In the competitive landscape of cycling accessories, sourcing a reliable CO2 inflator for bike tires is essential for B2B buyers aiming to enhance customer satisfaction and retention. With punctures being an inevitable challenge for cyclists, having an efficient and effective solution at hand can significantly reduce downtime and improve the overall riding experience. This guide offers an in-depth exploration of the various types of CO2 inflators available in the market, their applications, and critical factors to consider when sourcing these products.

From portable inflators suitable for road bikes to robust options for mountain biking, we cover a spectrum of solutions tailored to diverse cycling needs. Additionally, our guide delves into supplier vetting processes, enabling buyers to identify trustworthy manufacturers that align with their quality and sustainability standards. We also examine cost considerations, ensuring that international buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—can make informed purchasing decisions.

By equipping buyers with comprehensive insights into product specifications, market trends, and supplier credentials, this guide empowers businesses to confidently navigate the global market for CO2 inflators. Ultimately, investing in the right inflator not only enhances customer loyalty but also positions your business as a reliable partner in the cycling industry.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stand-Alone CO2 Inflators | Compact, easy to use, compatible with multiple valves | Retail bike shops, repair services | Pros: Quick inflation, lightweight; Cons: Limited to CO2 cartridges, potential for leaks. |

| Integrated CO2 Pumps | Combines CO2 inflator with a hand pump | Bike rental companies, touring services | Pros: Versatile, dual functionality; Cons: Bulkier, may require more maintenance. |

| Cartridge Packs | Various sizes (16g, 20g, 25g) for different tire volumes | Wholesale distributors, bike manufacturers | Pros: Cost-effective, bulk purchasing options; Cons: Storage and expiration issues. |

| Hybrid CO2 Inflators | Combines CO2 inflator and mini pump in one unit | E-commerce retailers, outdoor gear shops | Pros: Flexibility, suitable for emergencies; Cons: May sacrifice performance in both functions. |

| Smart CO2 Systems | Advanced models with pressure gauges and controls | High-end bike shops, performance cycling brands | Pros: Precision inflation, user-friendly; Cons: Higher cost, potential complexity for users. |

Stand-alone CO2 inflators are simple devices designed for quick tire inflation. Their compact size and lightweight nature make them ideal for cyclists who prioritize portability. Suitable for retail bike shops and repair services, these inflators can be easily integrated into repair kits. B2B buyers should consider their reliability and ease of use, as well as the trade-offs associated with relying solely on CO2 cartridges, which can lead to potential leaks.

Integrated CO2 pumps combine the functionality of a hand pump with a CO2 inflator, allowing for flexible tire inflation options. These units are particularly beneficial for bike rental companies and touring services where versatility is key. While they offer the convenience of two tools in one, B2B buyers should be aware that these pumps tend to be bulkier and may require more maintenance than stand-alone options, impacting their overall portability.

Cartridge packs come in various sizes, catering to different tire volumes and inflation needs. They are essential for wholesale distributors and bike manufacturers looking to provide customers with a variety of inflation solutions. The cost-effectiveness of bulk purchasing is a significant advantage, but buyers must also consider storage and expiration issues, which can affect inventory management.

Hybrid CO2 inflators merge the functionalities of a CO2 inflator and a mini pump, making them practical for emergency situations. E-commerce retailers and outdoor gear shops often stock these models for their flexibility. While they are beneficial in emergencies, B2B buyers should note that they might sacrifice performance in both pumping and inflating functions, which could impact user satisfaction.

Smart CO2 systems feature advanced designs with integrated pressure gauges and controls, providing precise inflation for high-performance bicycles. These systems are well-suited for high-end bike shops and performance cycling brands that cater to serious cyclists. Although they offer significant advantages in terms of user experience, B2B buyers should be prepared for a higher initial cost and potential complexity in usage, which may deter some customers.

| Industry/Sector | Specific Application of CO2 Inflator for Bike Tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Bike Rental Services | Quick tire inflation for rental bikes after use | Reduces downtime, enhances customer satisfaction | Reliability of inflators, availability of cartridges, ease of use |

| Tourism and Adventure Firms | On-the-go inflation for guided cycling tours | Ensures safety and convenience for clients | Weight and portability, compatibility with various bike types |

| Cycling Events and Competitions | Instant inflation during races or events | Minimizes disruption, improves participant experience | Speed of inflation, ease of operation under pressure |

| Bicycle Repair Shops | Efficient tire inflation for customer repairs | Increases service speed, enhances customer loyalty | Durability, availability of replacement parts, cartridge supply |

| E-commerce and Retail | Retailing CO2 inflators and cartridges | Expands product range, meets customer demand | Product quality, pricing, shipping logistics |

In bike rental services, CO2 inflators are essential for quickly reinflating tires after customers return bikes. This application significantly reduces downtime, allowing for a faster turnaround between rentals. Businesses must ensure that the inflators are reliable and easy to use, as staff may need to operate them frequently. Additionally, sourcing compatible cartridges in bulk can keep operations efficient, especially in high-demand tourist areas.

Tourism and adventure firms utilize CO2 inflators to provide quick tire inflation during guided cycling tours. This ensures that participants can continue their adventure without lengthy delays due to flat tires. For these businesses, lightweight and portable inflators are crucial, as they need to be easily carried by guides. Buyers should focus on inflators that are compatible with various bike types to cater to a diverse clientele.

During cycling events and competitions, CO2 inflators are invaluable for providing instant inflation to minimize disruptions. Cyclists often face punctures, and the ability to quickly inflate tires can mean the difference between finishing a race or not. Event organizers must prioritize inflators that allow for rapid inflation and are user-friendly, as participants may need to use them under pressure. Ensuring a supply of cartridges is also critical to meet the demands of large events.

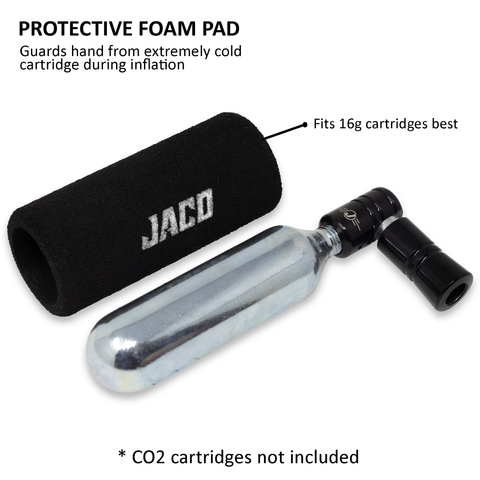

Illustrative image related to co2 inflator for bike tires

Bicycle repair shops benefit from CO2 inflators by enhancing service speed during tire repairs. These inflators allow technicians to quickly inflate tires, reducing wait times for customers and improving overall service efficiency. For repair shops, durability and the availability of replacement parts are key considerations when sourcing inflators. Additionally, having a reliable supply of cartridges ensures that the shop can meet customer needs without interruption.

E-commerce and retail businesses can expand their product offerings by selling CO2 inflators and cartridges. This not only meets the growing demand among cycling enthusiasts but also enhances the overall shopping experience. When sourcing these products, retailers should focus on quality and competitive pricing, as well as logistics for shipping to various regions. Understanding customer needs and preferences can help tailor inventory to maximize sales.

The Problem: B2B buyers often encounter challenges when sourcing CO2 inflators that are compatible with various tire valve types, such as Presta and Schrader. This is particularly critical for businesses that cater to a diverse customer base, including both road cyclists and mountain bikers. The incompatibility can lead to frustration during sales, as customers may find themselves unable to use the inflator on their bikes, which in turn reflects poorly on the retailer or service provider.

The Solution: To address this issue, buyers should prioritize sourcing CO2 inflators that feature dual compatibility, meaning they can accommodate both Presta and Schrader valves. When evaluating products, look for models that explicitly state this feature and come with adjustable fittings or included adapters. Additionally, educating staff on the differences between valve types can enhance customer service. Consider implementing a training program or creating informational materials that help staff guide customers in selecting the right inflator for their needs, thus reducing the risk of returns and enhancing customer satisfaction.

The Problem: Time efficiency is crucial in the cycling world, especially for professional riders or businesses that provide on-the-spot repairs. B2B buyers may find that some CO2 inflators do not provide rapid inflation, leading to longer wait times for customers who are eager to resume their rides. This inefficiency can lead to dissatisfaction and potential loss of customers who value quick service.

Illustrative image related to co2 inflator for bike tires

The Solution: To overcome this pain point, it is essential to select CO2 inflators that are designed for quick and effective tire inflation. Buyers should look for inflators that specify fast inflation capabilities, ideally completing the task in under a minute. Additionally, consider stocking a variety of inflator sizes and CO2 cartridge options, as larger cartridges can provide more air, reducing the number of inflations needed. Educating your sales team about the advantages of rapid-inflation models can further enhance customer experience, allowing them to recommend the best products for quick repairs.

The Problem: As sustainability becomes increasingly important in the cycling industry, B2B buyers face growing pressure to consider the environmental impact of the products they sell. CO2 cartridges, often single-use, can contribute to waste and may deter environmentally conscious customers from purchasing CO2 inflators. This concern can create a dilemma for businesses trying to balance customer demand with environmental responsibility.

The Solution: One effective approach is to source CO2 inflators that utilize recyclable cartridges or offer refillable options. Buyers should seek partnerships with manufacturers that provide eco-friendly solutions and communicate these benefits to their customers. Promoting refillable CO2 systems can also position your business as a leader in sustainability within the cycling market. Additionally, consider implementing a cartridge recycling program in your store, encouraging customers to return used cartridges for proper disposal. This initiative not only addresses environmental concerns but can also enhance your brand image and attract a customer base that values sustainability.

By focusing on these pain points and their solutions, B2B buyers can enhance their product offerings and customer satisfaction while staying ahead of industry trends.

When selecting materials for CO2 inflators for bike tires, it is crucial to consider properties that affect performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of these inflators, focusing on their key properties, advantages and disadvantages, and international considerations for B2B buyers.

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, making it a preferred choice for portable inflators. It can withstand high pressures and has good corrosion resistance, particularly when anodized.

Pros & Cons: The durability of aluminum allows it to endure the rigors of outdoor use, while its lightweight nature enhances portability. However, aluminum can be more expensive than some alternatives, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Aluminum is compatible with CO2 and is less likely to corrode when exposed to moisture, making it suitable for various environmental conditions.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer aluminum due to its compliance with European standards (EN) for safety and quality. In contrast, buyers in Africa and South America may focus on cost-effectiveness, which could influence their material choice.

Illustrative image related to co2 inflator for bike tires

Key Properties: Plastics used in CO2 inflators are typically lightweight and can be molded into intricate shapes. They offer decent pressure resistance but vary significantly based on the type of plastic used.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for mass production. However, plastics may not provide the same level of durability or pressure resistance as metals, making them less suitable for high-performance applications.

Impact on Application: While plastics can be effective for basic inflators, they may not withstand extreme temperatures or pressures, limiting their use in more demanding environments.

Considerations for International Buyers: Compliance with environmental regulations is crucial, particularly in Europe, where there are stringent guidelines regarding plastic use. Buyers in developing regions might prioritize affordability over compliance.

Key Properties: Steel is renowned for its strength and durability, capable of handling high pressures without deformation. It also has excellent corrosion resistance, especially when treated with protective coatings.

Pros & Cons: The robustness of steel makes it suitable for heavy-duty applications, providing long-lasting performance. However, steel inflators tend to be heavier and more expensive to manufacture, which could deter some buyers.

Illustrative image related to co2 inflator for bike tires

Impact on Application: Steel is ideal for inflators designed for rugged use, such as those intended for mountain biking or off-road applications, where durability is paramount.

Considerations for International Buyers: Buyers in Europe and Germany may favor steel due to its compliance with DIN standards for strength and safety. In contrast, buyers in regions with less stringent regulations may focus on cost and availability.

Key Properties: Composite materials combine the benefits of different materials, often featuring a blend of plastics and metals. They can be engineered for specific performance characteristics, such as enhanced strength and reduced weight.

Illustrative image related to co2 inflator for bike tires

Pros & Cons: The main advantage of composites is their ability to be tailored for specific applications, offering high performance in a lightweight package. However, they can be more expensive to produce and may require specialized manufacturing processes.

Impact on Application: Composites are suitable for high-end inflators where performance is critical, such as in competitive cycling.

Considerations for International Buyers: Buyers in advanced markets may seek out composite inflators for their innovative properties, while those in developing regions may find the cost prohibitive.

Illustrative image related to co2 inflator for bike tires

| Material | Typical Use Case for CO2 Inflator for Bike Tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable inflators for road and mountain bikes | Lightweight and durable | Higher manufacturing complexity | Medium |

| Plastic | Basic inflators for casual cyclists | Cost-effective and versatile | Limited durability and pressure resistance | Low |

| Steel | Heavy-duty inflators for rugged environments | Robust and reliable | Heavier and more expensive | High |

| Composite | High-performance inflators for competitive use | Tailored performance characteristics | Higher production costs | High |

This analysis provides B2B buyers with essential insights into material selection for CO2 inflators, helping them make informed decisions based on performance, cost, and regional compliance.

The manufacturing of CO2 inflators for bike tires involves several critical stages, ensuring that the final product meets the high performance and safety standards expected by both retailers and end-users. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: The process begins with the selection and preparation of raw materials. Common materials include high-grade aluminum or durable plastics for the body, and brass for the valve components. Suppliers often source these materials from reputable vendors to ensure quality. The materials are inspected for defects before being processed.

Forming: In this stage, the prepared materials undergo various forming techniques. Aluminum bodies are typically produced using extrusion or machining processes. For plastic components, injection molding is commonly employed. These methods allow for precise shapes and sizes, which are essential for the functionality of the inflator.

Assembly: Once the components are formed, they are assembled into the final product. This often includes the integration of valves, seals, and pressure regulators. Automation plays a significant role in assembly, but skilled labor is also essential for quality assurance and to address any complex assembly requirements.

Finishing: After assembly, the inflators undergo finishing processes, which can include anodizing, painting, or applying protective coatings. These not only enhance the aesthetic appeal but also improve corrosion resistance and durability. Final inspections are conducted to ensure all components fit together correctly and function as intended.

Ensuring the quality of CO2 inflators is paramount, especially considering their role in safety and convenience for cyclists. Various quality assurance measures are employed throughout the manufacturing process.

ISO 9001: This is a widely recognized standard for quality management systems. Manufacturers often obtain ISO 9001 certification to demonstrate their commitment to consistent quality and customer satisfaction. B2B buyers should look for suppliers with this certification as it indicates a structured approach to quality management.

CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly important for B2B buyers in Europe who must comply with these regulations.

API Standards: While more commonly associated with the petroleum and natural gas industries, API standards can also apply to certain mechanical components of inflators. B2B buyers should verify if suppliers adhere to relevant API standards, especially if the inflators are used in specialized applications.

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Here are the main checkpoints typically employed:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components as they arrive at the manufacturing facility. Ensuring that materials meet specified standards before production begins is crucial to preventing defects.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC is conducted to monitor production quality. This includes checks at various stages, such as after forming and assembly, to identify any issues that may arise during production.

Final Quality Control (FQC): After the inflators are fully assembled and finished, a final inspection takes place. This includes testing for functionality, leak testing, and ensuring the inflators meet pressure specifications. FQC is critical for verifying that each product adheres to the required standards before packaging and shipping.

B2B buyers should be aware of common testing methods that suppliers employ to ensure the reliability and safety of CO2 inflators:

Functional Testing: This involves testing the inflator’s ability to inflate tires to the specified pressure quickly and efficiently. It ensures that the product performs as expected under realistic conditions.

Leak Testing: This critical test checks for any leaks in the valve and body of the inflator. Suppliers may use pressure decay or bubble tests to ensure that no air escapes during inflation.

Durability Testing: Manufacturers often conduct durability tests to simulate the wear and tear an inflator might experience during use. This can include repeated inflation cycles and exposure to various environmental conditions.

When sourcing CO2 inflators, B2B buyers should take proactive steps to ensure that their suppliers maintain high-quality standards:

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can be done through on-site visits or by reviewing their quality management systems.

Reviewing Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC. Buyers should request these reports to assess the supplier’s commitment to quality.

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These services can evaluate the quality of products before shipment, ensuring that they meet the buyer’s specifications and international standards.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, must consider specific nuances in quality control:

Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should ensure that suppliers comply with local standards, especially when importing products.

Cultural Considerations: Understanding cultural attitudes towards quality and reliability in different regions can influence supplier selection. Buyers should engage with suppliers who demonstrate a strong commitment to quality and customer service.

Logistics and Supply Chain Management: Quality assurance doesn’t end with manufacturing. Buyers should also consider the logistics of transporting CO2 inflators, as improper handling can affect product integrity. Establishing clear communication with suppliers about shipping and handling procedures is vital.

By being informed about the manufacturing processes and quality assurance measures for CO2 inflators, B2B buyers can make better purchasing decisions, ensuring they source high-quality products that meet their business needs.

In this guide, we aim to provide B2B buyers with a practical checklist for sourcing CO2 inflators for bike tires. This essential tool is critical for cyclists to quickly address flat tires and ensure a seamless riding experience. By following these steps, buyers can make informed decisions that meet their operational needs while enhancing customer satisfaction.

Establish clear technical requirements for the CO2 inflators you intend to source. Consider factors such as compatibility with Presta and Schrader valves, inflation speed, and the size of CO2 cartridges. Having defined specifications helps streamline the selection process and ensures that the products you source align with the needs of your target market.

Understanding market trends is crucial for making informed purchasing decisions. Analyze the demand for CO2 inflators in various regions, focusing on emerging markets in Africa, South America, the Middle East, and Europe. Pay attention to consumer preferences, such as the popularity of compact designs or dual-function inflators, to align your offerings with market expectations.

Illustrative image related to co2 inflator for bike tires

Before committing to a supplier, conduct thorough due diligence. Request company profiles, product catalogs, and customer testimonials to assess their credibility and reliability. Consider their production capacity and quality assurance processes, as these factors directly impact the consistency and quality of the inflators you will be sourcing.

Once you have shortlisted potential suppliers, request samples of the CO2 inflators for testing. This step allows you to evaluate the products’ performance, ease of use, and overall quality. Pay attention to aspects such as inflation speed, durability, and user-friendliness to ensure the inflators meet your standards.

Collect detailed pricing information from your shortlisted suppliers, including bulk purchase discounts and payment terms. Compare these against your budget and financial forecasts to identify the most cost-effective options. Don’t forget to consider shipping costs and lead times, which can affect your overall expenses and inventory management.

Evaluate the after-sales support offered by potential suppliers, including warranty policies and customer service availability. Reliable support can significantly enhance your operational efficiency, especially if issues arise with the products post-purchase. Opt for suppliers who provide comprehensive warranties and responsive customer service to ensure your investment is protected.

After completing your evaluations, finalize contracts with your chosen supplier(s). Ensure that all terms and conditions are clearly outlined, including delivery schedules, payment arrangements, and quality assurance measures. Once contracts are in place, proceed to place your orders, keeping track of inventory levels and future demand to maintain a steady supply chain.

By following this checklist, B2B buyers can effectively navigate the sourcing process for CO2 inflators, ensuring they secure high-quality products that meet their business needs and customer expectations.

Understanding the cost structure of CO2 inflators for bike tires is crucial for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly impacts costs. Common materials for inflators include aluminum and high-grade plastics, which offer durability and lightweight properties. The cost of CO2 cartridges, typically made from steel, also contributes to the overall material expenses.

Labor: Labor costs vary by region. In countries with lower labor costs, such as those in parts of Africa or South America, manufacturing expenses may be reduced, affecting the final pricing of inflators.

Manufacturing Overhead: This encompasses utilities, factory space, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, benefiting the final pricing structure.

Tooling: Initial setup costs for molds and tools used in production can be significant, especially for custom designs. This is a crucial factor for buyers considering customized inflators.

Quality Control (QC): Implementing robust QC processes ensures product reliability and can lead to higher costs. Certifications such as ISO can further add to QC expenses but are essential for maintaining quality standards.

Logistics: Shipping costs, influenced by the distance between the manufacturer and the buyer, can vary widely. Additionally, the choice of shipping methods (air vs. sea) can greatly affect logistics costs.

Margin: Suppliers typically add a profit margin on top of production costs, which can vary based on market demand, competition, and the perceived value of the product.

Several factors influence pricing in the B2B market for CO2 inflators:

Volume and Minimum Order Quantity (MOQ): Bulk purchases can lead to discounts. Understanding MOQs can help buyers negotiate better deals and optimize their purchasing strategy.

Specifications and Customization: Custom designs or specific features (like dual heads for different valve types) often lead to higher costs. Buyers should clearly define their requirements to ensure accurate pricing.

Materials and Quality Certifications: Premium materials and certifications like CE or ISO can elevate costs but may be necessary for certain markets, especially in Europe.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers may charge more but offer better quality assurance and support.

Incoterms: Understanding Incoterms is crucial for pricing clarity. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total cost by determining who bears the shipping and insurance costs.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

Illustrative image related to co2 inflator for bike tires

Research Market Prices: Understanding the average market price for CO2 inflators can provide leverage during negotiations. This knowledge helps in identifying fair pricing and spotting inflated costs.

Leverage Relationships: Building strong relationships with suppliers can lead to more favorable terms. Long-term partnerships often result in better pricing and priority service.

Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, maintenance, and logistics. A higher upfront cost might be justified by lower long-term operational costs.

Pricing Nuances for International Transactions: Currency fluctuations and import tariffs can significantly impact pricing for international buyers. Understanding these factors can aid in budgeting and negotiations.

Prices for CO2 inflators can vary widely based on the factors mentioned above. The prices referenced in various sources (e.g., $19.00 to $54.99 for different inflators) are indicative and can fluctuate based on market conditions, supplier negotiations, and order quantities. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing.

When it comes to inflating bike tires, CO2 inflators are widely recognized for their speed and convenience. However, there are alternative solutions available that may better suit specific needs, particularly for B2B buyers looking to provide comprehensive support for cyclists. This analysis compares CO2 inflators with traditional hand pumps and electric pumps, helping businesses make informed decisions about which inflation method to offer.

| Comparison Aspect | CO2 Inflator For Bike Tires | Hand Pump | Electric Pump |

|---|---|---|---|

| Performance | Instant inflation; can fill tires in seconds | Slower; requires manual effort | Fast; can inflate multiple tires without cartridge replacement |

| Cost | Moderate; cartridges add ongoing cost | Low; one-time purchase, minimal ongoing costs | Higher initial investment; low ongoing costs |

| Ease of Implementation | Simple to use; requires cartridges | Requires effort; learning curve for effective use | Plug-and-play; user-friendly, but requires charging |

| Maintenance | Minimal; replace cartridges as needed | Low; occasional cleaning required | Moderate; needs battery maintenance and cleaning |

| Best Use Case | Emergency situations; racing | Regular use; touring cyclists | Long rides; workshops and bike shops |

Hand pumps remain a staple in the biking community due to their reliability and low cost. They are typically lightweight and portable, making them ideal for cyclists who prefer a no-fuss approach. However, they require physical effort and can be time-consuming compared to CO2 inflators. For B2B buyers catering to casual cyclists or those on long tours, hand pumps offer a dependable solution with minimal ongoing costs. The trade-off is the need for physical exertion, which may not be ideal in emergency situations.

Illustrative image related to co2 inflator for bike tires

Electric pumps represent a growing trend in tire inflation technology, offering speed and ease of use. They can inflate tires quickly and do not rely on cartridges, making them a sustainable choice for businesses focusing on long-term solutions. However, electric pumps come with a higher initial investment and require regular charging, which may be a drawback for some users. For B2B buyers looking to equip workshops or bike rental services, electric pumps provide a powerful and efficient alternative, especially for high-volume usage.

For B2B buyers, the choice between CO2 inflators, hand pumps, and electric pumps should be guided by the specific needs of their customers. CO2 inflators are ideal for quick fixes in emergencies, while hand pumps offer reliability at a lower cost for regular use. Electric pumps, though more expensive, can provide speed and convenience for high-demand environments. Understanding the unique selling propositions of each solution will enable businesses to effectively address the diverse requirements of cyclists across different markets, ensuring customer satisfaction and loyalty.

Understanding the technical properties of CO2 inflators is crucial for B2B buyers in the cycling industry. These specifications not only influence performance but also impact the overall user experience. Here are some critical specifications to consider:

Material Grade

CO2 inflators are typically made from aluminum, stainless steel, or high-grade plastics. Aluminum and stainless steel are preferred for their strength and durability, ensuring that the inflator withstands the rigors of outdoor use. The material grade affects the product’s weight, resistance to corrosion, and longevity, which are essential factors for retailers and manufacturers when evaluating product quality.

Pressure Rating

The pressure rating of a CO2 inflator indicates the maximum pressure it can safely deliver, usually measured in PSI (pounds per square inch). Higher pressure ratings are essential for high-performance bicycles, ensuring that tires can be inflated quickly and efficiently. B2B buyers should prioritize inflators that meet the pressure requirements of their target market, particularly in regions with diverse cycling conditions.

Flow Control Mechanism

Many CO2 inflators feature a flow control mechanism that allows users to regulate the gas release. This is crucial for achieving the desired tire pressure without over-inflating, which can lead to tire damage. For B2B buyers, understanding the flow control design can help in selecting products that enhance user satisfaction and safety.

Compatibility with Valve Types

CO2 inflators must be compatible with both Presta and Schrader valves, the two most common valve types used in bicycles. An inflator that accommodates both types can cater to a broader customer base, making it a more versatile product for retailers. Buyers should ensure that the inflators they procure offer this compatibility to meet diverse consumer needs.

Weight and Portability

The weight of the inflator is a critical factor for cyclists who prioritize portability. Lightweight designs are easier to carry during rides, making them more appealing to end-users. B2B buyers should consider how weight influences purchasing decisions, especially for products targeting competitive cyclists or long-distance riders.

CO2 Cartridge Size Compatibility

CO2 inflators come with varying cartridge sizes, typically ranging from 16g to 38g. The size impacts the volume of air delivered, affecting inflation speed and tire pressure. Understanding cartridge size compatibility helps B2B buyers identify which inflators will best suit their target market’s preferences and requirements.

Navigating the cycling industry involves familiarizing oneself with essential trade terminology. Here are several key terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. For CO2 inflators, knowing the OEM can help buyers assess the quality and reliability of the product, as established manufacturers often adhere to strict quality standards.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and cash flow effectively. It allows businesses to align their purchasing strategies with market demand.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. B2B buyers use RFQs to compare pricing, terms, and conditions from multiple suppliers, ensuring they receive the best deal for CO2 inflators.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers dealing with international suppliers to avoid misunderstandings regarding costs and responsibilities.

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This term is critical for B2B buyers to plan their inventory and sales strategies effectively, ensuring that they can meet customer demands without delays.

Warranty Terms

Warranty terms specify the conditions under which a product is guaranteed against defects. For B2B buyers, understanding warranty policies is essential for evaluating product reliability and ensuring customer satisfaction, particularly for high-use items like CO2 inflators.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing CO2 inflators for bike tires, ultimately enhancing their product offerings and customer satisfaction.

The CO2 inflator market for bike tires is witnessing robust growth, primarily driven by the rising popularity of cycling as a recreational activity and a sustainable mode of transportation. International B2B buyers are increasingly recognizing the value of quick and efficient tire inflation solutions, particularly in regions where cycling is becoming more integrated into urban mobility. In Africa and South America, where cycling is often utilized for both transportation and leisure, the demand for reliable inflators is rising. Meanwhile, European markets, particularly Germany and the Netherlands, are seeing a push for innovative inflators that combine functionality with compact design, reflecting a trend towards lightweight and portable cycling gear.

Emerging technologies are also shaping the market landscape. The integration of CO2 inflators into multi-tools and mini-pumps is gaining traction, offering cyclists a more versatile solution. Additionally, there is a noticeable shift towards electric pumps, although CO2 inflators remain popular for their speed and convenience. B2B buyers must consider these trends when sourcing products, as they can enhance customer satisfaction and drive sales.

Illustrative image related to co2 inflator for bike tires

Sustainability is increasingly becoming a focal point in the sourcing of CO2 inflators for bike tires. As environmental awareness grows, businesses are under pressure to adopt ethical sourcing practices and minimize their ecological footprint. B2B buyers should prioritize suppliers that demonstrate a commitment to sustainability through the use of recyclable materials in their products and packaging. For instance, some manufacturers are now utilizing recycled aluminum for inflator bodies and eco-friendly materials for cartridges, which can significantly reduce the environmental impact associated with production.

Moreover, certifications such as ISO 14001 for environmental management systems can guide buyers in choosing suppliers that adhere to sustainable practices. By opting for ethically sourced products, businesses not only improve their market appeal but also align with the values of environmentally conscious consumers. This shift towards sustainability is not just a trend but a critical component of long-term business strategy in the cycling accessories market.

The evolution of CO2 inflators dates back to the late 20th century when they were introduced as a lightweight alternative to traditional hand pumps. Initially, these devices were relatively simple, designed to provide quick inflation without the need for manual effort. Over the years, advancements in materials and design have significantly enhanced their functionality and user experience. The introduction of flow control mechanisms has allowed cyclists to achieve precise tire pressure, catering to a broader range of cycling disciplines, from road biking to mountain biking.

Illustrative image related to co2 inflator for bike tires

In recent years, the market has seen a surge in innovative designs, such as integrated inflators within multi-tools and compact pumps. This evolution reflects the changing needs of cyclists who prioritize convenience and portability. As the cycling community continues to grow globally, the demand for efficient and reliable CO2 inflators is expected to persist, driving further innovation and market expansion.

Navigating the dynamics of the CO2 inflator market requires a keen understanding of emerging trends and sustainability practices. International B2B buyers must adapt their sourcing strategies to align with these market shifts, ensuring they provide their customers with high-quality, environmentally friendly products that meet the demands of modern cyclists. By staying informed and responsive to these trends, businesses can enhance their competitive edge in the growing cycling accessories market.

How do I choose the right CO2 inflator for my business needs?

Selecting the right CO2 inflator involves assessing your target market’s requirements. Consider factors such as the inflator’s compatibility with different valve types (Presta and Schrader), inflation speed, and ease of use. Evaluate the durability and size, especially for customers who prioritize portability. Additionally, review customer feedback on performance and reliability, which can guide you in choosing a model that meets your clients’ expectations. Ensure that the inflator’s design aligns with the branding and quality standards of your business.

What are the key features to look for in a CO2 inflator for bikes?

When sourcing CO2 inflators, focus on features like flow control for precise inflation, compatibility with various valve types, and a compact design for easy transport. Durability is crucial, especially if your customers are outdoor enthusiasts who require reliable equipment. Look for inflators that come with a warranty or guarantee, as this can enhance customer trust. Additional features such as integrated storage for CO2 cartridges or multi-tool capabilities may also provide added value to your offering.

What are the typical minimum order quantities (MOQs) for CO2 inflators?

Minimum order quantities for CO2 inflators can vary significantly between suppliers. Many manufacturers set MOQs ranging from 100 to 500 units, depending on the product’s complexity and customization options. It’s essential to discuss your specific needs with potential suppliers, as some may offer flexibility on MOQs for first-time buyers or bulk orders. Establishing a good relationship with suppliers can also lead to more favorable terms in future transactions.

What payment terms should I expect when sourcing CO2 inflators internationally?

Payment terms for international orders can vary widely among suppliers. Common practices include a 30% deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer payment via letters of credit or escrow services for larger orders, providing added security. Always clarify payment terms in advance and consider negotiating terms that suit your cash flow needs. Be aware of any currency fluctuations that may affect the final cost.

How can I ensure the quality of CO2 inflators before making a bulk purchase?

To ensure product quality, request samples from potential suppliers before placing a bulk order. Conduct thorough inspections and performance testing to verify that the inflators meet your specifications. Additionally, inquire about the supplier’s quality assurance processes and certifications, such as ISO standards. If possible, arrange for a factory visit or third-party inspection to assess manufacturing practices. Building a long-term partnership with suppliers who prioritize quality can lead to consistent product performance.

What logistics considerations should I take into account when importing CO2 inflators?

Logistics considerations include shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder experienced in handling bicycle accessories to navigate customs regulations effectively. Understand the shipping costs associated with different carriers and consider options for expedited shipping if necessary. Ensure that you have the correct import documentation to avoid delays at customs. Additionally, factor in local storage and distribution capabilities to streamline your supply chain.

Are there customization options available for CO2 inflators?

Many manufacturers offer customization options for CO2 inflators, including branding, color choices, and packaging designs. Customization can enhance your product’s appeal in your target market and differentiate it from competitors. Discuss your specific requirements with suppliers and request quotes for different customization levels. Keep in mind that custom orders may have longer lead times and higher MOQs, so plan accordingly to align with your marketing strategy.

What are the environmental considerations when sourcing CO2 inflators?

As sustainability becomes increasingly important, consider the environmental impact of CO2 inflators. Assess the materials used in production and seek suppliers who prioritize eco-friendly practices. Inquire about the recyclability of cartridges and packaging, as well as any initiatives the manufacturer may have in place to reduce waste. Communicating your commitment to sustainability can resonate with environmentally conscious consumers, enhancing your brand’s reputation in the market.

Domain: ridepdw.com

Registered: 2008 (17 years)

Introduction: Timber to Town: Cloud Cap CO2 Inflator – $39.00; Shiny Object – from $19.00; Tiny Object – $22.00; Fatty Object – from $19.00; Timber to Town: Cloud Cap Gravel Pump + CO2 Inflator – $89.00; Ninja Pump – $35.00; 38g CO2 Cartridge – $15.00; 16g CO2 Cartridge – Packs from $10.00; Leather CO2 Cartridge Sleeve – $5.00; Pump Mount – $5.00; Shiny Object Rebuild Kit – $4.00; Tiny Object Rebuild Kit – $4.0…

Domain: ride.lezyne.com

Registered: 2007 (18 years)

Introduction: Lezyne CO2 inflators provide instant, reliable tire inflation in seconds, ideal for road bikes and mountain bikes. Key products include: PRESSURE DRIVE CFH ($54.99), CLIK™ DRIVE CO2 WITH 20G CARTRIDGE ($37.99), CADDY KIT ($32.99), CONTROL DRIVE CO2 (from $29.99), TWIN KIT (from $29.99), 25G CO2 – 5 PACK ($27.99), REPAIR KIT ($24.99), 20G CO2 – 5 PACK ($19.99), TRIGGER SPEED DRIVE CO2 (from $19.99)…

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Portland Design Works Shiny Object CO2 Inflator – Easy and simple to use, easy to take apart, no need for servicing but parts/o-rings are available from the manufacturer website.

2. Pro Bike Tool Inflator – Works well, used sparingly over the years.

3. Dynaplug – Two in one plug-it and air-it CO2 device.

4. Specialized Inflator – Threads onto the valve to prevent air loss, one model includes a …

Domain: northtownebikes.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘Serfas 12-Gram CO2 Non-Threaded Cartridges’, ‘price’: ‘$12.99’, ‘details’: ‘Compact, non-threaded 12-gram cartridges compatible with CO2 inflators, easily packable into seat bags.’}, {‘name’: ‘Planet Bike 25g CO2 Replacement Cartridges – Threaded’, ‘price’: ‘$8.99 – $99.99’, ‘details’: ‘Quick and easy tire repairs, compatible with most inflators, made of pure CO2, 100% recyclable steel….

Domain: genuineinnovations.com

Registered: 2004 (21 years)

Introduction: CO2 inflation units consist of two primary parts: inflator head (nozzle) and CO2 cartridge. CO2 cartridges are small cans filled with pressurized carbon dioxide gas, easy to store. There are threaded (screwed into inflator head) and non-threaded cartridges (pressed into inflator head). Some inflator heads allow flow control, with options like twist-to-inflate, push-to-inflate, or trigger controlle…

In conclusion, strategic sourcing of CO2 inflators for bike tires is essential for B2B buyers aiming to enhance their product offerings and meet the evolving demands of cyclists. Key considerations include selecting reliable and efficient inflators that provide quick inflation, compatibility with various valve types, and robust construction to withstand the rigors of outdoor use. By partnering with reputable manufacturers, buyers can ensure high-quality products that align with consumer preferences for convenience and performance.

As the market continues to evolve, especially in emerging regions such as Africa and South America, understanding local cycling trends and preferences will be crucial. Suppliers who can offer innovative solutions, such as eco-friendly alternatives or integrated inflator systems, will likely gain a competitive edge.

Illustrative image related to co2 inflator for bike tires

International B2B buyers are encouraged to actively engage with manufacturers and distributors to explore tailored solutions that cater to their specific markets. The future of cycling accessories, including CO2 inflators, promises growth and innovation. Make strategic sourcing a priority to capitalize on this opportunity and elevate your business in the global cycling landscape.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.