Navigating the global market for the Etenwolf tire inflator presents a unique challenge for B2B buyers who seek reliable, high-performance solutions tailored for diverse applications. With the increasing demand for portable tire inflators across various sectors, from automotive to recreational vehicles, sourcing the right product can significantly impact operational efficiency and customer satisfaction. This comprehensive guide delves into the range of Etenwolf tire inflators, exploring their specifications, applications, and advantages, while also addressing the critical factors involved in supplier vetting, pricing, and after-sales support.

International buyers, particularly those in emerging markets such as Brazil, Nigeria, and other regions in Africa, South America, the Middle East, and Europe, will find this guide invaluable for making informed purchasing decisions. By understanding the nuances of Etenwolf tire inflators, including their robust design, advanced features, and energy efficiency, businesses can enhance their service offerings and ensure customer loyalty. Moreover, the guide provides actionable insights into navigating the complexities of global sourcing, including logistics, compliance, and market trends, empowering buyers to optimize their procurement strategies. In a competitive landscape, leveraging this knowledge is key to capitalizing on opportunities and mitigating risks associated with tire inflation solutions.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| ETENWOLF Vortex S6 Heavy Duty Tire Inflator | Fast inflation, 15,600 mAh battery, max pressure 160 PSI | Heavy-duty vehicles, fleet management | Pros: High performance, versatile for various vehicles. Cons: Higher price point. |

| ETENWOLF Zephyr S3 Heavy Duty Tire Inflator | Compact design, 7,800 mAh battery, auto-stop feature | Automotive service centers, roadside assistance | Pros: Affordable, user-friendly. Cons: Lower battery capacity compared to Vortex models. |

| ETENWOLF Vortex S7 Heavy Duty Tire Inflator | 38,400 mAh battery, highest airflow speed, rugged design | Construction sites, off-road vehicles | Pros: Exceptional battery life and power. Cons: Bulky for some users. |

| ETENWOLF Zephyr S5 Heavy Duty Tire Inflator | Quick inflation, portable charger, 15,600 mAh battery | Retail automotive shops, personal use | Pros: Good balance of power and portability. Cons: Limited to lighter vehicles. |

| ETENWOLF Vortex S6 SE Heavy Duty Tire Inflator | Multiple nozzle attachments, designed for inflatables | Recreational vehicle owners, emergency kits | Pros: Versatile for various applications. Cons: May not be as powerful for heavy-duty tires. |

The ETENWOLF Vortex S6 is engineered for rapid tire inflation, featuring a 15,600 mAh battery that delivers up to 160 PSI. This model is particularly suited for heavy-duty vehicles and fleet management applications, where reliability and speed are critical. B2B buyers should consider its robust performance and versatility, although its higher price point may be a consideration for budget-conscious businesses.

The ETENWOLF Zephyr S3 is a compact tire inflator with an auto-stop feature that enhances user convenience. With a 7,800 mAh battery, it’s ideal for automotive service centers and roadside assistance operations. While its affordability and ease of use make it appealing, buyers should note its lower battery capacity compared to other models in the range, which could limit its application for larger vehicles.

Designed with a powerful 38,400 mAh battery, the ETENWOLF Vortex S7 offers the highest airflow speed among its peers, making it perfect for construction sites and off-road vehicles. Its rugged build ensures durability in demanding environments. While its exceptional battery life and power are significant advantages, its bulkiness might deter some users seeking portability.

The ETENWOLF Zephyr S5 strikes a balance between performance and portability, featuring a 15,600 mAh battery ideal for retail automotive shops and personal use. Its quick inflation capabilities and portable charger make it a practical choice. However, buyers should consider that it is best suited for lighter vehicles, as it may not meet the demands of heavier applications.

The ETENWOLF Vortex S6 SE is designed for versatility, equipped with multiple nozzle attachments suitable for various inflatables, from tires to sports equipment. This makes it a valuable addition to recreational vehicle owners and emergency kits. While its multifunctionality is a strong selling point, buyers should be aware that it may not deliver the same power for heavy-duty tires as dedicated models.

| Industry/Sector | Specific Application of etenwolf tire inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Service Centers | Tire inflation for various vehicle types | Ensures customer safety and satisfaction through timely service | Reliability, ease of use, and battery capacity for multiple inflations |

| Logistics and Transportation | On-site tire maintenance for fleet vehicles | Reduces downtime and enhances operational efficiency | Portability, fast inflation rates, and battery life |

| Construction | Inflation of heavy equipment tires | Minimizes equipment downtime, ensuring project timelines are met | Durability, max pressure capacity, and compatibility with heavy machinery |

| Sports and Recreation | Inflating sports equipment and recreational vehicles | Enhances user experience and safety for sports teams and outdoor activities | Versatility in inflating different types of equipment |

| Emergency Services | Quick tire inflation for emergency response vehicles | Ensures rapid deployment and readiness of emergency vehicles | Compact size, fast inflation speed, and built-in features like LED lights |

In automotive service centers, the Etenwolf tire inflator is utilized for quick and efficient tire inflation across a variety of vehicle types, including cars, SUVs, and trucks. This tool addresses common issues such as low tire pressure, which can lead to safety hazards and decreased fuel efficiency. Service centers require reliable inflators that can handle diverse tire sizes and pressures, making the Etenwolf a valuable asset due to its precision and ease of use. International buyers, particularly from regions like Africa and South America, should prioritize sourcing inflators that offer robust performance in varied climates and terrains.

In logistics and transportation, the Etenwolf tire inflator is essential for maintaining fleet vehicle tire pressure on-site. Keeping tires properly inflated not only enhances vehicle safety but also optimizes fuel efficiency, thereby reducing operational costs. Fleet managers need inflators that are portable and capable of rapid inflation to minimize downtime during operations. For international buyers, especially in the Middle East and Europe, sourcing inflators with high battery capacity and fast inflation rates will ensure that fleet maintenance is both efficient and effective.

Illustrative image related to etenwolf tire inflator

In the construction industry, the Etenwolf tire inflator is used to inflate tires on heavy equipment such as excavators and bulldozers. Proper tire inflation is critical to minimizing equipment downtime, which can significantly impact project timelines and budgets. Buyers in this sector should focus on inflators with high durability and maximum pressure capacities to handle the demands of heavy machinery. For international buyers, especially in developing regions, ensuring that the inflator can withstand rough working conditions is essential for long-term investment.

The Etenwolf tire inflator serves a vital role in the sports and recreation sector by providing a reliable solution for inflating sports equipment and recreational vehicles, such as bicycles and inflatable boats. Proper inflation is crucial for performance and safety during activities. Organizations and teams require versatile inflators that can handle various equipment types efficiently. For international buyers, particularly in regions like Brazil and Nigeria, the ability to quickly switch between different nozzles and inflation modes enhances usability and meets diverse needs.

Emergency services rely on the Etenwolf tire inflator for rapid tire inflation of emergency response vehicles, ensuring they are always ready for deployment. Quick inflation capabilities are essential in critical situations where every second counts. Buyers from this sector should consider inflators that are compact, lightweight, and equipped with features like LED lights for operation in low visibility conditions. This is particularly important for international buyers in regions with varying infrastructure and emergency response challenges, ensuring that vehicles remain operational regardless of circumstances.

Illustrative image related to etenwolf tire inflator

The Problem: For businesses that manage a fleet of vehicles—such as logistics companies or transportation services—maintaining optimal tire pressure is crucial for safety and fuel efficiency. However, fluctuating tire pressure can lead to increased fuel consumption, tire wear, and even accidents. Fleet managers often struggle to monitor and inflate tires efficiently, particularly when vehicles are in constant use or dispersed across various locations.

The Solution: To address this challenge, investing in ETENWOLF tire inflators can provide a reliable and portable solution for fleet maintenance. These inflators are designed for rapid inflation, allowing fleet managers to quickly service tires on-site, reducing downtime. Consider establishing a routine maintenance schedule where team members are trained to use the ETENWOLF inflators effectively. Ensure that each inflator is equipped with a battery indicator to avoid unexpected power loss during operation. Additionally, utilizing the preset pressure modes on the inflators can help staff achieve the correct tire pressure consistently, further enhancing safety and efficiency.

The Problem: B2B buyers, particularly those in the automotive service industry, face challenges when their equipment is not versatile enough to handle various types of tires—cars, trucks, bicycles, and heavy machinery. This limitation can hinder operations, as technicians may need to rely on multiple inflators, increasing costs and complicating logistics.

Illustrative image related to etenwolf tire inflator

The Solution: The ETENWOLF tire inflators are engineered for versatility, making them ideal for businesses that require multi-use capabilities. When sourcing these inflators, prioritize models like the Vortex S6 or S7, which can accommodate a wide range of tire sizes and types, including those used in heavy-duty vehicles. By investing in these robust inflators, businesses can streamline their operations and reduce the need for multiple devices. Implementing training sessions for staff on the various features of the inflators—such as the digital display and auto-stop functionality—will ensure that all team members are equipped to use the inflators efficiently, no matter the tire type.

The Problem: In high-demand settings, such as automotive repair shops or tire service centers, inflators can overheat due to prolonged use, leading to equipment failure and delays in service. This can be particularly frustrating for businesses that rely on quick turnaround times to maintain customer satisfaction and operational efficiency.

The Solution: To mitigate overheating issues, businesses should leverage the active cooling feature of ETENWOLF tire inflators, which is designed to manage heat buildup during operation. When utilizing these inflators, it’s advisable to establish a maximum continuous operation time, allowing for cooling periods between uses. Educating staff on recognizing signs of overheating and implementing a rotation system for inflators can also help maintain consistent performance. Additionally, ensure that all inflators are regularly maintained and checked for any signs of wear, which can affect their cooling efficiency. By actively managing usage and maintenance, businesses can extend the lifespan of their inflators while ensuring they remain ready for high-volume demands.

In summary, understanding these common pain points and implementing the suggested solutions can enhance the operational efficiency and reliability of ETENWOLF tire inflators within B2B contexts.

When selecting materials for the Etenwolf tire inflator, several key properties and considerations come into play. The choice of materials directly affects the product’s performance, durability, and suitability for various applications. Here, we analyze four common materials used in tire inflators, providing insights relevant to international B2B buyers.

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a pressure rating suitable for tire inflators, making it a popular choice for housing and structural components.

Pros:

– Durability: Aluminum is resistant to rust and corrosion, ensuring longevity in diverse environments.

– Cost-Effective: Generally more affordable than other metals like stainless steel.

– Manufacturing Simplicity: Easier to machine and shape, allowing for complex designs.

Cons:

– Strength Limitations: While strong for its weight, aluminum may not withstand extreme pressures as effectively as steel.

– Thermal Conductivity: Can lead to overheating if not designed with adequate cooling features.

Impact on Application: Aluminum’s lightweight nature makes it suitable for portable tire inflators, enhancing mobility. However, care must be taken to manage heat during operation.

Considerations for International Buyers: Compliance with international standards such as ASTM for aluminum alloys is essential. Buyers in regions like Africa and South America should ensure sourcing from certified suppliers to meet local regulations.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are commonly used for components like casings and nozzles. These materials are lightweight and can be engineered for specific performance characteristics.

Pros:

– Corrosion Resistance: Plastics do not rust, making them ideal for humid or wet conditions.

– Cost Efficiency: Generally lower in cost compared to metals, reducing overall production expenses.

– Versatility: Can be molded into complex shapes, allowing for innovative designs.

Cons:

– Temperature Sensitivity: Plastics can deform under high temperatures, limiting their use in high-performance applications.

– Mechanical Weakness: May not withstand high-pressure environments as effectively as metals.

Impact on Application: Plastics are ideal for non-structural components, providing a balance between functionality and weight. However, they may not be suitable for high-pressure applications.

Considerations for International Buyers: Buyers should consider the recycling and environmental impact of plastic materials, especially in regions with stringent regulations on plastic use.

Steel, particularly stainless steel, is renowned for its strength and durability. It is often used in high-pressure components of tire inflators, such as the motor casing and internal mechanisms.

Pros:

– High Strength: Excellent tensile strength allows for high-pressure applications.

– Corrosion Resistance: Stainless steel offers good resistance to rust and corrosion, extending product life.

– Longevity: Steel components typically have a longer lifespan than plastic or aluminum.

Illustrative image related to etenwolf tire inflator

Cons:

– Weight: Heavier than aluminum or plastic, which can affect portability.

– Cost: Generally more expensive, impacting the overall product price.

Impact on Application: Steel is essential for parts that require high durability and strength, making it a preferred choice for heavy-duty inflators.

Considerations for International Buyers: Compliance with international standards, such as DIN for steel grades, is crucial. Buyers should also consider local sourcing options to mitigate import costs.

Rubber is often used in seals and gaskets within tire inflators to ensure airtight operation. Its flexibility and resilience make it ideal for various applications.

Pros:

– Excellent Sealing Properties: Rubber effectively prevents air leaks, enhancing performance.

– Durability: Resistant to wear and tear, providing a long service life.

– Cost-Effective: Generally low-cost compared to other materials.

Cons:

– Temperature Sensitivity: Rubber can degrade over time when exposed to extreme temperatures or UV light.

– Limited Pressure Resistance: Not suitable for high-pressure applications.

Impact on Application: Rubber components are vital for ensuring the reliability of tire inflators, especially in fluctuating environmental conditions.

Illustrative image related to etenwolf tire inflator

Considerations for International Buyers: Buyers should ensure that rubber materials meet specific industry standards for durability and safety, particularly in regions with extreme climates.

| Material | Typical Use Case for etenwolf tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Limited strength under extreme pressure | Medium |

| Plastic | Casings and nozzles | Cost-effective and versatile | Temperature sensitivity and mechanical weakness | Low |

| Steel | High-pressure components | High strength and durability | Heavier and more expensive | High |

| Rubber | Seals and gaskets | Excellent sealing properties | Temperature sensitivity and limited pressure resistance | Low |

This strategic material selection guide provides insights into the materials used in Etenwolf tire inflators, helping B2B buyers make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing process of Etenwolf tire inflators involves several critical stages, each designed to ensure that the final product meets high standards of performance and durability.

The first step in manufacturing Etenwolf tire inflators is material preparation. High-quality materials are essential for producing reliable inflators. Common materials include:

Before production, materials undergo rigorous inspections to verify compliance with international quality standards.

The forming stage involves shaping the prepared materials into components. This typically includes:

These techniques are crucial for creating inflators that perform consistently across various applications.

During the assembly phase, all components are meticulously put together. This process includes:

By implementing a structured assembly process, Etenwolf can maintain high-quality standards while maximizing production efficiency.

The final stage of manufacturing involves finishing processes that enhance the product’s appearance and functionality. Key techniques include:

These finishing techniques are vital for delivering a product that not only looks good but also performs reliably.

Quality assurance is a cornerstone of Etenwolf’s manufacturing philosophy, ensuring that every tire inflator meets rigorous standards before it reaches the market.

Etenwolf adheres to several international quality standards, including:

These certifications provide a framework for continuous improvement and customer confidence in Etenwolf products.

Etenwolf employs multiple quality control checkpoints throughout the manufacturing process:

By implementing these checkpoints, Etenwolf minimizes the risk of defects and enhances product reliability.

To ensure quality and performance, Etenwolf utilizes various testing methods, including:

These testing methods help ensure that the tire inflators can withstand real-world conditions and provide reliable service to end-users.

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial.

These steps can help ensure that suppliers maintain high-quality standards, reducing the risk of defective products.

Illustrative image related to etenwolf tire inflator

International buyers must consider the following nuances:

By being aware of these factors, international B2B buyers can make informed decisions when sourcing tire inflators from Etenwolf.

In conclusion, understanding the manufacturing processes and quality assurance measures in place at Etenwolf is crucial for B2B buyers looking to invest in reliable tire inflators. By focusing on the key stages of production and rigorous quality control, Etenwolf ensures that its products not only meet but exceed market expectations, providing value to customers worldwide.

In this guide, we aim to provide a comprehensive checklist for B2B buyers looking to procure the ETENWOLF tire inflator. This step-by-step approach will help ensure that your sourcing process is efficient, thorough, and aligned with your operational needs.

Illustrative image related to etenwolf tire inflator

Begin by clearly defining the technical requirements for the tire inflator. Consider the types of vehicles you will be servicing, such as cars, SUVs, or trucks, and the necessary PSI range and airflow speed.

– Key Specifications to Consider:

– Maximum pressure capabilities (e.g., 160 PSI).

– Battery capacity and charging time.

– Airflow speed, which affects inflation time.

Explore the range of ETENWOLF tire inflators to identify models that meet your specifications. Each model offers unique features tailored to different needs, such as the Vortex S6 for heavy-duty use or the Zephyr S3 for lightweight applications.

– Considerations:

– Read customer reviews and ratings to gauge performance and reliability.

– Compare features such as auto-stop functions and digital displays.

Before finalizing your supplier, verify their certifications and compliance with industry standards. This ensures that the products you receive are safe, reliable, and of high quality.

– What to Look For:

– ISO certifications or equivalent.

– Compliance with local regulations in your target market.

– Warranty and return policies to protect your investment.

Illustrative image related to etenwolf tire inflator

Request samples of the tire inflators to conduct performance tests. This hands-on evaluation can provide insights into usability, efficiency, and durability.

– Testing Criteria:

– Speed of inflation under various conditions.

– Battery life and recharge time.

– Ease of use, particularly in emergency scenarios.

Evaluate the after-sales support provided by the supplier. Reliable customer service can be critical, especially when dealing with potential issues post-purchase.

– Key Questions to Ask:

– What is the duration and coverage of the warranty?

– Are there dedicated support channels for troubleshooting?

– How does the supplier handle returns or exchanges?

Once you have selected a preferred supplier, enter negotiations regarding pricing, payment terms, and delivery schedules. Establishing favorable terms can significantly impact your overall procurement costs.

– Negotiation Tips:

– Leverage volume discounts if placing a large order.

– Discuss shipping options and costs, especially for international deliveries.

– Confirm lead times to align with your inventory requirements.

After reaching a satisfactory agreement, ensure that all terms are documented in a formal purchase agreement. This protects both parties and clarifies expectations.

– Key Components of the Agreement:

– Detailed product specifications and quantities.

– Pricing, payment methods, and delivery timelines.

– Terms regarding warranties, returns, and support services.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for ETENWOLF tire inflators, ensuring that they select the right product and supplier for their business needs.

When sourcing Etenwolf tire inflators, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

Materials: High-quality raw materials are crucial for durability and performance. Etenwolf inflators utilize premium components, which can elevate the base price. Buyers should assess the material specifications to ensure they align with their quality requirements.

Labor: Labor costs vary significantly by region. In countries with higher labor standards, such as those in Europe, production costs may increase. However, outsourcing to regions with lower labor costs can reduce overall expenses.

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can minimize these costs, benefiting both the manufacturer and the buyer.

Tooling: Initial tooling costs for molds and machinery can be significant, particularly for customized inflators. Buyers should consider the potential for shared tooling costs in bulk orders to mitigate these expenses.

Quality Control: Rigorous QC processes ensure that each tire inflator meets industry standards. While this adds to the overall cost, it is essential for maintaining product reliability, especially in markets with stringent regulations.

Logistics: Shipping costs can fluctuate based on the destination, order volume, and chosen shipping method. For international buyers, understanding Incoterms is crucial for managing freight and insurance costs effectively.

Margin: Suppliers typically include a margin to cover their risks and profits. Negotiating this margin can be beneficial, particularly for larger orders.

Illustrative image related to etenwolf tire inflator

Several factors influence the pricing of Etenwolf tire inflators, which B2B buyers must consider to optimize their purchasing strategy.

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Higher volumes often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs carefully to determine the optimal order size.

Specifications/Customization: Custom features or specifications can increase production costs. Buyers should weigh the benefits of customization against potential price hikes to ensure they are investing wisely.

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can influence both price and durability. Buyers should verify that the products meet the necessary certifications for their respective markets to avoid compliance issues.

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge higher prices due to their proven track record but often offer better support and warranty options.

Illustrative image related to etenwolf tire inflator

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance cost-efficiency when sourcing Etenwolf tire inflators.

Negotiation: Always be prepared to negotiate pricing, especially for bulk orders. Establishing a good relationship with suppliers can lead to better deals and favorable terms.

Total Cost of Ownership: Consider not just the purchase price but the total cost of ownership, including maintenance, warranty, and replacement costs. A slightly higher initial investment may yield lower long-term costs if the product is more durable.

Pricing Nuances for International Buyers: Currency fluctuations and tariffs can affect overall costs. Buyers should factor in these variables when calculating their budgets and consider securing fixed pricing agreements where possible.

Logistics Planning: Choosing the right shipping method and understanding customs regulations can save significant costs. Collaborating with logistics experts can streamline the process and reduce unforeseen expenses.

Illustrative image related to etenwolf tire inflator

The prices mentioned for Etenwolf tire inflators are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

When it comes to tire maintenance, having the right inflator can make a significant difference in efficiency and convenience. While the Etenwolf tire inflator is a leading solution in the market, it’s essential for B2B buyers to explore alternative options. This analysis compares the Etenwolf tire inflator against other viable alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Etenwolf Tire Inflator | Portable Electric Tire Inflator | Manual Foot Pump |

|---|---|---|---|

| Performance | Fast inflation (up to 52L/min) | Moderate inflation speed (20-30L/min) | Slow inflation (5-10L/min) |

| Cost | $69.99 – $199.99 USD | $30 – $80 USD | $15 – $30 USD |

| Ease of Implementation | User-friendly, battery-operated | Requires AC power or car outlet | Simple, no power needed |

| Maintenance | Low (occasional cleaning) | Moderate (check power source) | Very low (manual operation) |

| Best Use Case | Ideal for various vehicle types and emergencies | Suitable for home use or roadside assistance | Best for low-frequency use or emergencies |

Portable electric tire inflators provide a convenient solution for those who prefer a lightweight, easy-to-carry option. These devices generally operate on battery power or can be plugged into a vehicle’s outlet. Their performance varies, but they typically inflate tires at a moderate speed, making them suitable for emergency use or general maintenance. However, the reliance on a power source can be a drawback in remote areas. Additionally, while they are less expensive than the Etenwolf, they may not offer the same durability or range of features.

Manual foot pumps are the most basic option for tire inflation. They require no electricity, making them universally usable in any setting. While they are the most affordable option, they come with significant drawbacks: they are labor-intensive and can take a considerable amount of time to inflate a tire. This option is best suited for infrequent use or situations where no other inflators are available. Despite their low cost and maintenance, the manual effort involved can deter users, especially in urgent situations.

Illustrative image related to etenwolf tire inflator

When selecting a tire inflator, B2B buyers should carefully consider their specific needs and usage scenarios. The Etenwolf tire inflator stands out for its high performance, ease of use, and versatility across different vehicle types, making it a superior choice for businesses that require reliable and quick tire inflation. Conversely, portable electric inflators may appeal to those with budget constraints, while manual foot pumps can serve as a backup option in emergencies. Ultimately, understanding the context of use, frequency of tire maintenance, and available power sources will guide buyers in making an informed decision that aligns with their operational needs.

When considering the purchase of Etenwolf tire inflators, understanding their technical properties is essential for making informed B2B decisions. Here are several critical specifications that define the performance and reliability of these products:

Max Pressure (160 PSI)

The maximum pressure rating indicates the highest air pressure that the inflator can achieve. For B2B buyers, this is crucial as it determines whether the inflator can handle the specific tire types and sizes in their fleet, ensuring optimal safety and performance.

Airflow Speed (L/min)

The airflow speed, measured in liters per minute (L/min), defines how quickly the inflator can fill a tire. Etenwolf models vary in airflow capabilities, with some reaching up to 52 L/min. High airflow rates translate to reduced downtime, allowing businesses to maintain productivity and efficiency.

Battery Capacity (mAh)

Battery capacity, measured in milliamp hours (mAh), indicates how long the inflator can operate before requiring a recharge. Etenwolf inflators come with capacities ranging from 7,800 mAh to 38,400 mAh, providing flexibility for various applications. A higher capacity is particularly beneficial for businesses requiring prolonged use without frequent recharges.

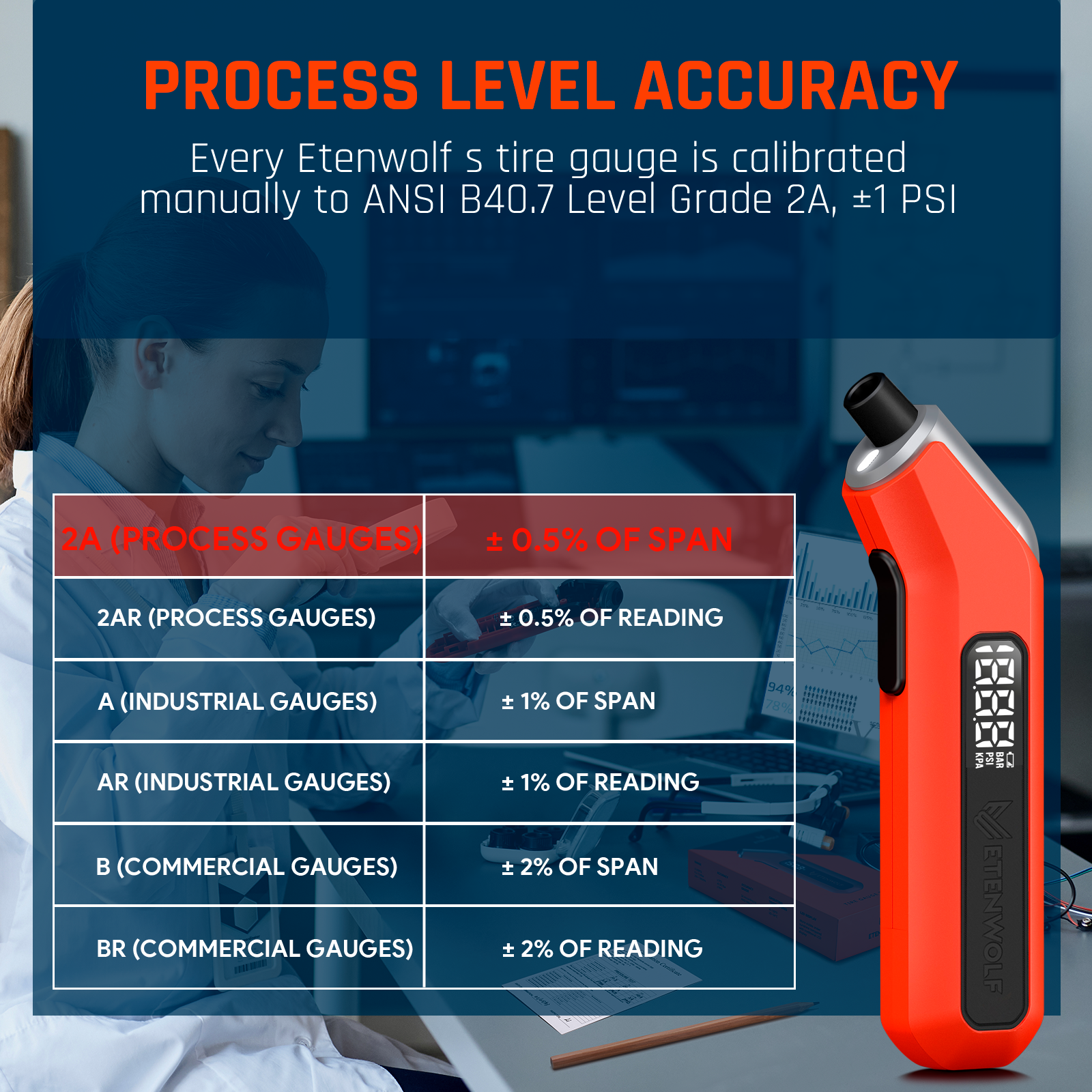

Sensor Accuracy (±1 PSI)

This specification refers to the precision of the built-in pressure sensor. An accuracy of ±1 PSI ensures that tires are inflated to the correct pressure, helping to prevent under-inflation or over-inflation. For B2B buyers, this translates to enhanced safety and improved fuel efficiency, as properly inflated tires contribute to better vehicle performance.

Portable Charger Capability

Etenwolf tire inflators feature USB charging ports that allow them to function as portable power banks. This dual functionality is invaluable for businesses operating in remote areas or those that require versatility in their tools, providing additional utility beyond tire inflation.

Additional Features

Features like digital displays, auto-stop mechanisms, and built-in LED lights enhance user experience and safety. These conveniences can reduce the learning curve for staff and improve operational efficiency in a B2B context.

Familiarity with industry-specific jargon is vital for B2B buyers to navigate procurement processes effectively. Here are some common terms associated with the purchase of Etenwolf tire inflators:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether Etenwolf products are OEM-compliant can help buyers ensure compatibility with existing equipment.

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ for Etenwolf tire inflators helps buyers plan their inventory and budget effectively, preventing overstock or stockouts.

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. When seeking bulk purchases of Etenwolf inflators, issuing an RFQ can facilitate competitive pricing and better terms.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms ensures that B2B buyers understand shipping costs, risks, and delivery points associated with purchasing Etenwolf products globally.

Warranty and Guarantee

Understanding the warranty and guarantee terms is crucial for evaluating the long-term value of the investment. Etenwolf offers a 90-day money-back guarantee and a two-year extended warranty, which can significantly influence purchasing decisions.

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is received. For B2B buyers, understanding lead times for Etenwolf inflators helps in planning and managing stock levels, especially in industries where equipment availability is critical.

By grasping these technical specifications and industry terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Illustrative image related to etenwolf tire inflator

The tire inflator market is witnessing significant growth, driven by a surge in vehicle ownership and a rising focus on vehicle maintenance across various global regions, particularly in Africa, South America, the Middle East, and Europe. The increasing prevalence of SUVs and pickup trucks in these markets has propelled demand for efficient, portable inflators like the Etenwolf range. B2B buyers are now looking for products that not only meet performance standards but also offer technological advancements such as smart pressure monitoring and rapid inflation capabilities.

Emerging trends include the integration of digital technology, allowing users to monitor tire pressure via mobile applications and receive alerts when maintenance is needed. Additionally, the shift towards cordless models, with long-lasting battery life, enhances convenience for consumers who prioritize mobility. The market is also seeing a growing inclination towards products that serve multiple purposes, such as inflating sports equipment or air mattresses, which adds value for both end-users and retailers.

International B2B buyers should be aware of regional preferences and regulatory requirements that may influence sourcing decisions. For example, compliance with safety standards and certifications is crucial, especially in markets with stringent regulations. Understanding these dynamics will help businesses better position their offerings and cater to the specific needs of diverse customer bases.

Sustainability is becoming a pivotal consideration in the sourcing of tire inflators. The environmental impact of manufacturing processes and the lifecycle of products are now critical factors for B2B buyers. Companies are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainable practices. This includes using recycled materials in production and minimizing carbon footprints throughout the supply chain.

Etenwolf is positioned to meet these demands by focusing on premium build quality that ensures durability, thereby extending the product lifecycle. Additionally, the company’s commitment to using eco-friendly materials and processes can be a significant selling point for B2B buyers looking to enhance their sustainability credentials. Certifications related to environmental standards can further bolster trust and appeal among consumers who are increasingly eco-conscious.

Illustrative image related to etenwolf tire inflator

As businesses seek to align with sustainability goals, prioritizing suppliers with transparent ethical practices will become essential. This not only enhances brand reputation but also meets the growing consumer expectation for responsible business practices.

The Etenwolf tire inflator brand has evolved significantly since its inception, adapting to changing consumer needs and technological advancements. Initially focused on basic inflation solutions, the company recognized the demand for more sophisticated, portable inflators as vehicle ownership surged globally. By investing in research and development, Etenwolf has introduced a range of products that cater to various segments, including heavy-duty models for trucks and versatile options for everyday consumers.

Over the years, Etenwolf has positioned itself as a leader in innovation, integrating features such as quick inflation times, user-friendly interfaces, and multi-functional capabilities. This evolution reflects broader market trends that prioritize convenience, efficiency, and sustainability, establishing Etenwolf as a preferred choice for B2B buyers seeking reliable and advanced tire inflation solutions.

Illustrative image related to etenwolf tire inflator

How do I ensure the ETENWOLF tire inflator meets my business needs?

To determine if the ETENWOLF tire inflator aligns with your business requirements, consider factors such as the types of vehicles in your fleet, the frequency of tire maintenance, and your specific inflation needs. Evaluate the inflator’s specifications, such as maximum pressure, battery capacity, and compatibility with various tire types. Additionally, reviewing customer testimonials and performance reviews can provide insights into its reliability and effectiveness in real-world applications, helping you make an informed purchasing decision.

What is the best ETENWOLF tire inflator for commercial use?

For commercial applications, the ETENWOLF Vortex S6 Heavy Duty Tire Inflator is an excellent choice. Designed for larger vehicles like SUVs and trucks, it features a robust motor, fast inflation capabilities, and a high battery capacity. Its user-friendly interface, auto-stop function, and digital display enhance usability for fleet maintenance teams. If your business requires versatility, the Vortex S6 can also handle various inflatables, making it a multifunctional tool for diverse operational needs.

What are the minimum order quantities (MOQ) for purchasing ETENWOLF tire inflators?

The MOQ for ETENWOLF tire inflators can vary based on the type of product and your purchasing agreement. Generally, bulk orders may offer advantageous pricing structures, which can be beneficial for businesses looking to equip fleets or retail outlets. It’s recommended to contact the ETENWOLF sales team directly to discuss your specific needs, potential discounts, and any available promotional offers that could apply to larger orders.

How can I verify the quality of ETENWOLF tire inflators before purchasing?

To verify the quality of ETENWOLF tire inflators, consider requesting samples or product demonstrations. Additionally, review certifications, warranties, and quality assurance processes the manufacturer follows. Look for third-party reviews and testimonials from other B2B buyers to gain insights into product performance and reliability. Engaging with the manufacturer’s customer support can also provide clarity on their commitment to quality and after-sales service.

What payment terms are available for purchasing ETENWOLF tire inflators?

ETENWOLF typically offers flexible payment terms, including options like credit card payments, wire transfers, and possibly installment plans for larger orders. For international buyers, it’s essential to confirm payment methods that align with your local banking regulations and currency preferences. Discussing your payment options with the sales team can ensure a smooth transaction process and help you understand any associated fees or conditions.

Are there customization options available for ETENWOLF tire inflators?

Yes, ETENWOLF may offer customization options for their tire inflators, including branding, color choices, and specific features tailored to meet your business needs. Customization can enhance your brand visibility and ensure that the products align with your operational requirements. Contact the sales team to discuss potential customization options and any associated costs or lead times.

What logistics options are available for shipping ETENWOLF tire inflators internationally?

ETENWOLF provides various logistics options for international shipping, including standard and expedited services. The choice of logistics will depend on your location, urgency, and budget. Ensure to inquire about shipping costs, delivery times, and tracking options. Additionally, understanding import regulations and customs duties in your region is crucial to avoid unexpected delays or fees during the shipping process.

How does ETENWOLF handle customer support and warranty claims?

ETENWOLF offers robust customer support, typically available Monday to Friday during business hours. For warranty claims, customers are advised to keep their purchase receipts and follow the outlined procedures provided by the company. The standard warranty period is generally two years, covering defects in materials and workmanship. Familiarizing yourself with the warranty policy can help you manage any potential issues efficiently, ensuring continued satisfaction with your purchase.

Domain: etenwolf.com

Registered: 2021 (4 years)

Introduction: ETENWOLF Tire Inflators:

1. **Models Available:**

– ZEPHYR S3

– ZEPHYR S5

– VORTEX S6

– VORTEX S6 SE

– VORTEX S7

2. **Key Features:**

– Fast and precise inflation solutions

– Cordless design suitable for various vehicles (pick-up trucks, SUVs, trailers, cars, bicycles)

– Built-in battery indicator

– Multiple nozzles for different inflatables

– Quick infla…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Etenwolf Vortex S6 tire inflator / air compressor, priced at USD$99, designed for mobile and versatile use to inflate tires of Ford Maverick, bikes, beds, balls, and inner tubes. Not suitable for SUPs.

The strategic sourcing of ETENWOLF tire inflators offers significant advantages for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a diverse range of products designed for varying vehicle types, ETENWOLF inflators stand out for their robust performance, ease of use, and innovative features, such as quick inflation and built-in battery indicators. These attributes not only enhance operational efficiency but also ensure safety and reliability in tire maintenance.

Engaging in strategic sourcing of ETENWOLF products allows businesses to leverage quality and durability, which are paramount in the automotive aftermarket. The competitive pricing and the assurance of a two-year warranty further solidify the value proposition for distributors and retailers seeking to enhance their product offerings.

Looking ahead, the demand for reliable tire inflation solutions will only grow, driven by increasing vehicle ownership and a focus on safety. We encourage international buyers to consider ETENWOLF tire inflators as a strategic addition to their inventory. By partnering with ETENWOLF, you can position your business to meet market needs effectively while ensuring customer satisfaction. Invest in quality today for a safer, more efficient tomorrow.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.