In the ever-evolving automotive industry, sourcing reliable compressed air solutions for car applications can pose significant challenges for international B2B buyers. The need for high-performance air compressors is critical, whether for enhancing vehicle maintenance, powering pneumatic tools, or ensuring optimal tire pressure in diverse environments. This comprehensive guide delves into the various types of compressed air systems available, their specific applications, and essential considerations for supplier vetting and cost analysis.

Our objective is to empower B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe—regions characterized by distinct market dynamics and consumer preferences. By navigating through the complexities of compressed air for automotive use, you will gain insights into evaluating product quality, understanding supplier capabilities, and making informed purchasing decisions that align with your operational needs.

From portable compressors for off-road adventures to stationary systems for automotive manufacturing, this guide provides the knowledge necessary to enhance your procurement strategy. Prepare to streamline your sourcing process, optimize your operational efficiency, and invest in durable, high-performance air solutions that can withstand the rigors of automotive applications across various global markets.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Air Compressors | Compact, battery-operated, easily transportable | Tire inflation, air tools, camping gear | Pros: Versatile, easy to use; Cons: Limited power/output compared to larger models. |

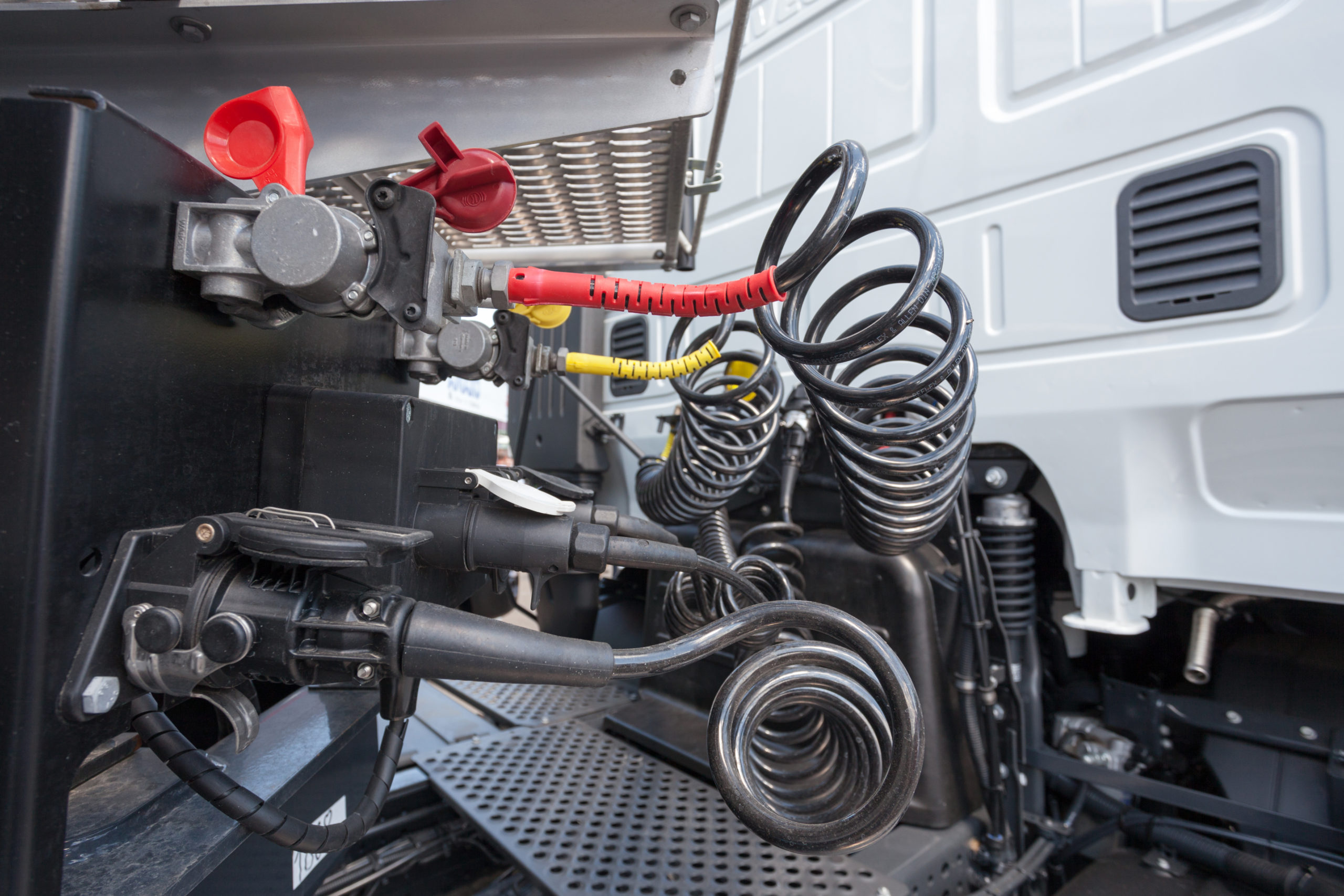

| Onboard Air Compressors | Installed within the vehicle, often 12V or 24V | Off-road vehicles, emergency inflation | Pros: Always available, powerful; Cons: Installation complexity, space requirements. |

| Industrial Air Compressors | High-capacity, robust, often stationary | Automotive manufacturing, repair shops | Pros: High efficiency, long-lasting; Cons: Higher initial investment, requires maintenance. |

| Brushless Air Compressors | Advanced motor technology, quieter operation | Precision tasks, professional detailing | Pros: Energy-efficient, low maintenance; Cons: Higher cost upfront. |

| Pneumatic Tools | Air-powered tools for various automotive tasks | Mechanic shops, assembly lines | Pros: High torque, versatile; Cons: Requires a compressor, can be noisy. |

Portable air compressors are lightweight and battery-operated, making them ideal for businesses that require mobility. These compressors are perfect for tire inflation, powering air tools, and inflating camping gear. When purchasing, consider factors such as pressure output, tank size, and battery life to ensure it meets the operational needs of your business. While they are versatile and user-friendly, their limited power output may not be suitable for heavy-duty applications.

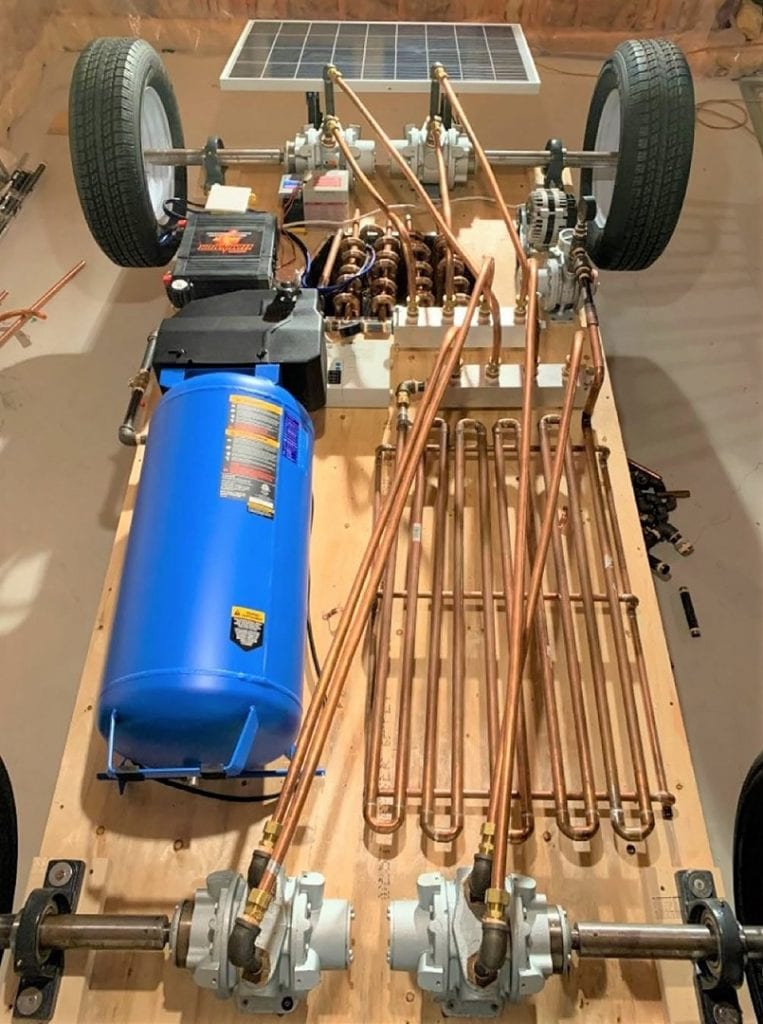

Onboard air compressors are integrated directly into vehicles, often running on 12V or 24V systems. They are particularly useful for off-road vehicles that need to adjust tire pressure according to terrain. For B2B buyers, the convenience of having a compressor readily available is a significant advantage. However, installation can be complex, and businesses must ensure they have adequate space within the vehicle to accommodate these systems.

Industrial air compressors are designed for high-capacity operations, making them essential for automotive manufacturing and repair shops. These robust units offer high efficiency and longevity, which are crucial for businesses that rely on continuous air supply. While they represent a higher initial investment, their durability and performance can lead to cost savings over time. Maintenance is a key consideration; businesses must be prepared for regular servicing to keep these compressors operational.

Illustrative image related to compressed air for car

Brushless air compressors utilize advanced motor technology that enhances energy efficiency and reduces noise levels. They are particularly suited for precision tasks such as professional detailing and automotive assembly. When considering a brushless compressor, B2B buyers should evaluate the cost against long-term savings in energy and maintenance. Although they may have a higher upfront cost, their operational benefits can justify the investment.

Pneumatic tools are air-powered devices that are widely used in mechanic shops and assembly lines for various automotive tasks. Their high torque and versatility make them an excellent addition to any compressed air system. B2B buyers should consider the compatibility of these tools with their existing compressors and evaluate the total cost of ownership, including the need for a compressor and potential noise levels. While they are powerful, the requirement for an air source may limit their usability in certain environments.

| Industry/Sector | Specific Application of Compressed Air for Car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Pneumatic Tools for Assembly and Maintenance | Increased efficiency and reduced manual labor costs | Reliability, compatibility with existing systems, and maintenance support |

| Automotive Repair Services | Tire Inflation and Pressure Monitoring | Enhanced service speed and improved customer satisfaction | Portability, ease of use, and accuracy of pressure gauges |

| Off-Road and Adventure Gear | Onboard Air Systems for Tire Adjustments and Tool Operation | Improved performance in varied terrains and conditions | Durability, power output, and ease of installation |

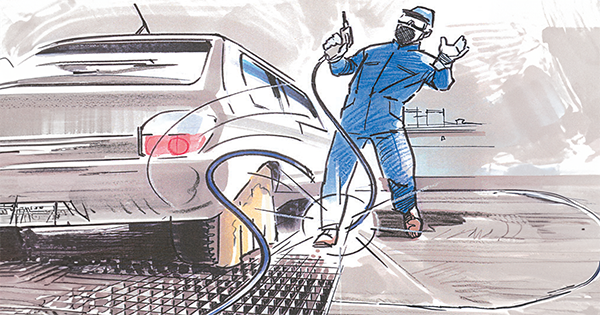

| Automotive Detailing | Compressed Air for Cleaning and Detailing Vehicles | Higher quality finishes and faster turnaround times | Air quality, filtration systems, and tool compatibility |

| Automotive Parts Suppliers | Packaging and Handling of Components | Enhanced safety and efficiency in handling fragile components | System integration, air quality control, and energy efficiency |

In the automotive manufacturing sector, compressed air is crucial for powering pneumatic tools used in assembly lines and maintenance operations. These tools enhance efficiency by automating tasks that would otherwise require manual labor, significantly reducing production time and labor costs. International buyers should prioritize reliability and compatibility with existing systems when sourcing pneumatic tools, ensuring they can maintain optimal performance throughout their operational lifespan.

Illustrative image related to compressed air for car

In automotive repair services, compressed air is commonly used for tire inflation and monitoring tire pressure. Quick and accurate inflation capabilities improve service speed, leading to enhanced customer satisfaction. Buyers in this sector should focus on the portability and ease of use of air compressors, along with the accuracy of pressure gauges, to ensure they can provide efficient and high-quality service to clients.

Off-road and adventure gear industries leverage compressed air systems for onboard tire adjustments and powering tools. These systems enable users to adjust tire pressures according to varying terrains, enhancing vehicle performance and safety. When sourcing these systems, buyers should consider durability and power output to ensure they can withstand extreme conditions and provide reliable performance during adventures.

In the automotive detailing industry, compressed air is essential for cleaning and detailing vehicles. It allows for the efficient removal of dust and debris from hard-to-reach areas, contributing to a higher quality finish. Buyers should seek compressors with effective filtration systems to maintain air quality and ensure compatibility with various detailing tools to maximize their service offerings.

Compressed air is utilized in the packaging and handling of automotive components to enhance safety and efficiency. By using compressed air systems, businesses can handle fragile components more safely and streamline their operations. Key considerations for buyers include system integration with existing workflows and air quality control to prevent contamination during the handling process.

The Problem: Many automotive businesses face the challenge of maintaining consistent air pressure when inflating tires. This is particularly critical for operations that require precise tire pressure for safety and performance, such as in tire service centers or automotive repair shops. Inconsistent air pressure can lead to customer dissatisfaction, increased tire wear, and potential safety hazards. Additionally, manual inflation methods can be time-consuming and prone to human error, complicating workflow efficiency.

Illustrative image related to compressed air for car

The Solution: To address this issue, B2B buyers should invest in high-quality, automated air compressors equipped with digital pressure gauges. These systems allow for precise inflation settings and can automatically shut off when the desired pressure is reached. When sourcing these compressors, look for models with a robust flow rate and quick recovery time to ensure they can handle the volume of vehicles serviced. Implementing regular maintenance schedules for the compressors, including checking for leaks and calibrating gauges, is essential to maintain accuracy and reliability over time.

The Problem: Automotive service providers often struggle with the lack of portability in their compressed air systems, limiting their ability to perform on-site repairs or services. For businesses that operate in multiple locations or provide mobile services, having a reliable, portable air compressor is crucial. Without it, they may face delays, increased operational costs, and reduced customer satisfaction, particularly in regions with challenging access or infrastructure.

The Solution: Investing in portable, battery-operated air compressors can significantly enhance operational flexibility. Look for models that are lightweight, compact, and equipped with rechargeable batteries to ensure they can be easily transported. Additionally, consider systems with multiple power options, such as 12V DC or 110V AC, to maximize usability in various environments. Training staff on how to efficiently set up and operate these portable systems will also ensure that they can quickly respond to customer needs, enhancing service delivery.

The Problem: Many businesses experience high operational costs due to inefficient use of compressed air. This inefficiency can stem from leaks, incorrect sizing of compressors, or outdated equipment that consumes more energy than necessary. Such issues not only inflate energy bills but also reduce the overall effectiveness of the compressed air systems, leading to downtime and reduced productivity.

The Solution: Conducting a thorough audit of the compressed air system is the first step in identifying inefficiencies. B2B buyers should work with experts to assess the entire compressed air network, including piping, fittings, and the compressors themselves. This audit will highlight areas for improvement, such as repairing leaks, resizing systems to match actual demand, and upgrading to energy-efficient models. Implementing a proactive maintenance program that includes regular inspections and repairs will ensure the longevity and efficiency of the air systems, ultimately reducing costs and improving performance.

Illustrative image related to compressed air for car

When selecting materials for compressed air systems in automotive applications, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Below are analyses of several common materials used in compressed air systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Key Properties: Aluminum is lightweight and exhibits excellent corrosion resistance, making it suitable for various automotive environments. Its temperature rating typically ranges from -40°C to 120°C, with pressure ratings often exceeding 300 psi.

Pros & Cons: The primary advantage of aluminum is its low weight, which reduces the overall vehicle weight and improves fuel efficiency. Additionally, aluminum is relatively easy to manufacture, allowing for complex shapes and designs. However, it can be more expensive than steel and may not perform as well under extreme pressure conditions.

Impact on Application: Aluminum is compatible with a wide range of media, including air and some gases, making it versatile for different automotive applications. However, care must be taken to avoid galvanic corrosion when used with dissimilar metals.

Illustrative image related to compressed air for car

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and cost fluctuations of aluminum. Compliance with international standards such as ASTM and DIN is essential for ensuring material quality.

Key Properties: Steel is known for its high strength and durability, with temperature ratings that can exceed 200°C and pressure ratings that can reach up to 600 psi.

Pros & Cons: The main advantage of steel is its robustness, making it ideal for high-pressure applications. It is also cost-effective compared to aluminum. However, steel is heavier and more susceptible to corrosion, requiring protective coatings or treatments to enhance longevity.

Impact on Application: Steel is suitable for applications involving high pressures and temperatures but may not be ideal for corrosive environments unless adequately protected.

Illustrative image related to compressed air for car

Considerations for International Buyers: Buyers in Europe, particularly Germany, often prefer steel due to its strength and availability. Compliance with local manufacturing standards is crucial to ensure safety and reliability.

Key Properties: Plastics, such as polyamide and polyethylene, offer excellent chemical resistance and can operate within a temperature range of -20°C to 80°C, with pressure ratings typically around 150 psi.

Pros & Cons: The lightweight nature of plastic reduces the overall weight of the system, and its resistance to corrosion makes it suitable for various applications. However, plastics may not withstand high pressures as effectively as metals, limiting their use in high-performance applications.

Impact on Application: Plastic components are often used in low-pressure applications or where chemical resistance is necessary. They are not suitable for high-temperature environments.

Considerations for International Buyers: Buyers from the Middle East should be aware of the potential for UV degradation in outdoor applications. Compliance with international standards such as JIS is essential for ensuring quality.

Key Properties: Composite materials, often made from a combination of fibers and resins, provide high strength-to-weight ratios. They can operate effectively at temperatures up to 120°C and pressures exceeding 300 psi.

Pros & Cons: Composites are lightweight and resistant to corrosion, making them ideal for automotive applications. However, they can be more expensive to manufacture and may require specialized handling during installation.

Impact on Application: Composite materials are particularly useful in applications where weight savings are critical, such as in performance vehicles. Their compatibility with various media makes them versatile.

Considerations for International Buyers: Buyers in Europe may find composites appealing due to their performance characteristics. Understanding local regulations regarding composite materials is essential for compliance.

Illustrative image related to compressed air for car

| Material | Typical Use Case for compressed air for car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Air tanks, piping | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Steel | High-pressure air tanks, structural parts | High strength and durability | Heavier and corrosion-prone | Low |

| Plastic | Low-pressure applications, fittings | Lightweight and chemically resistant | Limited high-pressure capability | Low |

| Composite | Performance vehicles, specialized applications | High strength-to-weight ratio | Higher manufacturing costs | High |

This guide provides a comprehensive overview of the materials commonly used in compressed air systems for automotive applications, offering actionable insights for international B2B buyers. Understanding these materials’ properties and implications can significantly influence purchasing decisions and application suitability.

The manufacturing of compressed air systems for automotive applications involves several critical stages that ensure the final product meets performance and quality standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the selection of high-grade materials, typically aluminum or steel, chosen for their strength and lightweight properties. These materials undergo rigorous quality checks to ensure they meet specified standards before moving to the next phase. Suppliers may provide material certifications to confirm compliance with international standards.

Forming: This stage includes processes such as machining, welding, and casting, which shape the components of the compressed air systems. Advanced CNC (Computer Numerical Control) machines are often utilized to achieve precise dimensions. Techniques like hydroforming may also be employed for complex shapes, ensuring optimal performance under high pressure.

Assembly: In this phase, the various components are brought together. This may involve the installation of motors, valves, and control systems. Automated assembly lines can enhance efficiency and consistency, while skilled technicians perform quality checks at each step to ensure that components fit together correctly and function as intended.

Finishing: The final stage involves surface treatments, such as powder coating or anodizing, to enhance durability and corrosion resistance. This not only improves aesthetics but also ensures longevity, which is crucial for automotive applications that face harsh conditions.

Quality control (QC) is essential throughout the manufacturing process to ensure that the compressed air systems meet both international and industry-specific standards.

Illustrative image related to compressed air for car

International Standards: Many manufacturers adhere to ISO 9001, which outlines the criteria for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Additionally, CE marking indicates compliance with European health, safety, and environmental protection standards, which is crucial for market access in Europe.

Industry-Specific Standards: For automotive applications, certifications such as API (American Petroleum Institute) and SAE (Society of Automotive Engineers) may also be relevant. These standards ensure that products are designed and manufactured to meet the rigorous demands of the automotive industry.

Quality Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials and components before they enter the production process. Suppliers are often required to provide documentation, such as material test reports and compliance certificates.

– In-Process Quality Control (IPQC): During assembly, periodic checks are conducted to ensure that manufacturing processes are adhered to and that components are assembled correctly. This may include functional testing of motors and valves.

– Final Quality Control (FQC): Before shipping, the finished products undergo comprehensive testing to ensure they meet all specifications. This can include pressure testing, performance testing, and safety checks.

The testing phase is critical for validating that the compressed air systems perform effectively and safely. Some common testing methods include:

Pressure Testing: This involves subjecting the system to pressures greater than operational levels to ensure that it can handle extreme conditions without leaking or failing.

Flow Rate Testing: Measuring the flow rate of compressed air helps verify that the system can deliver the necessary volume of air for its intended applications.

Noise Level Testing: Since excessive noise can be a concern in automotive applications, testing is done to ensure that the compressor operates within acceptable noise levels.

Durability Testing: Components may undergo accelerated life testing to simulate years of use in a shorter time frame, helping to identify potential failures before they occur in real-world applications.

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, ensuring the reliability of suppliers is paramount. Here are actionable steps to verify quality control processes:

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. This hands-on approach allows buyers to assess the capabilities and compliance of suppliers firsthand.

Quality Assurance Reports: Request detailed reports on quality control procedures and testing results. Suppliers should be able to provide documentation that outlines their QC processes, including any certifications obtained.

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality management system. These organizations can perform audits and tests to ensure compliance with international standards.

Feedback from Other Clients: Seeking feedback from existing customers of the supplier can provide valuable insights into product quality and reliability. Testimonials and case studies can serve as indicators of a supplier’s performance.

International buyers must navigate various certification and quality control nuances. Here are key considerations:

Understanding Regional Standards: Different regions may have varying standards and certifications. Buyers need to be aware of the specific requirements in their markets, such as CE marking in Europe or UL listing in the United States.

Compliance with Import Regulations: Familiarize yourself with import regulations and standards in your country. Non-compliance can lead to delays, fines, or product recalls.

Cultural and Language Barriers: Communication with suppliers from different regions can pose challenges. Ensuring clarity in specifications and quality requirements is crucial to avoid misunderstandings.

Logistics and Lead Times: Consider the impact of logistics on quality control. Long lead times can affect the ability to conduct thorough inspections before shipment. Establishing clear timelines with suppliers can mitigate this risk.

In summary, understanding the manufacturing processes and quality assurance measures for compressed air systems is essential for B2B buyers. By focusing on detailed manufacturing stages, rigorous quality control practices, and the verification of supplier compliance, buyers can make informed decisions that align with their operational needs and market standards.

This guide provides a practical checklist for B2B buyers seeking to procure compressed air systems for automotive applications. It aims to streamline the sourcing process, ensuring you acquire efficient, reliable, and high-quality solutions tailored to your specific needs.

Illustrative image related to compressed air for car

Before starting your search, outline the specific technical requirements of your compressed air system. Consider factors such as air pressure, volume, and the intended applications (e.g., inflating tires, powering tools). Clearly defined specifications will help you communicate your needs effectively to potential suppliers and ensure compatibility with your operations.

Establish a budget that encompasses not only the initial purchase price but also ongoing operational costs such as maintenance, energy consumption, and spare parts. Understanding your financial limitations is crucial to avoid overspending and to help prioritize features that provide the best value for your investment.

Conduct thorough evaluations of potential suppliers to ensure they can meet your technical and budgetary requirements. Request detailed company profiles, product specifications, and case studies to assess their expertise. Additionally, seek references from other buyers in your industry or region to gauge reliability and service quality.

Once you have shortlisted suppliers, request detailed quotations that include pricing, delivery timelines, and warranty terms. Comparing offers side-by-side will help you identify the best overall value, not just the lowest price. Pay attention to the quality of the components and the supplier’s reputation as these factors can impact long-term performance.

Evaluate the after-sales support provided by suppliers. Reliable maintenance options are essential for the longevity of your compressed air system. Confirm if the supplier offers training, on-site support, and readily available spare parts to minimize downtime in case of repairs.

Discuss delivery schedules and installation services with your chosen supplier. Timely delivery and professional installation can significantly affect your operational efficiency. Ensure that the supplier has a clear plan for installation, including any necessary adjustments to your existing infrastructure.

Before making a final decision, thoroughly review the purchase agreement. Pay attention to terms regarding warranty, return policies, and any hidden costs associated with the purchase. A well-defined agreement protects your interests and clarifies the obligations of both parties, ensuring a smoother procurement process.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement of compressed air systems, ensuring they select the right solution for their automotive needs.

When sourcing compressed air systems for automotive applications, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The quality and type of materials used in compressors significantly impact costs. High-performance components such as brushless motors or advanced materials for air tanks can lead to higher prices but offer better durability and efficiency.

Labor: Labor costs encompass both manufacturing and assembly. In regions with higher labor costs, such as parts of Europe, the overall price of compressors may be elevated. Conversely, sourcing from regions with lower labor rates can provide cost savings.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead, making it essential for suppliers to optimize their operations.

Tooling: Custom tooling for specific compressor designs can add to the initial investment. However, amortizing these costs over larger production volumes can yield savings.

Quality Control (QC): Ensuring reliable performance through rigorous QC processes is vital, especially for automotive applications. Investing in QC can increase initial costs but may reduce long-term warranty claims and maintenance expenses.

Logistics: Transportation costs can vary greatly depending on the origin of the compressor and the delivery location. Buyers should consider the total logistics cost, including shipping, tariffs, and local taxes.

Margin: Supplier margins can differ based on market conditions, competition, and the uniqueness of the product. Understanding how margins influence pricing can help buyers negotiate better deals.

Several factors can influence the pricing of compressed air systems:

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs. Negotiating for bulk pricing can yield significant savings for B2B buyers.

Specifications and Customization: Customization requests, such as specific pressure ratings or unique mounting configurations, can drive up costs. Buyers should be clear about their needs and assess whether customization is necessary.

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO standards) can increase costs but provide assurance regarding performance and reliability. Buyers should weigh the benefits of quality against budget constraints.

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may charge a premium for their reputation, while newer companies might offer competitive pricing to enter the market.

Incoterms: Understanding shipping terms is crucial for calculating total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the final pricing and logistics responsibilities.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies:

Illustrative image related to compressed air for car

Negotiation: Establish a good relationship with suppliers and negotiate terms that can lead to lower prices, especially for larger orders. Flexibility in payment terms can also be a bargaining chip.

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with ownership, including energy consumption, maintenance, and potential downtime. A lower initial purchase price may not always equate to better value if the TCO is higher.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can impact overall costs. Engaging with suppliers who understand the local market can help mitigate these risks.

Research and Compare: Conduct thorough market research to compare prices and specifications across different suppliers. This can provide leverage in negotiations and ensure you are getting the best deal.

Pricing for compressed air systems can vary significantly based on numerous factors outlined above. The figures mentioned in product listings are indicative and may change over time due to market fluctuations, supplier policies, and raw material costs. It is advisable to request quotes directly from suppliers for accurate pricing tailored to your specific requirements.

When considering compressed air systems for automotive needs, it’s essential to evaluate alternative solutions that may offer similar benefits or address specific challenges. This analysis will focus on two viable alternatives: electric tire inflators and nitrogen tire inflation systems. Each option has its distinct advantages and disadvantages, making it crucial for B2B buyers to understand their implications for operational efficiency, cost, and performance.

| Comparison Aspect | Compressed Air For Car | Electric Tire Inflator | Nitrogen Tire Inflation System |

|---|---|---|---|

| Performance | High versatility; can power tools and inflate tires quickly | Effective for tire inflation; limited to low-pressure applications | Maintains tire pressure better over time; reduces tire wear |

| Cost | Initial investment can be high; ongoing energy costs | Generally lower upfront cost; minimal maintenance | Higher initial setup cost; savings on fuel efficiency over time |

| Ease of Implementation | Requires a setup of compressor and storage tank; can be complex | Plug-and-play; very easy to use | Requires specialized equipment and training for staff |

| Maintenance | Regular maintenance needed; parts may wear out | Minimal maintenance; simple to operate | Low maintenance but requires periodic checks on nitrogen purity |

| Best Use Case | Ideal for workshops needing versatility in applications | Suitable for personal or small-scale use; best for occasional tire inflation | Best for fleet operations and environments where tire performance is critical |

Electric tire inflators present a simple and cost-effective alternative to compressed air systems. They are portable, easy to use, and ideal for quick tire inflation. Their low initial cost makes them appealing for businesses that do not require extensive air-powered tools. However, they are limited in their ability to handle high-pressure applications and may not be suitable for professional automotive settings where multiple tools need to be powered simultaneously.

Nitrogen tire inflation systems offer significant advantages, particularly in maintaining tire pressure over extended periods. Nitrogen molecules are larger than those of regular air, reducing the rate of leakage and improving tire longevity and fuel efficiency. This makes nitrogen inflation particularly beneficial for fleet operations. However, the initial investment in nitrogen-generating equipment can be high, and it requires staff training to ensure proper use and maintenance.

When selecting the appropriate system for automotive applications, B2B buyers should consider their specific operational needs, budget constraints, and the expected return on investment. For businesses requiring versatile air solutions for various applications, compressed air remains a strong choice. Conversely, for those focused on tire maintenance and performance, nitrogen systems may provide long-term savings and efficiency. Electric tire inflators serve well in low-demand environments where simplicity and portability are paramount. Ultimately, evaluating the specific use case and operational demands will guide buyers toward the most effective solution for their business.

When sourcing compressed air systems for automotive applications, understanding key technical properties is crucial for ensuring optimal performance and reliability. Here are some critical specifications to consider:

Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can deliver. For automotive applications, typical pressure requirements range from 90 to 150 PSI. A higher pressure rating ensures that the compressor can effectively power air tools, inflate tires, and operate pneumatic systems. Understanding this specification helps B2B buyers select equipment that meets the demands of their specific operations.

Cubic Feet per Minute (CFM)

CFM is a measure of airflow volume. It indicates how much air the compressor can deliver in a minute, which is vital for applications such as tire inflation and operating air tools. Different tools require varying CFM levels; thus, knowing the CFM rating helps buyers match compressors to their operational needs, ensuring efficiency and reducing downtime.

Duty Cycle

The duty cycle refers to the compressor’s operational time versus rest time, typically expressed as a percentage. For example, a 50% duty cycle means the compressor can run for 5 minutes and must rest for 5 minutes. Understanding this property is essential for applications requiring continuous air supply, as it impacts productivity and equipment lifespan.

Tank Size

The tank size affects the amount of compressed air stored and the compressor’s ability to maintain consistent pressure. Larger tanks can supply air for extended periods without the compressor needing to cycle on and off frequently. This is particularly important for automotive workshops that utilize multiple air tools simultaneously.

Noise Level (dB)

Noise level, measured in decibels (dB), is a critical consideration, especially in environments where sound regulation is a concern. A quieter compressor enhances the workplace experience and complies with local regulations. Buyers should consider noise levels to ensure that they select equipment that minimizes disruption.

Material Grade

The material grade of the compressor components affects durability and performance. Common materials include aluminum and steel, each with distinct properties regarding weight, strength, and corrosion resistance. Selecting the right material ensures longevity and reliability, reducing maintenance costs over time.

Familiarity with industry-specific terminology is vital for effective communication and negotiation in the B2B landscape. Here are some common terms:

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM products ensures that buyers source high-quality components designed to fit specific applications and maintain compatibility with existing systems.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers to understand their purchasing power and ensure they meet the supplier’s requirements for cost-effective ordering.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It’s a critical step in the procurement process, helping buyers compare offers and negotiate terms effectively.

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing logistics, shipping costs, and risk during transport.

Pneumatics

This term refers to the use of gas or pressurized air to create mechanical motion. In the automotive industry, understanding pneumatics is essential for selecting appropriate tools and systems that rely on compressed air.

FAD (Free Air Delivery)

FAD is the amount of air delivered by a compressor at a specified pressure and temperature. This specification helps buyers assess the performance of a compressor under real-world conditions, ensuring it meets their operational requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimizing their procurement processes for compressed air systems in automotive applications.

The compressed air market for the automotive sector is experiencing significant growth driven by several global factors. Increasing vehicle production, particularly in developing regions like Africa and South America, is a notable driver, as manufacturers seek efficient air compression solutions to enhance productivity in assembly lines. The rise of electric vehicles (EVs) is also reshaping the landscape, as the demand for lightweight and energy-efficient air compressors grows. Technological advancements are fostering innovation, with smart compressors equipped with IoT capabilities that allow for real-time monitoring and predictive maintenance, ultimately reducing downtime and operational costs.

In terms of sourcing trends, buyers are increasingly leaning towards modular and scalable solutions that can adapt to fluctuating production demands. This flexibility is crucial for international buyers who face varying market conditions across different regions. Furthermore, there is a noticeable shift towards portable and vehicle-mounted air compressor systems, which cater to the needs of both manufacturers and service providers. This trend is particularly prominent in regions like Europe and the Middle East, where off-road and recreational vehicle markets are expanding.

Sustainability has become a central theme in the sourcing of compressed air solutions, with a strong emphasis on reducing environmental impact. The automotive industry is under pressure to lower carbon emissions, and compressed air systems are being optimized for energy efficiency to meet these demands. Implementing energy-efficient compressors can significantly reduce electricity consumption, contributing to lower operational costs and a smaller carbon footprint.

Ethical sourcing is also gaining traction, with B2B buyers prioritizing suppliers who adhere to sustainable practices. This includes the use of ‘green’ certifications and materials that minimize environmental harm. For instance, choosing compressors that utilize refrigerants with low global warming potential (GWP) or are constructed from recyclable materials can enhance a company’s sustainability profile. This focus on ethical supply chains not only meets regulatory requirements but also appeals to environmentally conscious consumers and partners, ultimately strengthening brand reputation.

The evolution of the compressed air market for automotive applications can be traced back to the early 20th century when air compressors were primarily used in manufacturing settings. Over the decades, advancements in technology have transformed these systems, making them more efficient and versatile. The introduction of portable and vehicle-mounted compressors in the late 20th century expanded their applications, allowing for use in both professional automotive shops and consumer settings.

The rise of electronic and hybrid vehicles in the 21st century has further propelled innovation, as manufacturers seek to integrate lighter and more efficient air compression technologies. Today, the market is characterized by a strong emphasis on sustainability, digital integration, and the adaptation of products to meet the diverse needs of global automotive markets, particularly in emerging economies. As the industry continues to evolve, B2B buyers must stay attuned to these trends to make informed sourcing decisions.

Illustrative image related to compressed air for car

How do I select the right compressed air system for automotive applications?

Choosing the right compressed air system requires understanding your specific needs. Consider factors such as the required airflow rate (measured in CFM), pressure levels (PSI), and the types of tools you will be using. Assess whether you need a portable or stationary system based on your workspace. Additionally, evaluate energy efficiency and maintenance requirements. Consulting with suppliers who specialize in automotive applications can provide tailored recommendations based on your operational demands.

What is the best type of air compressor for automotive tasks?

The best type of air compressor for automotive tasks often depends on your specific applications. For general use, a 12V portable compressor is ideal for inflating tires and powering small pneumatic tools. For more extensive operations, a stationary rotary screw compressor can provide a continuous airflow for heavy-duty tasks. Brushless compressors are also gaining popularity due to their efficiency and longevity. Evaluate your power needs, frequency of use, and portability requirements before making a decision.

What should I consider when vetting international suppliers for compressed air systems?

When vetting international suppliers, assess their reputation, experience, and product quality. Request references and case studies from previous clients, particularly those within your industry. Ensure they comply with international standards and certifications relevant to compressed air systems. Additionally, evaluate their communication practices, customer support, and logistics capabilities. A reliable supplier should also offer transparent terms for warranties, maintenance, and spare parts availability.

What are typical minimum order quantities (MOQs) for compressed air systems?

Minimum order quantities (MOQs) for compressed air systems can vary significantly by supplier and product type. For smaller, portable units, MOQs may be as low as one unit, while larger, industrial systems may require orders of five or more. Discuss your needs with suppliers to negotiate MOQs that align with your purchasing capacity and business model. Some suppliers may offer flexible terms for first-time buyers or bulk orders.

What payment terms are commonly offered by compressed air suppliers?

Payment terms can differ widely among suppliers. Common options include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer credit terms, allowing payment within 30, 60, or 90 days post-delivery, especially for established business relationships. Always clarify payment methods accepted (e.g., wire transfer, credit card) and ensure there are no hidden fees. Negotiating favorable terms can enhance your cash flow management.

How can I ensure quality assurance (QA) for my compressed air systems?

To ensure quality assurance, request certifications for the compressors you plan to purchase, such as ISO or CE markings. Inquire about the supplier’s QA processes, including testing procedures for airflow, pressure, and durability. Regular maintenance schedules and warranties are also essential components of QA. Consider establishing a quality control checklist to evaluate incoming shipments against your specifications before acceptance.

What logistics considerations should I keep in mind when importing compressed air systems?

When importing compressed air systems, consider shipping options, customs regulations, and potential tariffs that may apply. Evaluate the supplier’s logistics capabilities, including packaging standards and delivery timelines. It’s also vital to ensure that all necessary documentation, such as bills of lading and customs declarations, is prepared accurately to avoid delays. Partnering with a reliable freight forwarder can streamline the logistics process and ensure compliance with international shipping laws.

How do I maintain my compressed air systems for optimal performance?

Regular maintenance is crucial for optimal performance of compressed air systems. Create a maintenance schedule that includes checking air filters, lubricating moving parts, and inspecting hoses for wear. Monitor the pressure gauges to ensure they are functioning correctly and calibrate them as necessary. Additionally, keep the compressor clean and free from debris to prevent overheating and inefficiency. Training your staff on proper operation and maintenance practices can significantly extend the life of your equipment.

Domain: store.arbusa.com

Registered: 1998 (27 years)

Introduction: Portable & Vehicle Mounted Air Compressor Systems from ARB 4×4 USA. Key features include: reliable, high-performance compressors for powering tires, tools, and Air Lockers. Product categories include Mounted Compressors, Portable Compressors, and Brushless Compressors. Notable products: Twin Motor Onboard 12V Air Compressor CKMTA12 ($593.95), Single Motor Onboard 12V Air Compressor CKMA12 ($323.95…

Domain: obsessedgarage.com

Registered: 2015 (10 years)

Introduction: Air Tools collection includes automotive and detailing tools such as digital tire inflators, pressure gauges, and tread depth gauges. Featured brand PCL offers the ACCURA 1 digital tire inflator with an accuracy of 0.2 psi and a 13 CFM fill rate. Other brands include Rupes for pneumatic polishers and Prevost for air compressor blowguns. Availability includes 15 in-stock products and 1 out-of-stock…

Domain: fluidairedynamics.com

Registered: 2006 (19 years)

Introduction: Fluid-Aire Dynamics offers customized compressed air solutions for the automotive manufacturing industry, including system design, servicing, and expert guidance. Key product offerings include: 1. PneuTech – Industrial Air Compressors 2. Unipipe – Aluminum Piping System 3. Anest Iwata – Oil Free Vacuum Pumps 4. Used Compressed Air Equipment 5. Replacement Parts. Common applications of compressed a…

Domain: zeropollutionmotors.us

Registered: 2006 (19 years)

Introduction: Zero Pollution Motors is set to produce the AIRPod 2.0, the first compressed air-powered car in the United States, with an estimated availability by mid-2024. Production in Europe began in Q1 2019, with US deliveries for pre-order customers expected in the second half of 2024. Additionally, golf carts powered by compressed air are scheduled for delivery in the USA by late 2025. The AIRPod is desig…

In the evolving landscape of automotive applications, strategic sourcing of compressed air solutions is paramount. International B2B buyers should prioritize reliability, efficiency, and adaptability when selecting compressed air systems. By investing in high-performance compressors, such as those suited for both portable and mounted configurations, businesses can enhance operational efficiency and reduce downtime. Furthermore, understanding the specific requirements of diverse markets—from the robust demands in Europe to the cost-sensitive regions of Africa and South America—will enable buyers to tailor their sourcing strategies effectively.

Strategic sourcing not only reduces costs but also fosters long-term partnerships with suppliers who can provide ongoing support and innovative solutions. Buyers are encouraged to evaluate suppliers based on their ability to deliver consistent quality and service, ensuring that their compressed air systems can withstand varying operational conditions. This foresight can lead to improved productivity and a stronger market position.

Looking ahead, businesses must remain agile and responsive to market changes and technological advancements in compressed air systems. Engaging with reputable suppliers and leveraging data-driven insights will be crucial in making informed purchasing decisions. As the automotive industry continues to innovate, now is the time for buyers from Africa, South America, the Middle East, and Europe to align their sourcing strategies with emerging trends. Take action today to secure a competitive edge in the compressed air market and ensure your operations are future-ready.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to compressed air for car

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.