In the competitive landscape of the global tire market, sourcing high-quality corded tires presents a unique challenge for B2B buyers. The need for reliable, durable, and performance-driven solutions is paramount, particularly in regions like Africa, South America, the Middle East, and Europe, where diverse terrains and economic conditions demand tailored approaches. This guide aims to demystify the complexities surrounding corded tires by providing a comprehensive overview of the types available, their applications across various industries, and critical factors to consider when vetting suppliers.

By equipping international buyers with actionable insights into cost structures, material specifications, and performance metrics, this resource empowers informed purchasing decisions. Whether you are sourcing tires for commercial vehicles, construction machinery, or agricultural equipment, understanding the nuances of corded tire selection can significantly impact your operational efficiency and profitability.

As you navigate this guide, you will discover best practices for evaluating suppliers, tips for negotiating favorable contracts, and strategies for ensuring compliance with international quality standards. With this knowledge at your fingertips, you can confidently approach your next procurement cycle, ensuring that you choose the right corded tires that meet both your performance needs and budget constraints.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Racing Slicks | Smooth, treadless surface for maximum grip | Motorsports, track events | Pros: Excellent grip, predictable handling. Cons: Limited lifespan, not suitable for wet conditions. |

| All-Season Corded Tires | Versatile tread patterns for various weather conditions | Commercial fleets, long-distance transport | Pros: Good traction in diverse conditions. Cons: May wear faster than specialized tires. |

| Off-Road Corded Tires | Aggressive tread patterns for rugged terrain | Construction, agriculture, off-road vehicles | Pros: Enhanced durability, superior traction. Cons: Increased rolling resistance, noise on pavement. |

| Performance Tires | Enhanced rubber compounds for improved handling and stability | Sports cars, high-performance vehicles | Pros: Better grip and cornering capabilities. Cons: Higher cost, may wear quickly under extreme conditions. |

| Heavy-Duty Truck Tires | Reinforced construction for heavy loads | Transportation, logistics, industrial use | Pros: High load capacity, durability. Cons: Heavier, may affect fuel efficiency. |

Racing slicks are designed for optimal performance on dry surfaces, featuring a smooth, treadless design that maximizes contact with the road. These tires are ideal for competitive motorsports where grip and handling are paramount. However, their lack of tread makes them unsuitable for wet conditions, limiting their versatility. B2B buyers should consider the specific racing conditions and ensure that they have a strategy for tire management, as these tires have a limited lifespan and can wear quickly under intense use.

All-season corded tires feature versatile tread patterns that provide adequate traction in various weather conditions, making them suitable for commercial fleets and long-distance transport. These tires balance performance, durability, and cost-effectiveness. B2B buyers should evaluate their operational environments and select tires that can handle diverse conditions, as these tires may wear faster than specialized options, potentially leading to increased replacement frequency.

Off-road corded tires are engineered with aggressive tread patterns to provide superior traction on rugged terrains. These tires are essential for industries such as construction and agriculture, where vehicles frequently navigate uneven surfaces. While they excel in durability and off-road performance, B2B buyers should be aware of the increased rolling resistance and noise levels when used on paved roads, which may impact operational efficiency.

Performance tires utilize advanced rubber compounds and engineering to enhance grip and stability, making them ideal for sports cars and high-performance vehicles. These tires are designed to improve cornering capabilities and overall driving dynamics. However, their higher cost and tendency to wear quickly under extreme conditions may deter some buyers. B2B customers should assess their driving requirements and the expected usage intensity to ensure a worthwhile investment.

Heavy-duty truck tires are constructed with reinforced materials to handle substantial loads, making them suitable for transportation, logistics, and industrial applications. Their durability and high load capacity are significant advantages for businesses that rely on heavy vehicles. However, these tires tend to be heavier, which can affect fuel efficiency. B2B buyers should weigh the benefits of durability against potential operational costs, ensuring that tire selection aligns with their business needs.

| Industry/Sector | Specific Application of corded tire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | High-performance racing and motorsport vehicles | Enhanced grip and handling, critical for competitive performance | Sourcing from specialized manufacturers with proven track records in motorsport tires |

| Construction | Heavy-duty vehicles and machinery | Improved durability and resistance to wear and tear, reducing downtime | Ensuring compliance with safety standards and certifications relevant to the region |

| Agriculture | Agricultural machinery and equipment | Increased traction on varied terrains, optimizing productivity | Evaluating tire compatibility with specific machinery and local soil conditions |

| Logistics and Transportation | Commercial trucking and freight transport | Maximized fuel efficiency and load-bearing capacity, lowering operational costs | Considering local regulations and availability of support services for tire maintenance |

| Mining and Quarrying | Heavy equipment used in mining operations | Enhanced durability and performance in rugged environments, minimizing breakdowns | Focusing on sourcing tires designed for extreme conditions and understanding local geological challenges |

In the automotive manufacturing sector, corded tires are primarily used in high-performance racing and motorsport vehicles. These tires are designed to provide exceptional grip and handling, which are critical in competitive racing scenarios. By utilizing corded tires, manufacturers can offer products that enhance vehicle performance, ultimately leading to higher customer satisfaction and brand loyalty. International buyers need to consider sourcing from specialized manufacturers who understand the rigorous demands of motorsport applications, ensuring both quality and performance.

In the construction industry, corded tires find application in heavy-duty vehicles and machinery, such as bulldozers and excavators. These tires are engineered for durability and resistance to wear, which is essential for operating in harsh environments. By investing in corded tires, construction companies can significantly reduce downtime caused by tire failure, leading to increased productivity and lower operational costs. Buyers should ensure that the tires meet local safety standards and certifications to mitigate risks associated with construction operations.

Agricultural machinery and equipment benefit significantly from corded tires, which provide increased traction on varied terrains. This enhanced traction is crucial for optimizing productivity in farming operations, especially in regions with challenging soil conditions. Corded tires help farmers maximize the efficiency of their machinery, allowing for smoother operations during planting and harvesting. Buyers should evaluate the compatibility of tires with their specific machinery and consider local soil characteristics when sourcing.

In logistics and transportation, corded tires are essential for commercial trucking and freight transport. These tires contribute to maximized fuel efficiency and enhanced load-bearing capacity, which directly lowers operational costs for businesses. The use of corded tires ensures that trucks can maintain performance over long distances, even under heavy loads. International buyers should be aware of local regulations regarding tire specifications and the availability of support services for maintenance, which can impact overall fleet performance.

In the mining and quarrying sectors, corded tires are used on heavy equipment that operates in rugged environments. These tires are designed to withstand extreme conditions, providing enhanced durability and performance, which minimizes the risk of breakdowns. This is particularly important in mining operations, where downtime can lead to significant financial losses. Buyers should focus on sourcing tires that are specifically designed for harsh mining conditions and understand the geological challenges present in their operational areas.

The Problem: B2B buyers, especially those managing fleets or operating in high-stakes environments, face significant challenges when it comes to the performance and safety of corded tires. As tires approach the point of cord exposure, handling deteriorates, which can lead to dangerous driving conditions. The risk of blowouts increases, which not only endangers the safety of drivers but can also lead to costly downtime and liability issues. Many buyers may underestimate the signs of cord exposure, relying on visual inspections that do not adequately convey the tire’s true condition.

The Solution: To mitigate these risks, companies should implement a comprehensive tire management program that includes regular monitoring and assessment of tire conditions. Utilizing advanced tire monitoring technology can provide real-time data on tire pressure, temperature, and wear patterns, allowing for proactive measures before reaching the corded stage. Additionally, training staff on the signs of tire wear and the implications of using corded tires can enhance safety. Establishing a routine schedule for tire replacements based on usage and wear metrics will help in maintaining optimal performance while minimizing risks associated with corded tires.

The Problem: Many B2B buyers often struggle with the financial implications of tire wear, particularly when it comes to managing budgets for fleet operations. The initial low cost of using corded tires can be deceptive, as the eventual costs associated with handling tire failures, accidents, and the impact on operational efficiency can accumulate rapidly. Without a clear understanding of the total cost of ownership, businesses may find themselves facing unexpected expenses that disrupt cash flow.

The Solution: Buyers should conduct a thorough cost-benefit analysis that includes not only the purchase price of corded tires but also potential costs associated with maintenance, downtime, and accidents. This analysis should factor in the lifespan of tires under different operating conditions and the potential savings from switching to higher-quality tires that might have a higher upfront cost but provide better longevity and safety. Engaging with tire manufacturers or suppliers who can provide detailed performance data and case studies can help in making informed decisions that align with long-term financial strategies.

The Problem: Sourcing the right corded tires for specific applications can be a complex task for B2B buyers, especially those operating in varied environments such as construction, logistics, or agriculture. Different applications require different tire specifications, and failing to match the right tire to the right application can lead to premature wear, reduced safety, and increased operational costs. Buyers may feel overwhelmed by the number of options and the technical specifications involved.

The Solution: To navigate this complexity, buyers should engage in a structured procurement process that includes detailed assessments of their operational needs. Collaborating with tire experts or consultants can provide valuable insights into selecting the appropriate corded tires based on specific requirements such as load capacity, terrain, and climate conditions. Creating a checklist of essential criteria for tire selection and establishing relationships with reputable suppliers can streamline the sourcing process. Additionally, leveraging feedback from other businesses in similar industries can help in identifying reliable tire brands and models that have proven effective in real-world applications.

When selecting materials for corded tires, it is crucial to consider the specific properties and performance characteristics that will meet the demands of various applications. Here, we analyze four common materials used in the production of corded tires, focusing on their key properties, advantages, disadvantages, and international considerations.

Key Properties: Steel wire is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-load applications. Additionally, steel exhibits excellent fatigue resistance.

Pros & Cons: The primary advantage of steel wire is its strength and longevity, which translates to a longer lifespan for tires. However, steel is heavier than other materials, which can impact fuel efficiency and performance. Manufacturing complexity is moderate, as steel wire needs to be treated to prevent corrosion.

Impact on Application: Steel wire is particularly effective in applications requiring high load-bearing capacity, such as commercial vehicles. Its compatibility with various types of rubber compounds enhances performance under extreme conditions.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Africa and South America may also consider local availability and cost implications of sourcing steel wire.

Key Properties: Polyester is lightweight and offers good tensile strength. It has excellent resistance to abrasion and is less prone to elongation under load, which helps maintain tire shape.

Pros & Cons: The lightweight nature of polyester contributes to improved fuel efficiency and handling. However, it has lower heat resistance compared to steel, which may limit its use in high-performance applications. Manufacturing processes for polyester are generally simpler and more cost-effective.

Impact on Application: Polyester is often used in passenger vehicle tires where weight savings and comfort are prioritized. It is compatible with various rubber compounds, making it versatile.

Considerations for International Buyers: Polyester materials must meet specific standards, and buyers should be aware of local regulations regarding synthetic materials, especially in regions with strict environmental guidelines.

Key Properties: Nylon is known for its high elasticity and resistance to impact. It provides excellent dimensional stability and can withstand high temperatures.

Pros & Cons: The key advantage of nylon is its flexibility, which contributes to better ride comfort and handling. However, it is more susceptible to moisture absorption, which can lead to degradation over time. The manufacturing complexity is moderate, as nylon requires specific processing conditions.

Impact on Application: Nylon is commonly used in tires designed for off-road or rugged terrain applications due to its durability and flexibility. It can handle various environmental conditions effectively.

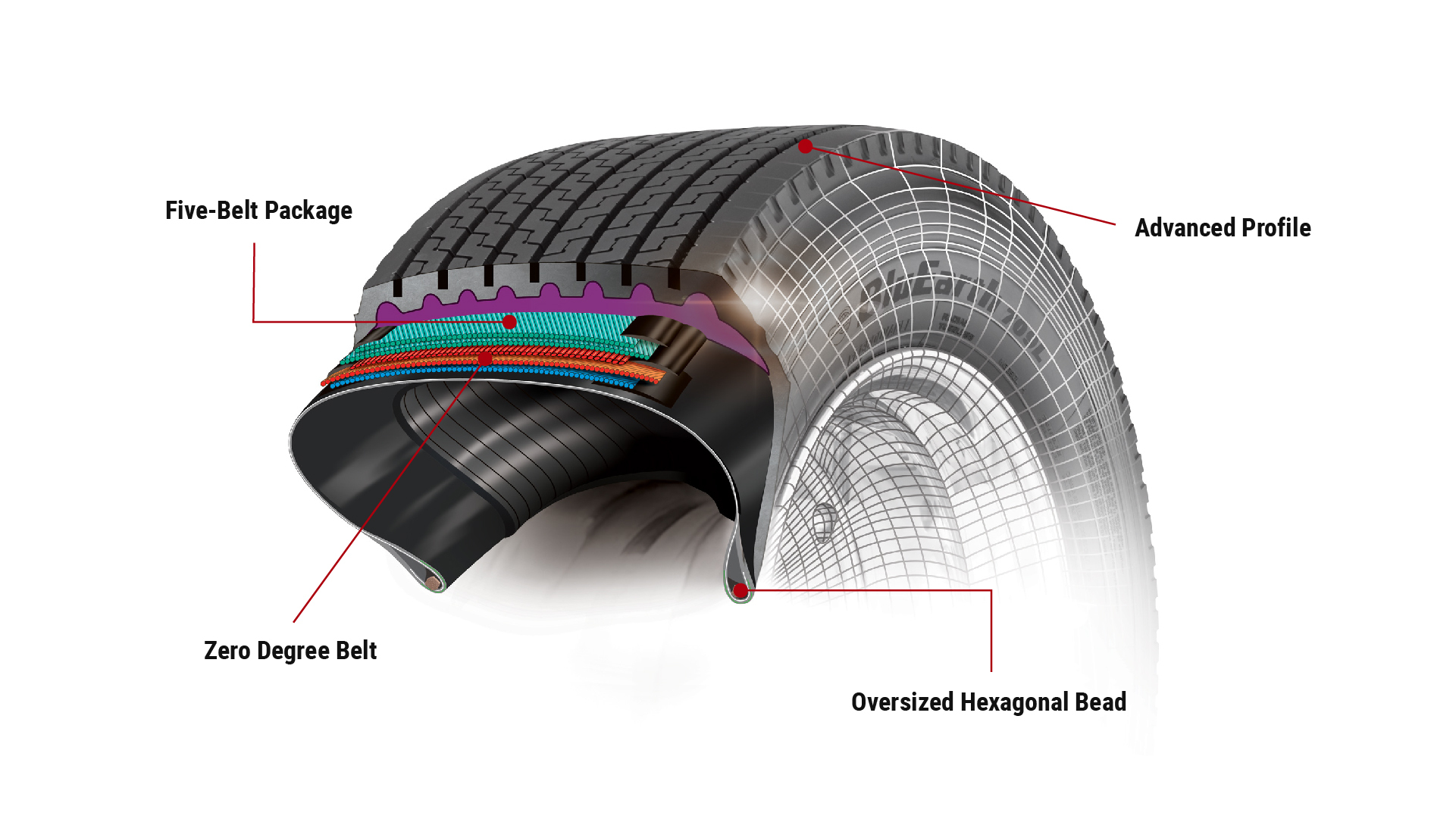

Illustrative image related to corded tire

Considerations for International Buyers: International buyers should ensure that nylon materials comply with local standards. In regions like the Middle East, where temperatures can be extreme, the heat resistance of nylon should be a primary consideration.

Key Properties: Aramid fiber is known for its exceptional strength-to-weight ratio and thermal stability. It is highly resistant to abrasion and impact.

Pros & Cons: The main advantage of aramid fiber is its lightweight nature combined with high strength, making it ideal for high-performance tires. However, it is typically more expensive than other materials, which can impact overall tire cost. Manufacturing processes can also be complex due to the specialized handling of aramid fibers.

Impact on Application: Aramid fiber is often used in high-performance and racing tires where performance and durability are critical. Its compatibility with various rubber compounds enhances tire performance under extreme conditions.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with aramid fiber and ensure compliance with international quality standards. In Europe, for instance, there may be stricter regulations on material sourcing and environmental impact.

| Material | Typical Use Case for corded tire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Wire | Heavy-load commercial vehicles | High tensile strength and durability | Heavier, impacting fuel efficiency | High |

| Polyester | Passenger vehicle tires | Lightweight, improves fuel efficiency | Lower heat resistance | Medium |

| Nylon | Off-road and rugged terrain tires | High elasticity and impact resistance | Moisture absorption susceptibility | Medium |

| Aramid Fiber | High-performance and racing tires | Exceptional strength-to-weight ratio | Higher cost and complex manufacturing | High |

This analysis provides a comprehensive overview of material options for corded tires, enabling international B2B buyers to make informed decisions based on performance requirements, cost considerations, and regional compliance standards.

The manufacturing process of corded tires involves several critical stages, ensuring that the final product meets the high performance and safety standards required by the industry. Understanding these stages can help B2B buyers assess suppliers’ capabilities and the quality of the products they offer.

The first stage in tire manufacturing involves selecting and preparing raw materials. Key components include:

Proper material selection is vital, as the properties of these materials directly impact the tire’s performance and safety.

Illustrative image related to corded tire

Once the materials are prepared, the next step is forming the tire components. This process includes:

Forming techniques are carefully monitored to ensure precision and consistency, which are critical for tire performance.

The assembly stage involves bringing together all the formed components. Key activities include:

Quality checks are performed throughout assembly to identify any defects early in the process.

In the finishing stage, tires undergo several processes to ensure they are market-ready:

This final stage is essential for ensuring that each tire meets safety and performance standards.

Quality assurance is paramount in tire manufacturing, given the safety implications of tire performance. International standards, such as ISO 9001, and industry-specific certifications like CE and API, guide quality management systems in the manufacturing process.

Understanding international quality standards is crucial for B2B buyers when evaluating potential suppliers. Key standards include:

These certifications assure buyers that suppliers adhere to recognized quality standards.

Quality control (QC) is integrated at various stages of the manufacturing process. Common QC checkpoints include:

Illustrative image related to corded tire

Implementing these checkpoints helps minimize defects and ensures product reliability.

Various testing methods are utilized to assess tire quality, including:

These testing methods provide valuable data on the tire’s performance and longevity.

B2B buyers need to ensure that their suppliers maintain high-quality standards. Here are actionable steps to verify supplier QC:

International buyers must consider regional regulations and standards when sourcing tires. These nuances may include:

By being aware of these factors, international buyers can make informed decisions that align with their quality assurance needs.

A comprehensive understanding of the manufacturing processes and quality assurance measures for corded tires is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous QC standards and testing methods, buyers can ensure they partner with reliable suppliers that meet their performance and safety expectations.

This practical sourcing guide is designed for B2B buyers looking to procure corded tires effectively. Corded tires, which exhibit visible wear indicating the tire’s end-of-life state, require careful evaluation to ensure safety, performance, and value. This checklist will help you navigate the procurement process, ensuring you make informed decisions that align with your business needs.

Before initiating the sourcing process, clearly define your technical specifications for corded tires. This includes understanding the intended application, load capacity, and environmental conditions the tires will face.

– Key Considerations: Determine factors such as tire size, tread pattern, and performance characteristics relevant to your operations.

Conduct thorough research to identify potential suppliers who specialize in corded tires. Look for companies with a solid track record in your region or industry.

– What to Look For: Consider supplier experience, customer reviews, and product offerings. Platforms like trade shows or industry forums can provide valuable insights into reputable suppliers.

Before finalizing your suppliers, ensure they hold relevant certifications and comply with international quality standards. Certifications such as ISO 9001 or specific automotive industry standards can indicate a commitment to quality.

– Importance of Certifications: Verified suppliers are more likely to provide safe, reliable products, reducing the risk of operational disruptions.

Once you have a shortlist of suppliers, request samples of their corded tires for testing. This step is crucial to evaluate the performance and quality of the products in real-world conditions.

– Testing Parameters: Assess factors such as grip, durability, and wear characteristics. This hands-on evaluation can help identify any potential issues before making a bulk purchase.

Compare pricing models and payment terms from different suppliers to ensure you receive competitive offers. Look beyond just the initial cost; consider long-term value and total cost of ownership.

– Negotiation Tips: Be open to negotiating terms, including discounts for bulk orders or extended payment options, which can enhance cash flow management.

Confirm the suppliers’ delivery capabilities, including lead times, shipping methods, and logistics support. Timely delivery is crucial for maintaining operational efficiency and avoiding downtime.

– Logistics Considerations: Assess whether the supplier can meet your specific delivery requirements, especially if you operate in remote or challenging locations.

Inquire about after-sales support and warranty terms before finalizing your purchase. A reliable supplier should offer support for installation, maintenance, and any potential issues that arise post-purchase.

– Warranty Importance: A strong warranty can provide peace of mind and protect your investment, ensuring you receive support if the tires do not perform as expected.

By following this step-by-step checklist, B2B buyers can navigate the procurement process for corded tires more effectively, ensuring they select the right products and suppliers for their needs.

When sourcing corded tires, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The quality and type of materials used (such as rubber, steel cords, and fabric) directly affect the overall cost. Higher-grade materials typically lead to increased durability and performance, impacting the final price.

Labor: Labor costs vary significantly across regions. Countries with lower labor costs, such as Vietnam, may offer competitive pricing, while European manufacturers may have higher costs due to stricter labor regulations and standards.

Manufacturing Overhead: This encompasses expenses related to the factory’s operational costs, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can minimize these overheads.

Tooling: Initial tooling costs for molds and manufacturing equipment can be significant. Customization or unique specifications will further increase these costs.

Quality Control (QC): Implementing stringent QC measures ensures product reliability, but it adds to manufacturing costs. Certifications and compliance with international standards can also affect pricing.

Logistics: Shipping costs, including freight, customs duties, and warehousing, vary based on the origin and destination of the tires. Choosing the right logistics partner is vital for managing these costs effectively.

Margin: Suppliers typically add a profit margin on top of their costs. This margin can fluctuate based on market demand, competition, and the supplier’s positioning in the market.

Several factors can influence the pricing of corded tires, particularly for international buyers:

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing based on their projected needs.

Specifications and Customization: Custom specifications, such as tread patterns or rubber compounds, can lead to higher costs. Buyers should assess whether customization is necessary for their operational needs.

Materials and Quality Certifications: The choice of materials significantly impacts pricing. Tires that meet specific quality certifications (such as ISO or DOT) may command higher prices but offer better reliability and performance.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

Incoterms: Understanding Incoterms is essential in international trade. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk, which can affect the total landed cost of the tires.

Negotiating the best price for corded tires requires strategic planning and an understanding of the market. Here are some actionable tips:

Leverage Total Cost of Ownership (TCO): Focus on the long-term value rather than just the upfront costs. Consider factors like durability, performance, and maintenance costs in your decision-making process.

Research and Benchmark: Conduct thorough research on market prices and benchmark against competitors. This knowledge can strengthen your position during negotiations.

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, improved service, and priority access to new products.

Be Flexible with Specifications: If possible, remain flexible on specifications to explore lower-cost options. Standardized products may have lower prices compared to customized solutions.

Consider Regional Suppliers: For buyers in Africa, South America, and the Middle East, engaging local suppliers may reduce shipping costs and lead times, enhancing overall cost efficiency.

The costs associated with sourcing corded tires are multifaceted, influenced by various components and market dynamics. By understanding the cost structure, price influencers, and negotiation strategies, international B2B buyers can make informed decisions that enhance their purchasing power and ensure a reliable supply chain. Always remember that prices can fluctuate based on market conditions, so it is prudent to seek indicative pricing while finalizing agreements.

When evaluating corded tires, it’s crucial to consider alternative solutions that may fulfill similar roles in industrial or automotive applications. Different technologies and methods come with their own sets of advantages and disadvantages, influencing factors such as performance, cost, and maintenance. This analysis provides a comprehensive comparison of corded tires against two viable alternatives: solid tires and traditional pneumatic tires.

| Comparison Aspect | ‘Corded Tire’ | Solid Tires | Traditional Pneumatic Tires |

|---|---|---|---|

| Performance | High traction, but can degrade rapidly when corded | Excellent durability, lower traction | Good traction and comfort, but susceptible to punctures |

| Cost | Moderate initial cost, potential for higher long-term expenses due to replacement | Higher upfront cost, lower long-term costs due to durability | Lower upfront cost, but frequent replacements can add up |

| Ease of Implementation | Requires specialized mounting and handling | Easy to install, no inflation required | Standard installation practices, but requires inflation management |

| Maintenance | Regular inspections needed to avoid blowouts | Minimal maintenance required | Requires frequent checks for pressure and punctures |

| Best Use Case | Performance-driven applications (e.g., motorsports) | Heavy-duty industrial applications (e.g., forklifts) | General-purpose vehicles and equipment |

Solid tires are made from a solid rubber compound and are often used in industrial environments where punctures and blowouts are common concerns. Their primary advantage lies in their durability; they do not deflate or suffer from wear in the same way that pneumatic tires do. This makes them ideal for heavy-duty applications such as forklifts and construction equipment. However, solid tires often provide less traction and a rougher ride compared to corded tires, which can be a significant drawback for performance-focused applications.

Illustrative image related to corded tire

Traditional pneumatic tires are filled with air and provide a comfortable ride with good traction. They are widely used in various vehicles and offer a balance of performance and cost-effectiveness. While their initial purchase price is typically lower than corded tires, they require regular maintenance to check air pressure and manage potential punctures. The trade-off here is between comfort and reliability; pneumatic tires may require more frequent replacements, especially in rugged environments, making long-term costs potentially higher.

Selecting the appropriate tire solution ultimately depends on your specific operational needs and the environment in which the tires will be used. If your business prioritizes high performance and traction in demanding conditions, corded tires may be the best choice despite their maintenance requirements and potential long-term costs. Conversely, if your application is more focused on durability and minimal maintenance, solid tires offer an excellent alternative. Traditional pneumatic tires serve well in general applications where comfort and cost savings are prioritized but require more ongoing management. Assessing your operational context will guide you in making the most cost-effective and efficient decision for your tire needs.

When evaluating corded tires for business purposes, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties to consider:

Material Grade

Corded tires are primarily constructed from synthetic rubber and steel cords. The material grade impacts durability, performance, and resistance to wear. High-grade materials often lead to longer tire life and better traction, which is essential for maintaining operational efficiency in industries like transportation and logistics.

Tread Depth

Tread depth is a critical specification that directly affects traction and handling. It is usually measured in millimeters. Tires with adequate tread depth ensure better grip on various surfaces, which is vital for safety and performance. Buyers should consider the required tread depth based on the intended application, such as off-road versus highway use.

Load Capacity

This specification indicates the maximum weight a tire can safely support. Load capacity is essential for businesses that transport heavy goods, as exceeding this limit can lead to tire failure and increased operational costs. Understanding load ratings helps buyers choose tires that meet their specific vehicle requirements.

Inflation Pressure

The recommended inflation pressure is crucial for optimal tire performance and safety. Proper inflation affects fuel efficiency, handling, and tread wear. Buyers must ensure that the tires they select are compatible with their vehicle’s requirements to avoid issues related to under- or over-inflation.

Tolerance

Tolerance refers to the allowable variation in tire dimensions, such as diameter and width. This specification is essential for ensuring that tires fit properly on vehicles and maintain performance standards. Tight tolerances can reduce the risk of premature wear and improve overall safety.

Temperature Resistance

This property indicates a tire’s ability to withstand high temperatures generated during operation. Tires that can handle elevated temperatures are less likely to suffer from blowouts or reduced performance. This specification is particularly important in regions with extreme weather conditions.

Understanding industry terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms associated with corded tires:

Illustrative image related to corded tire

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the tire industry, OEM tires are those that are supplied with new vehicles. B2B buyers often prefer OEM tires for their guaranteed quality and compatibility with specific vehicle models.

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is significant for businesses planning their inventory and budgeting. Understanding MOQ helps buyers avoid overstocking or understocking issues.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. This process is vital for B2B buyers to compare options and negotiate better terms. A well-crafted RFQ can lead to cost savings and improved supplier relationships.

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, which can affect overall pricing and logistics planning.

Lead Time

Lead time refers to the time taken from placing an order until it is delivered. This specification is crucial for supply chain management, as longer lead times can disrupt business operations. Buyers should factor lead time into their planning to ensure timely availability of tires.

Warranty

A warranty is a promise made by the manufacturer regarding the quality and durability of the tire. Understanding warranty terms helps buyers assess the risk and long-term value of their investment. A robust warranty can provide peace of mind and reduce future costs related to tire replacement.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions, enhancing their operational efficiency and ensuring safety in their tire selection.

The corded tire market is witnessing a surge in demand driven by several global factors. Increased vehicle production, particularly in emerging markets such as Africa and South America, is a primary catalyst. These regions are experiencing rapid urbanization and a growing middle class, leading to higher vehicle ownership rates. Furthermore, the demand for performance tires in motorsports and high-performance vehicles is amplifying the need for advanced corded tire technologies.

Current and emerging B2B technology trends are also shaping the sourcing landscape. Innovations in tire manufacturing, such as the integration of smart materials and IoT technologies, are enhancing product performance and reliability. For international buyers, particularly those from regions like the Middle East and Europe, access to real-time data and analytics is becoming essential for optimizing sourcing strategies. This allows buyers to evaluate supplier performance, manage inventory more effectively, and ensure timely deliveries.

Moreover, the competitive dynamics in the corded tire sector are shifting. With an increase in global players, international B2B buyers must be vigilant in assessing supplier capabilities, quality control processes, and compliance with international standards. The rise of e-commerce platforms is also transforming traditional sourcing methods, enabling buyers to compare products and prices more transparently, thus facilitating better decision-making.

Sustainability is becoming a central tenet in the sourcing strategies of international B2B buyers in the corded tire sector. The environmental impact of tire production and disposal is significant, prompting manufacturers to adopt more sustainable practices. This includes utilizing eco-friendly materials and processes that reduce carbon footprints.

Illustrative image related to corded tire

Ethical sourcing is paramount, as buyers increasingly prefer suppliers that demonstrate a commitment to social responsibility and environmental stewardship. Certifications such as ISO 14001 for environmental management and the Global Recycled Standard are becoming essential criteria for evaluating potential suppliers.

The shift towards ‘green’ materials, including natural rubber and recycled materials, is not just a trend but a necessity for many businesses aiming to meet regulatory requirements and consumer expectations. For buyers in regions like Europe and South America, where environmental regulations are stringent, aligning with suppliers who prioritize sustainability can enhance brand reputation and customer loyalty.

The evolution of corded tires dates back to the late 19th century when the first rubber tires were introduced. The transition from solid rubber to inflatable tires significantly improved vehicle performance. However, it wasn’t until the mid-20th century that corded tires, reinforced with materials like steel and polyester, became mainstream. This innovation enhanced tire durability and performance, setting a new standard in the automotive industry.

Illustrative image related to corded tire

In recent decades, advancements in manufacturing technologies and materials science have further propelled the development of corded tires. The introduction of synthetic materials and advanced tread designs has optimized traction and handling. As global demand for vehicles continues to rise, the corded tire sector remains at the forefront of innovation, catering to diverse market needs while addressing sustainability concerns.

By understanding these market dynamics and trends, international B2B buyers can navigate the complexities of the corded tire sector more effectively, ensuring they make informed sourcing decisions that align with their business objectives.

1. How do I determine when a corded tire needs replacement?

Corded tires typically exhibit signs of wear such as visible threads or blisters on the surface. It’s essential to perform regular visual inspections, especially after each use. Look for uneven tread wear, which can indicate that the tire is nearing its limit. If you notice a loss of grip during performance, this could be an early warning. Always prioritize safety; if you suspect a tire is corded, it’s advisable to replace it immediately to avoid potential blowouts.

2. What are the most common applications for corded tires in B2B settings?

Corded tires are primarily used in high-performance environments such as racing, motorsports, and specialized vehicle applications. They are favored for their durability and grip, making them ideal for track events and racing circuits. Additionally, they can be used in logistics and heavy-duty applications where robust tire performance is crucial. Understanding your specific operational needs will help in selecting the right corded tire for your business.

3. How can I vet suppliers of corded tires effectively?

When vetting suppliers, consider their reputation, certifications, and experience in the industry. Request samples of their products to assess quality firsthand. Check for customer reviews and testimonials to gauge reliability. Additionally, inquire about their production capabilities, lead times, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and customer service practices.

4. What customization options are available for corded tires?

Many manufacturers offer customization options for corded tires, including specific tread patterns, rubber compounds, and sizes tailored to your operational needs. When discussing customization, be clear about your requirements, such as load capacity or performance characteristics. Collaborating closely with the manufacturer can lead to the development of a tire that meets your unique specifications, enhancing efficiency and performance in your applications.

5. What is the minimum order quantity (MOQ) for corded tires?

The MOQ for corded tires can vary significantly among suppliers and often depends on the type of tire and customization requirements. Generally, manufacturers may require a minimum of 50 to 100 units for bulk orders. However, negotiating with suppliers is advisable, especially if you are a new customer or looking for trial orders. Establishing a good relationship can lead to more flexible terms in future transactions.

6. What payment terms should I expect when purchasing corded tires?

Payment terms can vary widely depending on the supplier and the scale of the order. Common terms include full payment upfront, partial payment with the balance due upon delivery, or net 30/60 days after invoice. It’s essential to clarify these terms during negotiations and ensure they align with your cash flow requirements. Additionally, consider discussing options for letters of credit or escrow services for larger transactions to mitigate risk.

7. How can I ensure the quality of corded tires upon delivery?

To ensure quality upon delivery, request a Certificate of Quality Assurance (CQA) from your supplier. This document should confirm that the tires meet specified standards and have undergone rigorous testing. Conduct a visual inspection upon receipt, checking for any signs of damage or defects. If possible, consider third-party quality inspections to provide an additional layer of assurance, especially for large shipments.

8. What logistics considerations should I keep in mind when sourcing corded tires internationally?

When sourcing corded tires internationally, consider shipping costs, delivery times, and customs regulations in both the exporting and importing countries. It’s crucial to work with a logistics provider experienced in handling automotive parts, as they can navigate the complexities of international shipping. Ensure you have all necessary documentation, such as bills of lading and import permits, to avoid delays. Additionally, plan for potential tariffs or duties that may apply to your shipments.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Falken RT660 tires, showing first signs of cords, used for approximately 15 autocross events with 10+ runs each day, and around 3000 miles total including street driving. The tires are considered worn out and unsafe for further use.

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: Nitto NT-01 tires; RA-1 tires; R compound tires; handling decreases as tires cord; visual inspection recommended; signs of wear include threads showing and blisters; tires may suddenly fail; suggested to replace tires before they cord to avoid accidents.

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: A cord tire is a type of tire that has a fabric cord structure, providing strength and flexibility. It is commonly used in various vehicles for improved performance and durability.

In today’s competitive landscape, strategic sourcing for corded tires offers significant advantages for international B2B buyers. By understanding the intricacies of tire performance and longevity, businesses can optimize their procurement processes, ensuring they acquire high-quality products that meet their specific operational needs. This approach not only enhances cost efficiency but also mitigates risks associated with tire failure, thereby safeguarding investments and enhancing safety.

Effective sourcing strategies should incorporate data-driven insights on tire performance, including wear patterns and handling characteristics as they approach the corded stage. By prioritizing suppliers who provide transparency in their product specifications and support ongoing maintenance education, buyers can make informed decisions that extend tire life and maximize operational uptime.

Illustrative image related to corded tire

As global markets evolve, the demand for sustainable and high-performance tire solutions will only intensify. B2B buyers in regions such as Africa, South America, the Middle East, and Europe must remain agile and responsive to market trends, leveraging strategic partnerships to ensure a competitive edge. Engage with trusted suppliers, invest in quality, and prioritize strategic sourcing to navigate the complexities of tire procurement effectively. Your proactive approach today will position your business for success tomorrow.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.