In today’s competitive global market, sourcing a reliable Prilotte tire inflator presents a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. With the increasing demand for portable air compressors that combine efficiency, portability, and eco-friendliness, businesses must navigate a landscape filled with varying product specifications, supplier reliability, and market pricing. This comprehensive guide offers invaluable insights into the Prilotte tire inflator, covering types and applications, supplier vetting processes, and cost considerations, tailored specifically for international buyers.

Understanding the nuances of tire inflators is crucial for businesses that prioritize both performance and sustainability. The guide empowers B2B purchasers by providing detailed information on product features, such as battery capacity, inflation speed, and multifunctionality—critical factors for making informed purchasing decisions. Moreover, we delve into strategies for evaluating suppliers, ensuring that businesses can partner with trusted manufacturers who meet their quality standards and ethical practices.

By leveraging the knowledge presented in this guide, international buyers can confidently select the right Prilotte tire inflator that aligns with their operational needs and budget constraints. Whether you’re based in bustling cities like São Paulo or Lagos, or navigating the diverse markets of the Middle East and Europe, this resource aims to simplify your sourcing journey, ultimately enhancing your business’s efficiency and sustainability.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Air Compressor | Cordless, 18000mAh battery, multiple pressure modes | Automotive repair shops, roadside assistance | Pros: High portability; Cons: Limited runtime |

| Heavy-Duty Tire Inflator | Higher PSI capacity, robust build, suitable for larger vehicles | Fleet management, heavy machinery maintenance | Pros: Durable; Cons: Higher initial cost |

| Digital Tire Inflator | Digital display, programmable settings, automatic shut-off | Automotive service centers, tire retailers | Pros: Precision; Cons: Requires charging |

| Compact Mini Inflator | Lightweight, easy to store, designed for small vehicles | Personal use, small businesses | Pros: Space-saving; Cons: Limited power |

| Multi-Function Inflator | Additional features like power bank, LED light, and various adapters | Emergency services, outdoor businesses | Pros: Versatile; Cons: Complexity in use |

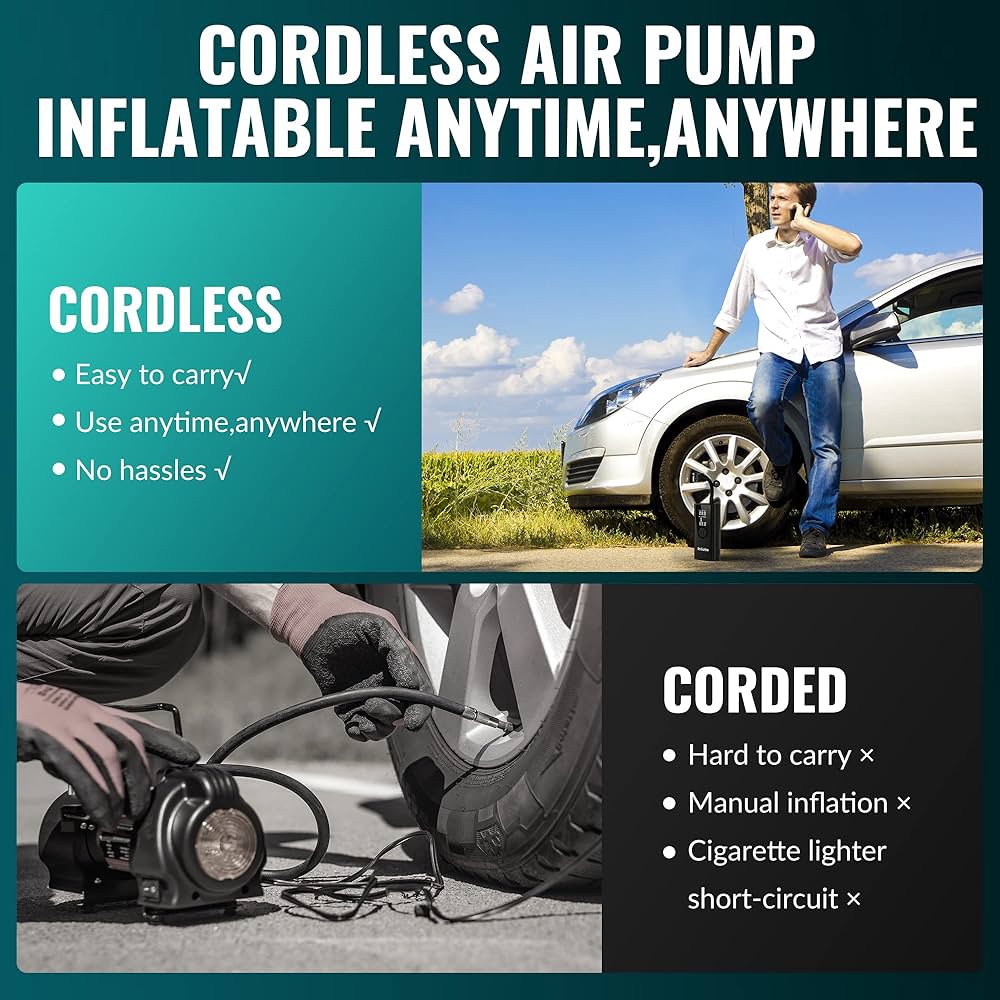

Portable air compressors, like the Prilotte model with an 18000mAh battery, are designed for ease of use and mobility. They typically feature multiple pressure modes, making them versatile for various inflation needs, from car tires to sports equipment. B2B buyers in automotive repair shops or roadside assistance services will find these inflators particularly useful due to their lightweight design and capability to operate without a direct power source. However, the limited runtime may necessitate frequent recharging, which could impact workflow in high-demand situations.

Heavy-duty tire inflators are built to handle higher PSI requirements and are often constructed with robust materials to endure rigorous usage. These inflators are suitable for fleet management and maintenance of heavy machinery, where reliability and durability are paramount. While their higher initial cost may deter some buyers, the long-term investment pays off through reduced downtime and enhanced operational efficiency, making them a preferred choice for businesses with demanding inflation needs.

Digital tire inflators come equipped with advanced features like a digital display, programmable pressure settings, and automatic shut-off functions, ensuring precise inflation. These models are particularly suited for automotive service centers and tire retailers that require accuracy and efficiency in their operations. While the precision and ease of use are significant advantages, these inflators often require regular charging, which may be a consideration for businesses operating in remote locations.

Compact mini inflators are designed to be lightweight and easily storable, making them ideal for personal use or small businesses with limited space. They cater primarily to small vehicles or bikes, offering an economical solution for inflation needs. However, their limited power may restrict their effectiveness for larger tires, so B2B buyers should assess their specific requirements before investing in this type.

Multi-function inflators, which often include features like a power bank, LED light, and various adapters, are designed for versatility. They are particularly beneficial for emergency services and outdoor businesses that may need to address diverse inflation requirements in various environments. While their complexity can be a disadvantage for some users, the range of functionalities they provide can significantly enhance operational capability, making them a valuable addition to any business toolkit.

| Industry/Sector | Specific Application of Prilotte Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Routine tire inflation and maintenance for customer vehicles | Enhances customer service and satisfaction through efficient service | Ensure sufficient battery capacity for high-volume usage |

| Logistics and Transportation | Quick tire inflation for delivery and transport vehicles | Minimizes downtime and improves fleet efficiency | Look for models with fast inflation rates and portability |

| Recreational Vehicle Rentals | Tire maintenance for rental vehicles and trailers | Increases safety and reduces liability for rental companies | Consider ease of use and reliability in remote locations |

| Construction and Heavy Machinery | Tire inflation for construction equipment | Ensures operational readiness and safety of heavy machinery | Assess durability and performance under rugged conditions |

| Sports and Leisure | Inflation of sports equipment (balls, bicycles, etc.) | Enhances customer experience and promotes product usage | Verify compatibility with various inflation needs and devices |

Automotive repair shops can utilize the Prilotte tire inflator to provide routine tire inflation and maintenance services. This portable air compressor allows technicians to quickly inflate customer vehicles, enhancing service efficiency and customer satisfaction. The ability to preset tire pressures ensures accuracy and safety. For B2B buyers in this sector, sourcing inflators with robust battery life and high air flow rates is crucial to accommodate high volumes of service.

In the logistics and transportation industry, the Prilotte tire inflator plays a pivotal role in maintaining the tire pressure of delivery and transport vehicles. By enabling quick tire inflation, it minimizes vehicle downtime, leading to improved fleet efficiency and reduced operational costs. International buyers should consider models that offer rapid inflation capabilities and portability, ensuring they can be used effectively on-site or during long hauls.

Recreational vehicle rental companies can leverage the Prilotte tire inflator to ensure their fleet is always ready for safe travel. Regular tire maintenance is essential to prevent accidents and reduce liability. The inflator’s ease of use makes it an ideal choice for both staff and customers. When sourcing, companies should prioritize reliability and user-friendly features, particularly for renters who may not be mechanically inclined.

Construction companies can benefit significantly from the Prilotte tire inflator by ensuring that heavy machinery is always operational. Regular tire inflation is vital for safety and efficiency on job sites. The inflator’s portability allows for quick adjustments in rugged environments, reducing downtime. Buyers in this sector should focus on durability and performance metrics to ensure the inflator can withstand challenging conditions.

Illustrative image related to prilotte tire inflator

In the sports and leisure sector, the Prilotte tire inflator can be used for the inflation of various sports equipment, including balls and bicycles. This not only enhances the customer experience by ensuring equipment is ready for use but also encourages more frequent participation in recreational activities. Buyers should verify the inflator’s versatility in handling different inflation needs and its compatibility with multiple devices, ensuring it meets diverse requirements.

The Problem: For businesses managing fleets in diverse regions, ensuring consistent tire pressure across various vehicles can be a daunting task. Tire pressure directly impacts fuel efficiency, safety, and overall vehicle performance. In areas with fluctuating temperatures or varying road conditions, maintaining the correct tire pressure becomes even more challenging. Fleet managers may struggle with traditional inflators that are either cumbersome or lack the necessary features to handle diverse tire sizes efficiently, leading to increased downtime and potential safety hazards.

The Solution: The Prilotte Tire Inflator is designed to address these challenges with its advanced features. With the ability to preset pressure values and automatically shut off when the desired PSI is reached, fleet managers can ensure each vehicle is inflated to the correct specifications without manual monitoring. To optimize the inflator’s use, businesses should consider bulk purchasing and training staff on its operation. Incorporating the Prilotte inflator into regular maintenance schedules can significantly reduce tire-related issues, thereby enhancing fleet reliability and safety. Additionally, businesses can leverage the portability of the inflator for on-the-go service, ensuring quick responses to tire emergencies.

The Problem: Companies operating in remote or rural areas often face challenges with power sources for equipment like tire inflators. In regions of Africa or South America, where access to electricity can be intermittent, relying on traditional inflators that require a constant power supply can halt operations, leading to costly delays. This can be especially problematic for businesses involved in logistics or delivery, where timely service is crucial.

The Solution: The Prilotte Tire Inflator’s battery-powered design provides a significant advantage in such scenarios. With an 18,000mAh battery, it can operate independently without the need for a direct power source, allowing users to inflate tires anywhere, anytime. To maximize this benefit, businesses should ensure that their teams are equipped with fully charged inflators before heading into remote areas. Additionally, establishing a routine to recharge these inflators during downtime can further enhance readiness for tire inflation needs. Consider creating a maintenance checklist that includes battery status checks to ensure the inflators are always operational when needed.

Illustrative image related to prilotte tire inflator

The Problem: For businesses employing a diverse workforce, training employees on how to use new tools can be a significant hurdle. Staff may come from varying backgrounds with differing levels of technical expertise, making it difficult to ensure everyone can operate equipment like the Prilotte Tire Inflator efficiently. Misuse can lead to equipment damage or inefficiencies, which can be costly for operations.

The Solution: The user-friendly design of the Prilotte Tire Inflator, featuring a large LCD touch screen and intuitive controls, simplifies the training process. To facilitate effective training, businesses should develop a structured onboarding program that includes hands-on demonstrations and easy-to-follow manuals. Additionally, creating a quick reference guide that highlights key features, such as setting pressure values or switching pressure units, can empower employees to use the inflator confidently. Regular refresher courses and hands-on workshops can also help maintain proficiency and encourage a culture of safety and efficiency in tire management. By investing in proper training, businesses can minimize errors and maximize the operational efficiency of their tire inflators.

When selecting materials for the Prilotte tire inflator, it is essential to consider the properties, advantages, and limitations of each material. The performance and durability of the inflator can significantly impact user satisfaction and operational efficiency. Here, we analyze four common materials used in the construction of tire inflators: plastic, aluminum, rubber, and steel.

Plastic is often used in the housing and components of tire inflators due to its lightweight and corrosion-resistant properties. Common types include ABS and polycarbonate, which can withstand a range of temperatures and pressures.

Illustrative image related to prilotte tire inflator

Pros: Plastic is cost-effective and easy to mold into complex shapes, making it suitable for various designs. It also provides good insulation against electrical components, enhancing safety.

Cons: While plastic is durable, it may not withstand extreme temperatures or heavy impacts as well as metals. Over time, exposure to UV light can degrade some plastics, leading to brittleness.

Impact on Application: Plastic components are typically compatible with air and can handle the pressures required for tire inflation.

Considerations for International Buyers: Compliance with international standards such as ASTM for material safety is crucial. Buyers from regions like Africa and South America may prefer products that are lightweight for easier transportation.

Aluminum is frequently used for structural components due to its excellent strength-to-weight ratio and corrosion resistance.

Pros: Aluminum is lightweight yet strong, making it ideal for portable devices. It also has good thermal conductivity, which can help in dissipating heat generated during operation.

Cons: Aluminum can be more expensive than plastic and may require additional coatings to enhance corrosion resistance in humid environments.

Impact on Application: Aluminum is compatible with air and can handle high pressures, making it suitable for use in tire inflators.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets international standards for quality and safety, particularly in regions with stringent regulations.

Rubber is commonly used for seals and hoses within tire inflators due to its flexibility and elasticity.

Pros: Rubber provides excellent sealing capabilities and can withstand a wide range of temperatures and pressures. It is also resistant to wear and tear, ensuring longevity.

Cons: Rubber can degrade over time due to exposure to ozone and UV light, which may limit its lifespan in outdoor applications.

Impact on Application: Rubber components are essential for maintaining airtight seals, which are critical for effective tire inflation.

Considerations for International Buyers: Buyers should look for rubber materials that comply with international standards like JIS for quality assurance, especially in regions with varying climate conditions.

Steel is sometimes used in the construction of tire inflators, particularly for internal components that require high strength.

Pros: Steel is incredibly durable and can withstand high pressures, making it ideal for components that experience significant stress.

Illustrative image related to prilotte tire inflator

Cons: Steel is heavier and more expensive than other materials, which may affect the portability of the inflator. It is also prone to corrosion if not properly coated.

Impact on Application: Steel components are suitable for high-pressure applications but may require additional treatments to prevent rust.

Considerations for International Buyers: Compliance with ASTM standards for steel quality is essential, particularly in regions with high humidity, such as parts of Africa and the Middle East.

| Material | Typical Use Case for prilotte tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-structural components | Lightweight and cost-effective | May degrade under UV exposure | Low |

| Aluminum | Structural components | Strong and corrosion-resistant | Higher cost and may require coatings | Medium |

| Rubber | Seals and hoses | Excellent sealing and flexibility | Degrades over time due to ozone | Low |

| Steel | Internal high-stress components | Extremely durable and pressure-resistant | Heavy and prone to corrosion | High |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that align with their operational needs and regional conditions.

Illustrative image related to prilotte tire inflator

The manufacturing process of Prilotte tire inflators involves several critical stages, ensuring the final product meets high standards of quality and performance. Understanding these stages can assist B2B buyers in evaluating suppliers and their capabilities.

The first step in manufacturing is the preparation of raw materials. For Prilotte tire inflators, this typically includes sourcing high-quality plastics, metals for the housing, and electronic components such as motors and batteries. Suppliers often focus on materials that ensure durability and performance under various environmental conditions. B2B buyers should inquire about the origin of these materials and whether they meet international safety and environmental standards.

Once materials are prepared, the next stage involves forming components through various techniques. Injection molding is commonly used for plastic parts, while metal components may undergo processes such as stamping or die casting. These techniques not only shape the parts but also ensure consistency and precision. B2B buyers should look for manufacturers that utilize advanced forming technologies to minimize defects and enhance product reliability.

The assembly stage is where individual components come together to create the final product. Prilotte tire inflators typically follow a systematic assembly line approach, which allows for efficient production while maintaining quality. Automated systems may be employed for repetitive tasks, while skilled workers handle more intricate assembly processes, such as integrating the electronic components. Buyers should inquire about the assembly methods used and the training provided to assembly line workers, as this can significantly impact the product’s overall quality.

Finally, the finishing stage involves quality checks and surface treatments to enhance the product’s appearance and performance. This may include painting, polishing, or applying coatings to improve durability. A thorough inspection process is critical at this stage to catch any defects before the products are packaged. B2B buyers should consider suppliers that implement stringent finishing processes to ensure that the final products are aesthetically pleasing and functionally sound.

Illustrative image related to prilotte tire inflator

Quality assurance (QA) is a cornerstone of manufacturing, particularly in industries where reliability is paramount. The Prilotte tire inflator is no exception, as manufacturers implement various QA measures to ensure that each unit meets established standards.

Manufacturers of Prilotte tire inflators typically adhere to several international standards, including ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer has met rigorous quality control benchmarks, ensuring a consistent approach to quality. Additionally, compliance with CE marking requirements ensures that products meet European safety, health, and environmental protection standards, which is particularly relevant for B2B buyers in Europe.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that any defects are caught early. Common QC checkpoints include:

Illustrative image related to prilotte tire inflator

Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified standards before they enter production. B2B buyers should verify that suppliers conduct thorough IQC processes.

In-Process Quality Control (IPQC): During assembly, IPQC measures check for defects at various stages, allowing for immediate corrective actions. Regular audits of these processes can help buyers assess supplier reliability.

Final Quality Control (FQC): After assembly, each unit undergoes a final inspection to confirm that it meets the required specifications. This includes functional tests, safety checks, and aesthetic evaluations.

Manufacturers employ various testing methods to validate the performance and safety of Prilotte tire inflators. These may include:

Pressure Testing: Ensures that the inflator can handle the pressure it is designed for without failure.

Durability Testing: Simulates prolonged usage to assess how the product withstands wear and tear.

Electrical Safety Testing: Confirms that electrical components meet safety standards to prevent hazards during use.

B2B buyers should ask suppliers about the specific testing protocols they follow and request access to testing reports to ensure transparency.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is crucial. Here are some effective strategies:

Regular audits are an essential way to assess a supplier’s adherence to quality standards. Buyers should consider scheduling on-site visits to review the manufacturing processes, quality control checkpoints, and overall facility conditions. This firsthand observation can provide valuable insights into the supplier’s operational integrity.

Illustrative image related to prilotte tire inflator

Buyers can request detailed quality assurance reports from suppliers, outlining their adherence to international standards and internal quality measures. These reports should include data on defect rates, testing results, and corrective actions taken for any issues that arose during production.

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality assurance practices. These independent organizations can conduct thorough assessments and offer certifications that validate the supplier’s compliance with industry standards.

B2B buyers must navigate specific challenges when it comes to quality control and certifications in international trade. Understanding these nuances can help buyers make informed decisions:

Illustrative image related to prilotte tire inflator

Certification Variability: Different regions may have varying certification requirements. For example, products sold in the EU must have CE marking, while those in the U.S. may need to comply with different safety standards. Buyers should ensure that suppliers are compliant with the relevant certifications for their target markets.

Language and Documentation Barriers: International transactions often involve language differences and complex documentation. Buyers should ensure that they have access to clear, translated documentation regarding quality assurance processes and certifications.

Cultural Considerations: Understanding cultural differences in business practices can impact negotiations and expectations regarding quality. Buyers should approach discussions with an open mind and seek to establish clear communication channels.

By comprehensively understanding the manufacturing processes and quality assurance measures for Prilotte tire inflators, B2B buyers can make informed purchasing decisions, ensuring they source reliable and high-quality products for their markets.

This sourcing guide is designed to assist B2B buyers in procuring the Prilotte Tire Inflator, a portable air compressor known for its efficiency and user-friendly features. By following this step-by-step checklist, you can ensure that your purchasing decision aligns with your business needs and sustainability goals.

Establishing clear technical specifications is the first step in sourcing the Prilotte Tire Inflator. Consider factors such as power supply options (battery versus corded), maximum PSI, and intended use (cars, bicycles, etc.). This clarity will help you filter suppliers and products that meet your precise requirements.

Illustrative image related to prilotte tire inflator

Understanding market trends in your region is crucial for making an informed purchase. Look into the demand for tire inflators in your target markets, such as Africa and South America, and gauge consumer preferences. This information can help you negotiate better pricing and terms with suppliers who are responsive to market demands.

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from other B2B buyers in similar industries or regions. Focus on:

– Supplier Certifications: Ensure they meet international quality and safety standards.

– Product Availability: Confirm that they can consistently supply the Prilotte Tire Inflator in the quantities you require.

Once you’ve shortlisted potential suppliers, request samples of the Prilotte Tire Inflator. This allows you to assess the product’s build quality, performance, and usability firsthand. Pay attention to:

– Functionality: Test the inflator’s pressure settings and ease of use.

– Durability: Evaluate the materials used and overall construction quality.

A robust warranty and after-sales support are essential for mitigating risks associated with product failure. Inquire about:

– Warranty Terms: Look for comprehensive coverage that includes functional defects.

– Customer Support: Ensure that the supplier offers accessible support channels for troubleshooting and repairs.

Once you are satisfied with your supplier and the product, it’s time to negotiate pricing and payment terms. Discuss bulk purchase discounts, payment schedules, and shipping costs. Ensure you have a clear understanding of:

– Total Cost of Ownership: Consider shipping, taxes, and potential tariffs.

– Payment Flexibility: Look for terms that align with your cash flow and procurement cycles.

After negotiations, draft a comprehensive purchase agreement that outlines all terms and conditions. Include delivery timelines, quality assurance measures, and penalties for non-compliance. This document will serve as a safeguard for both parties and ensure clarity throughout the transaction.

By following this checklist, you can make a well-informed decision when sourcing the Prilotte Tire Inflator, ensuring that it meets your operational requirements while fostering a sustainable purchasing approach.

When sourcing Prilotte tire inflators, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

Materials: The cost of raw materials such as plastic, metal components, and electronic parts can significantly affect the overall price. Sourcing high-quality materials may increase initial costs but can enhance product durability and performance.

Labor: Labor costs encompass both direct and indirect labor involved in manufacturing. This includes assembly line workers, quality control inspectors, and maintenance staff. Variations in labor costs across regions can impact the final pricing.

Manufacturing Overhead: This includes expenses related to factory operations that are not directly tied to production, such as utilities, rent, and equipment maintenance. Efficient overhead management can lead to lower prices for buyers.

Tooling: Initial tooling costs for molds and manufacturing equipment can be substantial, especially for customized products. These costs are typically amortized over the production run, affecting the unit price.

Quality Control (QC): Rigorous QC measures are necessary to ensure product reliability. Investing in quality assurance can lead to higher upfront costs but reduces the risk of returns and warranty claims, ultimately benefiting the buyer.

Logistics: Shipping and handling costs vary based on the shipping method, distance, and packaging requirements. Understanding these logistics can help buyers identify the most cost-effective shipping options.

Margin: Suppliers often include a profit margin in their pricing. Understanding the competitive landscape can help buyers negotiate better terms.

Several factors can influence the pricing of Prilotte tire inflators:

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower unit prices due to economies of scale. Buyers should consider their inventory needs to negotiate better pricing based on order volume.

Specifications and Customization: Customized inflators, whether in terms of features or branding, can lead to higher costs. Buyers should assess the necessity of customization against potential market benefits.

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (such as ISO or CE) can significantly impact pricing. Higher-quality materials often command a premium but may provide long-term savings through durability.

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, but they also reduce risks associated with product failure.

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for calculating the total landed cost. Different terms can shift responsibility and costs between the buyer and seller, impacting the overall price.

To maximize cost-efficiency when sourcing Prilotte tire inflators, consider the following tips:

Negotiation: Approach suppliers with a clear understanding of market prices and competitor offerings. Leverage your purchasing power, especially if you can commit to larger orders or long-term contracts.

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, warranty, and operational costs. A slightly higher upfront cost may be justified if it leads to lower long-term expenses.

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, currency fluctuations, tariffs, and import duties can significantly affect pricing. Conduct thorough research to understand these factors and factor them into your budget.

Supplier Relationships: Building strong relationships with suppliers can lead to better terms and pricing. Regular communication and feedback can foster trust and collaboration, resulting in favorable pricing adjustments.

The pricing information provided is indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult multiple suppliers to obtain the most accurate pricing for your needs.

In the realm of tire inflation, the Prilotte Tire Inflator stands out due to its portability, efficiency, and advanced features. However, B2B buyers should consider various alternatives that may better suit their specific needs, budget constraints, or operational environments. This analysis will compare the Prilotte Tire Inflator with two viable alternatives: traditional manual tire pumps and electric tire inflators, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Prilotte Tire Inflator | Traditional Manual Tire Pump | Electric Tire Inflator |

|---|---|---|---|

| Performance | High efficiency (25000+ RPM, 36 L/min) | Moderate (manual effort required) | Variable; some models are high-powered |

| Cost | $44.83 (affordable for quality) | Low (typically under $20) | Moderate to high ($30-$150) |

| Ease of Implementation | Plug and play, user-friendly interface | Requires manual pumping | Generally easy, may require AC/DC power |

| Maintenance | Minimal; battery checked periodically | Low; mechanical wear possible | Moderate; may require cleaning/replacing parts |

| Best Use Case | Ideal for emergency roadside assistance | Suitable for basic, infrequent use | Best for frequent use, especially in workshops |

Traditional manual tire pumps are a straightforward and cost-effective solution for tire inflation. They require physical effort to operate, making them less convenient than powered options. However, they are lightweight, portable, and do not rely on batteries or electrical outlets, making them suitable for remote areas. The main drawback is the time and effort needed for inflation, which can be a significant disadvantage in urgent situations or for businesses with high turnover rates.

Illustrative image related to prilotte tire inflator

Electric tire inflators are another common alternative that offers a balance between performance and ease of use. Many models are equipped with features such as automatic shut-off and various pressure settings. While they can inflate tires quickly and efficiently, their reliance on power sources can limit their usability in remote locations or during power outages. Additionally, the cost can vary significantly based on the brand and features, which may not align with budget constraints for all businesses.

When selecting a tire inflation solution, B2B buyers should assess their unique operational requirements, budgetary limits, and the frequency of use. The Prilotte Tire Inflator offers a robust and efficient option for those needing a portable and user-friendly device, particularly in emergency scenarios. However, businesses that operate in remote areas or require minimal inflation needs may find traditional manual pumps sufficient. Conversely, electric inflators might be the best choice for frequent use in workshops or service centers. Evaluating these factors will help buyers make informed decisions that align with their specific needs and enhance operational efficiency.

When considering the Prilotte Tire Inflator for commercial use, understanding its technical properties is crucial for B2B buyers. Here are some key specifications that impact performance and usability:

Battery Capacity (18000mAh)

This specification indicates the inflator’s ability to operate without being plugged into a power source. A higher mAh rating means longer usage time, which is vital for businesses that require multiple inflations on the go. This is particularly significant in regions with limited access to electricity, allowing for flexibility in various environments.

Pressure Output (Up to 150 PSI)

The maximum pressure output is essential for ensuring that the inflator can meet the demands of different vehicles, including cars, SUVs, and motorcycles. This versatility allows businesses to cater to a broader customer base, as they can service various types of vehicles. Meeting specific pressure requirements is crucial for maintaining safety and performance standards.

Airflow Rate (36 Liters per Minute)

This metric measures how quickly the inflator can pump air into a tire. A higher airflow rate translates to faster service, which is a competitive advantage in the automotive industry. For businesses offering roadside assistance or tire repair services, reducing inflation time can significantly enhance customer satisfaction.

Noise Level (50 dB)

Understanding the noise level is important for compliance with local regulations and for customer comfort. A quieter machine can be more appealing in urban environments or residential areas, where noise pollution is a concern. This specification can also influence purchasing decisions, as businesses may prefer quieter models for use in public spaces.

Operating Voltage (12 Volts)

The operating voltage affects the inflator’s compatibility with various vehicles and power sources. A 12-volt inflator is standard in automotive applications, ensuring that it can be easily used in cars, trucks, and other vehicles. This compatibility makes it a practical choice for businesses involved in automotive services.

Familiarity with industry jargon is essential for effective communication in the B2B landscape. Here are some common terms that may arise in discussions about the Prilotte Tire Inflator:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help businesses determine the reliability and quality of the inflator, as well as its compatibility with other automotive products.

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for businesses when negotiating purchases, as it affects inventory management and cash flow. For bulk buyers, understanding MOQ can lead to cost savings and better pricing.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. For businesses looking to procure Prilotte Tire Inflators, sending an RFQ can help them compare prices, negotiate terms, and make informed purchasing decisions.

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms is essential for understanding shipping, insurance, and delivery responsibilities, particularly when importing products like the Prilotte Tire Inflator.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement. Understanding warranty terms can help businesses assess the long-term viability of their investment in the Prilotte Tire Inflator, ensuring they are protected against defects and performance issues.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring that their investment in the Prilotte Tire Inflator aligns with their operational needs and market demands.

The global market for tire inflators, particularly portable models like the Prilotte tire inflator, is experiencing significant growth driven by increasing vehicle ownership, rising demand for convenience, and a focus on safety. In regions such as Africa, South America, the Middle East, and Europe, the need for reliable and efficient tire maintenance solutions is critical, especially as urbanization leads to a growing number of vehicles on the road.

Emerging trends indicate a shift towards advanced technology integration, including wireless capabilities and smart features that enhance user experience. The incorporation of touch screens and preset modes, as seen in the Prilotte tire inflator, offers users a more intuitive and efficient inflation process. Additionally, the demand for dual-purpose devices—those that function both as inflators and power banks—is gaining traction, catering to the needs of consumers who value multifunctionality.

For international B2B buyers, understanding these dynamics is crucial. Factors such as local market regulations, consumer preferences, and distribution channels will significantly impact sourcing decisions. Buyers must also remain attuned to competitive pricing strategies as the market matures and more players enter the space, particularly with the rise of refurbished and certified pre-owned products that offer cost-effective solutions without compromising quality.

Sustainability is a paramount concern in today’s B2B landscape, influencing sourcing decisions across industries, including the tire inflator sector. The environmental impact of manufacturing and disposal practices has led to a growing emphasis on ethical supply chains and sustainable materials. For the Prilotte tire inflator, sourcing practices that prioritize low carbon footprints and minimal waste are becoming increasingly critical.

International buyers are increasingly interested in products that are certified as refurbished or pre-owned, contributing to a circular economy that reduces waste and conserves resources. The Prilotte tire inflator’s design, which emphasizes durability and long-term usability, aligns with these values, as it encourages consumers to invest in quality products that last.

Moreover, certifications that verify environmental standards, such as ISO 14001 for effective environmental management, are becoming essential for B2B buyers who wish to align with sustainability goals. By choosing suppliers who adhere to these standards, buyers can enhance their brand reputation and appeal to environmentally-conscious consumers.

The Prilotte tire inflator has evolved significantly from its earlier iterations, which were often bulky and less efficient. Initial models focused primarily on functionality, with limited user-friendly features. However, as consumer expectations shifted towards convenience and technology integration, manufacturers like Prilotte began incorporating advanced features such as touch screens, multiple pressure settings, and portable designs.

This evolution reflects broader trends in consumer electronics, where portability and smart technology have become paramount. The contemporary Prilotte tire inflator not only serves its primary function of tire inflation but also offers additional benefits, such as serving as a power bank, thus catering to the modern consumer’s multifaceted needs.

As the market continues to evolve, international B2B buyers can leverage these insights to make informed sourcing decisions, ensuring they select products that not only meet current demands but are also aligned with future trends in technology and sustainability.

How can I ensure the quality of Prilotte tire inflators when sourcing from suppliers?

To ensure quality when sourcing Prilotte tire inflators, conduct thorough supplier vetting. Verify certifications and quality control processes, and request product samples for testing. Additionally, review customer feedback and case studies to assess reliability. Establish communication channels for ongoing support and quality assurance. Consider visiting the supplier’s facility if feasible, or utilizing third-party inspection services to confirm adherence to quality standards before placing bulk orders.

What are the most critical features to look for in a Prilotte tire inflator?

When evaluating Prilotte tire inflators, prioritize features such as battery capacity, inflation speed, and preset pressure modes. An 18000mAh battery is optimal for extended use, while a flow rate of 36 liters per minute ensures quick tire inflation. Look for user-friendly interfaces, such as touch screens, and safety features like automatic shut-off. Additionally, consider portability and the ability to serve multiple applications, including cars, motorcycles, and sports equipment, to maximize utility for diverse customers.

What is the minimum order quantity (MOQ) for Prilotte tire inflators?

The MOQ for Prilotte tire inflators can vary by supplier and location. Typically, it’s advisable to inquire directly with potential suppliers to understand their specific requirements. Some manufacturers may offer flexible MOQs for new customers or larger orders, while others might have fixed quantities. Establishing a good relationship with your supplier can lead to more favorable terms, including the possibility of lower MOQs or trial orders for initial testing.

What payment terms should I negotiate when sourcing Prilotte tire inflators?

Negotiating payment terms is crucial for cash flow management. Common terms include a deposit upfront (usually 30-50%) with the balance due before shipping or upon delivery. Consider discussing payment methods that provide security, such as letters of credit or escrow services. Always clarify any potential fees related to currency exchange, and be mindful of regional banking practices that may affect transaction processing times.

How do I handle logistics and shipping for Prilotte tire inflators?

When managing logistics for shipping Prilotte tire inflators, consider factors such as shipping methods, costs, and delivery timelines. Collaborate with reliable freight forwarders experienced in international shipping to navigate customs regulations. Determine the most efficient shipping routes based on your target markets in Africa, South America, the Middle East, and Europe. Always account for potential delays and ensure that your supplier provides necessary shipping documentation to facilitate smooth customs clearance.

What should I expect in terms of warranty and after-sales support for Prilotte tire inflators?

Most reputable suppliers of Prilotte tire inflators offer warranties ranging from 12 months to several years, covering functional defects. Ensure that warranty terms are clearly defined in your purchase agreement, including what is covered and the process for claims. After-sales support is equally important; check if the supplier provides technical assistance, spare parts, or repair services. Having a reliable support system can enhance customer satisfaction and foster repeat business.

Can I customize Prilotte tire inflators for my brand?

Yes, many suppliers offer customization options for Prilotte tire inflators, including branding, color choices, and packaging design. Customization can help differentiate your product in the market and enhance brand recognition. Discuss your specific requirements with potential suppliers, and ensure that they have the capabilities to meet your branding needs without compromising quality or increasing lead times significantly.

How can I assess the environmental impact of sourcing Prilotte tire inflators?

To assess the environmental impact of sourcing Prilotte tire inflators, inquire about the manufacturer’s sustainability practices. Look for certifications related to eco-friendliness and waste reduction. Consider sourcing certified pre-owned units, which can significantly lower the carbon footprint associated with new production. Additionally, evaluate the materials used in manufacturing and the potential for recycling at the product’s end of life to align with your company’s sustainability goals.

Domain: reebelo.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Prilotte Tire Inflator Portable Air Compressor-Air Pump for Car 18000mAh”, “Brand”: “Prilotte”, “Model Name”: “Prilotte Tire Inflator Portable Air Compressor-Air Pump for Car 18000mAh”, “Color”: “Black”, “Condition”: “Excellent”, “Price”: “$44.83”, “Warranty”: “3 Months”, “Shipping”: “Free delivery by December 3 – 8”, “Power Supply”: “Battery powered”, “Voltage”: “12 Volts”, “Noi…

Domain: manuals.plus

Introduction: {“products”:[{“model”:”Prilotte P005 Pro Max”,”type”:”Electric Tire Inflation”,”pressure”:”150 PSI”,”manual”:”User Manual”},{“model”:”Prilotte YX15 Pro Max”,”type”:”Portable Air Compressor”,”features”:[“enhanced touch interface”,”robust power supply”,”wireless”,”time-efficient”],”manual”:”User Manual”},{“model”:”Prilotte 4K-Y15″,”type”:”Dash Camera”,”features”:[“Super Night Vision”,”front camera”,…

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“name”: “Prilotte cars tire inflator air compressor”, “condition”: “Used”, “price”: “US $29.99 or Best Offer”, “seller_feedback”: “100% positive”, “shipping_cost”: “US $35.34”, “location”: “Oakland, CA, United States”, “delivery_estimate”: “between Thu, Jan 15 and Mon, Feb 9”, “return_policy”: “30 days returns, buyer pays for return shipping”, “item_specifics”: {“brand”: “Prilotte”, “type”: “tire…

In conclusion, the Prilotte Tire Inflator presents an exceptional opportunity for B2B buyers looking to enhance their product offerings in the automotive tools market. Its robust features, including a powerful 18000mAh battery, versatile inflation capabilities, and user-friendly design, position it as a competitive choice for both retail and distribution channels. The growing demand for portable and efficient tire inflators across diverse regions, particularly in Africa, South America, the Middle East, and Europe, underscores the necessity for strategic sourcing to secure reliable and high-quality products.

Strategic sourcing not only ensures cost-effectiveness but also strengthens supply chain resilience, enabling businesses to meet customer needs promptly. As international buyers seek innovative solutions, aligning with suppliers like Prilotte can facilitate growth in a rapidly evolving market.

Looking ahead, it is essential for B2B buyers to leverage the advantages of partnerships with reputable brands that prioritize quality and sustainability. By investing in products like the Prilotte Tire Inflator, companies can enhance their value proposition while contributing to a greener economy. Explore strategic sourcing opportunities today to stay ahead of market trends and meet the rising demand for high-performance automotive tools.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to prilotte tire inflator