durability before placing a bulk order. Additionally, establish clear quality standards and return policies in your contract to protect your interests in case of defects or unsatisfactory products.

What logistics considerations should I keep in mind when importing tire inflators?

Logistics are crucial when importing tire inflators. Factor in shipping methods (air, sea, or land) based on cost and urgency. Understand customs regulations in your destination country, including tariffs and taxes, to avoid unexpected charges. Collaborate with reliable freight forwarders to streamline the shipping process and track your order. Additionally, plan for warehousing and distribution logistics once the products arrive to ensure timely availability to your customers.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. **Viair 88P**: Recommended by a user for inflating to 95 psi, operates off truck battery clamps, compact size fits behind the seat. 2. **Milwaukee Inflator**: Mentioned as a primary option for airing up after trips, but specific model details not provided.

In today’s competitive market, selecting the right portable tire inflator is crucial for enhancing operational efficiency and ensuring customer satisfaction. As identified in our review, products like the AstroAI Cordless Tire Inflator and Craftsman 12V Max Portable Air Inflator stand out due to their reliability, compact design, and user-friendly features. These attributes not only contribute to effective maintenance of vehicles but also align with the increasing demand for versatile and efficient tools across various sectors.

Strategic sourcing is essential for B2B buyers to secure high-quality inflators that meet regional demands while optimizing cost and performance. By prioritizing suppliers who offer robust customer support and innovative features, businesses can ensure they are equipped to handle a diverse range of tire inflation needs.

Looking ahead, the market for portable tire inflators is poised for growth, particularly in emerging regions such as Africa and South America, where vehicle ownership is on the rise. As an international B2B buyer, now is the time to evaluate your supply chain and invest in high-quality inflators that will not only enhance your service offerings but also drive customer loyalty. Embrace this opportunity to stay ahead of market trends and elevate your business’s operational capabilities.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to best tire inflator portable air compressor