In the competitive landscape of industrial tools, sourcing the right Milwaukee tire inflator from Home Depot presents a unique set of challenges for international B2B buyers. Whether you are operating in the fast-paced markets of Africa, South America, the Middle East, or Europe—countries like Saudi Arabia and Germany—the need for reliable, high-performance inflators is paramount. This guide serves as a comprehensive resource, addressing the various types of Milwaukee tire inflators available, their specific applications across different industries, and crucial insights into supplier vetting and cost considerations.

As businesses strive to enhance operational efficiency and minimize downtime, selecting the right tire inflator becomes critical. This guide empowers B2B buyers by providing actionable insights into the features and benefits of Milwaukee inflators, helping you make informed purchasing decisions. We will delve into the technology behind these inflators, explore their versatility in diverse settings—from automotive to industrial applications—and highlight key factors to consider when assessing suppliers.

With a focus on quality and performance, this resource aims to equip international buyers with the knowledge necessary to navigate the global market effectively. By understanding the nuances of sourcing Milwaukee tire inflators, you can ensure that your organization is well-equipped to meet the demands of your industry, ultimately driving success in an increasingly competitive marketplace.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| M18 18-Volt Lithium-Ion Cordless Inflator | Cordless design, portable, compatible with M18 battery system | Automotive repair, tire service shops | Pros: Portable, no cords; Cons: Battery life may vary. |

| M18 18-Volt Lithium-Ion Inflator with Batteries | Comes with battery and charger, higher capacity options | Fleet maintenance, roadside assistance | Pros: Ready-to-use; Cons: Initial higher investment. |

| M12 12-Volt Compact Inflator | Compact size, lightweight, suitable for smaller applications | Bicycle shops, personal use | Pros: Easy to store and transport; Cons: Limited power. |

| M18 High Output Inflator with Extended Battery | Enhanced battery life, faster inflation rates | Heavy-duty applications, construction sites | Pros: High performance; Cons: Heavier and bulkier. |

| M18 Inflator with Digital Gauge | Integrated digital pressure gauge for precision | Automotive diagnostics, tire fitting | Pros: Accurate readings; Cons: Electronic components may require maintenance. |

The M18 18-Volt Lithium-Ion Cordless Inflator is designed for mobility and ease of use, making it ideal for automotive repair and tire service applications. Its cordless feature allows for operation in various environments without the need for a power outlet. When considering this product, B2B buyers should evaluate the compatibility with existing M18 battery systems and assess the potential need for additional batteries based on usage frequency.

This model comes equipped with both a battery and charger, making it a convenient option for businesses like fleet maintenance and roadside assistance. The inclusion of batteries ensures that the inflator is always ready for use, which is crucial for operations that require quick response times. B2B buyers should weigh the upfront cost against the time savings and increased operational efficiency it provides.

The M12 12-Volt Compact Inflator is lightweight and easily portable, making it suitable for smaller applications such as bicycle shops or personal use. Its compact design allows for easy storage and transport, which is beneficial for businesses with limited space. However, B2B buyers should consider its lower power output and ensure that it meets their specific inflation needs.

The M18 High Output Inflator is designed for heavy-duty use, featuring an extended battery life and faster inflation rates. This makes it particularly useful for construction sites and other demanding environments. Buyers should consider the trade-off between its high performance and the added weight, which may affect portability.

This model features an integrated digital pressure gauge, providing precise inflation readings that enhance accuracy in automotive diagnostics and tire fitting. The convenience of having an electronic gauge eliminates guesswork, making it a valuable tool for businesses that prioritize precision. Buyers should be mindful of the potential need for maintenance on electronic components to ensure long-term reliability.

| Industry/Sector | Specific Application of Milwaukee Tire Inflator Home Depot | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation for vehicles and heavy machinery | Reduces downtime by ensuring optimal tire pressure for safety and efficiency | Battery compatibility, portability, and inflation speed |

| Transportation & Logistics | Quick tire inflation for fleet vehicles | Enhances operational efficiency and minimizes delays in service | Power source options and durability for outdoor use |

| Construction & Heavy Equipment | Inflating tires on construction vehicles and equipment | Increases productivity and ensures equipment readiness on-site | Weight, ease of transport, and ruggedness for job sites |

| Agriculture | Tire maintenance for agricultural machinery | Promotes safety and efficiency in farming operations | Adaptability to different tire sizes and battery life |

| Outdoor Recreation | Inflating tires for ATVs, bikes, and recreational vehicles | Supports leisure activities, enhancing customer satisfaction | Lightweight design and versatility for various inflatables |

In the automotive repair sector, the Milwaukee tire inflator is essential for maintaining optimal tire pressure on a variety of vehicles, including passenger cars and heavy machinery. By ensuring proper inflation, businesses can significantly reduce the risk of tire blowouts and improve fuel efficiency. This tool is particularly beneficial for workshops in regions with fluctuating climate conditions, as it allows quick adjustments to tire pressure. International buyers should consider battery compatibility and the inflator’s ability to operate in remote areas without access to power.

For transportation and logistics companies, the Milwaukee tire inflator serves as a critical tool for maintaining fleet vehicles. Quick tire inflation minimizes downtime, ensuring that vehicles remain operational and deliveries are timely. The inflator’s portability and rechargeable battery make it ideal for use in various locations, including roadside assistance and loading docks. Buyers should focus on the inflator’s durability and performance under different weather conditions, especially in regions with extreme temperatures.

In the construction industry, the Milwaukee tire inflator is used for maintaining the tires of heavy equipment, such as bulldozers and cranes. Proper tire inflation is vital for safety and performance on job sites, where equipment reliability can directly impact project timelines. This tool’s rugged design and portability make it suitable for harsh working environments. Buyers should evaluate the inflator’s weight and transportability to ensure it meets the demands of various construction sites.

Agricultural operations rely on the Milwaukee tire inflator for maintaining the tires of tractors and other farm machinery. Consistent tire pressure is crucial for maximizing efficiency and safety in the field. The inflator’s ability to accommodate different tire sizes and its long battery life make it a valuable asset for farmers. International buyers, particularly in rural areas, should consider the tool’s adaptability and ease of use in diverse agricultural settings.

In the outdoor recreation sector, the Milwaukee tire inflator is used to inflate tires for ATVs, bicycles, and other recreational vehicles. This enhances customer experiences by ensuring that vehicles are ready for use at any moment. The inflator’s lightweight design and versatility make it ideal for outdoor enthusiasts who may need to inflate tires in remote locations. Buyers should prioritize the inflator’s portability and efficiency to cater to the needs of adventure-seeking customers.

The Problem: B2B buyers often encounter challenges when sourcing compatible accessories for Milwaukee tire inflators. This can lead to confusion and frustration, especially when managing a fleet of vehicles or equipment that requires regular tire maintenance. Buyers may find it difficult to identify which hoses, nozzles, and adaptors are suitable for their specific models, resulting in potential delays in operations and increased downtime.

The Solution: To overcome this issue, it is crucial for buyers to consult the Milwaukee inflator’s specifications and user manual, which detail compatible accessories. Additionally, engaging directly with Home Depot representatives can provide valuable insights into the most suitable accessories for specific inflator models. Buyers should also consider creating a checklist of essential accessories for their operations, ensuring they stock commonly used items like inflation hoses and adaptors. By establishing a direct relationship with suppliers and leveraging online resources, businesses can streamline their procurement processes and ensure they have the necessary tools on hand for efficient tire maintenance.

The Problem: B2B buyers frequently express concerns regarding the battery life and performance of Milwaukee tire inflators, especially in different climates and operational conditions. For instance, in regions with extreme heat or cold, the efficiency of the lithium-ion batteries may fluctuate, leading to unpredictable inflator performance. This uncertainty can hinder operational planning and increase the risk of equipment failures at critical times.

The Solution: To mitigate battery-related concerns, buyers should invest in a thorough understanding of the inflator’s battery specifications and performance ratings. It’s advisable to conduct tests in varying environmental conditions to gauge the inflator’s reliability and battery longevity. Furthermore, businesses can benefit from investing in additional batteries, enabling them to rotate and charge units while maintaining continuous operation. Utilizing Milwaukee’s battery management systems, which provide real-time data on battery health, can also be beneficial. By proactively managing battery resources and understanding their limitations, B2B buyers can ensure consistent performance and minimize operational disruptions.

The Problem: Many B2B buyers find the warranty and service options for Milwaukee tire inflators confusing. Misunderstandings about what the warranty covers can lead to unexpected repair costs or difficulties in obtaining service when issues arise. This is particularly critical for companies that rely on these tools for daily operations, as any downtime can result in significant financial losses.

The Solution: To navigate warranty and service options effectively, buyers should familiarize themselves with the warranty terms outlined by Milwaukee. Reviewing the warranty documentation and discussing it with Home Depot’s customer service can clarify coverage details and service processes. Additionally, maintaining a log of purchase dates and service records can facilitate smoother claims if repairs are needed. B2B buyers should also consider investing in extended warranty plans, which can provide additional peace of mind. By proactively managing warranty inquiries and service needs, businesses can protect their investments and minimize risks associated with equipment failures.

When selecting materials for the Milwaukee tire inflator, it is crucial to consider their properties, advantages, disadvantages, and suitability for various applications. This analysis will help international B2B buyers make informed decisions that align with their operational needs and local standards.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is commonly used in the housing and components of Milwaukee tire inflators. These materials exhibit excellent impact resistance, lightweight characteristics, and good chemical resistance, making them suitable for portable tools. They typically operate effectively within a temperature range of -40°C to 80°C (-40°F to 176°F) and can withstand moderate pressure levels.

Pros & Cons: The primary advantage of plastic is its lightweight nature, which enhances portability. Additionally, it is generally cost-effective, reducing manufacturing expenses. However, plastics can be less durable compared to metals, especially under extreme conditions, and may degrade over time when exposed to UV radiation.

Impact on Application: Plastic components are ideal for protecting internal mechanisms from dust and moisture, ensuring longevity in diverse environments. However, they may not be suitable for high-pressure applications or extreme temperature fluctuations.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the plastics used comply with local environmental regulations and standards, such as REACH in Europe. Understanding the specific grades of plastic and their certifications is essential for ensuring product safety and compliance.

Metals, particularly aluminum and steel, are integral to the structural framework and internal components of Milwaukee tire inflators. Aluminum is lightweight, corrosion-resistant, and can handle higher pressure ratings, while steel offers superior strength and durability.

Pros & Cons: The key advantage of aluminum is its resistance to corrosion and its lightweight nature, making it an excellent choice for portable applications. Steel, while heavier, provides enhanced durability and is often more cost-effective in high-stress environments. However, aluminum can be more expensive and may require additional treatments to enhance its corrosion resistance.

Impact on Application: Metal components are crucial for maintaining structural integrity under pressure and ensuring safe operation. They are particularly important in applications involving high-pressure air delivery.

Considerations for International Buyers: Compliance with international standards such as ASTM for metals is vital. Buyers in Europe, for instance, should be aware of the EN standards governing materials used in tools and machinery.

Rubber is predominantly used in seals and hoses within Milwaukee tire inflators. Its elasticity and flexibility make it an ideal choice for creating airtight seals, while its ability to withstand a range of temperatures (typically from -30°C to 100°C) is beneficial for various operating conditions.

Pros & Cons: The primary advantage of rubber is its excellent sealing properties, which prevent air leaks and ensure efficient operation. However, rubber can degrade over time due to exposure to ozone and UV light, leading to potential failures.

Impact on Application: Rubber components are essential for maintaining pressure and ensuring the inflator operates effectively. They also contribute to the overall safety of the tool by preventing accidental air leaks.

Considerations for International Buyers: Buyers should verify that the rubber used meets local standards for durability and environmental compliance. In regions like South America and Africa, understanding the local climate’s impact on rubber longevity is crucial for product performance.

Composite materials, such as fiberglass-reinforced plastics, are increasingly used in advanced inflator designs. These materials combine the lightweight properties of plastics with the strength of fibers, resulting in enhanced durability and performance.

Pros & Cons: The key advantage of composites is their superior strength-to-weight ratio, making them ideal for portable applications. However, they can be more expensive to manufacture and may require specialized processing techniques.

Impact on Application: Composite materials can significantly enhance the inflator’s resistance to impact and environmental stressors, making them suitable for rugged applications.

Considerations for International Buyers: B2B buyers should consider the availability of composite materials in their local markets and ensure compliance with relevant standards. In Europe, for example, buyers may need to adhere to specific regulations governing composite materials.

| Material | Typical Use Case for Milwaukee Tire Inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and components | Lightweight and cost-effective | Less durable under extreme conditions | Medium |

| Metal | Structural framework and internal components | Corrosion-resistant and durable | Heavier and potentially more costly | Medium |

| Rubber | Seals and hoses | Excellent sealing properties | Degrades over time due to UV exposure | Low |

| Composite | Advanced structural components | Superior strength-to-weight ratio | Higher manufacturing costs | High |

This strategic material selection guide provides essential insights for B2B buyers, aiding in the selection of materials that enhance the performance and reliability of Milwaukee tire inflators while ensuring compliance with international standards.

The manufacturing process for Milwaukee tire inflators is a multi-stage operation designed to ensure efficiency and high-quality output. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with sourcing high-grade materials, including durable plastics, metals, and electronic components. Suppliers are typically vetted to meet specific quality standards, which is crucial for ensuring longevity and performance. Materials undergo initial inspection to verify compliance with industry standards.

Forming: This stage involves shaping the materials into the required components. Advanced techniques such as injection molding for plastic parts and stamping or machining for metal components are employed. These methods ensure precision in dimensions and surface finishes.

Assembly: In this phase, all components are brought together. Automated assembly lines are often utilized to enhance productivity and reduce human error. Each inflator is assembled under strict guidelines to maintain consistency and quality. Workers are trained to follow specific protocols for electrical and mechanical assembly.

Finishing: The final stage includes surface treatments, painting, and quality checks. Finishing processes not only enhance the aesthetic appeal but also protect against corrosion and wear. This stage is critical as it prepares the inflators for packaging and shipment.

Milwaukee employs various advanced manufacturing techniques to optimize production efficiency and product quality. These include:

Quality assurance is paramount in the manufacturing of Milwaukee tire inflators. The company adheres to several international standards and industry-specific certifications, ensuring that its products meet or exceed market expectations.

Milwaukee implements a comprehensive quality control system with several checkpoints throughout the manufacturing process:

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability. There are several strategies to achieve this:

When dealing with international suppliers, B2B buyers must navigate various quality control nuances, particularly in regions like Africa, South America, the Middle East, and Europe.

By understanding the manufacturing processes and quality assurance measures in place for Milwaukee tire inflators, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

In the competitive landscape of B2B procurement, finding the right tools and equipment is critical for operational efficiency. This practical sourcing guide aims to assist international buyers in acquiring the Milwaukee tire inflator from Home Depot. Following these steps will ensure a streamlined purchasing process that meets your specific business needs.

Before initiating your search, clearly outline the technical specifications required for the Milwaukee tire inflator. Consider factors such as power source (cordless vs. corded), pressure output, and portability. This clarity will help you select a model that aligns with your operational requirements and usage scenarios.

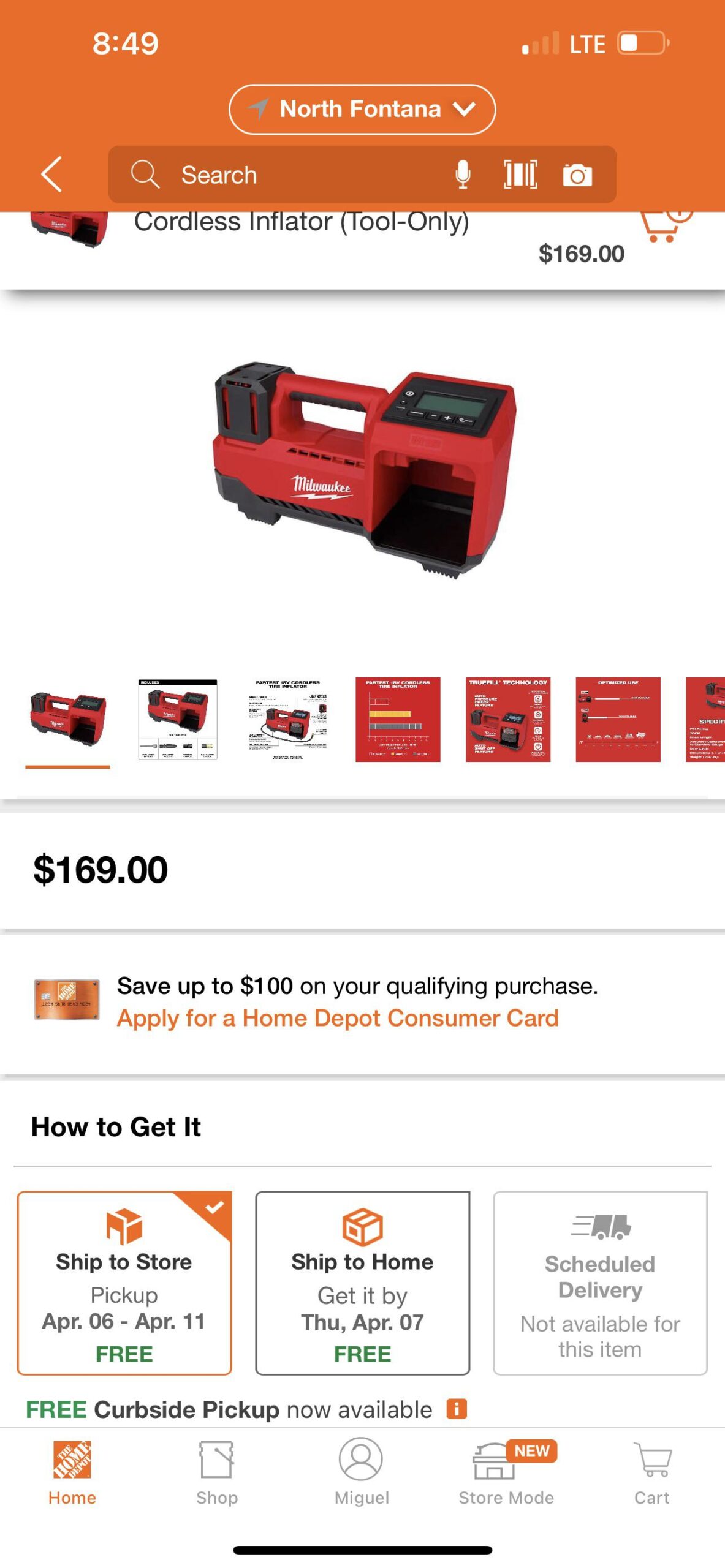

Illustrative image related to milwaukee tire inflator home depot

Investigate the different models of Milwaukee tire inflators available at Home Depot. Pay attention to features such as battery capacity, inflation speed, and additional functionalities like built-in pressure gauges or LED lights. Understanding these features will aid in selecting a model that provides the best value for your investment.

It is essential to vet Home Depot as a supplier. Review their reputation in the market, focusing on customer reviews and ratings specific to the Milwaukee inflator. Reliable suppliers ensure that products are genuine, backed by warranties, and supported by customer service for post-purchase assistance.

Gather price quotes for the Milwaukee tire inflator from Home Depot and compare them with other suppliers. Additionally, consider the warranty options available for the inflator. A comprehensive warranty can mitigate potential risks and provide peace of mind regarding the product’s longevity and performance.

As an international buyer, it’s crucial to understand the shipping policies and import regulations applicable to your region. Check Home Depot’s shipping options to your location, and ensure that the inflator complies with local electrical and safety standards. This step will prevent delays and additional costs associated with non-compliance.

Review the payment options and any financing terms that Home Depot offers for bulk purchases. Understanding the payment structure can help you manage cash flow and budget effectively. Look for options that provide flexibility, such as net terms or discounts for large orders.

Once you have gathered all necessary information and made your decision, proceed to finalize your order. Confirm all delivery details, including estimated shipping times and tracking options. This diligence will ensure that your Milwaukee tire inflator arrives on time and meets your operational needs.

Following this checklist will streamline your procurement process and enhance your overall purchasing experience. By taking a structured approach, you can make informed decisions that positively impact your business operations.

When evaluating the cost structure for Milwaukee tire inflators, several components must be considered. The primary cost elements include:

Materials: The quality and type of materials used in the inflators significantly influence the overall cost. Higher-grade lithium-ion batteries and durable housing materials add to the price but also enhance product longevity and performance.

Labor: Labor costs are a critical factor, particularly in regions with varying wage standards. Skilled labor is often required for assembly and quality checks, impacting the overall manufacturing cost.

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads.

Tooling: Initial tooling costs for specialized manufacturing processes can be high but are essential for maintaining product consistency. These costs are typically amortized over the production run.

Quality Control (QC): Rigorous quality control processes ensure that the inflators meet industry standards, which may involve additional inspection and testing costs.

Logistics: Shipping and handling costs can vary significantly based on the destination. International shipping may incur tariffs and customs fees that need to be factored into the total cost.

Margin: Suppliers will add a profit margin to cover their risks and operational costs, which can vary based on market conditions and competition.

Several factors can influence the pricing of Milwaukee tire inflators, particularly for international B2B buyers:

Illustrative image related to milwaukee tire inflator home depot

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Bulk purchases often lead to discounts, making it economically viable for larger operations.

Specifications and Customization: Custom features or specifications can increase production costs. Buyers should assess whether they need standard models or if customization is essential for their market.

Materials: The choice of materials directly impacts pricing. Opting for higher-quality components may result in a higher upfront cost but could offer better performance and lower maintenance in the long run.

Quality Certifications: Products that meet specific quality standards or certifications may command higher prices but provide assurance of reliability and compliance with regulatory requirements.

Supplier Factors: The supplier’s reputation, reliability, and production capacity can also affect pricing. Established suppliers may offer more consistent quality but at a premium.

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for international buyers. They determine who is responsible for shipping, insurance, and tariffs, influencing the overall cost.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, a strategic approach to sourcing Milwaukee tire inflators can yield significant cost savings. Here are some actionable tips:

Negotiate Terms: Leverage your purchasing power to negotiate favorable terms, including pricing, payment terms, and delivery schedules. Building a strong relationship with suppliers can facilitate better negotiations.

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, energy consumption, and potential downtime, rather than focusing solely on the purchase price.

Be Aware of Pricing Nuances: Different regions may have varying market dynamics, including currency fluctuations and local economic conditions. Understanding these factors can help in making informed purchasing decisions.

Research Local Regulations: Ensure compliance with local regulations regarding product safety and quality standards. This can prevent costly delays and fines.

Utilize Technology: Employ procurement software to streamline the sourcing process, track costs, and analyze supplier performance, helping to make data-driven decisions.

Prices for Milwaukee tire inflators can vary widely based on the factors discussed above. Buyers should conduct thorough market research and consult multiple suppliers to obtain indicative pricing tailored to their specific needs and regional conditions.

In the competitive landscape of tire inflators, the Milwaukee tire inflator available at Home Depot stands out due to its robust features and reliability. However, businesses must consider alternative solutions that may better suit their specific needs, especially in diverse international markets. This section provides a comparative analysis of the Milwaukee tire inflator against other viable options, helping B2B buyers make informed decisions.

| Comparison Aspect | Milwaukee Tire Inflator Home Depot | Ryobi 18V One+ Cordless Inflator | DEWALT 20V MAX Cordless Inflator |

|---|---|---|---|

| Performance | High PSI with quick inflation | Moderate PSI, slower inflation | High PSI with fast inflation |

| Cost | Medium price range | Lower price range | Medium to high price range |

| Ease of Implementation | User-friendly, compact design | Simple operation, lightweight | Easy to use, slightly bulkier |

| Maintenance | Minimal maintenance required | Minimal maintenance required | Slightly higher maintenance due to size |

| Best Use Case | Professional and heavy-duty use | Home and light-duty applications | Professional and heavy-duty use |

The Ryobi 18V One+ Cordless Inflator is a cost-effective alternative for businesses that require a basic inflating solution. It offers lightweight portability and ease of use, making it ideal for home and light-duty applications. However, its performance is limited compared to the Milwaukee inflator, as it produces moderate PSI and has a slower inflation rate. This option is well-suited for casual users who don’t need heavy-duty capabilities but might not meet the demands of more rigorous applications.

The DEWALT 20V MAX Cordless Inflator is another strong contender in the market, boasting high PSI and fast inflation capabilities similar to the Milwaukee option. It is particularly advantageous for professional environments requiring efficiency and quick turnaround times. However, it tends to be bulkier and may require more maintenance than the Milwaukee inflator. This makes it a great choice for businesses that prioritize performance and speed but may not be as portable as other models.

When choosing between the Milwaukee tire inflator and its alternatives, B2B buyers should assess their specific requirements. Considerations such as frequency of use, inflation speed, and maintenance needs are crucial. For businesses engaged in heavy-duty tasks or requiring quick service, the Milwaukee and DEWALT options may be preferable. Conversely, for light-duty or occasional use, the Ryobi inflator could provide a more economical solution. Ultimately, understanding the unique demands of your operations will guide you to the most suitable inflator for your needs.

Understanding the technical specifications of the Milwaukee Tire Inflator is crucial for international B2B buyers to ensure compatibility and efficiency in various applications. Below are some of the key properties to consider:

The Milwaukee Tire Inflator typically operates on an 18-volt lithium-ion battery. This specification is important as it indicates the power efficiency and portability of the tool. Lithium-ion batteries are known for their longer life cycles and lighter weight, making them ideal for on-the-go applications, particularly in regions where electricity access may be inconsistent.

The inflator’s inflation rate, usually measured in PSI (pounds per square inch), indicates how quickly it can inflate a tire. A higher inflation rate is beneficial for businesses that require rapid service, such as automotive repair shops or roadside assistance providers. Understanding this metric helps businesses gauge productivity and efficiency.

While portable inflators may not have a tank, their pressure range is critical. Most Milwaukee models can achieve a pressure range of 0-120 PSI, accommodating various types of tires and inflatables. This flexibility is vital for businesses that service multiple vehicle types, ensuring they can meet diverse customer needs.

The construction materials used in the inflator affect its durability and longevity. High-quality plastic and metal components contribute to a robust design that can withstand rigorous use in diverse environments. For B2B buyers, understanding material grades helps assess the product’s suitability for their specific operational conditions, particularly in harsh climates.

The compact design and lightweight nature of the Milwaukee Tire Inflator make it easy to transport and store. This is particularly advantageous for businesses with limited space or those that require mobility, such as mobile tire services. Knowing the dimensions and weight allows buyers to plan logistics effectively.

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the Milwaukee Tire Inflator:

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether a product is OEM can influence decisions regarding quality and compatibility with existing equipment.

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for budgeting and inventory management, as it can affect cash flow and storage considerations. Knowing the MOQ helps buyers align their purchasing strategies with operational needs.

An RFQ is a document that businesses send to suppliers to solicit price quotes for specific products or services. This process is essential for comparing costs and ensuring competitive pricing, especially for bulk purchases of Milwaukee Tire Inflators.

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is vital for logistics planning and risk management, ensuring clarity on who bears costs and responsibilities during shipping.

Illustrative image related to milwaukee tire inflator home depot

Lead time refers to the amount of time it takes for an order to be fulfilled and delivered. This is a critical factor for B2B buyers, as it impacts project timelines and inventory management. Knowing the lead time for Milwaukee Tire Inflators can help businesses plan their operations more effectively.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions, ensuring they select the right Milwaukee Tire Inflator for their operational needs.

The Milwaukee tire inflator market is experiencing significant growth driven by several global trends. First, the increasing demand for portable and efficient tools among automotive professionals and DIY enthusiasts has positioned Milwaukee as a leader in the tire inflator segment. As more consumers prioritize convenience, the cordless and battery-operated designs, such as the M18 and M12 series, are gaining traction. Furthermore, the rise in e-commerce has facilitated easier access to these products for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

Emerging B2B technologies such as smart inflators with integrated pressure monitoring systems are also shaping the market landscape. These innovations provide added value, enabling users to achieve accurate inflation without manual adjustments. Additionally, the trend towards multifunctional tools is becoming prominent, with inflators that offer additional features such as air compression for various applications, further appealing to the B2B segment.

Sustainability is increasingly becoming a priority for B2B buyers in the Milwaukee tire inflator market. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting companies to adopt sustainable practices. Buyers are now seeking suppliers who demonstrate a commitment to reducing carbon footprints and using recyclable materials in their products.

Ethical sourcing is equally important, as companies aim to ensure that their supply chains adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and Fair Trade ensure that suppliers meet specific sustainability criteria. B2B buyers are encouraged to inquire about these certifications when sourcing Milwaukee tire inflators, as they indicate a commitment to sustainable and ethical practices, which can enhance brand reputation and customer loyalty.

The Milwaukee tire inflator has evolved significantly since its inception, reflecting broader trends in technology and consumer needs. Initially, inflators were basic, manually operated devices that served a singular purpose. However, with advancements in battery technology and user feedback, Milwaukee transitioned towards developing more sophisticated, cordless models that cater to the needs of both professionals and everyday consumers.

Today, Milwaukee’s product range includes high-capacity lithium-ion battery models, which not only enhance performance but also extend usability across various applications. This evolution highlights the importance of adaptability in product design, allowing Milwaukee to maintain its competitive edge in the B2B marketplace. As international buyers continue to seek innovative solutions, Milwaukee remains at the forefront of delivering high-quality, reliable tire inflators that align with market demands.

Illustrative image related to milwaukee tire inflator home depot

How do I ensure the Milwaukee tire inflator meets my operational needs?

To ensure the Milwaukee tire inflator aligns with your operational requirements, consider the specific applications you’ll be using it for. Review its specifications, such as PSI capacity, portability, and battery life. Comparing these features with your intended use cases, like inflating vehicle tires or powering air tools, will help you determine if it meets your needs. Additionally, consult with your team or industry experts for insights on reliability and performance in various conditions.

What is the best Milwaukee tire inflator for commercial use?

The best Milwaukee tire inflator for commercial use is the M18 18-Volt Lithium-Ion Cordless Inflator, known for its high PSI output and portability. This model is designed for heavy-duty applications and can quickly inflate tires and other inflatables, making it ideal for businesses such as automotive services or construction. When selecting, consider battery capacity and runtime to ensure it can handle your workload without frequent recharging.

What are the minimum order quantities (MOQ) for purchasing Milwaukee tire inflators?

Minimum order quantities for Milwaukee tire inflators can vary based on the supplier and your location. Typically, wholesale orders may start from as few as 10 units, but larger orders might be required for better pricing or shipping efficiency. It’s advisable to discuss MOQ directly with your supplier to negotiate terms that suit your purchasing strategy, especially if you are looking to stock inventory for resale.

What payment terms can I expect when sourcing Milwaukee tire inflators internationally?

Payment terms for international orders of Milwaukee tire inflators generally vary based on the supplier’s policies and your negotiation. Common terms include upfront payment, net 30/60 days, or letters of credit for larger transactions. It’s crucial to discuss these terms early in your negotiations to align with your cash flow and financial strategy, especially when dealing with suppliers from different regions.

How can I vet suppliers for Milwaukee tire inflators effectively?

To vet suppliers effectively, start by researching their reputation in the industry. Look for reviews, testimonials, and their history of fulfilling orders. Request samples to evaluate product quality firsthand. Additionally, verify their certifications and compliance with international trade regulations. Engaging in direct communication can also provide insights into their reliability and customer service responsiveness.

What logistics considerations should I keep in mind for importing Milwaukee tire inflators?

When importing Milwaukee tire inflators, consider shipping methods, customs regulations, and potential tariffs specific to your country. Choose a reliable freight forwarder familiar with your destination’s logistics to ensure a smooth delivery process. Factor in lead times for production and shipping to avoid stock shortages, and ensure you have the necessary documentation, such as import licenses and invoices, ready for customs clearance.

Can I customize Milwaukee tire inflators for my brand?

Customization options for Milwaukee tire inflators may be limited, as they are branded products. However, you can inquire with your supplier about potential branding opportunities, such as custom packaging or co-branding arrangements. Discussing your requirements early in the negotiation process can help you identify feasible options for personalizing the product to enhance brand visibility.

What quality assurance measures should I implement when sourcing Milwaukee tire inflators?

Implementing quality assurance measures involves establishing clear specifications and standards with your supplier before placing an order. Request product samples for testing to ensure they meet your quality criteria. Additionally, consider conducting periodic inspections during manufacturing and before shipment. Building a strong relationship with your supplier can facilitate better communication regarding quality expectations and prompt resolution of any issues that arise.

Could not verify enough suppliers for milwaukee tire inflator home depot to create a list at this time.

In the current global market, the Milwaukee tire inflator presents a compelling opportunity for B2B buyers looking to enhance their operational efficiency and service offerings. The M18 18-Volt Lithium-Ion Cordless Electric Portable Inflator stands out due to its portability, rapid inflation capabilities, and battery compatibility, making it an invaluable asset for businesses in diverse sectors—from automotive repair to logistics.

Strategic sourcing of this product not only ensures access to high-quality tools but also fosters long-term supplier relationships that can lead to better pricing and availability. By aligning with a trusted brand like Milwaukee, international buyers can ensure reliability and performance, which are critical in maintaining competitive advantages in their respective markets.

As we look forward, businesses across Africa, South America, the Middle East, and Europe should consider integrating Milwaukee’s inflators into their inventory. This strategic move can bolster service efficiency and customer satisfaction. Engaging with suppliers at Home Depot or authorized distributors will facilitate smoother procurement processes. Embrace the opportunity to enhance your tool offerings and strengthen your market position today.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.