In today’s fast-paced global market, sourcing high-quality tire air tools can pose significant challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With the increasing demand for efficient and reliable tire maintenance solutions, businesses face the critical task of identifying tools that not only meet performance standards but also align with their specific operational needs. This guide aims to provide a comprehensive overview of the tire air tool market, covering various types of tools—including digital inflators, manual gauges, and portable compressors—alongside their applications across different industries.

By delving into essential topics such as supplier vetting, pricing structures, and the latest technological advancements, this guide empowers international buyers to make informed purchasing decisions. Buyers will find valuable insights into evaluating product quality, understanding market trends, and navigating regional differences in availability and pricing. Moreover, with the global supply chain constantly evolving, knowing how to source effectively from reputable suppliers can significantly enhance operational efficiency and reduce costs.

As you explore this guide, you will gain the knowledge needed to confidently select tire air tools that enhance performance and reliability, ensuring your business stays competitive in an ever-changing marketplace. Whether you are based in bustling urban centers or remote areas, this resource equips you with the tools to thrive in the global tire maintenance landscape.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Tire Inflators | Equipped with digital gauges for precise pressure readings | Automotive service centers, fleets | Pros: Accurate, easy-to-read; Cons: May require batteries or charging. |

| Portable Tire Compressors | Compact design, often battery-operated or AC/DC compatible | Mobile tire services, roadside assistance | Pros: Versatile, convenient for on-the-go use; Cons: Limited power output compared to larger models. |

| Pneumatic Tire Inflators | Connects to air compressors, high efficiency for rapid inflation | Tire shops, commercial garages | Pros: Fast inflation; Cons: Requires a compressor, less portable. |

| Manual Tire Inflators | Simple hand-operated tools, often more affordable | Small workshops, DIY enthusiasts | Pros: Cost-effective, easy to use; Cons: Labor-intensive, less efficient. |

| Multi-Tire Inflation Systems | Systems designed for inflating multiple tires simultaneously | Fleet operations, automotive workshops | Pros: Saves time, increases productivity; Cons: Higher initial investment. |

Digital tire inflators are designed with advanced features such as digital gauges that provide precise pressure readings. This type of inflator is particularly suitable for automotive service centers and fleet maintenance operations where accuracy is critical. When purchasing, B2B buyers should consider the durability of the device and whether it requires batteries or can be directly powered, as this can impact operational efficiency.

Portable tire compressors are compact and often battery-operated or compatible with AC/DC power sources, making them ideal for mobile tire services and roadside assistance. Their versatility allows users to inflate tires anywhere, enhancing service delivery. Buyers should evaluate the compressor’s power output and battery life to ensure it meets their operational needs, especially in remote locations.

Pneumatic tire inflators are known for their high efficiency and speed, connecting directly to air compressors to provide rapid tire inflation. This makes them a preferred choice for tire shops and commercial garages that require quick turnaround times. When selecting a pneumatic inflator, buyers should consider the compatibility with existing air compressor systems and the inflator’s durability for heavy-duty use.

Manual tire inflators are straightforward, hand-operated tools that are often more affordable than their powered counterparts. They are suitable for small workshops or DIY enthusiasts who may not require high-volume tire servicing. Buyers should weigh the cost against the labor intensity and efficiency of manual inflators, particularly if they anticipate frequent use.

Multi-tire inflation systems are designed to inflate several tires at once, significantly reducing the time spent on tire maintenance. These systems are especially beneficial for fleet operations and automotive workshops with high tire turnover. B2B buyers should consider the initial investment and the potential for increased productivity when evaluating these systems, as they can lead to significant long-term savings.

| Industry/Sector | Specific Application of Tire Air Tool | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and pressure maintenance in workshops | Improved vehicle safety and performance; reduced tire wear | Reliability of tools; compatibility with existing equipment |

| Construction | Inflation of tires on heavy machinery and vehicles | Enhanced productivity and reduced downtime | Durability under heavy use; portability for job sites |

| Transportation & Logistics | Routine tire pressure checks for fleet vehicles | Increased fuel efficiency and extended tire life | Calibration accuracy; ease of use for operators |

| Agriculture | Tire maintenance for tractors and agricultural equipment | Improved operational efficiency and reduced fuel costs | Adaptability to various tire sizes; ruggedness for field use |

| Mining | Inflation of tires on mining trucks and equipment | Enhanced safety and performance in challenging terrains | High PSI capacity; specialized attachments for large tires |

In automotive repair shops, tire air tools are essential for maintaining proper tire pressure, which is crucial for vehicle safety and performance. Technicians use these tools to quickly inflate or deflate tires, ensuring they meet the manufacturer’s specifications. This application not only enhances vehicle safety but also helps in reducing tire wear and increasing fuel efficiency. International buyers should consider the reliability and compatibility of these tools with existing air compressor systems to ensure seamless operations.

In the construction industry, tire air tools are used to inflate tires on heavy machinery such as excavators, bulldozers, and trucks. Proper tire inflation is vital for maintaining optimal traction and stability on uneven surfaces, which directly impacts productivity. The durability and portability of tire air tools are critical considerations for construction companies, especially in remote job sites where access to power sources may be limited. Buyers should seek tools that can withstand rugged conditions while providing consistent performance.

For transportation and logistics companies, regular tire pressure checks using tire air tools are essential for fleet vehicles. Maintaining correct tire pressure leads to better fuel efficiency and longer tire lifespan, which translates into cost savings. Businesses in this sector should prioritize sourcing tools that offer calibration accuracy and ease of use, as operators often need to perform checks quickly and efficiently during routine vehicle maintenance.

In agriculture, tire air tools are used for maintaining the tires of tractors and other farming equipment. Proper inflation is crucial for operational efficiency, as under-inflated tires can lead to increased fuel consumption and reduced productivity. Buyers in this sector should look for tools that can adapt to various tire sizes and are rugged enough to withstand the demanding conditions of agricultural work. This ensures that farmers can maintain their equipment with minimal downtime.

In mining, tire air tools are indispensable for inflating tires on large trucks and machinery that operate in harsh environments. Properly inflated tires enhance safety and performance on uneven and rocky terrains, reducing the risk of blowouts. When sourcing tire air tools for mining applications, businesses should consider tools with high PSI capacity and specialized attachments designed for large tires. This ensures that the tools can handle the rigorous demands of the mining industry while providing reliable performance.

The Problem:

B2B buyers, especially those managing fleets or tire service centers, often struggle with achieving accurate tire pressure readings. Inconsistent tire pressure can lead to increased fuel consumption, reduced tire life, and safety hazards. Traditional mechanical gauges may provide unreliable readings due to wear and tear, while digital gauges might lack calibration, leading to further discrepancies. This inconsistency can frustrate technicians who rely on precise measurements to ensure optimal vehicle performance.

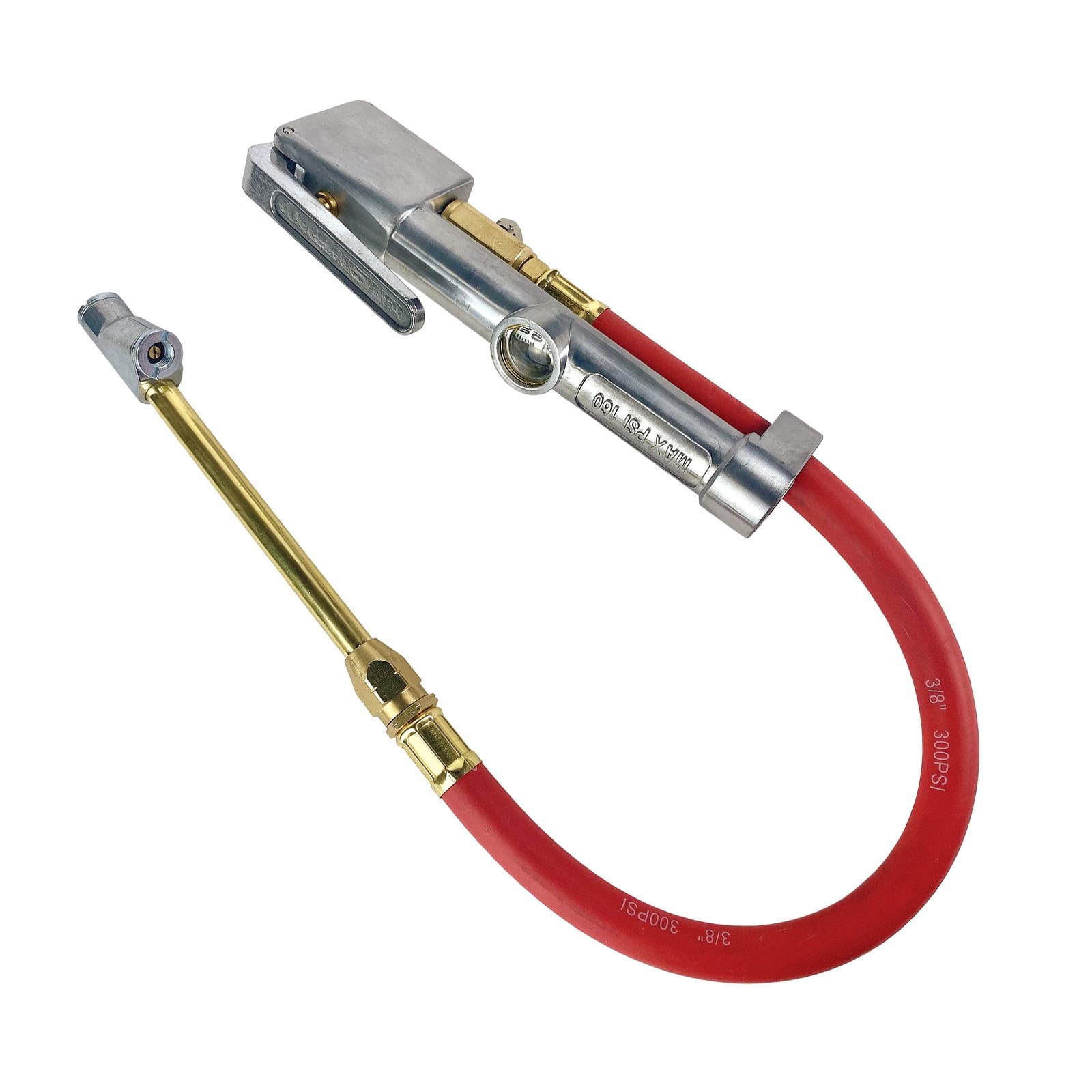

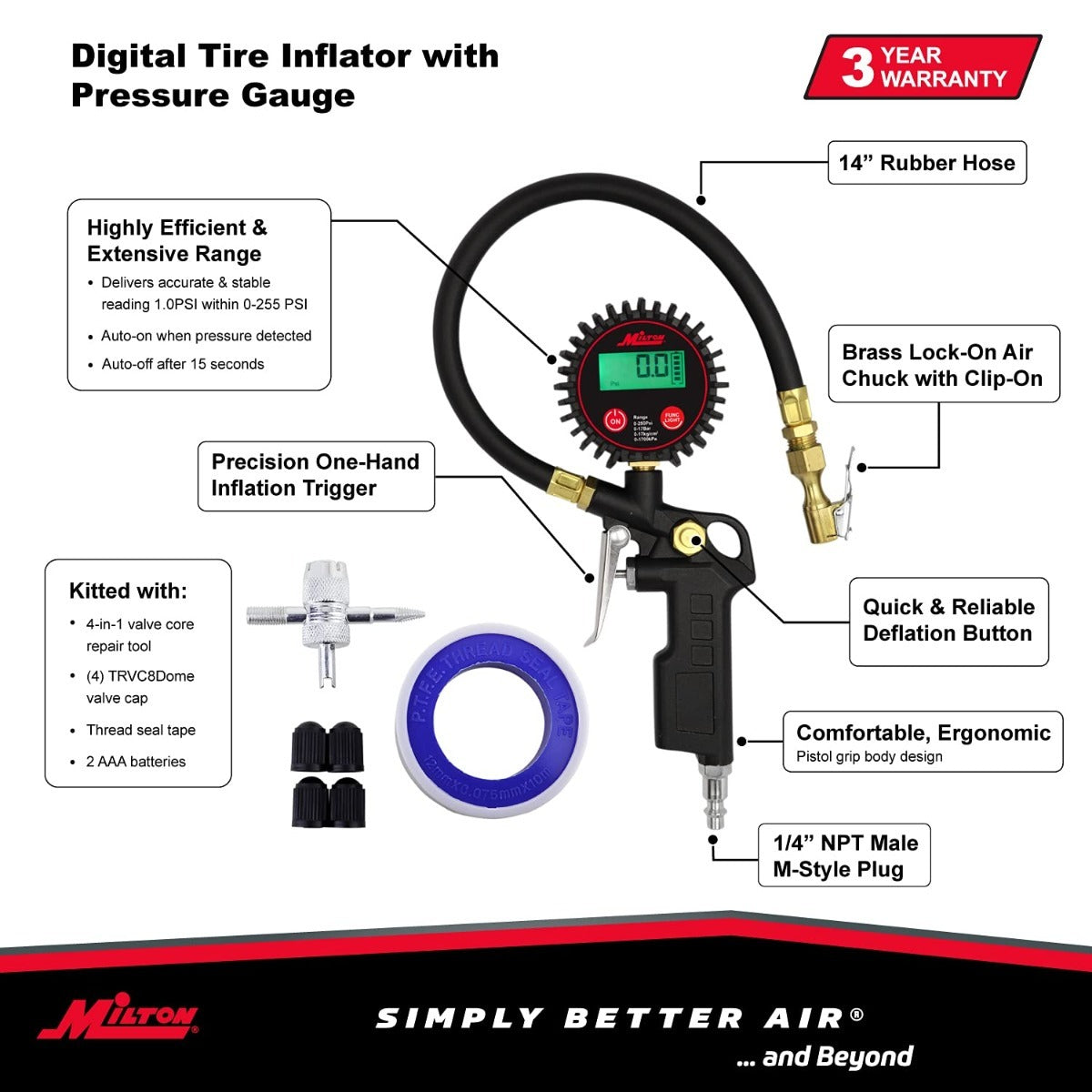

Illustrative image related to tire air tool

The Solution:

Investing in high-quality digital tire inflators with integrated pressure gauges can significantly mitigate this issue. Look for models that feature temperature compensation, which accounts for environmental fluctuations, ensuring accurate readings regardless of the conditions. Regularly calibrate these devices according to manufacturer specifications, and consider a maintenance schedule that includes checking gauge accuracy every few months. By standardizing the equipment used across your fleet or service center, you can enhance reliability and accuracy, ultimately leading to better tire management and cost savings.

The Problem:

In busy tire shops or fleet maintenance operations, time is of the essence. Workers often face pressure to complete tire maintenance quickly, which can lead to rushed procedures and potential mistakes. Manual inflators or outdated air tools can slow down operations, leading to longer wait times for customers and decreased overall productivity. This inefficiency not only frustrates employees but can also result in lost business opportunities.

The Solution:

To address this challenge, consider investing in high-capacity tire inflators that offer rapid inflation and deflation capabilities. Look for models that can connect to multiple tire types and are equipped with automatic shut-off features to prevent over-inflation. Additionally, training your staff on efficient workflows and the optimal use of these tools can significantly reduce time spent on each tire. Implementing a system for regular equipment checks will also ensure that your inflators are functioning at peak efficiency, minimizing downtime and enhancing customer satisfaction.

Illustrative image related to tire air tool

The Problem:

B2B buyers often encounter difficulties when their tire air tools are incompatible with a range of tire types, particularly in diverse markets like those in Africa and South America. This can lead to delays in service, increased operational costs, and dissatisfaction among customers who expect timely and efficient service. Variations in valve types, sizes, and configurations can make it challenging to find a one-size-fits-all solution.

The Solution:

To overcome compatibility issues, it is essential to select versatile tire inflators that come with multiple attachments or adapters designed for different tire valve types. Investigate products that offer a range of air chucks, including dual-foot and angled options, which can accommodate various vehicles, from passenger cars to heavy-duty trucks. Additionally, conducting a thorough assessment of your customer base’s needs can help you stock the appropriate tools. Training employees to use these tools effectively will also ensure that they can adapt to different tire types without delay, improving overall service efficiency.

When selecting materials for tire air tools, several factors influence performance, durability, and compliance with international standards. The most common materials include aluminum, steel, plastic, and rubber. Each material presents unique properties and considerations that can impact the effectiveness of the tools in various environments, especially for international B2B buyers from diverse regions.

Illustrative image related to tire air tool

Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for tire air tools. Its temperature and pressure ratings are suitable for most automotive applications, ensuring reliable performance. However, while aluminum is durable, it can be more susceptible to deformation under extreme stress compared to other metals.

Pros:

– Lightweight, enhancing portability.

– Excellent corrosion resistance, ideal for humid or saline environments.

Cons:

– Higher manufacturing complexity, which can lead to increased costs.

– Less durable than steel under heavy use.

For international buyers, aluminum tools may require compliance with specific standards like ASTM B221 for aluminum extrusions, which is particularly relevant in regions with strict quality regulations.

Steel, particularly stainless steel, is widely used in tire air tools due to its strength and durability. It can withstand high pressures and is resistant to corrosion when treated properly. Steel tools often have a longer lifespan, making them suitable for heavy-duty applications.

Illustrative image related to tire air tool

Pros:

– Exceptional strength and durability, ideal for high-pressure applications.

– Cost-effective compared to aluminum for bulk manufacturing.

Cons:

– Heavier than aluminum, which may reduce portability.

– Prone to rust if not properly coated or maintained.

International buyers should consider compliance with standards such as ASTM A240 for stainless steel, ensuring that the tools meet the necessary quality and safety benchmarks in their respective markets.

Plastic is often used in non-structural components of tire air tools, such as handles or casings. It is lightweight, resistant to corrosion, and can be molded into complex shapes, offering versatility in design.

Pros:

– Lightweight and easy to handle.

– Cost-effective and allows for intricate designs.

Cons:

– Limited temperature and pressure resistance compared to metals.

– Less durable, particularly under extreme conditions.

For B2B buyers in regions like Africa and South America, where environmental conditions can vary, it is crucial to ensure that the plastic used complies with standards such as ISO 9001 for quality management, ensuring reliability in diverse climates.

Illustrative image related to tire air tool

Rubber is primarily used in seals and hoses within tire air tools, providing flexibility and a tight seal to prevent air leaks. Its elasticity allows for effective operation under varying pressures.

Pros:

– Excellent sealing properties, preventing air loss.

– Flexible and can withstand a range of temperatures.

Cons:

– Degrades over time, especially when exposed to UV light or extreme temperatures.

– Can be more expensive than plastic alternatives.

Illustrative image related to tire air tool

For international buyers, it’s essential to consider rubber compliance with standards like ASTM D2000, which governs the quality of rubber products, ensuring they can withstand the rigors of their intended applications.

| Material | Typical Use Case for tire air tool | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Inflator bodies and gauges | Lightweight and corrosion-resistant | Less durable under heavy use | Medium |

| Steel | Structural components and air chucks | Exceptional strength and durability | Heavier, prone to rust | Low |

| Plastic | Handles and non-structural parts | Cost-effective and versatile | Limited pressure resistance | Low |

| Rubber | Seals and hoses | Excellent sealing properties | Degrades over time | Medium |

In summary, selecting the right material for tire air tools is crucial for ensuring performance, durability, and compliance with international standards. By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their operational needs and regional requirements.

The manufacturing process for tire air tools is intricate and involves several key stages that ensure the final product is both functional and reliable. Understanding these stages is crucial for B2B buyers who prioritize quality and performance in their procurement decisions.

The first step in manufacturing tire air tools involves the selection and preparation of materials. Common materials include high-grade steel, aluminum, and plastic components, which are chosen for their durability, weight, and resistance to corrosion.

During this stage, raw materials undergo rigorous inspections to ensure they meet specific quality standards. This often involves checking for impurities and inconsistencies that could affect performance. Buyers should inquire about the sourcing of materials to ensure they are compliant with international quality standards.

The forming stage involves shaping the prepared materials into the necessary components of the tire air tool. Techniques such as stamping, casting, and machining are commonly employed. For example, steel components may be stamped or forged to create robust parts, while plastic components can be molded to achieve precise shapes.

Advanced technologies, such as Computer Numerical Control (CNC) machining, are frequently used to ensure high precision and repeatability in the manufacturing process. B2B buyers should look for suppliers that utilize modern manufacturing techniques as they often lead to better product consistency and performance.

Once individual components are formed, the assembly stage begins. This involves the systematic assembly of parts, such as valves, gauges, and hoses, into a complete tire air tool.

Quality control checkpoints during assembly are crucial. For instance, each assembly line may include automated testing stations to ensure that components fit together correctly and function as intended. Buyers should consider suppliers that have robust assembly processes in place, as this can greatly influence the tool’s reliability and performance.

The finishing stage includes surface treatments, painting, and packaging of the tire air tools. Surface treatments may involve anodizing, powder coating, or galvanization to enhance corrosion resistance and aesthetic appeal.

Quality checks during this stage often focus on the appearance and functional integrity of the final product. B2B buyers should ensure that their suppliers adhere to high finishing standards to avoid issues related to premature wear or failure.

Quality assurance (QA) is critical in the manufacturing of tire air tools, as it ensures that products meet or exceed industry standards. Various international standards govern this process, providing guidelines for manufacturers and reassurance for buyers.

Illustrative image related to tire air tool

ISO 9001 is one of the most recognized international standards for quality management systems. It sets forth criteria for ensuring that companies consistently provide products that meet customer and regulatory requirements. Buyers should prioritize suppliers who are ISO 9001 certified, as this indicates a commitment to quality.

Additionally, industry-specific standards such as CE marking in Europe and API standards in the oil and gas sector may also apply. These certifications often require rigorous testing and compliance with safety regulations, further ensuring product reliability.

Quality control (QC) is integral to the manufacturing process, with several checkpoints established to ensure that the final products meet stringent quality criteria.

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. Inspections may include material testing and verification against specifications.

In-Process Quality Control (IPQC): As the manufacturing process unfolds, IPQC is employed to monitor production operations. This includes regular inspections of machinery, tooling, and assembly processes to catch defects early.

Final Quality Control (FQC): This final inspection takes place after the assembly is complete but before products are packaged. FQC often includes functional testing, safety checks, and visual inspections to ensure that the tools operate correctly and meet all specifications.

For international B2B buyers, verifying a supplier’s quality control measures is essential for ensuring product reliability. Here are some actionable steps to undertake:

Illustrative image related to tire air tool

Buyers should request documentation such as quality management system reports, audit results, and product testing certifications. Regular audits by third-party organizations can provide an unbiased assessment of a supplier’s adherence to quality standards.

Common testing methods for tire air tools include pressure testing, durability testing, and performance evaluations. Buyers should inquire about the specific testing protocols used by suppliers to ensure that products meet the required performance specifications.

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control and certification.

Different regions may have varying regulations and standards for tire air tools. For instance, CE marking is crucial for products sold in Europe, while other regions may have their own compliance requirements. Understanding these differences is vital for ensuring that products can be marketed and sold in target markets without legal complications.

Utilizing third-party inspection services can provide an additional layer of assurance for B2B buyers. These services can independently verify that products meet quality standards and specifications, offering peace of mind in the procurement process.

Manufacturing processes and quality assurance for tire air tools are multifaceted and require a comprehensive understanding for successful B2B transactions. By grasping the stages of manufacturing, relevant international standards, and quality control measures, buyers can make informed decisions that ensure they acquire reliable, high-quality products. Prioritizing suppliers with robust manufacturing practices and verified quality control systems will ultimately lead to greater satisfaction and operational efficiency.

In today’s competitive market, sourcing the right tire air tools is essential for ensuring efficiency and reliability in tire maintenance operations. This guide provides a practical checklist for B2B buyers looking to procure tire air tools that meet their specific needs. By following these steps, you can make informed decisions that align with your operational requirements and budget constraints.

Begin by outlining the specific features and capabilities you require in tire air tools. Consider factors such as pressure ratings, compatibility with existing equipment, and the types of tires you’ll be servicing.

– Pressure Requirements: Identify whether you need tools with PSI ratings suitable for passenger vehicles, trucks, or specialty tires.

– Tool Type: Decide if you need inflators, gauges, or a combination of both based on your operational needs.

Stay updated on the latest innovations and trends in tire air tools. This knowledge can help you identify products that offer superior performance and reliability.

– Product Reviews: Look for reviews from automotive magazines or industry experts that discuss the latest models and their features.

– Technological Advancements: Be aware of advancements such as digital gauges, automatic inflators, and portable compressors that can enhance productivity.

Illustrative image related to tire air tool

Before making a commitment, thoroughly vet potential suppliers. Request comprehensive company profiles, case studies, and references from buyers in similar industries or regions.

– Supplier Reliability: Assess their track record for delivering quality products on time.

– Geographical Considerations: Ensure that the supplier can efficiently service your location, especially if you are in regions like Africa or South America where logistics may be challenging.

Verify that the suppliers’ products comply with international safety and quality standards. Certifications can be a strong indicator of product reliability and safety.

– ISO Certifications: Look for suppliers with ISO certifications that demonstrate adherence to quality management systems.

– Regional Standards: Ensure compliance with local regulations in your target markets, such as CE marking in Europe or other regional certifications.

Before placing a bulk order, request samples of the tire air tools you are considering. Testing these samples can help you assess their performance and suitability for your operations.

– Performance Testing: Evaluate the tools under actual working conditions to determine their efficiency and reliability.

– User Feedback: Involve your team in the testing process to gather feedback on usability and effectiveness.

Once you’ve narrowed down your choices, engage in negotiations to secure the best pricing and terms. This step is crucial for optimizing your budget while ensuring you receive quality products.

– Bulk Purchase Discounts: Inquire about discounts for bulk orders or long-term contracts.

– Payment Terms: Clarify payment terms and conditions, including any warranties or return policies.

Illustrative image related to tire air tool

Maintain open lines of communication with your selected supplier. This relationship can be beneficial for future orders, support, and updates on new products.

– Feedback Loop: Provide feedback on the products and service to help the supplier improve.

– Updates on New Offerings: Stay informed about new products or enhancements that may benefit your operations.

By following this checklist, B2B buyers can ensure they are well-equipped to source tire air tools that meet their operational needs and contribute to their business success.

When evaluating the cost structure for tire air tools, several components come into play:

Materials: The choice of materials significantly impacts the overall cost. High-quality metals and durable plastics are often used to ensure longevity and performance. The sourcing of these materials can vary widely in cost based on geographic availability and market conditions.

Labor: Labor costs can fluctuate based on the region where the manufacturing occurs. In countries with higher wage standards, labor can constitute a significant portion of the total cost. Conversely, sourcing from regions with lower labor costs can improve profit margins but may impact quality.

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer competitive pricing.

Tooling: The initial investment in tooling is critical, especially for custom designs. Specialized molds or equipment can add to upfront costs, impacting the pricing of the final product.

Quality Control (QC): Implementing stringent QC processes ensures product reliability and safety, especially for tire inflators that must meet specific industry standards. Investing in quality assurance can lead to higher upfront costs but reduce long-term warranty claims and customer dissatisfaction.

Logistics: Shipping costs are influenced by the mode of transport, distance, and weight of the products. For international shipments, tariffs, customs duties, and handling fees can further complicate cost calculations.

Margin: Suppliers typically add a profit margin that reflects their operational costs, market positioning, and competition. Understanding the typical margins in the tire air tool industry can assist buyers in negotiating better deals.

Several factors play a crucial role in determining the pricing of tire air tools:

Volume and Minimum Order Quantity (MOQ): Bulk purchases can lead to significant discounts. Suppliers often have set MOQs, and exceeding these can yield lower per-unit costs.

Specifications and Customization: Custom tools or features tailored to specific needs often come at a premium. Buyers should weigh the benefits of customization against its cost implications.

Material Quality and Certifications: Tools made from higher-grade materials or those that meet certain certifications (e.g., ISO standards) may command higher prices. Buyers should verify that the tools meet necessary industry standards for safety and performance.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more due to their perceived value.

Incoterms: The choice of Incoterms (International Commercial Terms) affects the total landed cost of the products. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears responsibility for shipping costs and risks.

To maximize value when sourcing tire air tools, consider the following strategies:

Negotiation: Build relationships with suppliers and be prepared to negotiate pricing based on volume, payment terms, and long-term partnerships. Leverage market data to substantiate your position.

Cost-Efficiency: Look beyond initial pricing; assess the total cost of ownership, including maintenance, warranty, and replacement costs. Tools that may seem cheaper upfront could result in higher costs over time if they are less durable.

Understand Pricing Nuances: Different regions may have varying pricing strategies based on local market conditions and competition. Familiarize yourself with pricing standards in your target markets, such as Africa, South America, the Middle East, and Europe.

Evaluate Quality vs. Price: While lower prices may be enticing, ensure that quality is not compromised. Cheaper tools may lead to higher failure rates and increased costs in the long run.

Consider Local Regulations: Ensure compliance with local laws and standards, which can impact the usability and acceptance of tire air tools in specific markets.

In conclusion, a comprehensive understanding of cost components and pricing influencers is essential for international B2B buyers in the tire air tool market. By employing strategic sourcing practices and negotiation techniques, buyers can achieve a favorable balance between cost and quality, ultimately enhancing their operational efficiency.

In the competitive landscape of tire maintenance and inflation, various solutions exist that can serve as alternatives to traditional tire air tools. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific use cases. Below, we compare tire air tools against two viable alternatives: electric tire inflators and manual tire pumps.

| Comparison Aspect | Tire Air Tool | Electric Tire Inflator | Manual Tire Pump |

|---|---|---|---|

| Performance | High efficiency, quick inflation | Fast and automatic inflation | Slower, requires physical effort |

| Cost | Moderate price range ($35-$170) | Varies ($30-$150) | Low-cost options available ($10-$40) |

| Ease of Implementation | Requires air compressor setup | Plug-and-play, user-friendly | Requires manual operation |

| Maintenance | Low maintenance, durable | Minimal maintenance | Generally low maintenance |

| Best Use Case | Professional garages and workshops | Home use, roadside emergencies | Casual users, low-frequency use |

Electric tire inflators have gained popularity due to their convenience and speed. They typically feature automatic shut-off mechanisms that prevent over-inflation, making them user-friendly, especially for those unfamiliar with tire pressure standards. Their compact design allows for easy transport, making them ideal for roadside emergencies. However, electric inflators require a power source, which may not be available in all situations. Additionally, while they are generally reliable, their performance can diminish over time, leading to potential issues in accuracy.

Manual tire pumps are the most basic and cost-effective option available. They are easy to carry and do not require any power source, making them suitable for remote locations. However, the primary drawback is the physical effort required to achieve the desired tire pressure, which can be time-consuming and labor-intensive. Manual pumps are best suited for infrequent users who may not need to inflate tires regularly. While they are low in cost and maintenance, their efficiency and performance do not match the capabilities of tire air tools or electric inflators.

When selecting the right tire inflation solution, B2B buyers should consider their specific operational needs and the environment in which they will be used. For businesses that require high-performance and quick tire inflation, especially in professional settings like workshops or garages, tire air tools are the best choice. Conversely, if convenience and portability are paramount, electric tire inflators may serve better for home use or roadside emergencies. Lastly, for those operating on a tight budget or requiring an occasional inflation tool, manual tire pumps can be a viable option. By evaluating performance, cost, ease of implementation, and maintenance needs, buyers can make a well-informed decision that aligns with their business objectives.

When sourcing tire air tools, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties to consider:

Pressure Rating (PSI)

The pressure rating indicates the maximum pressure the tool can handle, typically measured in pounds per square inch (PSI). For tire inflators, common ratings range from 100 PSI to 200 PSI. A higher PSI rating is essential for heavy-duty applications, such as commercial tire service, ensuring that the tool can inflate a variety of tire sizes efficiently.

Material Grade

The material of the air tool significantly affects its durability and performance. Common materials include high-grade aluminum, steel, and reinforced plastic. Tools made from higher-grade materials offer better resistance to corrosion, wear, and extreme temperatures, leading to a longer service life, which is particularly important in diverse climates found in regions like Africa and the Middle East.

Air Flow Rate (CFM)

The flow rate, measured in cubic feet per minute (CFM), indicates how quickly the tool can inflate a tire. A higher CFM rating allows for faster inflation and deflation, which is particularly beneficial for businesses that require quick turnaround times, such as tire shops or service centers.

Chuck Type

The chuck type refers to the design of the connector that attaches the inflator to the tire valve. Options include straight, dual foot, and lock-on chucks. The choice of chuck affects ease of use and versatility. A lock-on chuck, for example, ensures a secure connection, minimizing air loss during inflation.

Power Source

Tire air tools can be powered by various sources, including AC/DC electricity or battery-operated options. Understanding the power source is vital for selecting tools that meet operational needs, especially in areas with limited power supply or for mobile applications.

Portability

The weight and design of the tool impact its portability. For businesses that require on-the-go solutions, such as roadside assistance services, lightweight and compact designs are preferred. A portable tire inflator can enhance service efficiency and customer satisfaction.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of tire air tools, sourcing from OEMs can ensure high-quality, compatible components for replacement or assembly.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for budget planning, as it affects inventory levels and overall purchasing costs. This is particularly relevant for buyers in regions with varying demand patterns.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It’s a vital tool for comparing offers and negotiating favorable conditions, ensuring that buyers receive the best value for their investments.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps in understanding shipping costs, insurance, and liability, which is especially important for international buyers in diverse markets like South America and Europe.

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. Understanding warranty terms can help businesses assess the risk and reliability of tire air tools, influencing purchasing decisions.

Lead Time

Lead time refers to the period between placing an order and receiving the product. Knowing lead times is essential for planning inventory and ensuring that operations run smoothly, especially in high-demand seasons.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, enhancing their procurement strategies and operational efficiency in the tire air tool market.

Illustrative image related to tire air tool

The tire air tool sector is experiencing significant transformation driven by technological advancements, evolving consumer expectations, and changing market dynamics. Internationally, there is a growing demand for high-quality, durable inflators and gauges that offer precision and efficiency. Emerging technologies such as digital pressure gauges and automatic inflators are gaining traction, particularly in regions like Europe and the Middle East, where consumers prioritize performance and reliability. In Africa and South America, the focus is shifting towards portable and versatile tools that can function in diverse environments, catering to both urban and rural markets.

Additionally, the trend towards automation in manufacturing processes is reshaping sourcing strategies. B2B buyers are increasingly seeking suppliers that can provide technologically advanced products, ensuring that their offerings meet the needs of a more tech-savvy customer base. The rise of e-commerce platforms is also influencing how buyers source tire air tools, as they can easily compare prices and features across global suppliers, enhancing competition and driving innovation.

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the tire air tool sector. As environmental regulations tighten globally, companies are under pressure to adopt greener practices and reduce their ecological footprint. This shift is influencing sourcing decisions, with buyers increasingly favoring suppliers who demonstrate a commitment to sustainability through their manufacturing processes and materials.

The use of eco-friendly materials and sustainable manufacturing techniques is gaining popularity. For instance, tire air tools made from recycled or recyclable materials are being prioritized. Certifications such as ISO 14001 (Environmental Management) and products labeled with ‘green’ certifications are becoming essential for suppliers aiming to attract environmentally conscious buyers. This trend is particularly relevant in markets like Europe, where consumers are more likely to support brands that align with their values on sustainability.

The evolution of tire air tools dates back to the early 20th century when pneumatic technology began to revolutionize the automotive industry. Initially, tire inflation was a manual process, often inefficient and time-consuming. The introduction of mechanical air inflators marked a significant advancement, paving the way for electric and digital models that dominate the market today.

Over the decades, innovations such as digital gauges and automatic inflators have enhanced accuracy and user-friendliness, making it easier for both professionals and consumers to maintain optimal tire pressure. This evolution is crucial for B2B buyers, as understanding the historical advancements helps in recognizing the value of investing in modern, efficient tools that can improve operational efficiency and customer satisfaction.

In conclusion, navigating the tire air tool sector requires a keen understanding of market dynamics, sustainability trends, and the historical context shaping current product offerings. By aligning sourcing strategies with these insights, B2B buyers can enhance their competitive edge and meet the evolving needs of their customers.

How do I choose the right tire air tool for my business needs?

When selecting a tire air tool, consider the specific requirements of your operations, such as the types of vehicles you service and the frequency of use. Look for features like pressure ratings (e.g., PSI), portability, and compatibility with existing air compressors. Research brands known for durability and reliability in professional settings. Additionally, read reviews and seek recommendations from industry peers to ensure the tool meets performance expectations.

What are the key features to look for in a tire inflator?

The best tire inflators typically feature high PSI ratings, digital gauges for accurate readings, and durable construction for longevity. Look for models with automatic shut-off capabilities to prevent over-inflation and those that offer portability for on-the-go use. Enhanced features such as built-in LED lights and multiple power options (AC/DC) can also add value, especially for businesses operating in diverse environments.

How can I ensure the quality of tire air tools from suppliers?

To ensure quality, vet suppliers by checking their certifications, product reviews, and compliance with international standards. Request samples before committing to larger orders to evaluate the product’s performance and durability. Additionally, consider suppliers who offer warranties or guarantees, as this indicates confidence in their products and provides assurance for your investment.

What are the common payment terms in international B2B transactions for tire air tools?

Payment terms can vary significantly by supplier and region. Common options include upfront payment, partial payment upon order confirmation, and balance due upon delivery. Letters of credit are also popular for larger transactions, providing security for both parties. Always clarify payment terms in your contract to avoid misunderstandings and ensure smooth transactions.

What is the typical minimum order quantity (MOQ) for tire air tools?

Minimum order quantities can vary widely based on the supplier and the specific product. Generally, MOQs for tire air tools range from 50 to 500 units. Some manufacturers may offer lower MOQs for first-time buyers or pilot orders, while others might have higher MOQs for customized or branded products. Always discuss MOQs upfront to align with your inventory needs and budget.

How do logistics and shipping work for international orders of tire air tools?

Logistics for international orders typically involve selecting a reliable freight forwarder who can handle customs clearance and ensure timely delivery. Discuss shipping terms (e.g., FOB, CIF) with your supplier to understand who bears the shipping costs and risks. Additionally, consider lead times, as manufacturing and shipping can take several weeks, especially for customized products. Always factor in potential delays at customs to plan your inventory effectively.

Can I customize tire air tools to meet specific requirements?

Many suppliers offer customization options, such as branding, color changes, or specific feature enhancements to tailor products to your needs. Discuss your requirements during the initial negotiation phase, and request samples or prototypes to evaluate the modifications. Keep in mind that customization may affect pricing and lead times, so ensure these factors align with your project timelines and budget.

What are the best practices for maintaining tire air tools?

Regular maintenance of tire air tools is essential for optimal performance and longevity. Clean the tools after each use, checking for dust or debris that could affect functionality. Inspect air hoses and connections for wear or leaks, and lubricate moving parts as recommended by the manufacturer. Additionally, store tools in a dry, protected environment to prevent damage from moisture or extreme temperatures.

Domain: jacosuperiorproducts.com

Registered: 2014 (11 years)

Introduction: FlowPro® Digital Tire Inflator with Pressure Gauge – 200 PSI: $39.95 (originally $89.99), rated “Best Inline Tire Pressure Gauge” by Car and Driver Magazine. FlowPro® Tire Inflator with Pressure Gauge – 100 PSI: $35.95 (originally $79.99). FlowPro® 2.0 Digital Tire Inflator with Pressure Gauge – 200 PSI: $39.95 (originally $89.99), features patented Lightning® Air Chuck. FlowPro® Digital Tire Infl…

Domain: steelmantools.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”STEELMAN # 75052 Straight Chuck Tire Inflator with Built-In Gauge and Green 12-Inch Hose”,”price”:”$29.99″,”availability”:”In stock”},{“name”:”STEELMAN # 75051 Straight Chuck Tire Inflator with Built-In Gauge and 12-Inch Hose”,”price”:”$21.99″,”availability”:”In stock”},{“name”:”STEELMAN # 97977 High Accuracy Digital Gauge Tire Inflator with Temperature Compensation and 15-In…

Domain: gemplers.com

Registered: 1996 (29 years)

Introduction: This company, Gemplers – Tire Inflation Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

The tire air tool market presents significant opportunities for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. Understanding the nuances of product quality, supplier reliability, and technological advancements is crucial in making informed purchasing decisions. Buyers should prioritize sourcing tools that not only meet performance standards but also offer durability and versatility for both automotive and industrial applications.

Strategic sourcing can streamline your procurement process, enabling businesses to reduce costs while ensuring high-quality products. By forging strong relationships with reputable suppliers, buyers can gain access to innovative tire air tools that enhance operational efficiency and safety. Investing in advanced inflators and gauges will not only improve tire maintenance but also contribute to overall vehicle performance and longevity.

Looking ahead, the demand for tire air tools is expected to grow, driven by increasing vehicle ownership and the need for regular maintenance across diverse markets. B2B buyers are encouraged to stay ahead of industry trends by continuously evaluating new technologies and adapting their sourcing strategies. Embrace this opportunity to enhance your toolkit and secure a competitive edge in the marketplace. Engage with trusted suppliers today to explore the best options tailored to your specific needs.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to tire air tool

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.