In today’s competitive automotive landscape, understanding how to effectively inflate tires at gas stations is essential for international B2B buyers looking to enhance their service offerings. Proper tire inflation is not only crucial for vehicle safety and performance but also significantly impacts fuel efficiency and tire longevity. For businesses in regions such as Africa, South America, the Middle East, and Europe, sourcing reliable and efficient tire inflation solutions presents a unique set of challenges. This guide aims to address those challenges by providing comprehensive insights into various tire inflation methods, evaluating the different types of air compressors available, and outlining their applications in diverse market contexts.

Throughout this guide, we will delve into the nuances of selecting the right tire inflation equipment, including key factors such as supplier vetting and cost analysis. By understanding the diverse options available—from manual inflators to advanced digital systems—B2B buyers will be empowered to make informed purchasing decisions that align with their operational needs and market demands. Additionally, we will explore regional considerations, ensuring that businesses in countries like Saudi Arabia and Nigeria can adapt best practices to their local environments. Ultimately, this guide serves as a valuable resource for enhancing tire maintenance services, driving customer satisfaction, and fostering business growth in the global automotive market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Coin-Operated Air Machines | Require coins or tokens for operation | Gas stations, service stations | Pros: Low initial cost, easy installation. Cons: Ongoing maintenance, revenue sharing with station owners. |

| Digital Air Pumps | Equipped with digital displays for precise PSI readings | Auto repair shops, fleet service centers | Pros: Accurate readings, user-friendly. Cons: Higher upfront cost, potential for electronic malfunctions. |

| Portable Air Compressors | Compact, often battery-operated for convenience | Mobile tire services, roadside assistance | Pros: Versatile, can be used anywhere. Cons: Limited air capacity, may require frequent recharging. |

| Self-Serve Tire Inflation Stations | Automated systems that guide users through the inflation process | Urban areas, busy gas stations | Pros: Reduces labor costs, enhances customer experience. Cons: Initial investment can be high, requires regular maintenance. |

| Fleet Tire Inflation Systems | Centralized systems for inflating multiple tires simultaneously | Commercial fleets, logistics companies | Pros: Efficient for large operations, can improve tire longevity. Cons: High installation and maintenance costs. |

Coin-operated air machines are a staple at gas stations and service centers. They require users to insert coins or tokens to activate the air compressor, making them a low-cost option for businesses. These machines are typically straightforward to install and maintain, appealing to small gas station operators. However, ongoing maintenance can be a concern, and revenue-sharing agreements may limit profitability for station owners.

Digital air pumps are increasingly popular due to their user-friendly interfaces and precise PSI displays. These machines are commonly found in auto repair shops and fleet service centers, where accuracy is paramount. The ability to provide real-time pressure readings helps reduce the risk of over-inflation, which can lead to tire damage. However, the initial investment is higher compared to traditional machines, and they may require electronic maintenance.

Portable air compressors are ideal for mobile tire services and roadside assistance. Their compact design allows for easy transport, making them suitable for businesses that need to inflate tires on-the-go. While they offer flexibility and convenience, their air capacity is often limited, necessitating frequent recharging. B2B buyers should consider the compressor’s power source and capacity when purchasing.

Self-serve tire inflation stations automate the inflation process, guiding users through each step. These systems are especially beneficial in urban areas where time is of the essence. By reducing labor costs and enhancing customer experience, they can attract more traffic to gas stations. However, the initial investment can be significant, and regular maintenance is crucial to ensure reliability.

Fleet tire inflation systems are designed for commercial fleets, allowing for the simultaneous inflation of multiple tires. This efficiency can significantly improve the longevity of tires and reduce downtime. While they represent a substantial investment in terms of installation and maintenance, the long-term savings in tire replacement and fuel efficiency can make them a worthwhile consideration for logistics companies. B2B buyers should evaluate the total cost of ownership when considering these systems.

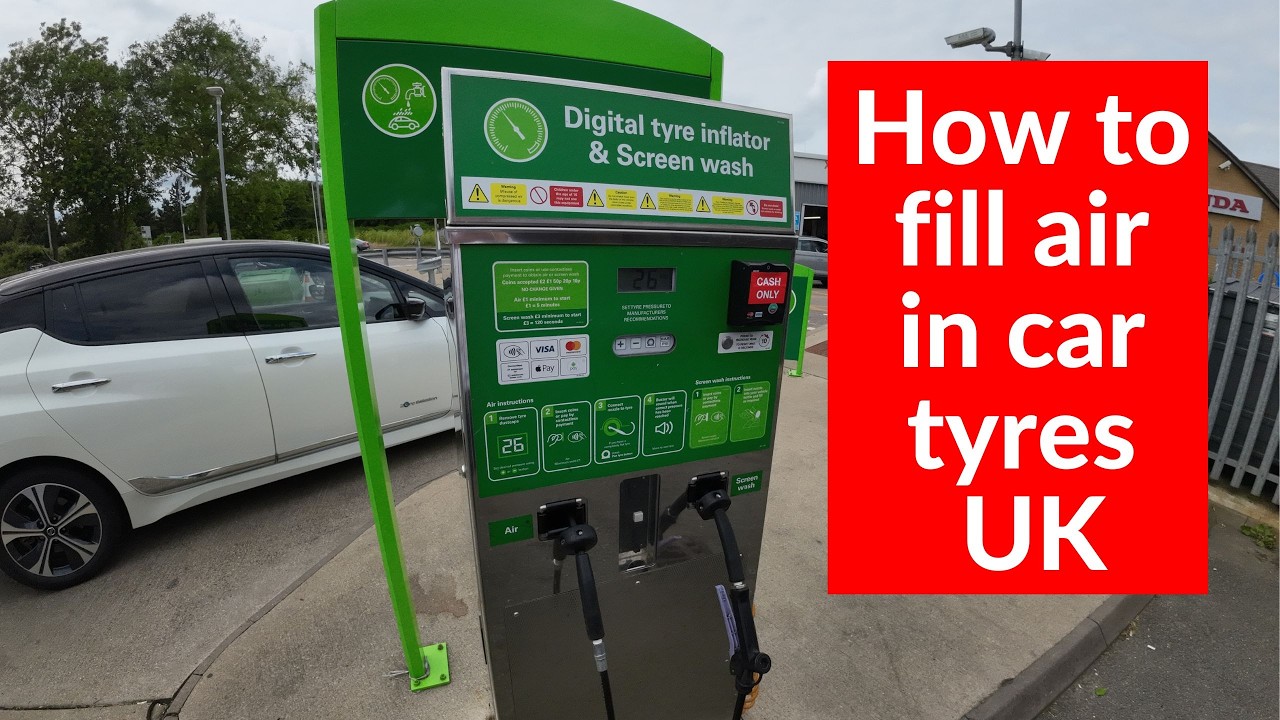

Illustrative image related to how to inflate tires gas station

| Industry/Sector | Specific Application of how to inflate tires gas station | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Fleet Maintenance at Gas Stations | Enhanced vehicle safety and reduced operational costs | Reliable tire inflators, ease of use, and maintenance support |

| Automotive Services | Tire Inflation Services for Customers | Increased customer satisfaction and loyalty | Quality air compressors, accessibility, and service speed |

| Agriculture | Tire Inflation for Agricultural Equipment | Improved efficiency and reduced downtime | Durable equipment suitable for various tire sizes |

| Construction | Tire Maintenance for Heavy Machinery | Enhanced safety and extended machinery lifespan | Robust inflating systems, portability, and reliability |

| Retail | Self-Service Tire Inflation Stations | Additional revenue stream and convenience for customers | User-friendly design, payment systems, and maintenance plans |

In the transportation and logistics sector, gas stations often serve as crucial maintenance hubs for fleet vehicles. Regular tire inflation ensures that trucks and delivery vehicles operate safely and efficiently, minimizing the risk of accidents caused by under-inflated tires. Fleet managers must prioritize sourcing high-quality tire inflators that are easy to use and maintain, ensuring they can quickly service vehicles to keep operations running smoothly. Reliable inflators can significantly reduce fuel consumption and extend tire life, which are critical cost-saving factors for logistics companies.

Automotive service providers frequently offer tire inflation as part of their maintenance services. By providing customers with easy access to tire inflation stations, these businesses can enhance customer satisfaction and encourage repeat visits. For B2B buyers in this sector, sourcing efficient and reliable air compressors is essential. They should consider factors such as the speed of inflation, ease of use, and customer service capabilities to ensure they meet the demands of their clientele effectively.

In agriculture, maintaining proper tire pressure on tractors and other farming equipment is vital for operational efficiency. Gas stations equipped with tire inflation services can cater to local farmers, reducing their downtime due to tire issues. Buyers in this sector should look for durable inflating equipment that can handle various tire sizes and pressures. Additionally, they should ensure that their inflation solutions are portable and easy to use in remote agricultural settings, where access to maintenance services can be limited.

For construction companies, the safety and performance of heavy machinery heavily rely on properly inflated tires. Gas stations that provide tire inflation services can help construction firms minimize risks associated with tire failures. When sourcing tire inflation solutions, construction businesses must prioritize robust systems that can withstand harsh working conditions. Reliability and ease of transportation are also critical, as construction sites often require mobility and quick access to maintenance tools.

Retail businesses can increase foot traffic and revenue by offering self-service tire inflation stations at gas stations. These stations provide a convenient solution for customers who need to inflate their tires quickly. For B2B buyers in retail, it is essential to source user-friendly designs that include payment systems and easy maintenance options. By providing a valuable service to customers, retailers can enhance their brand reputation and foster customer loyalty, making tire inflation stations a strategic investment.

Illustrative image related to how to inflate tires gas station

The Problem: B2B buyers, particularly those managing fleets or transport services, often face the challenge of inconsistent tire pressure readings at gas station air compressors. Variations in calibration between different machines can lead to confusion and potential over or under-inflation of tires, which compromises vehicle safety and efficiency. This inconsistency can lead to premature tire wear and increased operational costs due to frequent replacements or repairs.

The Solution: To mitigate this issue, B2B buyers should consider investing in a high-quality, portable tire pressure gauge. By using a reliable gauge, fleet managers can verify the tire pressure before and after using gas station compressors, ensuring accuracy. Additionally, buyers should establish a partnership with specific gas stations known for maintaining their air compressors, or consider installing in-house tire inflation stations that guarantee consistent pressure readings. Regular training for staff on how to correctly check and maintain tire pressure can further enhance safety and efficiency.

The Problem: In certain regions, particularly in Africa or South America, the availability of functional air compressors at gas stations can be limited. This scarcity can hinder operations for businesses reliant on transport, as drivers may spend excessive time searching for a working machine, leading to delays and reduced productivity. For fleet operators, this scenario can escalate into significant financial losses due to downtime.

The Solution: B2B buyers should explore partnerships with local gas stations to ensure their fleets have access to reliable air compressors. Establishing a network of preferred stations can streamline operations. Additionally, investing in mobile air compressors for fleet vehicles can provide a backup option, allowing drivers to inflate tires on-site without the need to locate a gas station. Regular communication with drivers about nearby stations with working equipment can also optimize route planning and minimize delays.

The Problem: Fleet operators often encounter poorly maintained air inflation equipment at gas stations, which can lead to malfunctioning machines that either fail to inflate tires or provide incorrect pressure levels. This not only frustrates drivers but can also result in safety issues if tires are improperly inflated. For businesses, this represents a significant risk, potentially leading to accidents or costly repairs.

The Solution: To address this pain point, B2B buyers should implement a proactive strategy by conducting regular assessments of gas station air inflation equipment. This could involve setting up a feedback system where drivers report the condition of air compressors after use. Building relationships with station owners to advocate for regular maintenance of their equipment can improve reliability. Furthermore, buyers might consider providing incentives for gas stations to maintain their air inflation machines, ensuring that their fleet has access to dependable services. Educating drivers on how to identify faulty equipment and encouraging them to seek alternatives can also minimize risks associated with subpar inflation practices.

When it comes to inflating tires at gas stations, the choice of materials used in the equipment is critical. The materials must withstand various environmental conditions, ensure safety, and maintain performance standards. Here’s an analysis of four common materials used in tire inflation systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to how to inflate tires gas station

Key Properties: Steel is known for its high tensile strength and resistance to deformation under pressure. It typically has a pressure rating that can exceed 200 PSI, making it suitable for tire inflation applications.

Pros & Cons: Steel is highly durable and can withstand harsh environmental conditions, including temperature fluctuations and exposure to moisture. However, it is prone to corrosion if not properly coated or treated, which can lead to maintenance issues. The manufacturing process for steel components can be complex and costly, but the long lifespan of steel products often justifies the initial investment.

Impact on Application: Steel is compatible with air and nitrogen, the two most common media used for tire inflation. Its strength makes it ideal for high-pressure applications, ensuring safety during operation.

Illustrative image related to how to inflate tires gas station

Considerations for International Buyers: Buyers should ensure that the steel used complies with international standards such as ASTM or DIN, especially in regions with high humidity or corrosive environments like parts of Africa and the Middle East.

Key Properties: Aluminum has a lower density than steel, offering a good strength-to-weight ratio. It can handle pressures up to 150 PSI, which is adequate for most passenger vehicle tires.

Pros & Cons: Aluminum is lightweight and resistant to corrosion, which makes it suitable for outdoor use. However, it is less durable than steel and may be prone to dents and deformation under extreme pressure. The manufacturing process is generally simpler, leading to lower production costs.

Impact on Application: Aluminum is suitable for portable tire inflators and smaller inflation equipment where weight is a concern. Its corrosion resistance makes it ideal for regions with high humidity.

Considerations for International Buyers: Compliance with standards such as JIS is crucial, particularly in markets like Japan and South Korea. Buyers should also consider the availability of aluminum recycling options in their region to promote sustainability.

Key Properties: Rubber is flexible and can withstand a range of temperatures, typically rated for use between -40°F to 200°F. It is essential for seals and hoses in tire inflation systems.

Pros & Cons: Rubber’s elasticity allows it to absorb shock and vibration, making it ideal for components that experience movement. However, it can degrade over time due to exposure to UV light and ozone, leading to potential failures. The cost of rubber components is relatively low, making them economically viable for mass production.

Impact on Application: Rubber is primarily used in hoses and seals, ensuring airtight connections between the inflation equipment and the tire valve. Its compatibility with air and nitrogen makes it versatile.

Considerations for International Buyers: Buyers should look for rubber materials that meet specific standards for temperature and pressure ratings, particularly in regions with extreme climates like Saudi Arabia and Nigeria.

Key Properties: Composites, often made from a combination of plastics and fibers, can be engineered to have high strength and low weight. They can handle pressures similar to aluminum, around 150 PSI.

Pros & Cons: Composites offer excellent corrosion resistance and can be molded into complex shapes, which is advantageous for design flexibility. However, they may not be as durable as metals and can be more expensive to produce, depending on the formulation.

Impact on Application: Composites are suitable for lightweight, portable tire inflators and can be designed to be user-friendly. Their resistance to corrosion makes them ideal for outdoor use.

Considerations for International Buyers: Compliance with international safety and performance standards is critical, especially in markets with stringent regulations. Buyers should also consider the availability of local suppliers to reduce lead times.

| Material | Typical Use Case for how to inflate tires gas station | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Air compressor tanks and inflation hoses | High durability and strength | Prone to corrosion without treatment | High |

| Aluminum | Portable tire inflators and small compressors | Lightweight and corrosion-resistant | Less durable under extreme pressure | Medium |

| Rubber | Hoses and seals for inflation systems | Flexibility and shock absorption | Degrades over time due to UV exposure | Low |

| Composite | Lightweight, portable tire inflators | Excellent corrosion resistance | Potentially less durable than metals | Medium to High |

This guide provides a comprehensive overview of the materials commonly used in tire inflation systems at gas stations, equipping B2B buyers with the necessary insights to make informed purchasing decisions.

In the manufacturing of tire inflation stations typically found at gas stations, the process can be segmented into several key stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques and quality checks to ensure the final product meets industry standards.

The manufacturing process begins with material preparation, where high-quality raw materials are sourced. Common materials include:

Sourcing materials from reputable suppliers is crucial. B2B buyers should verify that suppliers follow international material standards, such as ISO 9001, to ensure quality and consistency.

Illustrative image related to how to inflate tires gas station

The forming stage involves shaping the prepared materials into specific components using techniques such as:

During the assembly stage, components are meticulously put together. This phase often employs automated machinery alongside skilled labor to ensure precision. Key techniques include:

Finishing techniques are crucial in enhancing the durability and aesthetic appeal of tire inflation stations. Processes involved include:

Illustrative image related to how to inflate tires gas station

Attention to detail during this stage can significantly impact the longevity and reliability of the product.

Quality assurance is integral to the manufacturing of tire inflation stations. It ensures that the final product meets or exceeds industry standards and customer expectations.

Manufacturers of tire inflation stations typically adhere to several international standards, including:

Illustrative image related to how to inflate tires gas station

Understanding these standards helps B2B buyers assess the credibility of suppliers and the quality of their products.

Quality control (QC) checkpoints are implemented throughout the manufacturing process to identify and rectify issues early. Typical checkpoints include:

Implementing these checkpoints helps maintain a consistent quality level, reducing the likelihood of defects in the final product.

B2B buyers need to ensure that their suppliers adhere to stringent quality control measures. Here are actionable steps to verify supplier QC:

Conducting regular audits of potential suppliers can provide insights into their quality management systems. Buyers should consider:

Engaging third-party inspection services can further validate a supplier’s quality control processes. These independent organizations typically provide:

For B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, understanding regional regulations and standards is crucial. Here are some nuances to consider:

By being informed about these factors, international buyers can make better purchasing decisions and establish successful partnerships with suppliers of tire inflation stations.

In today’s competitive automotive landscape, ensuring that your gas station is equipped with reliable tire inflation systems is essential for customer satisfaction and operational efficiency. This guide provides a step-by-step checklist for B2B buyers looking to procure tire inflation solutions for gas stations. By following these steps, you can make informed decisions that align with your business needs.

Before sourcing suppliers, assess the specific requirements for your gas station. Consider factors such as the types of vehicles your customers drive and the volume of tire inflations expected daily. Understanding these needs will help you choose the right equipment that can handle your customer traffic efficiently.

Explore the various types of tire inflation systems available in the market, including manual and automatic air compressors. Each system offers different features, such as digital pressure gauges and built-in payment systems. Make a list of potential options that fit your operational model, keeping in mind the ease of use for both customers and staff.

Before committing, thoroughly vet potential suppliers to ensure they meet your quality standards. Request company profiles, product specifications, and case studies from other clients, especially those in similar regions or industries. This step is vital to ascertain the reliability and reputation of the supplier.

Whenever possible, request demonstrations or samples of the tire inflation systems you are considering. This hands-on experience allows you to evaluate the ease of operation and reliability firsthand. Pay attention to the user interface, speed of inflation, and accuracy of the pressure readings during the demonstration.

Understand the installation process and ongoing maintenance needs of the tire inflation systems. Some units may require professional installation, while others can be set up easily by your staff. Additionally, inquire about maintenance services offered by suppliers to ensure longevity and optimal performance of the equipment.

Obtain detailed quotes from multiple suppliers and compare pricing structures. Look for transparent pricing that includes installation, maintenance, and any additional fees. Also, explore financing options that may be available, as this could significantly affect your budget and cash flow.

After thorough evaluation and comparison, make your final procurement decision based on the gathered information. Ensure that the chosen tire inflation system aligns with your operational needs and budget. Once selected, negotiate the contract terms to secure the best possible deal, including delivery timelines and service level agreements.

By following this checklist, B2B buyers can confidently procure tire inflation solutions that enhance customer service, improve operational efficiency, and ultimately contribute to the success of their gas stations.

When assessing the cost structure for tire inflation services at gas stations, several components come into play. The primary cost components include:

Materials: This encompasses the air compressor systems and any additional equipment required for tire inflation. High-quality compressors with advanced features may incur higher initial costs but can enhance efficiency and reliability.

Labor: Staffing costs are essential, particularly if the gas station offers additional services. Labor costs will vary based on regional wage standards and the level of service provided.

Manufacturing Overhead: This includes indirect costs such as utilities, maintenance, and administrative expenses associated with operating the inflation equipment.

Tooling: Investment in specialized tools for maintenance and calibration of tire inflation equipment can affect overall costs. Regular maintenance ensures accuracy and longevity, impacting long-term operational efficiency.

Quality Control (QC): Implementing QC measures is crucial to ensure that the inflation systems provide accurate pressure readings and are safe to use. This may involve periodic inspections and certifications, contributing to the overall cost.

Logistics: Transporting equipment and supplies to and from the gas station can introduce additional costs, especially in remote areas or regions with challenging infrastructure.

Margin: Gas stations must also factor in their profit margin, which can vary based on market conditions and competitive pricing strategies.

Several factors influence the pricing of tire inflation services at gas stations:

Volume and Minimum Order Quantity (MOQ): Higher volume purchases of inflation equipment or supplies can lead to significant discounts. Gas stations should negotiate based on expected usage to lower unit costs.

Specifications and Customization: Custom features or specialized equipment may come at a premium. Understanding the specific needs of the customer base is essential when selecting equipment.

Materials: The quality and type of materials used in compressors and related equipment can significantly impact pricing. High-end materials may lead to better durability and performance, justifying a higher price.

Quality and Certifications: Equipment that meets higher standards or holds specific certifications may command higher prices. Buyers should assess the long-term benefits of investing in certified equipment.

Supplier Factors: The reliability and reputation of suppliers can influence costs. Established suppliers may offer warranties or service agreements, which can reduce long-term operational risks.

Incoterms: Understanding the shipping terms (Incoterms) is crucial, particularly for international buyers. These terms dictate who is responsible for shipping costs, insurance, and tariffs, affecting the overall landed cost of equipment.

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency when sourcing tire inflation services:

Negotiation: Engage suppliers in discussions about bulk purchasing discounts or long-term contracts, which can lead to better pricing. Emphasizing a commitment to a sustained partnership can yield favorable terms.

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase costs, maintenance, and operational expenses. A lower upfront cost may not always translate to better value over time.

International Pricing Nuances: Be aware of currency fluctuations and regional economic conditions that can affect pricing. Building relationships with local suppliers can mitigate some of these challenges.

Quality over Price: Prioritize quality and reliability over the lowest price. Investing in high-quality equipment can lead to lower maintenance costs and fewer service interruptions.

Market Research: Conduct thorough market research to understand prevailing prices and trends in the tire inflation service sector. This knowledge equips buyers to make informed decisions and negotiate effectively.

The prices and cost structures discussed here are indicative and can vary widely based on geographical location, market conditions, and specific supplier agreements. Buyers should conduct their due diligence and seek tailored quotes to ensure accurate budgeting for their tire inflation service needs.

When it comes to maintaining optimal tire pressure, businesses have multiple options to consider beyond the conventional method of inflating tires at gas stations. These alternatives vary in terms of performance, cost, ease of implementation, and maintenance requirements. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | How To Inflate Tires Gas Station | Portable Air Compressor | Tire Inflation Kiosk |

|---|---|---|---|

| Performance | Effective for quick inflation; typically provides adequate PSI | High efficiency; can inflate multiple tires before needing a recharge | Automated inflation with accurate pressure settings |

| Cost | Generally low cost (coins or tokens) | Moderate initial investment (approx. $50-$150) | Higher upfront cost (around $2,000-$5,000) with ongoing maintenance fees |

| Ease of Implementation | Simple, requires minimal skills; accessible at many locations | Requires user knowledge; some may need training | User-friendly interface; minimal training needed |

| Maintenance | Low; infrequent maintenance required for gas station equipment | Low to moderate; requires regular checks and possible repairs | Moderate; requires regular servicing and software updates |

| Best Use Case | Ideal for occasional users or individual drivers | Best for businesses with fleet vehicles needing regular tire maintenance | Suitable for businesses with high vehicle turnover or heavy usage |

Portable Air Compressor

Portable air compressors are compact devices that allow users to inflate tires anywhere, making them ideal for businesses with a mobile workforce or those operating in remote locations. The primary advantage is their efficiency; they can quickly inflate multiple tires without the need for a power source if they are battery-operated. However, they require an upfront investment and a basic understanding of tire inflation. Businesses must also consider the potential need for maintenance, although this is usually minimal.

Tire Inflation Kiosk

Tire inflation kiosks are automated stations often found in commercial settings or dedicated parking lots. These kiosks provide users with a straightforward experience, offering accurate inflation based on preset pressure levels. The main benefits include a high level of user-friendliness and the ability to serve multiple customers simultaneously, which can enhance operational efficiency. However, the initial investment can be significant, and ongoing maintenance is required to ensure proper functionality. This makes them more suitable for businesses with high vehicle utilization rates, such as logistics or transportation companies.

For B2B buyers evaluating tire inflation solutions, the decision should be based on specific operational requirements and budget considerations. Gas station inflation is a cost-effective solution for occasional users, while portable air compressors offer flexibility for businesses needing regular tire maintenance. Tire inflation kiosks, although more expensive, provide a streamlined experience for high-traffic scenarios. Ultimately, the best choice will depend on factors such as the frequency of tire maintenance, the scale of operations, and the available budget for equipment investment. By carefully assessing these alternatives, businesses can enhance their vehicle maintenance processes and ensure safer, more efficient operations.

When dealing with tire inflation at gas stations, understanding certain technical properties is essential for ensuring efficiency, safety, and compliance. Here are critical specifications to consider:

Illustrative image related to how to inflate tires gas station

Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the optimal inflation level for tires. For most passenger vehicles, this typically ranges between 30-35 PSI. In a B2B context, ensuring that air compressors at gas stations can deliver and display accurate PSI readings is vital for customer satisfaction and safety, as incorrect inflation can lead to tire blowouts or uneven wear.

Compressor Output Capacity

The output capacity of air compressors, often measured in cubic feet per minute (CFM), determines how quickly tires can be inflated. A higher CFM allows for faster service, which can enhance customer throughput at gas stations. For B2B buyers, investing in high-capacity compressors is crucial to cater to high volumes of customers, particularly during peak hours.

Durability of Components

The materials used in air hoses and fittings must withstand high pressures and frequent use. Common materials include reinforced rubber or synthetic composites. B2B buyers should prioritize equipment made from durable materials to reduce maintenance costs and downtime, ensuring that service stations remain operational and efficient.

Temperature Tolerance

Tire pressure can be affected by temperature fluctuations, as air expands when heated. Understanding the temperature tolerance of the compressor and its components is essential for maintaining accurate pressure readings. This knowledge can help prevent equipment failure and ensure consistent tire inflation across various climate conditions.

Flow Rate

The flow rate refers to the volume of air the compressor can deliver over a specific time frame. A higher flow rate means quicker inflation times, which is particularly important in busy gas stations. For B2B buyers, selecting compressors with optimal flow rates can lead to improved customer satisfaction and reduced wait times.

Understanding industry jargon is crucial for effective communication and decision-making in the tire inflation sector. Here are several key terms relevant to B2B buyers:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tire inflation, B2B buyers should ensure they source from reputable OEMs to guarantee quality and compatibility with existing systems.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses purchasing tire inflation equipment, understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate terms that align with their operational needs.

RFQ (Request for Quotation)

An RFQ is a document that solicits pricing and other details from suppliers. B2B buyers should prepare RFQs to obtain competitive pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions.

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers manage shipping logistics and costs effectively, which is particularly important when sourcing equipment from overseas suppliers.

Calibration

Calibration refers to the process of adjusting and verifying the accuracy of tire pressure gauges and compressors. Regular calibration is essential for maintaining precise inflation levels. B2B buyers should prioritize suppliers who offer calibration services to ensure compliance with safety standards.

Service Level Agreement (SLA)

An SLA is a contract that outlines the expected level of service between a provider and its customers. For B2B buyers, understanding SLAs is crucial when engaging with service providers for maintenance or equipment supply, as it sets clear expectations for performance and support.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when investing in tire inflation solutions, ultimately enhancing operational efficiency and customer satisfaction at gas stations.

The market for tire inflation solutions at gas stations is witnessing significant evolution, influenced by various global drivers. One of the foremost trends is the increasing awareness of vehicle maintenance among consumers, particularly in regions like Africa, South America, the Middle East, and Europe. As fuel efficiency and safety become paramount, drivers are more inclined to ensure their tires are adequately inflated, driving demand for accessible tire inflation services at gas stations.

Another critical trend is the integration of technology in tire inflation systems. Advanced air compressor models now offer digital interfaces that provide real-time pressure readings and automated inflation, enhancing user experience and accuracy. These innovations cater to the growing expectations of tech-savvy consumers and can significantly reduce the risk of user error, which is particularly beneficial in markets with varying levels of consumer knowledge about vehicle maintenance.

Additionally, the rise of mobile applications that help locate nearby gas stations with air services is reshaping how consumers interact with these facilities. B2B buyers should consider investing in partnerships with tech providers that offer integrated solutions for tire inflation, including digital payment options and user-friendly interfaces, to stay competitive in this evolving landscape.

Illustrative image related to how to inflate tires gas station

Sustainability is becoming a crucial factor in the sourcing of tire inflation solutions for gas stations. The environmental impact of tire maintenance is significant, with improperly inflated tires leading to increased fuel consumption and higher emissions. As a result, gas stations are increasingly adopting eco-friendly practices, such as promoting tire maintenance awareness campaigns that encourage customers to check their tire pressure regularly.

Ethical sourcing of materials and equipment is also gaining traction. Suppliers that can demonstrate sustainable manufacturing processes, such as using recycled materials for air compressors or energy-efficient technologies, are becoming more desirable. Certifications such as ISO 14001 (Environmental Management) can enhance credibility and appeal to environmentally-conscious buyers in regions like Europe, where regulatory standards are stringent.

Furthermore, gas stations are exploring partnerships with manufacturers that prioritize ‘green’ technologies, such as solar-powered air compressors or systems that reduce energy consumption. By aligning with these sustainability initiatives, B2B buyers not only contribute to environmental preservation but also enhance their brand image in a market that increasingly values corporate responsibility.

The evolution of tire inflation services at gas stations can be traced back to the early 20th century when automobiles became commonplace. Initially, tire inflation was a manual process using handheld pumps, which required considerable effort and skill. As gas stations began to proliferate, the need for efficient tire maintenance solutions became apparent.

By the mid-20th century, gas stations started incorporating air compressor systems, allowing for quicker and more accessible tire inflation for consumers. The introduction of self-service air pumps in the 1980s marked a significant turning point, empowering drivers to manage their tire pressure independently.

Today, with technological advancements and a heightened focus on sustainability, the tire inflation services offered at gas stations continue to evolve, providing a vital service that enhances vehicle safety and efficiency while responding to the demands of modern consumers.

How do I ensure the air compressor at a gas station is functioning properly?

To ensure the air compressor at a gas station is functioning properly, first check for any visible signs of damage or malfunction, such as leaking air or unusual noises. Before using it, make sure that the machine is powered on and that it displays a pressure gauge. If possible, use your own tire pressure gauge to verify readings after inflation. If the compressor seems faulty, it’s best to seek another station, as using a malfunctioning compressor can lead to under-inflation or over-inflation, compromising tire safety.

What are the recommended tire pressure levels for different types of vehicles?

Tire pressure levels vary based on vehicle type and model. Generally, passenger cars require a pressure range of 30-35 PSI, while SUVs and trucks may need 35-40 PSI. This information can typically be found in the vehicle’s owner manual or on a sticker inside the driver’s door jamb. When sourcing tire inflation equipment, ensure that it can accommodate various PSI requirements to cater to a diverse clientele.

How can I verify the quality of air compressors before purchasing?

To verify the quality of air compressors, consider factors such as build material, pressure range, and brand reputation. Research manufacturers and read reviews from other businesses that have used their products. Request samples or demonstrations where possible. Additionally, check for compliance with international safety and performance standards, which can be crucial for operational reliability in different markets.

What is the standard minimum order quantity (MOQ) for tire inflation equipment?

The standard MOQ for tire inflation equipment can vary widely depending on the supplier and product type. Generally, it ranges from 10 to 100 units for bulk orders, while custom equipment may have higher MOQs. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are a new business entering the market.

What payment terms should I expect when sourcing tire inflation equipment internationally?

When sourcing internationally, payment terms can vary significantly. Common options include payment upfront, 30% deposit with the balance upon shipment, or net 30/60 days after delivery. Always clarify payment terms before finalizing the order to avoid misunderstandings. Consider using secure payment methods and letters of credit for larger transactions to mitigate risk.

How do I ensure compliance with international shipping regulations for tire inflation equipment?

To ensure compliance with international shipping regulations, familiarize yourself with the import/export laws of your country and the supplier’s country. Verify that the equipment meets safety and quality standards required in your target market. It is also advisable to work with a freight forwarder who understands these regulations to avoid delays or penalties during shipping.

What quality assurance measures should I implement when sourcing tire inflation products?

Implement quality assurance measures such as conducting supplier audits, requesting product samples, and reviewing compliance certifications. Consider establishing a quality control checklist that includes performance specifications and safety standards. Regularly communicate with suppliers about quality expectations and establish a process for addressing any defects or issues that arise post-delivery.

How can I effectively manage logistics for importing tire inflation equipment?

Effectively managing logistics for importing tire inflation equipment involves selecting a reliable shipping partner, understanding customs procedures, and planning for potential delays. Create a detailed logistics plan that includes timelines, shipping methods, and costs. Utilize tracking systems to monitor shipments in real time and communicate with your supplier to stay updated on any changes that may affect delivery.

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: This company, WikiHow – Tire Inflation Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In conclusion, the process of inflating tires at gas stations is more than just a routine maintenance task; it represents a significant opportunity for B2B buyers to enhance their service offerings and improve customer satisfaction. By ensuring that tire inflation systems are readily available, businesses can address critical factors such as safety, fuel efficiency, and tire longevity, which are paramount to drivers across diverse markets.

Strategic sourcing plays a vital role in optimizing the procurement of air compressor equipment and maintenance tools. B2B buyers should prioritize suppliers who not only provide high-quality equipment but also offer ongoing support and training to ensure proper usage. This not only enhances the customer experience but also fosters brand loyalty.

Looking forward, businesses in Africa, South America, the Middle East, and Europe should seize the opportunity to invest in advanced tire inflation technologies and customer education. By doing so, they can position themselves as leaders in automotive care, contributing to safer driving environments and improved vehicle performance. Embrace this opportunity to innovate and elevate your service offerings, ensuring that your business remains competitive in an evolving marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to inflate tires gas station